Patents

Literature

44results about How to "Accurate measurement structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

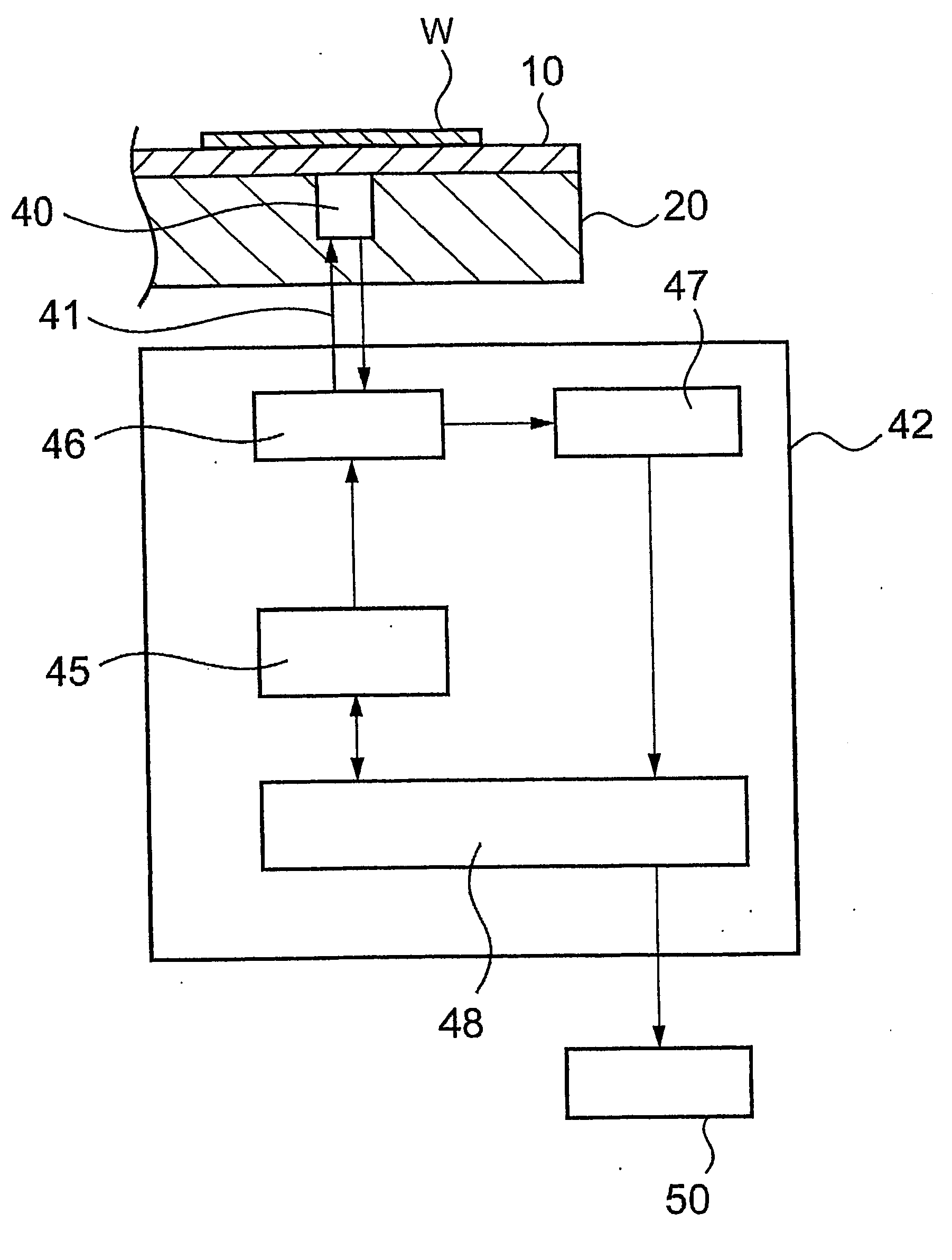

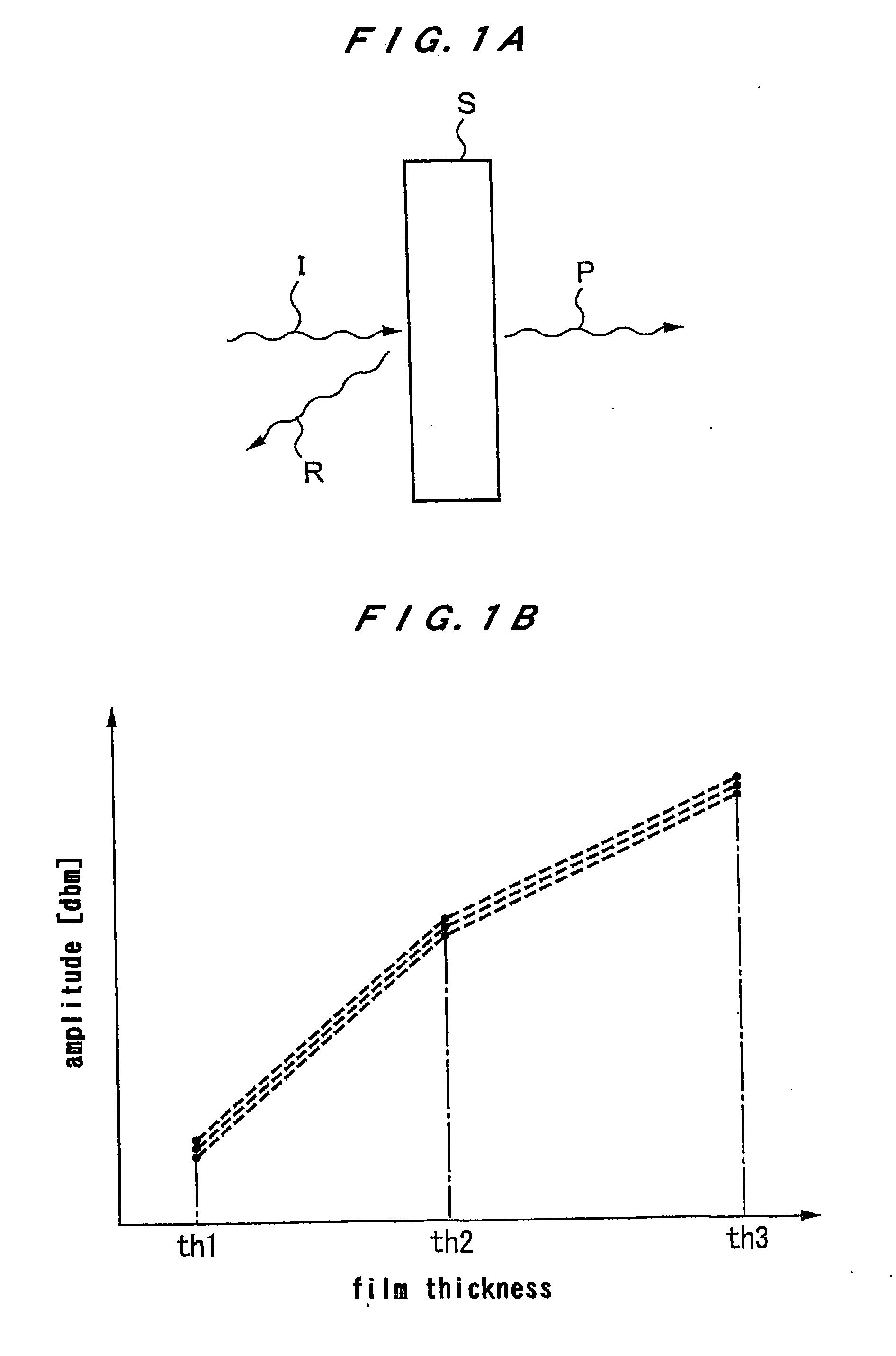

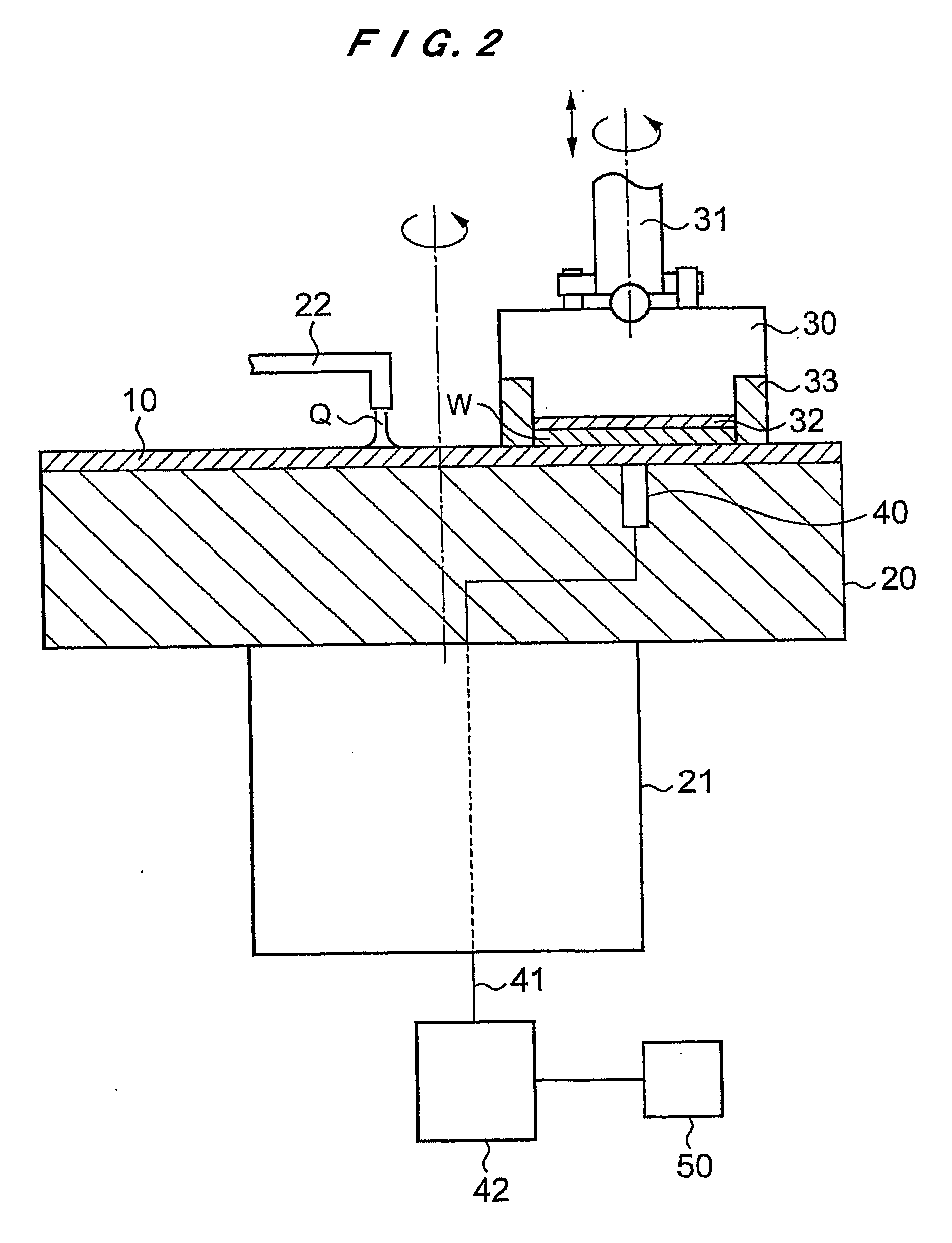

Measuring apparatus

InactiveUS20060164104A1Reduce manufacturing costAccurate measurementSemiconductor/solid-state device testing/measurementResistance/reactance/impedenceMeasurement deviceMeasuring instrument

The present invention relates to a measuring apparatus for measuring a thickness or the like of a thin film formed on a surface of a substrate such as a semiconductor wafer. The measuring apparatus includes a microwave emission device (40) for emitting a microwave to a substance, a microwave generator (45) for supplying the microwave to the microwave emission device (40), a detector (47) for detecting an amplitude or a phase of the microwave which has been reflected from or passed through the substance, and an analyzer (48) for analyzing a structure of the substance based on the amplitude or the phase of the microwave which has been detected by the detector (47).

Owner:EBARA CORP

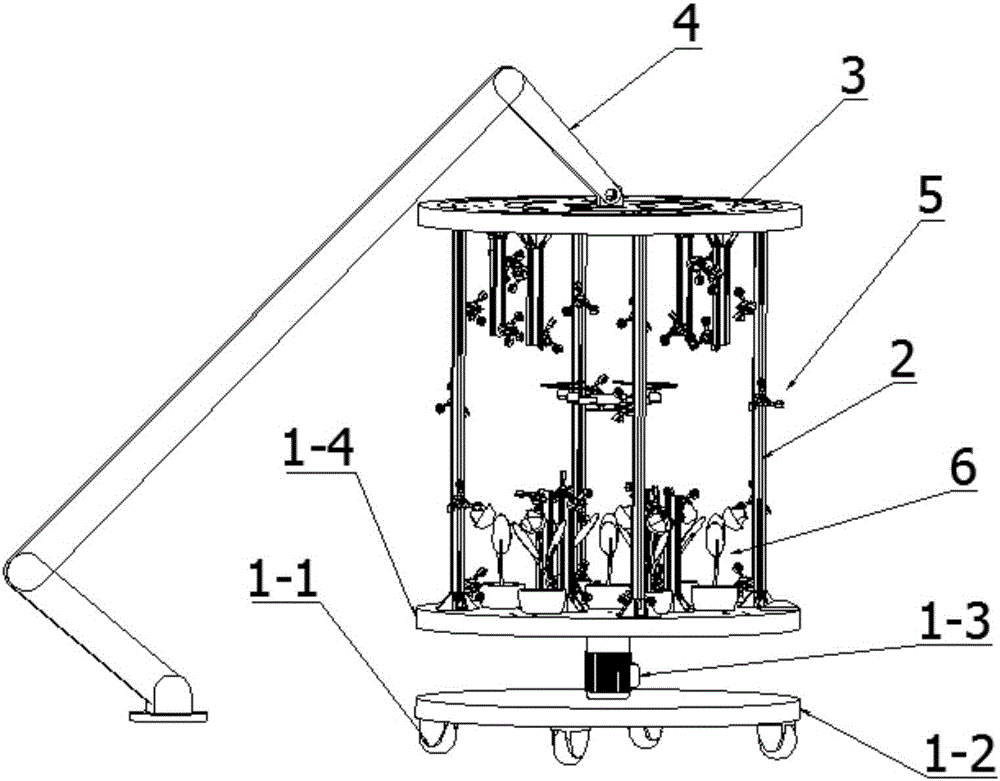

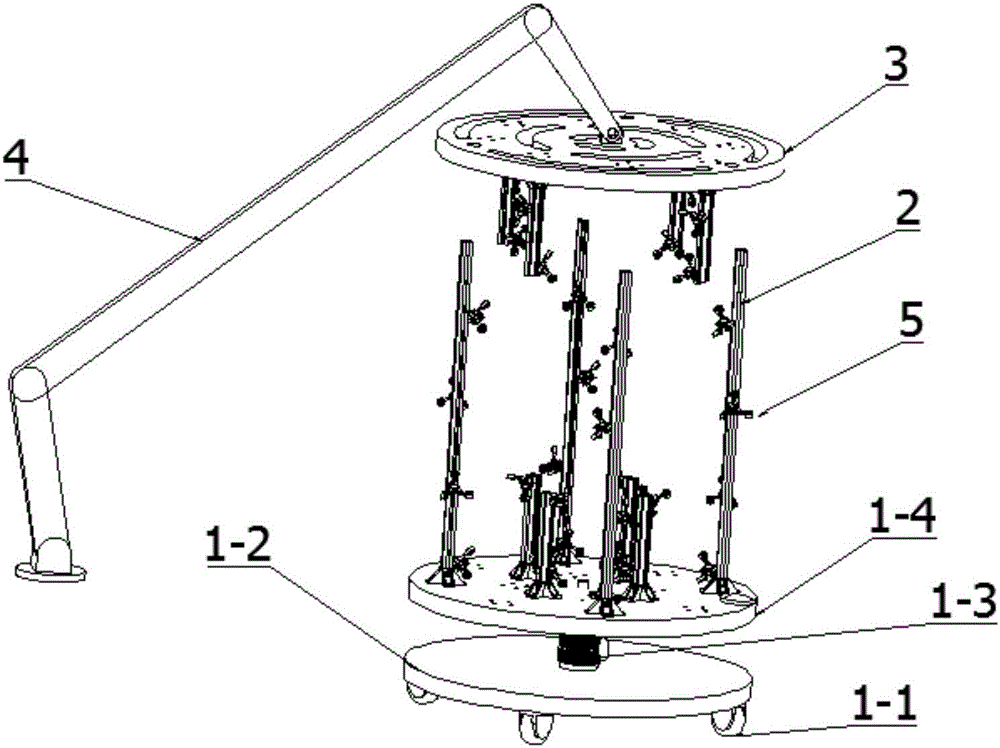

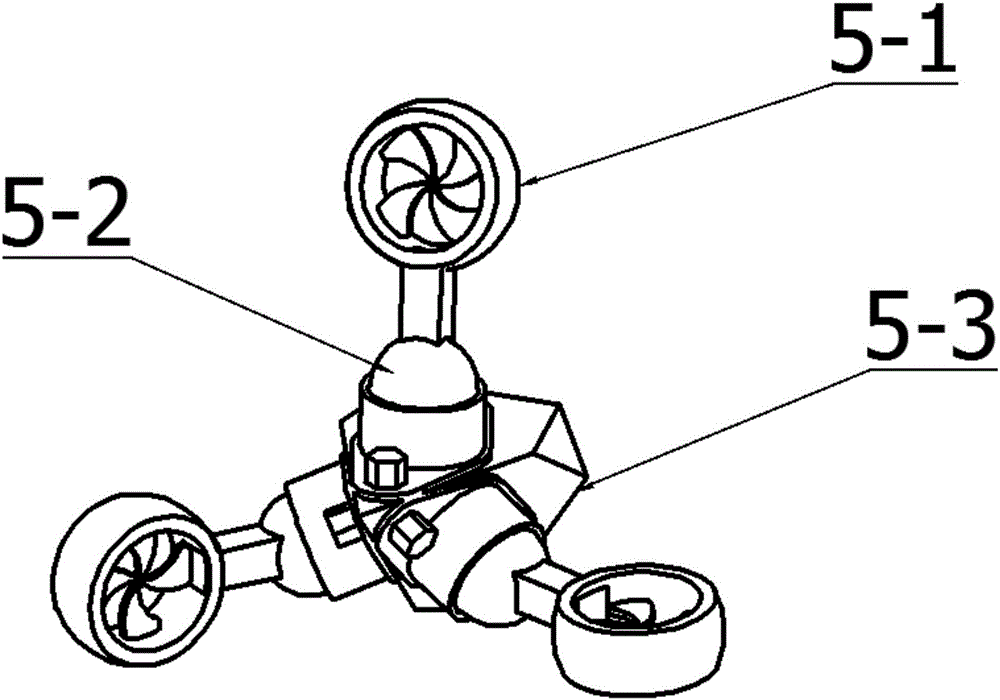

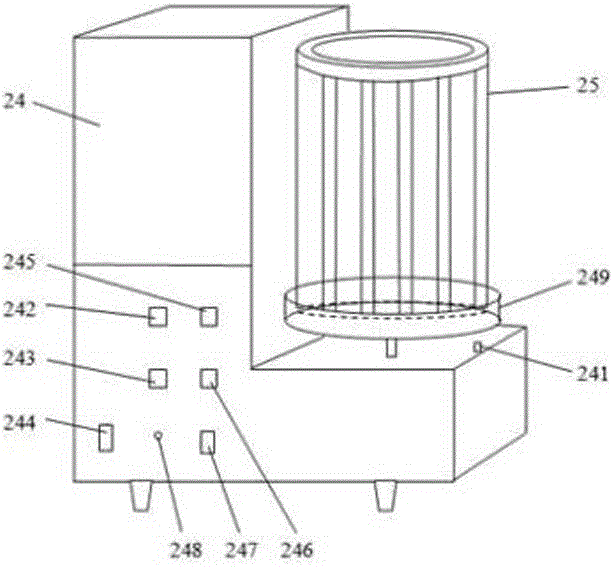

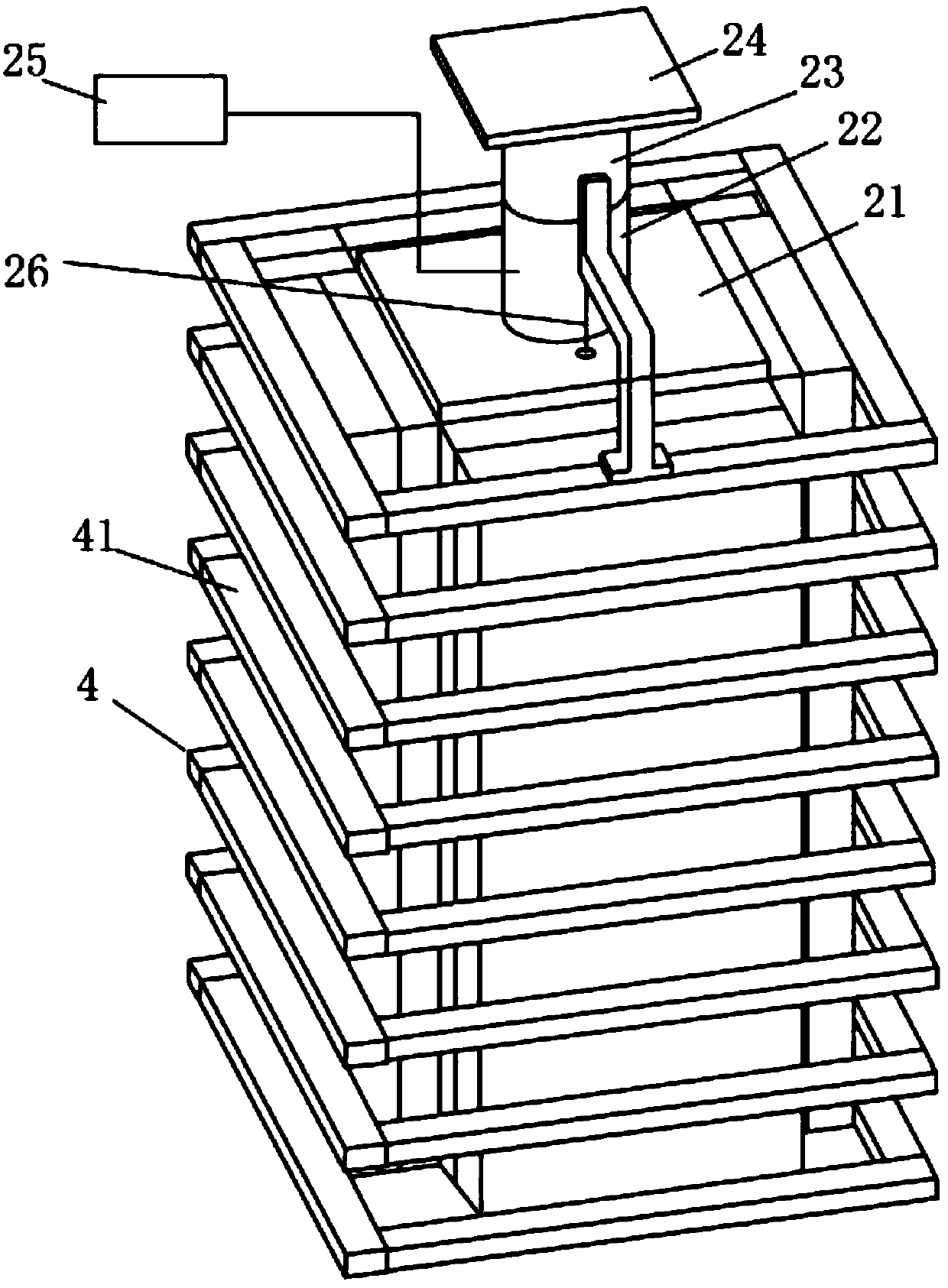

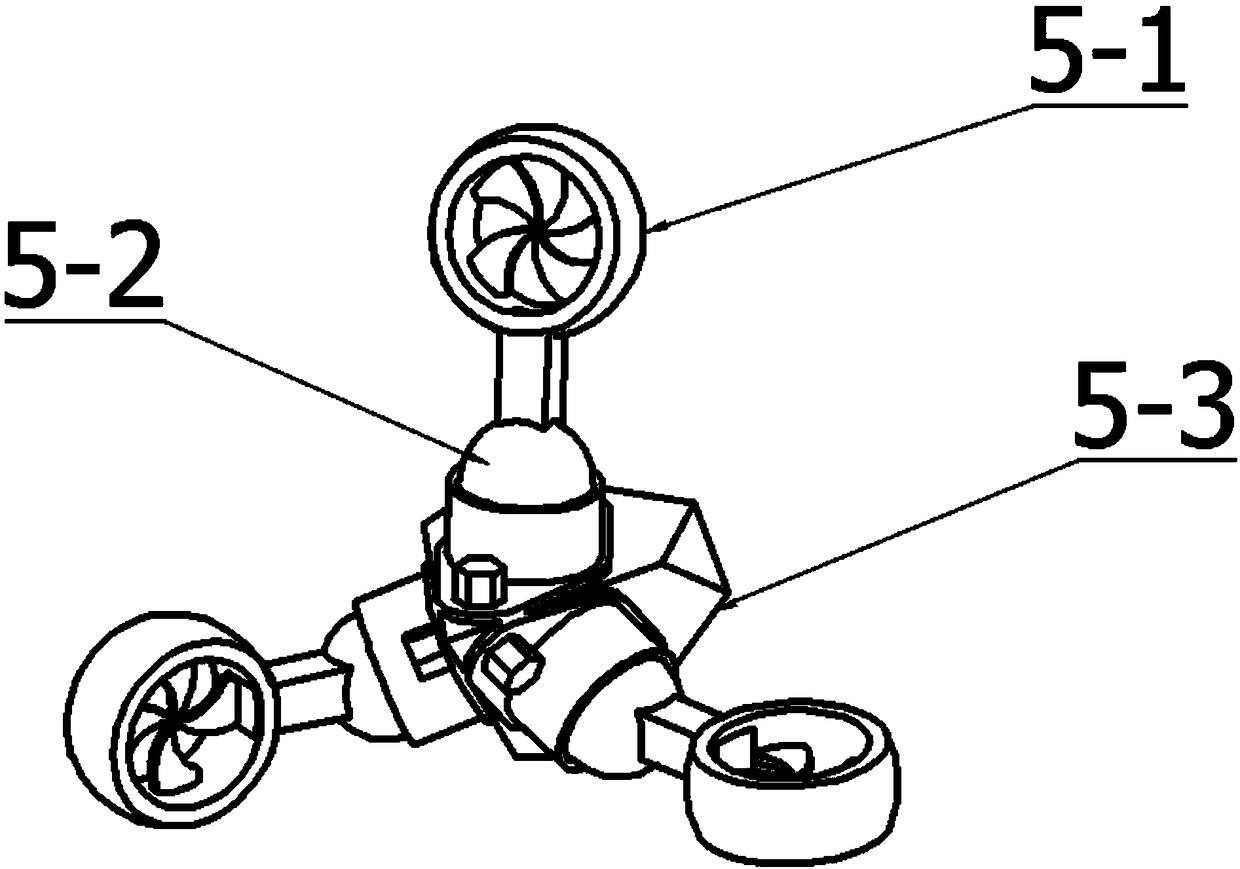

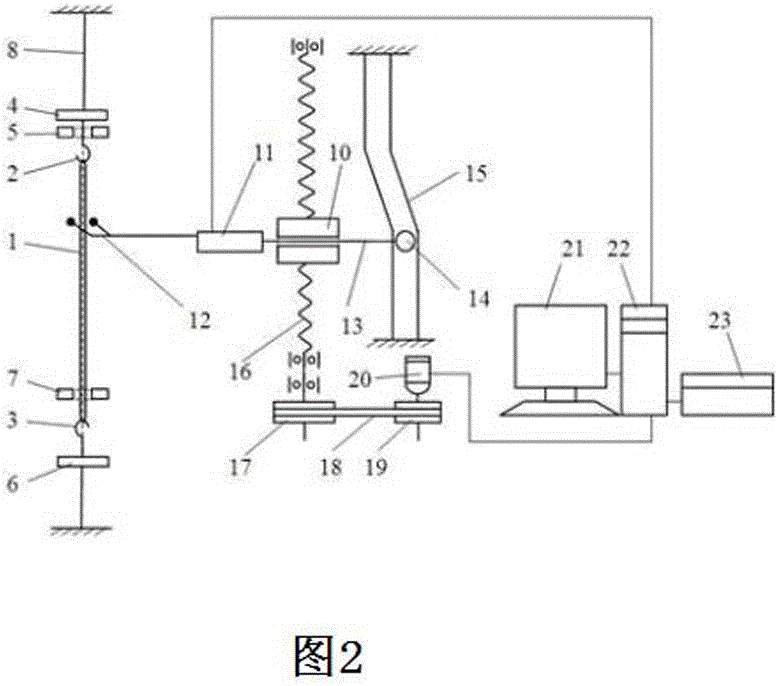

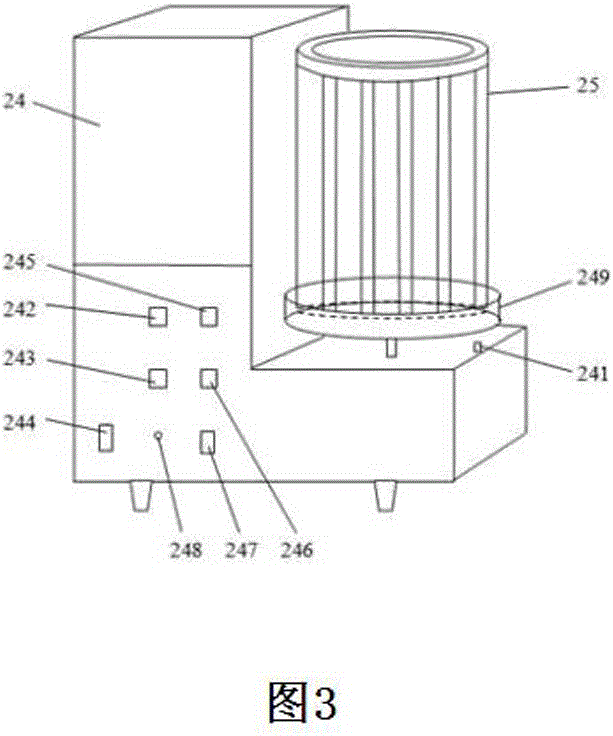

Three-dimensional wind field measurement system applicable to unmanned aerial vehicle and use method of three-dimensional wind field measurement system

ActiveCN106679928AThe measurement structure is completeAccurate measurement structureAerodynamic testingFluid speed measurementControl systemThree-dimensional space

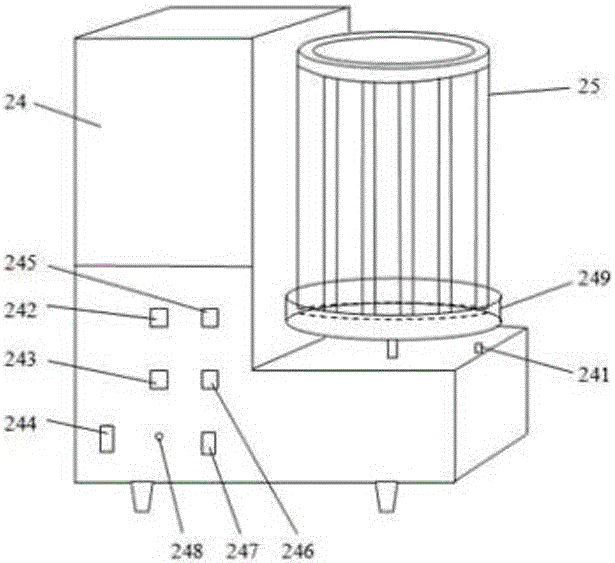

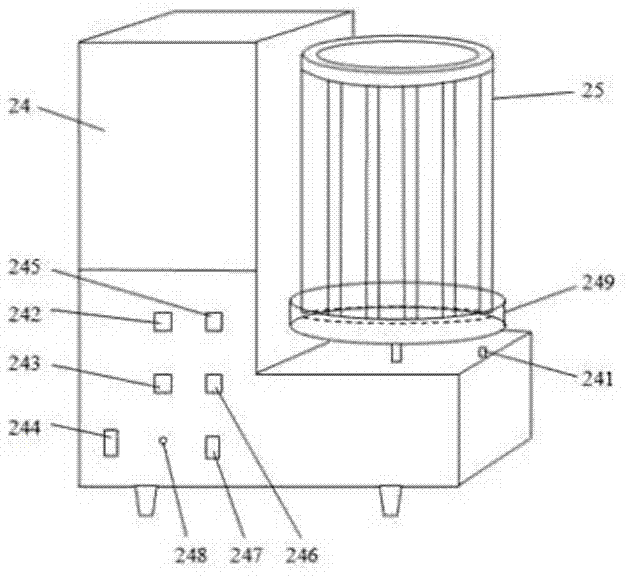

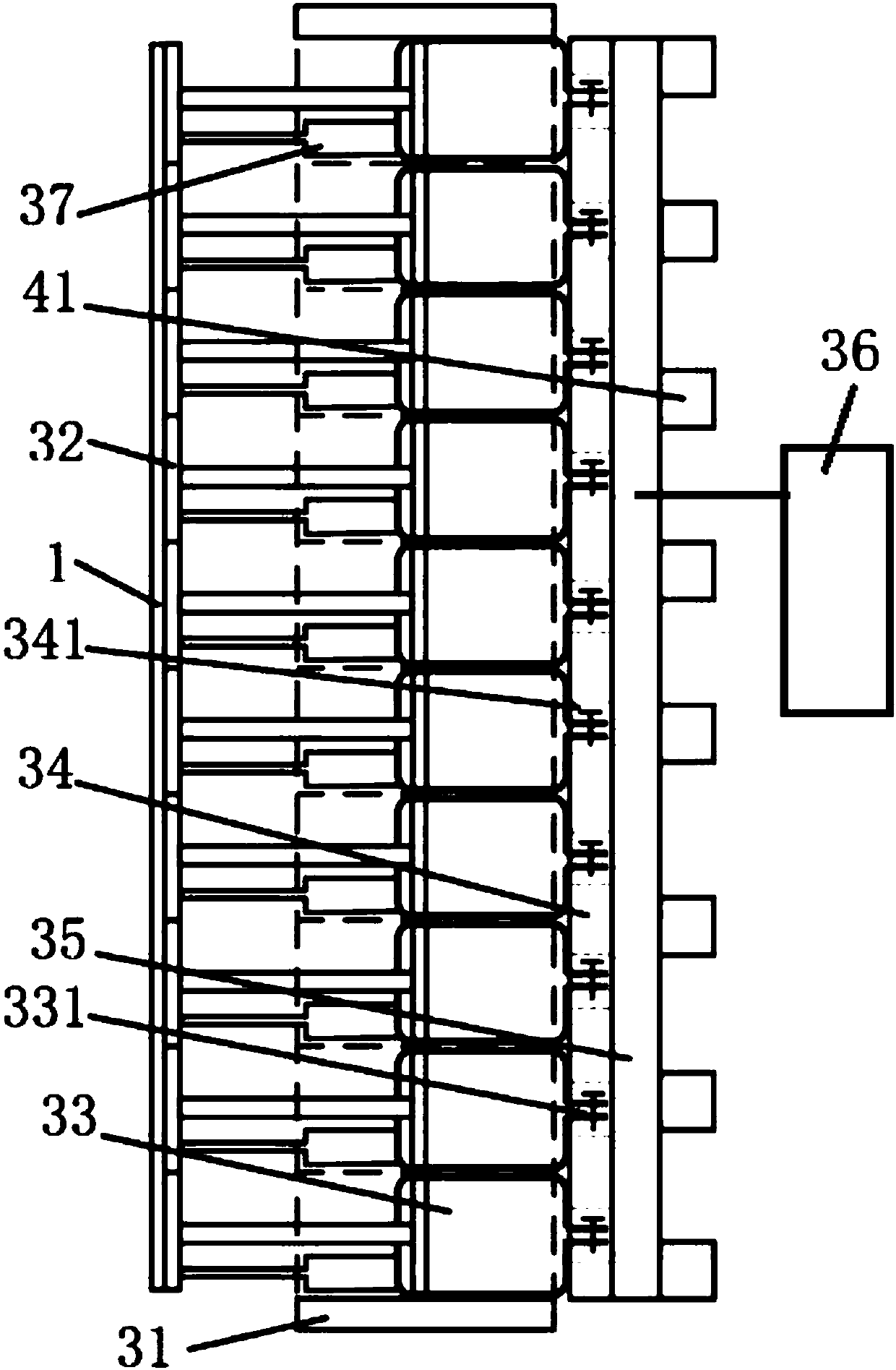

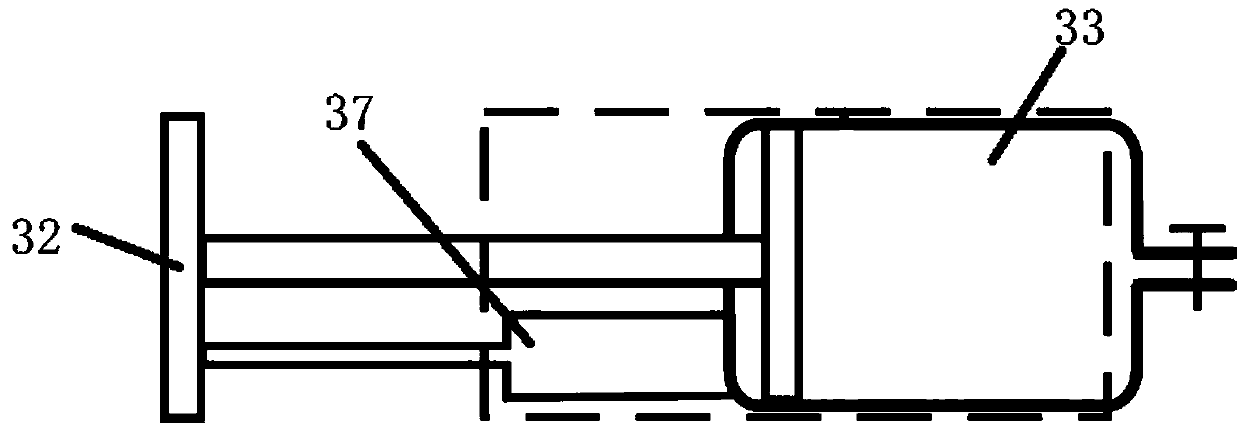

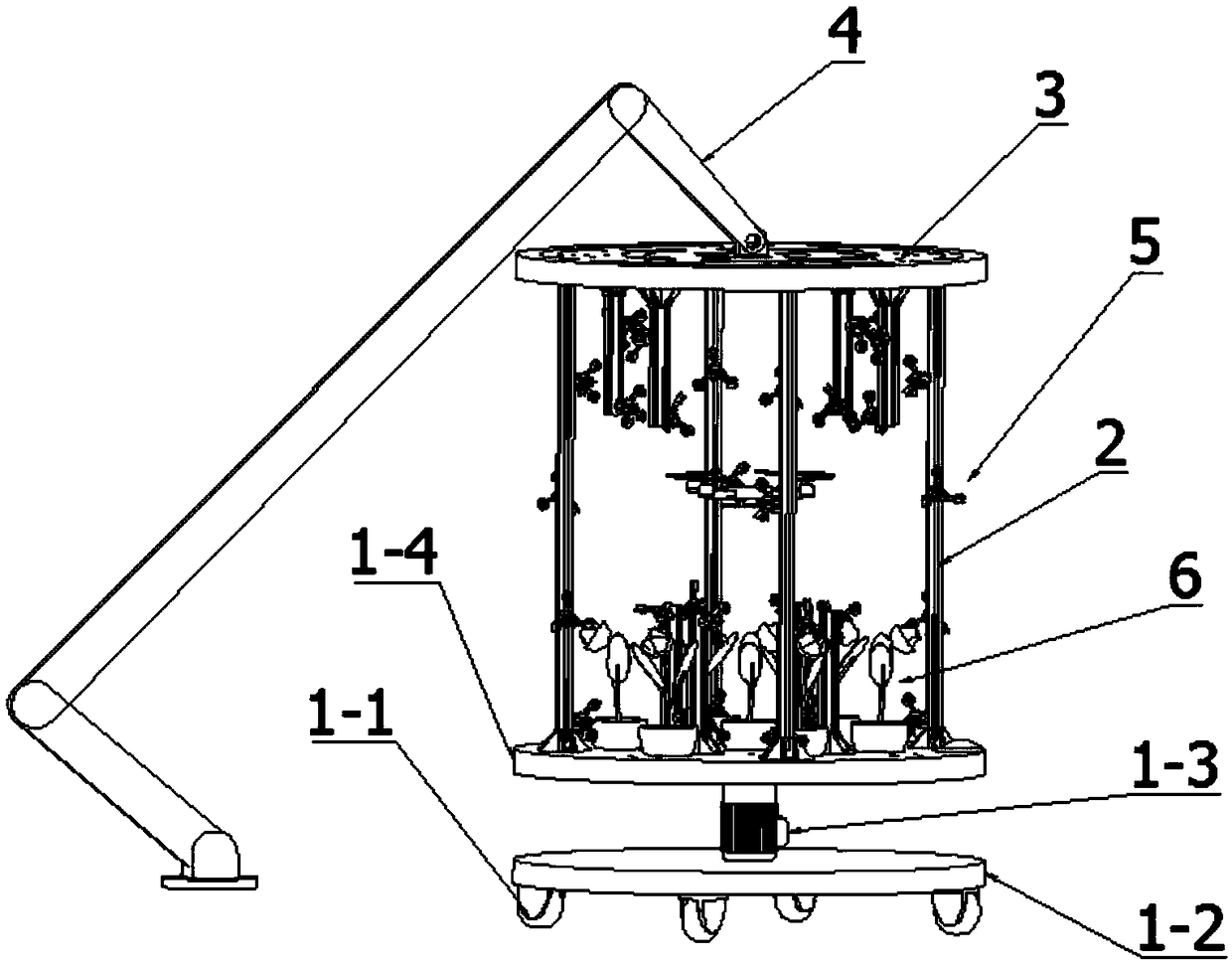

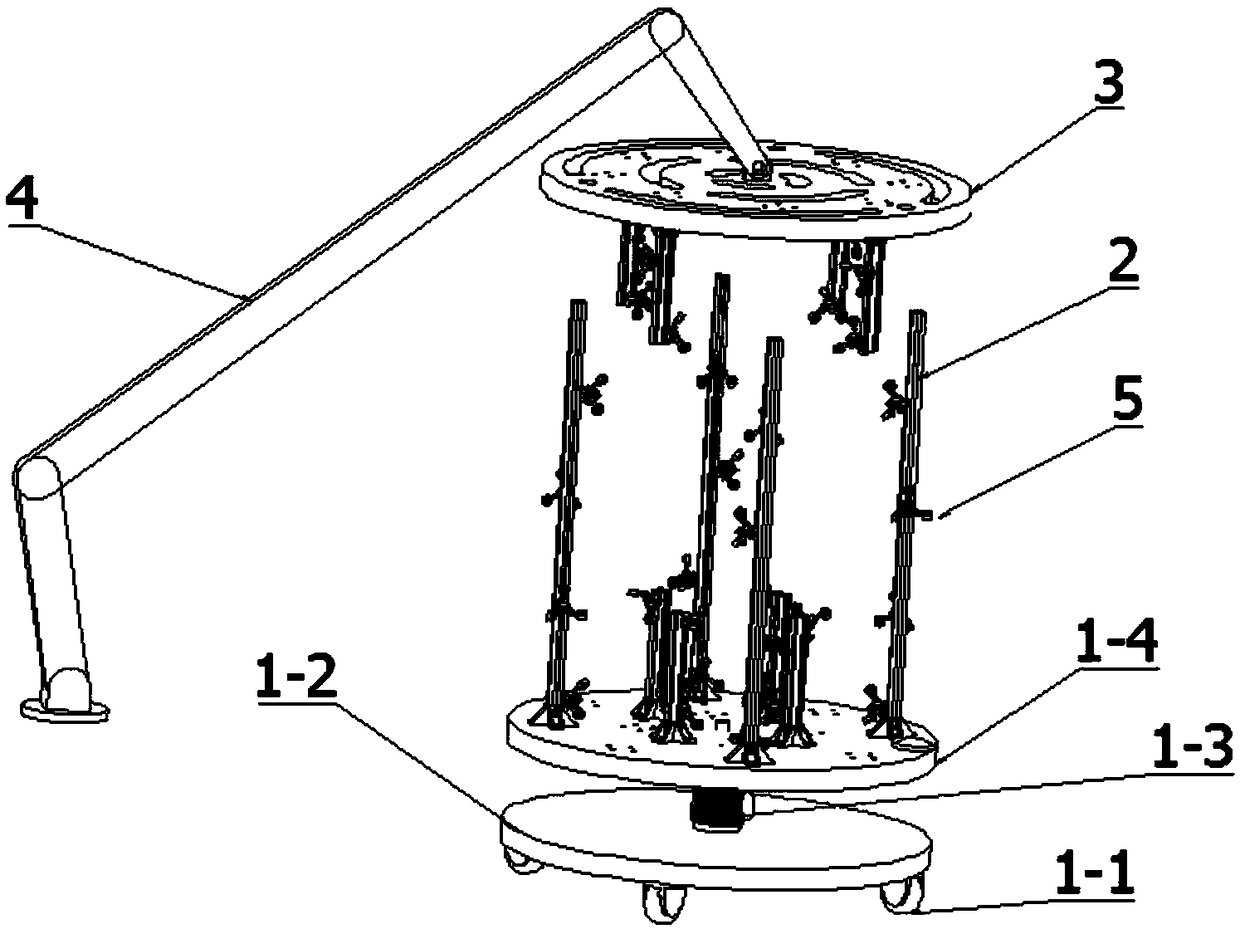

The present invention discloses a three-dimensional wind field measurement system applicable to an unmanned aerial vehicle and a use method of the three-dimensional wind field measurement system. The three-dimensional wind field measurement system comprises a data acquisition device and a control system; the data acquisition device comprises a plurality of wind speed measuring devices and a wind speed acquisition support; each wind speed measuring device includes wind speed sensors and a wind speed sensor fixing mechanism; the wind speed acquisition support includes a base main body, upright columns and a top cover; the base main body includes an upper-layer base and a lower-layer base; the top surface of the upper-layer base is provided with the plurality of upright columns which are distributed circumferentially; the upright columns are provided with the wind speed measuring devices; the lower-layer base is provided with a rotation driving device for driving the upper-layer base to rotate; and the top surface of the upper-layer base and the bottom surface of the top cover are both provided with the wind speed measuring devices. With the three-dimensional wind field measurement system of the invention adopted, the measurement of a three-dimensional space wind field at a specific area around the unmanned aerial vehicle can be realized. The three-dimensional wind field measurement system has the advantages of simple structure, convenient operation, easiness in arrangement and high applicability.

Owner:SOUTH CHINA AGRI UNIV

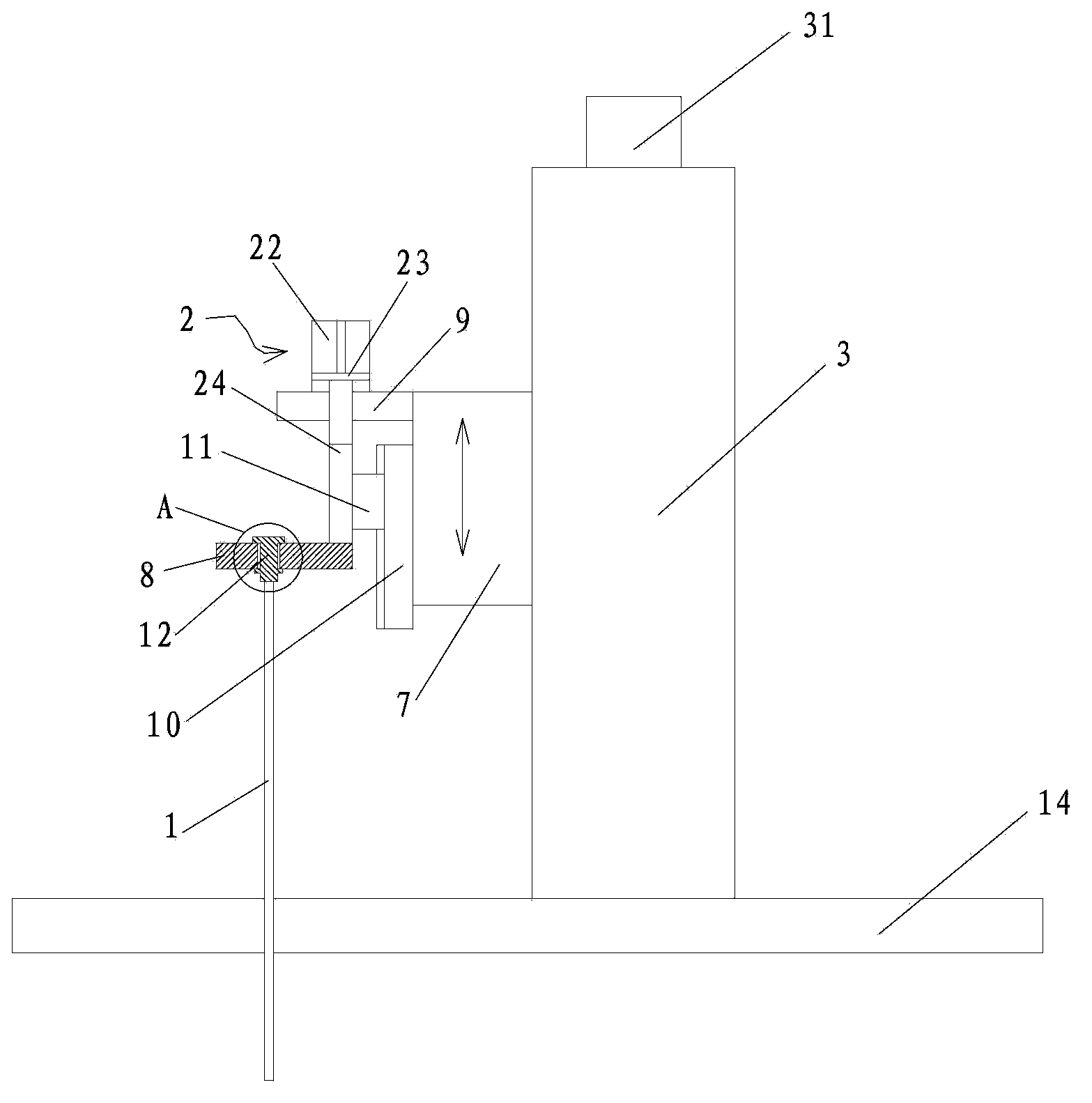

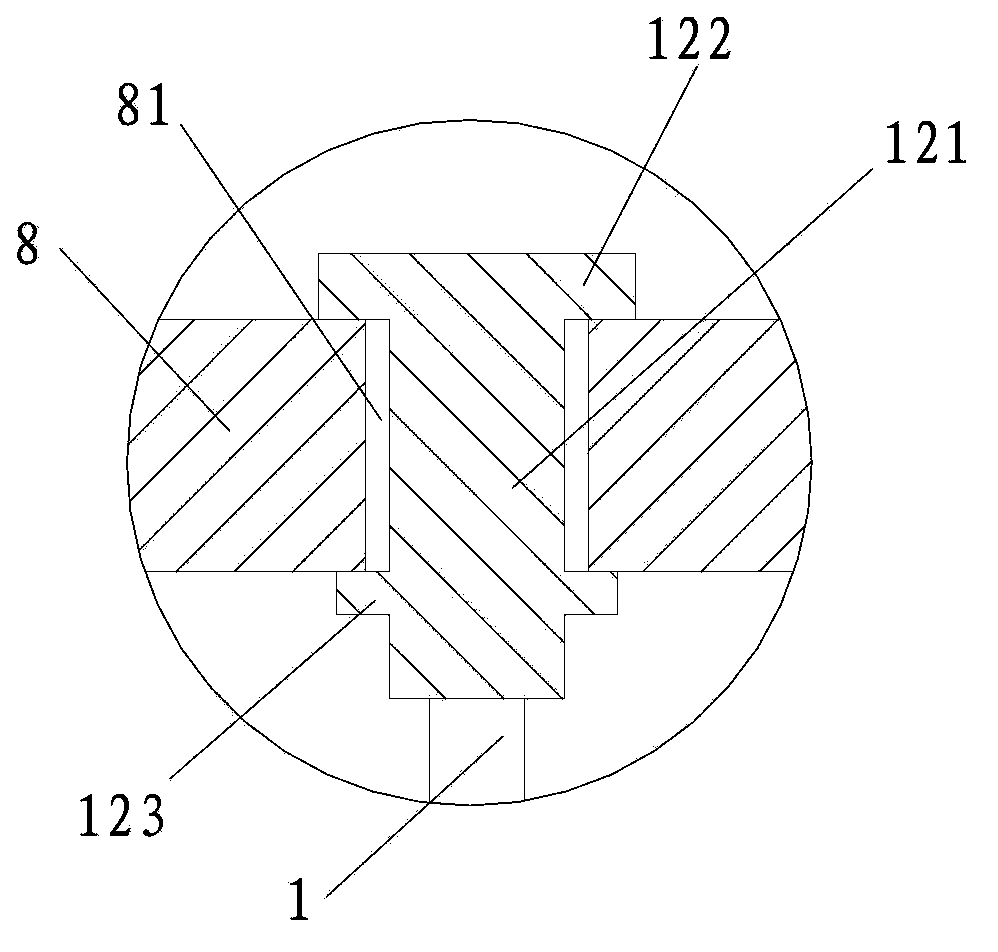

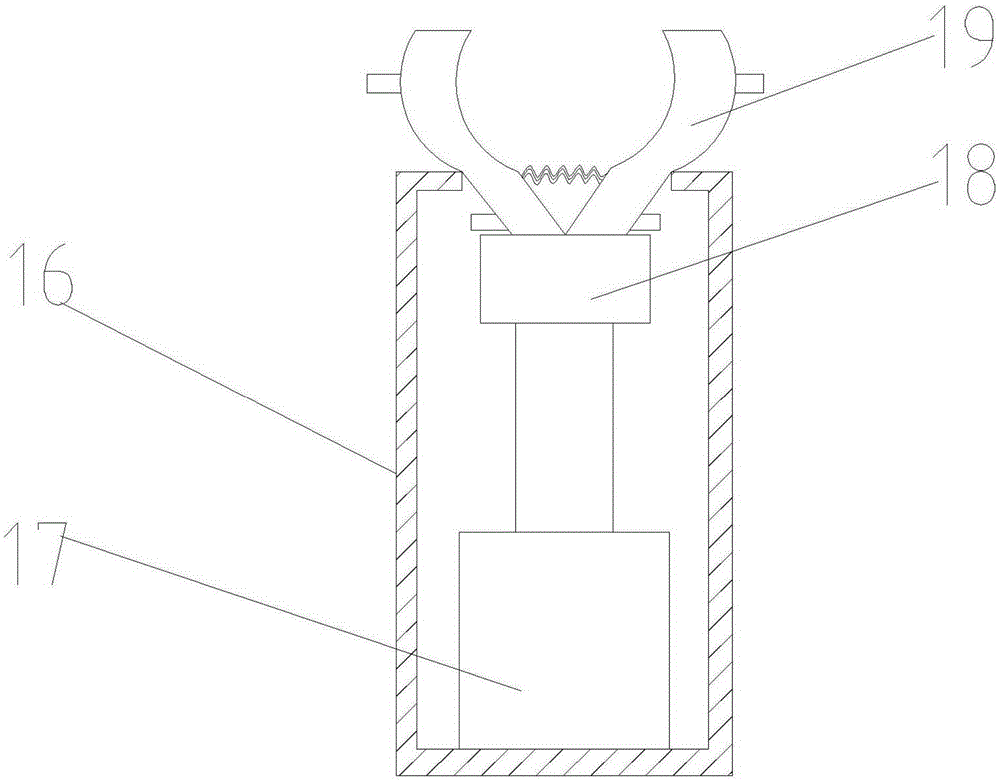

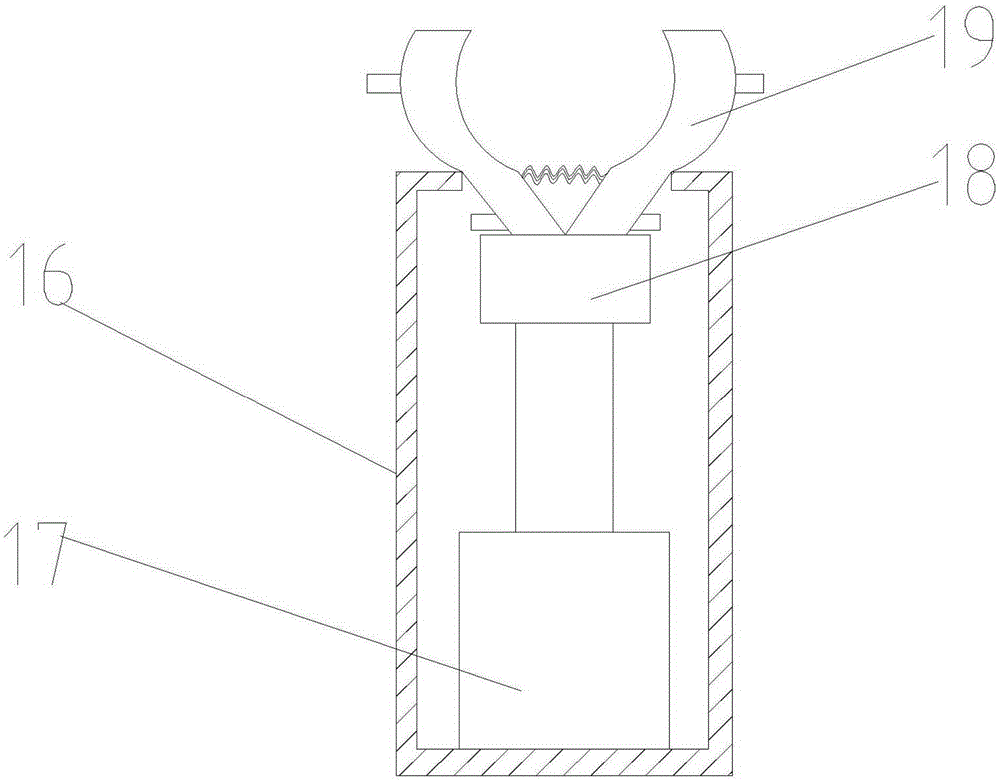

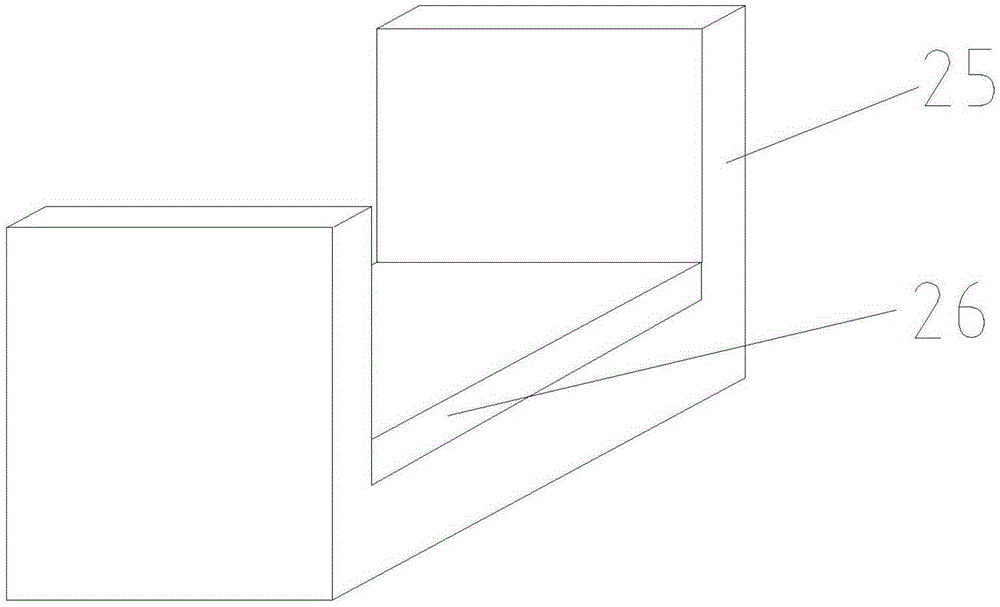

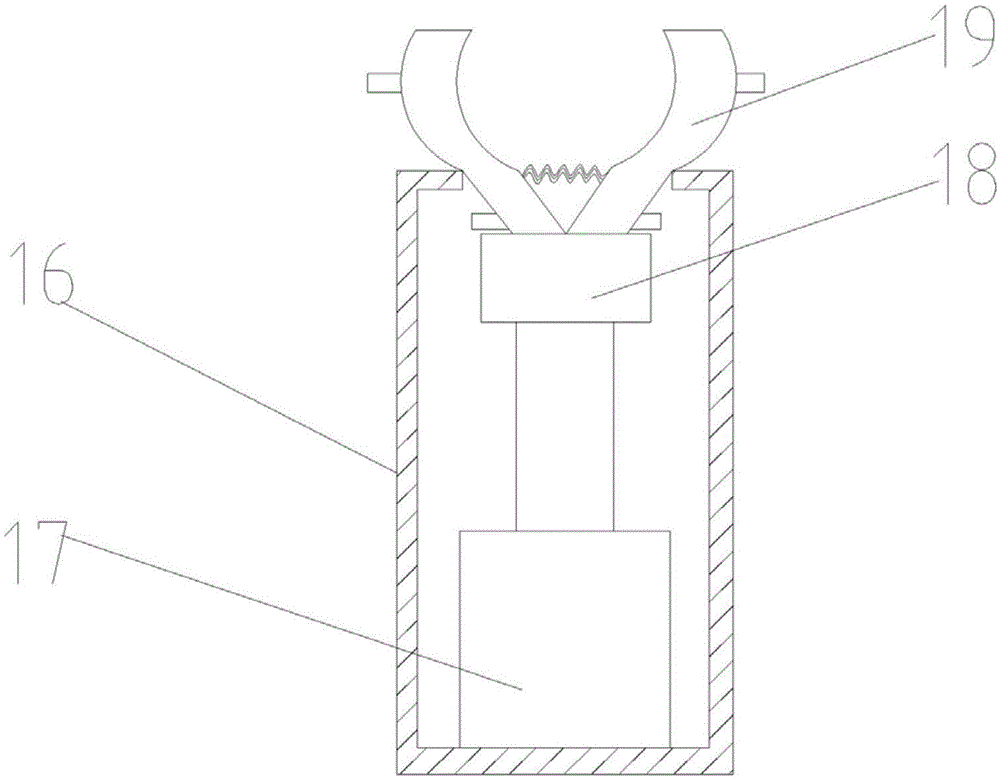

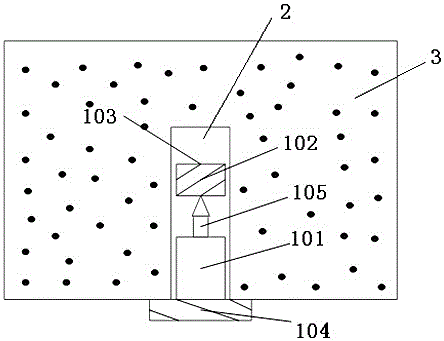

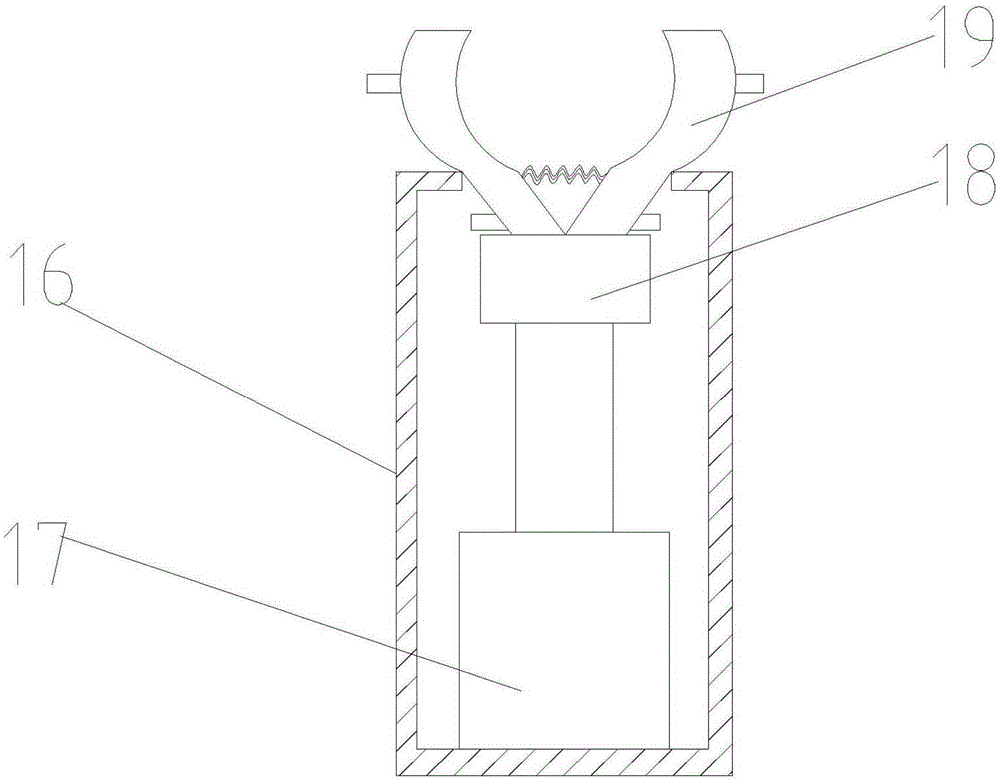

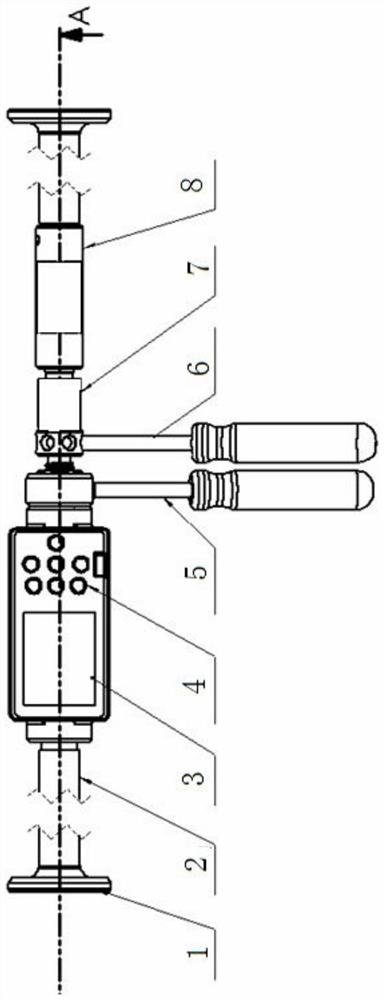

Solid-liquid interface determination device for silicon ingot furnace

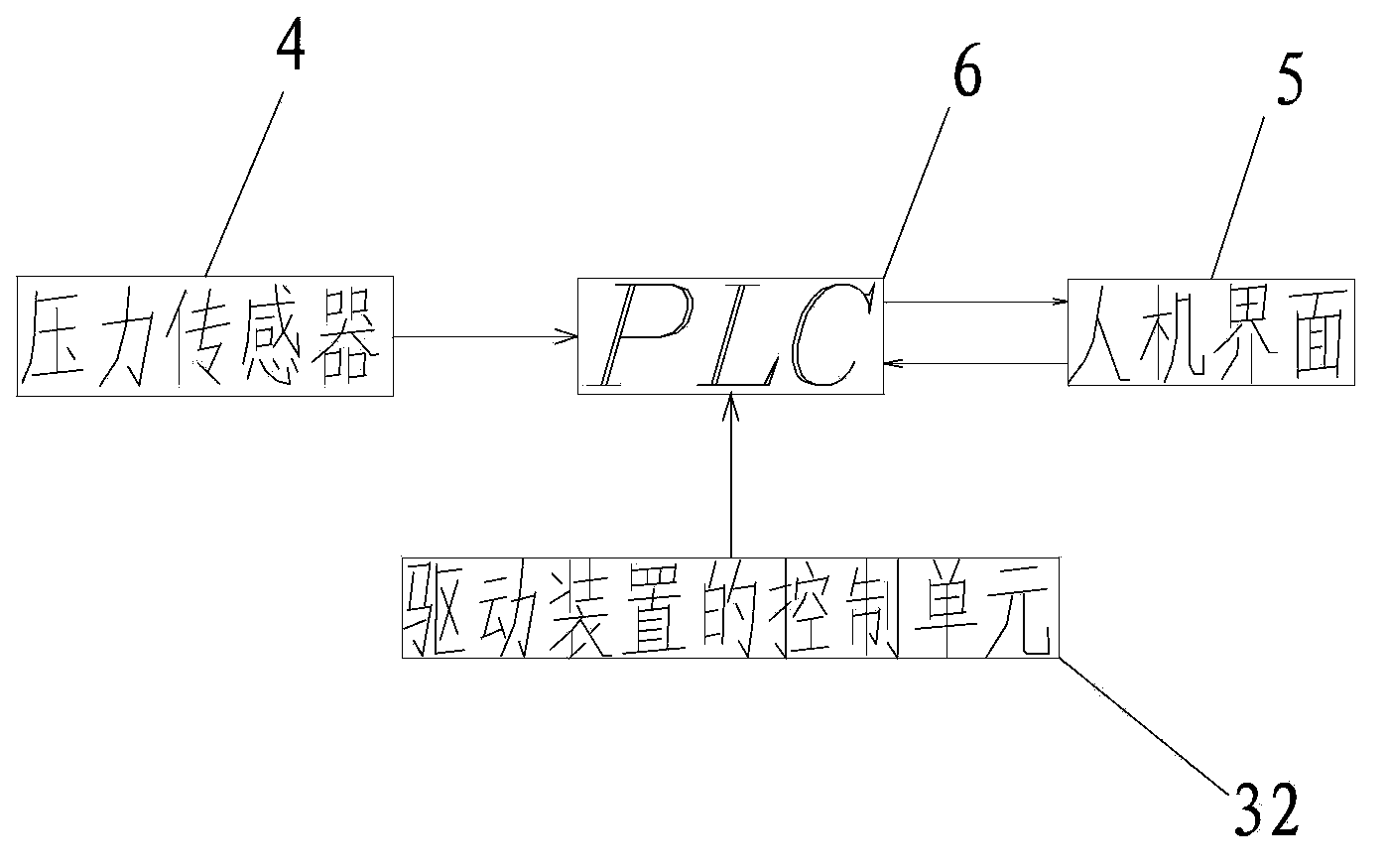

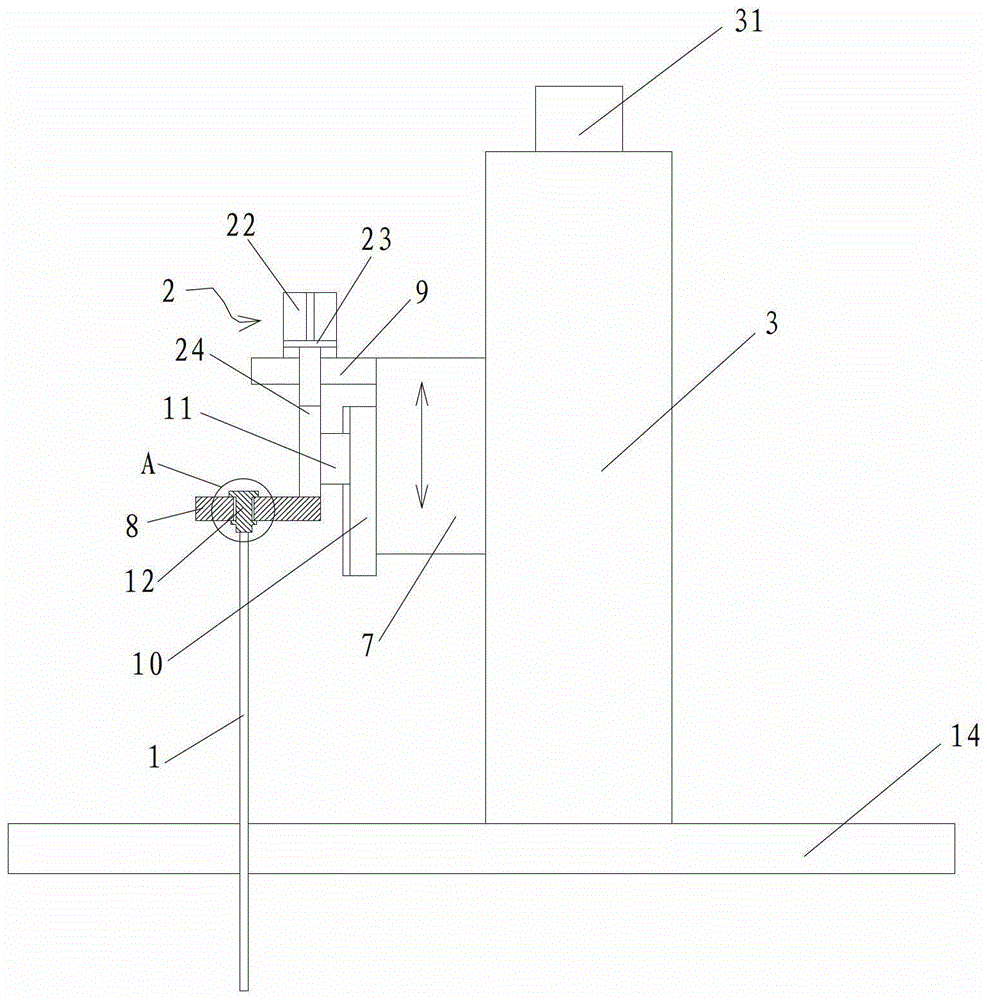

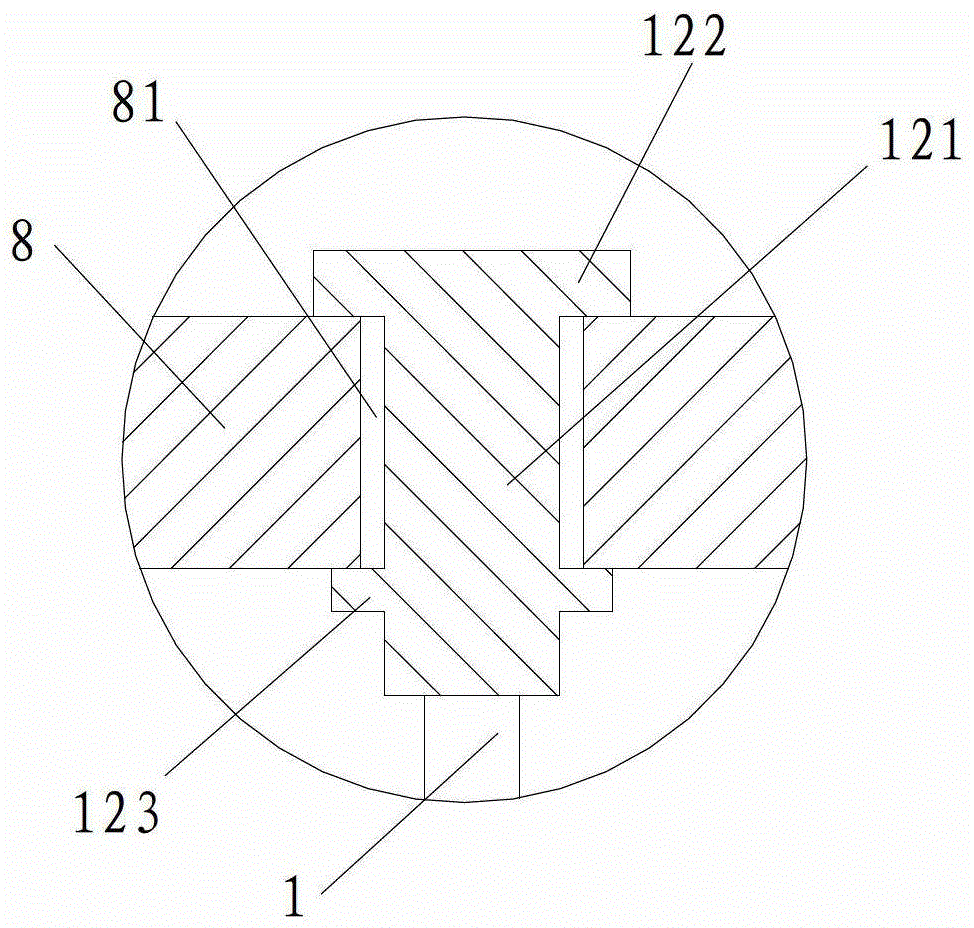

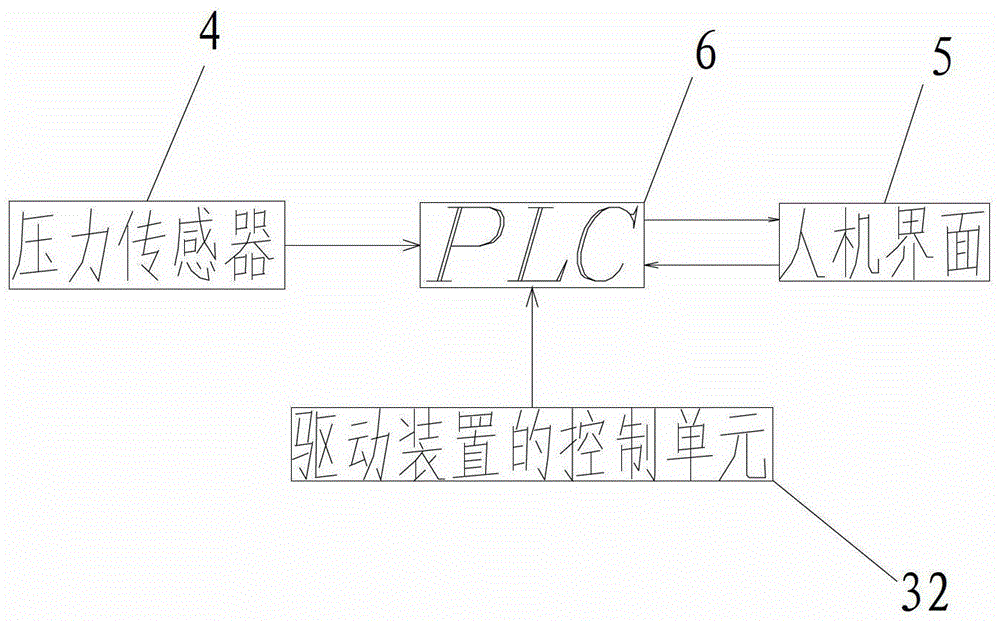

InactiveCN103668449ASimple structureReduce manufacturing costPolycrystalline material growthMeasurement devicesElectricityProgrammable logic controller

The invention discloses a solid-liquid interface determination device for a silicon ingot furnace. The solid-liquid interface determination device comprises a quartz rod, a cylinder, a driving device, a pressure sensor and a PLC (programmable logic controller), wherein the quartz rod is used for being in contact with solid polysilicon in a silicon ingot furnace; a first piston rod of the cylinder is in a extending state and is connected with the quartz rod; the driving device is used for driving the quartz rod to make a rectilinear motion in the vertical direction; the pressure sensor is mounted between the first piston rod of the cylinder and the quartz rod and is used for sensing an acting force generated by the contact between the quartz rod and the solid polysilicon; and the PLC is electrically connected with the driving device and the pressure sensor respectively, and is used for receiving signals collected by the pressure sensor and controlling the driving device to drive the quartz rod to ascend or descend according to the received signals. The solid-liquid interface determination device for a silicon ingot furnace is simple in structure, low in manufacturing cost, convenient to use and accurate in measuring structure, and can automatically obtain depth of molten silicon in the silicon ingot furnace without requiring measuring personnel to manually insert the quartz rod into the silicon ingot furnace and read frequently, thereby relieving the measuring personnel.

Owner:镇江荣德新能源科技有限公司

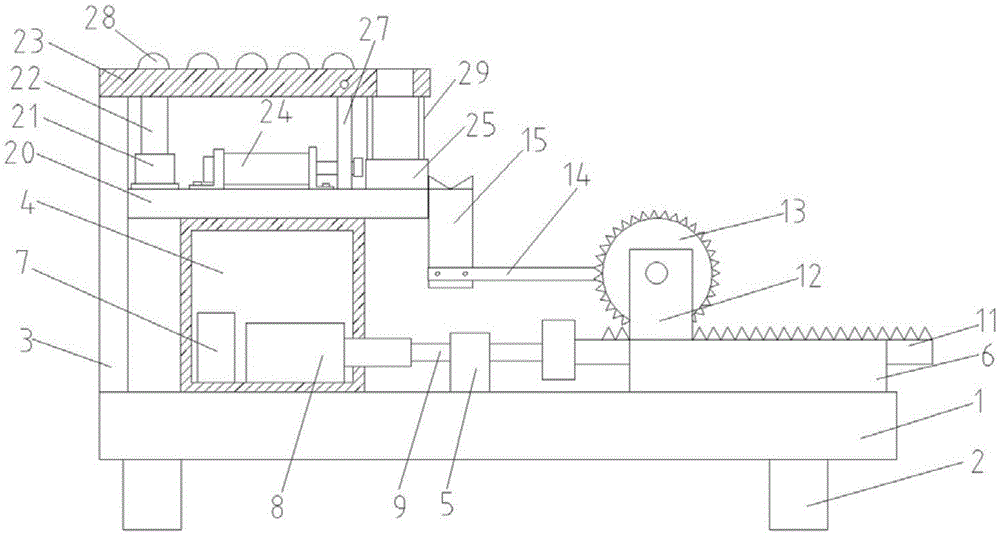

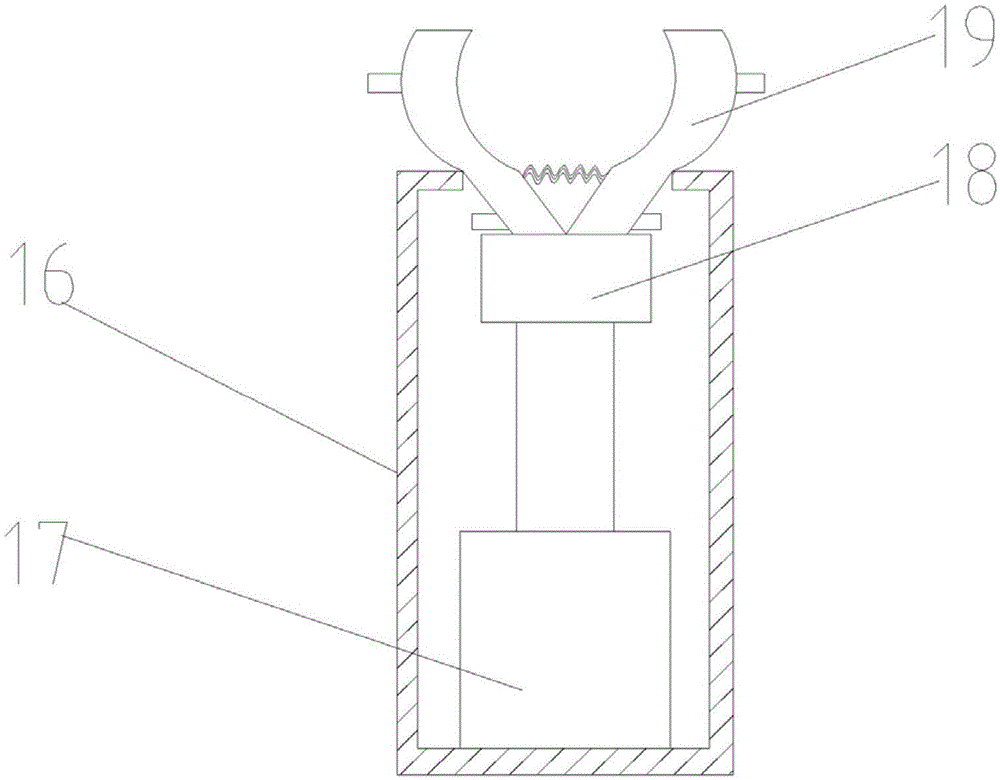

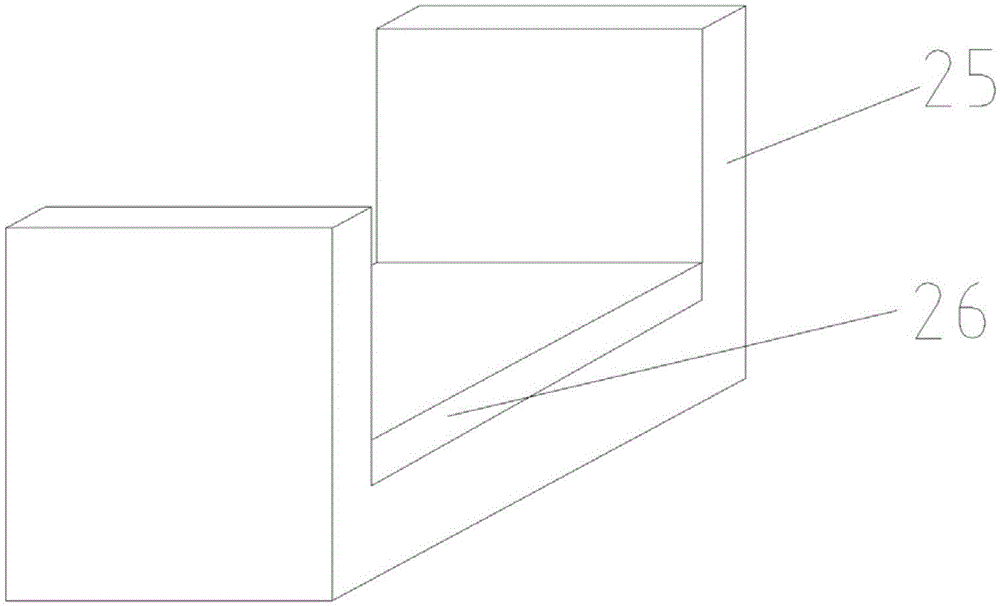

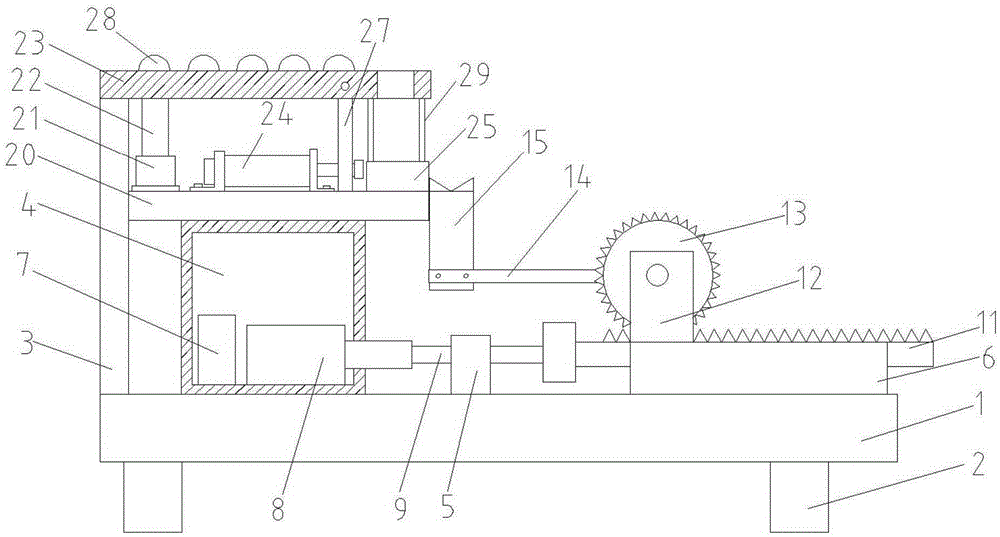

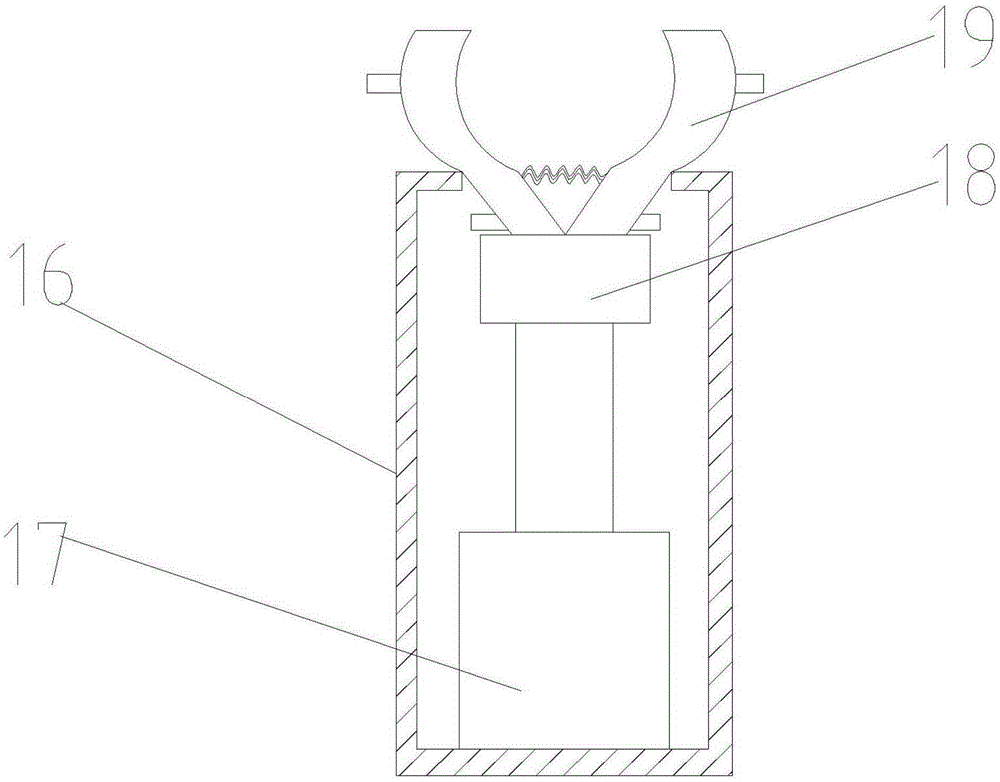

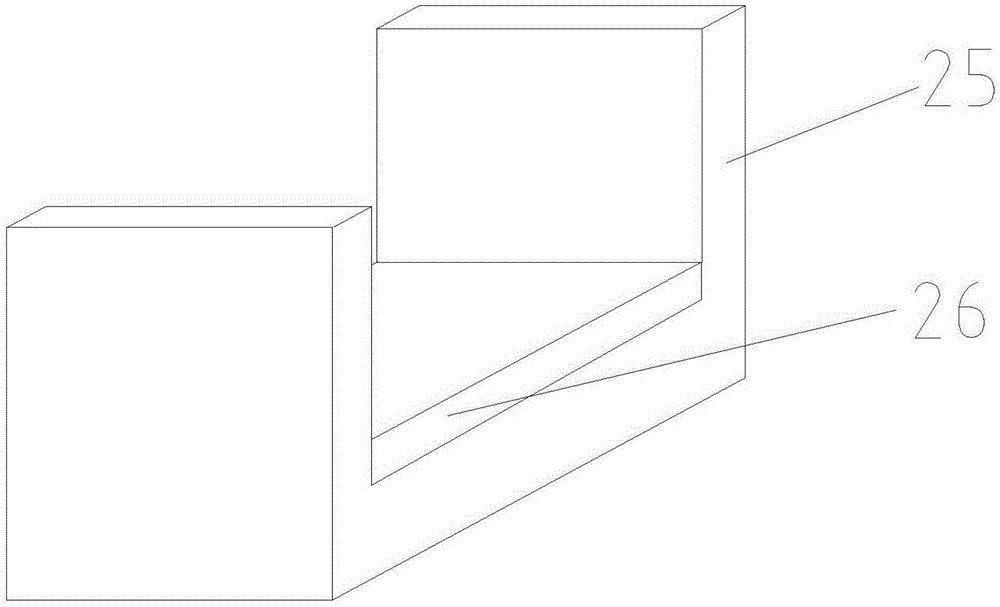

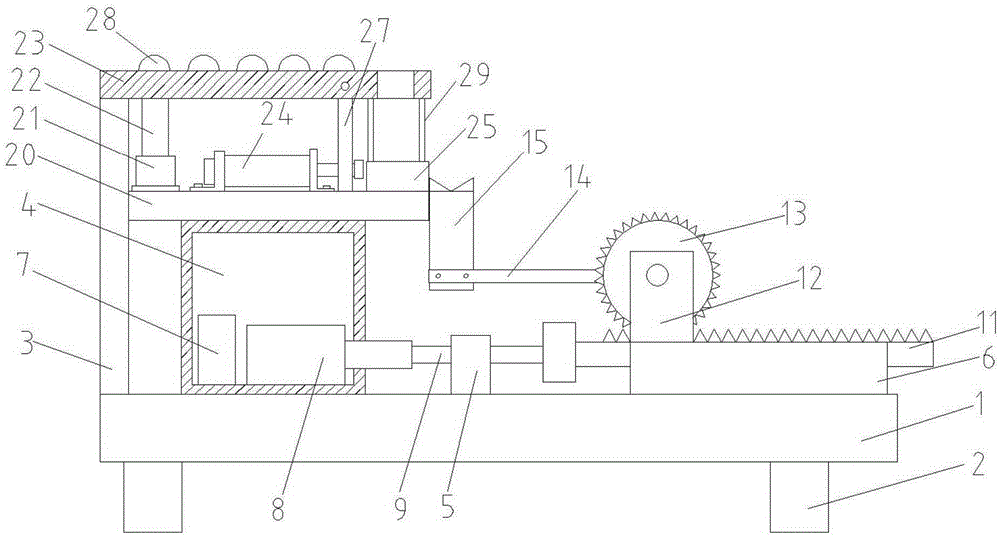

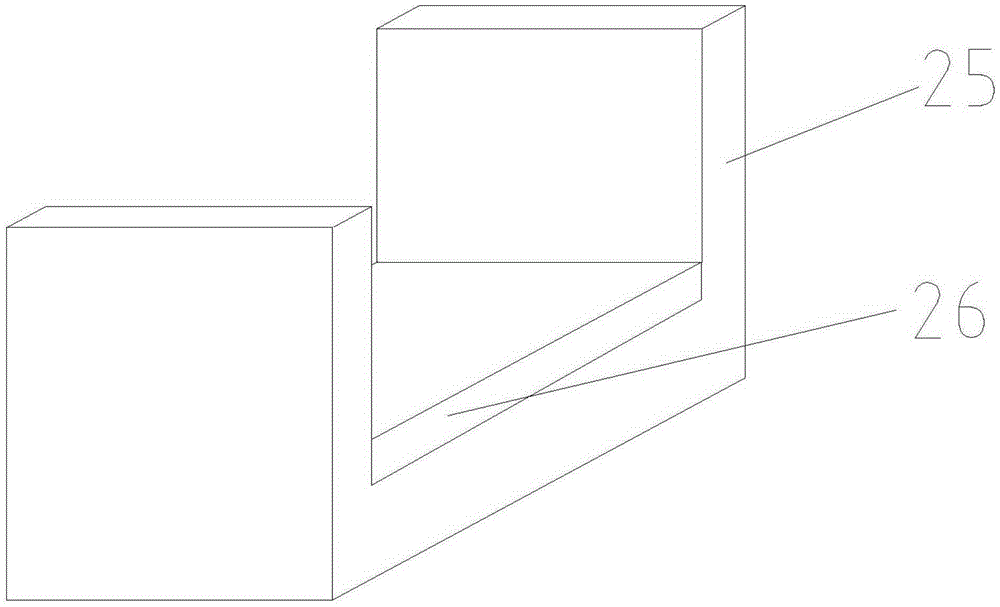

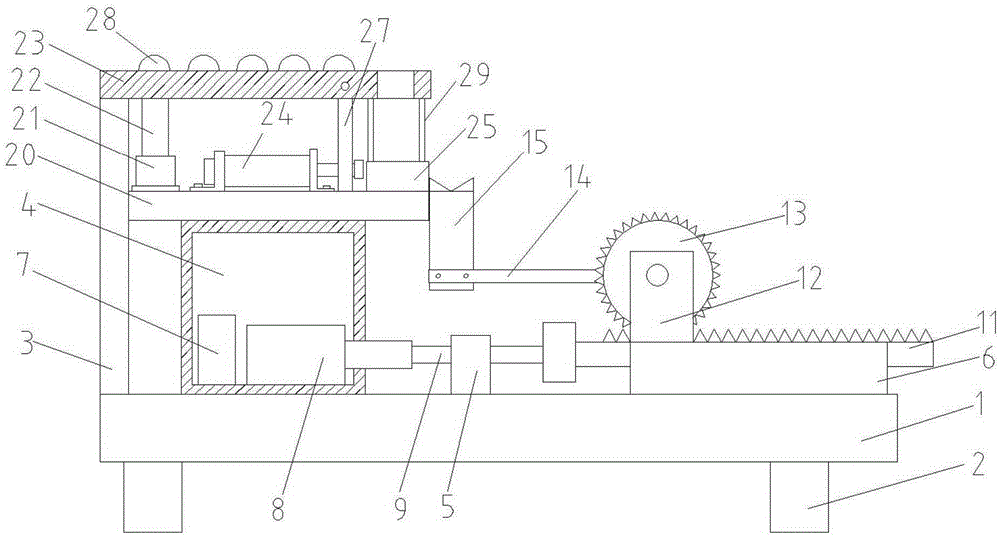

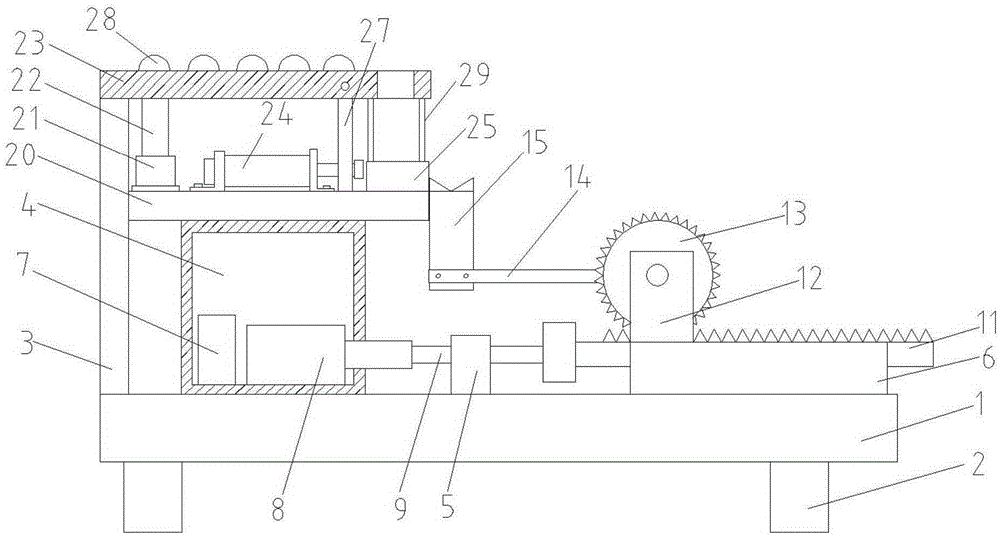

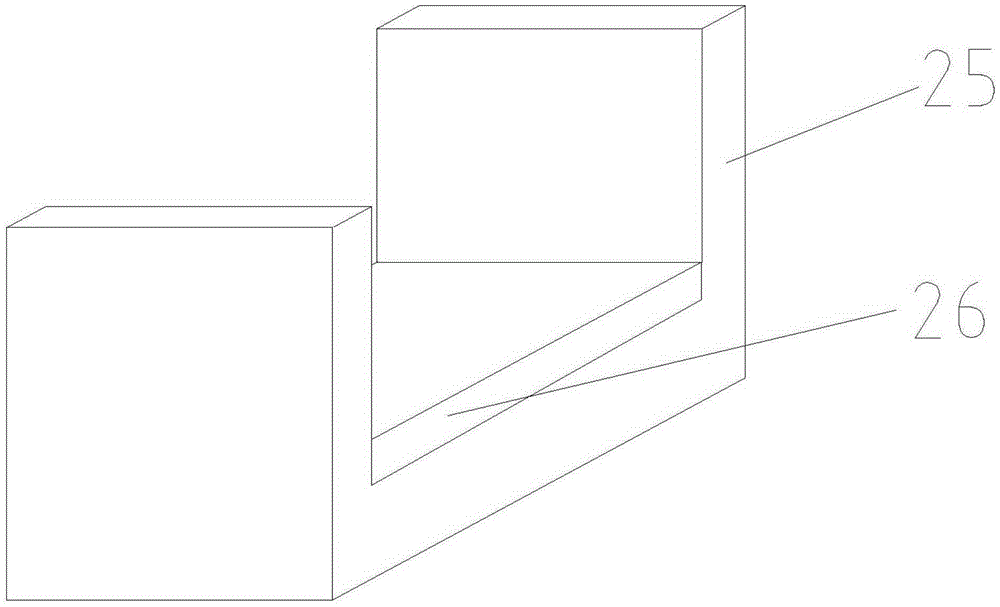

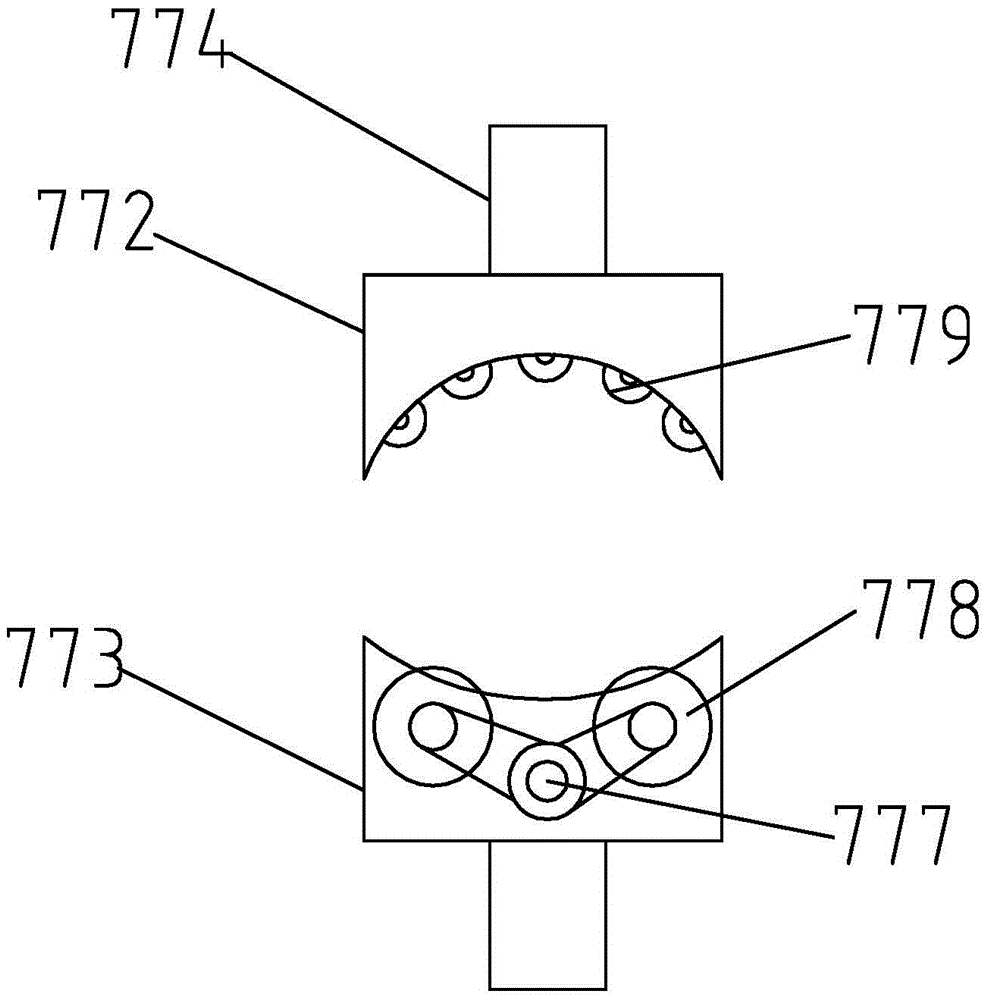

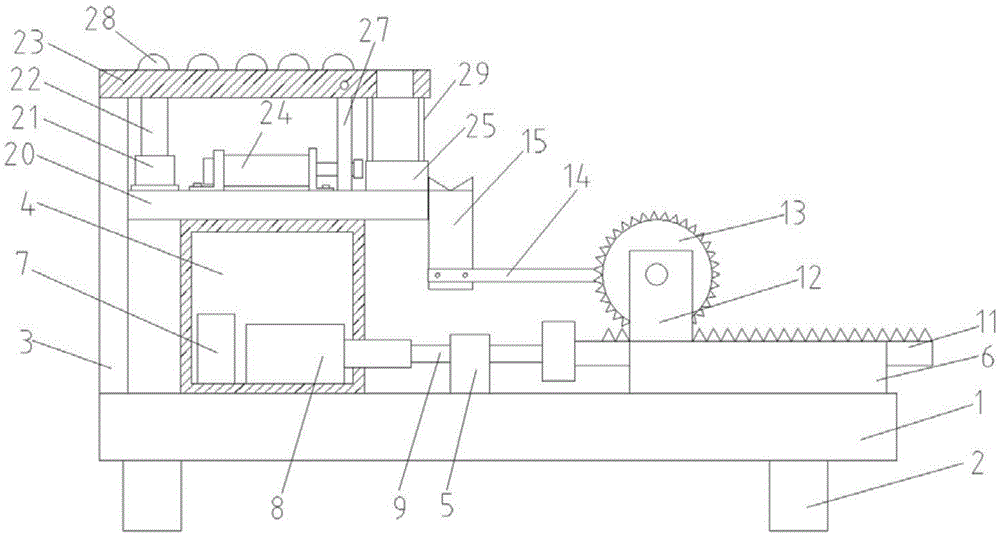

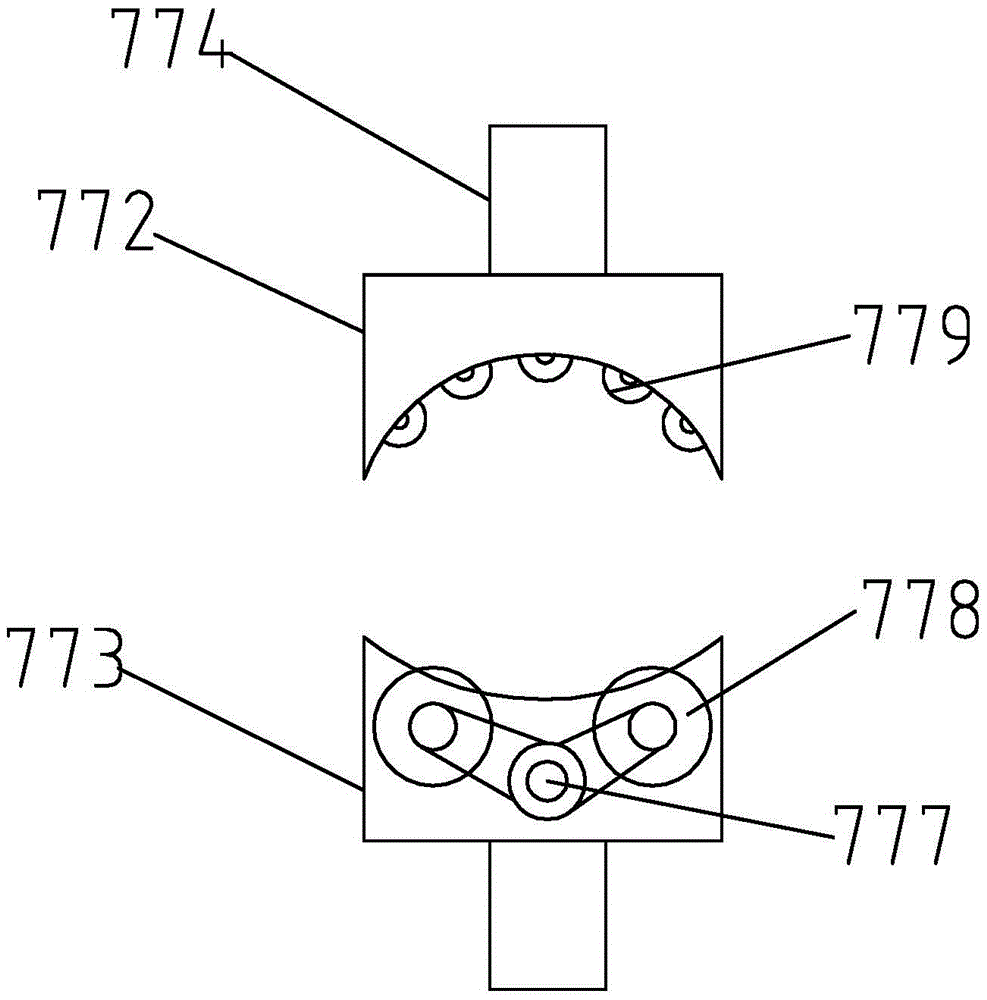

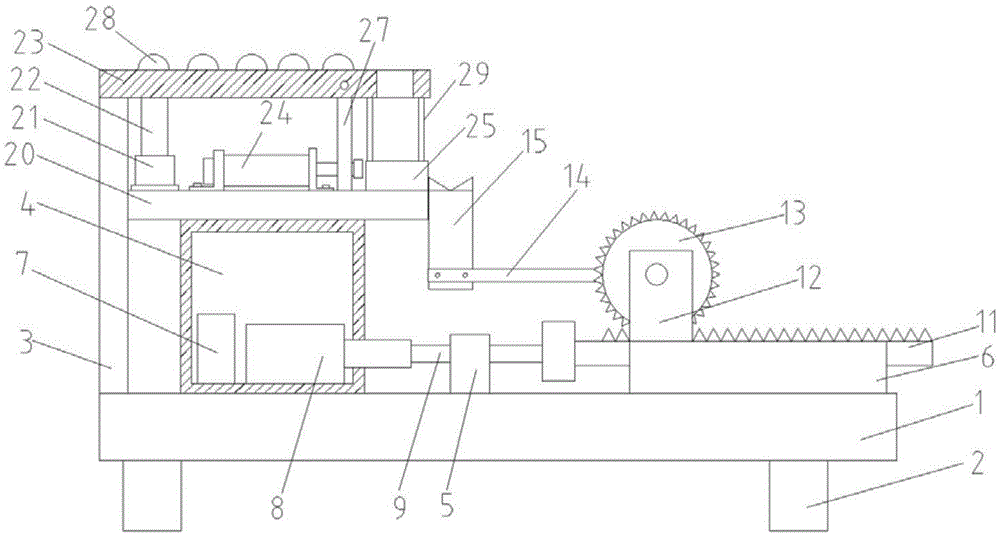

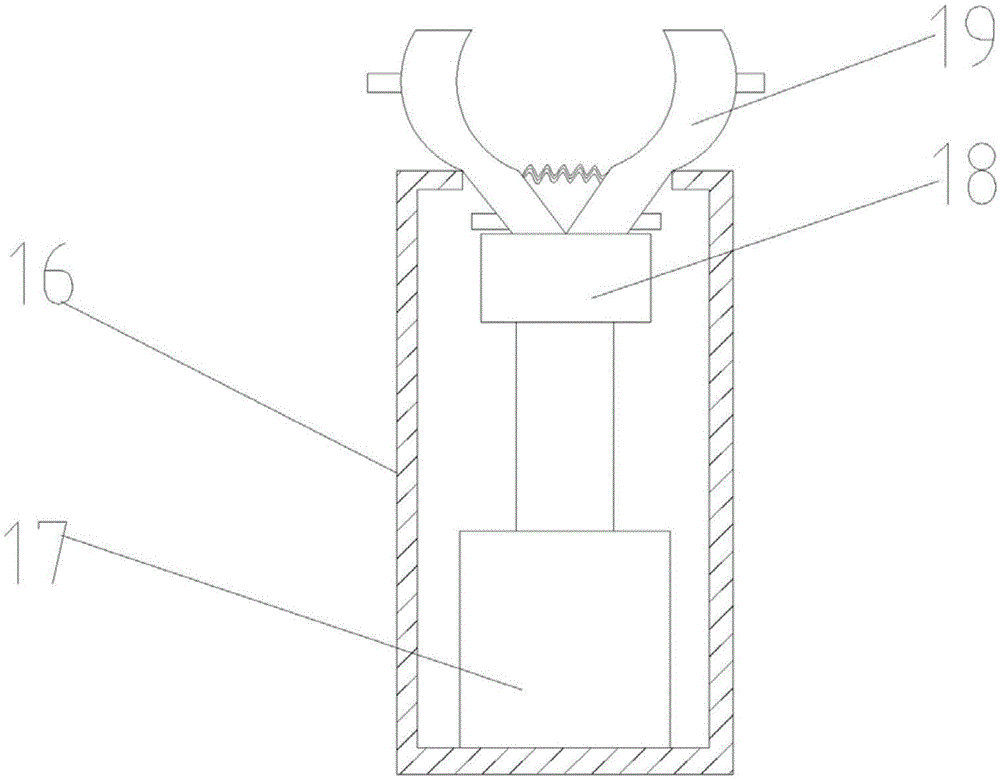

Automatic loading and grinding equipment for pipe fittings

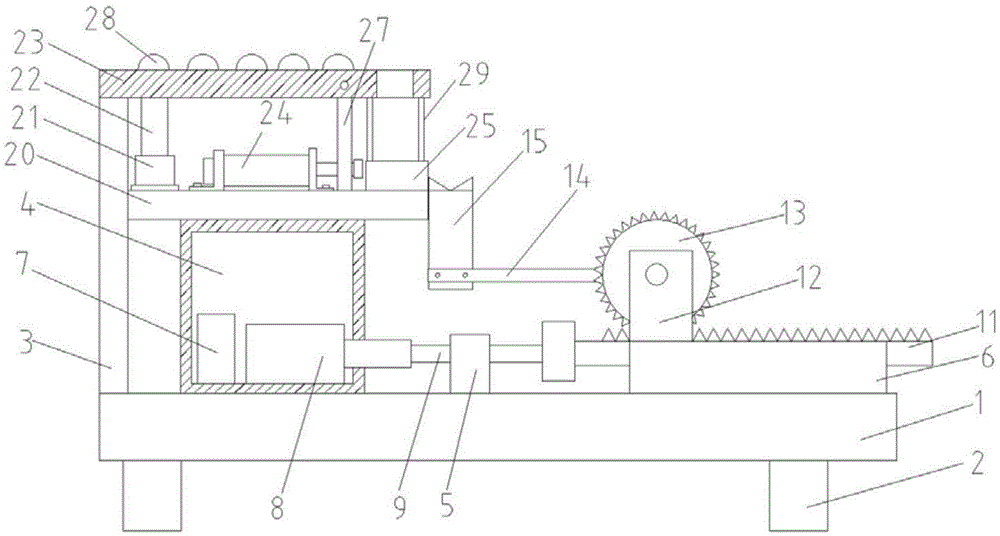

InactiveCN105538139ALabor savingImprove work efficiencyRevolution surface grinding machinesGrinding feed controlEngineeringPipe fitting

The invention discloses automatic loading and grinding equipment for pipe fittings, comprising a loading device, a support device, a grinding device and a measuring device, wherein the support device is located at the discharge end of the loading device, the grinding device is located above the support device, and the measuring device is located at the discharge end of the grinding device. According to the invention, automatic loading can be realized by the loading device, a support mechanism with an adjusting function is adopted, the structure is simple, the operation is convenient, an effect of being adjustable is achieved, and after grinding is completed, due to match of a first clamping device and a second clamping device, the measuring device can carry out multi-angle measurement on a steel pipe which can be rotated when being clamped, and vibration and shake of the steel pipe can be reduced; and since a bearing plate is arranged, the steel pipe can be placed more firmly, steel pipe measurement is more accurate, errors can be reduced, and the steel pipe measuring effect is better.

Owner:RONGCHANG YONGXIN STEEL STRUCTURE PROCESSING FACTORY

Plastic pipe surface treatment device

InactiveCN105397622AImprove securitySecurity threatRevolution surface grinding machinesGrinding feed controlMeasurement deviceSteel tube

The invention discloses a plastic pipe surface treatment device which comprises a feeding device, a clamping and locating device, a grinding device and a measuring device. The clamping and locating device is located at the discharging end of the feeding device. The grinding device is located above the clamping and locating device. The measuring device is located at the discharging end of the grinding device. The automatic feeding purpose is achieved through the feeding device; a material carrying mechanism with the adjusting function is adopted, the structure is simple, operation is convenient, and the adjusting effect is achieved; a lifting device is arranged so that a whole grinding head mechanism can move upwards, downwards, leftwards and rightwards, and the use limitation is avoided; after grinding is finished and through the cooperation of a first clamping device and a second clamping device, a steel pipe can be rotated when clamped and can be measured by the measuring device at multiple angles, and vibration and shakes of the steel pipe are reduced; and a carrying board is arranged, so that the steel pipe is placed more stably and measured more accurately, errors are reduced, and the measuring effect of the steel pipe is better.

Owner:CHONGQING XINYONG LIGHTINGS FACTORY

Surface treatment system for plastic tubes

InactiveCN105415173AImprove securitySecurity threatRevolution surface grinding machinesGrinding feed controlMeasurement deviceEngineering

The invention discloses a surface treatment system for plastic tubes. The surface treatment system for the plastic tubes comprises a loading device, a clamping and locating device, a grinding device and a measurement device, wherein the clamping and locating device is located at the discharge end of the loading device; the grinding device is located above the clamping and locating device; and the measurement device is located at the discharge end of the grinding device. According to the invention, automatic loading is realized through the loading device, and locating is carried out by virtue of the clamping and locating device; the surface treatment system for the plastic tubes is simple in structure and convenient to operate; by arranging a lifting device, a whole grinding head mechanism is capable of moving up and down, and a left-and-right moving element is arranged, so that use limits are avoided; after grinding, through matching between a first clamping device and a second clamping device, steel tubes are capable of rotating while being clamped, the measurement device is capable of carrying out multi-angle measurement, and vibration and shake of the steel tubes are reduced; and by arranging a bearing plate, the steel tubes are more stable in placement and more accurate in measurement, and generation of errors is reduced, so that the measurement effect of the steel tubes is better.

Owner:CHONGQING XINYONG LIGHTINGS FACTORY

Plastic pipe surface super-finishing and polishing device

InactiveCN105382683AImprove securitySecurity threatPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

The invention discloses a plastic pipe surface super-finishing and polishing device which comprises a feeding device, a clamping positioning device and a measuring device. The clamping positioning device is located at the discharging end of the feeding device. According to the plastic pipe surface super-finishing and polishing device, automatic feeding is achieved through the feeding device, and the clamping positioning device is used for positioning; by means of the cooperation of a first clamping device and a second clamping device, a steel pipe can rotate while being clamped so that the measuring device can measure the steel pipe in multiple dimensions after grinding is finished; in addition, vibration and shaking of the steel pipe are reduced; a bearing plate is arranged so that the steel pipe can be placed more stably, steel pipe measurement is more accurate, errors are reduced, and the steel pipe measurement effect is better.

Owner:CHONGQING XINYONG LIGHTINGS FACTORY

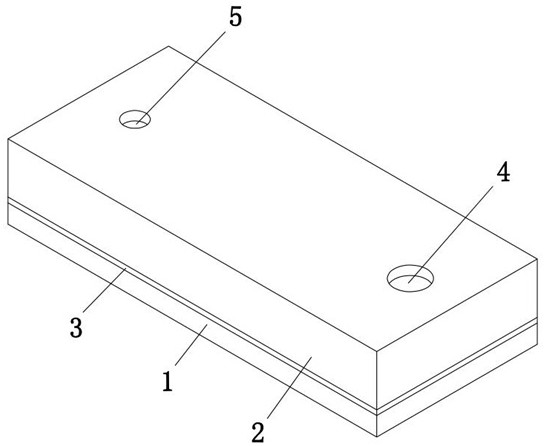

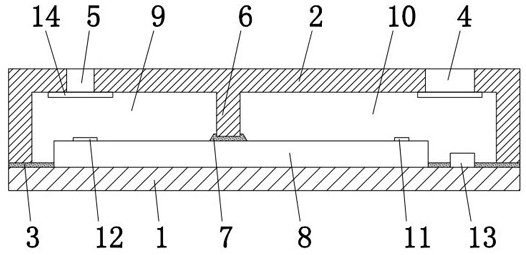

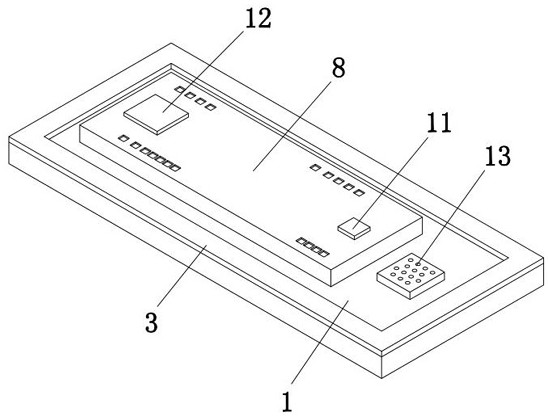

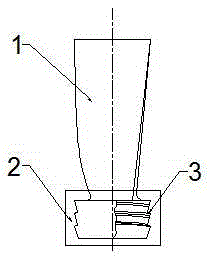

Packaging structure of time-of-flight distance sensor

InactiveCN112327273ASimple structureLow costWave based measurement systemsSemiconductor/solid-state device detailsStructural engineeringErbium lasers

The invention discloses a packaging structure of a time-of-flight distance sensor. The packaging structure comprises a substrate and a top cover, a chip is bonded on the outer wall of the top of the substrate, a reference detector and a measurement detector are respectively integrated on the two sides of the outer wall of the top of the chip, and a laser is bonded on the side, close to the reference detector, of the outer wall of the top of the substrate. First opaque glue is arranged at the position, close to the edge, of the outer wall of the top of the substrate, the top cover is adhered tothe outer wall of the top of the substrate through the first opaque glue, a baffle is integrally formed on the outer wall of the bottom of the top cover, second opaque glue is adhered to the outer wall of the bottom of the baffle, and the baffle is adhered to the upper face and the two sides of the chip through the second opaque glue. A light outlet and a light inlet are formed in the two sides of the outer wall of the top of the top cover respectively, and optical filters are bonded to the positions, close to the light outlet and the light inlet, of the inner wall of the bottom of the top cover. The packaging structure is simple, and the packaging operation can be completed only by using opaque glue with lower cost, so that the cost of the device is reduced.

Owner:VISIONICS MICROELECTRONICS TECH CO LTD

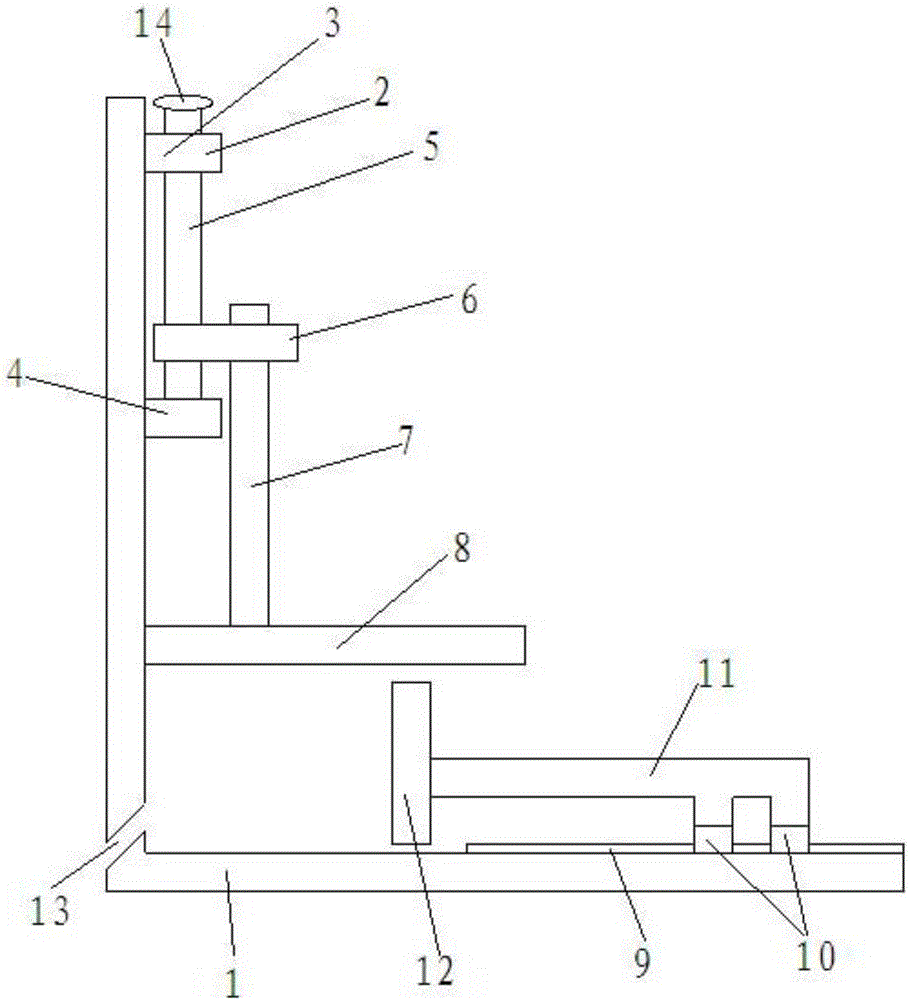

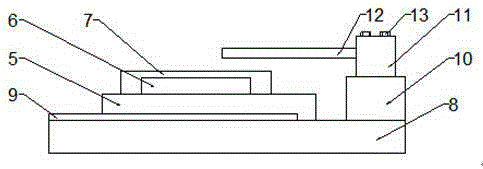

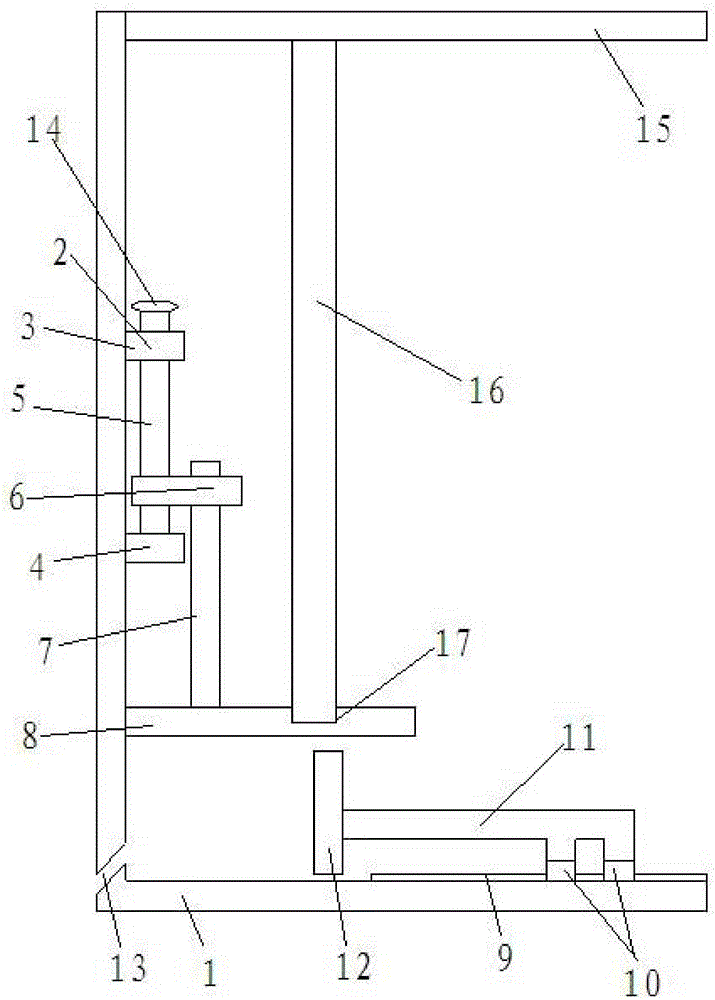

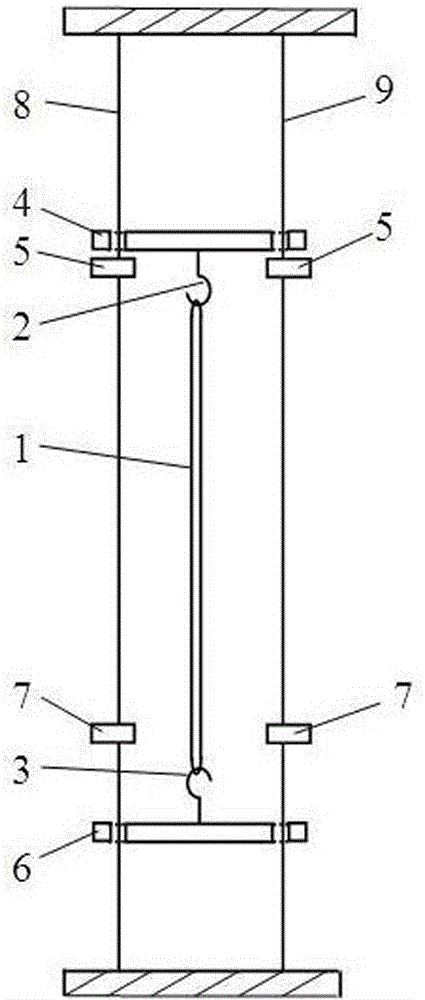

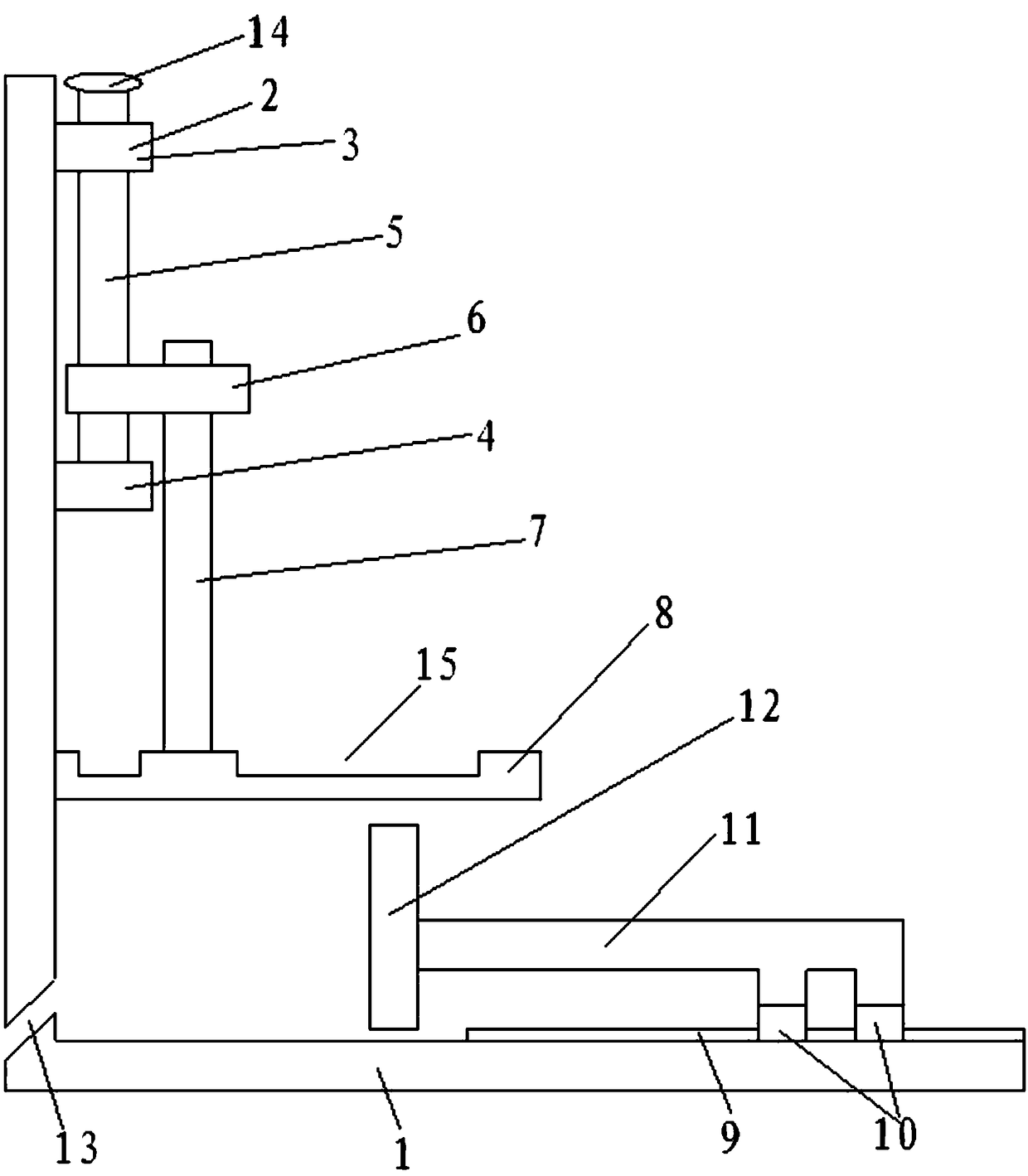

A device for detecting the stiffness of an automobile airbag

ActiveCN106018085BIncrease stiffnessPrecise adjustment of up and down displacementMaterial strength using tensile/compressive forcesEngineeringAirbag

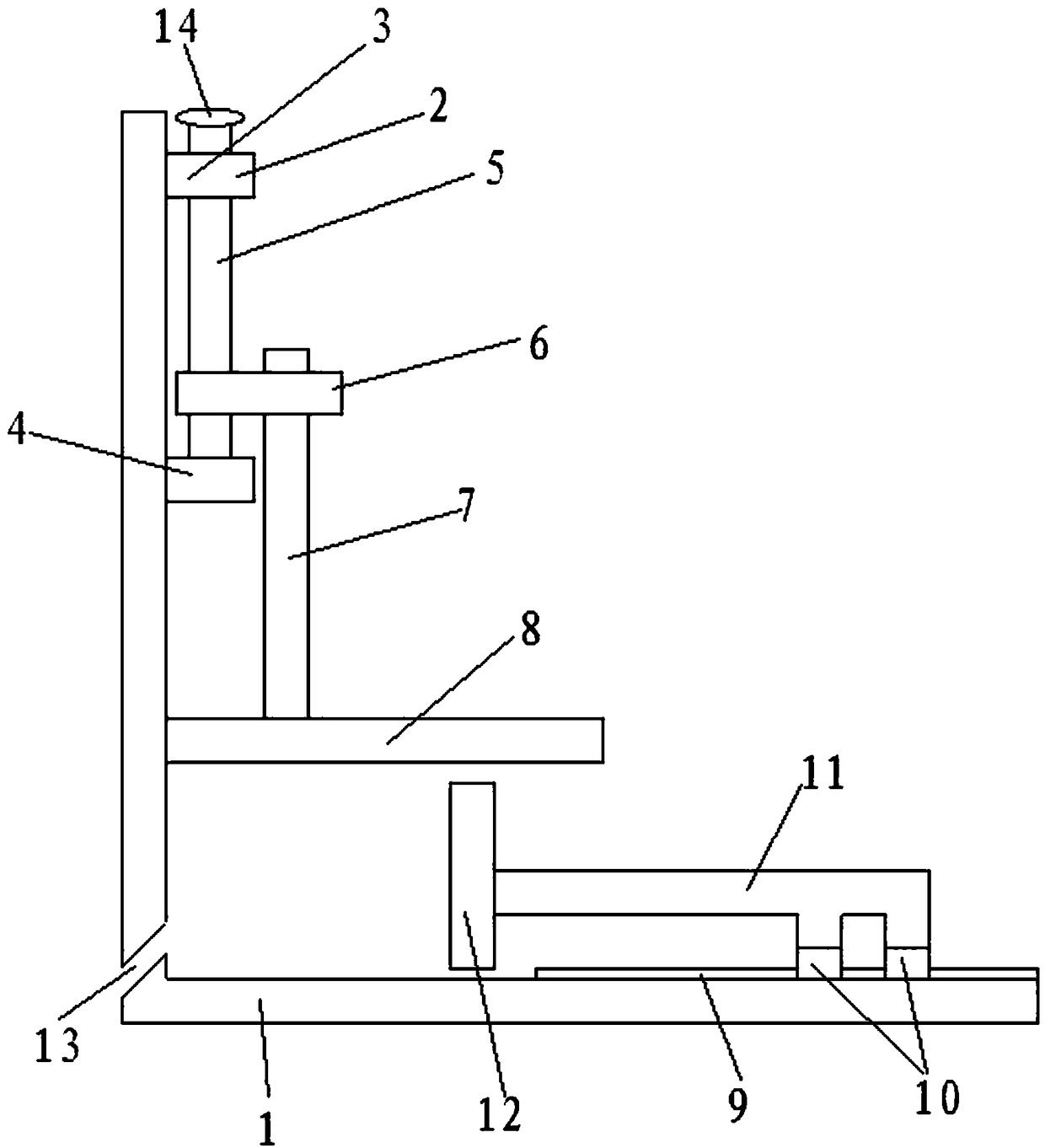

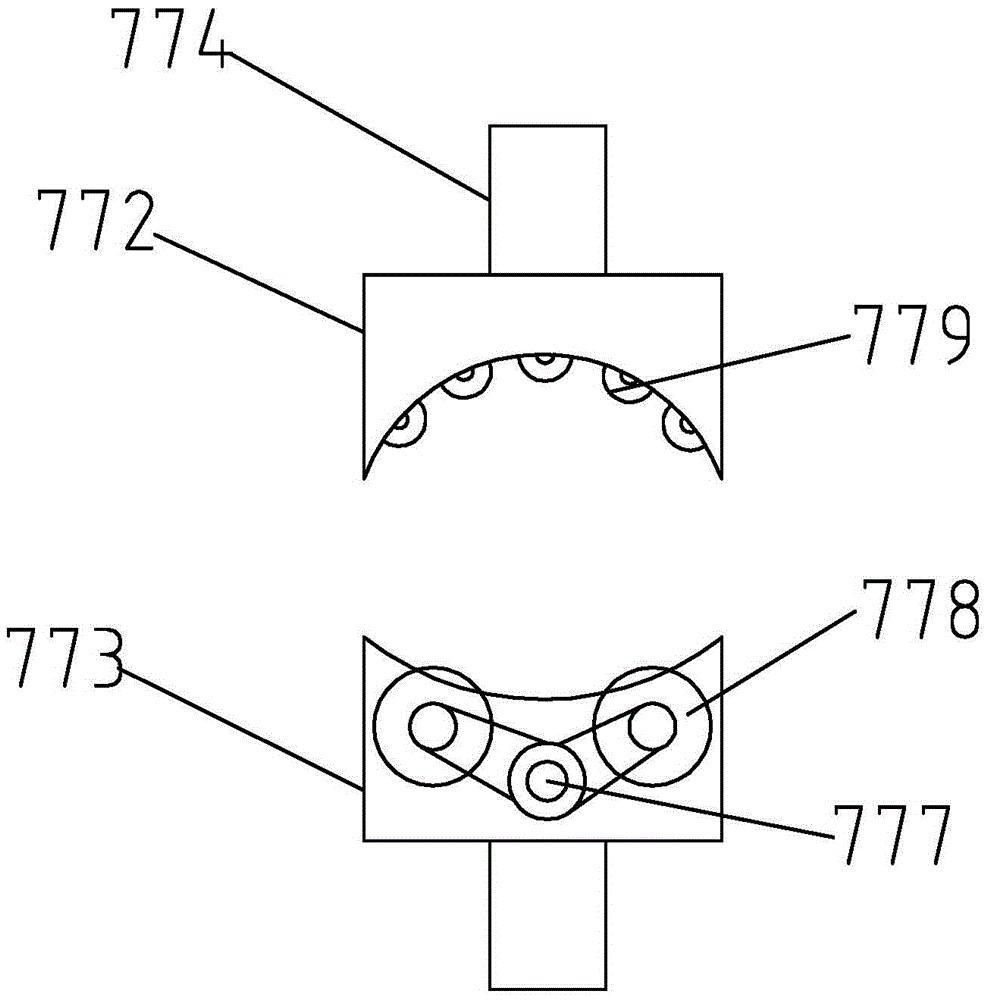

The invention discloses an automobile airbag rigidity detection device. The automobile airbag rigidity detection device comprises an L-shaped operating platform (1), wherein two fixed blocks (2) are arranged on a vertical surface of the operating platform (1) in the vertical direction, the fixed blocks (2) comprise an upper fixed block (3) and a lower fixed block (4), the upper fixed block (3) is provided with a smooth through hole for a screw (5) to pass through, the upper surface of the lower fixed block (4) is provided with a circular groove for holding the bottom end of the screw (5), the screw (5) is connected with a movable block (6) in a threading manner, the movable block (6) is connected with an upper extrusion plate (8) in the horizontal direction through a vertical rod (7), and a surface, contacting the upper extrusion plate (8), of the vertical surface is provided with a square groove for preventing the left-right displacement of the upper extrusion plate (8). The automobile airbag rigidity detection device is high in automation degree, real and reliable in detection result, high in universality and applicable to the detection of various airbags in a car.

Owner:南京一顺汽车零部件有限公司

Device for detecting rigidity of automobile safety airbag

InactiveCN105910903AIncrease stiffnessPrecise adjustment of up and down displacementMaterial strength using tensile/compressive forcesEngineeringAutomobile safety

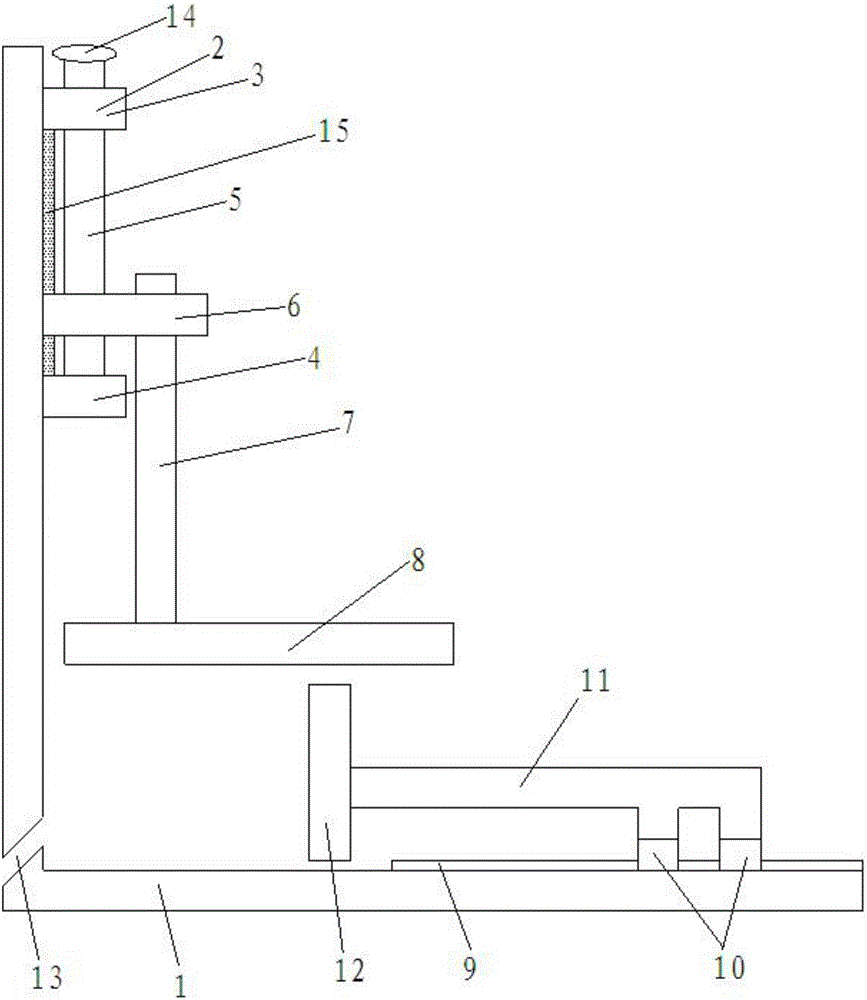

The invention discloses a device for detecting rigidity of an automobile safety airbag. The device comprises an L-shaped operation platform (1), wherein two fixing blocks (2) are upward and downward arranged on the vertical surface of the L-shaped operation platform (1); a vertical slide rail (15) is arranged between the two fixing blocks (2); each of the fixing blocks (2) comprises an upper fixing block (3) and a lower fixing block (4); a smooth through hole penetrating through a screw rod (5) is formed on the upper fixing block (3); a circuit groove used for loading the bottom end of the screw rod (5) is formed on the upper surface of the lower fixing block (4); a moveable block (6) is in threaded connection with the screw rod (5); the moveable block (6) can slide on the vertical slide rail (15); the moveable block (6) is connected with a horizontal upper extruding plate (8) through a vertical rod (7). The device for detecting the rigidity of the automobile safety airbag provided by the invention has the advantages of high degree of automation, true and reliable detection result, strong universality and applicability to the detection for various airbags in the automobile.

Owner:重庆市綦江区鼎盛机动车检测有限公司

Pipe grinding device

InactiveCN105643437AImprove securitySecurity threatRevolution surface grinding machinesGrinding feed controlMeasurement deviceEngineering

The invention discloses a pipe grinding device comprising a feeding device, a supporting device, a grinding device and a measuring device, wherein the supporting device is located at the discharging end of the feeding device; the grinding device is located above the supporting device; and the measuring device is located at the discharging end of the grinding device. Automatic feeding is realized through the feeding device; due to the adoption of a supporting mechanism with an adjusting function, the pipe grinding device is simple in structure and convenient to operate, and an adjustable effect is achieved; due to the arrangement of a lifting device, the whole grinding head mechanism not only can vertically move, but also can horizontally move, and service restrictions are avoided; the measuring device used after grinding is provided with a first clamping device, so that a steel pipe can rotate when being clamped, multi-angle measurement can be realized, and the vibration and shake of the steel pipe are reduced; and due to the arrangement of a bearing plate, the steel pipe is more stable and is more accurately measured, errors are reduced, and the steel pipe measuring effect is better.

Owner:RONGCHANG YONGXIN STEEL STRUCTURE PROCESSING FACTORY

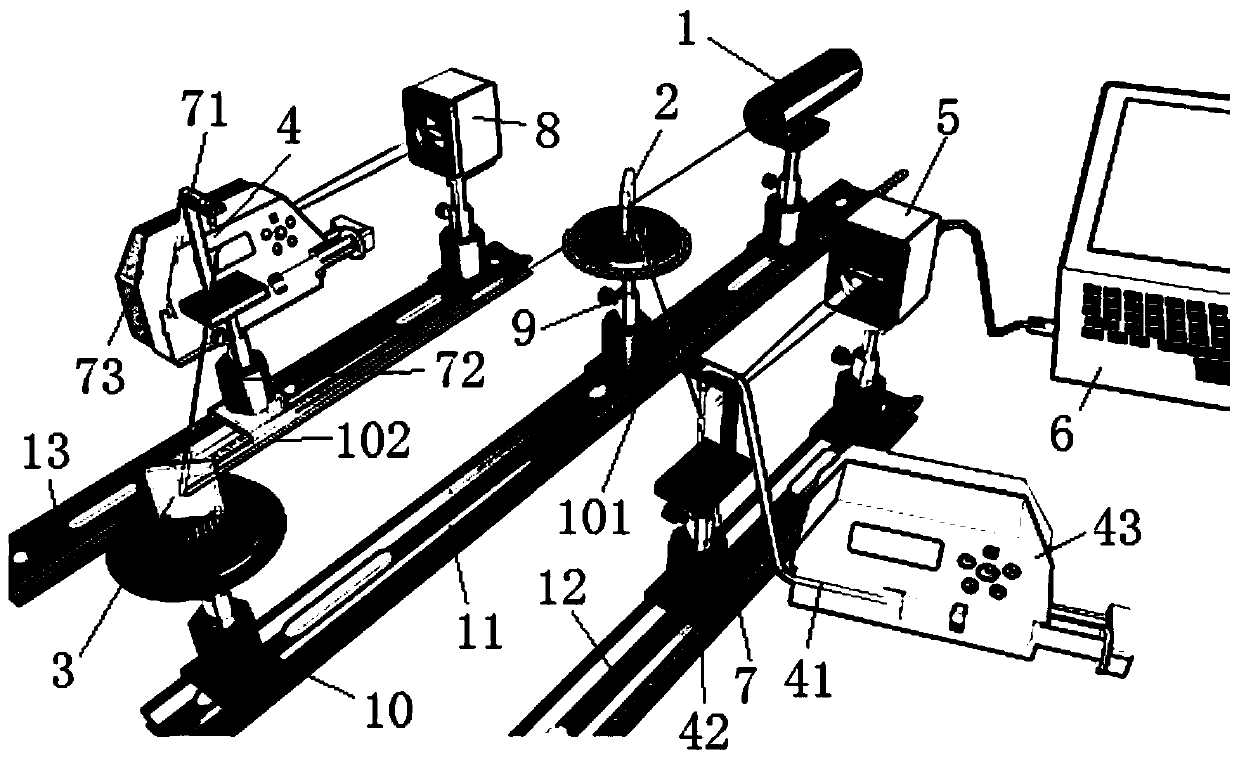

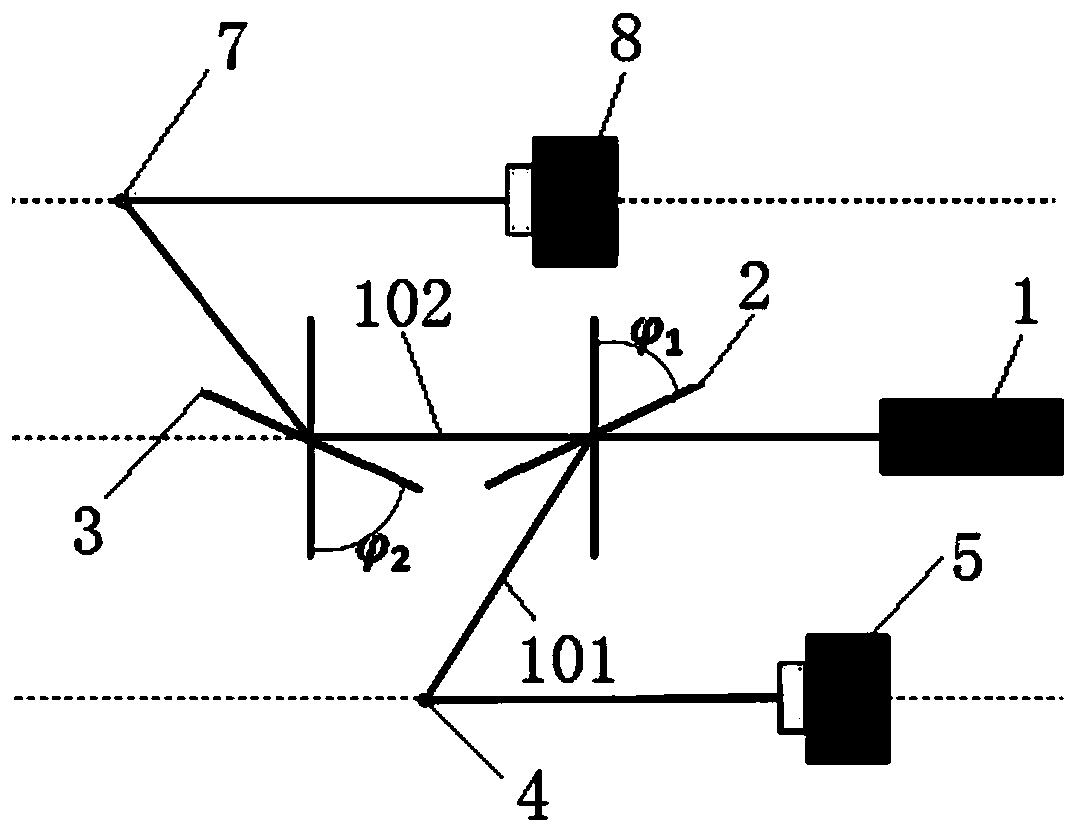

Liquid refractive index measurement device and measurement method

PendingCN110132895AThe result is accurateEasy to operatePhase-affecting property measurementsRainbowMeasurement device

The invention discloses a liquid refractive index measurement device and measurement method. The measurement device comprises a light source, used for emitting parallel light beams; a half-transparentsemi-reflective mirror is arranged on a light path, and used for dividing the parallel light beams emitted by the light source into a first light beam and a second light beam; the first light beam irradiates a liquid column to be measured, and is formed into rainbow distribution of the liquid to be measured via scattering; a first linear array CCD is used for recording the rainbow distribution ofstandard liquid; both the first linear array CCD and a second linear array CCD are connected with the computer; the second light beam irradiates a plane mirror, and irradiates a standard liquid column after being reflected by the plane mirror, and is formed into rainbow distribution of the standard liquid after being scattered; the second linear array CCD is used for recording to the rainbow distribution of the standard liquid. According to the measurement device and measurement method provided by the invention, after the parallel light beams irradiate the standard liquid column and the liquid column to be measured, a first-order rainbow is separately formed at the standard liquid column and the liquid column to be measured in parallel; the refractive index of the liquid to be measured isacquired through analyzing the first-order rainbows at the standard liquid column and the liquid column to be measured; the measurement method is simple and easy to operate.

Owner:SHAANXI UNIV OF SCI & TECH

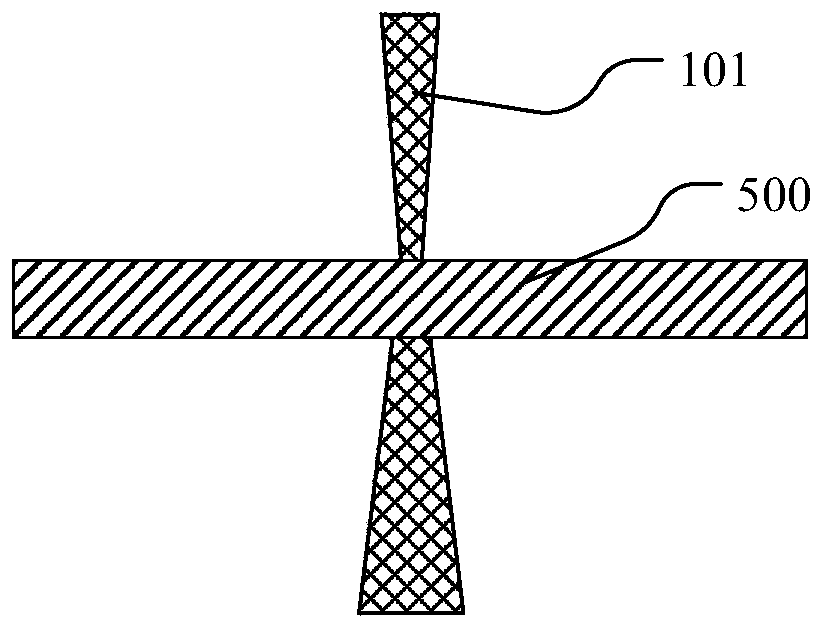

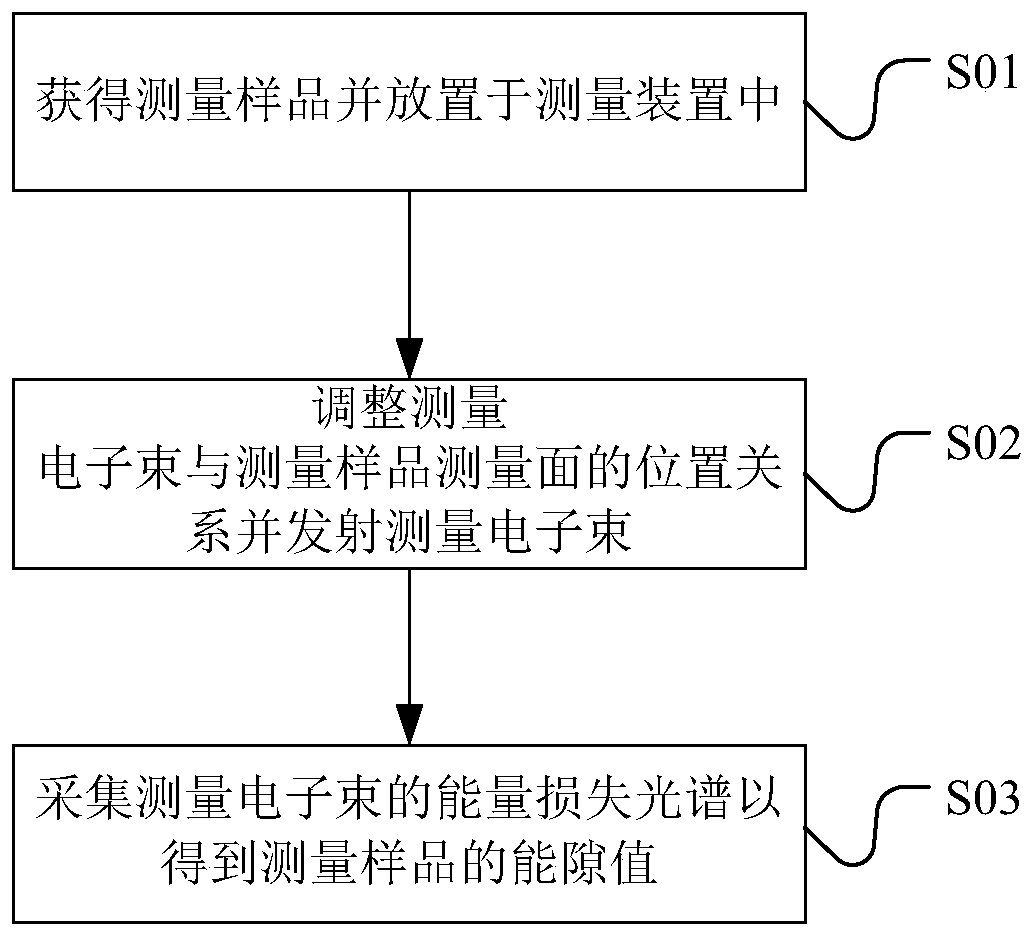

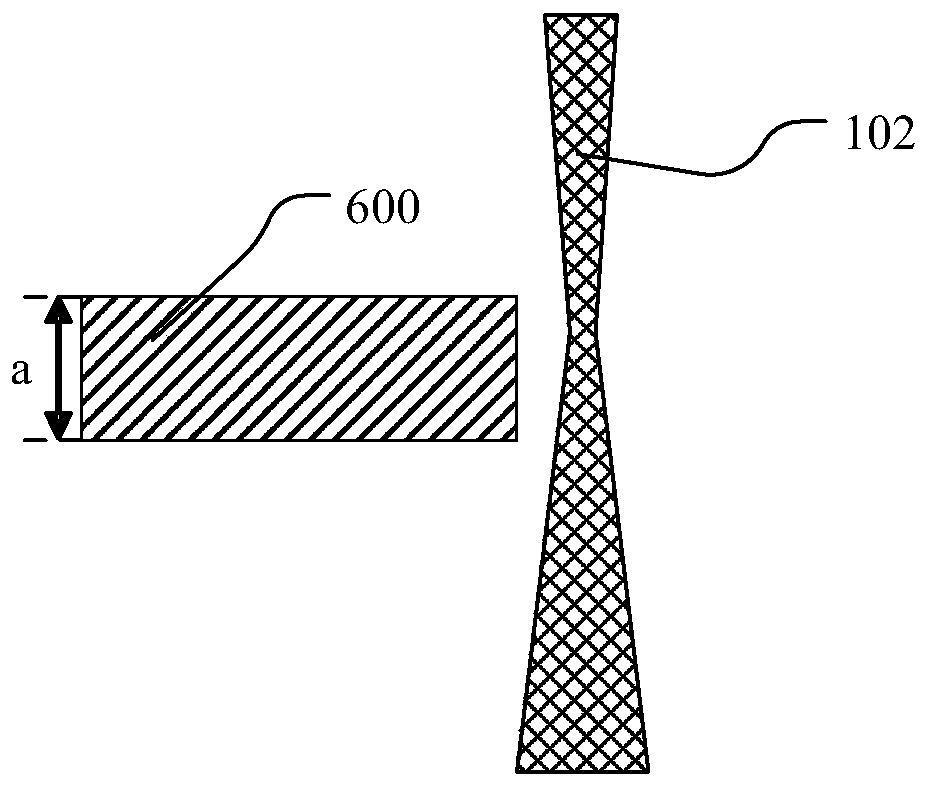

Semiconductor material energy gap measuring method and device

ActiveCN111198198AHigh precisionAvoid includingMaterial analysis by measuring secondary emissionSemiconductor materialsParticle physics

The invention provides a semiconductor material energy gap measuring method and device. The measuring method comprises the steps: a measuring sample is obtained and placed in a measuring device; the position relationship between the measurement electron beam and the measurement surface of the measurement sample is adjusted and the measurement electron beam is emitted; and an energy loss spectrum of the measurement electron beam is collected to obtain an energy gap value of the measurement sample, wherein the emitting direction of the measurement electron beam is parallel to the measurement surface of the measurement sample. The measurement electron beam and the measurement surface of the measurement sample are parallel to each other and are not in contact with each other, so that the acquired electron energy loss spectrum is prevented from containing exciton information, and the energy gap measurement accuracy is further improved.

Owner:YANGTZE MEMORY TECH CO LTD

Automobile airbag rigidity detection device

ActiveCN106018085AIncrease stiffnessPrecise adjustment of up and down displacementMaterial strength using tensile/compressive forcesEngineeringAirbag deployment

The invention discloses an automobile airbag rigidity detection device. The automobile airbag rigidity detection device comprises an L-shaped operating platform (1), wherein two fixed blocks (2) are arranged on a vertical surface of the operating platform (1) in the vertical direction, the fixed blocks (2) comprise an upper fixed block (3) and a lower fixed block (4), the upper fixed block (3) is provided with a smooth through hole for a screw (5) to pass through, the upper surface of the lower fixed block (4) is provided with a circular groove for holding the bottom end of the screw (5), the screw (5) is connected with a movable block (6) in a threading manner, the movable block (6) is connected with an upper extrusion plate (8) in the horizontal direction through a vertical rod (7), and a surface, contacting the upper extrusion plate (8), of the vertical surface is provided with a square groove for preventing the left-right displacement of the upper extrusion plate (8). The automobile airbag rigidity detection device is high in automation degree, real and reliable in detection result, high in universality and applicable to the detection of various airbags in a car.

Owner:南京一顺汽车零部件有限公司

Installation method for fiber grating drill hole stress meter in deep coal seam

The invention relates to an installation method for a fiber grating drill hole stress meter in a deep coal seam. The installation method comprises the steps that the drill hole stress meter and glue are put into a drill hole of the deep coal seam; the void space between the drill hole stress meter and the drill hole is filled with the glue; the glue is solidified, and the drill hole stress meter and the coal seam form a stress whole; and the drill hole stress meter truly measures the disturbance of stress from the outside of the coal seam. According to the installation method for the fiber grating drill hole stress meter in the deep coal seam, the hardness of the solidified glue is similar to that of the coal seam structure, thus, the drill hole stress meter and the coal seam which are connected with the glue can be closely attached to each other, the coal seam stress transfer continuity is ensured, the measurement structure is more real and accurate, and the installation method can be used in various application occasions where close contact between measuring sensors and measuring holes needs to be achieved.

Owner:BANDWEAVER TECH CO LTD

Multifunctional integration measuring tool of blade on the basis of two ejector pins

ActiveCN105352385AAvoid the problem of different positioning datumsThe test result is accurateMechanical measuring arrangementsEngineeringTailstock

The present invention relates to a multifunctional integration measuring tool of a blade on the basis of two ejector pins. The multifunctional integration measuring tool comprises a pedestal, a measuring tool base plate installed on the pedestal, and a stop block and a blade two-ejector pins measuring tool which are installed on the measuring tool base plate. The blade two-ejector pins measuring tool includes a measuring tool base plate, a tailstock fixedly installed at one end of the measuring tool base plate in a vertical manner, a headstock vertically and fixedly installed at the other end of the measuring tool base plate, and a blade root stand comparison block vertically and fixedly installed between the headstock and the tailstock on the measuring tool base plate and positioned close to the tailstock. The multifunctional integration measuring tool of a blade on the basis of two ejector pins is characterized in that: the measuring tool is able to accurately position and install a blade, the size of the blade is measured by a measuring scale which is rotatable around a hinge joint and one end of which is hinged to the pedestal, and other important parameters may be obtained through simple calculation according to the measured size; and different parameters are acquired through measurement on the same location measuring tool, and the problem of different location references which occur when a measuring tool is changed is avoided so that the detection result is more accurate and the detection efficiency is higher.

Owner:NANTONG ZHONGNENG MACHINERY

Plastic pipe surface treatment equipment

InactiveCN105397624AImprove securitySecurity threatPolishing machinesRevolution surface grinding machinesSteel tubeSurface finishing

The invention discloses plastic pipe surface treatment equipment which comprises a feeding device, a clamping and locating device, a grinding device and a measuring device. The clamping and locating device is located at the discharging end of the feeding device. The grinding device is located above the clamping and locating device. The measuring device is located at the discharging end of the grinding device. The automatic feeding purpose is achieved through the feeding device; a material carrying mechanism with the adjusting function is adopted, the structure is simple, operation is convenient, and the adjusting effect is achieved; a lifting device is arranged so that a whole grinding head mechanism can move upwards, downwards, leftwards and rightwards, and the use limitation is avoided; after grinding is finished and through the cooperation of a first clamping device and a second clamping device, a steel pipe can be rotated when clamped and can be measured by the measuring device at multiple angles, and vibration and shakes of the steel pipe are reduced; and a carrying board is arranged, so that the steel pipe is placed more stably and measured more accurately, errors are reduced, and the measuring effect of the steel pipe is better.

Owner:CHONGQING XINYONG LIGHTINGS FACTORY

Anti-shock automobile safety airbag stiffness test device

ActiveCN106052984AIncrease stiffnessPrevent rotationElasticity measurementEngineeringAutomobile safety

The invention discloses an anti-shock automobile safety airbag stiffness test device comprising an L-shaped operation platform (1). Two fixing blocks (2) are arranged up and down on the vertical side of the operation platform (1), and the fixing blocks (2) include an upper fixing block (3) and a lower fixing block (4). The upper fixing block (3) is provided with a smooth through hole for a screw (5) to pass through. The upper surface of the lower fixing block (4) is provided with a circular groove. The screw (5) is in threaded connection with a moving block (6), and the moving block (6) is connected with an upper extruding board (8) in the horizontal direction. The top end of the vertical side is connected with a top board (15). A telescopic rod (16) is vertically arranged on the lower surface of the top board (15). The upper surface of the upper extruding board (8) is provided with a groove (17). According to the anti-shock automobile safety airbag stiffness test device provided by the invention, the test result is real and reliable, and the upper extruding board has an anti-shock function.

Owner:WM MOTOR TECH GRP CO LTD

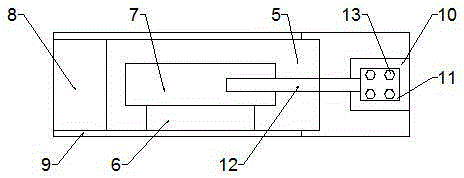

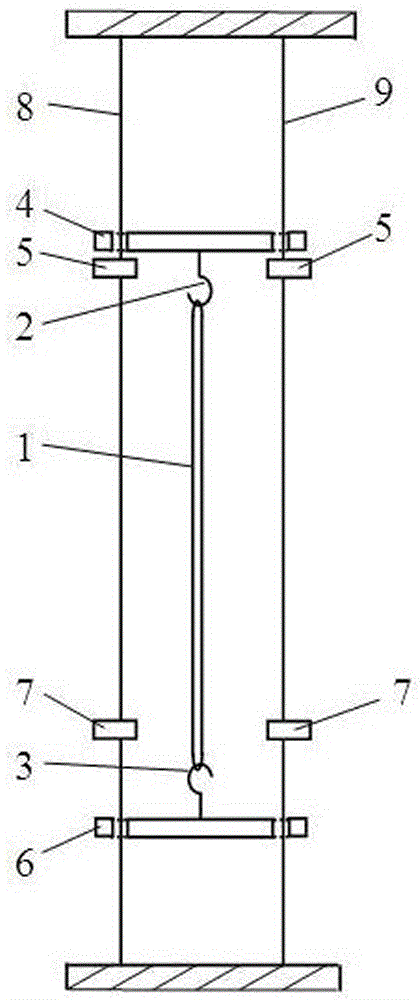

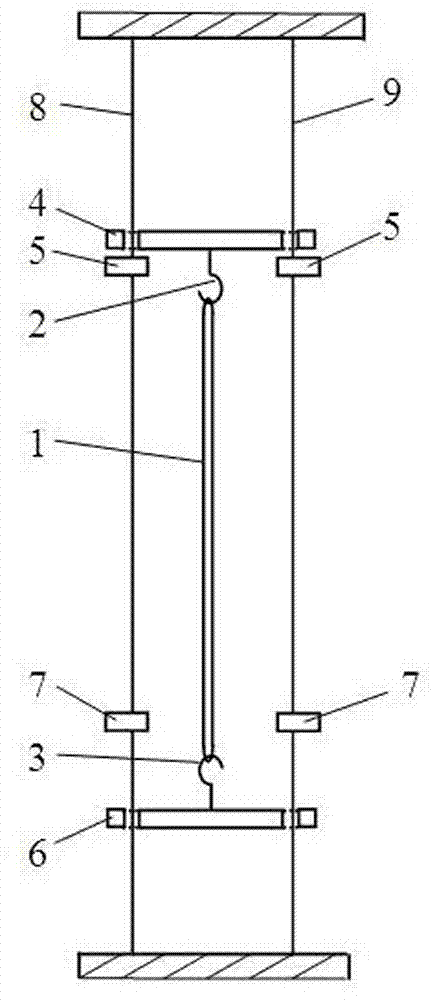

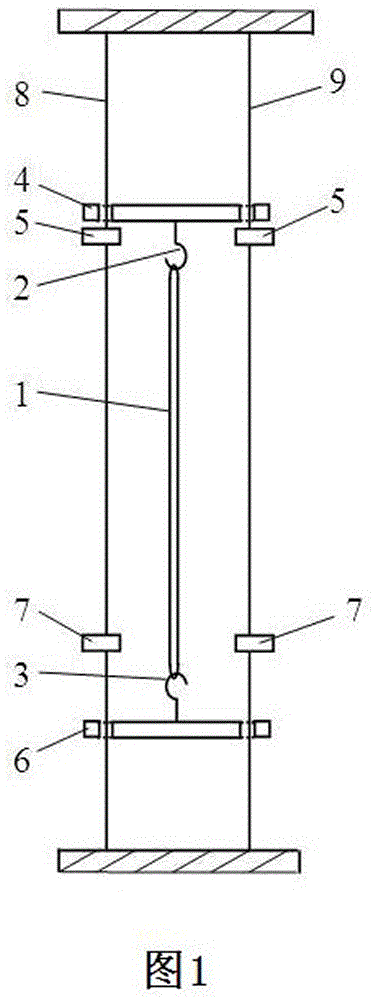

Testing device for testing hot shrinkage rate of chemical fiber filament and testing method thereof

InactiveCN106153669ASolve the problem of force value calibrationWell-structured testsMaterial thermal coefficient of expansionFiberShrinkage rate

The invention relates to a test device and a test method for the thermal shrinkage rate of chemical fiber filaments. The test device includes a double limiter structure and a load cell; the double limiter structure includes an upper hook, a lower hook, an upper hook plate, The upper limiter, the lower hook plate, the lower limiter, and the metal guide wire; the installation of the load cell and the toggle mechanism connected to it can support the upper hook plate to move upward, and the lower hook plate moves upward to the lower limiter. Blocking and stopping movement, the upper hook plate continues to rise to apply tension to the skein sample, the load cell bears the load in the downward direction, and the instrument automatically measures the skein sample under the preset standard tension before and after heating Length value, thereby measuring the thermal shrinkage rate of the chemical fiber filament sample. The test device and test method obviously improve the test accuracy of the thermal shrinkage rate of the chemical fiber filament sample, the calibration and calibration of the force measuring system is convenient, the structure is reliable, and the failure rate is greatly reduced.

Owner:肥西县碧涛建材有限公司

Freely-adjustable novel pipe grinding system

InactiveCN105643436ALabor savingImprove work efficiencyRevolution surface grinding machinesGrinding feed controlSteel tubeMeasurement device

The invention discloses a freely-adjustable novel pipe grinding system comprising a feeding device, a supporting device, a grinding device and a measuring device, wherein the supporting device is located at the discharging end of the feeding device; the grinding device is located above the supporting device; and the measuring device is located at the discharging end of the grinding device. Automatic feeding is realized through the feeding device; due to the adoption of a supporting mechanism with an adjusting function, the freely-adjustable novel pipe grinding system is simple in structure and convenient to operate, and an adjustable effect is achieved; through the match of a first clamping device and a second clamping device of the measuring device used after grinding, a steel pipe can rotate when being clamped, multi-angle measurement can be realized, and the vibration and shake of the steel pipe are reduced; and due to the arrangement of a bearing plate, the steel pipe is more stable and is more accurately measured, errors are reduced, and the steel pipe measuring effect is better.

Owner:RONGCHANG YONGXIN STEEL STRUCTURE PROCESSING FACTORY

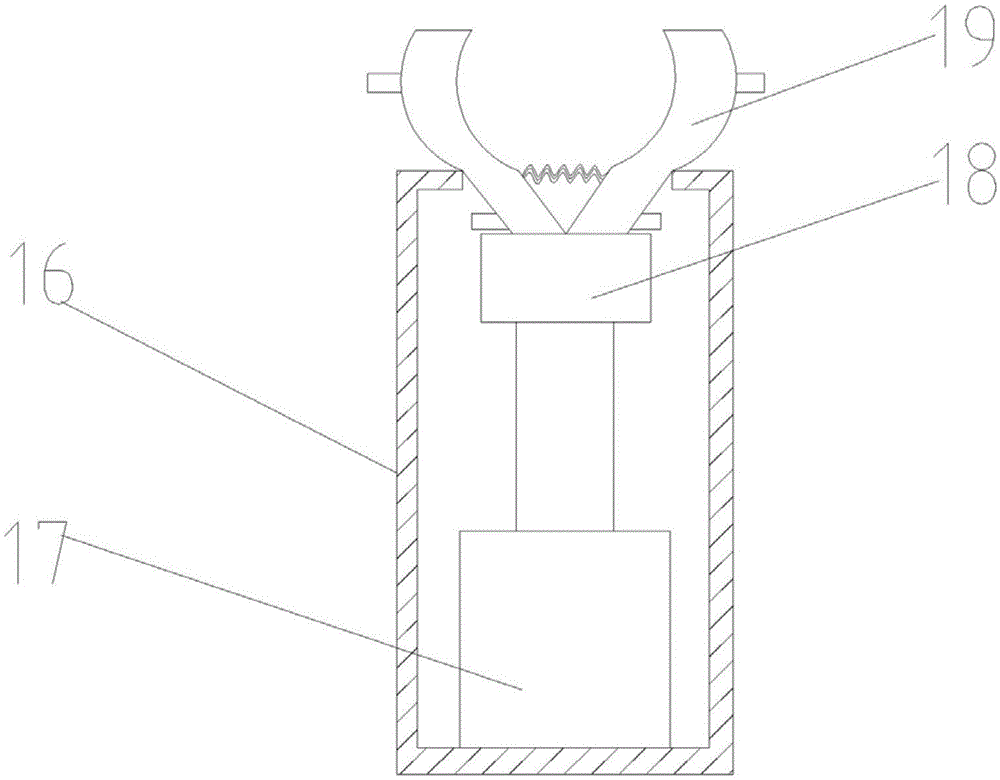

Testing device and method of thermal shrinkage rate of chemical fiber filaments

InactiveCN104990950ASolve the problem of force value calibrationWell-structured testsMaterial thermal coefficient of expansionFiberContraction rate

The invention relates to a testing device and method of a thermal shrinkage rate of chemical fiber filaments. The testing device comprises a double-limiter structure and a force cell. The double-limiter structure comprises an upper hook, a lower hook, an upper hook disk, an upper limiter, a lower hook disk, a lower limiter and a metal guide wire. The installed force cell and a stirring mechanism connected with the force cell can support the upper hook disk to move upwards, when moving to the lower limiter, the lower hook disk is stopped by the lower limiter and stops moving, the upper hook disk continues to rise to exert tension on a twisted wire sample, the force cell bears a downward load, an instrument automatically measures the lengths of the twisted wire sample under preset standard tension before heating and after heating, and therefore the thermal shrinkage rate of samples of the chemical fiber filaments is measured. By the adoption of the testing device and method, the testing precision of the thermal shrinkage rate of the samples of the chemical fiber filaments is remarkably improved, the calibration of a force testing system is convenient, the structure is reliable, and the fault rate is greatly lowered.

Owner:ANHUI JOYFULL INFORMATION SCI & TECH

Test device and test method for thermal shrinkage ratio of chemical fiber filaments

InactiveCN104849304AWell-structured testsAccurate measurement structureMaterial thermal coefficient of expansionLimiterEngineering

The invention relates to a test device and test method for the thermal shrinkage ratio of chemical fiber filaments. The test device comprises a double-limiter structure and a force measuring sensor; the double-limiter structure comprises an upper hanging hook, a lower hanging hook, an upper hanging hook disc, an upper limiter, a lower hanging hook disc, a lower limiter and metal lead wires; through mounting the force measuring sensor and a toggle mechanism connected with the force measuring sensor, the upper hanging hook disc can be supported to move upwards, the lower hanging hook disc upwards moves to the lower limiter and then is blocked to stop moving, the upper hanging hook disc continues to rise and applies a tensile force to a reeled silk sample, the force measuring sensor bears a downwards-directional load, and length values of the reeled silk sample before heating and after heating under preset standard tension are automatically measured by instruments, so that the thermal shrinkage ratio of a chemical fiber filament sample is measured. By adopting the test device and the test method, the accuracy of measuring of the thermal shrinkage ratio of the chemical fiber filament sample is obviously increased, a force measuring system is convenient to standardize and calibrate and is reliable in structure, and the failure rate is greatly lowered.

Owner:ANHUI LUXUN ELECTRONICS TECH

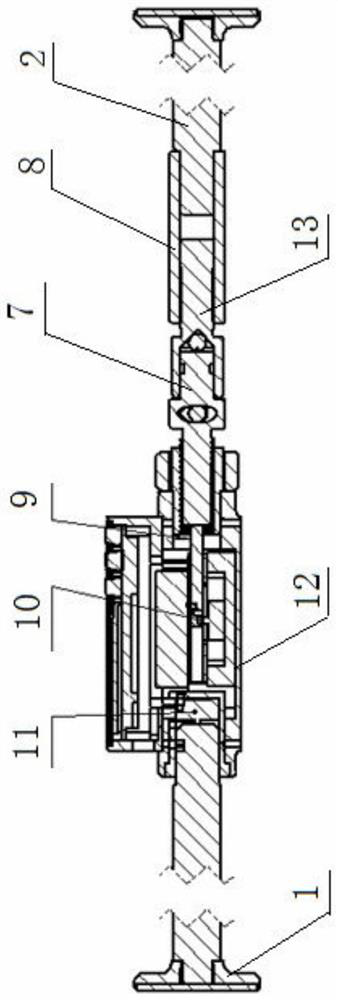

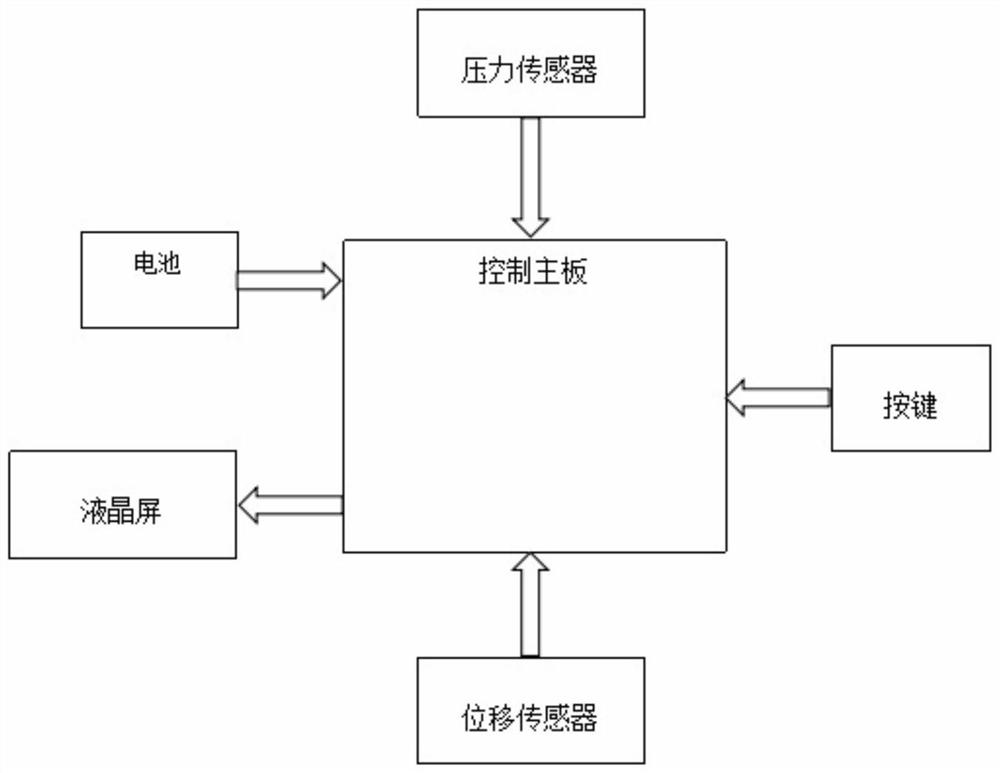

Escalator skirt panel strength detection device

PendingCN112444444ASuitable measurementAccurate measurementMaterial strength using tensile/compressive forcesElasticity measurementDisplay deviceStructural engineering

The invention discloses an escalator skirt panel strength detection device, which comprises a main body and an operation display system, wherein the main body comprises a left pressure foot and a right pressure foot, the left pressure foot is fixedly installed in a shell through a pressure shaft, and a pressure sensor is arranged at the rear end of the left pressure shaft; the right pressure footis installed at the outer end of a right pressure shaft, the right pressure shaft is connected with an adjusting shaft, the adjusting shaft is internally in threaded connection with the outer end of aconnecting rod, the inner end of the connecting rod is fixedly connected with the outer end of a measuring shaft which is connected with a transmission rod located in the shell, and a displacement sensor is mounted on the transmission rod; and the displacement sensor and the pressure sensor are connected with the operation display system. According to the escalator skirt panel rigidity detectiondevice, the strength of the skirt panel can be properly and accurately measured, it is ensured that the skirt panel can bear specified pressure, it is ensured that the skirt panel meets the national standard requirement, and safety accidents are avoided; and the measuring device and the display device are integrally designed, a single-machine mode and an on-line mode can be adopted, the portability is good, the use is convenient, and the measuring structure is accurate.

Owner:大连达发科技有限公司

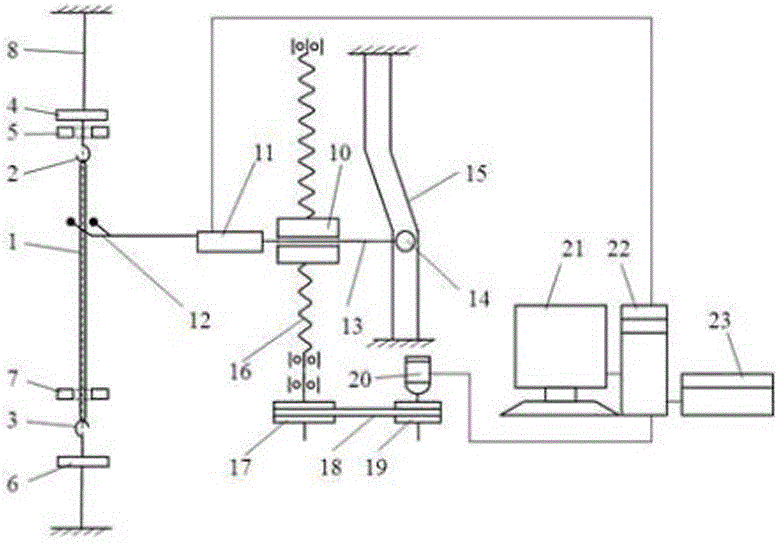

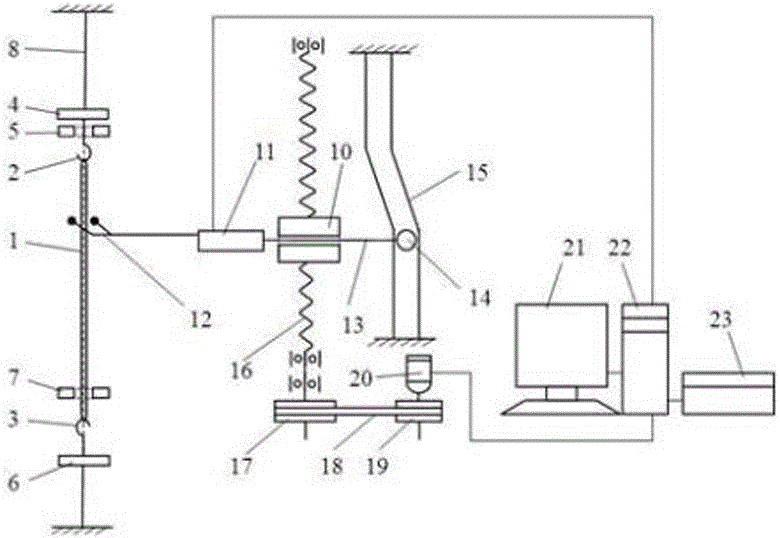

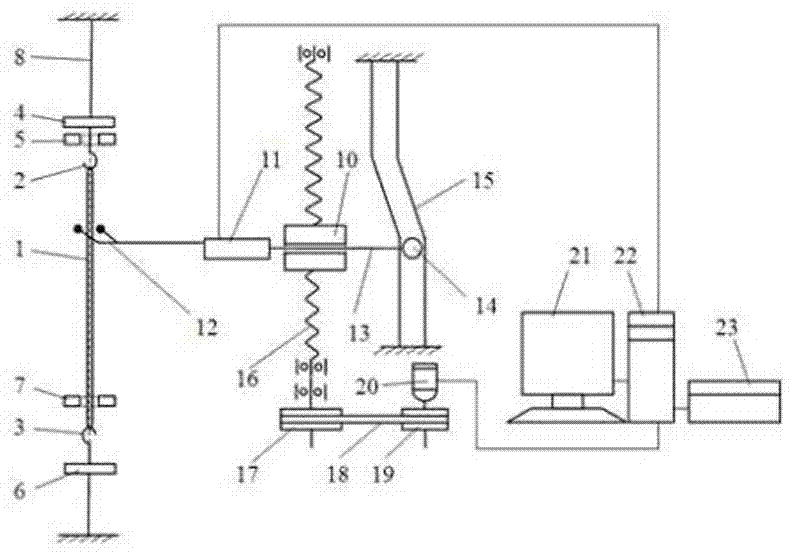

A large-scale in-situ triaxial creep test system for rock and soil

InactiveCN106546492BSufficient room for deformationStable confining pressurePreparing sample for investigationMaterial strength using tensile/compressive forcesSoil massAxial pressure

The invention relates to a rock-soil mass large size in-situ triaxial creep test system. The system includes an axial pressure loading subsystem, confining pressure loading subsystems and a background control computer. The axial pressure loading subsystem is disposed at the top of a to-be-tested cylindrical rock-soil mass test block and has a first displacement meter, and the axial pressure loading subsystem and the first displacement meter are connected to the background control computer respectively through a line; the side wall of the to-be-tested cylindrical rock-soil mass test block is wrapped with a rubber layer, the confining pressure loading subsystems disposed on the outer surface of the rubber layer and have a plurality of second displacement meters internally, and the confining pressure loading subsystems and the plurality of second displacement meters are connected to the background control computer respectively through a line; and the confining pressure loading subsystems are externally sleeved with a counter-force fixation frame module. The system provided by the invention has the advantages of simple structure and convenient use, in the test process, the rock-soil mass test block has sufficient deformation space and stable confining pressure, at the same time rock-soil mass creep deformation wholeness can be monitored in real time, and the measurement structure is accurate.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

A three-dimensional wind field measurement system suitable for unmanned aerial vehicles and its application method

ActiveCN106679928BThe measurement structure is completeAccurate measurement structureAerodynamic testingFluid speed measurementControl systemThree-dimensional space

The present invention discloses a three-dimensional wind field measurement system applicable to an unmanned aerial vehicle and a use method of the three-dimensional wind field measurement system. The three-dimensional wind field measurement system comprises a data acquisition device and a control system; the data acquisition device comprises a plurality of wind speed measuring devices and a wind speed acquisition support; each wind speed measuring device includes wind speed sensors and a wind speed sensor fixing mechanism; the wind speed acquisition support includes a base main body, upright columns and a top cover; the base main body includes an upper-layer base and a lower-layer base; the top surface of the upper-layer base is provided with the plurality of upright columns which are distributed circumferentially; the upright columns are provided with the wind speed measuring devices; the lower-layer base is provided with a rotation driving device for driving the upper-layer base to rotate; and the top surface of the upper-layer base and the bottom surface of the top cover are both provided with the wind speed measuring devices. With the three-dimensional wind field measurement system of the invention adopted, the measurement of a three-dimensional space wind field at a specific area around the unmanned aerial vehicle can be realized. The three-dimensional wind field measurement system has the advantages of simple structure, convenient operation, easiness in arrangement and high applicability.

Owner:SOUTH CHINA AGRI UNIV

Automatic pipe fitting feeding and grinding system

InactiveCN105643435AImprove securitySecurity threatRevolution surface grinding machinesGrinding feed controlPipe fittingEngineering

The invention discloses an automatic pipe fitting feeding and grinding system comprising a feeding device, a supporting device, a grinding device and a measuring device, wherein the supporting device is located at the discharging end of the feeding device; the grinding device is located above the supporting device; and the measuring device is located at the discharging end of the grinding device. Automatic feeding is realized through the feeding device; due to the adoption of a supporting mechanism with an adjusting function, the automatic pipe fitting feeding and grinding system is simple in structure and convenient to operate, and an adjustable effect is achieved; due to the arrangement of a lifting device, the whole grinding head mechanism not only can vertically move, but also can horizontally move, and service restrictions are avoided; through the match of a first clamping device and a second clamping device of the measuring device used after grinding, a steel pipe can rotate when being clamped, multi-angle measurement can be realized, and the vibration and shake of the steel pipe are reduced; and due to the arrangement of a bearing plate, the steel pipe is more stable and is more accurately measured, errors are reduced, and the steel pipe measuring effect is better.

Owner:RONGCHANG YONGXIN STEEL STRUCTURE PROCESSING FACTORY

A solid-liquid interface measuring device for silicon ingot furnace

InactiveCN103668449BSimple structureReduce manufacturing costPolycrystalline material growthMeasurement devicesElectricityProgrammable logic controller

The invention discloses a solid-liquid interface determination device for a silicon ingot furnace. The solid-liquid interface determination device comprises a quartz rod, a cylinder, a driving device, a pressure sensor and a PLC (programmable logic controller), wherein the quartz rod is used for being in contact with solid polysilicon in a silicon ingot furnace; a first piston rod of the cylinder is in a extending state and is connected with the quartz rod; the driving device is used for driving the quartz rod to make a rectilinear motion in the vertical direction; the pressure sensor is mounted between the first piston rod of the cylinder and the quartz rod and is used for sensing an acting force generated by the contact between the quartz rod and the solid polysilicon; and the PLC is electrically connected with the driving device and the pressure sensor respectively, and is used for receiving signals collected by the pressure sensor and controlling the driving device to drive the quartz rod to ascend or descend according to the received signals. The solid-liquid interface determination device for a silicon ingot furnace is simple in structure, low in manufacturing cost, convenient to use and accurate in measuring structure, and can automatically obtain depth of molten silicon in the silicon ingot furnace without requiring measuring personnel to manually insert the quartz rod into the silicon ingot furnace and read frequently, thereby relieving the measuring personnel.

Owner:镇江荣德新能源科技有限公司

Test apparatus and test method of hot shrinkage rate of chemical fiber filament

InactiveCN106198610ASolve the problem of force value calibrationWell-structured testsMaterial thermal coefficient of expansionFailure rateFiber

The invention relates to a test apparatus and test method of the hot shrinkage rate of a chemical fiber filament. The test apparatus comprises a double-limiter structure and a force measuring sensor; the double-limiter structure comprises an upper hook, a lower hook, an upper hook disc, an upper limiter, a lower hook disc, a lower limiter and a metal guiding wire; and a poking mechanism provided with the force measuring sensor and connected with the force measuring sensor can support the upper hook disc to make the upper hook disc move upward, the lower hook disc moves upward to the lower limiter, and is blocked and stopped by the lower limiter, the upper hook disc continuously rises to apply tension to a twisted wire sample, the force measuring sensor bears downward load, and the apparatus automatically measures the length of the twisted wire sample under preset standard tension before and after heating in order to obtain the hot shrinkage rate of the chemical fiber filament sample. The test apparatus and the test method have the following advantages of: the test precision of the hot shrinkage rate of the chemical fiber filament is obviously improved, calibration and correction of a force measuring system are convenient, the structure is reliable, and the failure rate is greatly reduced.

Owner:合肥仁德电子科技有限公司

Anti-impact car airbag stiffness testing device

The invention discloses an impact-proof automobile air bag rigidity detection device. The impact-proof automobile air bag rigidity detection device comprises an L-shaped operation bench (1). Two fixed blocks are arranged on a vertical surface of the operation bench (1) in an up-down manner. The fixed blocks include an upper fixed block (3) and a lower fixed block (4). A smooth through hole penetrating a screw (5) is formed in the upper fixed block (3). A circular groove for accommodating the bottom end of the screw (5) is formed in the upper surface of the lower fixed block (4). The screw (5) is in threaded connection with a movable block (6). The movable block (6) is connected with a horizontal upper extruding plate (8) through an upright column (7). A plurality of grooves (15) for accommodating heavy objects are formed in the upper surface of the upper extruding plate (8). The impact-proof automobile air bag rigidity detection device provided by the invention is high in automatic degree and is real and reliable in detection result, the upper extruding plat has an impact-proof function, and the universality is high.

Owner:WM MOTOR TECH GRP CO LTD

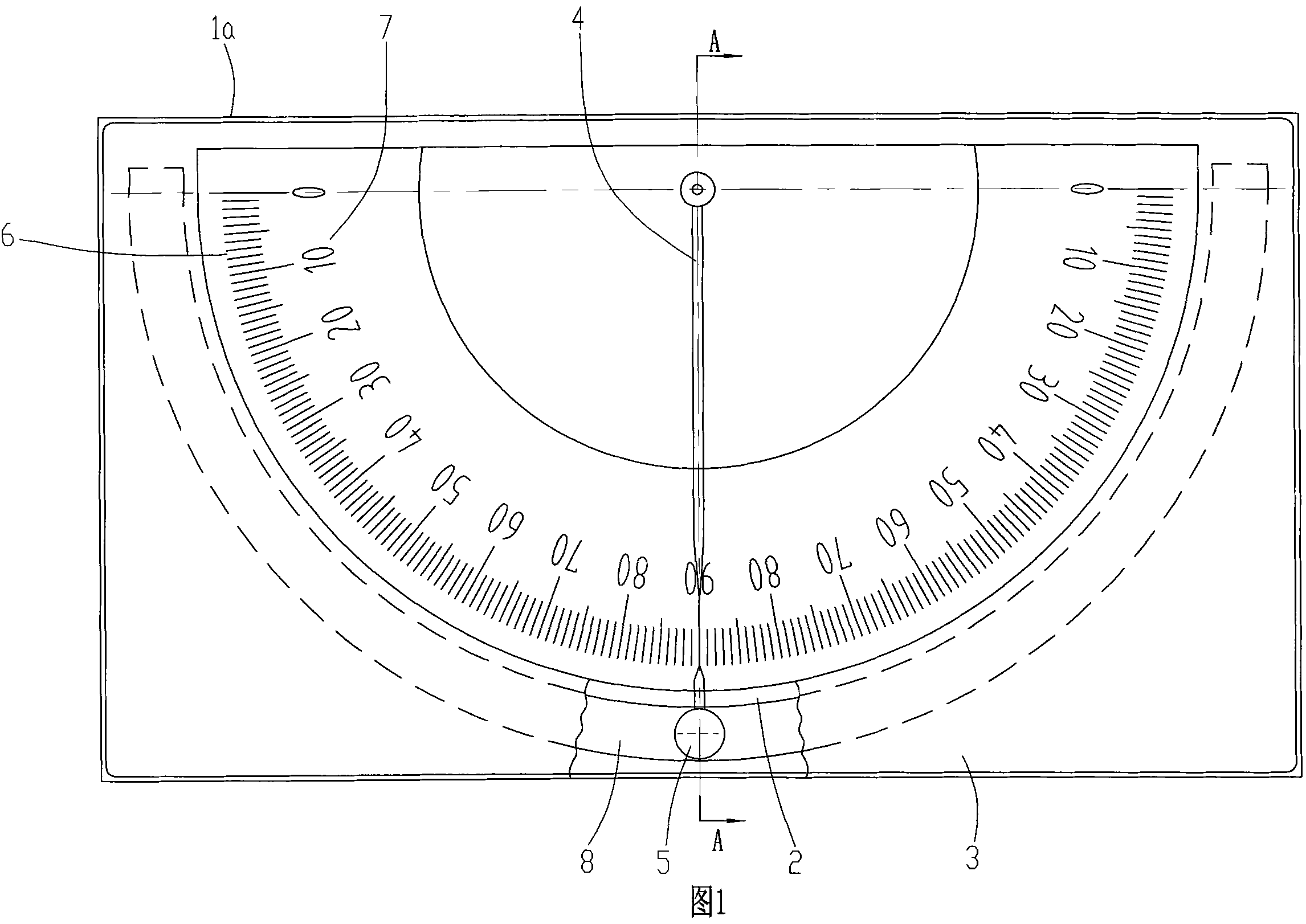

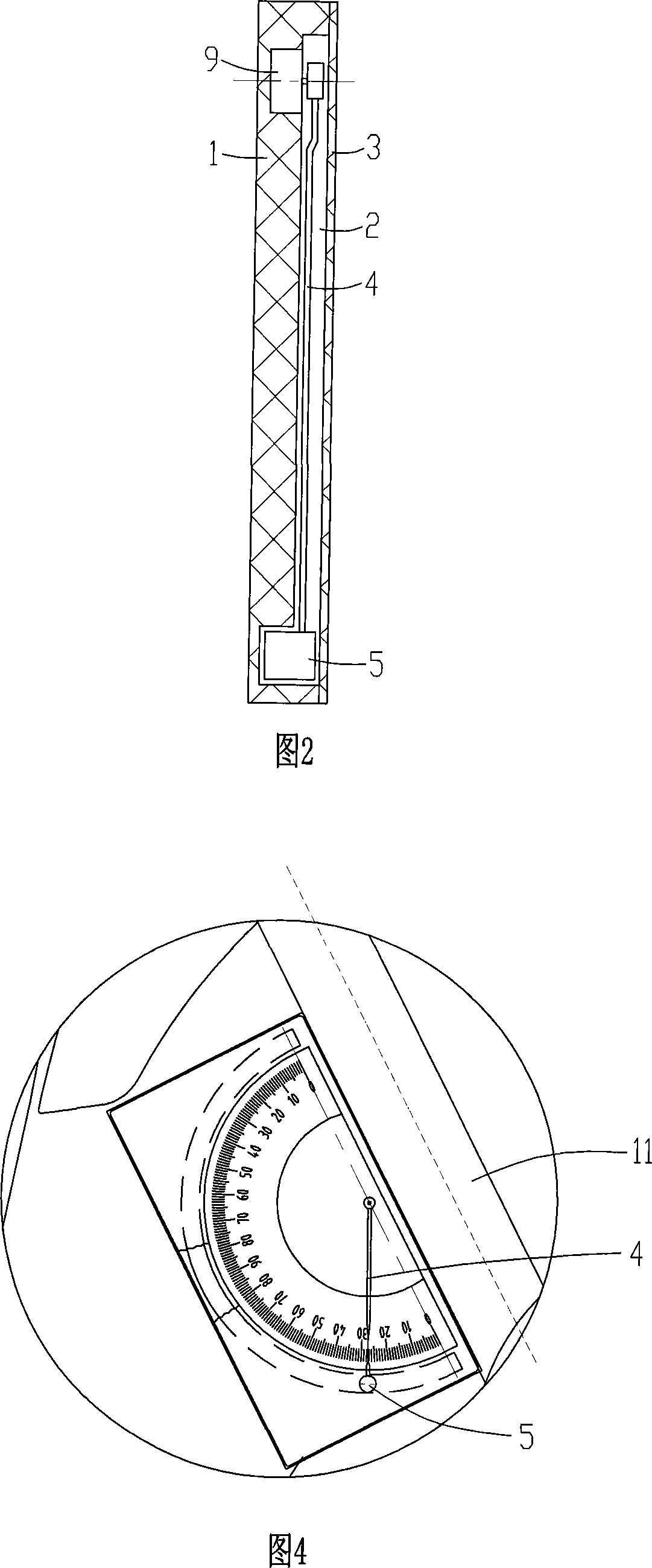

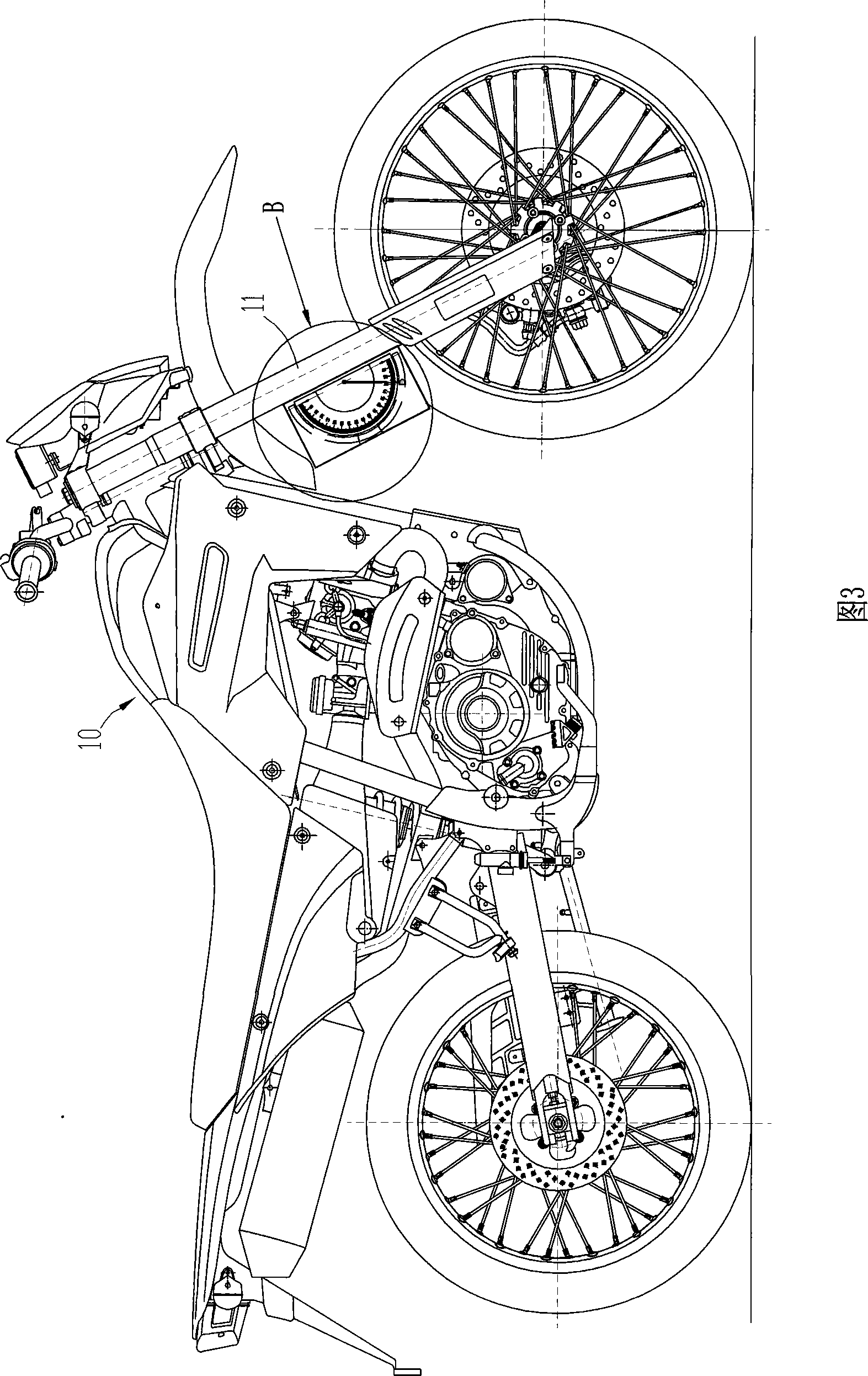

Front inclination angle measurement mechanism for motorcycle

InactiveCN101398302BReduce labor intensityEasy to measureIncline measurementMeasurement deviceEngineering

The invention discloses a front rake measuring device of a motorcycle. A substrate is opened with a semicircular groove which is sealed by a transparent panel covering the surface of the substrate, and straight edges of the groove are parallel and adjacent to the top surface of the substrate; a pointer is arranged inside the groove, the top end of the pointer is articulated in the middle part of the upper end of the substrate, and a heavy bob is fixed on a tip at the bottom of the pointer; scale marks matched with scale values are arranged on the transparent panel and distributed evenly in a circular arc, and the centre of the circular arc is positioned on the central extension line of hinge joint of the pointer and in a same straight line with two end points of the circular arc. The front rake measuring device of the motorcycle can simply and quickly measure the motorcycle front rake, intuitively and accurately obtain measurement results, effectively lower the labor intensity of workers in batch measurement, and ensure the motorcycle production to meet the consistency requirement, and is characterized by ingenious conception, simple structure, easy implementation, and the like.

Owner:力帆科技(集团)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com