Manufacturing method for torsion balance composite yarn for knitting

A production method and composite yarn technology, which is applied in yarn, textile and papermaking, etc., can solve the problems of complex structure, high cost, inconvenient manufacture and use of spinning device, etc., so as to improve cutting utilization rate, reduce production cost and maintain smoothness beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

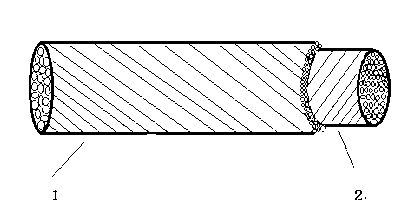

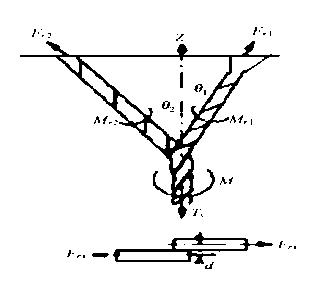

[0026] The core yarn is pure cotton spun yarn JC with a linear density of 7.3 tex and a twist of 145 twists / 10cm, and the outer roving is 3.74g / 10m Polygonatum fiber. The yarn density is 18.3tex, the front roller speed is 8m / min, the spindle speed is 8000r / min, and the twist produced by the spindle is 100 twists / 10cm. The double-fold kink number of the torsion balance composite yarn spun by the above-mentioned process is 10 / 50cm.

Embodiment 2

[0028] The core yarn is cotton yarn with a linear density of 11tex and a twist of 140 twists / 10cm, and the outer roving is 760 tex cotton / linen / bamboo / polyester (45.7 / 14.4 / 19.2 / 20.1) to spin a 32tex torque-balanced composite yarn. Process parameters: The speed of the front roller is 8m / min, the speed of the spindle is 6800r / min, and the twist produced by the spindle is 85 twists / 10cm. The double-fold kink number of the torsion balance composite yarn spun by the above-mentioned process is 12 / 50cm.

Embodiment 3

[0030] The core yarn is pure cotton spun yarn JC with a linear density of 12 tex and a twist of 145 twists / 10cm, and the outer fiber is 551 tex cotton / bamboo (35 / 65) blended sliver to spin 25 tex torsion balance composite yarn: front roller The speed is 8m / min, the spindle speed is 5800r / min, and the twist produced by the spindle is 72.5 twists / 10cm. The double-fold kink number of the torsion balance composite yarn spun by the above-mentioned process is 17 / 50cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com