Device for detecting rigidity of automobile safety airbag

A technology of automobile safety and detection device, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of unreliable measurement results, low degree of automation, and small pressure sensor values, and achieves true and reliable detection results. The effect of high degree of automation and controllable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

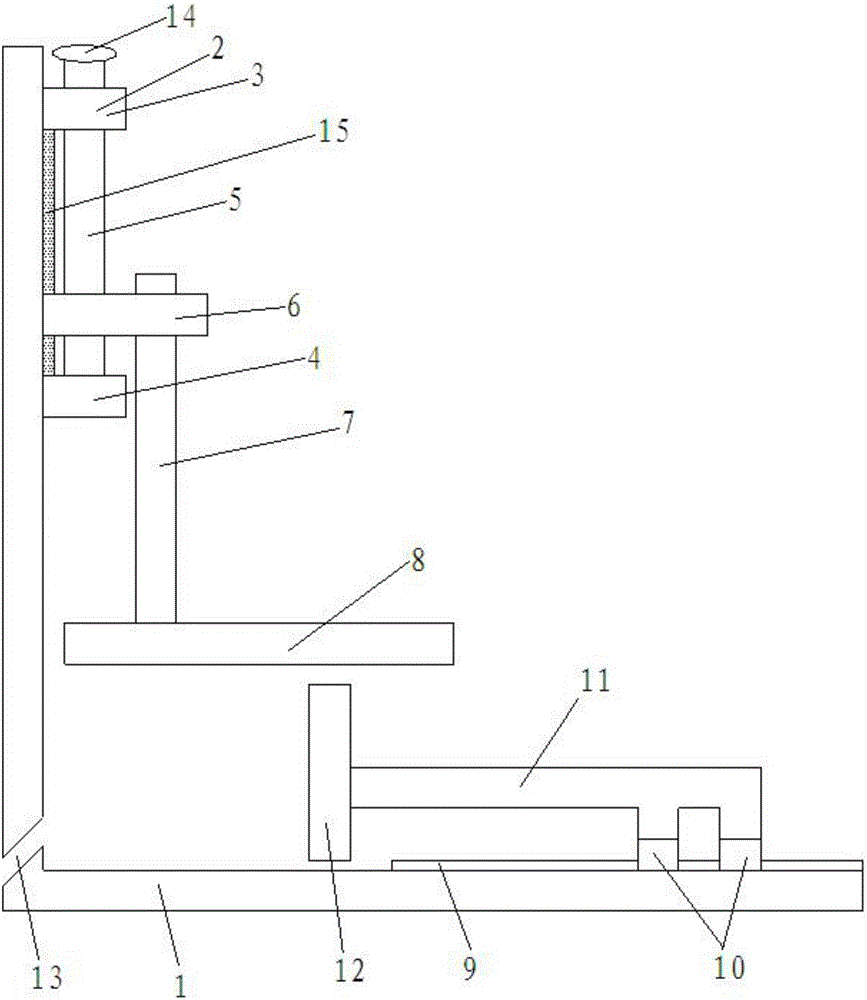

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, the automotive airbag stiffness detection device includes an L-shaped console 1, two fixed blocks 2 are arranged up and down on the vertical surface of the console 1, and a vertical slide rail 15 is arranged between the two fixed blocks 2. , the fixed block 2 includes an upper fixed block 3 and a lower fixed block 4, the upper fixed block 3 is provided with a smooth through hole for passing through the screw rod 5, and the upper surface of the lower fixed block 4 is provided with a hole for placing the The circular groove at the bottom of the screw rod 5, the screw rod 5 is screwed with a movable block 6, the movable block 6 can slide on the vertical slide rail 15, and the movable block 6 is connected to the horizontal rail by the vertical rod 7. The upward extruding plate 8 is connected; the horizontal bottom surface of the console 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com