Production process special for PA66 plate product

A PA66, production technology technology, applied in the field of production technology dedicated to PA66 plate products, can solve the problems of low yield, deformation, rough surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

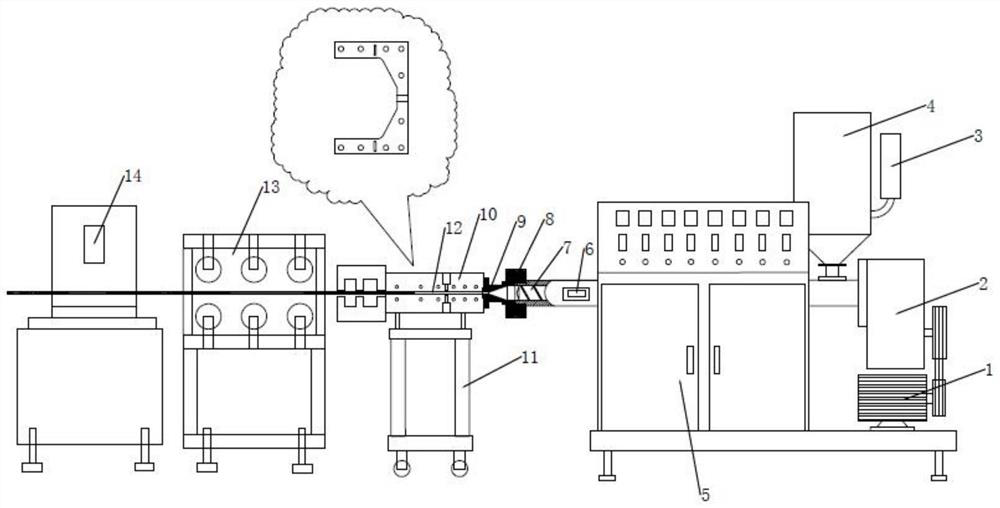

[0063] A kind of production technology specially used in PA66 plate products provided by the present invention, through figure 1 The PA66 special production equipment shown is used for production. Such as figure 1 As shown, the equipment includes a motor 1, a reduction box 2, a hopper 3, a dryer 4, a control cabinet 5, an exhaust hole 6, a screw 7, a flange joint 8, a square plate for the nozzle 9, a mold 10, and a mold frame 11 , brake seat 13, cutting machine 14, and oven etc.

[0064] The motor 1 , the reduction box 2 , the hopper 3 , the dryer 4 , the control cabinet 5 , the screw 7 etc. can constitute the main part of the equipment, and the screw 7 is arranged in the barrel. In the present invention, when producing PA66 sheet material, the dryer 4 can also be removed, and the common machine barrel can be replaced with a vented machine barrel, and the said PA66 plastic raw material can be heated by using the machine barrel and the extruding screw, The water contained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com