[0010] Additional objects, features and advantages of the various aspects of the present invention will become apparent from the following description of its preferred embodiments, which description should be taken in conjunction with the accompanying drawings.

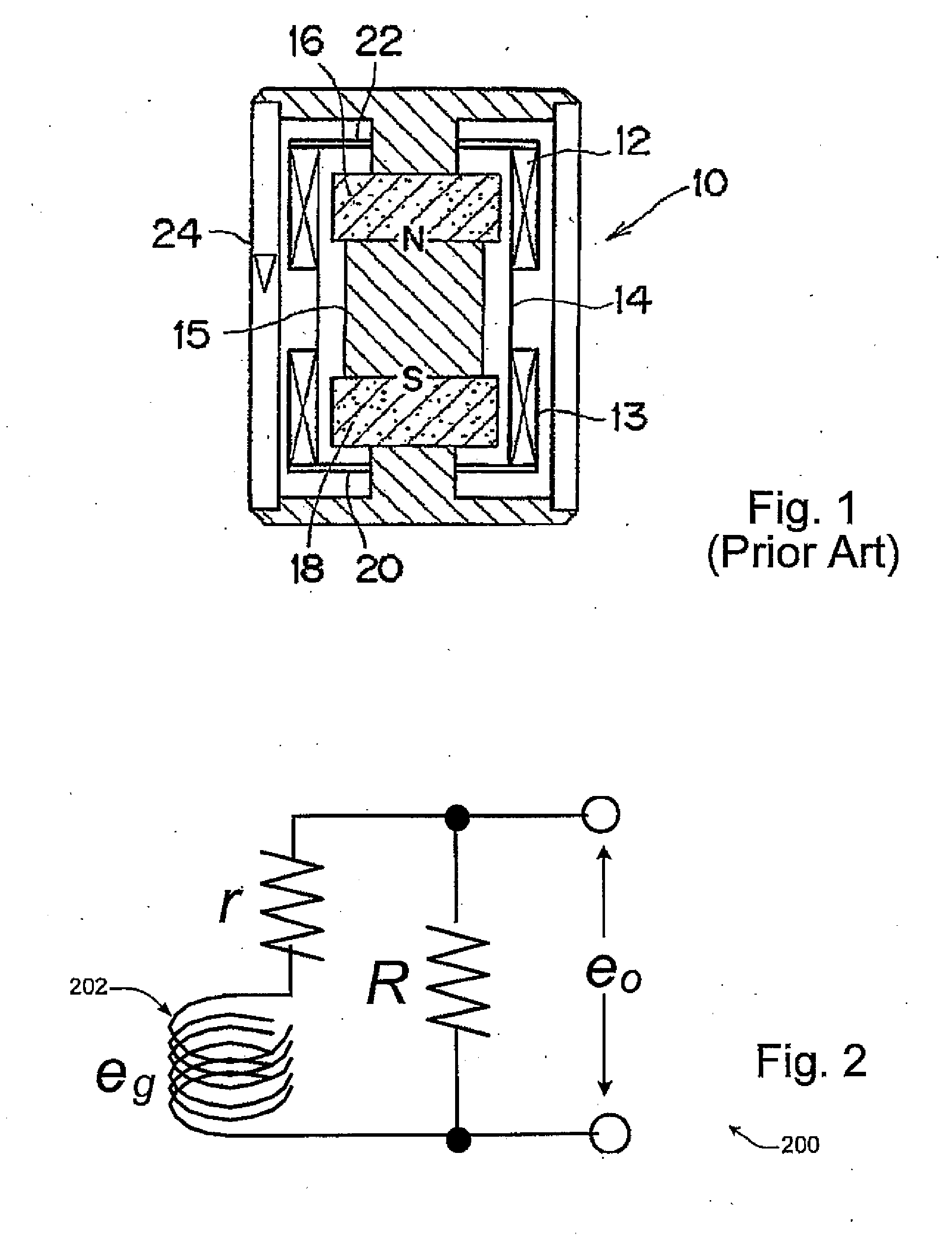

[0011]FIG. 1 shows an example of a conventional geophone 10.

[0012]FIG. 2 shows a simplified electric circuit representation of the geophone of FIG. 1.

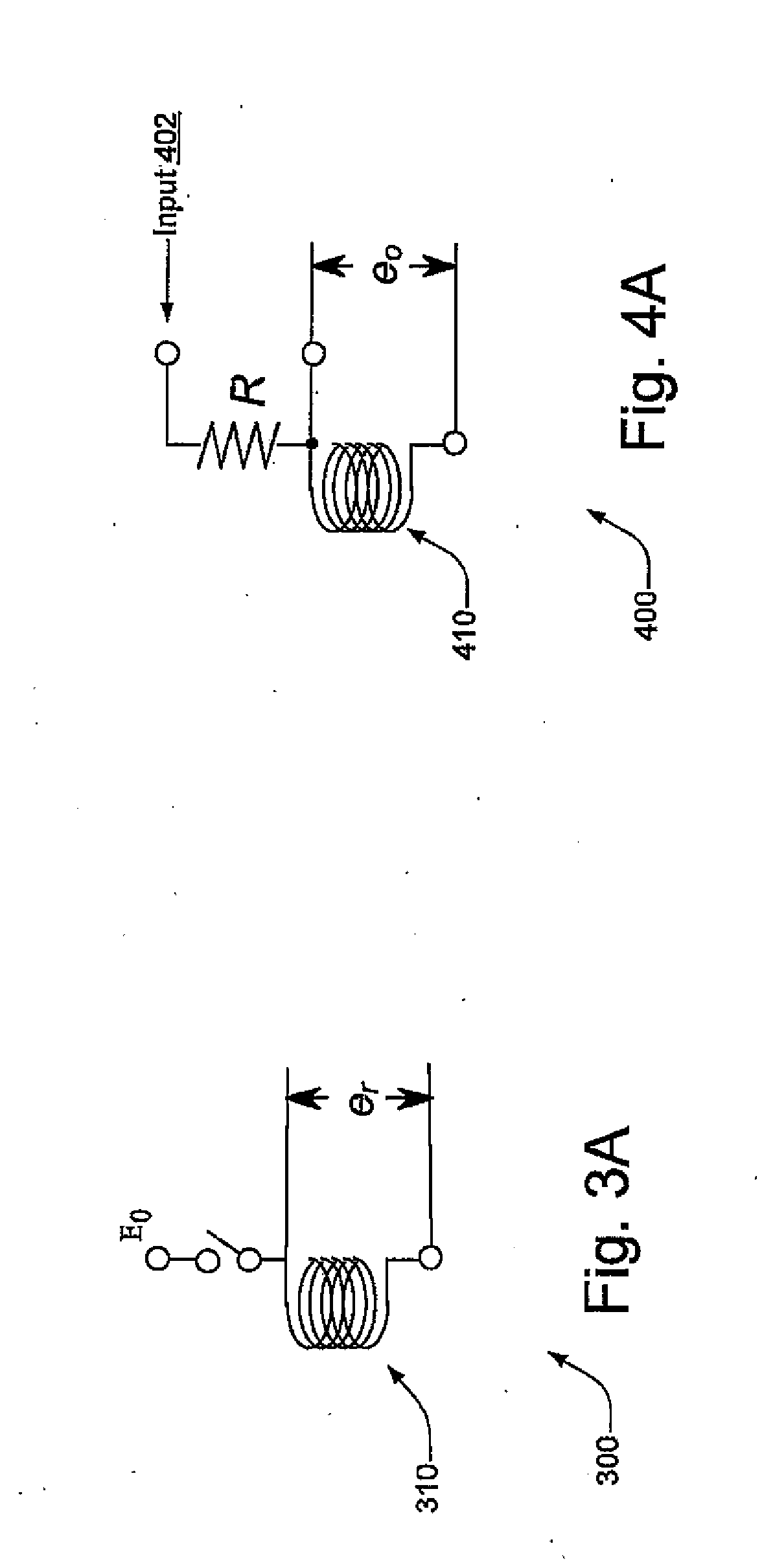

[0013]FIGS. 3A and 3B provide examples of a step

calibration test technique for measuring geophone response properties.

[0014]FIGS. 4A and 4B provide examples of an impulse

calibration test technique for measuring geophone response properties.

[0015]FIG. 5 provides an example of an impedance

calibration test technique for measuring geophone response properties.

[0016]FIG. 6 provides an example of a dynamic calibration test technique for measuring geophone response properties.

[0017]FIGS. 7A and 7B provide examples of a reciprocity calibration test technique for measuring geophone response properties.

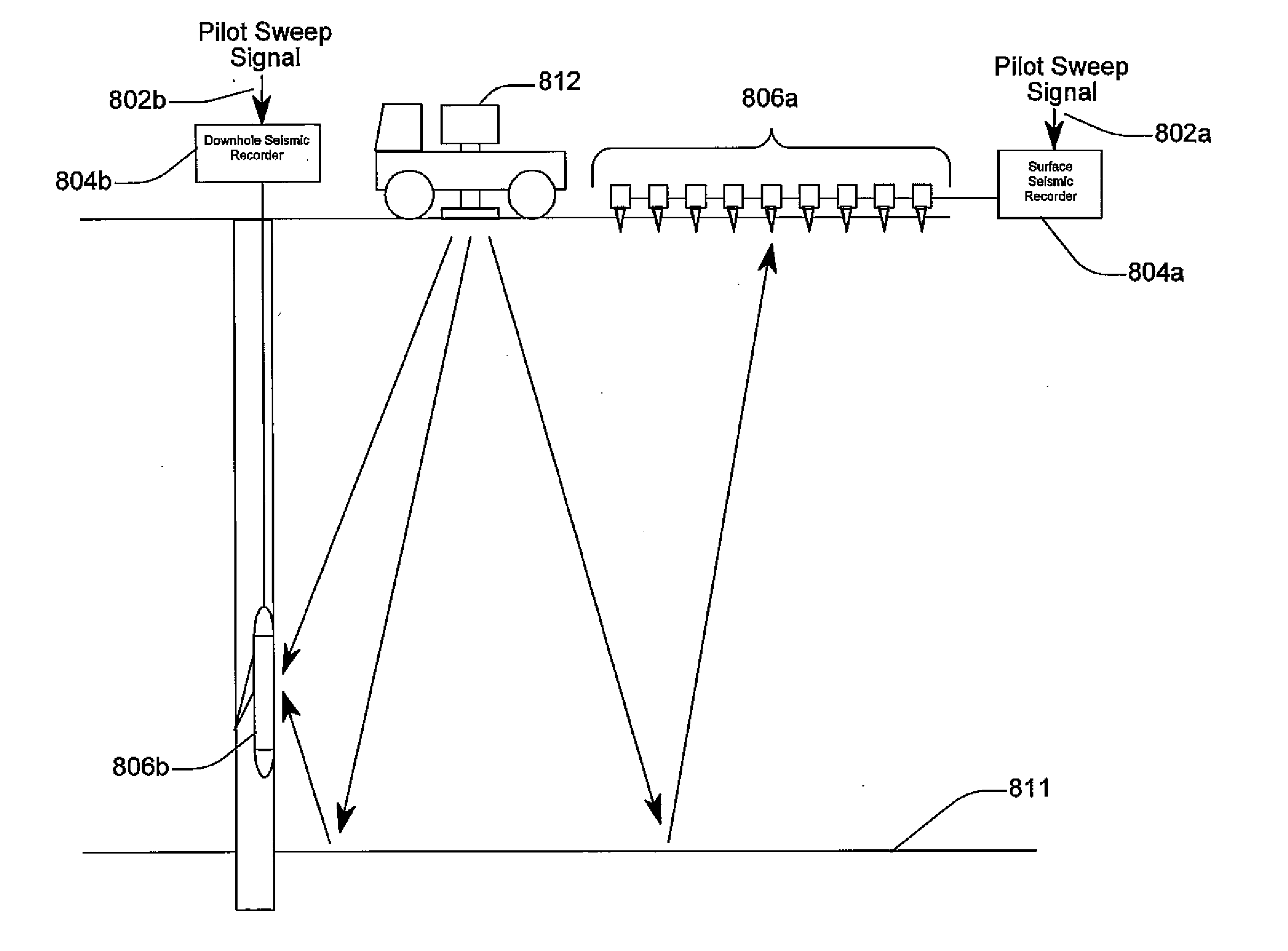

[0018]FIG. 8 shows an example of various equipment configurations which may be used for vibroseis

prospecting.

[0019]FIG. 9 shows an example of different

signal paths which may flow between the various features and devices illustrated in FIG. 8.

[0020]FIG. 10A shows an example of an unfiltered sweep

signal, which may vary in frequency (e.g., 5 Hz to 50 Hz) over a given time period.

[0021]FIG. 10B shows an example of a simulated sweep

signal after geophone

filtration.

[0022]FIG. 11 graphically illustrates an example of the correlation between an unfiltered (original) sweep signal 1102 and a geophone filtered sweep signal 1104.

[0023]FIG. 12 shows a

block diagram illustrating one embodiment of how the geophone response compensation technique of the present invention may be applied to an array of geophones which have been deployed for vibroseis

prospecting operations.

[0024]FIG. 13 shows a

block diagram illustrating an alternate embodiment of how the geophone response compensation technique of the present invention may be applied to an array of geophones which have been deployed for vibroseis

prospecting operations.

[0025]FIGS. 14 and 15 graphically illustrate differences between uncompensated geophone response signals and geophone response signals which have been compensated using the geophone response compensation technique of the present invention.

[0026]FIG. 16 shows a

schematic diagram 1600 which may be used for describing a specific embodiment of the impedance calibration test technique.

[0027]FIG. 17 illustrates the real and imaginary parts of an impedance equation, as represented as a circle on a complex plane.

[0028]FIG. 18 illustrates a network device 60 suitable for implementing various aspects of the geophone calibration and compensation techniques of the present invention.

[0029] As described in greater detail below, the present invention provides various techniques which may be used to facilitate and improve seismic exploration activities. For example, one aspect of the present invention is directed to a technique for enabling in-situ measurement of geophone

response parameters. Another aspect of the present invention is directed to a technique for improving geophone calibration and for improving the accuracy of measurement of geophone response parameters. Yet another aspect of the present invention is directed to a technique for compensating geophone response output data in order to improve the accuracy of such data.

[0030] In order to

gain a better understanding the various techniques and features described in this application, a brief description of geophone measurement techniques will now be described.

[0031] A

seismic survey measures seismic

waves propagated through the earth to map structural images in the earth. Geophones are often used to detect seismic signals at various locations, such as, for example, down holes, ground surfaces and / or seabeds. An example of a conventional geophone is shown in FIG. 1. The geophone 10 of FIG. 1 includes moving coils 12, 13 mounted on a

bobbin 14, a

magnet 15, a pair of pole pieces 16, 18 with suspension springs 20, 22 and a housing 24 as shown in FIG. 1. The pole pieces 16, 18 and housing 24 are made of magnetically permeable material and form a

magnetic field in which the moving coils 12, 13 are suspended. In the example of FIG. 1, the moving coils 12, 13,

bobbin 14, and suspension springs 20, 22 collectively form the effective moving

mass portion (m) of the geophone. As used in this application, the term “geophone” includes conventional-type geophones such as that illustrated in FIG. 1, as well as geophone

accelerometer (GAC) devices which, for example, may be configured or designed to measure relatively wider acceleration ranges than conventional-type geophones.

[0032] As shown in the embodiment of FIG. 1, the geophone 10 includes a moving

mass of coil suspended in a

magnetic flux by means of a spring or a pair of springs. The moving coil tries to stay in the same position while the housing of

magnetic circuit is moved in response to external vibrations. FIG. 2 shows a simplified illustration of the geophone of FIG. 1. As illustrated in FIG. 2, a moving coil 202 generates a

voltage eg in response to external vibration. The coil has an associated

DC resistance r. The geophone output is shorted by R to provide a desired

damping factor.

[0033] The geophone response is usually defined by its associated response properties, such as, for example, its

natural frequency,

damping factor, sensitivity and

DC resistance of coil at

room temperature. An example of traditional geophone response properties may be expressed by the following equations (1)-(6). For purposes of illustration, it is assumed that the geophone responds to sinusoidal earth accelerations. Thus, for example, the earth accelerations expressed by

[0034] In the acquisition of seismic data, seismic

waves are used to interpret subsurface geological formations. One type of

geophysical prospecting technique is generally known as “vibroseis” prospecting or simply vibroseis. Vibroseis employs a seismic vibroseis source used to generate a controlled wavetrain that propagates through the earth or water to be detected by seismic detectors (e.g., geophones).

[0035]FIG. 8 shows an example of various equipment configurations which may be used for vibroseis prospecting. As shown in the example of FIG. 8, surface acquisition of seismic data may be performed using a surface vibroseis source 812. Typically, surface vibroseis sources emit an energized wavefield over a selected time period known as sweep time. Seismic detectors (e.g., surface acquisition geophones 806a, downhole acquisition geophones 806b) detect earth movements during the sweep time period and during an additional time period commonly referred to as listen time. Typically, the energization takes the form of a sinusoidal wavefield of continuously varying frequency applied to the earth or a body of water during a sweep time lasting from about two to about 20 seconds or even more. For marine acquisition of seismic data, marine air gun seismic sources are generally used to generate the source signal, which typically includes a

single pulse having multiple frequencies.

[0036] In seismic acquisitions which utilize a vibrator 812 such as that illustrated in FIG. 8, a

pilot sweep signal drives the vibrator, causing the vibrator to inject acoustic signals into the earth in accordance with the

pilot sweep signal. The geophones (806a, 806b) on the

earth surface and / or downhole pick up signals propagated through the earth as shown in FIG. 8. The signals detected by the geophones are filtered by the geophone

transfer function described by Equations (1) and (2) above. The recorded signals are then correlated with the

pilot sweep signal(s) (802a, 802b) which are fed directly to the seismic recorders (e.g., surface seismic recorder 804a, downhole seismic recorder 804b).

[0037]FIG. 9 shows an example of different signal paths which may flow between the various features and devices illustrated in FIG. 8. For purposes of illustration, an example of a vibroseis cross-correlation technique will now be described by way of example with reference to FIGS. 9, 10A, 10B, and 11.

[0038]FIG. 10A shows an example of an unfiltered sweep signal, which may vary in frequency (e.g., 5 Hz to 50 Hz) over a given time period. As illustrated in FIG. 9, the unfiltered electronic sweep signal may be fed to vibrator 902 and cross-correlation unit 912. According to one implementation, the vibrator 902 uses the electronic sweep signal to produce corresponding seismic vibrations in the earth formation 904. These vibrations are detected by geophone 910, which produces a filtered output geophone response signal. FIG. 101B shows an example of a simulated sweep signal after geophone

filtration. In the example of FIG. 10B, the signal is filtered by a 10 Hz geophone with 70% damping.

[0039] The cross-correlation unit 912 compares the unfiltered pilot sweep signal with the geophone filtered sweep signal. FIG. 11 graphically illustrates an example of the correlation between the unfiltered (i.e., original or source) sweep signal 1102 and the geophone filtered sweep signal 1104. As illustrated in FIG. 11, the correlated results are no longer

zero phase for various ranges of sweep signal frequencies, such as, for example, from 10 Hz to 1004 Hz and from 5 Hz to 50 Hz.

[0040]

Geophone manufacturers typically supply geophones with nominal response properties at

room temperature, and provide assurances that the response properties are within specified tolerance ranges. For example, a manufacturer may specify that the tolerance ranges at

room temperature may be, for example, + / −5% for

natural frequency, open circuit sensitivity, open circuit damping and

DC resistance. However, tests performed by the present inventive entity have shown that 5% errors in the geophone response properties can result in amplitude measurement errors of 15% or more.

[0041] In order to process seismic signals with sufficient

high fidelity to be able to extract precise information, it is preferable to calibrate the geophone prior to use, and to compensate for geophone response properties by adjusting, for example, data produced from the geophone response to take into account geophone calibration and / or response properties.

[0042] Traditionally, geophone calibration is accomplished by performing one or more tests on the geophone in order to determine the geophone's response properties, namely

natural frequency,

damping factor, sensitivity and DC resistance. Typically, the geophone's DC resistance (r) of the moving coil is measured using a

multimeter. The natural frequency, damping factor, and sensitivity characteristics of the geophone may be measured using different measurement or testing techniques such as, for example, step calibration test techniques, impulse calibration test techniques, impedance calibration test techniques or dynamic calibration test techniques. The sensitivity characteristics of the geophone may also be measured using a reciprocity calibration test technique. Each of these different measurement techniques is described below.

[0043] An example of a step calibration test technique for measuring geophone response properties may be illustrated with reference to FIGS. 3A and 3B. FIG. 3A shows a simplified

schematic of a geophone 300. According to one embodiment of the step calibration test technique, a

voltage may be applied at E0 to dislocate the moving coil 310 from its

neutral position. The

voltage applied at E0 is then released (e.g., at time T0), and the geophone responds according to its natural vibration. The natural vibration is measured as the response signal from the output of the geophone. This is illustrated, for example, in FIG. 3B of the drawings, which graphically illustrates the

step test input voltage 352 (at E0) and the geophone output signal 354. Using the

step test, sensitivity, natural frequency and damping factor characteristics of the geophone may be calculated based on a given set of initial parameters, including the value of E0, the DC resistance of the moving coil, and the amount of moving

mass of the geophone.

[0044] An example of an impulse calibration test technique for measuring geophone response properties may be illustrated with reference to FIGS. 4A and 4B. FIG. 4A shows a simplified

schematic of a geophone 400. According to one embodiment of the impulse calibration test technique an impulse test signal is input to the geophone at 402. An example of the impulse test signal is represented by signal line 452 of FIG. 4B. Ranges for portions of the geophone response output signal 454 (e.g., a1, a2, T) are pre-calculated for sensitivity, damping and natural frequency based on stated tolerances of the geophone response properties. The impulse test signal may be applied at time T0, and the geophone response for a1, a2 and T may then be measured to see if the geophone the response properties are within their stated tolerance ranges. Typically, the impulse calibration test technique is not used for calibrating the geophone, but rather is typically used to verify that the geophone response properties are within their stated tolerance ranges.

[0045] An example of an impedance calibration test technique for measuring geophone response properties may be illustrated with reference to FIG. 5 of the drawings. According to one embodiment of the impedance calibration test technique, input signal(s) (e.g., sinusoidal signals) are applied at 504 and output voltages e1 and e2 are measured as shown in FIG. 5. The impedance at the

measurement frequency may be derived in accordance with the following equation: Z=e2i=e2Re1(7)

[0046] In Equation 7 above, the

electric signal applied to the coil is represented by e2. The current which flows into the coil may be determined by e1 and R.

[0047] Calculation of impedance utilizes at least two measurements at the frequencies ω1 and ω2.

[0048] The natural frequency (ω0), damping factor (ζ0) and sensitivity (S0) may be calculated according to: ω0=(A·ω1-ω2)ω1ω2A·ω2-ω1(9)f0=12 π·ω0(10)ζ0=(ω02-ω12)(Re(Z(ω1))-Rc)2 ω0ω1Im(Z(ω1))(11)Sg=m Im{Z(ω1)}{(ω02-ω12)2+4 ζ02ω02ω12}(ω02-ω12)ω1where,(12)A=Re(Z(ω1))-rIm(Z(ω1))Re(Z(ω2))-rIm(Z(ω2))(13)

Sg corresponds to open-circuit sensitivity derived from nominal moving mass [V / m / s],

[0049] It will be appreciated that calculation of the geophone response properties using the above-described impedance calibration test technique relies upon utilizing a known value for the amount of moving mass (m) of the geophone. Typically, this known value for m corresponds to the nominal value of the moving mass which is provided by the manufacturer.

[0052] The embodiment of FIG. 6 illustrates one implementation of the dynamic calibration test using a vertical configuration. According to an alternate implementation of the present invention, the dynamic calibration test may also be performed using a horizontal configuration. In such an embodiment, the geophone(s),

reference sensor and

shaker device

assembly may be positioned horizontally, and excitation applied in a horizontal direction.

[0050] An example of a dynamic calibration test technique for measuring geophone response properties may be illustrated with reference to FIG. 6 of the drawings. According to one embodiment of the dynamic calibration test technique, a calibrated

reference sensor 604 and one or more geophones 602 to be calibrated are positioned on top of a shaking device 606, as illustrated, for example, in FIG. 6. The geophone(s) 602 and

reference sensor 604 are then shaken (e.g., in a vertical direction of excitation) using shaking device 606. The geophone response properties may then be determined by comparing the geophone response output to the reference sensor output. For example, since the phase and

amplitude response are known from the reference sensor measurements, the natural frequency and damping factor of the subject geophone may be determined from the

transfer function between the two.

[0051] It will be appreciated that the relative accuracy of the dynamic calibration test technique depends upon the accuracy of calibration of the reference sensor and the response of the reference sensor. Typically, the reference sensor 604 is calibrated by a

third party which is associated with some type of entity for measurement standards.

[0052] The embodiment of FIG. 6 illustrates one implementation of the dynamic calibration test using a vertical configuration. According to an alternate implementation of the present invention, the dynamic calibration test may also be performed using a horizontal configuration. In such an embodiment, the geophone(s), reference sensor and

shaker device

assembly may be positioned horizontally, and excitation applied in a horizontal direction.

[0053] According to at least one embodiment, the geophone(s), reference sensor and

shaker device may be enclosed in a housing which, for example, may be made with iron, steel, and / or materials which help to prevent magnetic

coupling between the shaker and the geophones.

[0054] According to a specific implementation of the dynamic calibration test technique, the reference sensor 604 may correspond to a reference geophone in which the moving mass of the reference geophone has been substantially accurately measured and / or determined. Various techniques for accurately measuring a geophone's moving mass are described in greater detail below.

[0055] An example of a reciprocity calibration test technique for measuring geophone response properties may be illustrated with reference to FIGS. 7A and 7B.

[0056] According to one embodiment, the reciprocity calibration test technique may be used to determine the sensitivity of multiple geophones in situations where

no reference sensor is used.

[0057] For example, as shown in the embodiment of FIG. 7A, three uncalibrated geophones (Ga, Gb, Gc) are mounted on a block 710. A sinusoidal

electric signal e0 is then input into one of the geophones (Ga), which causes excitation of the geophone Ga in the direction indicated. This excitation results in the shaking of block 710, and consequently results in the shaking of geophones Gb and Gc.

[0058] In open circuit conditions, the responses output signals of geophones Gb and Gc (namely eab and eac) may be expressed as a function of input signal voltage and geophone impedances as shown below: ea b=Sae0Msabs{Za(ω)}ω(ωa2-ω2)2+(2 Daωaω)2Sbω2(ωb2-ω2)2+(2 Dbωbω)2ea c=Sae0Msabs{Za(ω)}ω(ωa2-ω2)2+(2 Daωaω)2Sbω2(ωc2-ω2)2+(2 Dcωcω)2(14)

[0059] Another sinusoidal

electric signal is then input into geophone Gb to thereby shake geophone Ge along with block 710 (as illustrated, for example, in FIG. 7B).

[0058] In open circuit conditions, the responses output signals of geophones Gb and Gc (namely eab and eac) may be expressed as a function of input signal voltage and geophone impedances as shown below: ea b=Sae0Msabs{Za(ω)}ω(ωa2-ω2)2+(2 Daωaω)2Sbω2(ωb2-ω2)2+(2 Dbωbω)2ea c=Sae0Msabs{Za(ω)}ω(ωa2-ω2)2+(2 Daωaω)2Sbω2(ωc2-ω2)2+(2 Dcωcω)2(14)

[0061] The absolute sensitivities of three geophones may be determined by solving the equations below: Sa=ea bea ceb ce0Ms{Za(ω)}2{Zb(ω)}(ωa2-ω2)2+(2 Da ωa ω)2ω3Sb=ea beb cea ce0Ms{Zb(ω)}(ωb2-ω2)2+(2 Db ωb ω)2ω3Sc=ea ceb cea be0Ms{Zb(ω)}(ωc2-ω2)2+(2 Dc ωc ω)2ω3(16)

[0062] The embodiment of FIG. 7A-7B illustrate one implementation of the reciprocity calibration test using a horizontal configuration. According to an alternate implementation of the present invention, the reciprocity cahibration test may also be performed using a vertical configuration. In such an embodiment, the geophones may be positioned vertically, and excitation applied in a vertical direction.

[0063] Additional details relating to the reciprocity calibration test technique may be found in the reference “The Reciprocity Calibration of Piezoclectric Accelerometers,” by Mark Harrison, A. O. Sykers, and Paul G. Marcotte, THE JOURNAL OF THE ACCOUSTICAL SOCIETY OF AMERICA, Volume 24, Number 4, July, 1952, herein incorporated by reference in its entirety for all purposes.

[0064] A detailed description of various embodiments of the reciprocity calibration test technique for geophone calibration is deslobed in U.S. Pat. No. 5,644,067 to Gabrielson, entitled “APPARATUS AND) METHOD FOR CALIBRATION OF SENSING TRANSDUCERS”, the entirety of which is incorporated herein by reference for all purposes.

[0067] According to at least one implementation, the moving mass value is a constant which does not change with varying temperature or tilt of the geophone. Thus, once the moving mass is known, a geophone can be tested in-situ any time using one or more of the above-described techniques. Additionally, it will be appreciated that the technique of the shown by Equation 6 (above). The open circuit sensitivity may also be reduced by the temperature as shown, for example, in FIG. 7. Temperature also affects the open circuit damping characteristics.

Geophone response may also be affected by its tilt. Additionally, if a geophone is used under tilt, the displacement of the internal springs may change the geophone's natural frequency.

[0068] In addition to the above-described factors which may affect geophone response measurements and / or response properties, it will be appreciated that many of the above-described geophone calibration and geophone response property test techniques are dependent upon utilizing known values for various geophone properties in order to determine values for unknown geophone properties. For example, as described previously, at least a portion of the above-described geophone calibration test techniques and geophone response property test techniques rely upon using a pre-known value for the amount of moving mass (m) of the geophone. As described previously with respect to FIG. 1, moving coils 12, 13,

bobbin 14, and suspension springs 20, 22 collectively form the moving mass portion (m) of the geophone 10. Typically, the value for m corresponds to the nominal value of the moving mass which is provided by the manufacturer. One technique which may be used by manufacturers for determining the geophone moving mass value is to compute the moving mass value by adding together estimated or average mass values of the each of the individual components (e.g., moving coil, bobbin, suspension springs) which collectively form the moving mass.

[0069] Because geophone manufacturers typically provide values for nominal geophone response properties, and provide assurances that the response properties are within specified tolerance ranges, it is common practice in the industry, when performing geophone calibration tests, to rely upon the nominal value of the moving mass which is provided by the manufacturer. Moreover, precise calculation of the geophone moving mass value is extremely difficult to ascertain. One reason for this is that the moving mass is comprised of several different (and sensitive) components within the geophone which are typically inaccessible to the user. Another reason is that it is difficult to determine the precise portion of moving

suspension spring mass which contributes to the geophone moving mass value.

[0070] Moreover, there has conventionally been no need or desire to perform independent measurements of geophone moving mass values since, conventionally, there has been no recognition in the industry of the possibility that errors in geophone moving mass values may significantly contribute to errors in geophone calibration and / or geophone

response characteristics. As a result, there has been no motivation to one having ordinary skill in the relevant art to measure the geophone moving mass value to a

degree of precision which is greater than that of the nominal value provided by the manufacturer.

[0074] It will be appreciated that the technique of the present invention may be used to more precisely quantify the geophone response parameters, such as, for example, sensitivity, damping, and / or natural frequency. For example, by using a more precise, calculated moving mass value, the impedance test may be used to more precisely quantify the geophone response parameters, such as, for example, open circuit sensitivity, open circuit damping, and / or natural frequency. Consequently, the improved accuracy of the geophone response parameters not only allows the geophone to be calibrated with greater precision, but also allows for greater accuracy of geophone response compensation techniques.

[0072] According to a specific embodiment of the present invention, one technique for improving geophone calibration measurements and / or geophone response compensation techniques is to determine the moving mass by measuring the mass of the moving coil, bobbin, and suspension springs before fabrication of a geophone, and stamp the determined moving mass value on the geophone. In this way, the actual moving mass value for each geophone may be ascertained and used for subsequent operations. This technique differs from conventional techniques which use the manufacturer's estimated or nominal value of the moving mass. Moreover, by using a more precise moving mass value, greater precision of the geophone response parameters may also be obtained, for example, using the impedance method described by Equations 9, 11, and 12.

Login to View More

Login to View More  Login to View More

Login to View More