Solid-liquid interface determination device for silicon ingot furnace

A technology of silicon ingot furnace and solid-liquid interface is applied in the field of solid-liquid interface measuring device and device for measuring the depth of molten silicon, which can solve the problems of difficult to guarantee the measurement accuracy, high labor intensity of measuring personnel, etc. The effect of low manufacturing cost and accurate measurement structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

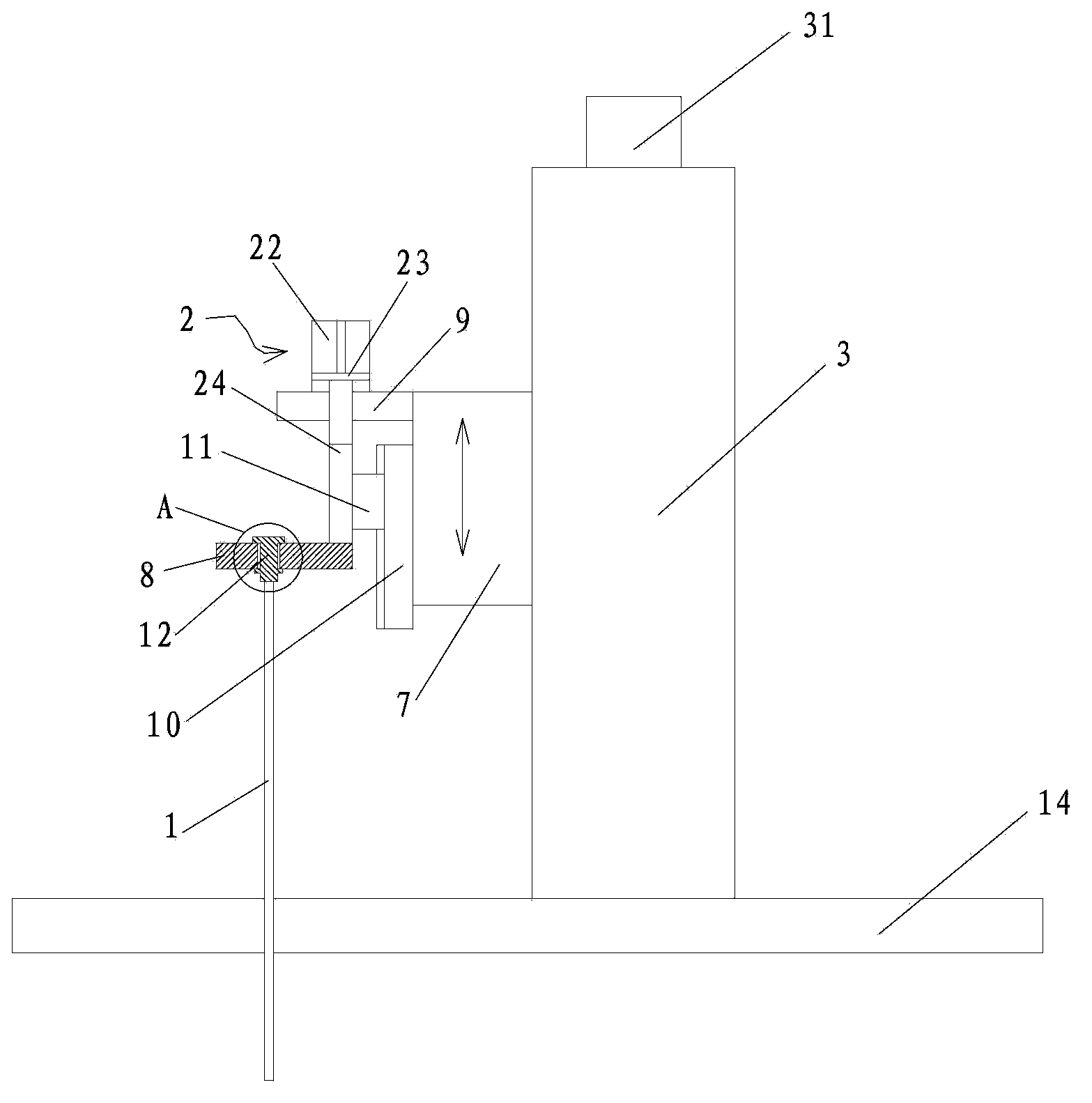

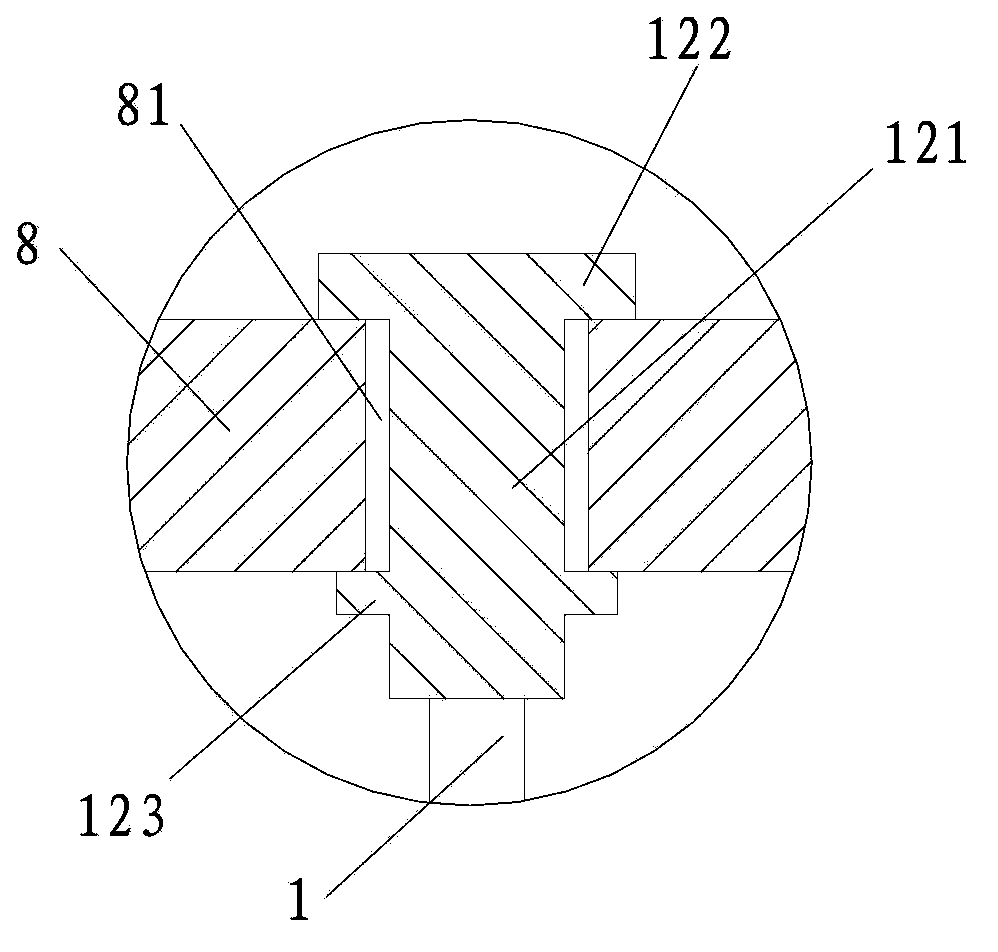

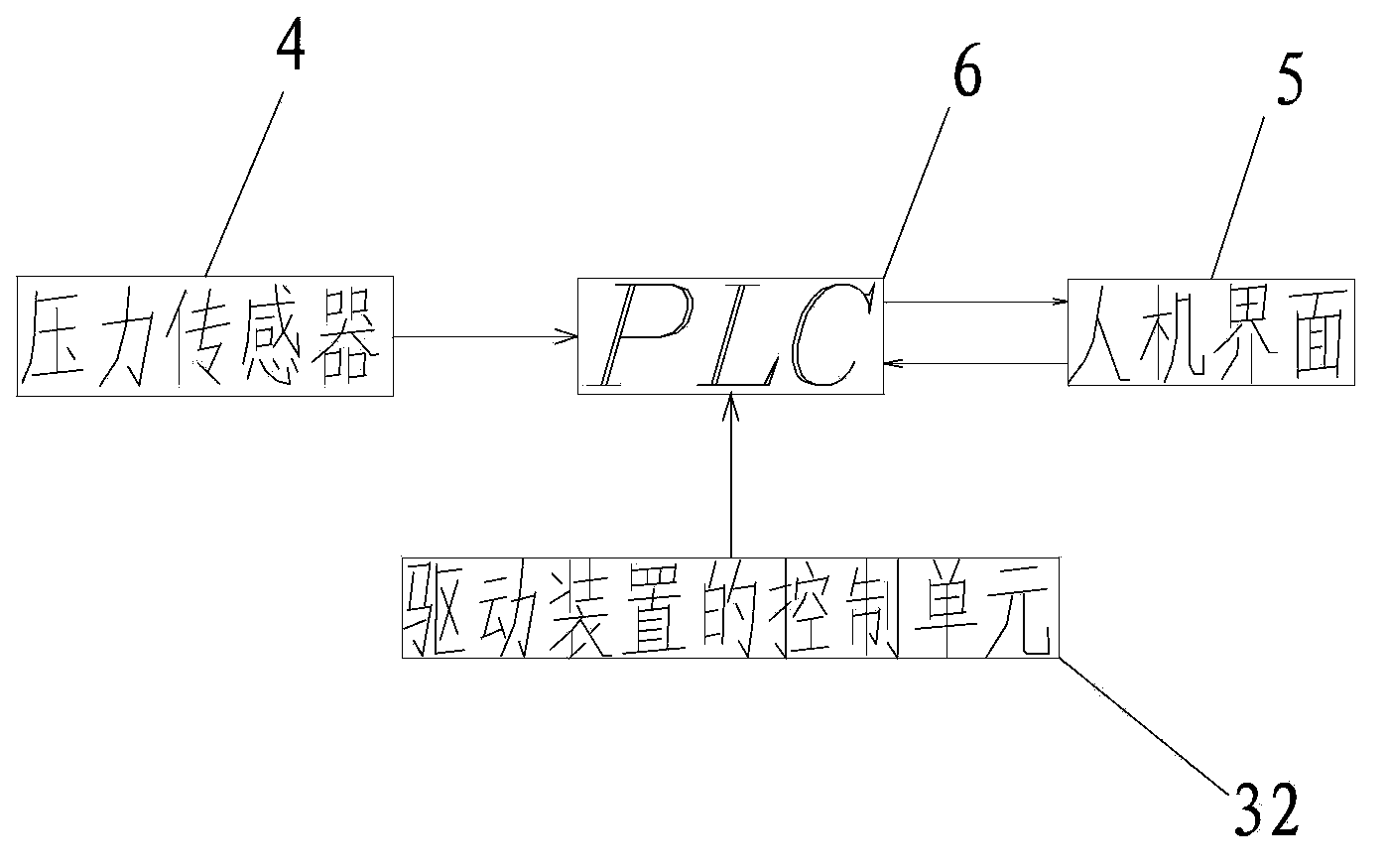

[0046] Such as Figure 1 to Figure 3 As shown, the solid-liquid interface measuring device for a silicon ingot furnace of the present invention includes: a quartz rod 1, a cylinder 2, a driving device 3, a pressure sensor 4 and a PLC 6, and the quartz rod 1 is vertically arranged for contact with the silicon ingot furnace. The solid polysilicon in the ingot furnace is contacted to detect the height of the solid polysilicon, that is, the depth of the molten silicon material in the silicon ingot furnace, figure 1The silicon ingot furnace is not shown in the figure, only the upper cover 14 of the silicon ingot furnace is shown, and the quartz rod 1 extends into the silicon ingot furnace from the opening of the upper cover 14 . The first piston rod 24 of the cylinder 2 is always in an extended state, and the first piston rod 24 is connected with the quartz rod 1 . The driving device 3 is used to drive the cylinder 2 to move linearly up and down. Since the quartz rod 1 is fixedly ...

Embodiment 2

[0066] Such as Figure 4 and Figure 5 As shown, the difference between the second embodiment and the first embodiment is only that the cylinder is different. The cylinder 2 of the present embodiment adopts a secondary protection cylinder, and one side of the piston 23 of the cylinder 2 is connected to the first piston rod 24 connected to the quartz rod 1 , the other side of the piston 23 is connected with a second piston rod 25 , and a position sensor 13 is arranged on the second piston rod 25 or on the cylinder body 22 .

[0067] The setting of this embodiment is to prevent the pressure sensor 4 from sensing a sudden change when the lower end of the quartz rod 1 detects a solid-liquid interface when the pressure sensor 4 is no longer sensitive to pressure after being used too many times or the pressure sensor 4 fails. Force, the driving device 3 does not drive the quartz rod 1 to move upwards. At this time, the quartz rod 1 will move upwards under the reaction force of soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com