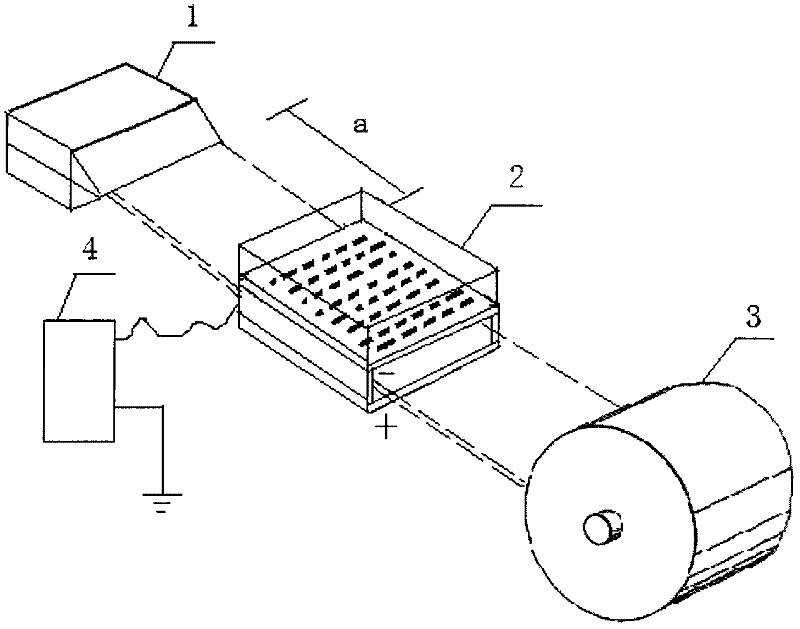

Production method of breathable melt-blown nonwoven fabrics

A melt-blown non-woven fabric and melt-blown technology, applied in the field of non-woven fabrics, can solve the problems of limited thickness and pressure resistance of non-woven fabrics, unsolved perspiration and moisture conduction, etc., achieving obvious thermal insulation effect and light weight , The effect of evenly mixing the fiber web

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

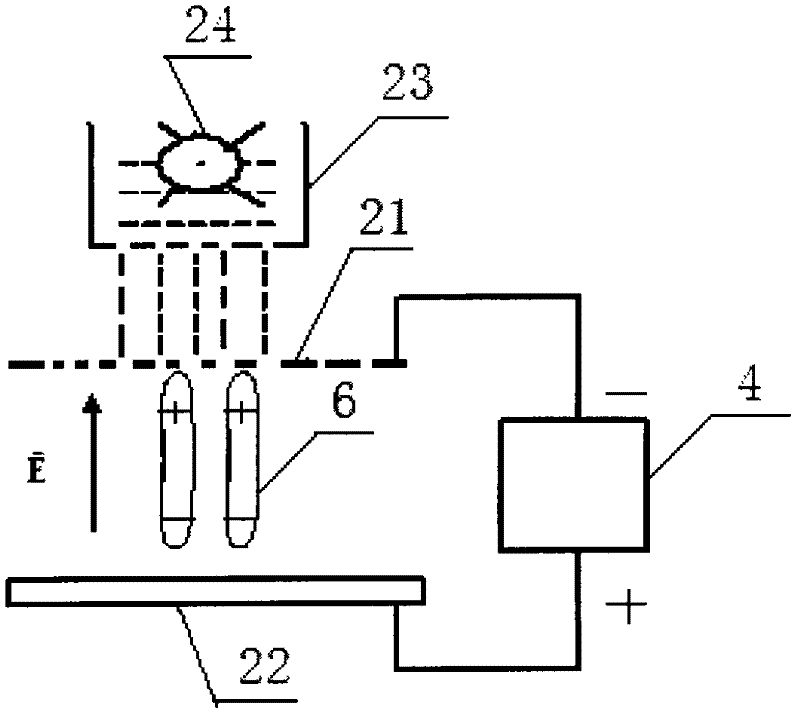

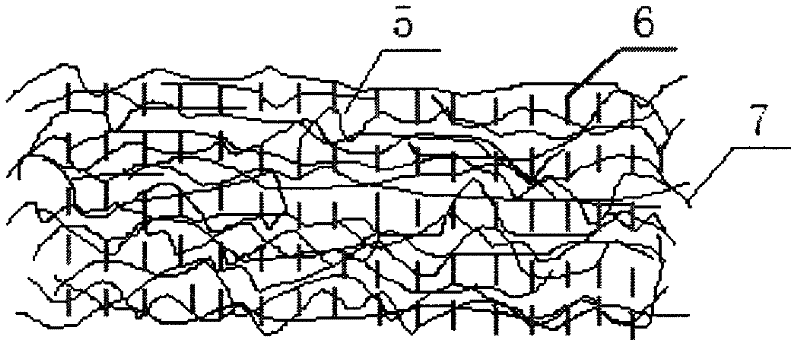

Method used

Image

Examples

preparation example Construction

[0028]The preparation method adopted in the present invention is to refer to the existing mature electrostatic flocking technology, and implant the short fibers into the melt-blown fiber web in the vertical direction, so as to realize the significant improvement of the pressure resistance and mixing uniformity of the nonwoven flakes. The preparation method has the advantages of being simple and easy to implement, low in cost and very favorable for popularization.

[0029] What is not mentioned in the present invention is applicable to the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com