Multifunctional integration measuring tool of blade on the basis of two ejector pins

A measuring tool and thimble technology, applied in the field of measuring tools, can solve the problems of low detection size, waste of time, error in detection results, etc., and achieve the effects of accurate detection results, high efficiency, and accurate measurement structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

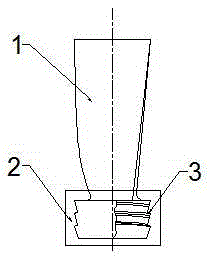

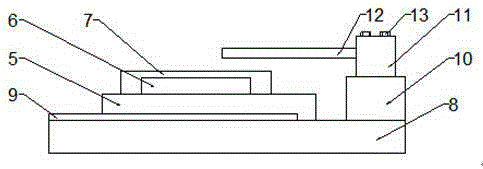

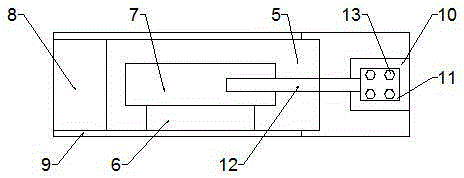

[0021] Such as figure 2 with image 3 As shown, the present invention discloses a blade multifunctional comprehensive measuring tool based on two thimbles, including a base, a measuring tool bottom plate 5 installed on the base, a limit block 6 installed on the measuring tool bottom plate 5, and a blade two thimble measuring tool 7.

[0022] The base includes a horizontally arranged cuboid base body 8 and a base baffle 9 vertically arranged on both sides of the base body; The middle part of the top of the seat 10 is connected by a bolt 14 to install a measuring ruler hinged platform 11, the measuring ruler hinged platform 11 is hinged with one end of a linear measuring ruler 12, and the other end of the measuring ruler 12 protrudes horizontally and is suspended, and is parallel to the base body 8 And it can rotate around the hinge point of the measuring ruler hinge table 11; the measuring tool bottom plate 5 is horizontally arranged on the base, and is limited between the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com