High-sensitivity flexible piezoresistive transducer as well as preparation method and application thereof

A piezoresistive sensor, flexible technology, used in the application field of high-sensitivity flexible piezoresistive sensors, can solve the problems of poor diameter dispersion of nanomaterials, large diameter variation coefficient, and insufficient sensitivity, and achieve good repeatability and recovery effects , Large compression strain, high compression sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

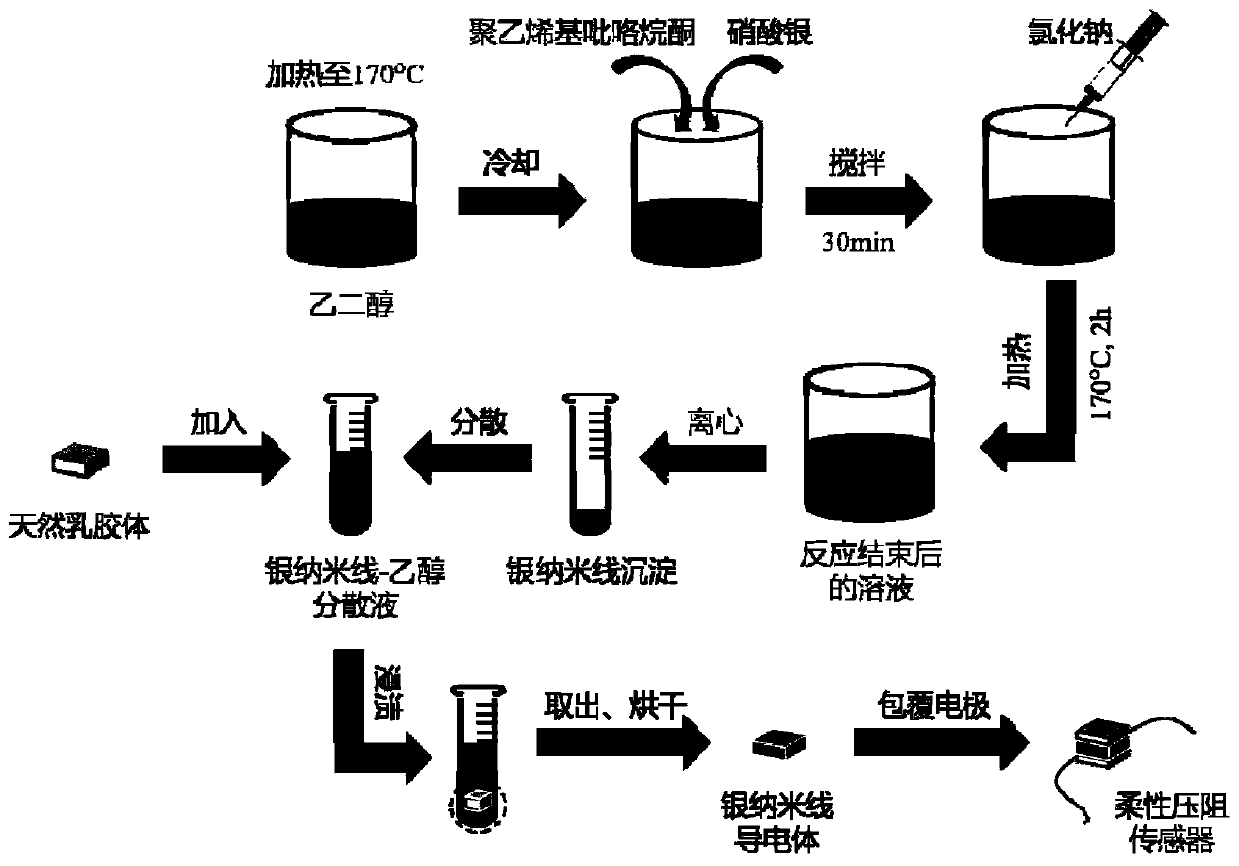

[0039] The invention relates to a preparation method and application of a pressure sensor based on silver nanowires. It has a sensitive piezoresistive effect and can be used to detect human hand movement and grip state data. It has great potential in the fields of medical treatment, sports, and health protection. application potential. A preparation method and application of a flexible piezoresistive sensor based on silver nanowires, characterized in that it comprises the following steps:

[0040] a. Silver nanowires were prepared by the classic polyol method, the synthesized precipitate was centrifuged and washed 5 times, and finally the precipitate was dispersed in a solvent to form a silver nanowire dispersion;

[0041] b. After the natural latex is pretreated, it is placed in the silver nano-dispersion liquid for dipping and coating process. After completion, it is taken out for drying process, and finally forms a three-dimensional conductor based on silver nanowires;

[...

Embodiment 1

[0047] Heat 20mL of ethylene glycol at 170°C for 30 minutes, add 0.4g of polyvinylpyrrolidone and 0.2g of silver nitrate after cooling, add 200μL of 0.1mol / L sodium chloride dropwise after stirring for 30 minutes, heat at 170°C for 2 hours, then add Acetone was centrifuged twice, ethanol was added and centrifuged three times, and the centrifugation time was 10 minutes each time. After centrifugation, 50 mL of ethanol solution was added to form a silver nanowire-ethanol dispersion. Such as Figure 5 It can be seen that the length and fineness of the synthesized silver nanowires are relatively uniform, naturally distributed in a network, and the diameters are all within 100nm, and the diameter variation coefficient is within 20%.

Embodiment 2

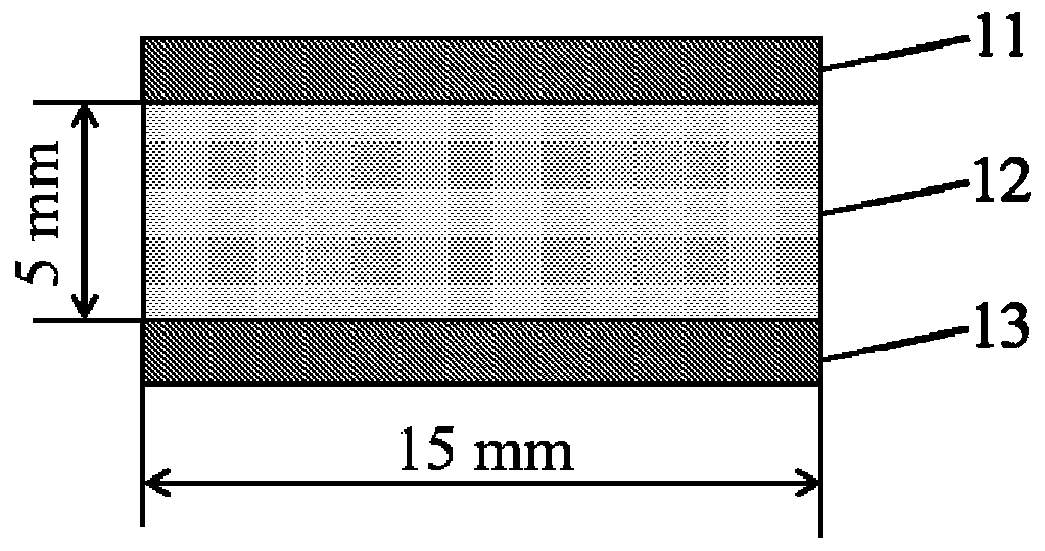

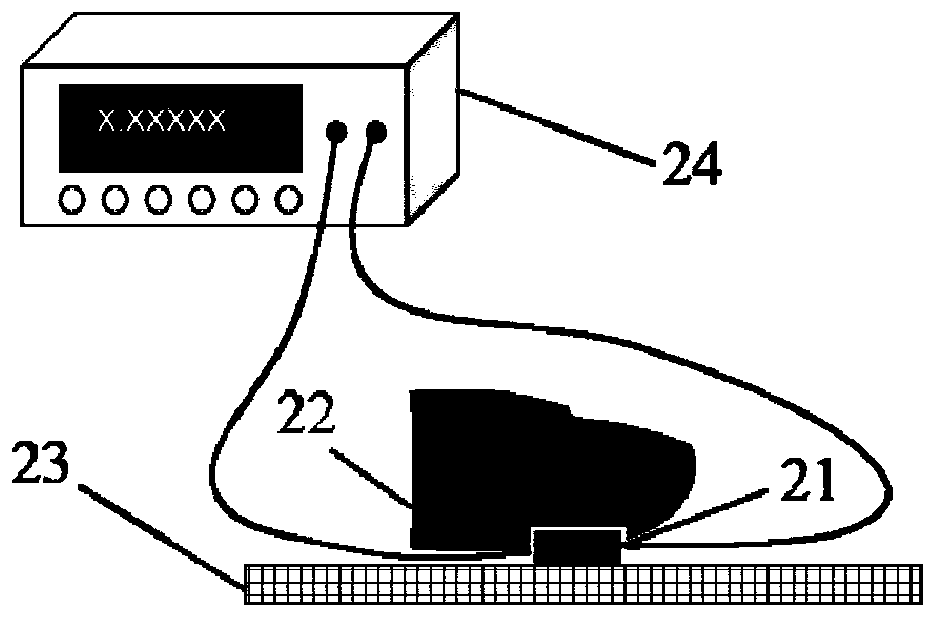

[0049] After the natural emulsion is pretreated, it is placed in the silver nano-dispersion liquid for dipping and coating process. After completion, it is taken out for drying process, and finally a three-dimensional conductor based on silver nanowires is formed. The upper and lower parts of the obtained silver nanowire three-dimensional conductor The surface is covered with an electrode layer and two wires are respectively drawn out to form a flexible piezoresistive sensor based on silver nanowires. Attach the flexible piezoresistive sensor based on silver nanowires to the finger cot, and connect the data acquisition instrument to form a sensor test system. The two wires of the sensor are respectively connected to the positive and negative ends of the data acquisition instrument. The instrument transmits the test electrical signal data, the result is as follows Image 6 Shown is the relative resistance change of the flexible piezoresistive sensor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com