Thermal state research method for improving flame center deflection of corner tangential boiler

A flame center and four-corner tangential circle technology, which is applied in lighting and heating equipment, indirect carbon dioxide emission reduction, combustion equipment, etc., can solve the problem of excessive heat state, boiler defocused fire extinguishing, four-corner tangential circle boiler flame center deflection, etc. problem, to achieve the effect of improving air volume accuracy, improving data accuracy, and reducing primary air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

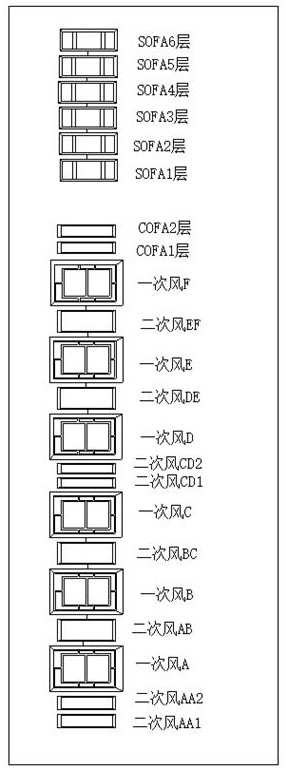

[0036] The 660MW ultra-supercritical burner is arranged in a tangential circle at the four corners of the pulverized coal boiler. The burner arrangement is as follows figure 1 , the main burner is provided with 6 layers of pulverized coal nozzles, which are layer A, layer B, layer C, layer D, layer E, layer F in order from bottom to top, layer A pulverized coal burner is arranged with micro-oil ignition device, adjacent 2 Auxiliary air nozzles are arranged between the pulverized coal nozzles, which are AB layer, BC layer, CD1 layer, CD2 layer, DE layer, and EF layer secondary air. There are two layers of bottom air nozzles at the lower part of the main burner, namely AA1 Layer, AA2 layer secondary air, the upper end air is equipped with compact combustion air, namely COFA1 layer, COFA2 layer secondary air, above the main burner are arranged 6 sets of separate combustion combustion air, namely SOFA1 layer, SOFA2 layer, SOFA3, SOFA4, SOFA5, SOFA6 secondary air. All primary air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com