Installation method for fiber grating drill hole stress meter in deep coal seam

A technology of borehole stress gauge and installation method, which is used in earth-moving drilling, wellbore/well components, sealing/packaging, etc. Accurate and reliable results, simple equipment and tooling, elimination of pressure relief effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

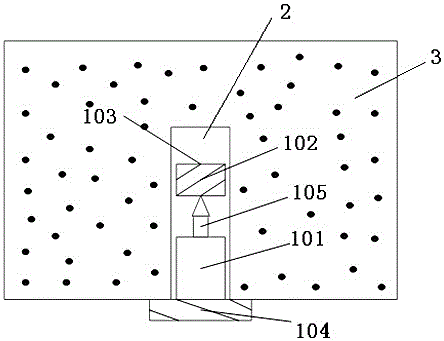

[0031] figure 1 It is a schematic structural diagram of Embodiment 1 of the present invention. As shown in the figure, the installation method of the drilling stress gauge of the present invention includes a drilling stress gauge 101 , glue 102 , glue stick 103 , flexible baffle 104 and nails 105 . The glue 102 is placed in the glue stick 103 , the flexible baffle 104 is installed at the tail of the drilling stress gauge 101 , and the nail 105 is installed at the front end of the drilling stress gauge 101 . Wherein, the glue stick structure is a thin film, and its influence on the stress induction of the optical fiber grating can be neglected. The glue is formed by mixing resin and catalyst at a volume ratio of 1:1. The glue can quickly penetrate into the fine cracks of coal and rock mass, and its hardness after solidification is similar to that of the coal seam structure. The size of the flexible baffle is larger than the diameter of the borehole.

[0032] The glue stick fi...

Embodiment 2

[0034]A thin blade (or other sharp device) is first inserted into the bottom of the drilled hole, with the drilled strain gauge in the glue stick containing the glue, which is fed into the drilled hole with the installation tool, when it reaches the drilled hole At the bottom, due to the existence of the blade, the glue stick will be cut and the glue will flow out. When the glue solidifies, the tight combination of the drilling stress gauge and the coal seam can be realized, and the continuity of the stress transmission of the coal seam can be realized.

Embodiment 3

[0036] First insert the borehole stress gauge into the bottom of the borehole, and then use a booster filled with glue to push the glue into the borehole. Make sure that the glue in the booster is enough to fill the gap between the borehole stress gauge and the surrounding coal seam Otherwise, air may enter when the glue is pushed in for the second time. After the glue is pushed in, the booster should be withdrawn in time. After the glue is solidified, the continuity of the stress transmission of the coal seam can also be achieved, making the measurement results true and accurate. precise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com