Elastic telescopic fender

An elastic expansion and fender technology, applied in shipping equipment, climate change adaptation, etc., can solve the problems of high reaction force, consumption of manpower and material resources, air leakage, etc., and achieve the effect of improving service life and excellent compression recovery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

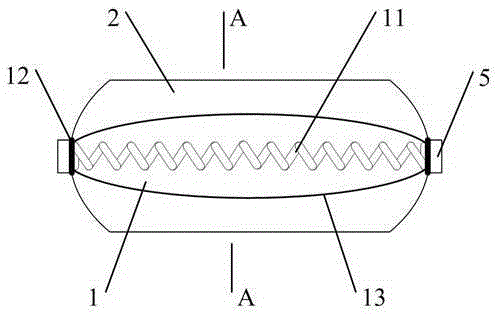

[0014] The present invention will be further described below in conjunction with accompanying drawing.

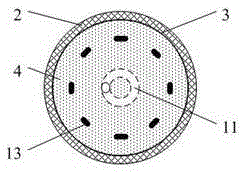

[0015] Such as figure 1 and figure 2 As shown, the present invention provides an elastic telescopic fender, comprising an elastic telescopic shaft 1, a wear-resistant layer 2, a reinforced layer 3, and a rubber foam layer 4; the elastic telescopic shaft 1, the reinforced layer 3 and the wear-resistant layer 2 sequentially Inside-out coaxial package arrangement, rubber foam material is filled between the reinforcement layer 3 and the elastic telescopic shaft 1 to form a rubber foam layer 4, flanges 5 are installed at both ends of the elastic telescopic shaft 1.

[0016] Such as figure 2 As shown, the elastic telescopic shaft 1 includes a spring 11, a connecting plate 12 arranged at both ends of the spring 11, and a plurality of arcuate elastic pieces 13. The arcuate elastic pieces 13 form a cage structure around the spring 11 along the length direction of the spring 11. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com