Patents

Literature

36results about How to "Improve skew" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

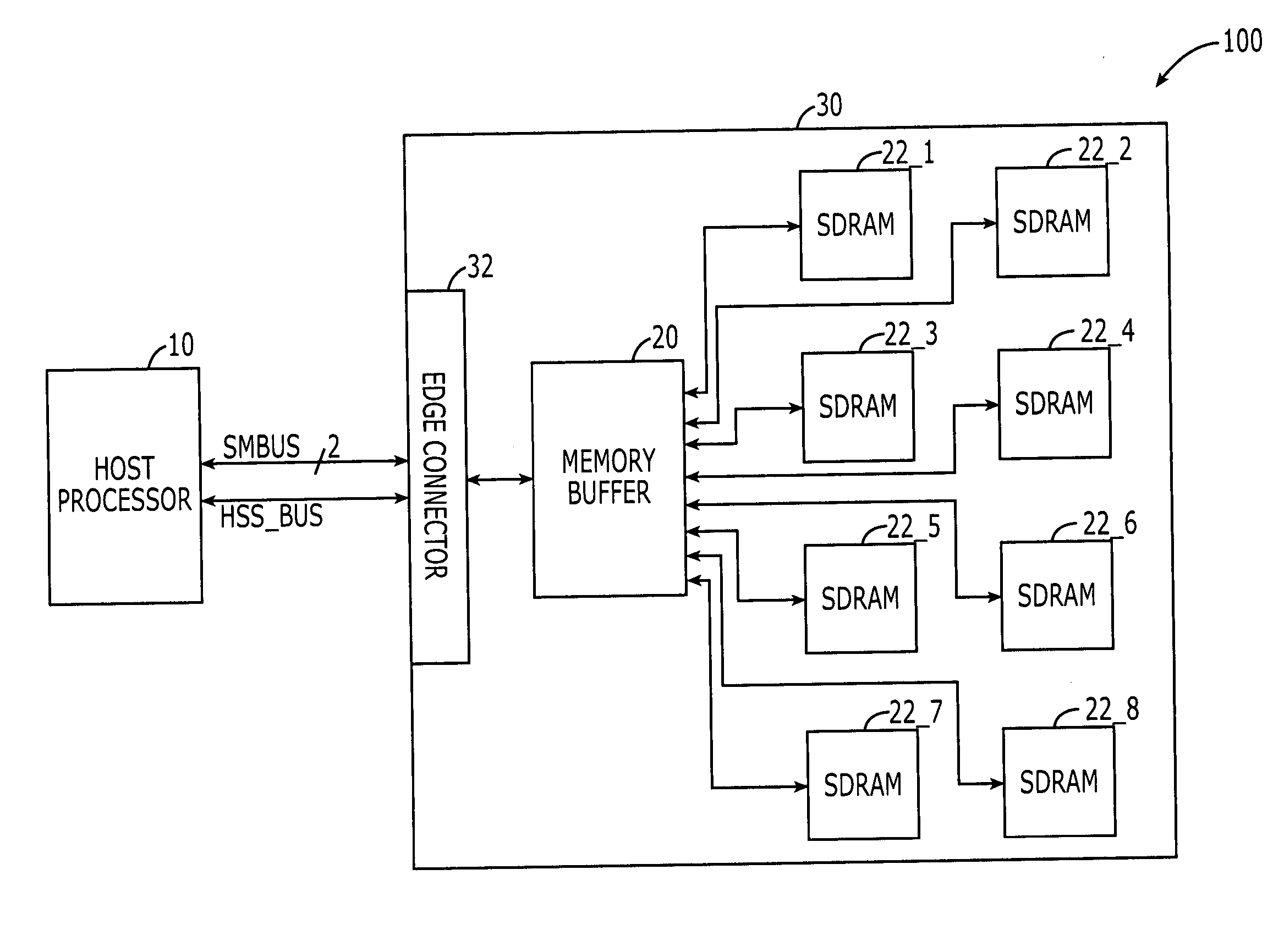

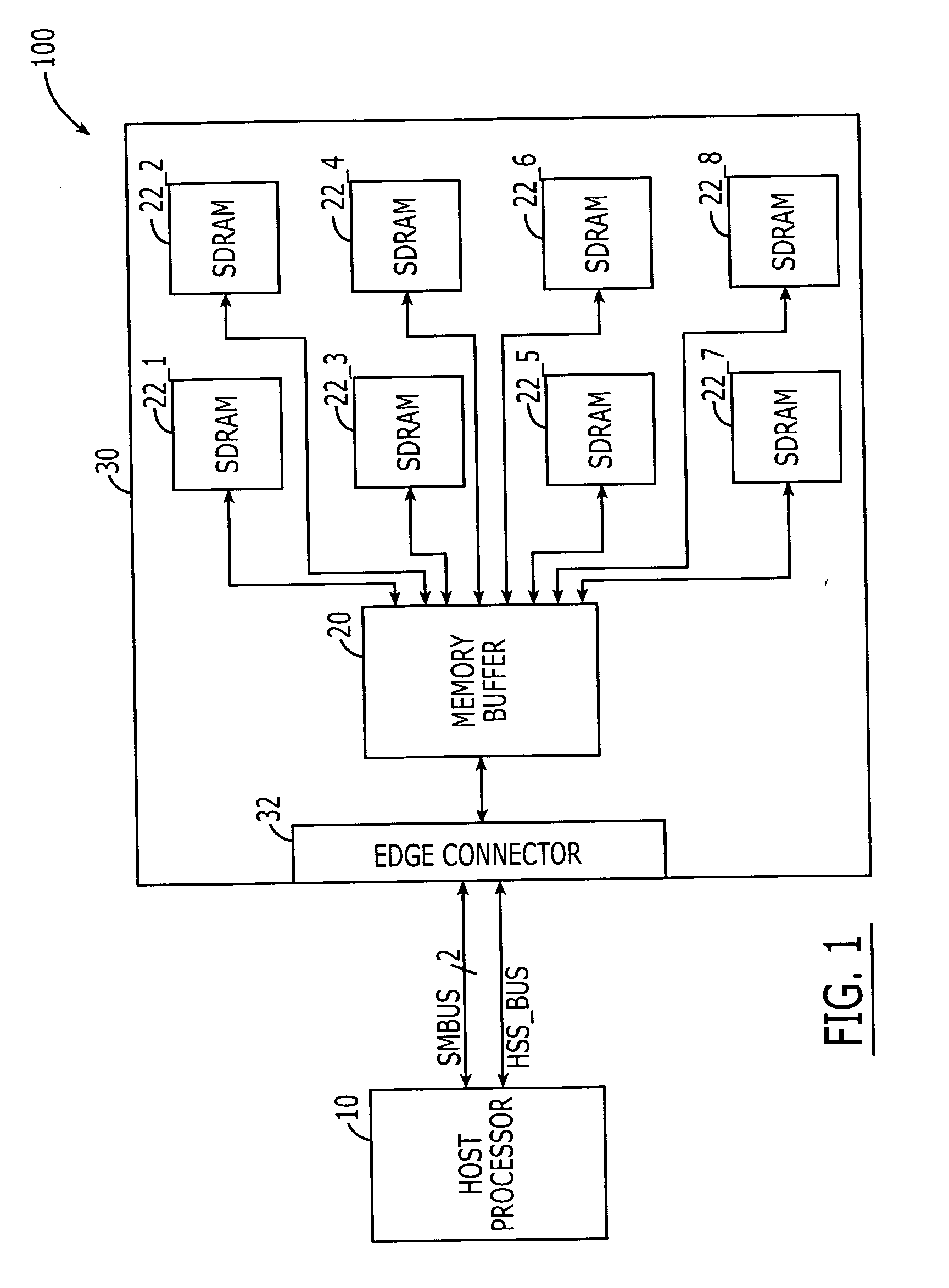

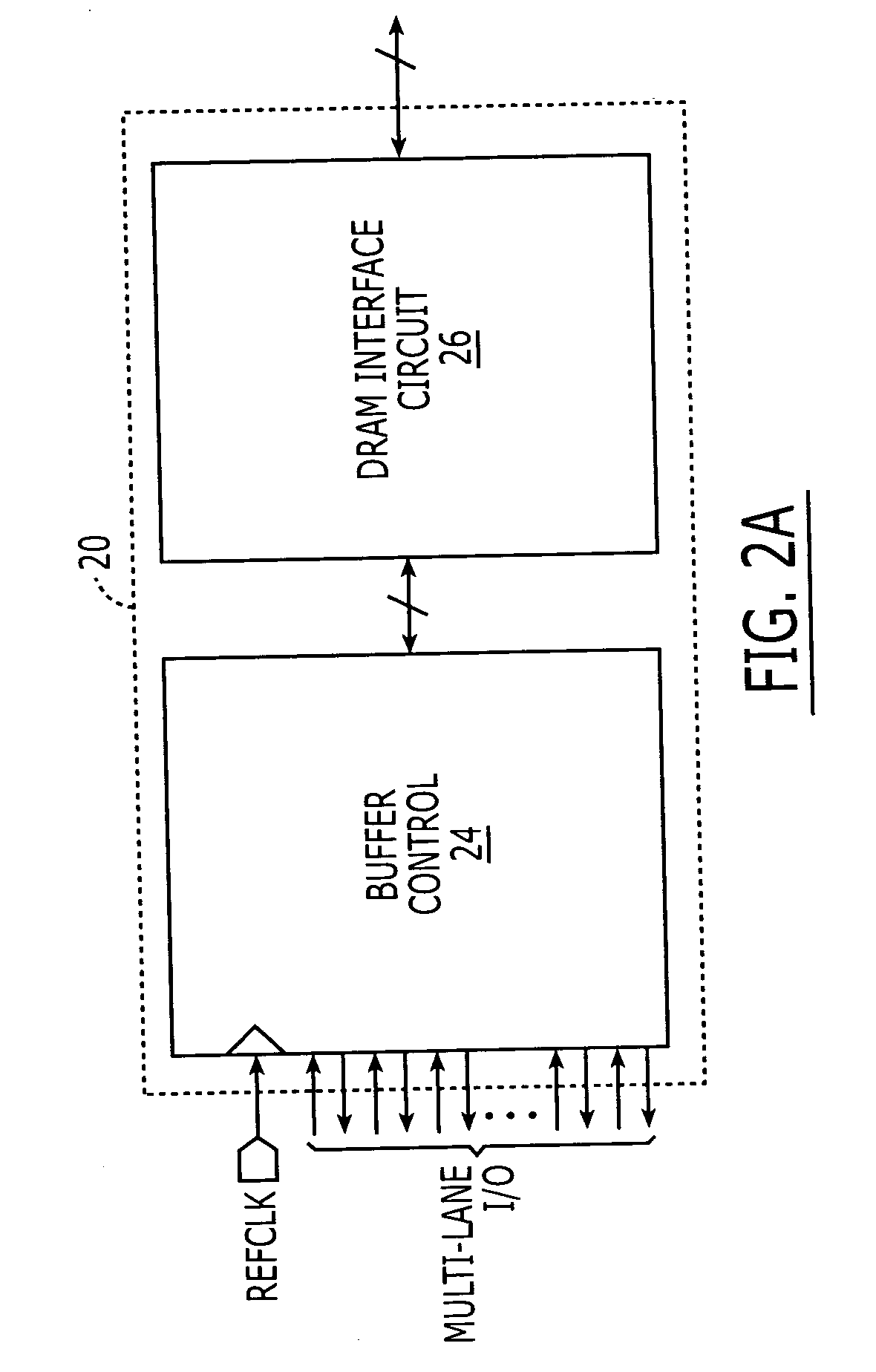

DRAM interface circuits having enhanced skew, slew rate and impedance control

Fully-buffered dual in-line memory modules (FB-DIMM) include advanced memory buffers (AMBs) having enhanced skew, slew rate and output impedance control. The AMB includes user accessible registers that can be programmed to carefully control the edge placement (or phase) of signals generated from the AMB to multiple DRAMs on the module. This control of edge placement, which may be performed independently for each group of signals: clock (CLK, CLK#), command (RAS, CAS, WE), address (including bank address), data (DQ) and data strobe (DQS), provides 360 degrees of control (or one period). This means that any group of signals can be moved independently by one complete period relatively to any other group.

Owner:INTEGRATED DEVICE TECH INC

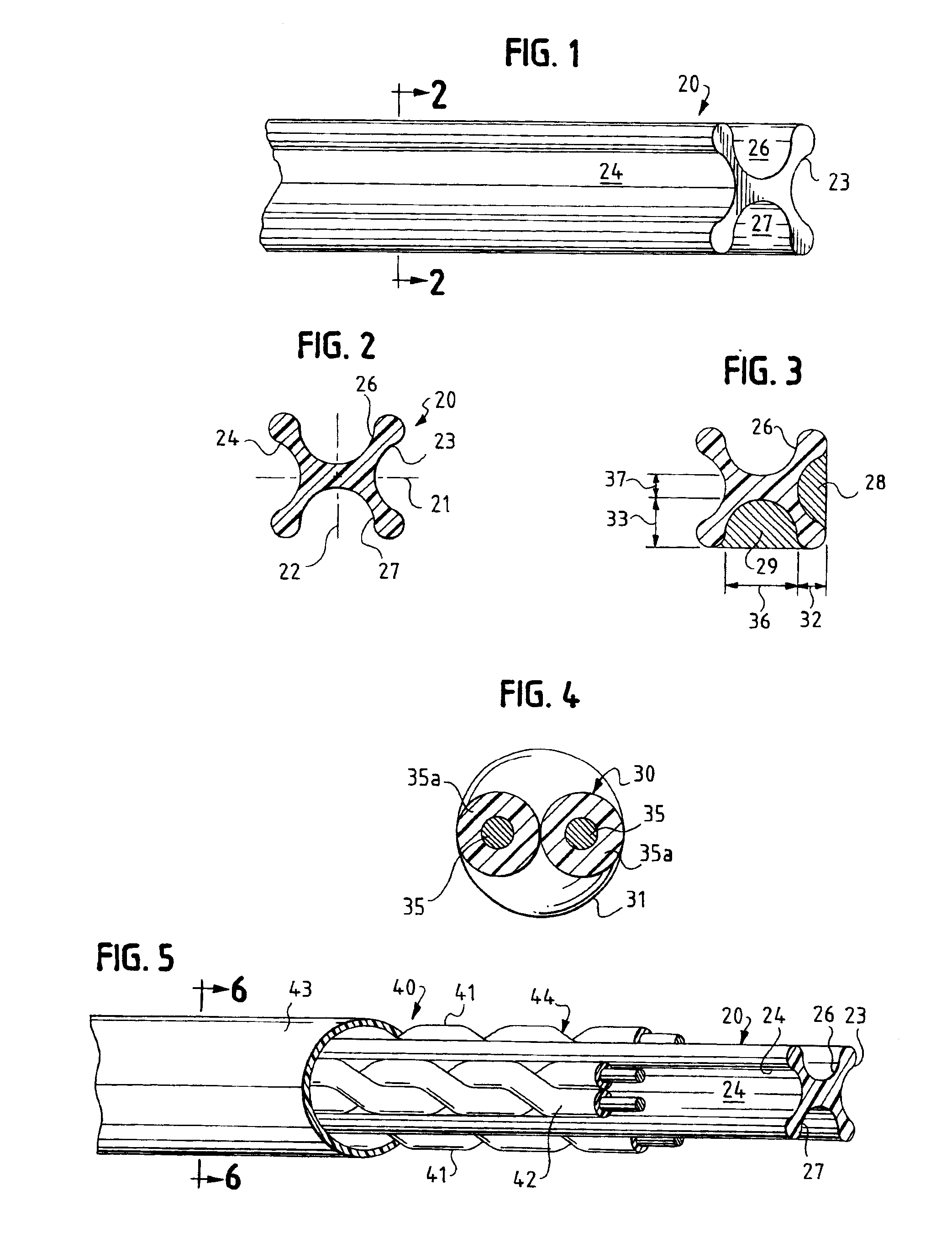

Cable separator spline

InactiveUS6855889B2Acceptable NEXT performanceGood flexibilityInsulated cablesInsulated conductorsLong axisMechanical engineering

A cable separator spline and a cable containing the cable separator spline in its core. The spline extends longitudinally and has a plurality of spaced longitudinally extending open pockets in which cables, such as twisted pair cables, can be placed and form part of the core. A cross-section of the spline has a major axis and a minor axis with the major axis being longer than the minor axis. At least one and preferably at least two pockets are on the major axis, and at least one and preferably at least two pockets are on the minor axis. The core containing the twisted pair cables in the pockets can of course be shielded and jacketed, just jacketed or any other desired cable construction that would benefit from the use of my elongated separator spline.

Owner:BELDEN TECHNOLOGY INC

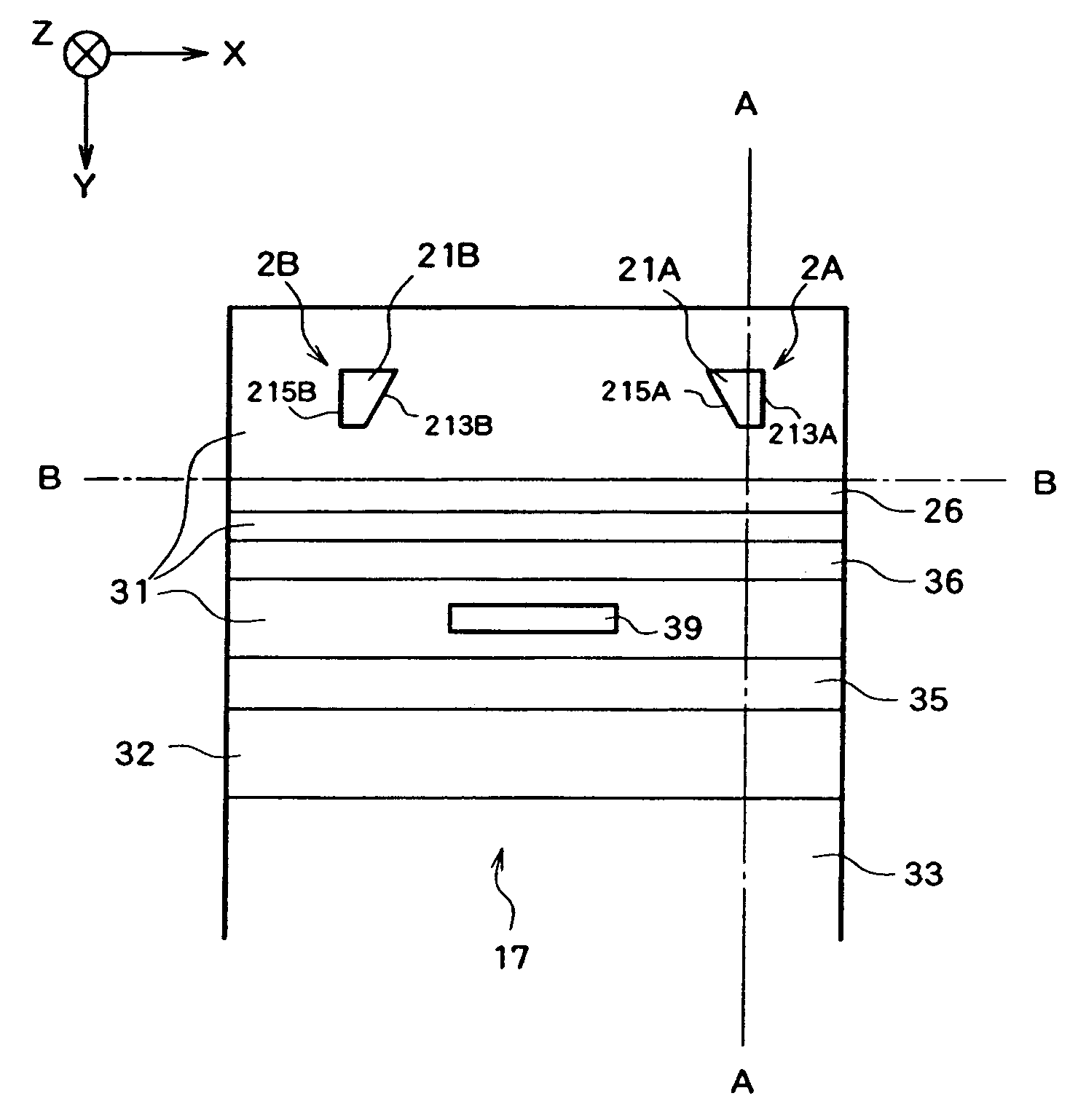

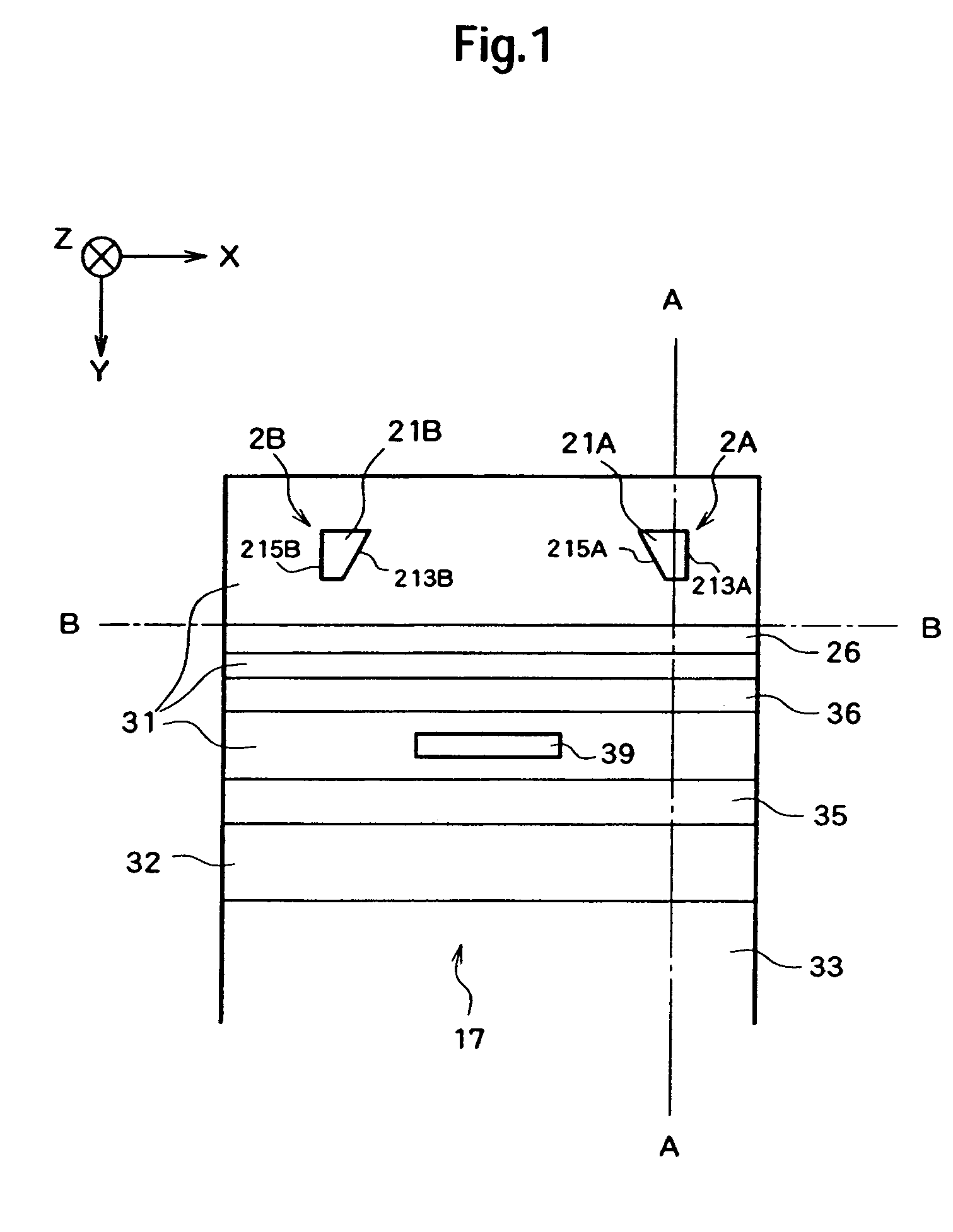

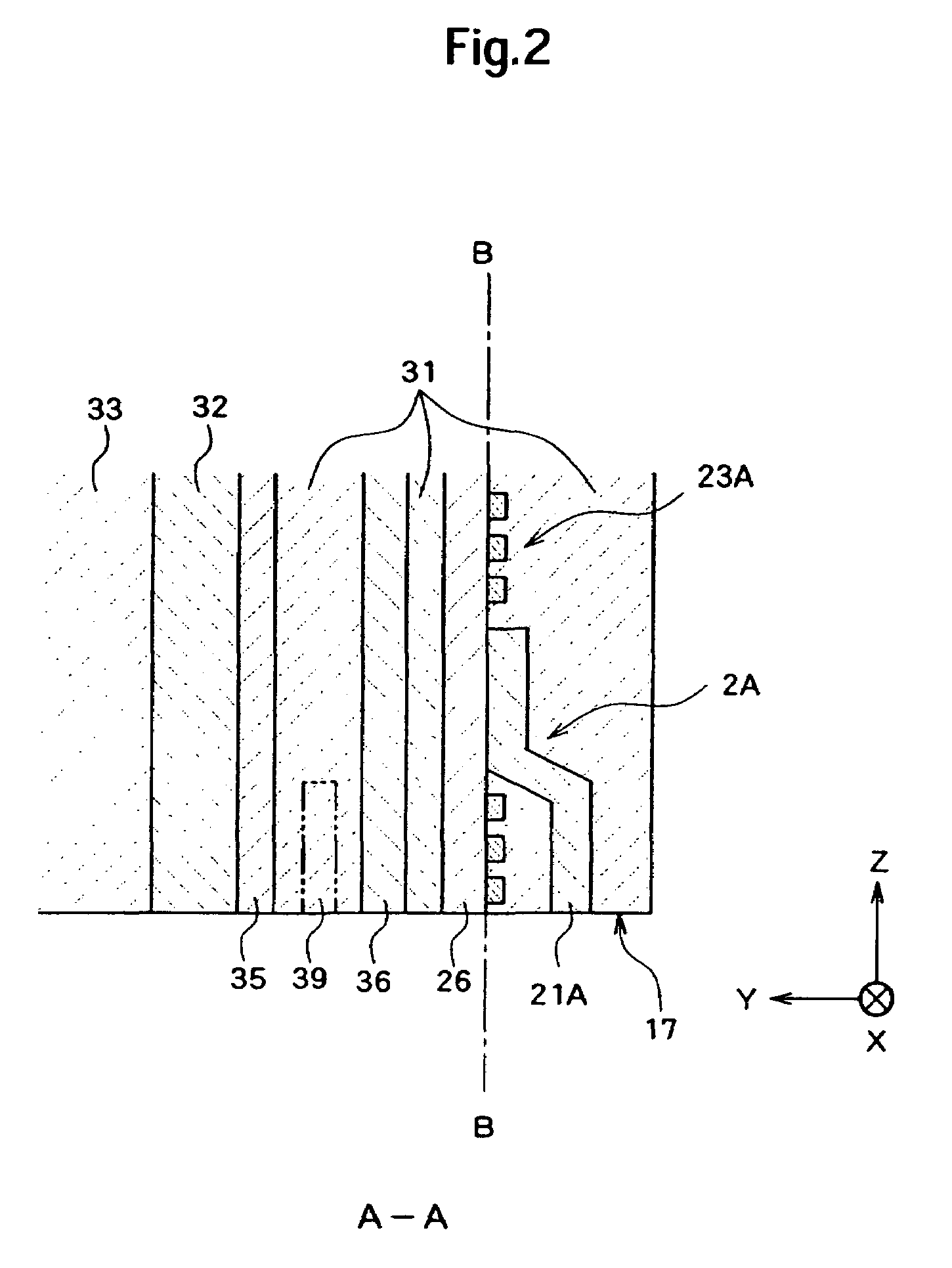

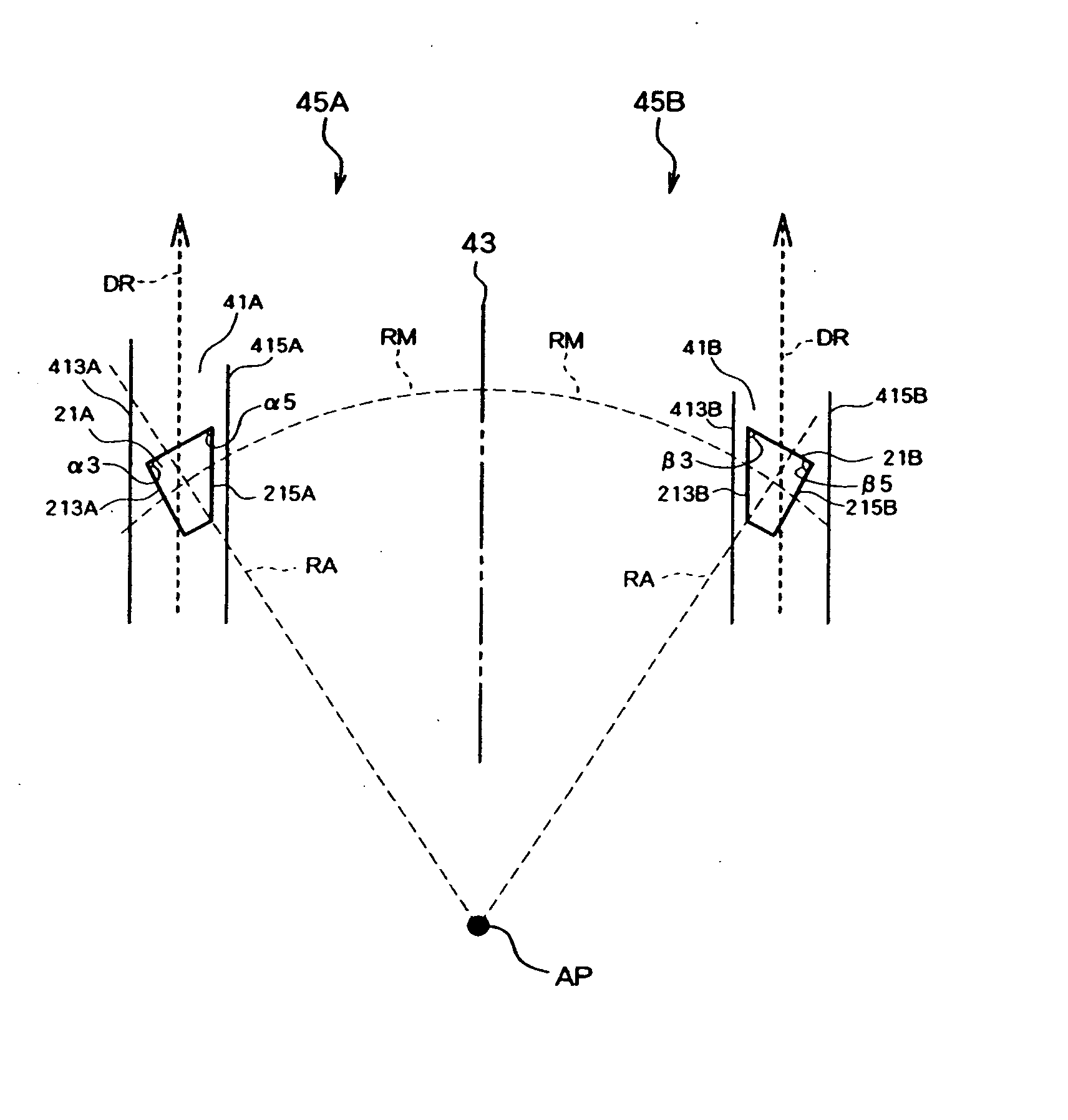

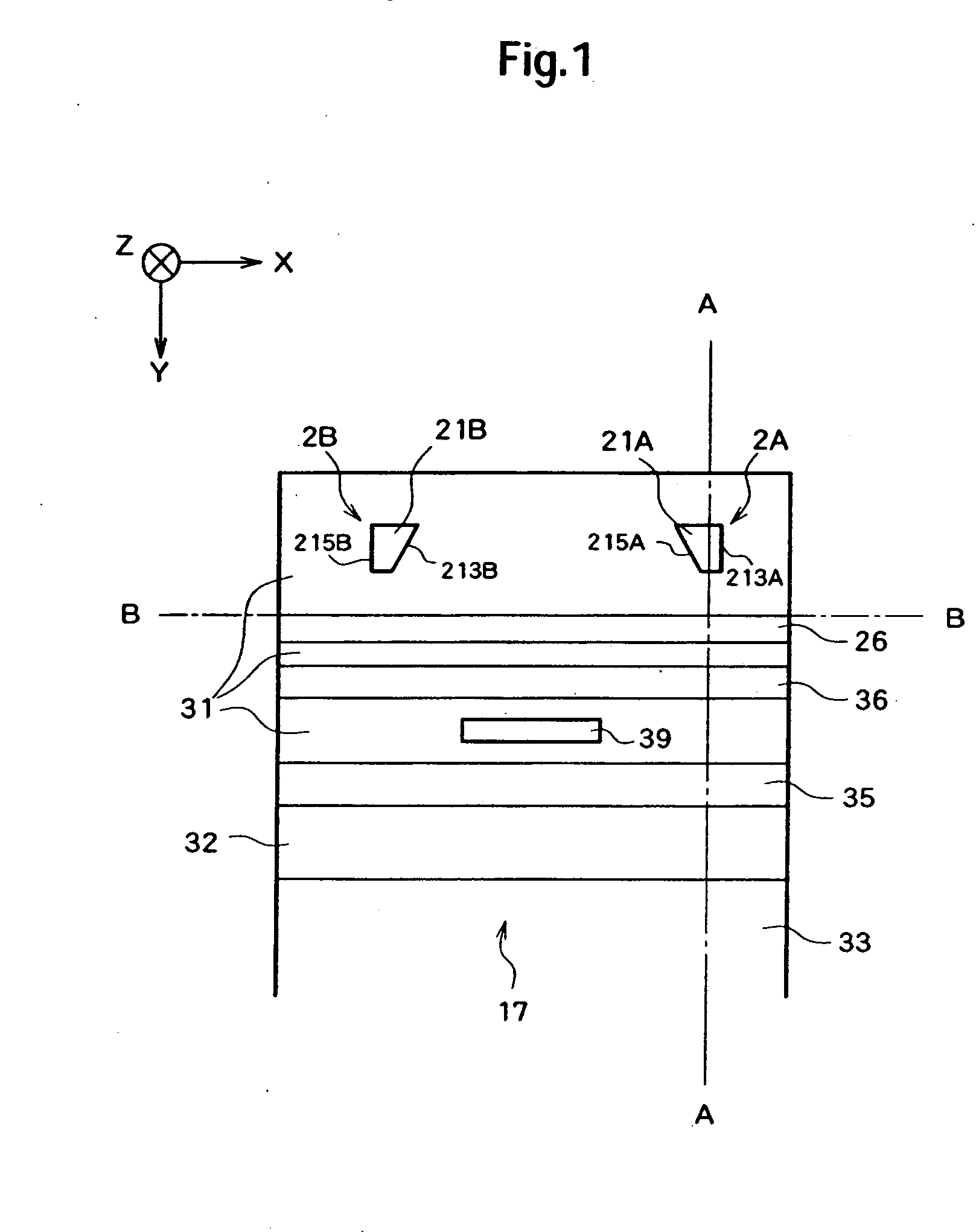

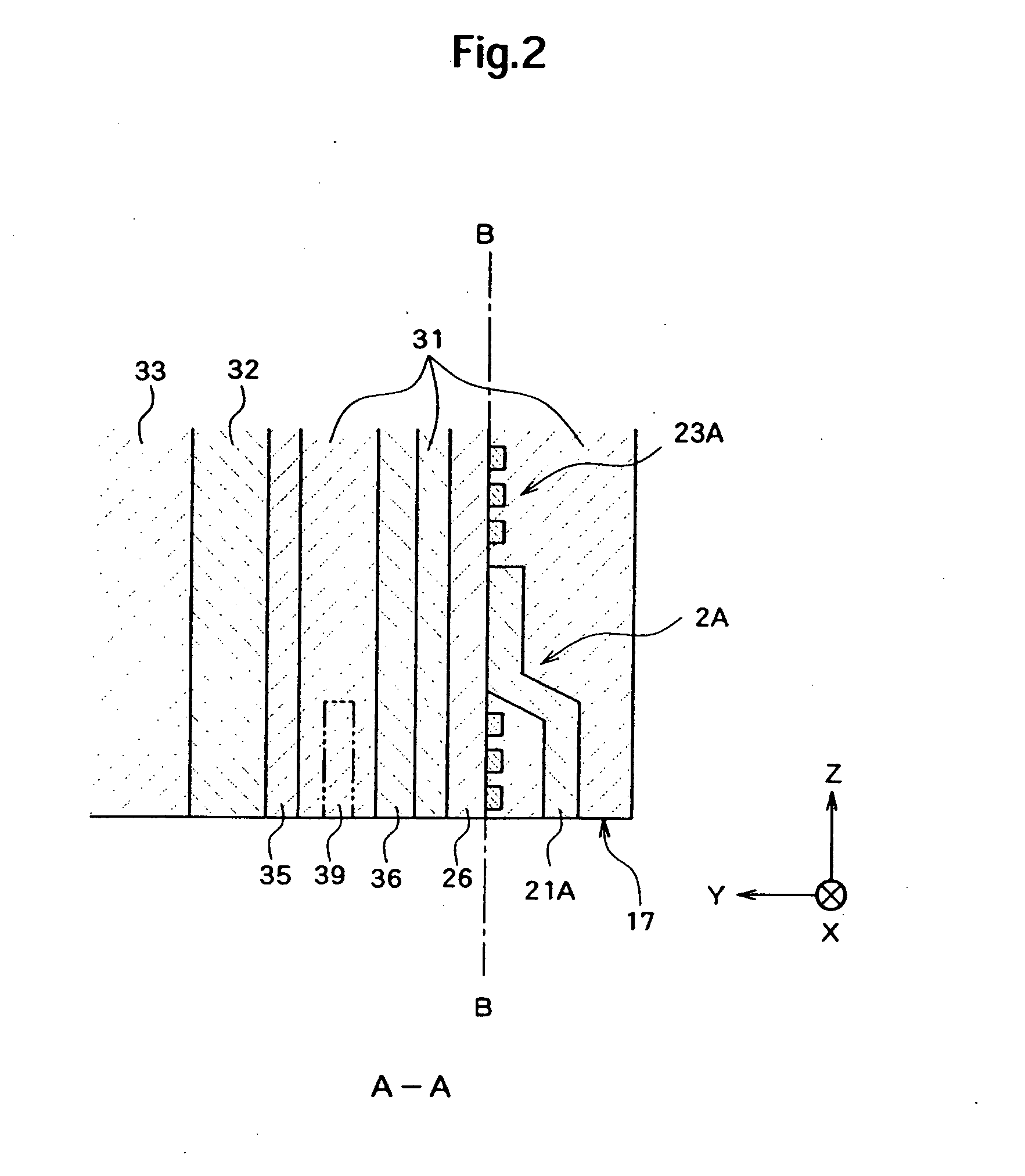

Magnetic head and magnetic disc drive

InactiveUS7508619B2Preventing a side eraseImprove featuresDriving/moving recording headsManufacturing heads with multiple gapsSkew angleMagnetic poles

Embodiments in accordance with present invention provide a magnetic head and a magnetic disc drive capable of preventing a side erase while providing excellent recording characteristics. According to one embodiment, in order to prevent the side erase in an increased skew angle state, a first magnetic pole surface is formed in such a shape that the projection area of the first magnetic pole surface follows a track edge positioned on the boundary side in the track in the state where the first magnetic pole surface is positioned on the track at the innermost periphery thereof included in a first region. Likewise, to prevent the side erase in the increased skew angle state, a second magnetic pole surface is formed in such a shape that the projection area of the second magnetic pole surface follows a track edge positioned on the boundary side with respect to a track in the state where the second magnetic pole surface is positioned on the track at the outermost periphery thereof included in a second region.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

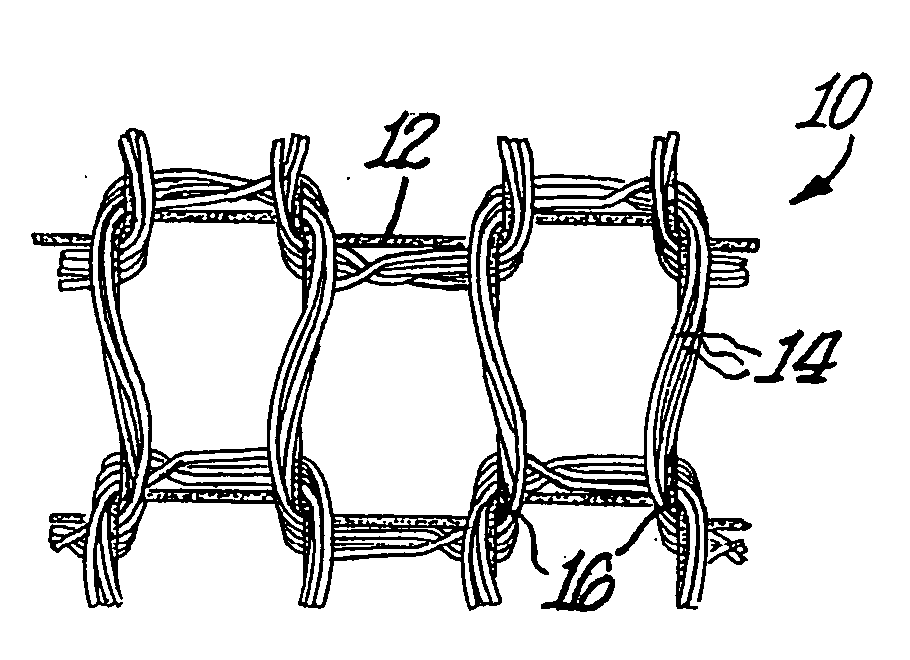

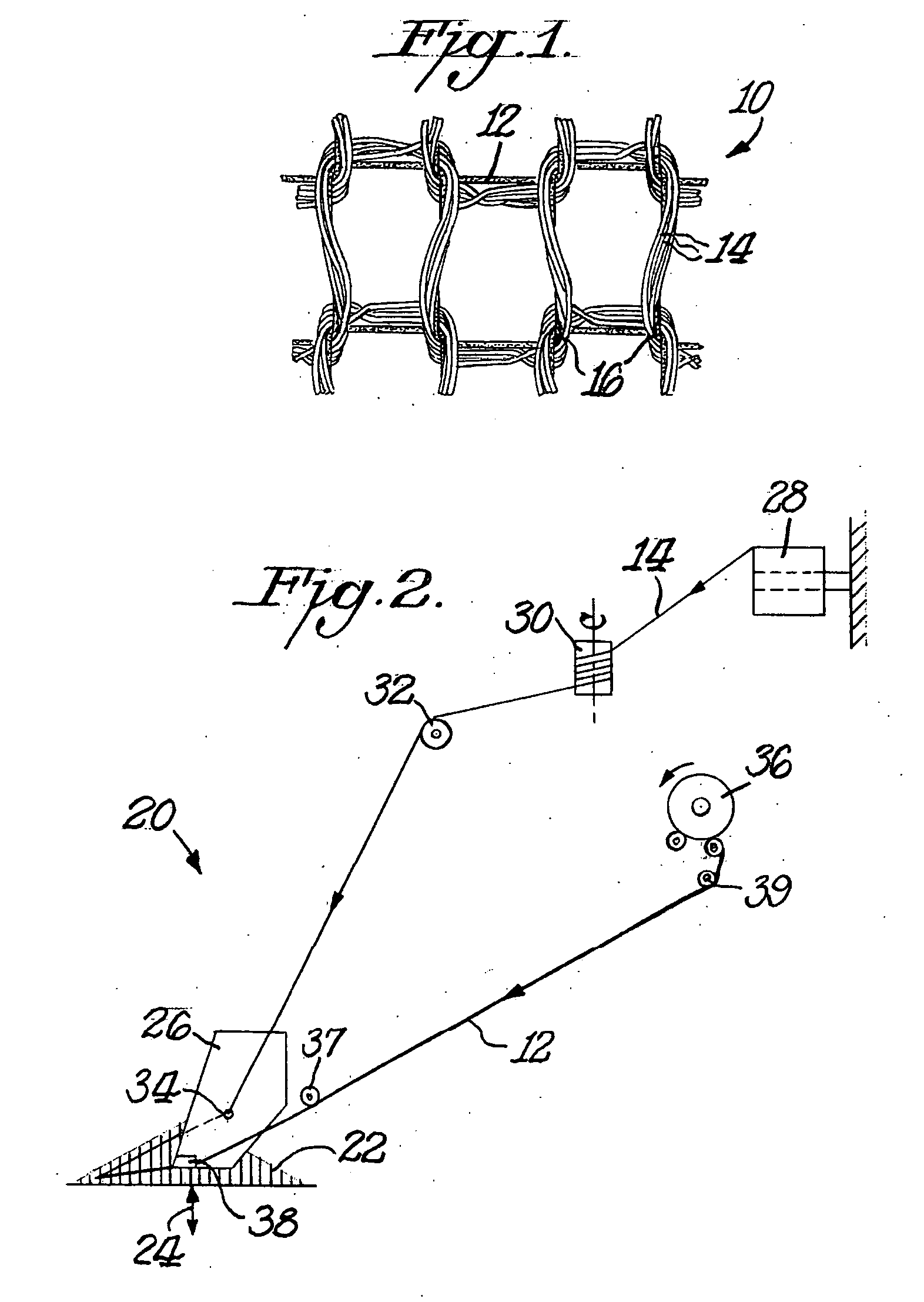

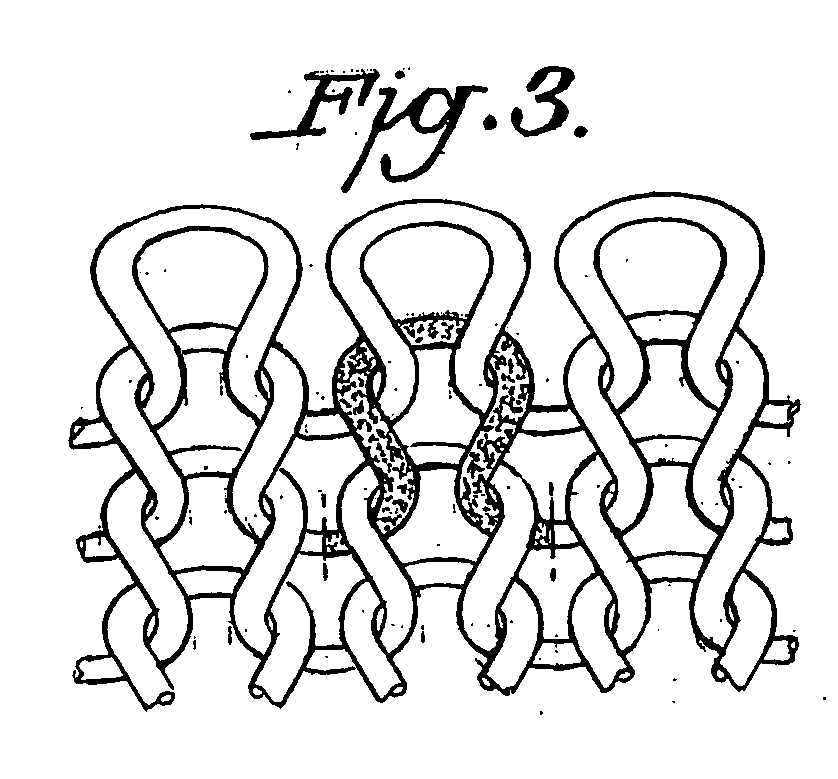

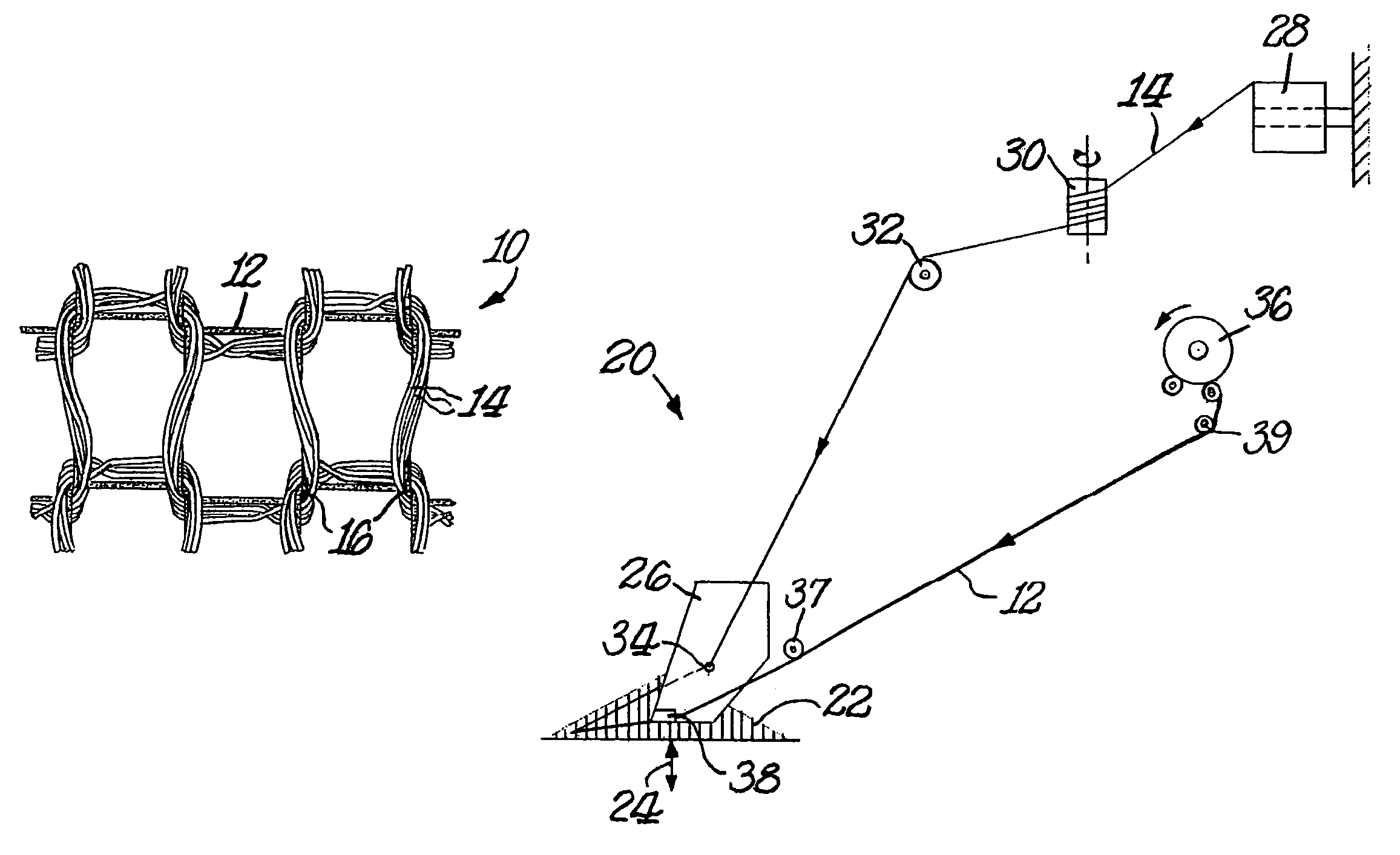

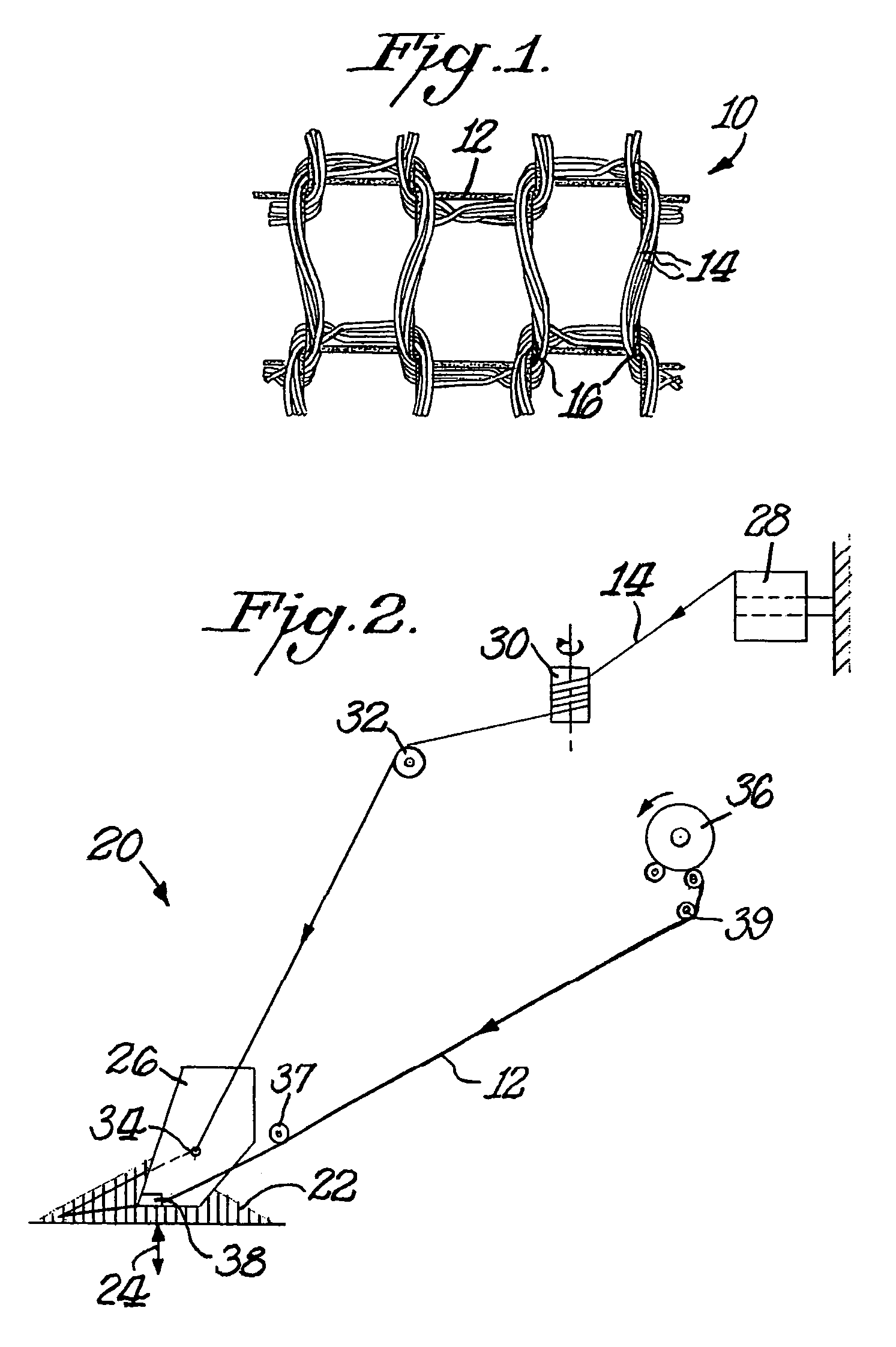

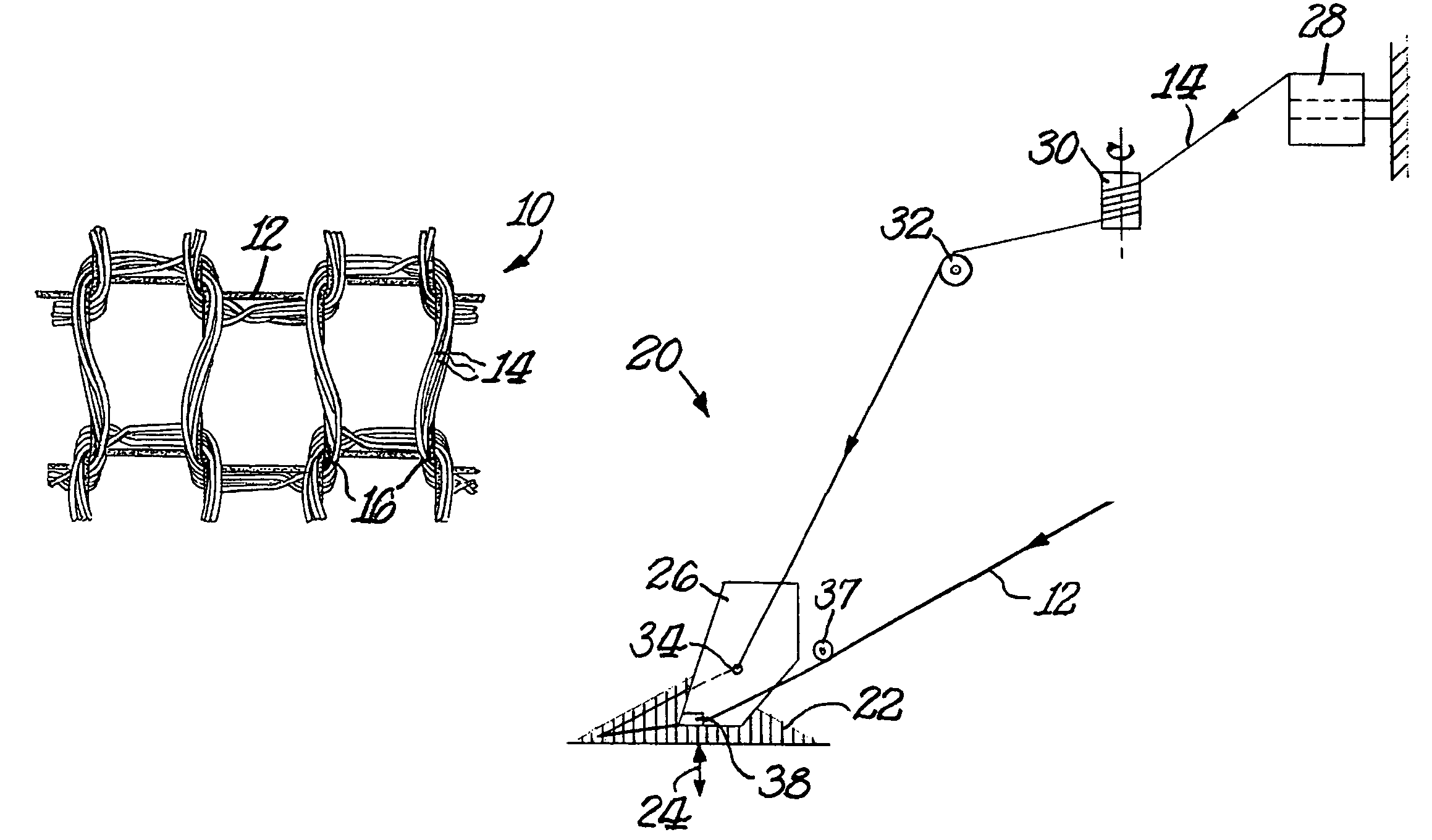

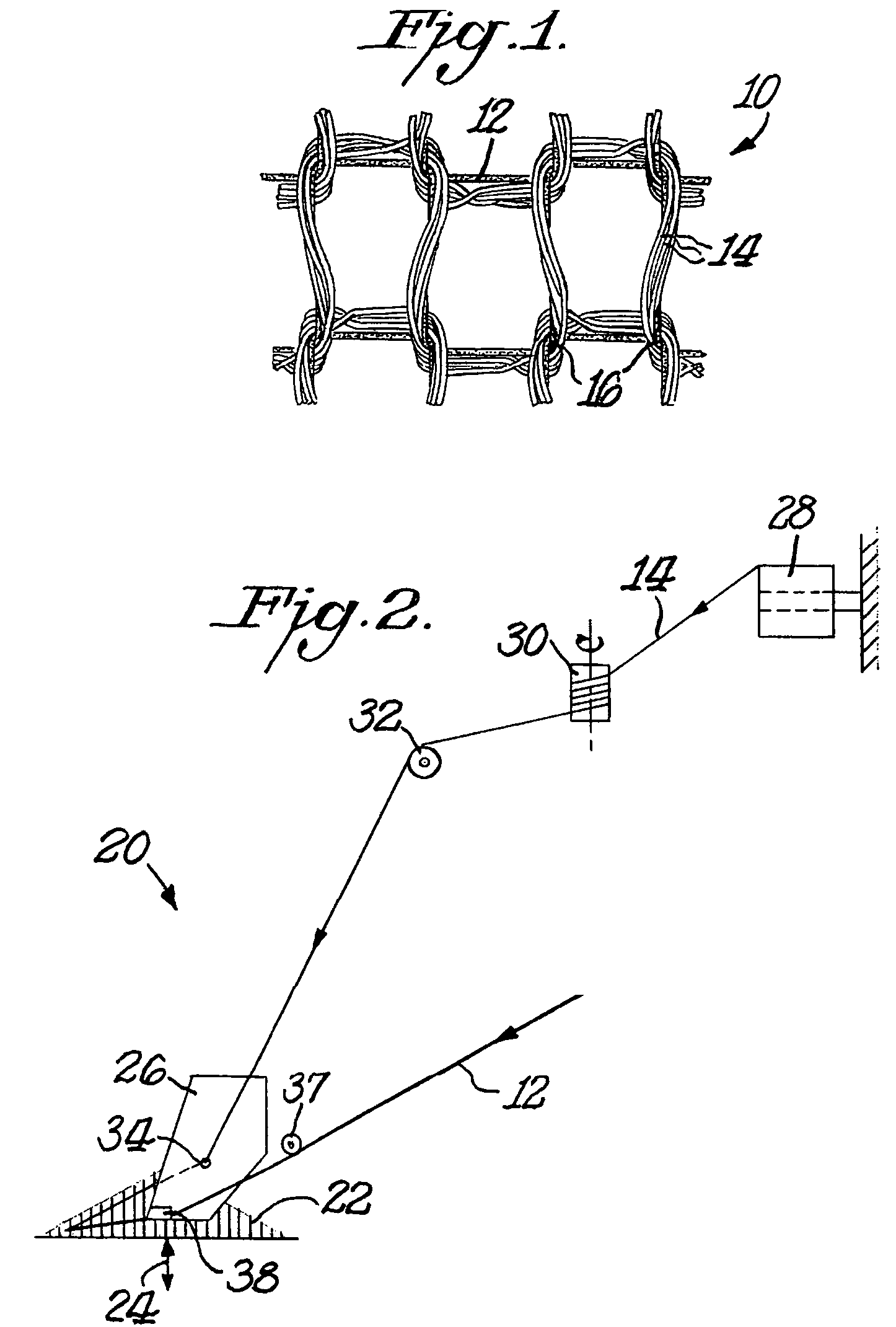

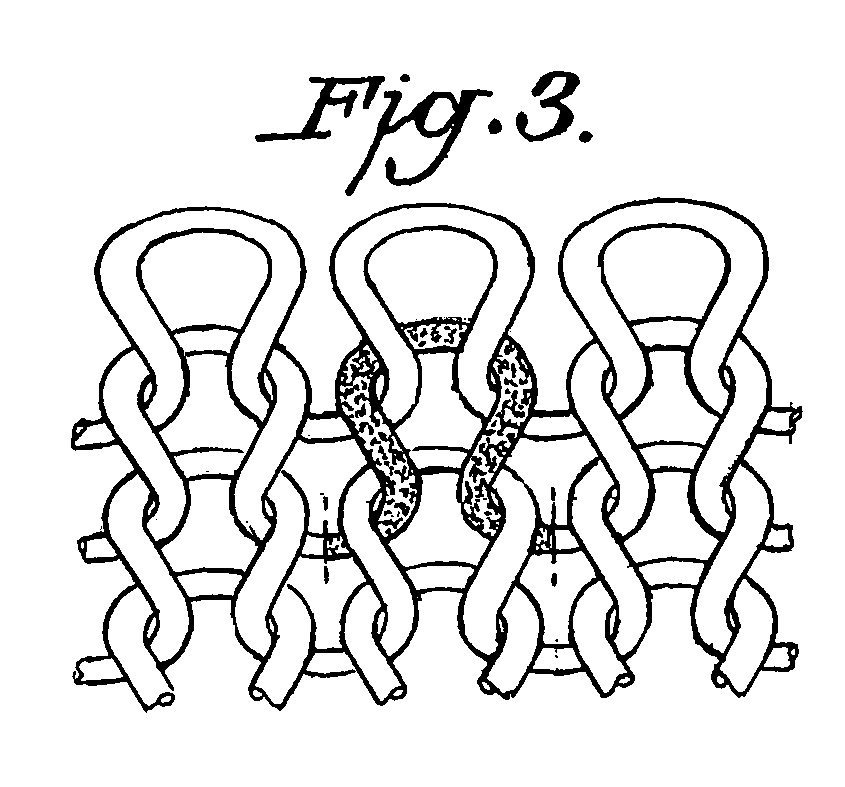

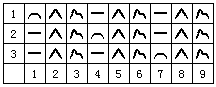

Knit by design method and fabric

InactiveUS20060010929A1Increase productionImprove skewOrnamental textile articlesCircular knitting machinesElastomerEngineering

Circular knit, elastic fabrics of at least one of single jersey, French terry, and fleece are disclosed that include a bare elastomeric material plated with spun and / or continuous filament hard yarns. The circular knit, elastic fabrics of at least one of single jersey, French terry, and fleece are manufactured by a method that does not require a dry heat setting step. The method requires drafting the bare elastomeric material no more than about 2.5× its original length when knitting to form the circular knit, elastic fabrics of at least one of single jersey, French terry, and fleece.

Owner:THE LYCRA CO LLC

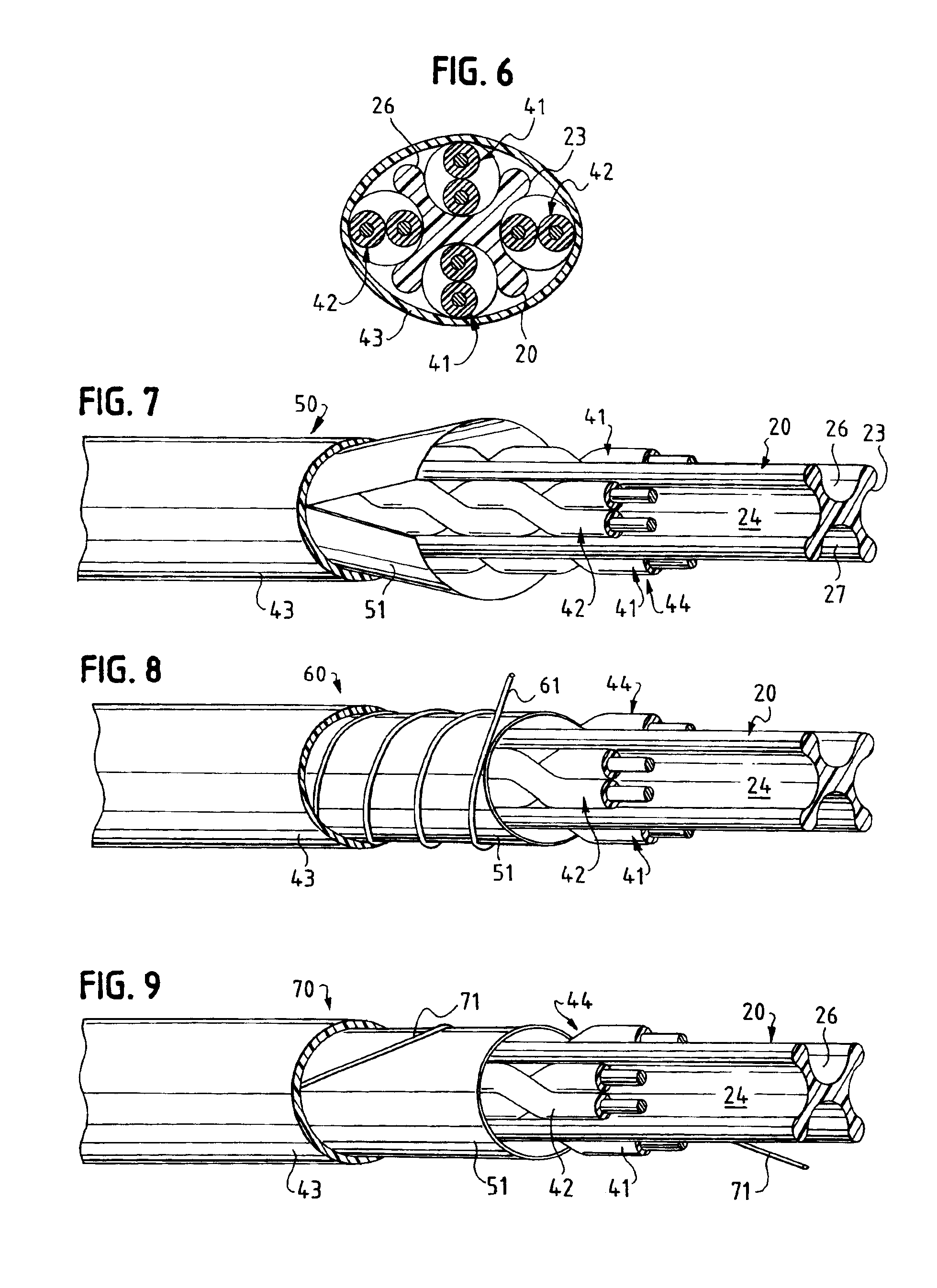

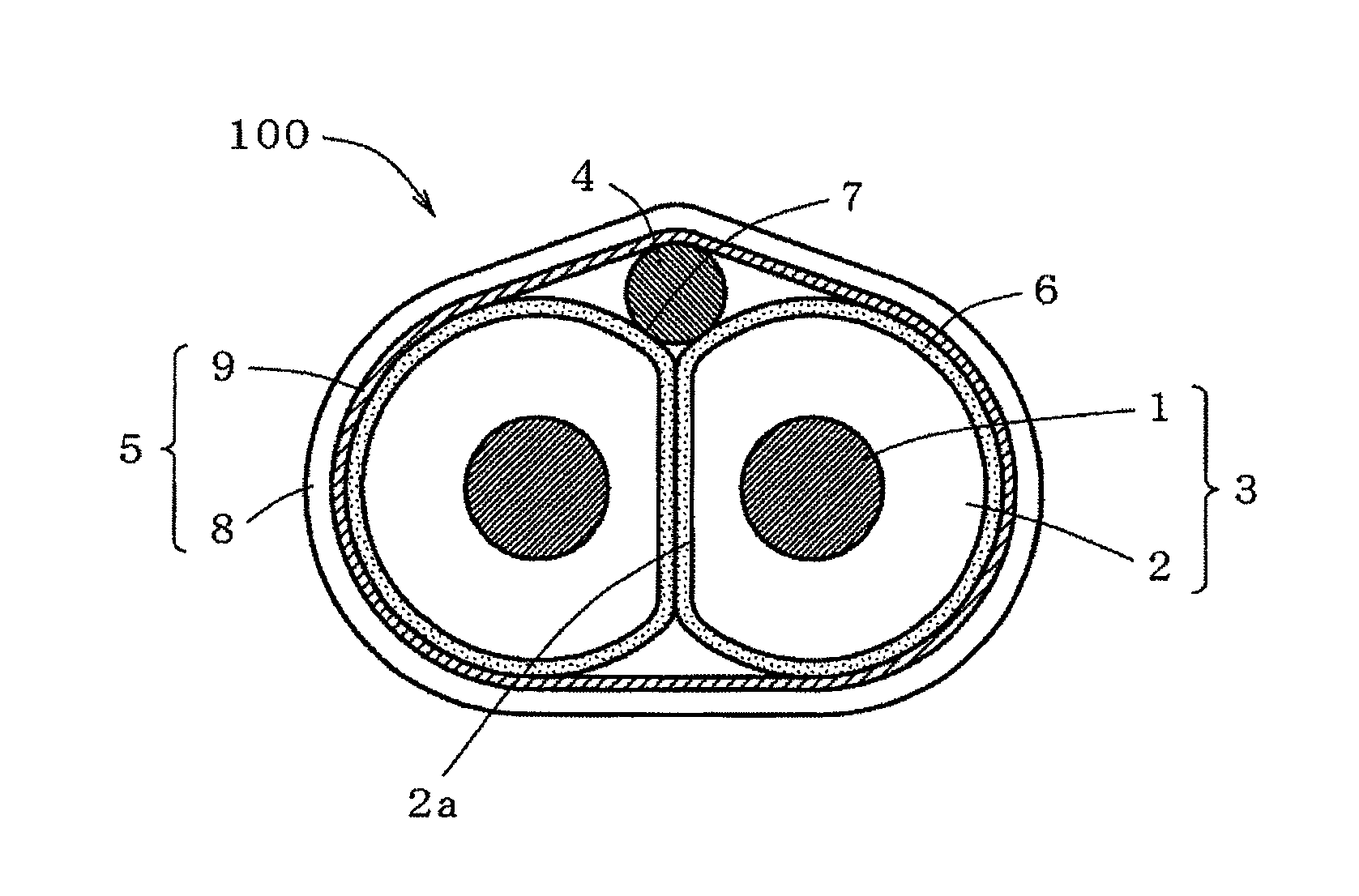

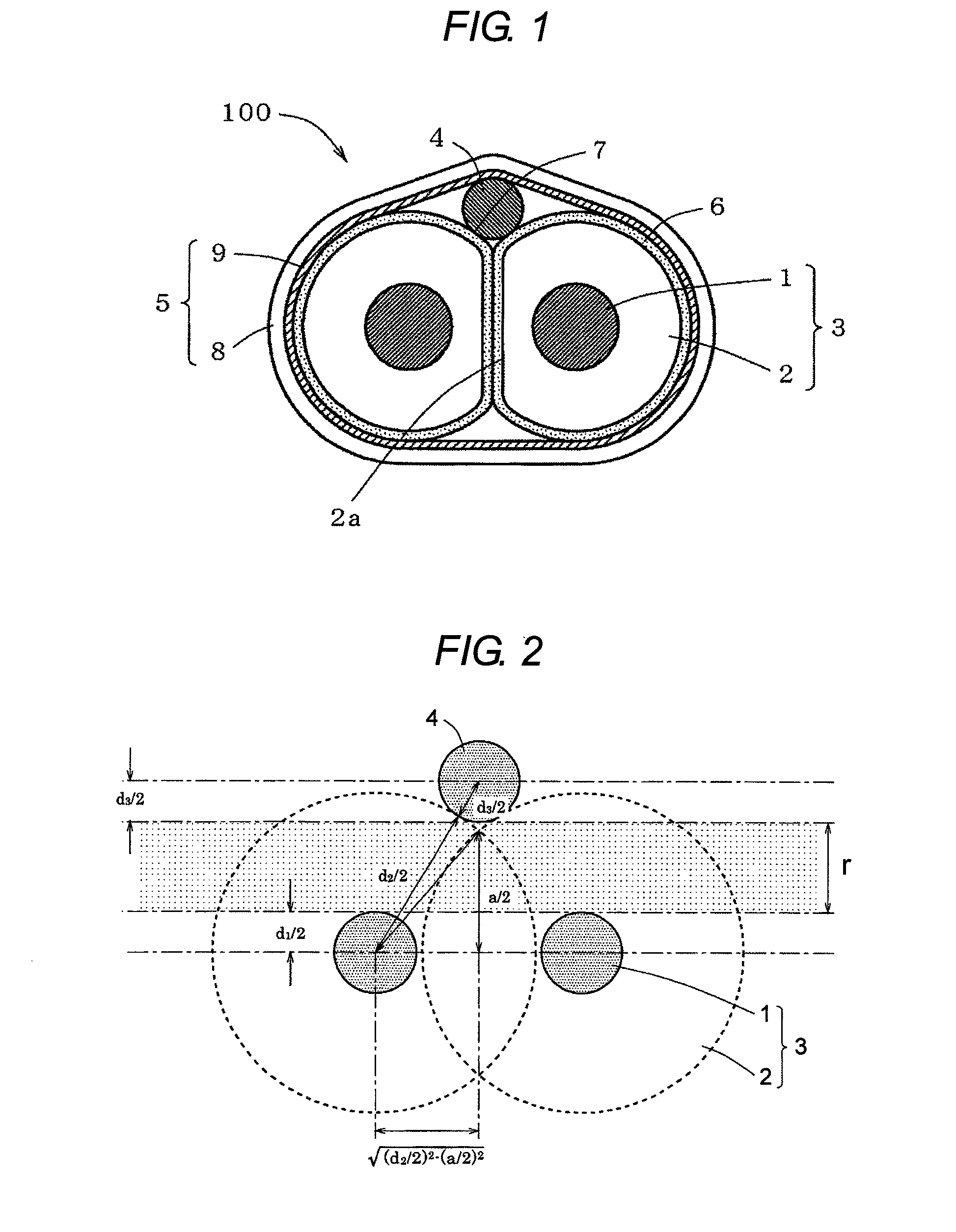

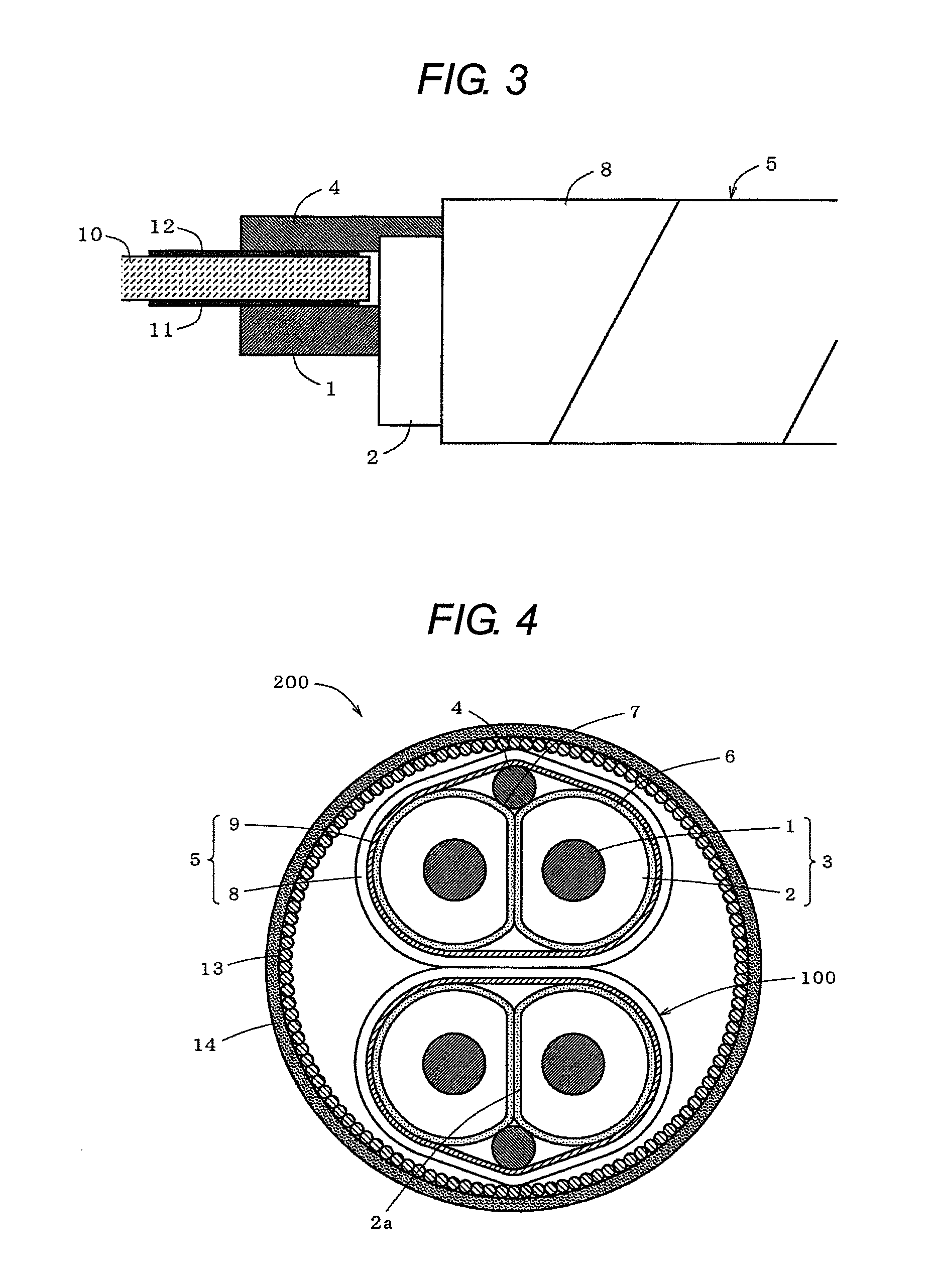

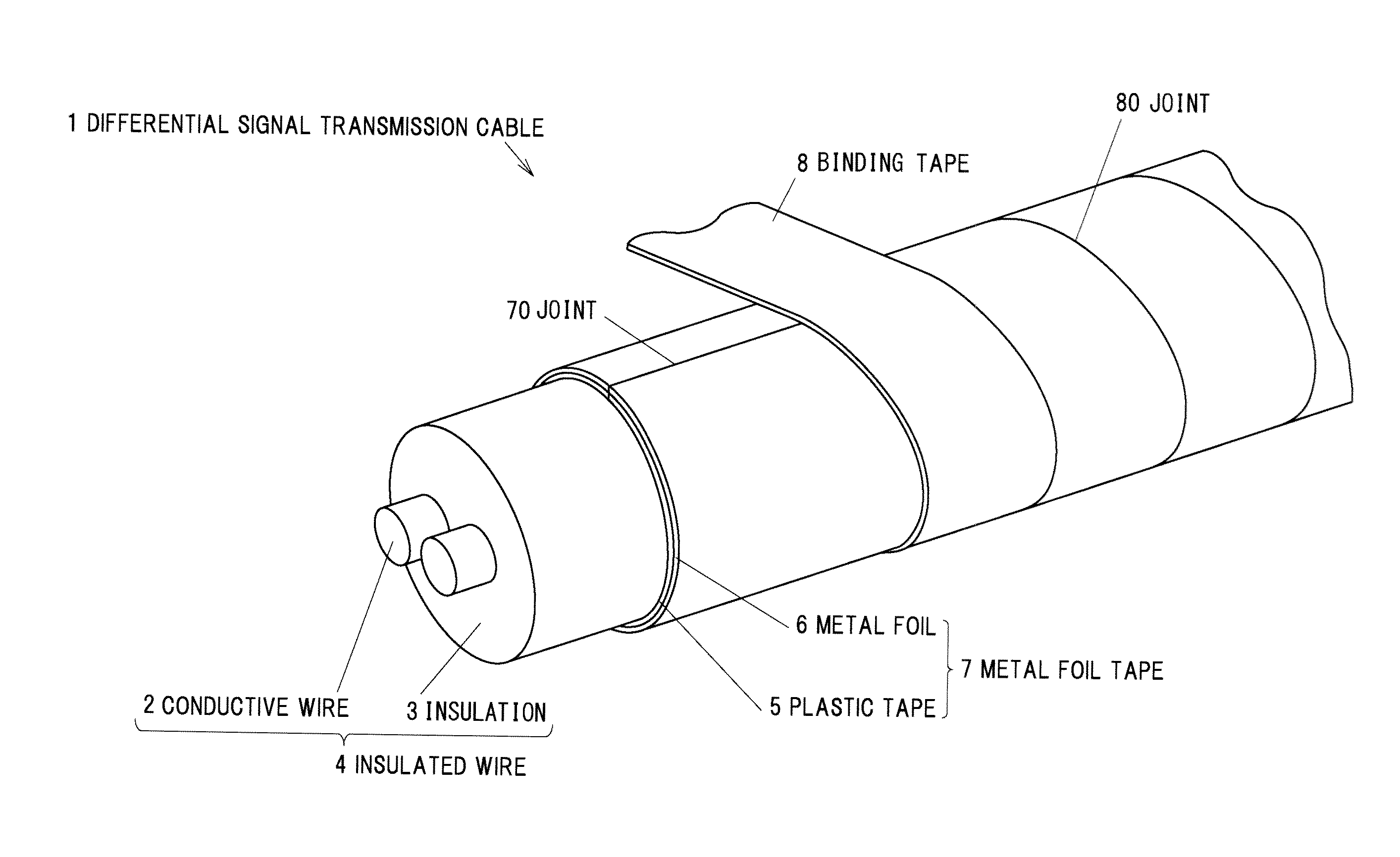

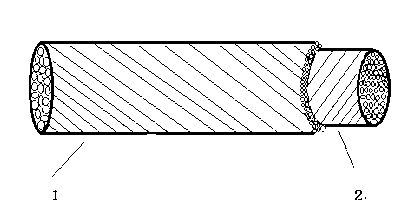

Differential signal cable, and cable assembly and multi-pair differential signal cable using the same

ActiveUS8378217B2Promote generationUniform impedanceFlat/ribbon cablesPrinted circuitsElectrical conductorDifferential signaling

A differential signal cable for transmitting high-speed digital differential signals of several Gbit / s or more is provided to minimize characteristic impedance mismatch and to repress increase in the skew, or increase in disturbance due to differential-mode to common-mode conversion. A differential signal cable comprises two insulated wires arranged parallelly in a contact, each of said two insulated wires comprising a conductor and an insulator jacketing the conductor; a fusion layer provided on the surface of each of said two insulated wires; a drain wire placed longitudinally in a recess created in the interstice between said two insulated wires; and a shield tape lapping around said two insulated wires and said drain wire together, wherein a surface of said insulator of each of said two insulated wires is partially deformed so as to have a flat portion and said two insulated wires are fused each other at said flat portions.

Owner:HITACHI CABLE +1

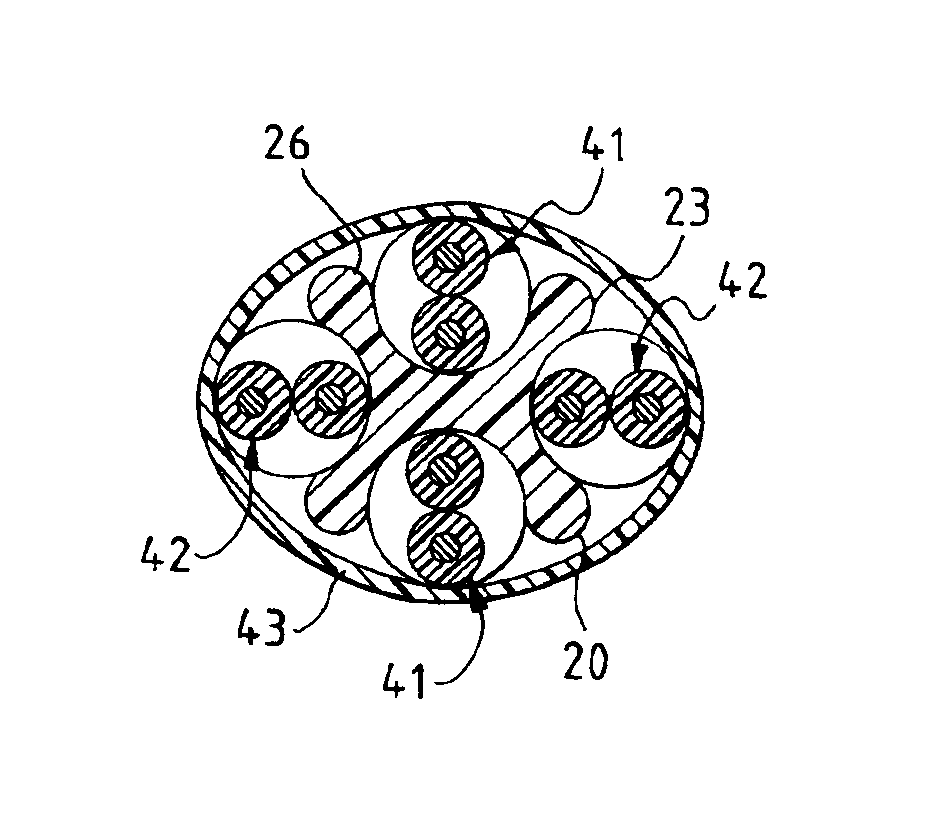

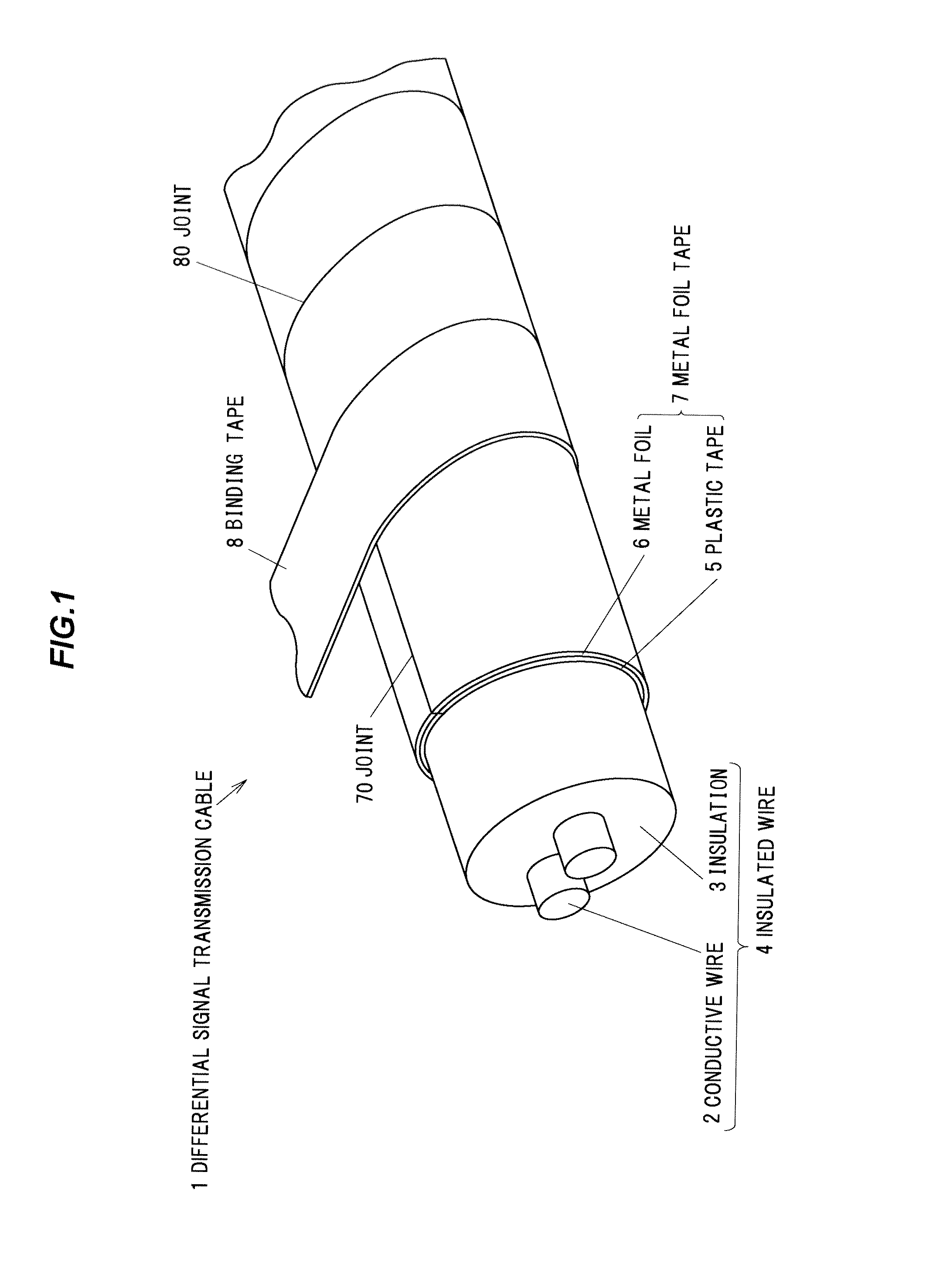

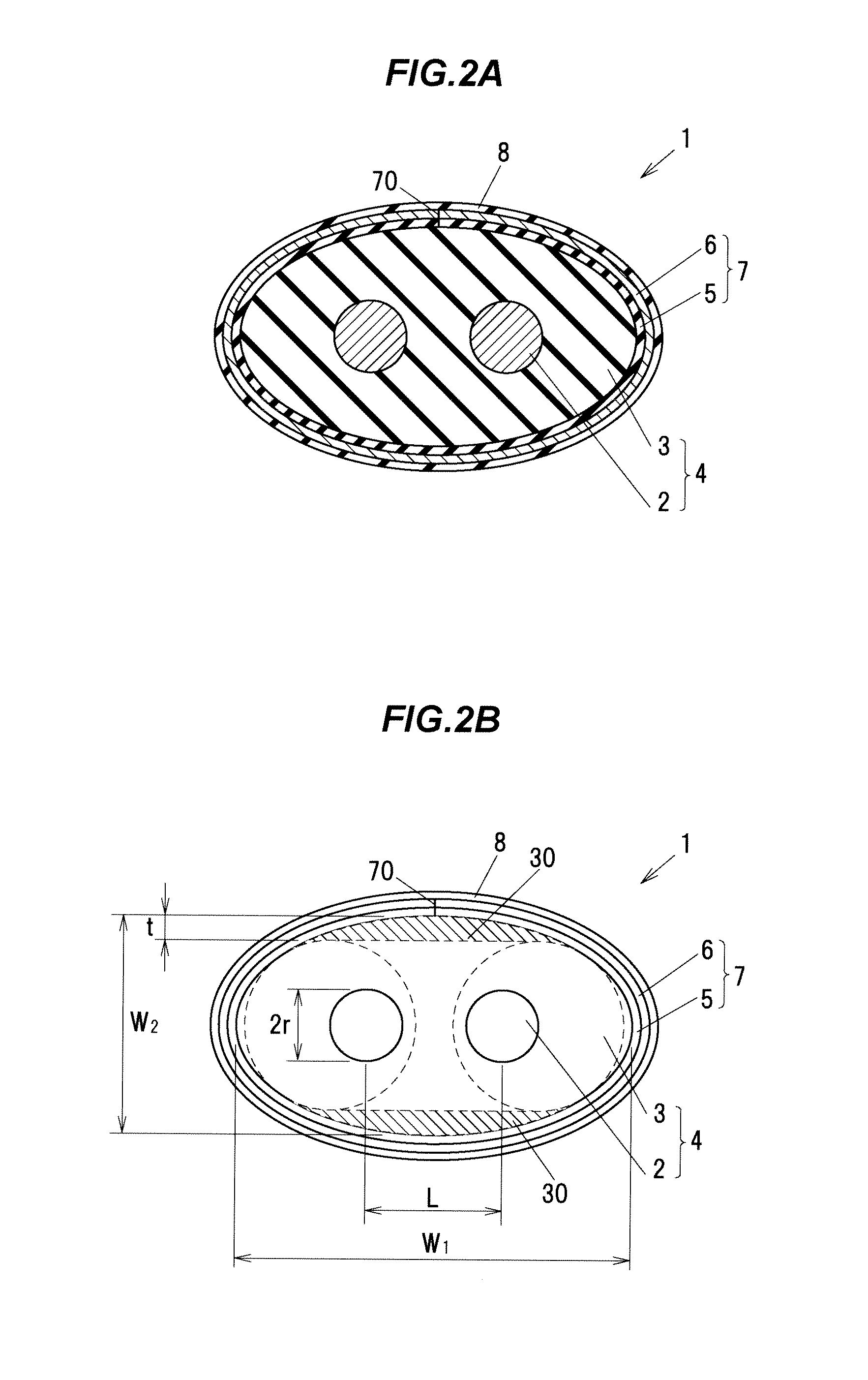

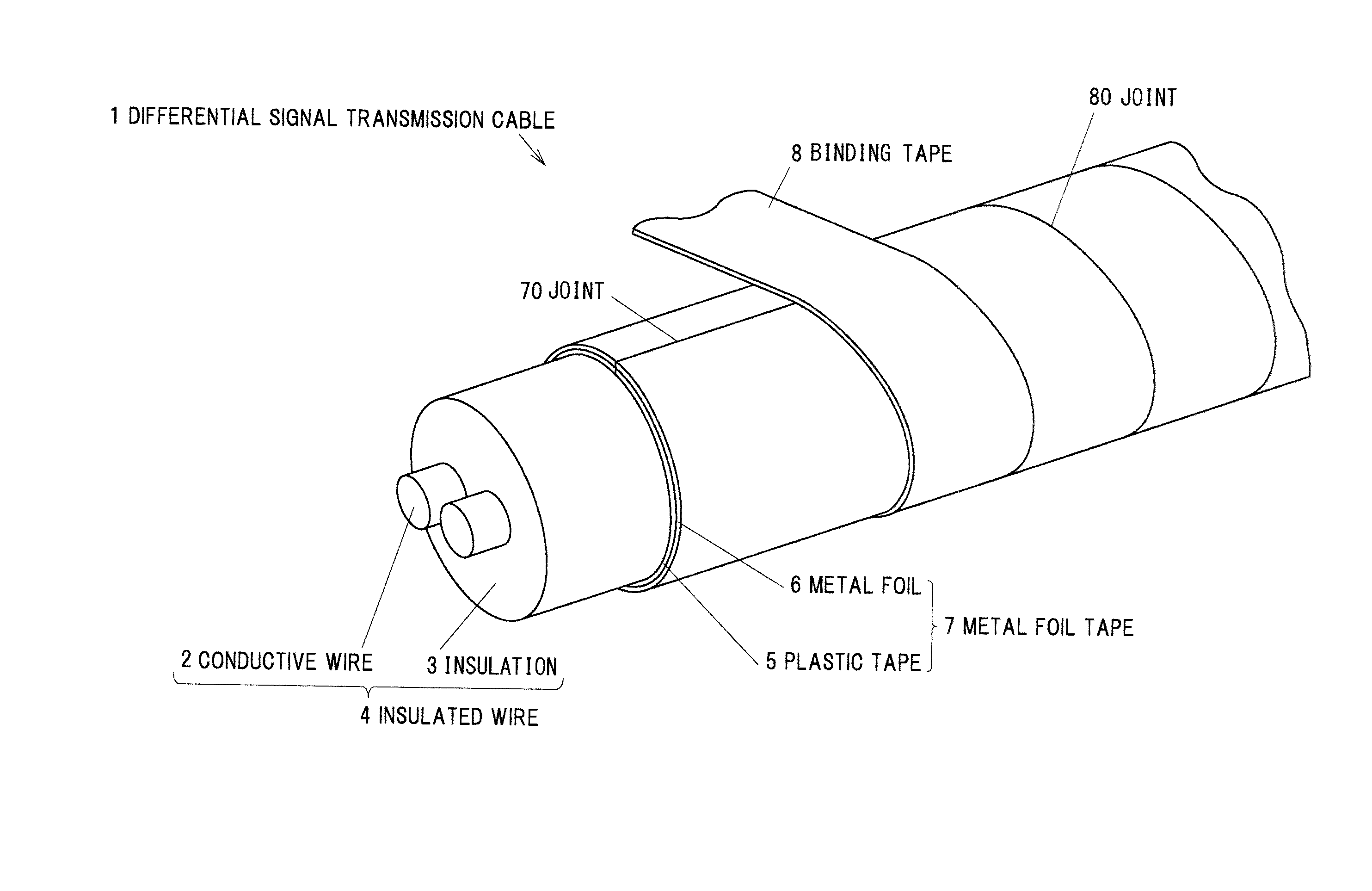

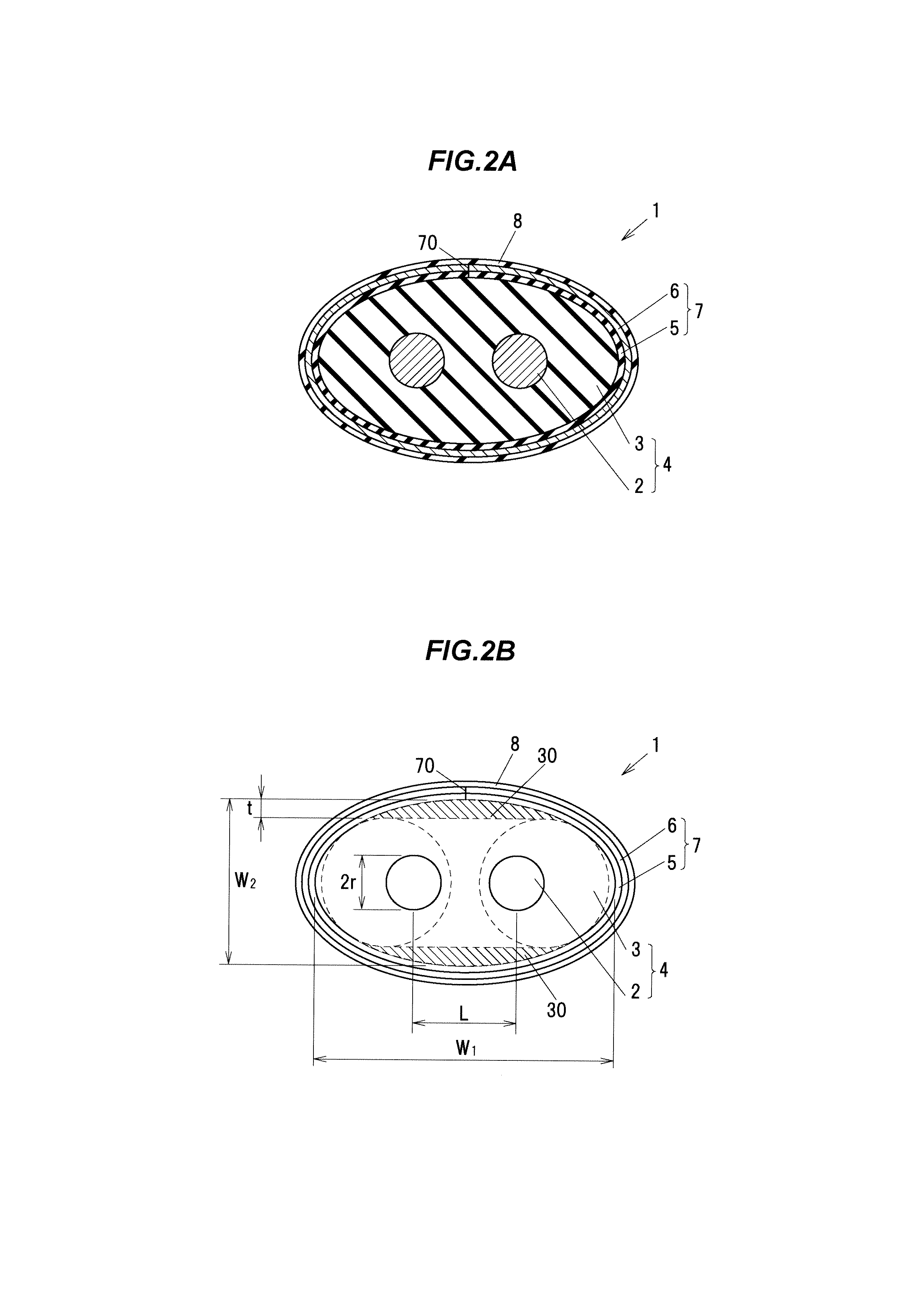

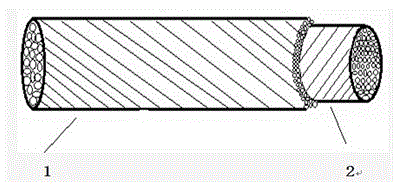

Differential signal transmission cable

ActiveUS8546691B2Improve skewElectrically conductive connectionsMagnetic/electric field screeningElectrical conductorEllipse

A differential signal transmission cable includes a pair of differential signal lines arranged in parallel to each other, an insulation for bundle-covering the pair of differential signal lines, and a shield conductor wound around an outer periphery of the insulation. The insulation is configured such that an outer circumference thereof in a cross section perpendicular to a longitudinal direction thereof has an oval shape formed with a continuous convex arc-curve. The oval shape has a width in a first direction along the arrangement direction of the pair of differential signal lines being larger than a width in a second direction orthogonal to the first direction.

Owner:HITACHI CABLE

Differential signal transmission cable

ActiveUS20130175081A1Prevent looseningImprove skewElectrically conductive connectionsMagnetic/electric field screeningElectrical conductorElectric cables

A differential signal transmission cable includes a pair of differential signal lines arranged in parallel to each other, an insulation for bundle-covering the pair of differential signal lines, and a shield conductor wound around an outer periphery of the insulation The insulation is configured such that an outer circumference thereof in a cross section perpendicular to a longitudinal direction thereof has an oval shape formed with a continuous convex arc-curve The oval shape has a width in a first direction along the arrangement direction of the pair of differential signal lines being larger than a width in a second direction orthogonal to the first direction

Owner:HITACHI CABLE

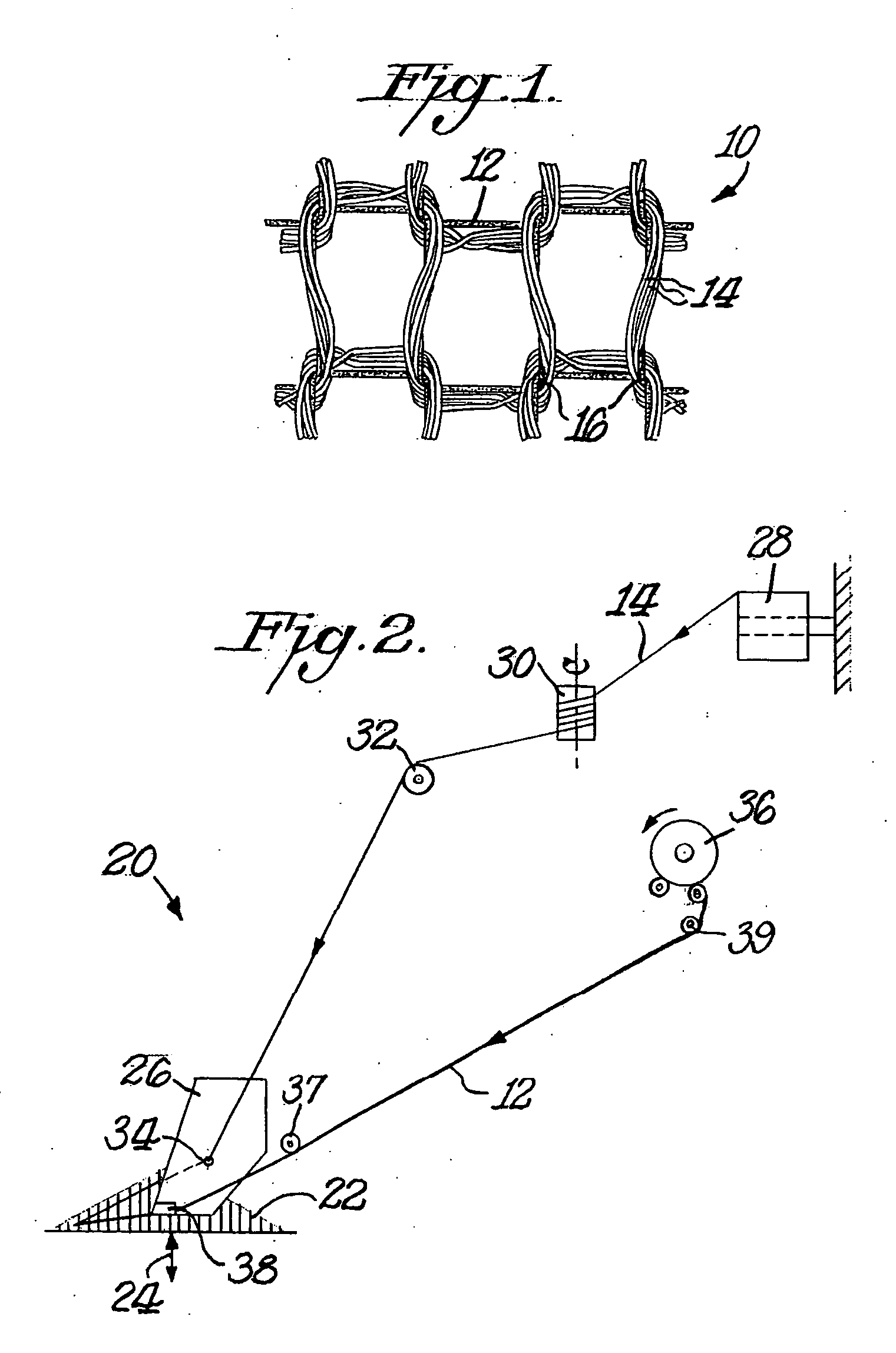

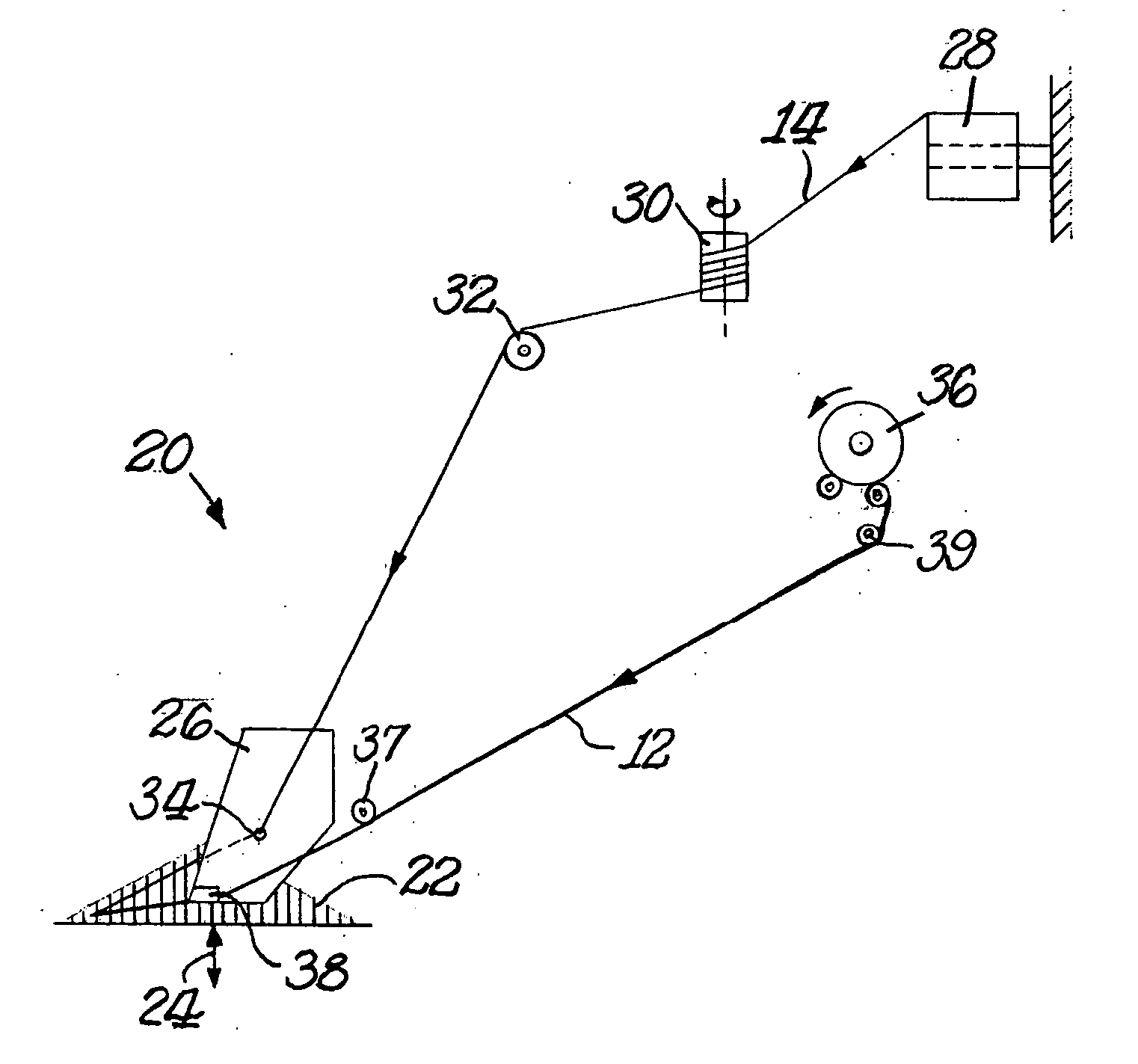

Method to make circular knit elastic fabric comprising spandex and hard yarns

InactiveUS20060021387A1Increase productionReduced “ skew ”Ornamental textile articlesCircular knitting machinesYarnElastomer

Circular knit, elastic fabrics of at least one of single jersey, French terry, and fleece are disclosed that include a bare elastomeric material plated with spun and / or continuous filament hard yarns. The circular knit, elastic fabrics of at least one of single jersey, French terry, and fleece are manufactured by a method that does not require a dry heat setting step. The method requires drafting the bare elastomeric material no more than about 7× its original length when knitting to form the circular knit, elastic, single jersey, French terry, or fleece fabric. The method includes contacting the knit fabric with an aqueous solution under very low tension and under conditions of temperature and pressure for a period of time sufficient to substantially set the elastomeric material.

Owner:THE LYCRA CO LLC

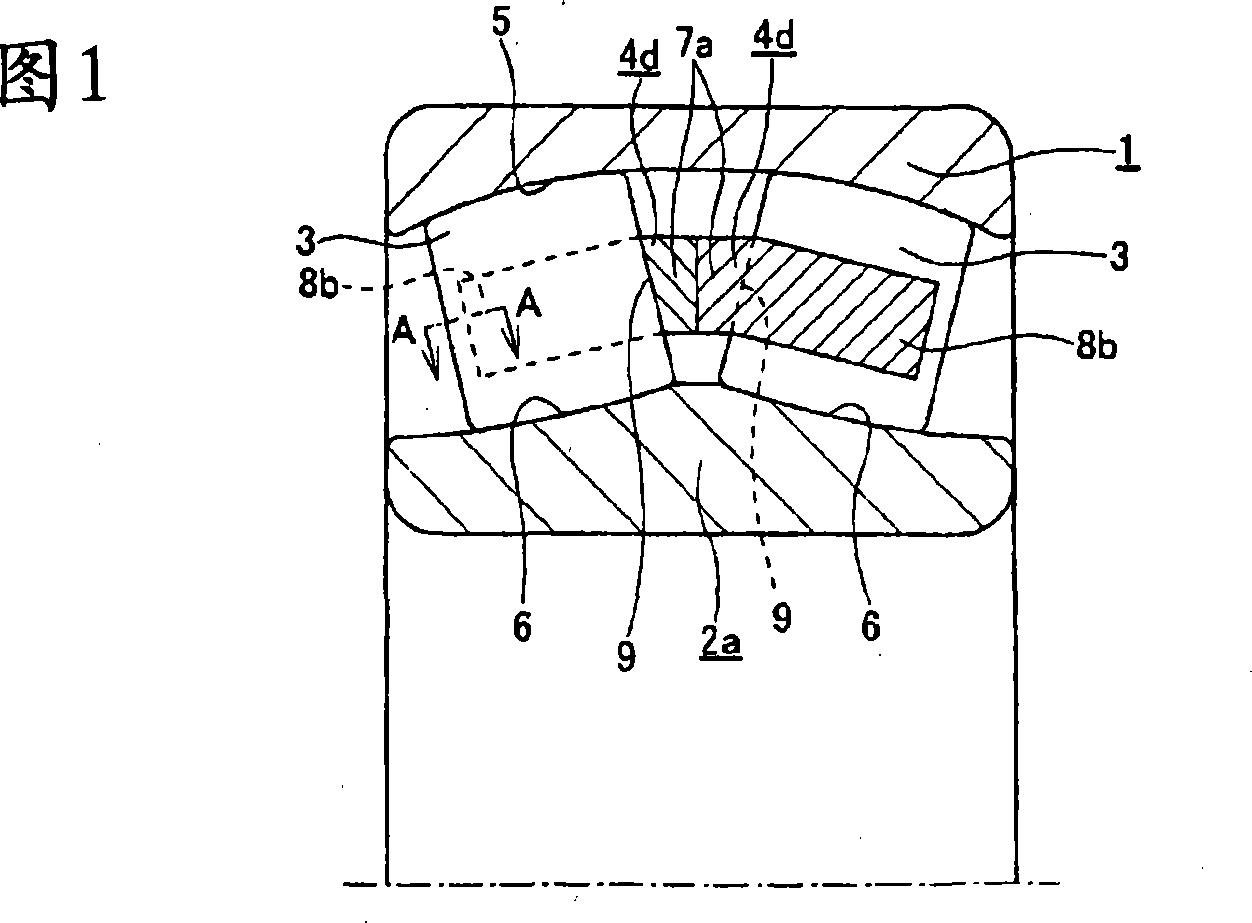

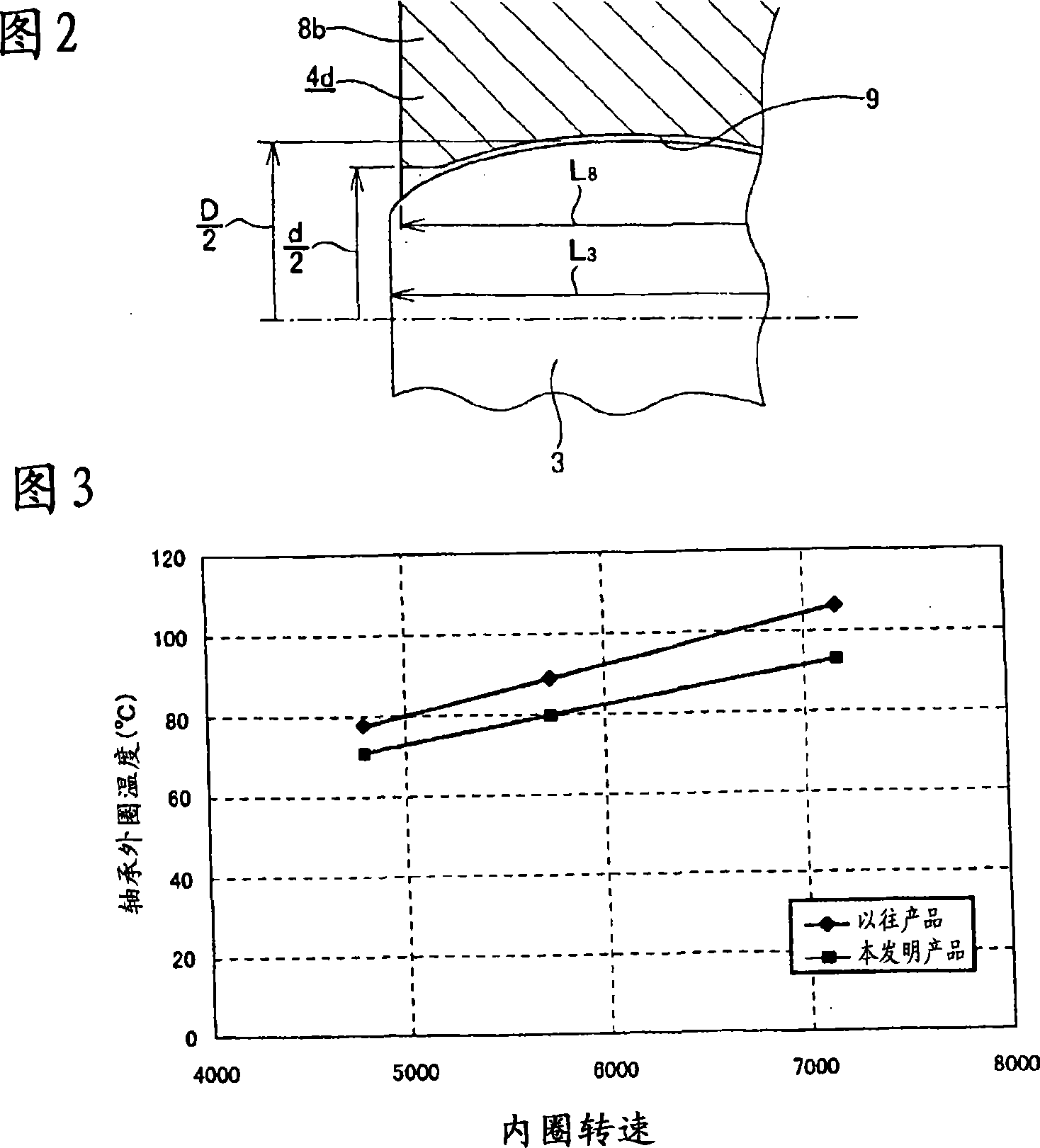

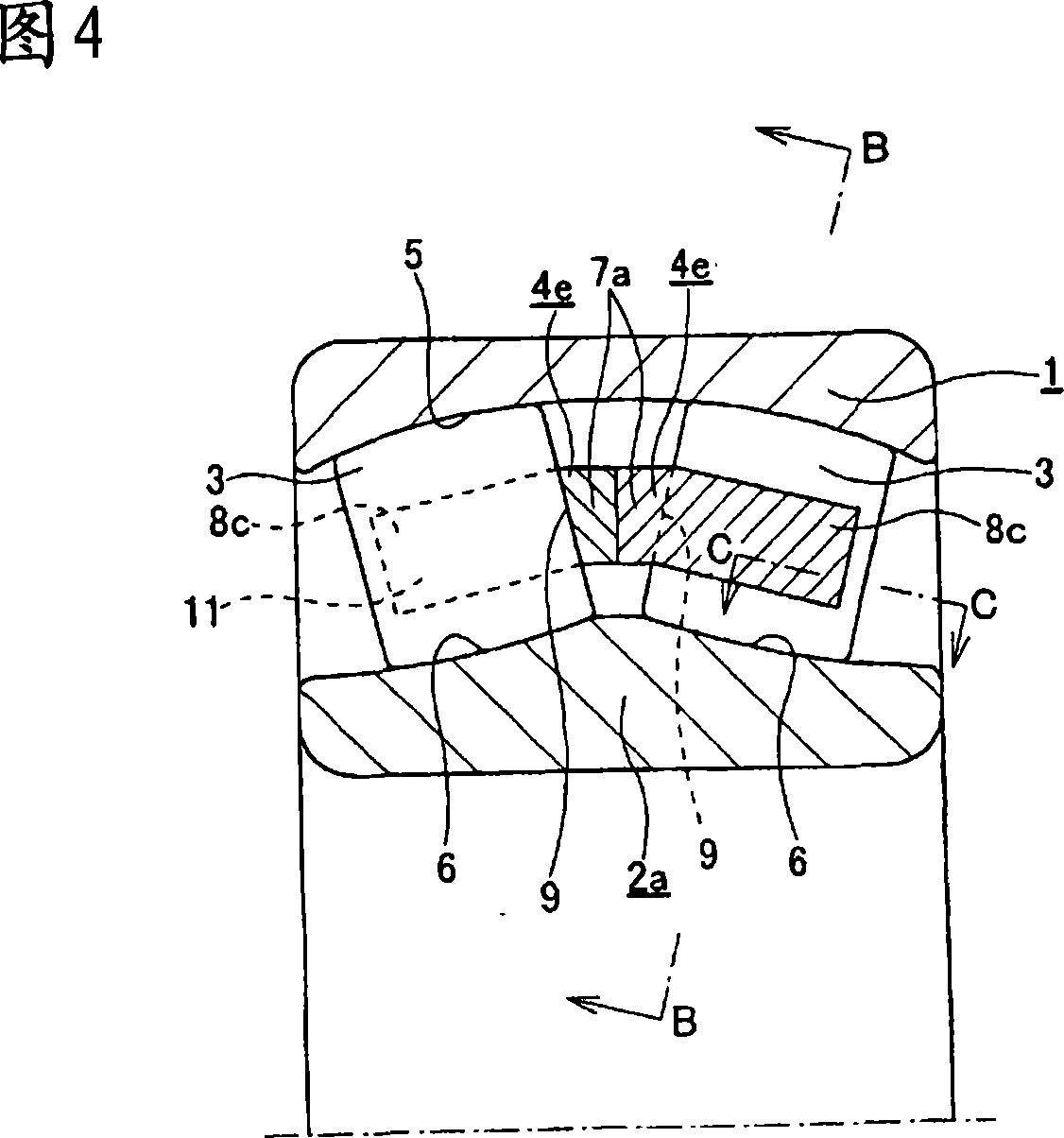

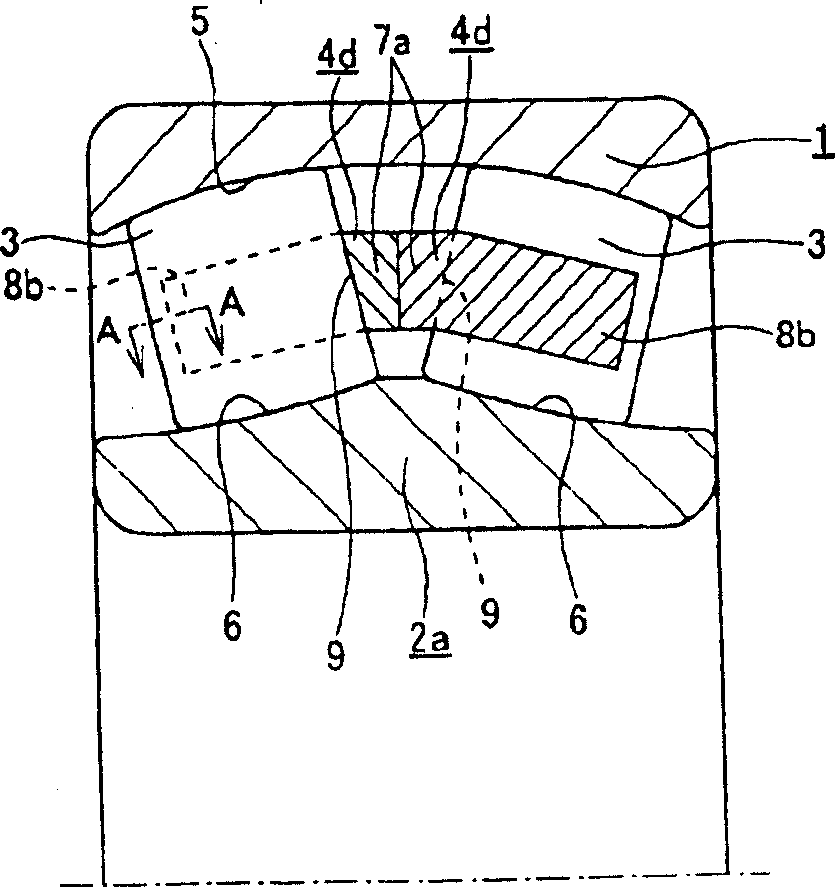

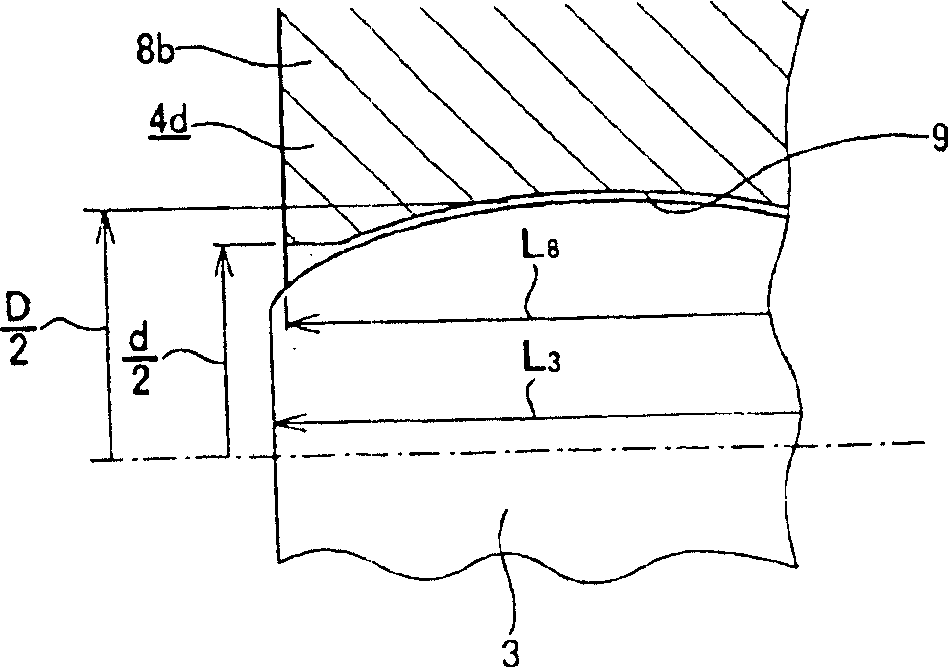

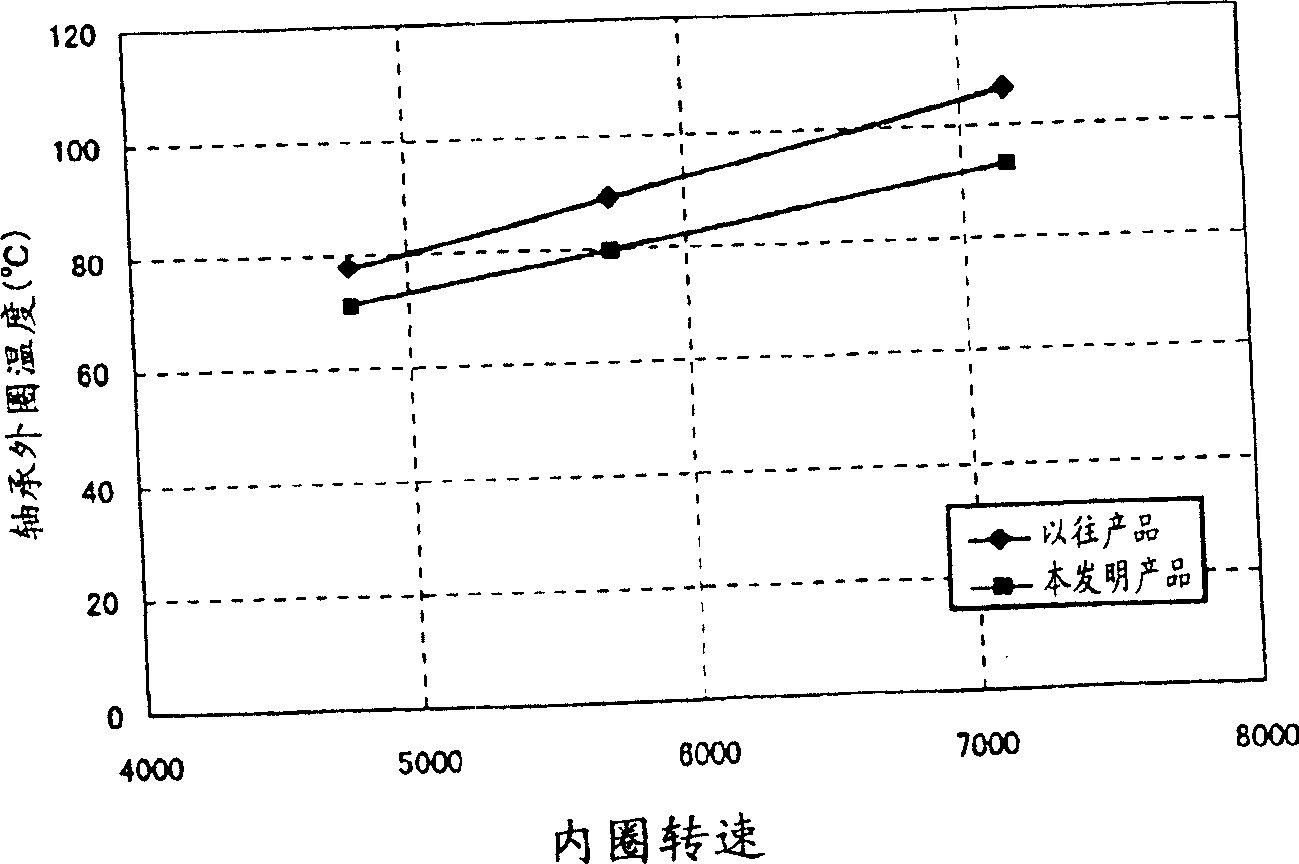

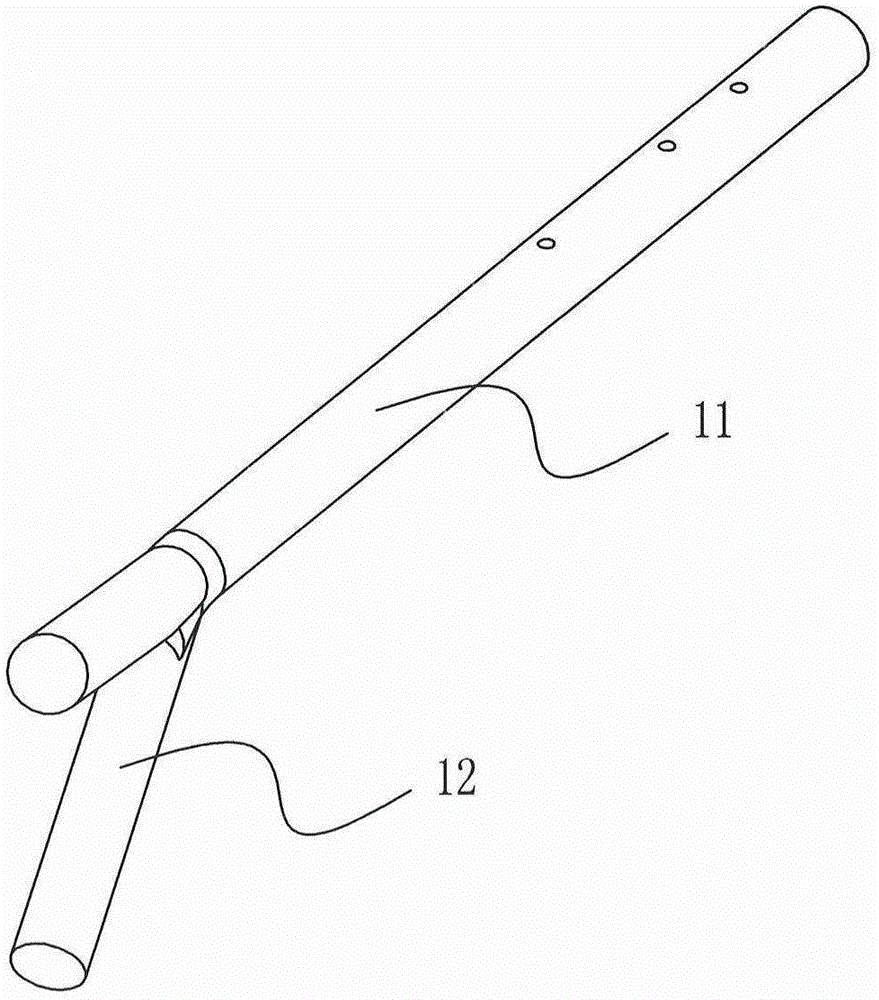

Self-aligning roller bearing with retainer and method of manufacturing the retainer for the self-aligning roller bearing

ActiveCN101035995AEasy to processLow costRoller bearingsBearing componentsBarrel ShapedSpherical roller bearing

There is realized a self-aligning roller bearing with retainer that stabilizes the orientation of spherical rollers and prevents these spherical rollers from skewing, and which can be rotated at high speed, and furthermore which enables efficient lubricant feed into pockets 9. By rotating a turning tool 14 as it revolves, the surfaces on both sides in the circumferential direction of respective column sections are processed into concave curved surfaces that oppose a rolling surface of the respective spherical rollers across a pocket clearance into which lubricant oil can be fed. The length of the column sections 8c is less than the length in the axial direction of the spherical rollers, and greater than a half of the length, and an end portion of the side surface in the circumferential direction of the respective column sections 8c projects further in the circumferential direction than an intermediate portion thereof, and the spherical rollers are embraced in the pockets 9.A self-aligning roller bearing with a retainer enabling high speed operation by stabilizing the attitude of barrel shaped rollers to prevent the barrel shaped rollers from being skewed and the efficient feeding of a lubricant into pockets (9) and a method of manufacturing the retainer for the self-aligning roller bearing. In the self-aligning roller bearing, the both side faces of each column part (8c) in the circumferential direction are machined to recessed curved faces facing the rolling surface of each barrel shaped roller through pocket clearances allowing the lubricant to feed thereto with a cutting tool (14) revolving while rotating on its axis. Also, the length of each column part (8c) is set equal to or less than the axial length of each barrel shaped roller and more than the half of the axial length thereof, the side face tip portion of each column part (8c) in the circumferential direction are projected from the intermediate portion thereof in the circumferential direction.

Owner:NSK LTD

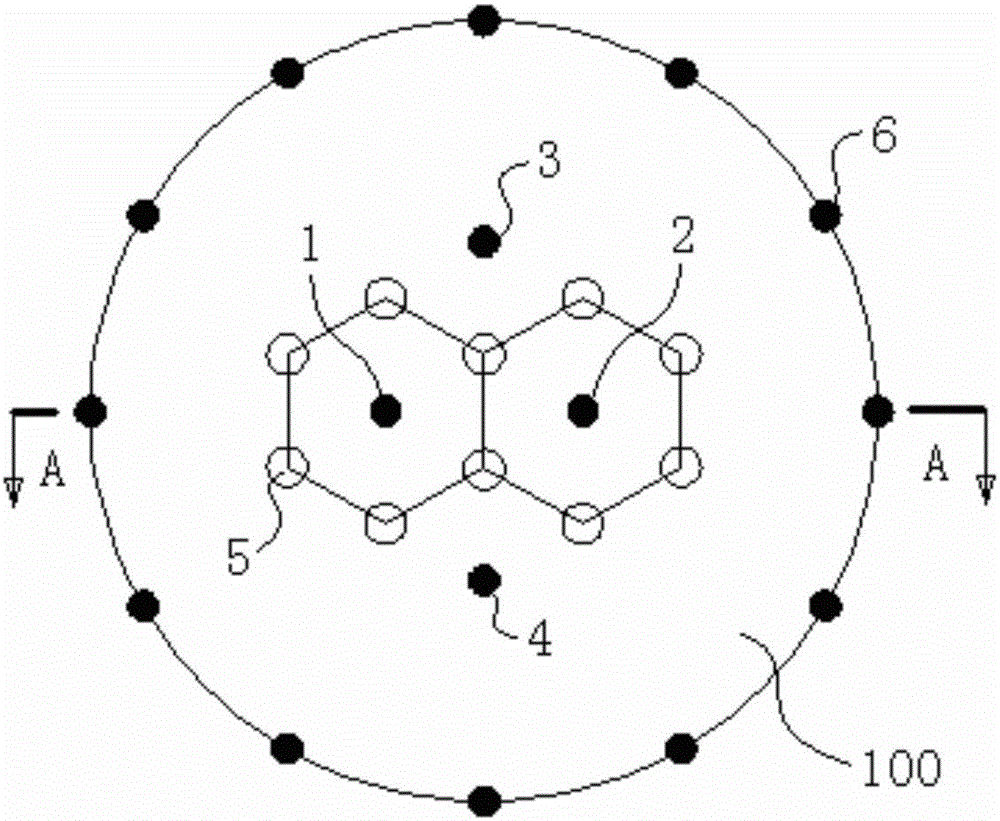

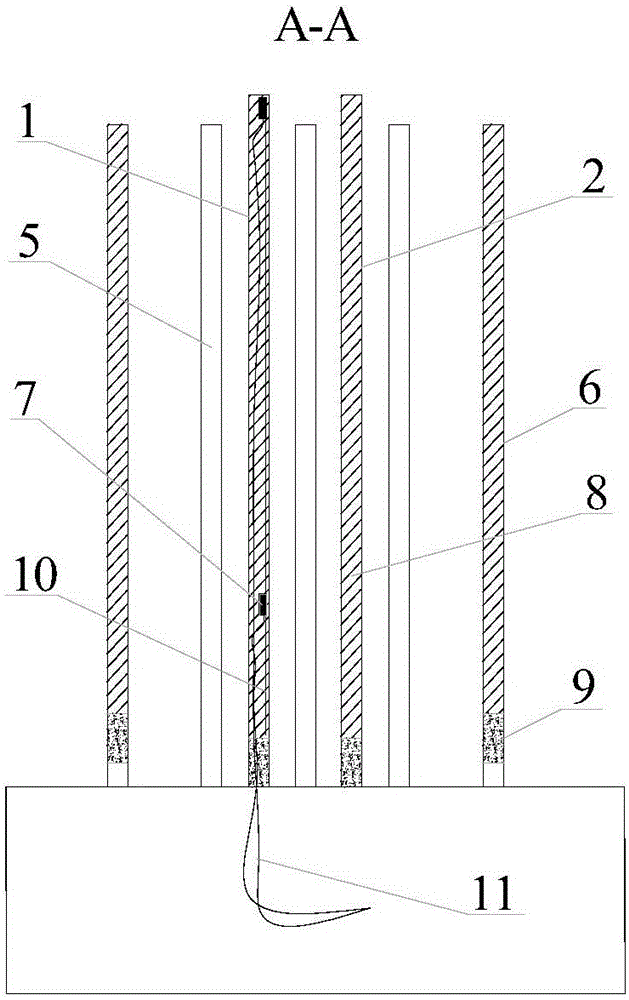

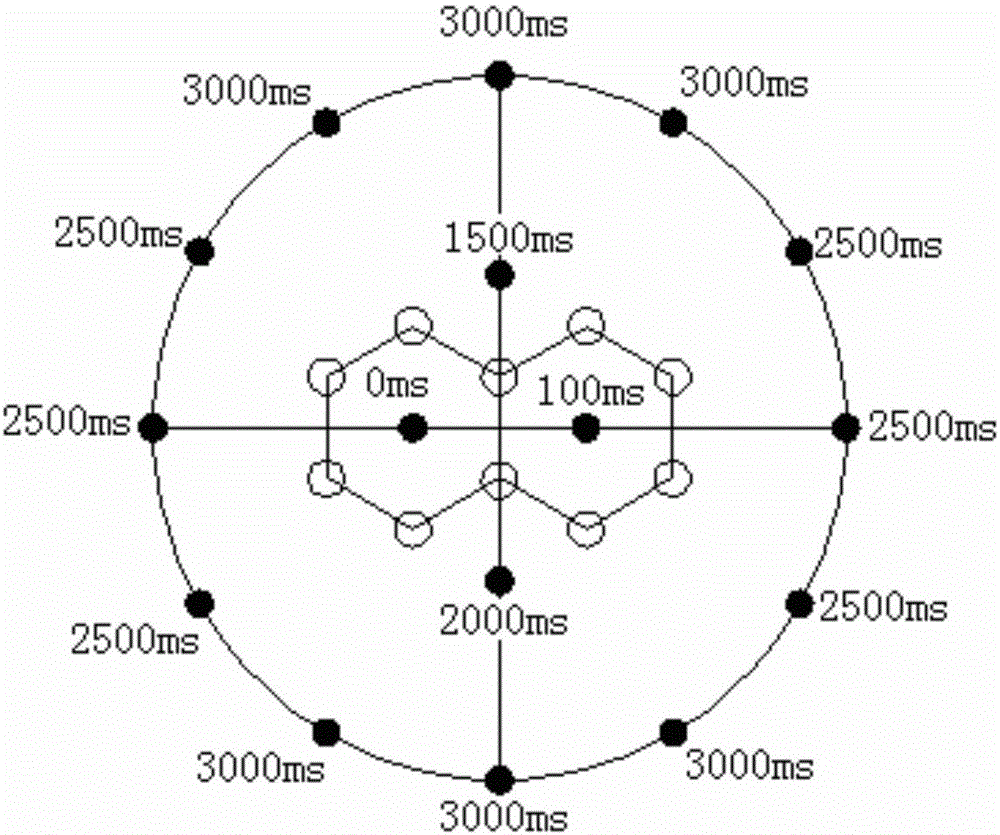

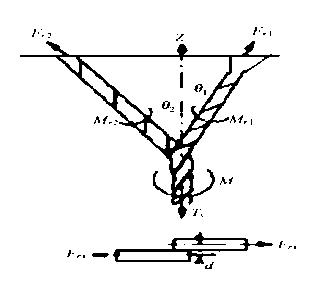

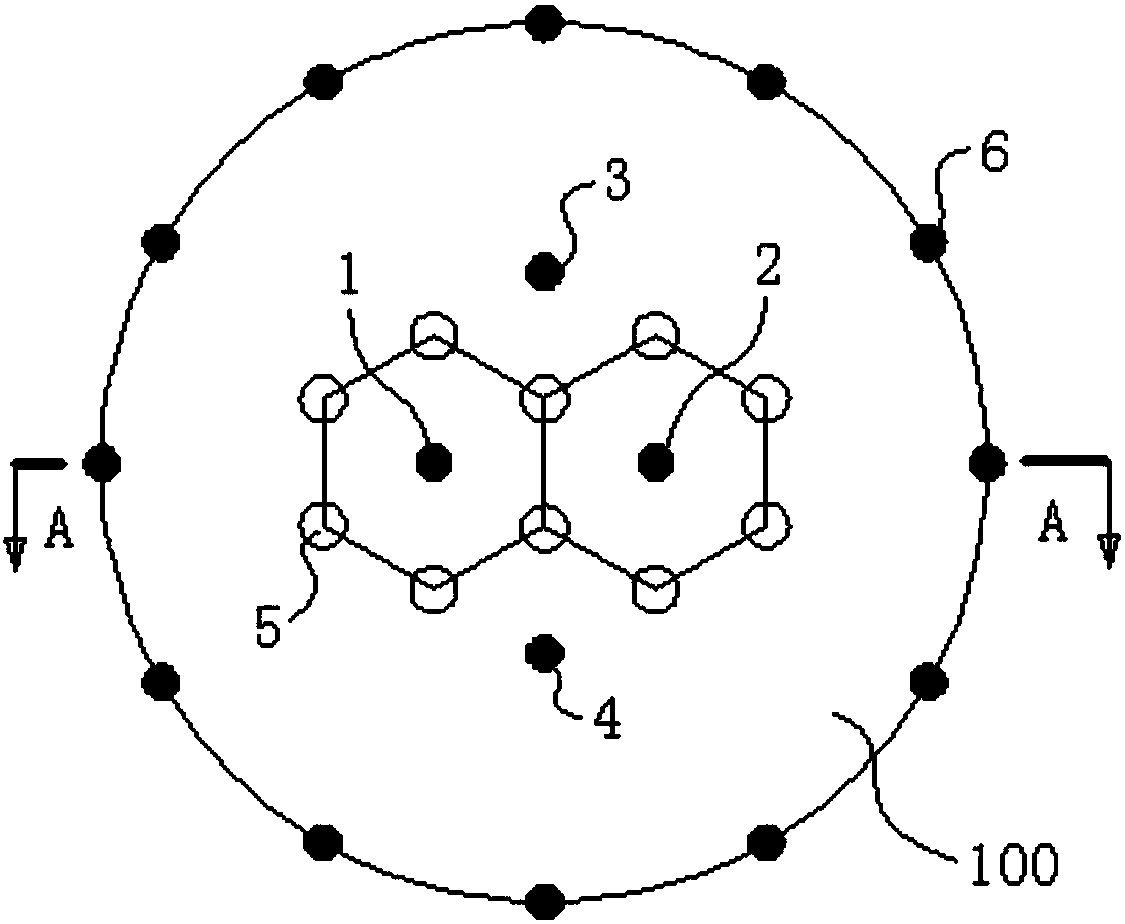

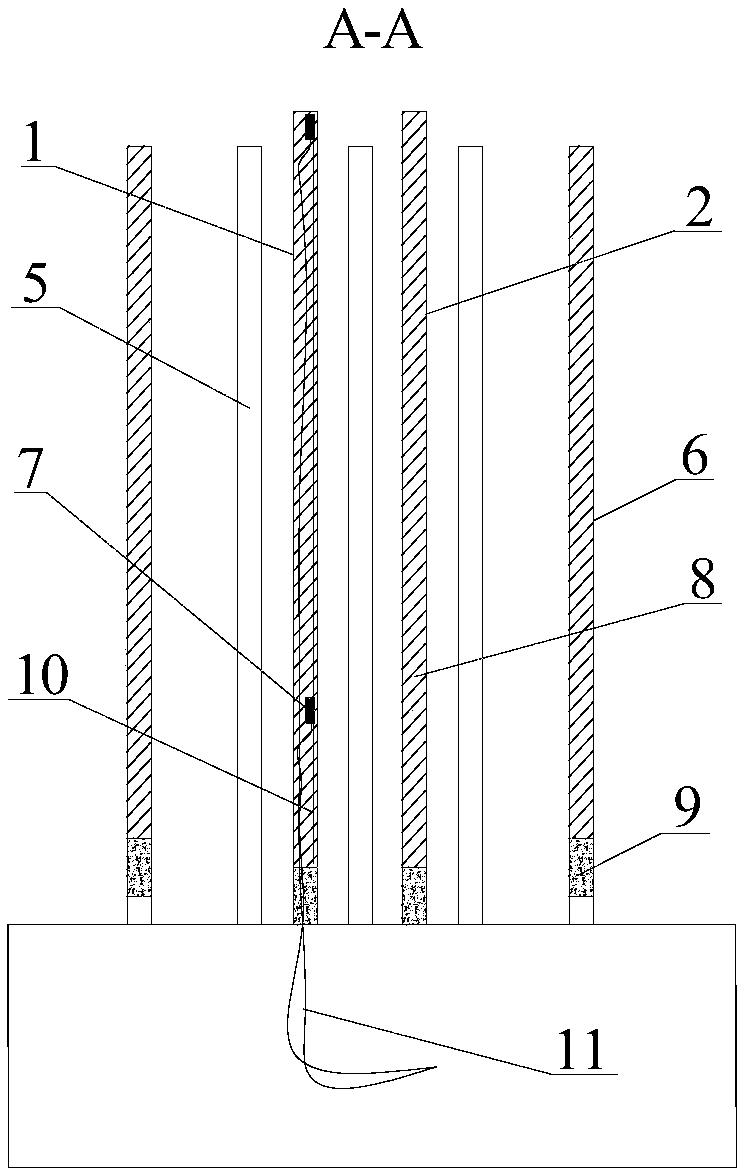

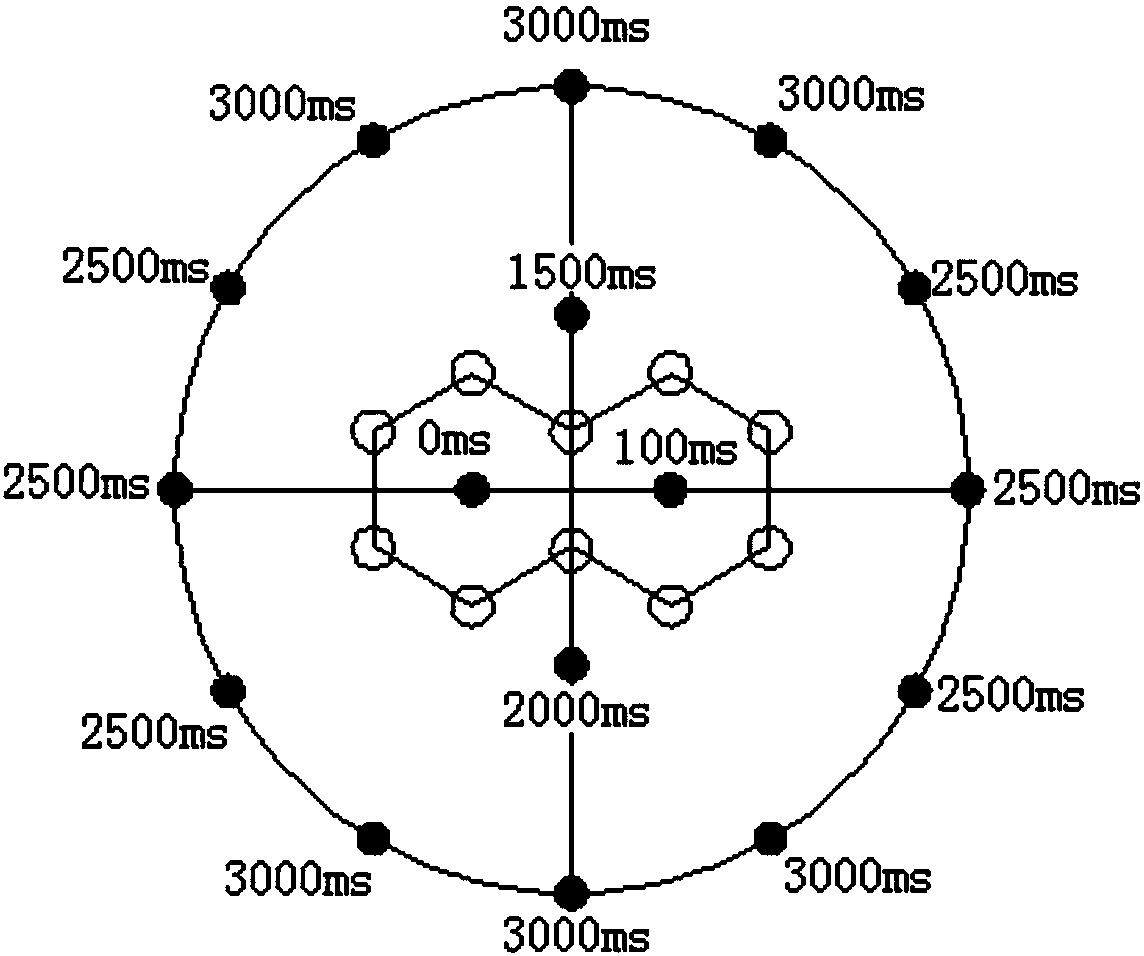

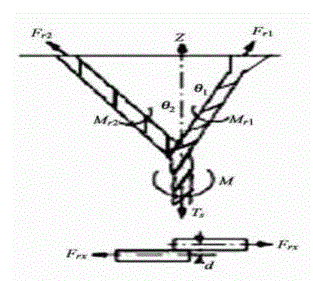

Dual-area slotting blast hole arrangement structure and blasting sinking method applied to structure

ActiveCN106767212AReduced precision requirementsIncrease heightBlastingEngineeringBlasting vibration

The invention discloses a dual-area slotting blast hole arrangement structure and a blasting sinking method applied to the structure. The structure comprises two blasting slotting hole areas symmetrically arranged with respect to the center of the free face of a courtyard, each blasting slotting hole area comprises a center charging hole and a plurality of empty holes arranged around the center charging hole; a ring of peripheral holes are formed in the periphery of each blasting slotting area, the center charging holes and the peripheral hoes are filled with explosive charges, and a plurality of auxiliary holes are formed between the blasting slotting areas and the peripheral holes and are filled with explosive charges. The method is simple in working procedure, operation is easy, the one-time sinking height is large, reliability is high, the sinking effect is good, the number of drilled holes is small, energy consumption is low, and the blasting vibration is small.

Owner:CENT SOUTH UNIV

Knit by design method and fabric

InactiveUS7634924B2Increase productionImprove skewOrnamental textile articlesCircular knitting machinesElastomerEngineering

Owner:THE LYCRA CO LLC

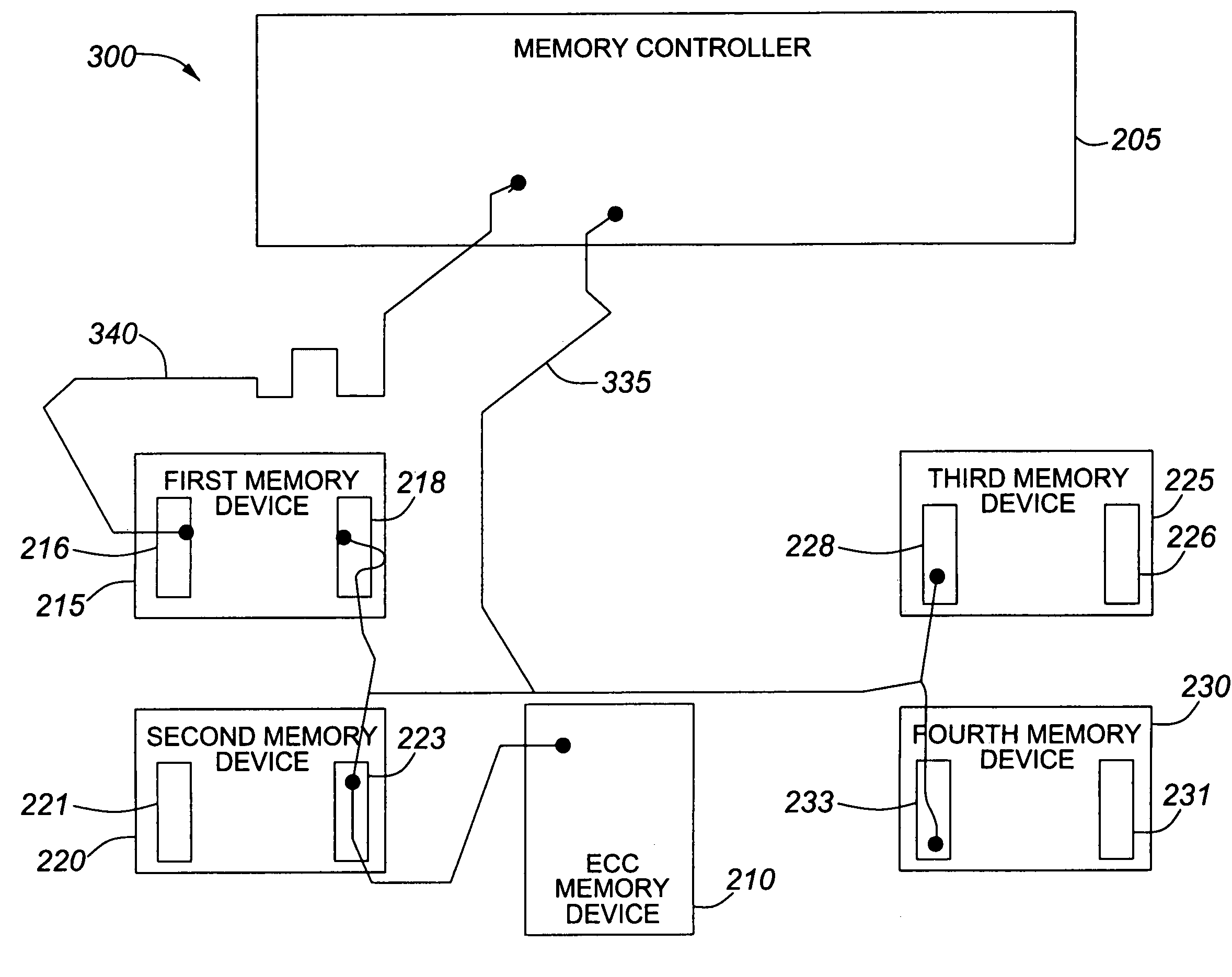

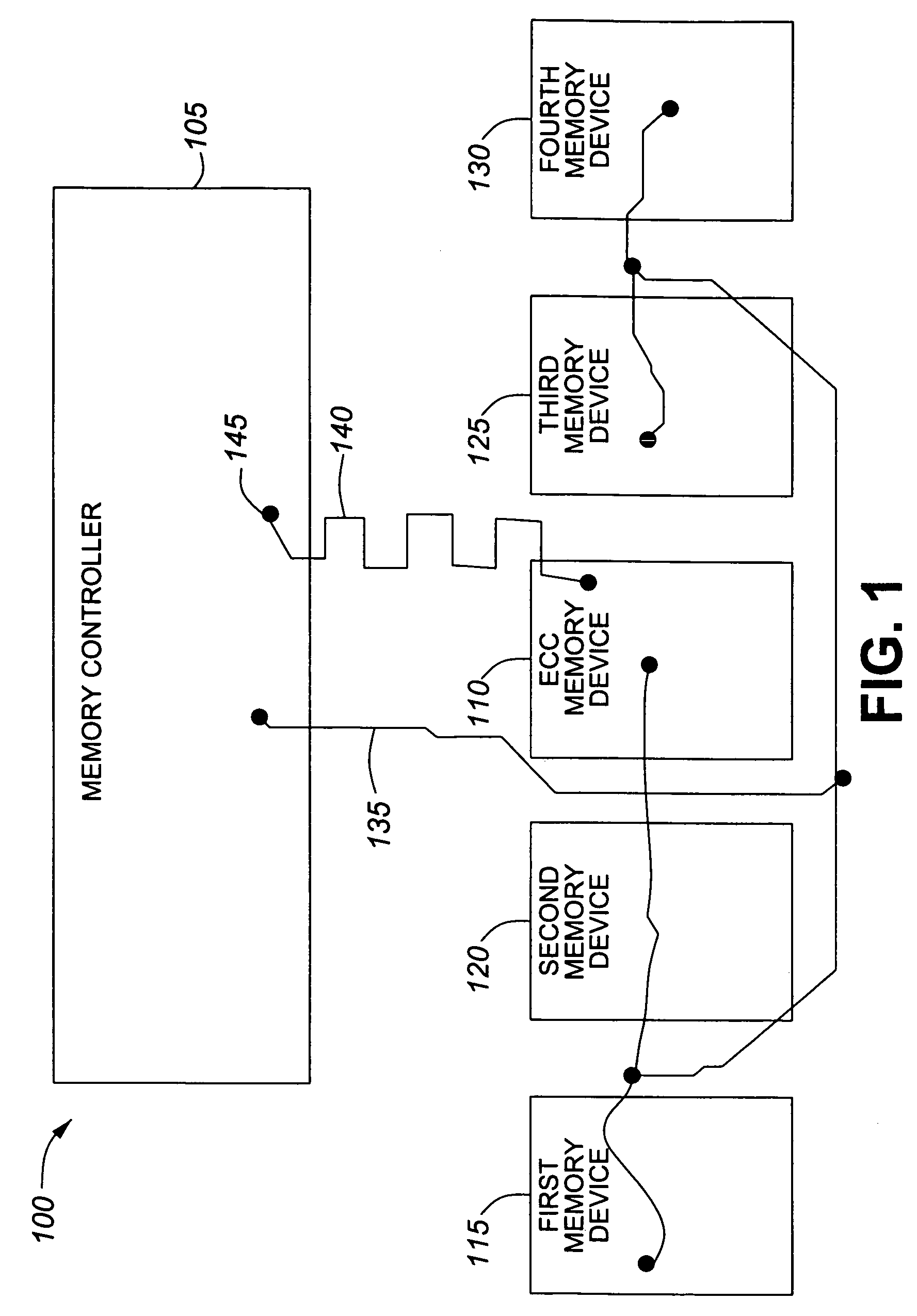

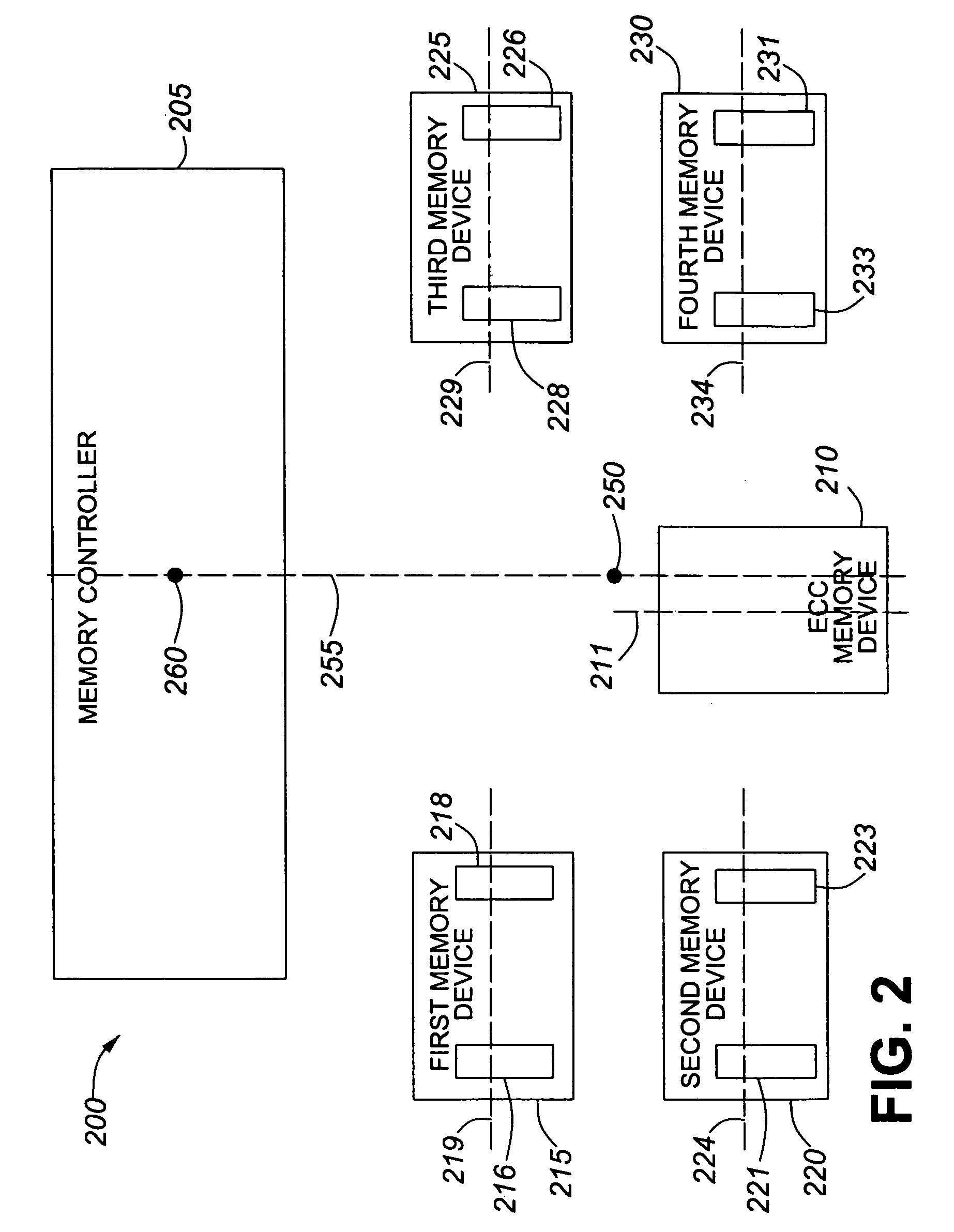

Placement and routing of ECC memory devices for improved signal timing

InactiveUS7697332B2Promote resultsMinimize timeWave amplification devicesError detection/correctionData memoryMemory controller

A printed circuit board may include a memory controller, a plurality of synchronous data memory devices, each synchronous memory device including at least one data pin and at least one address / command pin, an ECC memory device including at least one ECC data pin and at least one ECC address / command pin, and at least one surface. The plurality of synchronous data memory devices may be arranged around a central location on the at least one surface and each synchronous data memory device may be oriented such that the at least one data pin is further from the memory controller than the at least one address / command pin.

Owner:RPX CORP

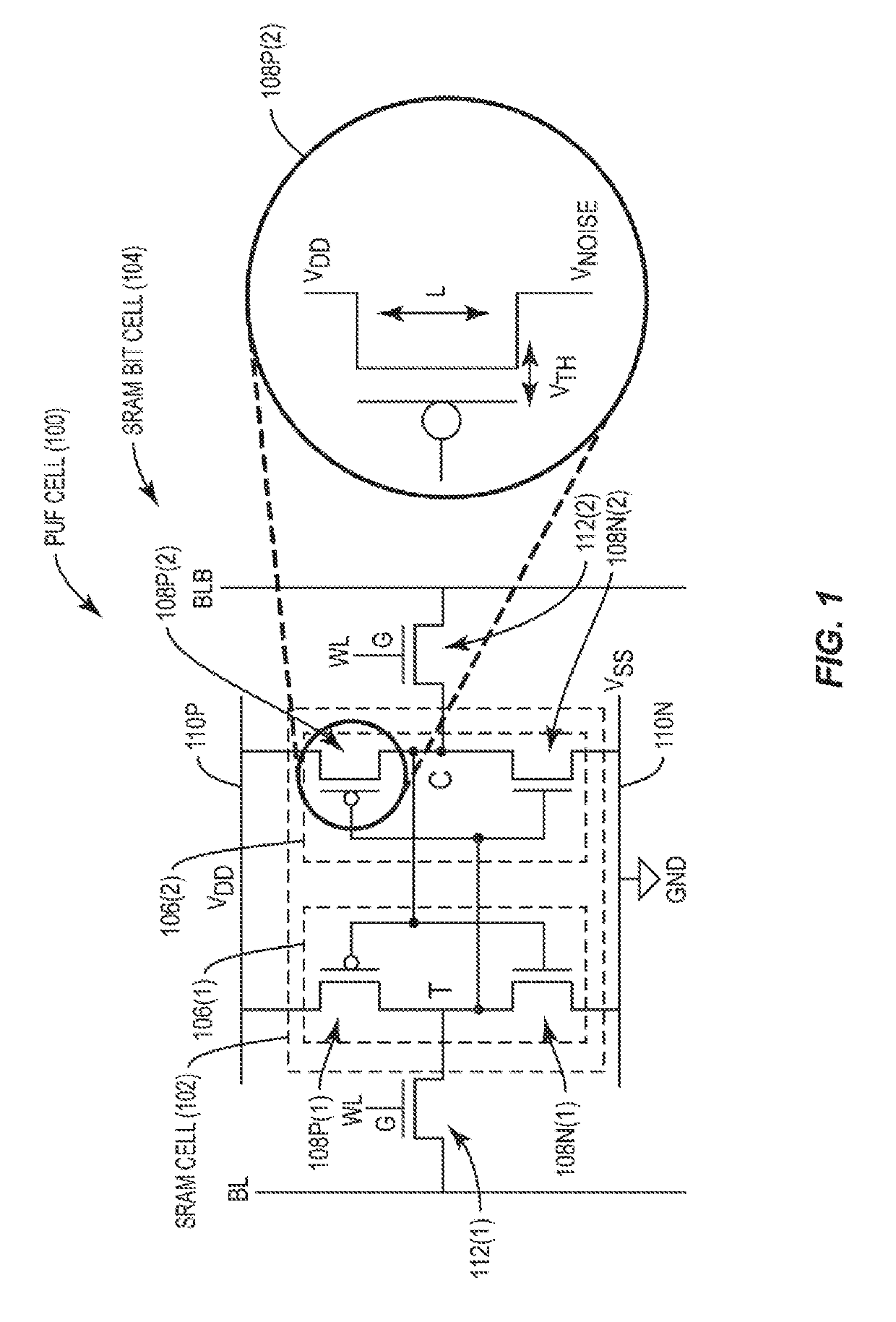

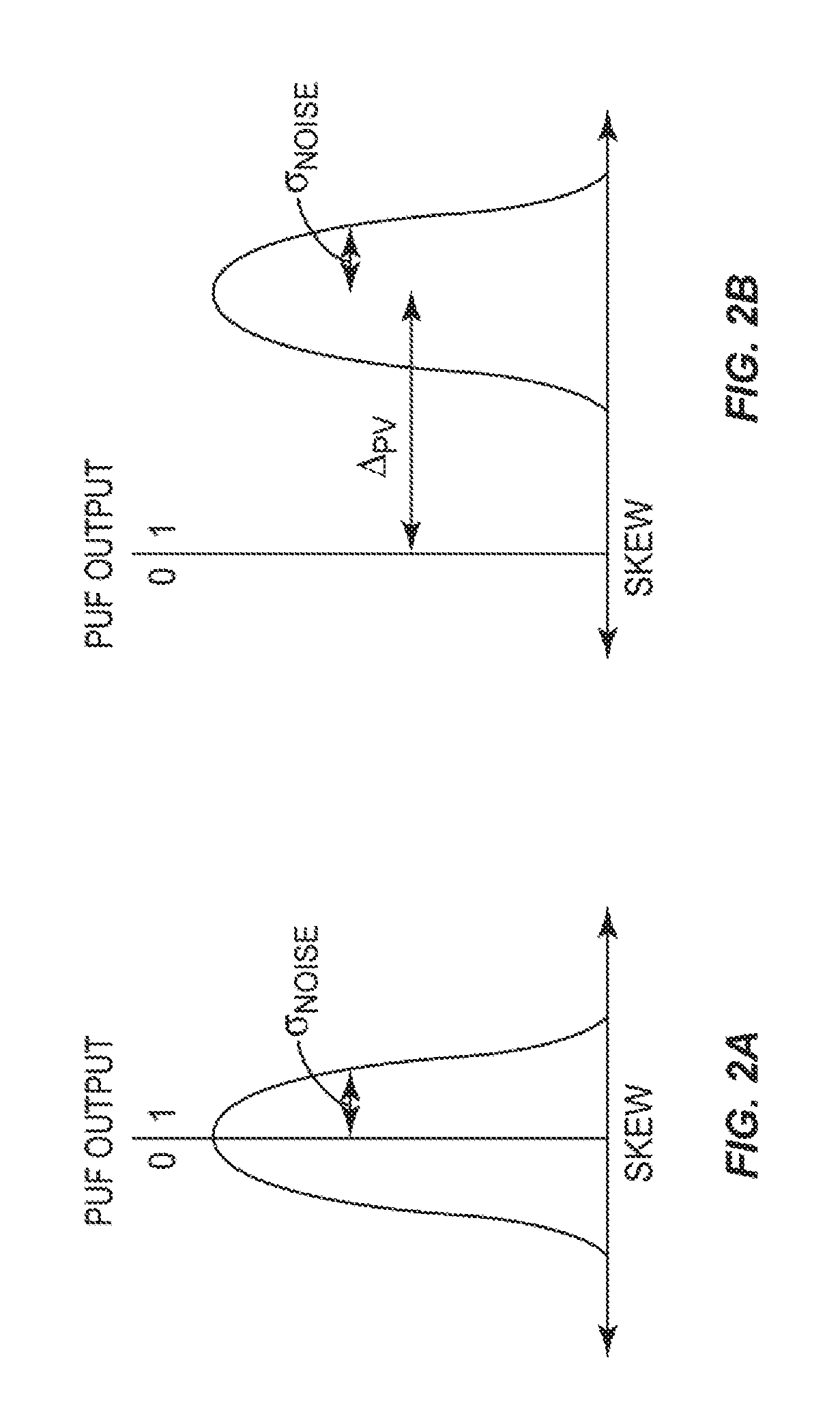

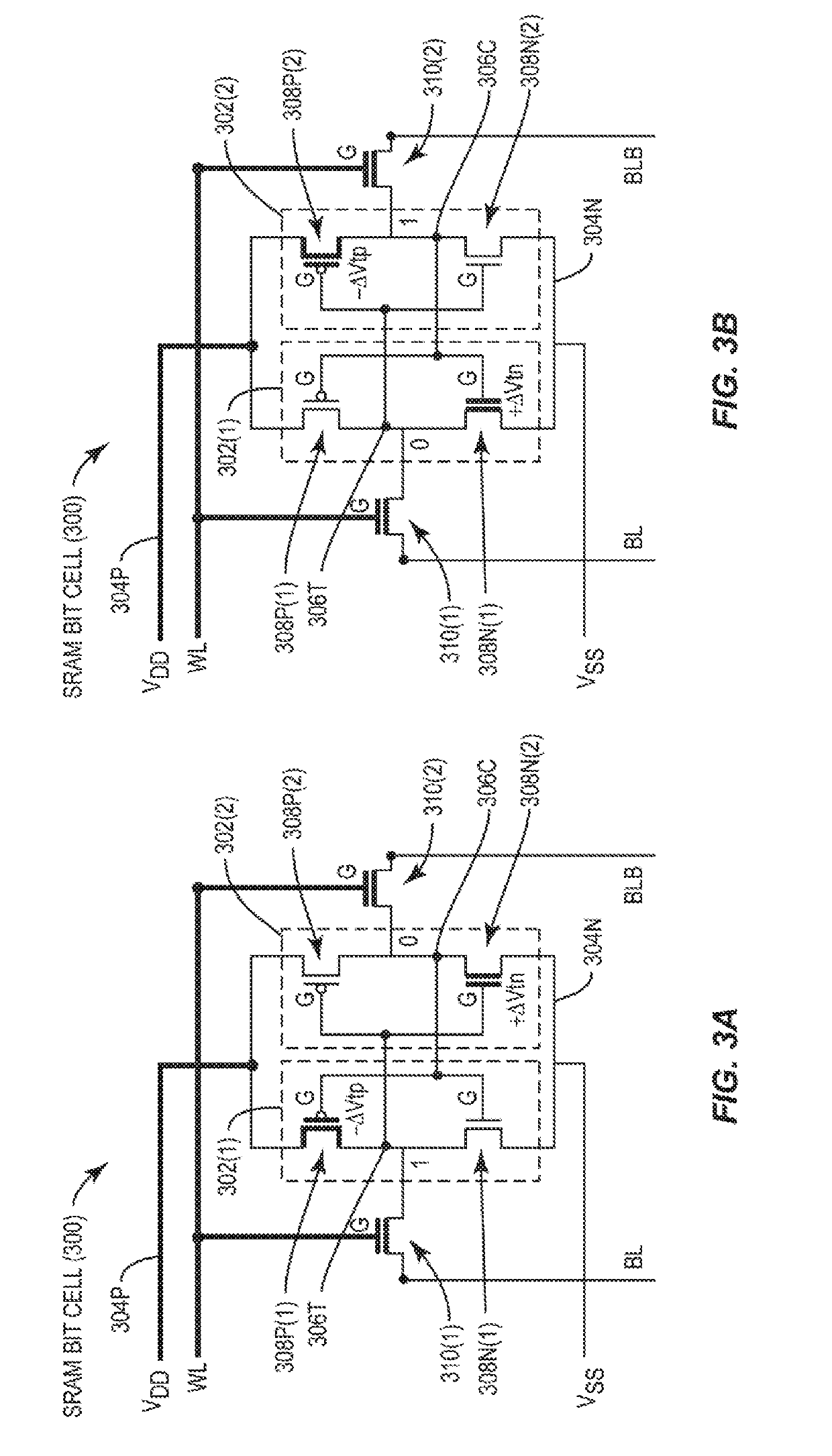

Physically unclonable function (PUF) memory employing static random access memory (SRAM) bit cells enhanced by stress for increased puf output reproducibility

InactiveUS20190305971A1Increase reproducibilityEnhance their skewUser identity/authority verificationDigital storageTransistor agingBit cell

Physically unclonable function (PUF) memory employing static random access memory (SRAM) bit cells enhanced by stress for increased PUF output reproducibility. Stress voltage applied to SRAM bit cells enhances their skew so that the SRAM bit cells output their preferred initial state in subsequent PUF read operations regardless of process variation and other external environmental variations, such as temperature. The application of stress voltage on the SRAM bit cells in a PUF memory array takes advantage of the recognition of aging effect in transistors, where turning transistors on and off over time can increase threshold voltage resulting in lower drive current. Stress voltage can be applied to the SRAM bit cells to bias their threshold voltage to simulate this aging effect to enhance mismatch between transistors in the SRAM bit cell to more fully skew the SRAM bit cells for increased PUF output reproducibility with less susceptible to noise.

Owner:QUALCOMM INC

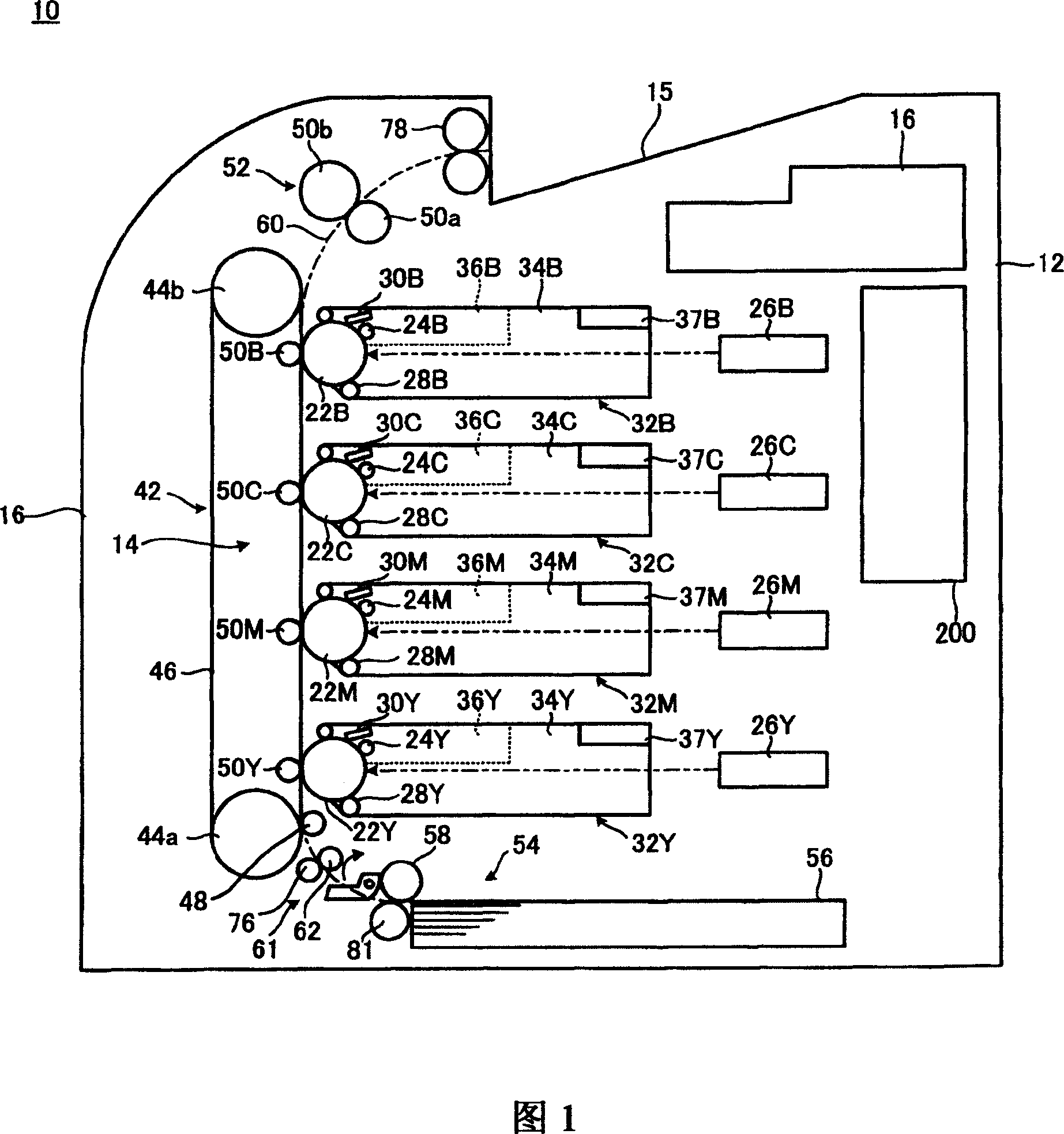

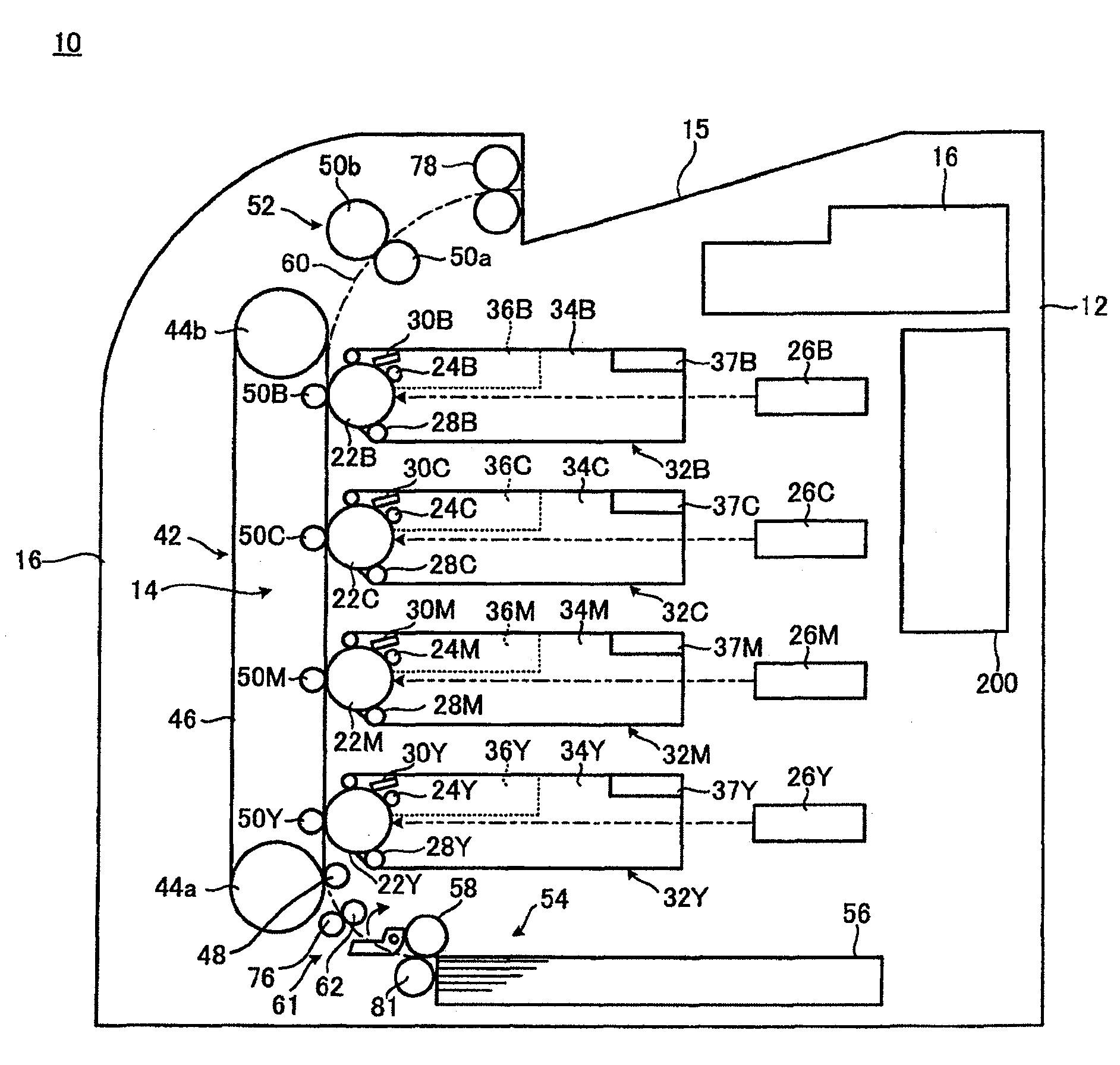

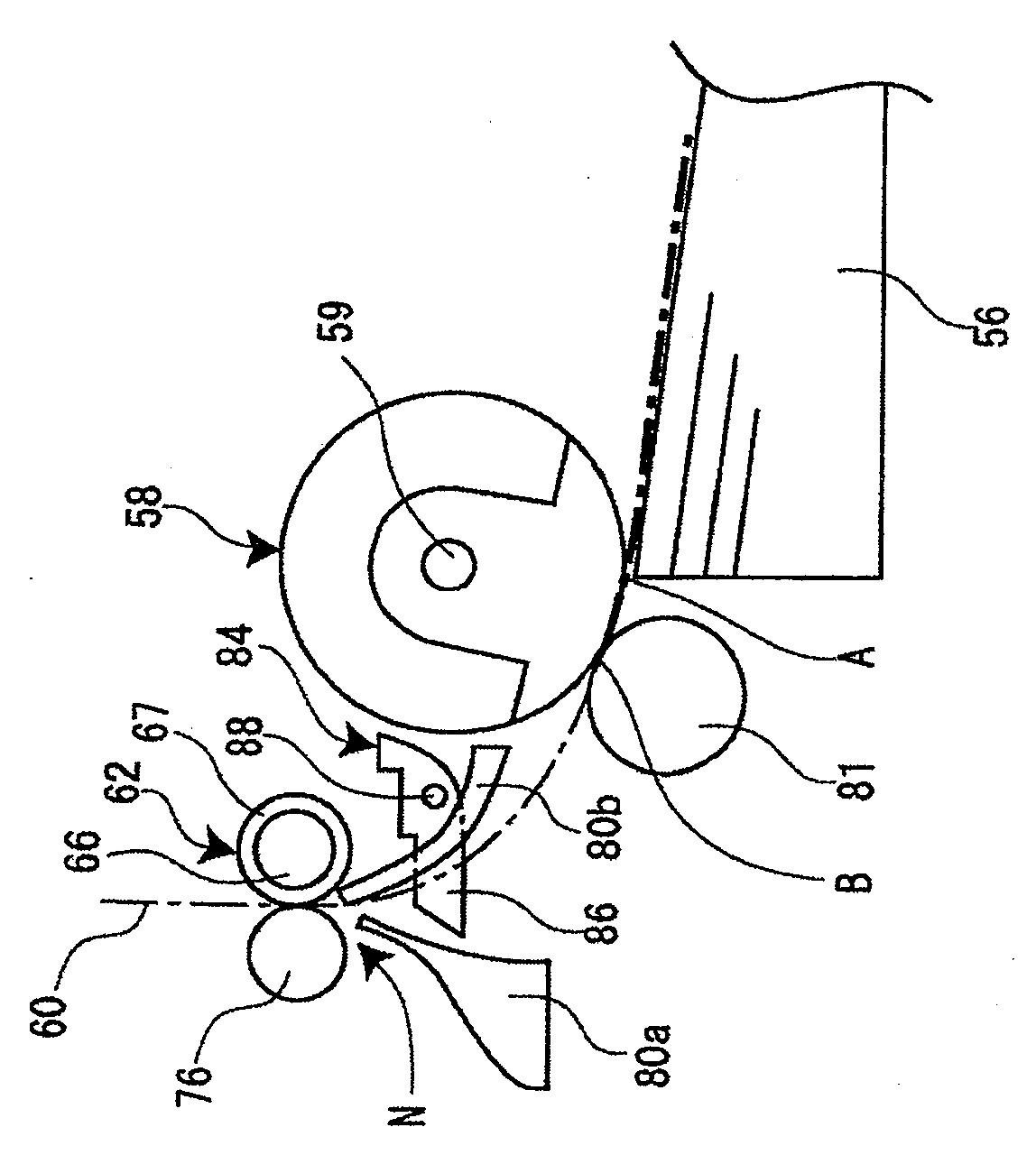

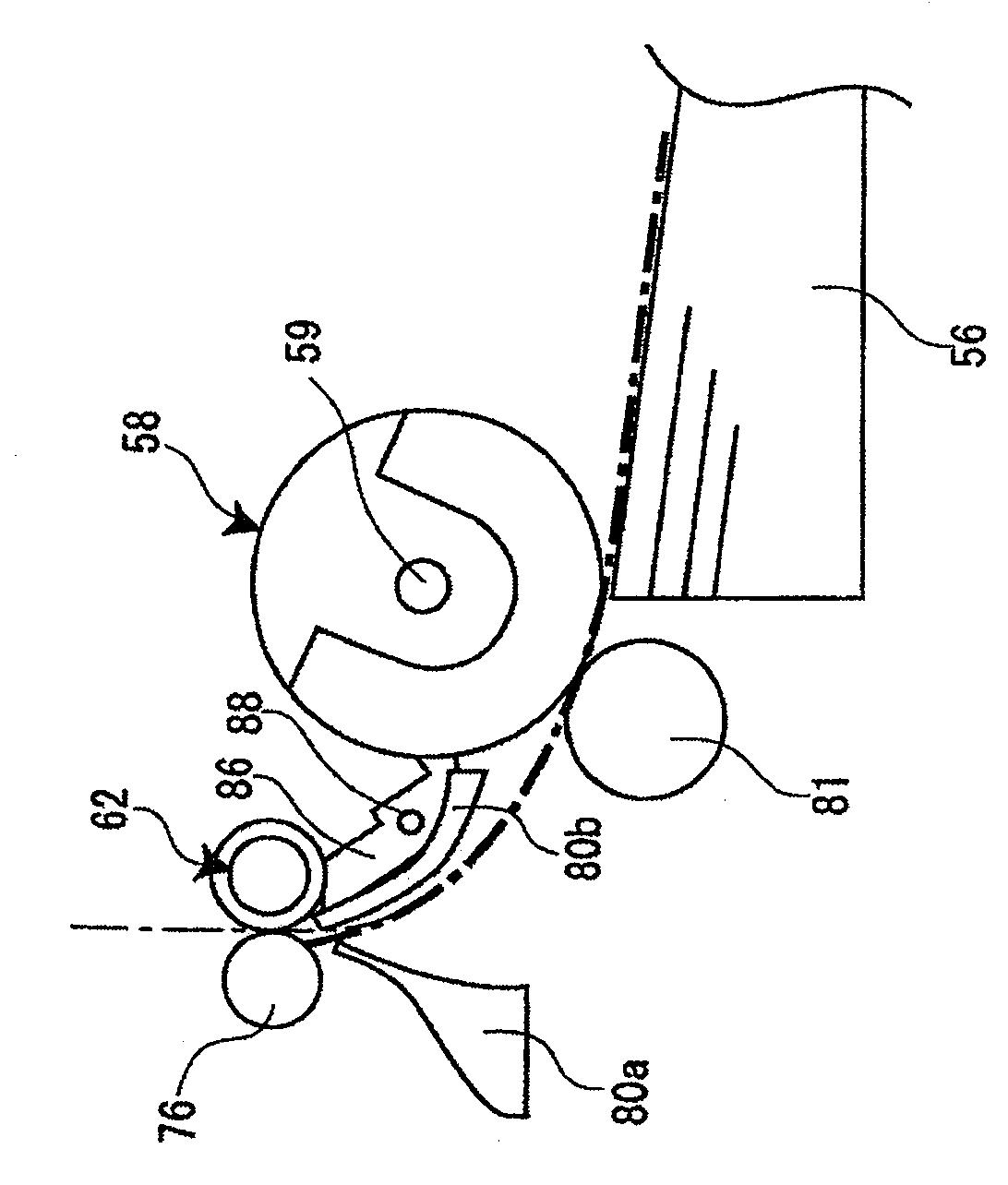

Image forming apparatus and conveyance device

InactiveCN1987671AImprove skewEffective correctionElectrographic process apparatusLeading edgeImage formation

Owner:FUJIFILM BUSINESS INNOVATION CORP

Magnetic head and magnetic disc drive

InactiveUS20080024900A1Excellent recording characteristicPreventing side eraseDriving/moving recording headsManufacturing heads with multiple gapsSkew angleMagnetic poles

Embodiments in accordance with present invention provide a magnetic head and a magnetic disc drive capable of preventing a side erase while providing excellent recording characteristics. According to one embodiment, in order to prevent the side erase in an increased skew angle state, a first magnetic pole surface is formed in such a shape that the projection area of the first magnetic pole surface follows a track edge positioned on the boundary side in the track in the state where the first magnetic pole surface is positioned on the track at the innermost periphery thereof included in a first region. Likewise, to prevent the side erase in the increased skew angle state, a second magnetic pole surface is formed in such a shape that the projection area of the second magnetic pole surface follows a track edge positioned on the boundary side with respect to a track in the state where the second magnetic pole surface is positioned on the track at the outermost periphery thereof included in a second region.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Method to make circular knit elastic fabric comprising spandex and hard yarns

InactiveUS7797968B2Increase productionReduced “ skew ”Ornamental textile articlesCircular knitting machinesElastomerDry heat

Circular knit, elastic fabrics of at least one of single jersey, French terry, and fleece are disclosed that include a bare elastomeric material plated with spun and / or continuous filament hard yarns. The circular knit, elastic fabrics of at least one of single jersey, French terry, and fleece are manufactured by a method that does not require a dry heat setting step. The method requires drafting the bare elastomeric material no more than about 7× its original length when knitting to form the circular knit, elastic, single jersey, French terry, or fleece fabric. The method includes contacting the knit fabric with an aqueous solution under very low tension and under conditions of temperature and pressure for a period of time sufficient to substantially set the elastomeric material.

Owner:THE LYCRA CO LLC

Manufacturing method for torsion balance composite yarn for knitting

The invention relates to a manufacturing method for torsion balance composite yarn for knitting and belongs to the technical field of knitting. The existing spinning device is used, and when the composite yarn is spun, a piece of core yarn with the twisted direction opposite to that of spindle rotation is fed. Simultaneously, a relation between spindle rotation speed and core yarn twisting degree is adjusted, and when the ratio of the twisting degree generated by spindle rotation to the twisting degree of the fed core yarn is 50%-68%, wrap yarn with the twisted direction of inner-layer core yarn opposite to that of an outer-layer fiber strip is spun to achieve torsional balance of the yarn itself. Under the premise that an additional device is not added, and production cost is reduced, remaining torsion of the yarn is eliminated, biasfilling of knitted fabric is controlled fundamentally, cutting use rate of fabric is improved, and smoothness and appearance of fabric surface are maintained.

Owner:WUHAN TEXTILE UNIV +1

Self-aligning roller bearing with retainer and method of manufacturing the retainer for the self-aligning roller bearing

ActiveCN100489328CCost containmentInhibit sheddingRoller bearingsBearing componentsBarrel ShapedSpherical roller bearing

There is realized a self-aligning roller bearing with retainer that stabilizes the orientation of spherical rollers and prevents these spherical rollers from skewing, and which can be rotated at high speed, and furthermore which enables efficient lubricant feed into pockets 9. By rotating a turning tool 14 as it revolves, the surfaces on both sides in the circumferential direction of respective column sections are processed into concave curved surfaces that oppose a rolling surface of the respective spherical rollers across a pocket clearance into which lubricant oil can be fed. The length of the column sections 8c is less than the length in the axial direction of the spherical rollers, and greater than a half of the length, and an end portion of the side surface in the circumferential direction of the respective column sections 8c projects further in the circumferential direction than an intermediate portion thereof, and the spherical rollers are embraced in the pockets 9.A self-aligning roller bearing with a retainer enabling high speed operation by stabilizing the attitude of barrel shaped rollers to prevent the barrel shaped rollers from being skewed and the efficient feeding of a lubricant into pockets (9) and a method of manufacturing the retainer for the self-aligning roller bearing. In the self-aligning roller bearing, the both side faces of each column part (8c) in the circumferential direction are machined to recessed curved faces facing the rolling surface of each barrel shaped roller through pocket clearances allowing the lubricant to feed thereto with a cutting tool (14) revolving while rotating on its axis. Also, the length of each column part (8c) is set equal to or less than the axial length of each barrel shaped roller and more than the half of the axial length thereof, the side face tip portion of each column part (8c) in the circumferential direction are projected from the intermediate portion thereof in the circumferential direction.

Owner:NSK LTD

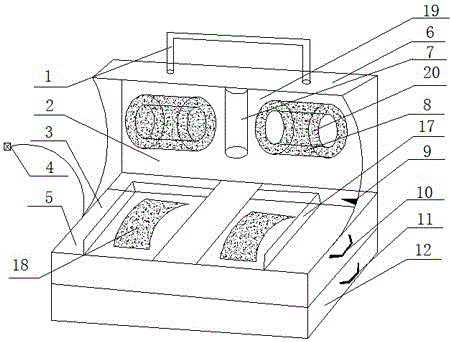

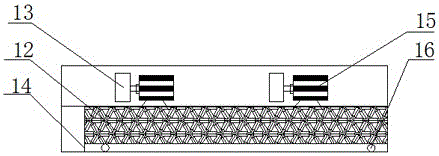

Automatic shoe sole cleaning machine

The invention belongs to the technical field of cleaning equipment, and discloses an automatic shoe sole cleaning machine. The automatic shoe sole cleaning machine comprises a cleaning machine body, the cleaning machine body comprises a cleaning device and a motor chamber, a fixing plate is arranged on the cleaning device, and rotating shafts are arranged on the fixing plate and are fixedly connected with cleaning brushes; mud scrapping brushes are arranged on the motor chamber, a motor handle is arranged on the motor chamber, motors are arranged in the motor chamber and fixedly connected with the rotating shafts, the double motors are arranged and electrically connected with a power source, and a water storage box is arranged below the motor chamber. According to the automatic shoe sole cleaning machine, the rotating shafts are fixedly connected with the cleaning brushes to clean vamps conveniently; mud and water spots on shoe soles can be cleared conveniently through the mud scrapping brushes on the motor chamber; the motor chamber can be opened conveniently to be cleaned through the handle on the motor chamber, and as the double motors are arranged, the other motor is standby to meet unexpected needs when one motor breaks down.

Owner:王剑

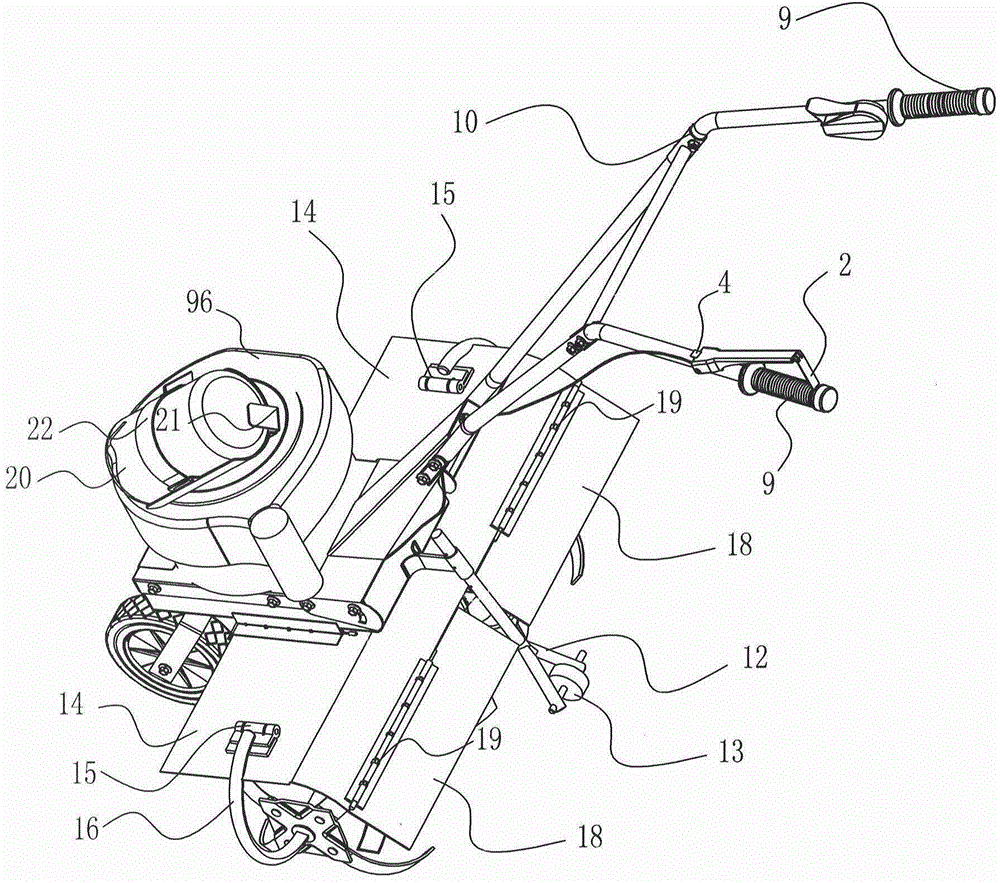

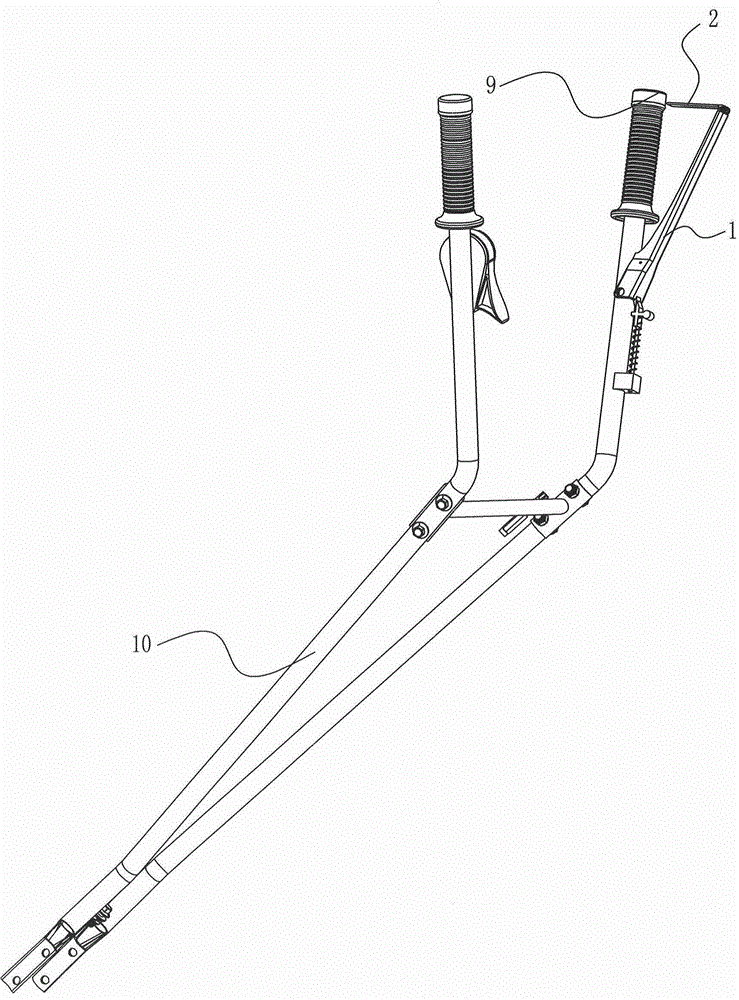

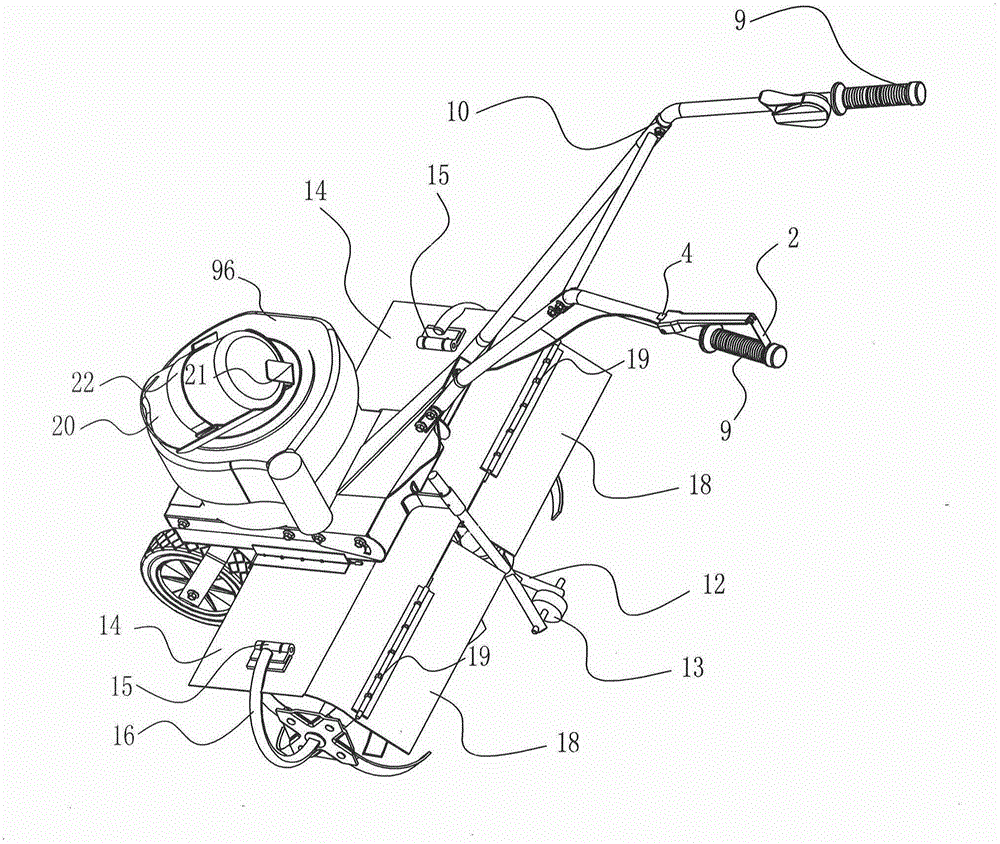

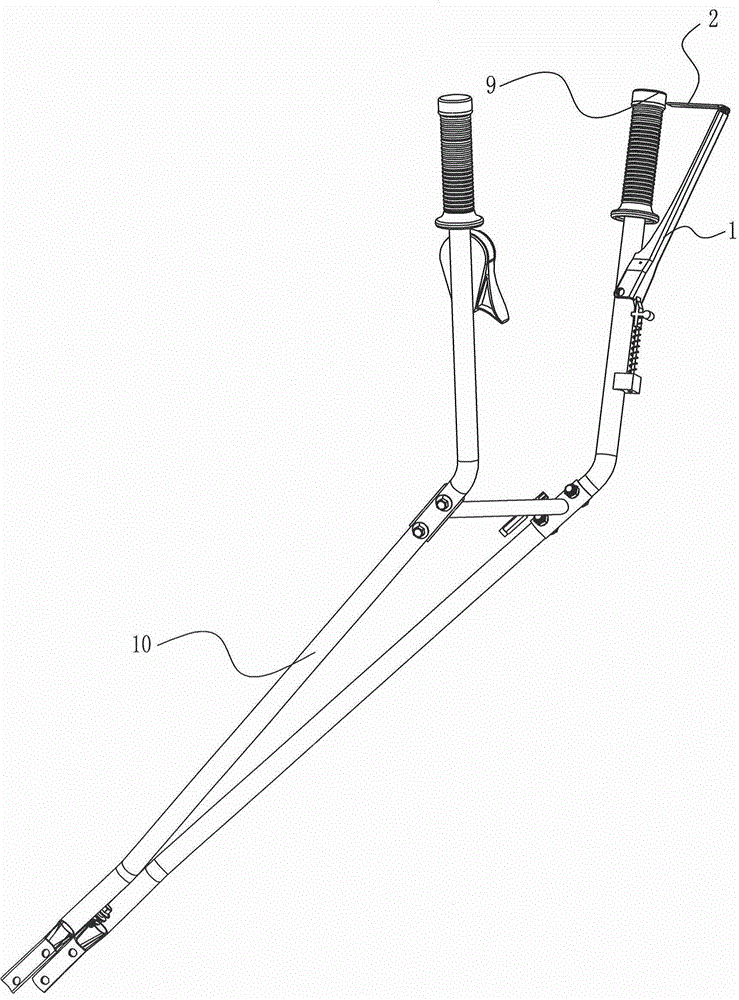

Improved rotary cultivator with engine provided with fuel gas and fuel tank

ActiveCN104541621AEasy to replaceNot easy to skewSpadesInternal combustion piston enginesFuel tankFour-stroke engine

The invention relates to an improved rotary cultivator with an engine provided with a fuel gas and fuel tank. The improved rotary cultivator comprises a rotary cultivator body and a wide-breadth horizontal mini-tiller, wherein the rotary cultivator body is provided with a miniature propane fuel tank and is driven by a four-stroke engine; the wide-breadth horizontal mini-tiller is provided with a blade protection plate and has the function of eliminating middle missed ploughing by combination of a guide wheel and a lift-throwing type moldboard plough. The invention also relates to a rotary cultivator adopting multiple safety measures. A safety resistance fork wheel is unlikely to incline and easy to guide, and a movable protection plate is a detachable plate; the safety is further improved by means of an external protection plate assembly, and the rotary cultivator can bounce up after being pressed and deformed since a function wave external protection plate is adopted, and the function wave external protection plate has the effects of wide breadth, vibration attenuation and multi-point balance; the rotary cultivator is provided with the blade protection plate and has the effect of eliminating the middle missed ploughing by the combination of the guide wheel and the lift-throwing type moldboard plough. Fuel gas is adopted to realize noise reduction and emission reduction. The emission of carbon dioxide and hydrocarbon is reduced, so that particle effluents are improved and the emission of oxynitride is reduced. Since the fuel gas is used, the toxicity of harmful effluents is lower than that of gasoline for combustion use. The emission effect of the fuel gas in a heating turbine is superior to that in a gasoline engine within 40 seconds, so that the safety of the complete machine is good. The fuel gas and fuel tank is easy to replace.

Owner:NINGBO DAYE GARDEN EQUIP

Cotton polyurethane light side-stretch high-end fabric preparation method

ActiveCN109097900ARelease the bondageIncrease elasticityWeft knittingHeating/cooling textile fabricsRecovery performanceEngineering

The invention relates to a knitted fabric preparation method, in particular to a cotton polyurethane light side-stretch high-end fabric preparation method. A fabric comprises loop yarns, middle yarnsand ground yarns. The method includes: step A, weaving a gray fabric; step B, subjecting the surface of the gray fabric to pilling; step C, dyeing the gray fabric; step D, dewatering the gray fabric;step E, drying the gray fabric; step F, subjecting the gray fabric to re-shaping. Compared with the prior art, the method has advantages that the fabric woven according to the method is high in elasticity and excellent in elastic recovery performance, and by adoption of the novel weaving mode, fabric skewness is effectively improved, and great handfeel and anti-pilling performances of the fabric are kept.

Owner:NINGBO DAQIAN TEXTILE

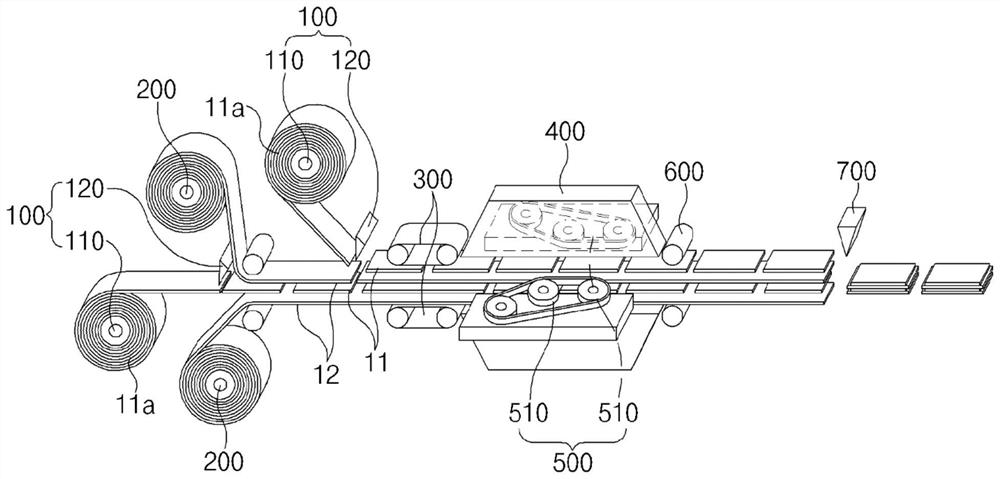

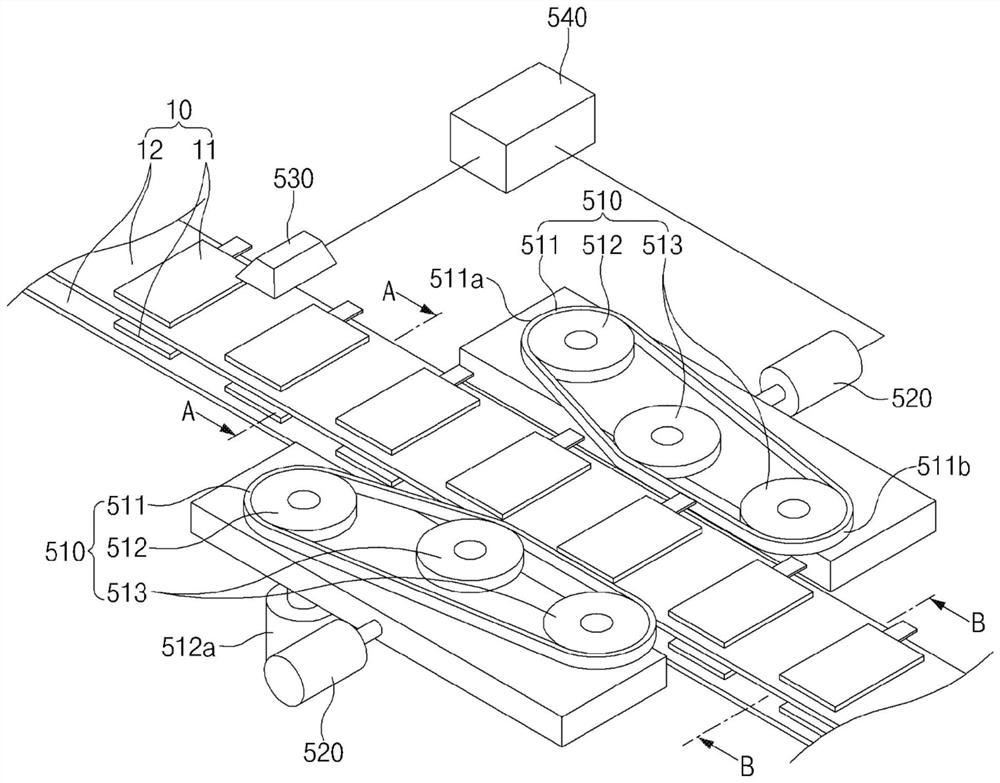

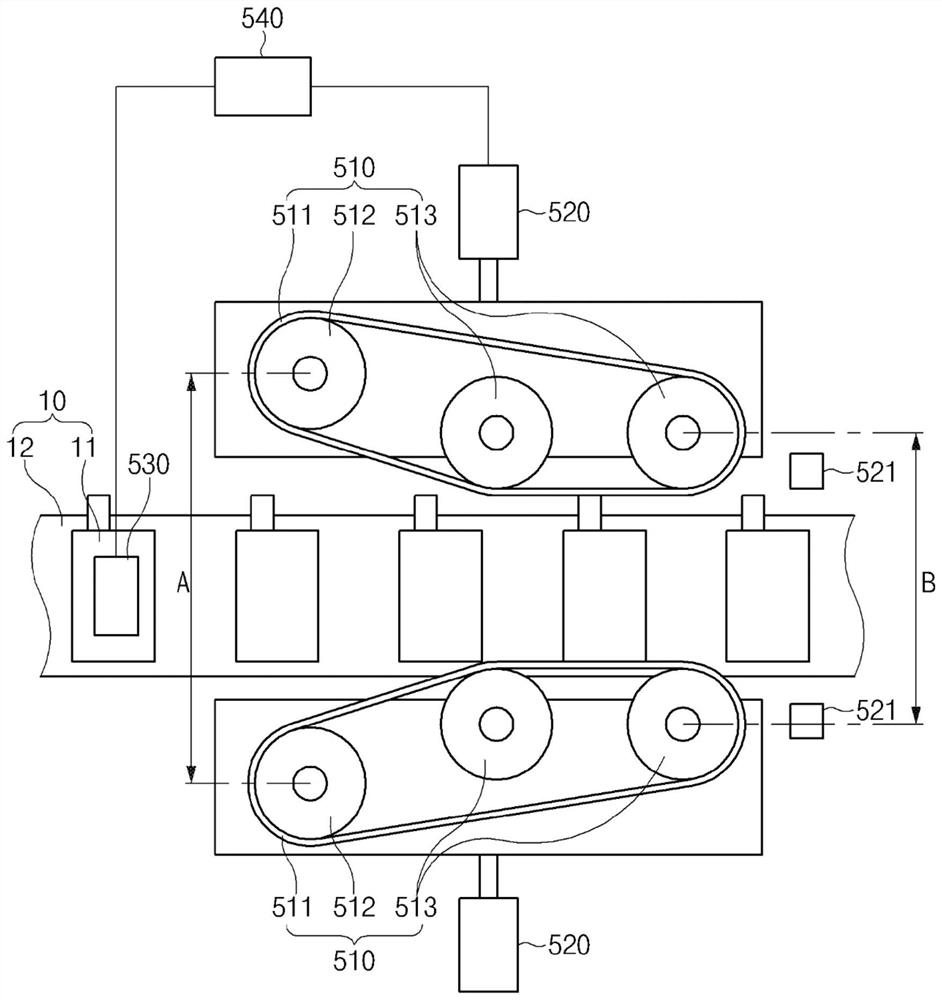

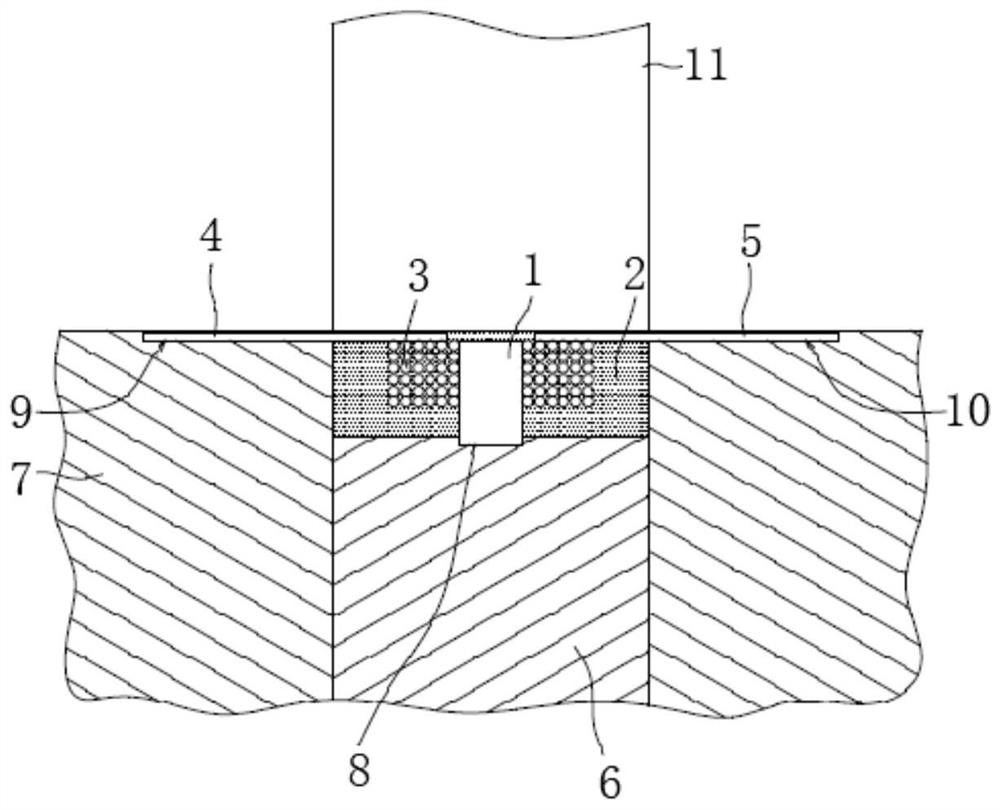

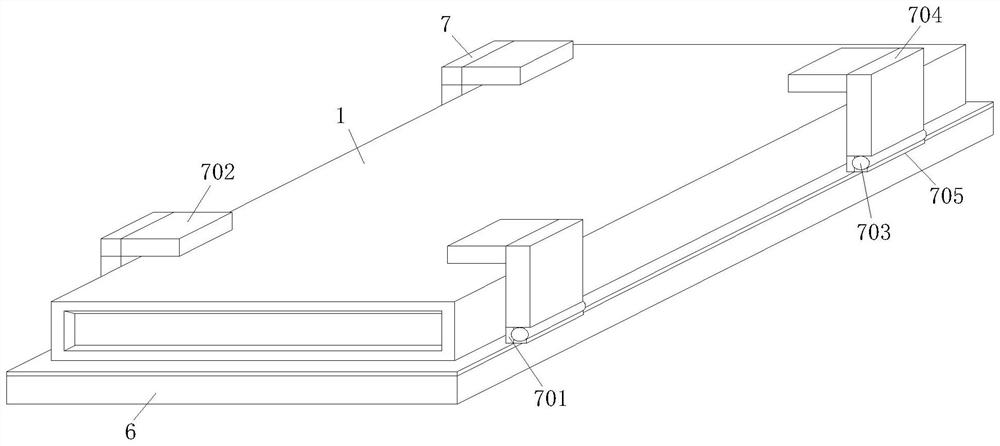

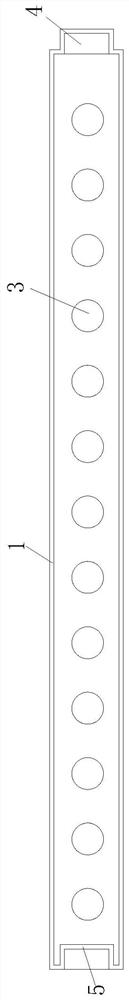

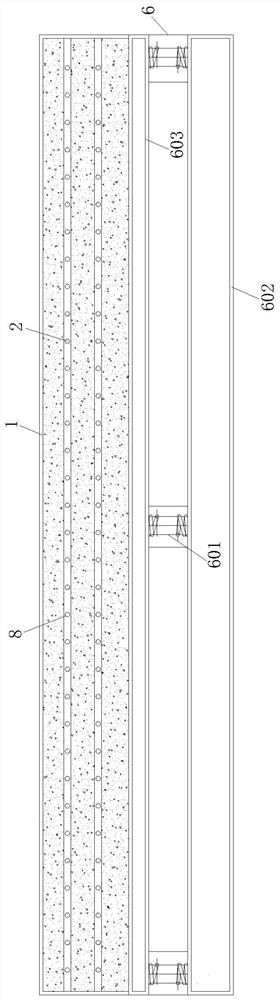

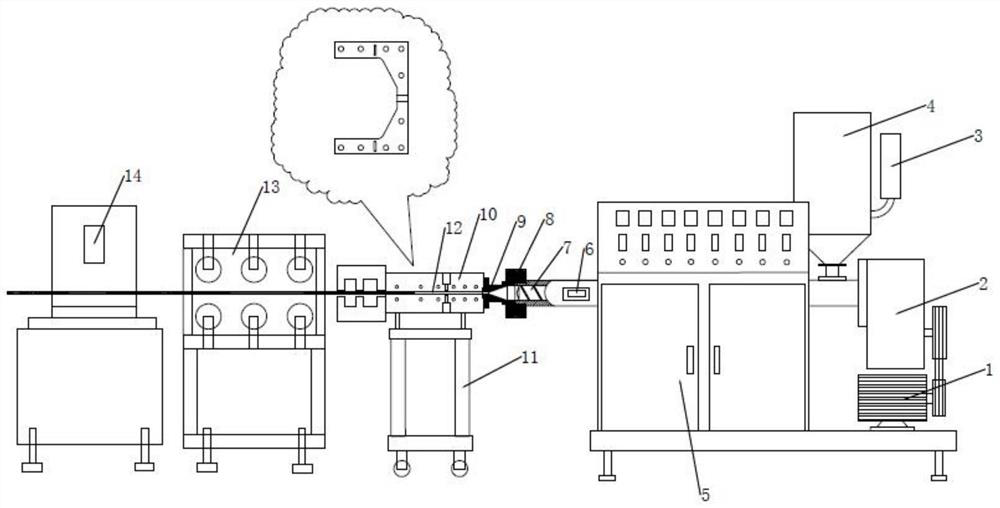

Lamination apparatus and method for secondary battery

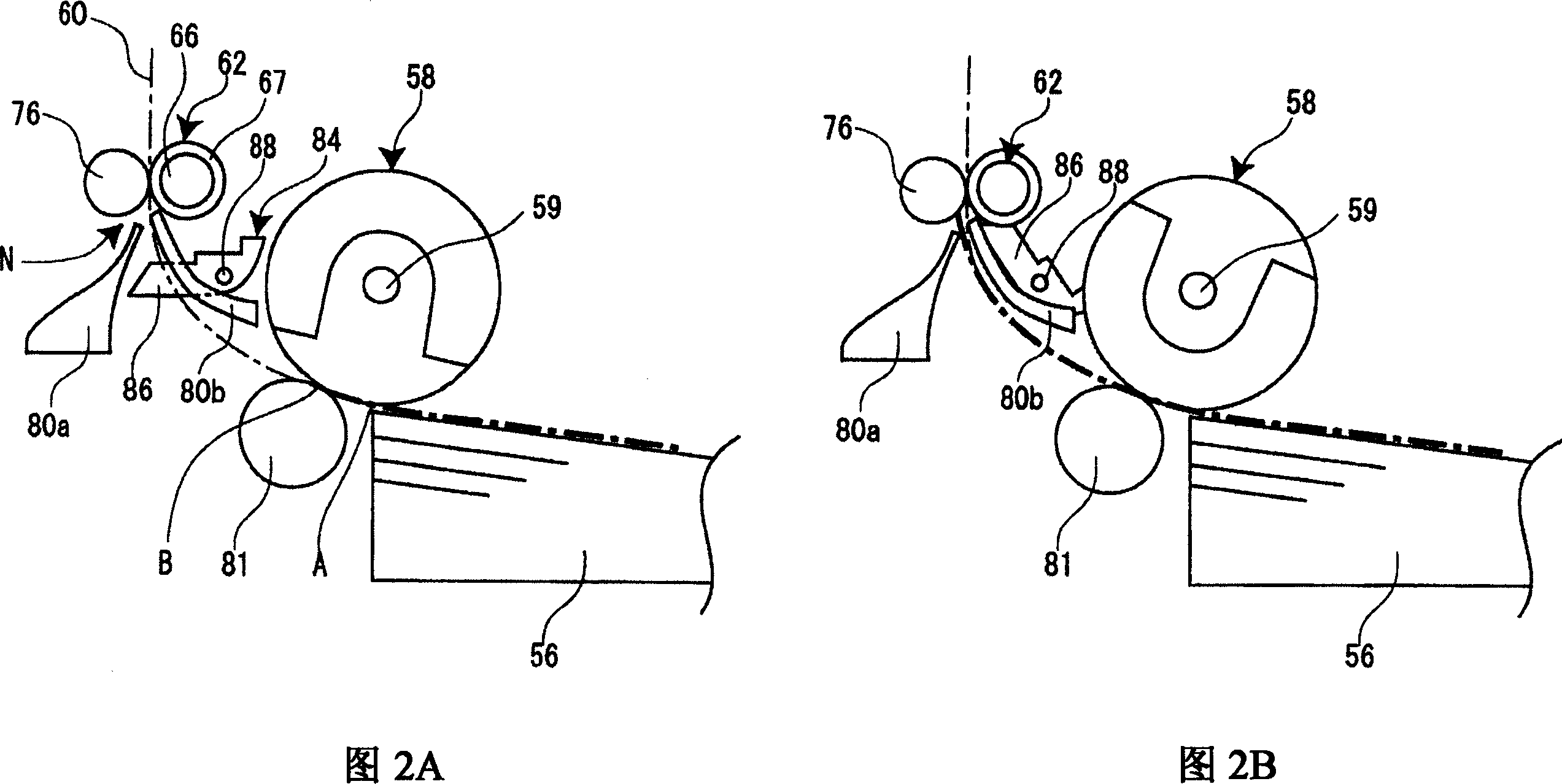

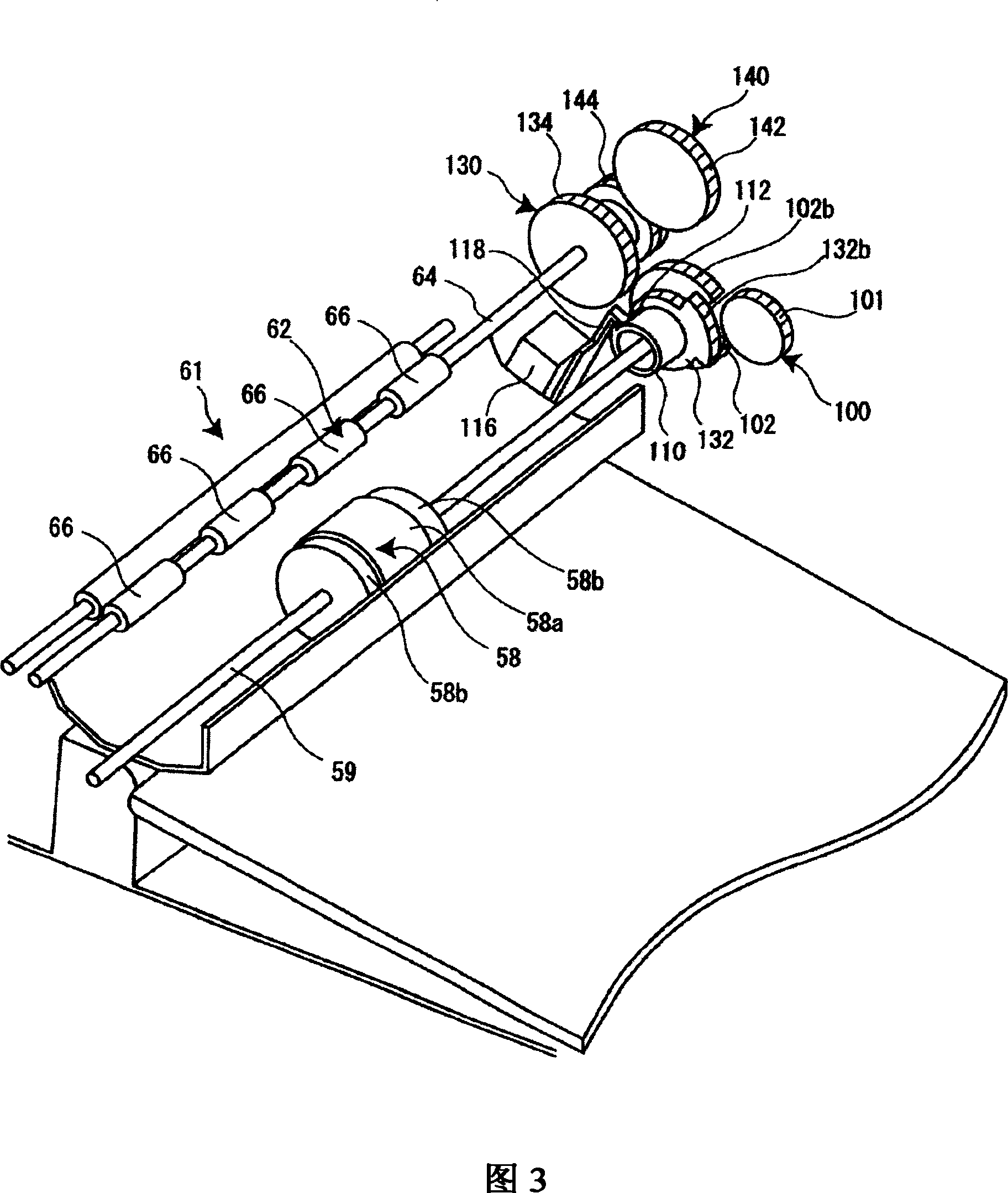

ActiveCN113574710AEasy alignmentImprove skewLamination ancillary operationsAssembling battery machinesElectrical batteryEngineering

The present invention relates to a lamination apparatus for a secondary battery, the lamination apparatus comprising: an electrode transfer unit for transferring one or more electrodes; a separator transfer unit for transferring one or more separators; a joining unit for joining the electrodes and the separators to each other such that the electrodes and the separators are arranged alternately from top to bottom, and transferring the joined electrodes and separators; and a position correction unit for correcting the position of the uppermost electrode placed at the top of the electrodes and separators joined by the joining unit to align the uppermost electrode with the set position of the separators.

Owner:LG ENERGY SOLUTION LTD

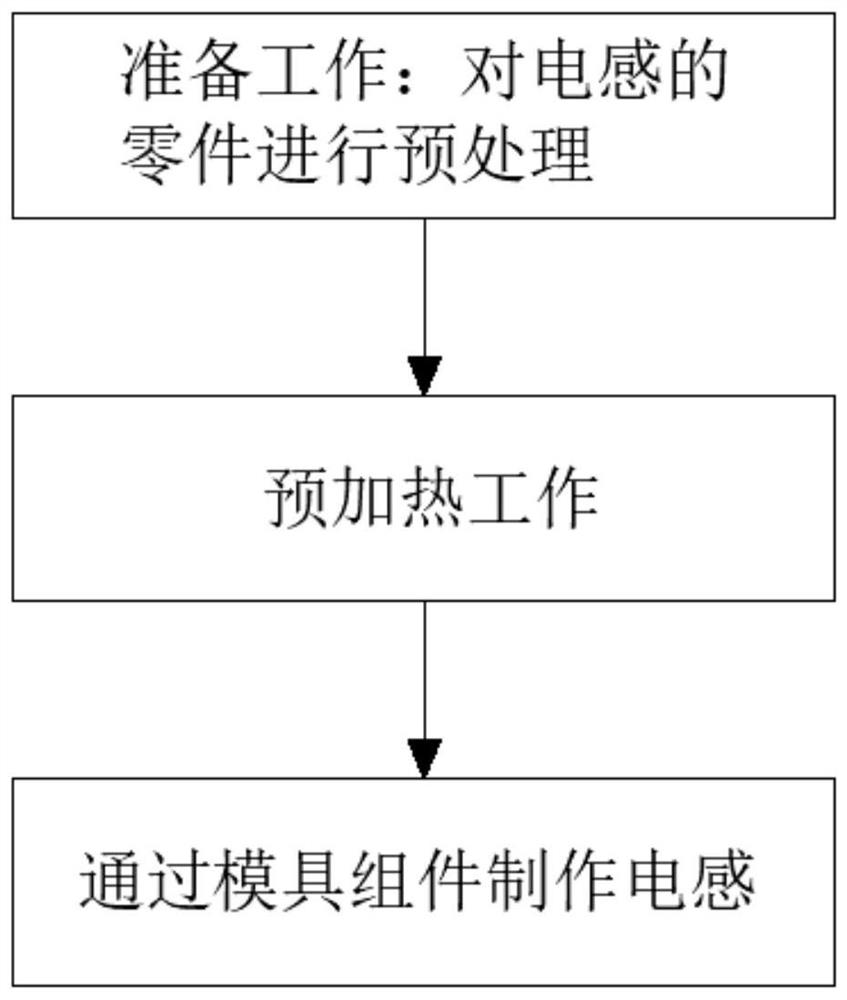

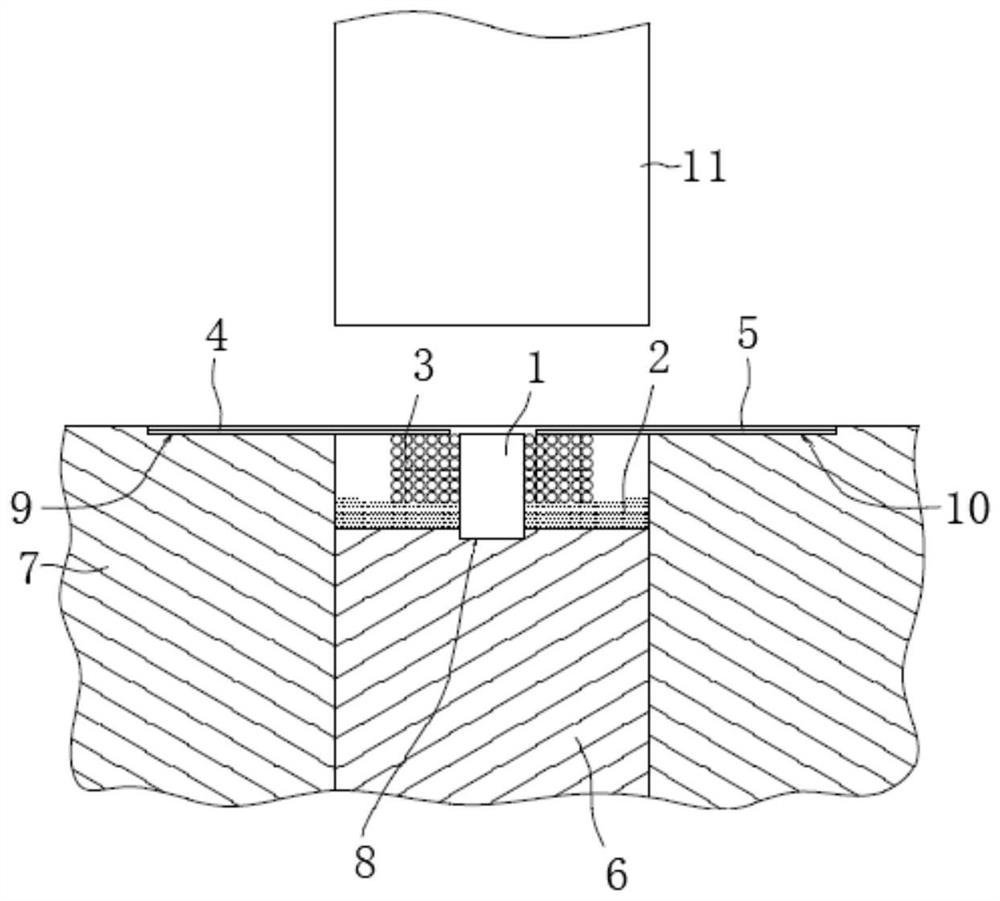

Inductor manufacturing method and inductor

InactiveCN114360878AAvoid crackingPreventer gapInductances/transformers/magnets manufactureEngineeringInductor

The invention discloses an inductor manufacturing method and an inductor. The preparation work comprises the steps of preprocessing parts of the inductor; preheating work is conducted, specifically, the mold assembly is preheated, and the core body is baked; the method for manufacturing the inductor through the mold assembly comprises the following steps that a baked core body is placed in a mold, and a groove matched with the core body is formed in the inner bottom wall of a lower mold core; the lower mold core is filled with about 1 / 3 powder, the powder is heated to the set temperature of 60-200 DEG C, and the 1 / 3 powder is cured and supports the front, rear, left and right positions of the core body and the mold. According to the coil, internal cracks caused by internal stress generated by volatilization or heating of central gas or other compounds are avoided, cracks or gaps of the core body are prevented, the coil can bear pressure during forming due to the fact that the core body has a certain density, and deformation of the coil or damage of a varnished film can be prevented.

Owner:美磊电子科技(昆山)有限公司

Precast reinforced concrete with enhanced plasticity

PendingCN111851851APlay the role of shock absorberAvoid crackingConstruction materialProtective buildings/sheltersReinforced concreteArchitectural engineering

The invention relates to the technical field of constructional engineering, in particular to precast reinforced concrete with enhanced plasticity. The precast reinforced concrete comprises a precast slab and a shockproof mechanism, wherein a reinforcing steel bar is arranged in the precast slab, and one side of the reinforcing steel bar is connected to a reinforced steel bar; the reinforcing steelbar and the reinforced steel bar are poured to form an integrated connection; an air hole is arranged in the precast slab, and a fixing block is welded to one end of the precast slab; and a first groove is embedded in the inner side of the other end of the precast slab, and the shockproof mechanism is arranged at the bottom end of the precast slab. Through the arrangement of springs, the crackingof the precast slab on the way due to the uneven road gradient in a process of transporting the precast slab can be prevented, the springs can play a shock reduction role, a situation that a worker directly puts the precast slab on a transportation vehicle and needs to handle with care in the past is improved, the cracking of the precast slab due to collision is avoided, the crack can reduce theanti-seepage ability and the anti-freezing ability while the rust and corrosion of the reinforcing steel bar can be caused, and the later repair and reinforcement work can be very difficult.

Owner:张占群

A Double Zone Cutting Blasting Hole Arrangement Structure and Its Applied Blasting Well Formation Method

ActiveCN106767212BReduced precision requirementsIncrease heightBlastingStructure of the EarthEngineering

The invention discloses a dual-area slotting blast hole arrangement structure and a blasting sinking method applied to the structure. The structure comprises two blasting slotting hole areas symmetrically arranged with respect to the center of the free face of a courtyard, each blasting slotting hole area comprises a center charging hole and a plurality of empty holes arranged around the center charging hole; a ring of peripheral holes are formed in the periphery of each blasting slotting area, the center charging holes and the peripheral hoes are filled with explosive charges, and a plurality of auxiliary holes are formed between the blasting slotting areas and the peripheral holes and are filled with explosive charges. The method is simple in working procedure, operation is easy, the one-time sinking height is large, reliability is high, the sinking effect is good, the number of drilled holes is small, energy consumption is low, and the blasting vibration is small.

Owner:CENT SOUTH UNIV

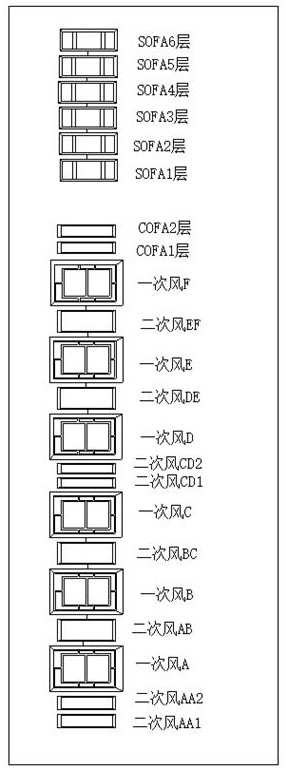

Thermal state research method for improving flame center deflection of corner tangential boiler

PendingCN114857578AImprove air volume accuracyImprove data accuracyIndirect carbon-dioxide mitigationCombustion apparatusThermal stateAir volume

The invention provides a thermal state research method for improving flame center deflection of a corner tangential boiler, and the method can improve the operation economy and safety of a unit. The method comprises the following steps that when a boiler runs, the proportion of burnout air and secondary air of a low-nitrogen combustor is designed, and the actual proportion difference is rechecked; performing temperature-state ventilation on the coal mill after shutdown, measuring the air volume of each powder pipe under three air volume working conditions, and checking the air volume of the coal mill; measuring the air volume of each powder pipe in a hot state of the running coal mill one by one under three air volume working conditions, and checking the air volume of the coal mill; pulverized coal is sampled and weighed within the set time, meanwhile, a backrest pipe is used for measuring the speed of pulverized coal airflow under the working condition of a coal mill, and shrinkage cavities are used for conducting primary air thermal state leveling on the same layer; the auxiliary air door distributes air to a smoke temperature field and an oxygen field at an outlet of the economizer in different modes; an SOFA air door, a fuel air door and a main combustor swing angle are used for measuring a smoke temperature field and an oxygen amount field at an outlet of the economizer under different opening degrees.

Owner:邹平县宏旭热电有限公司 +1

Improved rotary tiller with gas fuel tank engine

ActiveCN104541621BNot easy to skewHard to skew and easy to skewSpadesInternal combustion piston enginesFuel tankFour-stroke engine

The invention relates to an improved rotary cultivator with an engine provided with a fuel gas and fuel tank. The improved rotary cultivator comprises a rotary cultivator body and a wide-breadth horizontal mini-tiller, wherein the rotary cultivator body is provided with a miniature propane fuel tank and is driven by a four-stroke engine; the wide-breadth horizontal mini-tiller is provided with a blade protection plate and has the function of eliminating middle missed ploughing by combination of a guide wheel and a lift-throwing type moldboard plough. The invention also relates to a rotary cultivator adopting multiple safety measures. A safety resistance fork wheel is unlikely to incline and easy to guide, and a movable protection plate is a detachable plate; the safety is further improved by means of an external protection plate assembly, and the rotary cultivator can bounce up after being pressed and deformed since a function wave external protection plate is adopted, and the function wave external protection plate has the effects of wide breadth, vibration attenuation and multi-point balance; the rotary cultivator is provided with the blade protection plate and has the effect of eliminating the middle missed ploughing by the combination of the guide wheel and the lift-throwing type moldboard plough. Fuel gas is adopted to realize noise reduction and emission reduction. The emission of carbon dioxide and hydrocarbon is reduced, so that particle effluents are improved and the emission of oxynitride is reduced. Since the fuel gas is used, the toxicity of harmful effluents is lower than that of gasoline for combustion use. The emission effect of the fuel gas in a heating turbine is superior to that in a gasoline engine within 40 seconds, so that the safety of the complete machine is good. The fuel gas and fuel tank is easy to replace.

Owner:NINGBO DAYE GARDEN EQUIP

Image forming apparatus and conveyance device

InactiveCN100561366CImprove skewEffective correctionElectrographic process apparatusLeading edgeImage formation

The invention discloses an image forming apparatus, comprising: an image forming part; a first conveying roller, which conveys a recording medium to the image forming part; a reversible second conveying roller, which is positioned at the between the first conveying roller and the image forming portion; a contact member in contact with the second conveying roller, forming a nip between the second conveying roller and the contact member; a first conveying roller a driver that rotationally drives the first conveying roller in the same direction as the recording medium conveying direction; and a drive transmission mechanism that performs drive transmission from the first conveying roller driver to the second conveying roller, to start rotating the second conveying roller in a direction opposite to the conveying direction of the recording medium before the leading edge of the recording medium reaches the nip.

Owner:FUJIFILM BUSINESS INNOVATION CORP

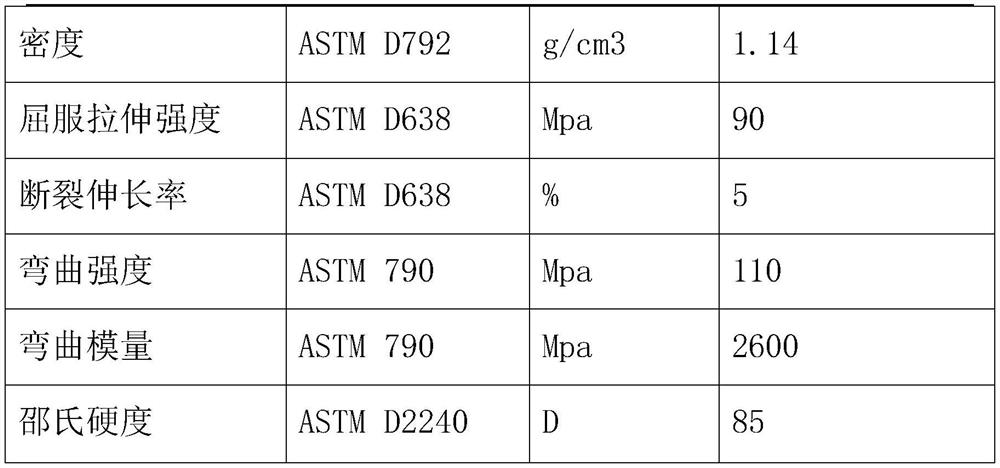

Production process special for PA66 plate product

InactiveCN111873356AImprove the dullness of the surface colorImprove skewCompression moldingPlasticulture

The invention provides a production process special for a PA66 plate product. The production process comprises the steps that plastifying extrusion is performed, specifically, a machine barrel is divided into three areas to be heated at the specific temperature, and the specific extrusion speed is adopted; forming / shaping is performed, specifically, a compression forming area is divided into twelve areas for temperature constancy, and melts are constantly cooled by a cooling forming area, finally solidified, crystalized and shaped to be extruded; and plate cutting is performed. According to aPA66 plate obtained by the production process, the situation of the dark color of the surface is greatly relieved, the situations of pores, bubbles and acne scars inside the PA plate are reduced, performance is greatly improved, the rate of the finished product is high, skewing and deformation of the product are obviously relieved, and the smoothness of the product is obviously improved.

Owner:深圳市恩欣龙特种材料股份有限公司

A kind of preparation method of torsion balance composite yarn for knitting

Owner:WUHAN TEXTILE UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com