Inductor manufacturing method and inductor

A production method and inductor technology, which is applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve problems affecting electrical properties, life-span voltage withstand and structural strength, gaps between cores and powders, and cracks in cores To achieve the effect of improving the magnetic inductance and coil uniformity, increasing the voltage tolerance, preventing coil deformation or damage to the enamelled film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] see Figure 1-3 , the present invention provides a technical solution:

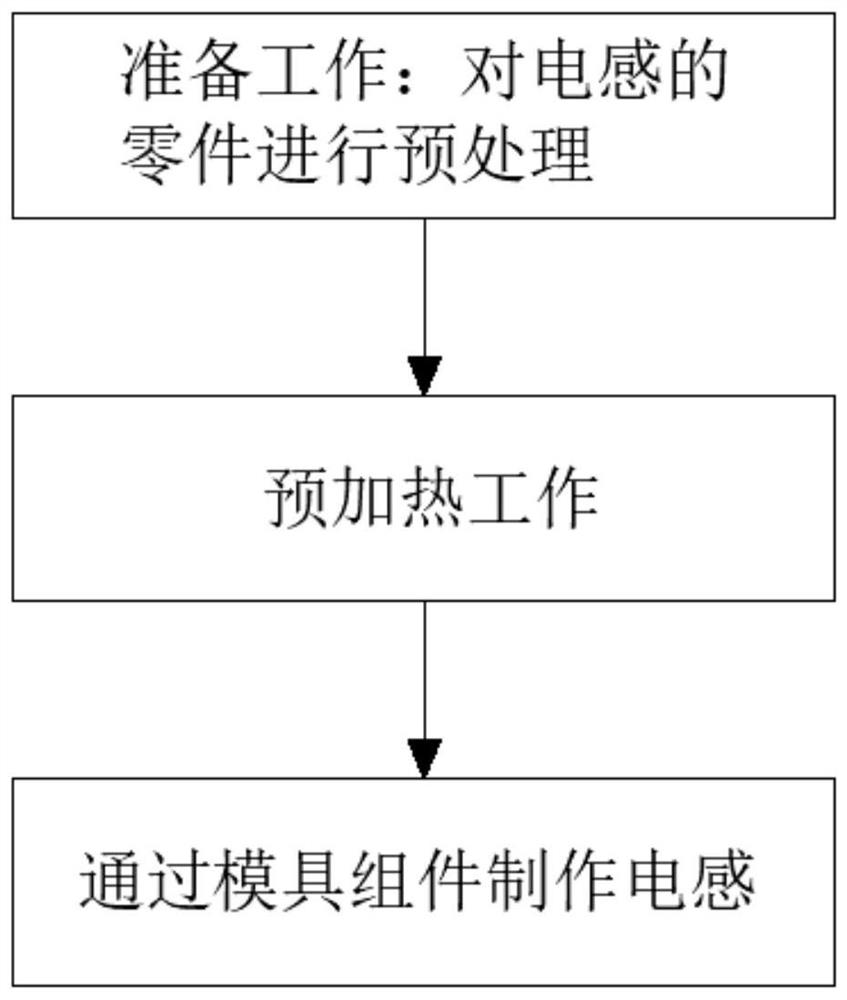

[0031] A method for manufacturing an inductor, comprising the steps of:

[0032] S1. Preparatory work: pre-treat the parts of the inductor. The pre-treatment steps include basic inspection of the parts of the inductor, whether the core 1 is intact, whether there is a crack, and whether the paint film of the coil 3 is intact;

[0033] S2. Preheating work: Preheat the mold components, bake the core body 1, the baking time of the core body 1 is 6-12 hours, and the temperature is 60-200 degrees;

[0034] S3, making inductors through mold components, including the following steps:

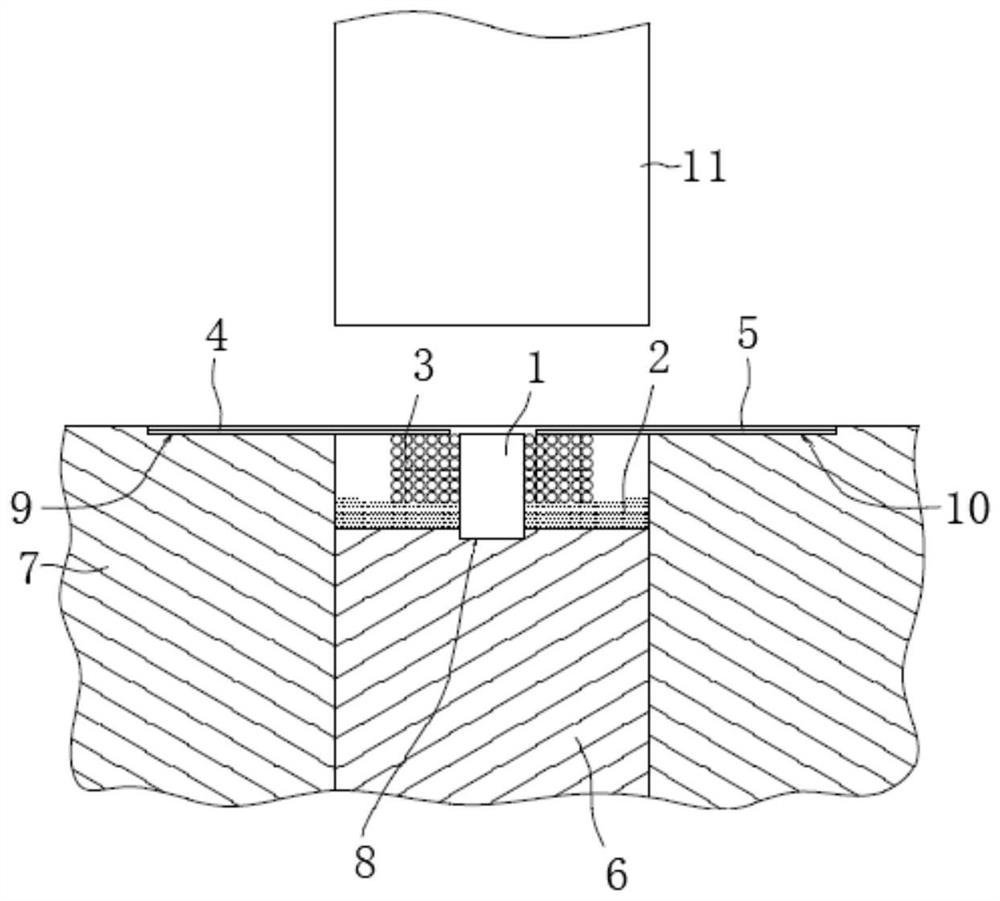

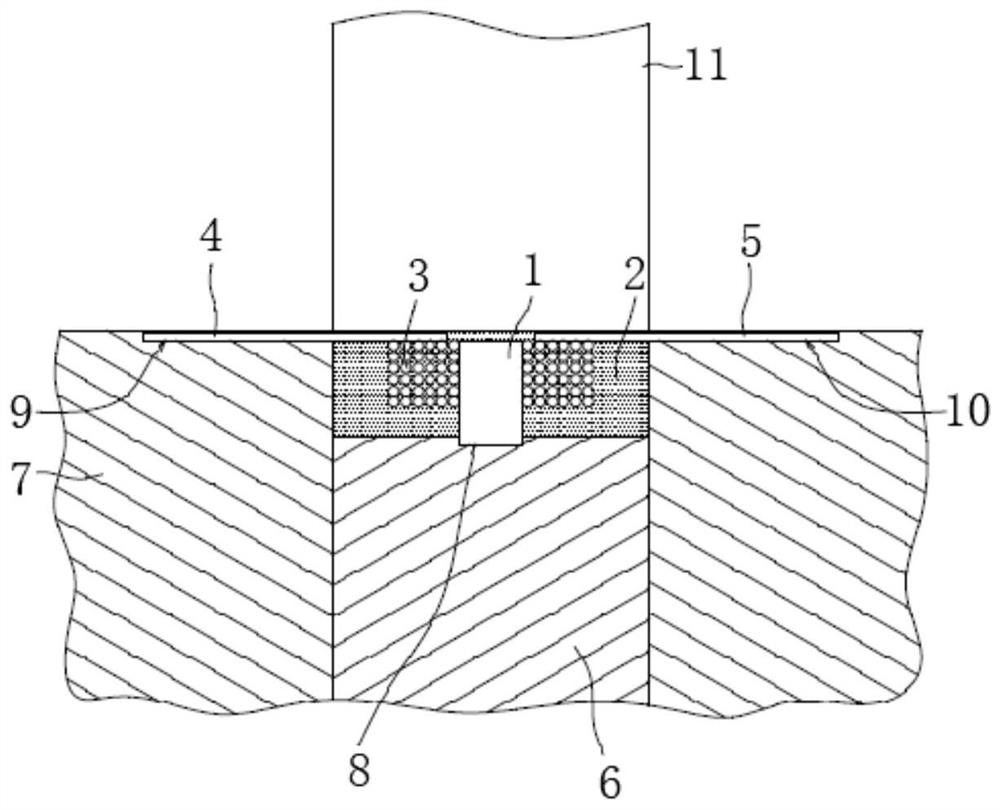

[0035] S3.1. Put the baked core 1 into the mold. The mold assembly includes an upper mold core 11 and a lower mold core 6. The inner bottom wall of the lower mold core 6 is provided with a groove 8, and the outer side of the lower mold core 6 is movable. The lower mold 7 is sleeved, and the top two sides of the lower mold...

Embodiment 2

[0041] The difference between this embodiment 2 and embodiment 1 is:

[0042] A method for manufacturing an inductor, comprising the steps of:

[0043] S1. Preparatory work: pre-treat the parts of the inductor. The pre-treatment steps include basic inspection of the parts of the inductor, whether the core 1 is intact, whether there is a crack, and whether the paint film of the coil 3 is intact;

[0044] S2. Preheating work: Preheat the mold components, bake the core body 1, the baking time of the core body 1 is 6, and the temperature is 60 degrees;

[0045] S3, making inductors through mold components, including the following steps:

[0046] S3.1. Put the baked core 1 into the mold. The mold assembly includes an upper mold core 11 and a lower mold core 6. The inner bottom wall of the lower mold core 6 is provided with a groove 8, and the outer side of the lower mold core 6 is movable. The lower mold 7 is sleeved, and the top two sides of the lower mold core 6 are respectivel...

Embodiment 3

[0051] The difference between this embodiment 3 and embodiment 2 is:

[0052] A method for manufacturing an inductor, comprising the steps of:

[0053] S1. Preparatory work: pre-treat the parts of the inductor. The pre-treatment steps include basic inspection of the parts of the inductor, whether the core 1 is intact, whether there is a crack, and whether the paint film of the coil 3 is intact;

[0054] S2. Preheating work: Preheat the mold components, bake the core body 1, the baking time of the core body 1 is 12 hours, and the temperature is 200 degrees;

[0055] S3, making inductors through mold components, including the following steps:

[0056] S3.1. Put the baked core 1 into the mold. The mold assembly includes an upper mold core 11 and a lower mold core 6. The inner bottom wall of the lower mold core 6 is provided with a groove 8, and the outer side of the lower mold core 6 is movable. The lower mold 7 is sleeved, and the top two sides of the lower mold core 6 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com