Metal foam/high entropy metal glass composite material with large compressive strain and preparation method thereof

A technology of metallic glass and composite materials, which is applied in the field of high-entropy metallic glass material preparation, can solve the problems of high cost, complicated process, and high energy consumption, and achieve the effects of increasing room temperature compressive strain, simple preparation process, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The first step is to prepare a high-entropy metallic glass test rod

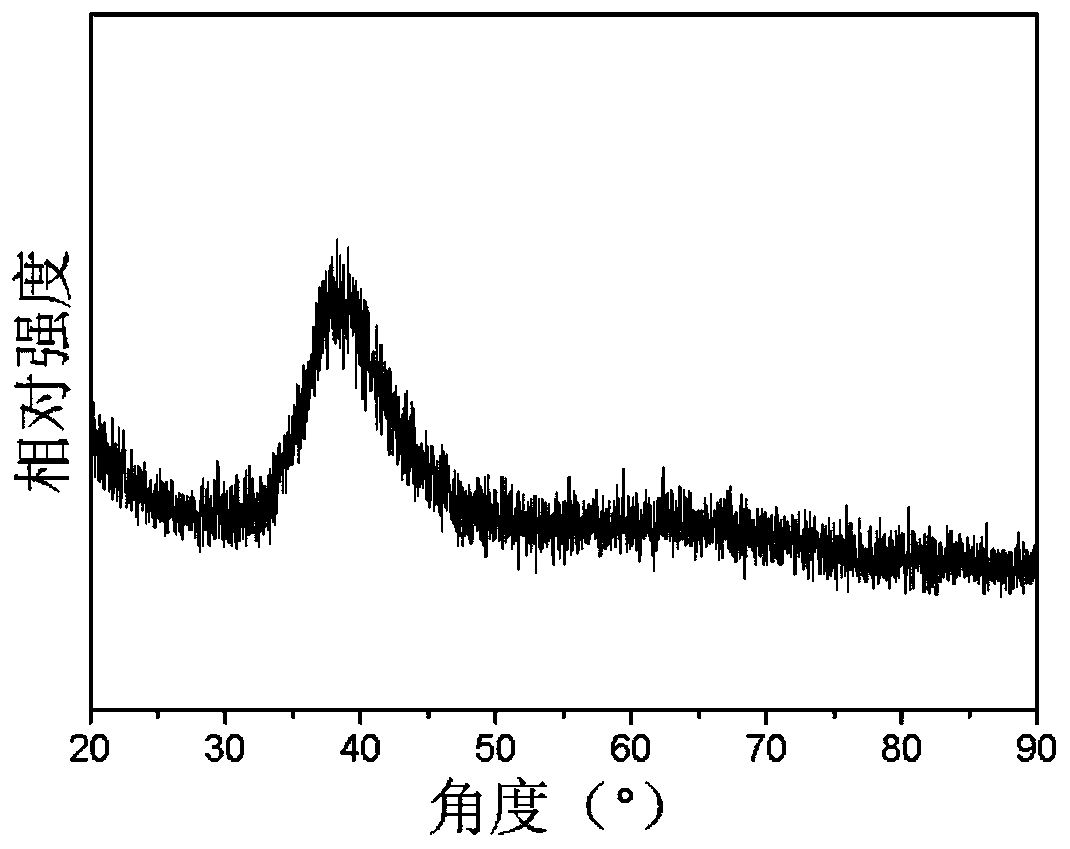

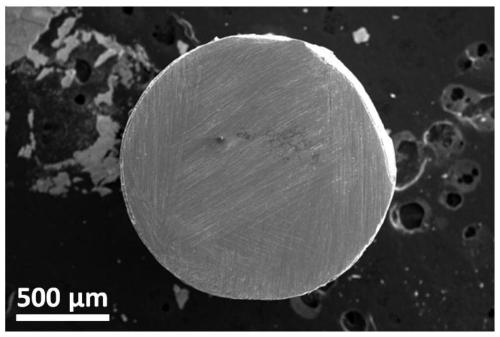

[0036] Press Ti 20 Zr 20 f 20 Cu 20 PD 20 Components (wherein, the subscript numbers are the atomic percentages of the corresponding metal elements in the alloy, the following examples are the same), respectively weigh high-purity (mass fraction greater than 99.9wt.%) Ti, Zr, Hf, Cu and Pd metals. Before smelting, control the vacuum degree in the furnace to 3.5×10 -3 MPa. The arcing current was set to 50A, and the sample was formally smelted at a current of 60A, each time the molten state was kept for 30s, and the smelting was repeated 3 times to ensure the uniformity of the composition of the alloy ingot. Finally, use the manipulator in the furnace to clamp the alloy ingot to the smelting and suction casting station, increase the current to 100A, and suck the molten metal into the copper mold under the suction casting pressure of 0.1MPa to obtain a Ti alloy with a diameter of 1mm. 20 Zr 20 f...

Embodiment 2

[0041] The first step, smelting and suction casting to prepare high-entropy metallic glass test rods

[0042] Press Ti 20 Zr 20 f 20 Cu 20 PD 20 Components, respectively weigh the corresponding mass of high-purity (mass fraction greater than 99.9wt.%) Ti, Zr, Hf, Cu and Pd metals. Before smelting, control the vacuum degree in the furnace to 3.5×10 -3 MPa. The arcing current was set to 50A, and the sample was formally smelted at a current of 70A, each time the molten state was kept for 35s, and the smelting was repeated 3 times to ensure the uniformity of the composition of the alloy ingot. Finally, use the manipulator in the furnace to clamp the alloy ingot to the smelting and suction casting station, increase the current to 110A, and suck the molten metal into the copper mold under the suction casting pressure of 0.15MPa to obtain a Ti alloy with a diameter of 1.5mm. 20 Zr 20 f 20 Cu 20 PD 20 High-entropy metallic glass test rod;

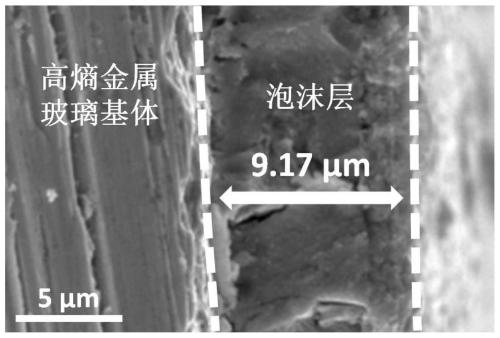

[0043] The second step, dealloyi...

Embodiment 3

[0048] The first step, smelting and suction casting to prepare high-entropy metallic glass test rods

[0049] Press Ti 20 Zr 20 f 20 Cu 20 PD 20 Components, respectively weigh the corresponding mass of high-purity (mass fraction greater than 99.9wt.%) Ti, Zr, Hf, Cu and Pd metals. Before smelting, control the vacuum degree in the furnace to 3.5×10 -3 MPa. The arcing current was set to 50A, and the sample was formally smelted at a current of 80A, each time the molten state was kept for 40s, and the smelting was repeated 3 times to ensure the uniformity of the composition of the alloy ingot. Finally, use the manipulator in the furnace to clamp the alloy ingot to the smelting and suction casting station, increase the current to 120A, and suck the molten metal into the copper mold under the suction casting pressure of 0.2MPa to obtain a Ti alloy with a diameter of 1.5mm. 20 Zr 20 f 20 Cu 20 PD 20 High-entropy metallic glass test rod;

[0050] The second step, dealloyin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com