A resistance type fire detection/early warning sensor and its application

An early warning sensor and fire detection technology, which is applied in the direction of electric fire alarms, etc., can solve the problems of fire alarm influence, fast spreading, poor penetration ability, etc., and achieves low price, simple preparation method and easy availability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

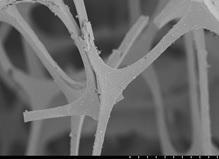

[0030] Soak 25mg of melamine foam in 1mg / ml graphene oxide aqueous solution prepared with graphite as raw material, take it out and centrifuge at 3000rpm for 5 minutes, and then bake at 80°C for 3h. Repeat the experiment several times until 8 mg of graphene oxide is dip-coated on the melamine foam. Then immerse it in a 0.5mg / ml n-octyltriethoxysilane modified dual-scale (10nm and 200nm) nano-silica (mass ratio 1:1 mixed) tetrahydrofuran dispersion at 3000 rpm for 5 minutes, Then bake at 80°C for 3h. This is repeated many times until 67 mg of modified superhydrophobic particles are dip-coated on the graphene oxide / melamine foam composite material to obtain a fire detection / early warning composite material 1.

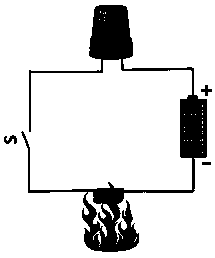

[0031] Connect dry batteries, warning lights, and the fire detection / early warning composite material 1 prepared in Example 1 through wires, such as figure 1 As shown, a resistance type fire detection / early warning sensor 1 is obtained.

Embodiment 2

[0033] Soak 45 mg of melamine foam in a 1 mg / ml graphene oxide aqueous solution prepared with carbon nanotubes as raw materials, take it out and centrifuge at 500 rpm for 10 minutes, and then bake at 80°C for 3 hours. Repeat the experiment several times until 40 mg of graphene oxide is dip-coated on the melamine foam. Then immerse it in a 0.5mg / ml n-octyltriethoxysilane-modified two-scale (10nm and 200nm) nano-silica (mass ratio 1:1 mixing) tetrahydrofuran dispersion and centrifuge at 500rpm for 10 minutes, Then bake at 80°C for 3h. This is repeated many times until 15 mg of modified super-hydrophobic particles are dip-coated on the graphene oxide / melamine foam composite material, a fire detection / early warning composite material 2.

[0034] Connect dry batteries, warning lights, and the fire detection / early warning composite material 2 prepared in Example 2 through wires, such as figure 1 As shown, a resistance type fire detection / early warning sensor 2 is obtained.

Embodiment 3

[0036] 35mg of melamine foam was immersed in 1mg / ml graphene oxide aqueous solution prepared with carbon nanofiber as raw material, taken out and centrifuged at 5000rpm for 2 minutes, and then baked at 80°C for 3h. Repeat the experiment several times until 24 mg of graphene oxide is dip-coated on the melamine foam. Then immerse it in a 0.5mg / ml n-octyltriethoxysilane modified two-scale (25nm and 500nm) nanometer titanium dioxide (mixed by mass ratio of 1:1) in tetrahydrofuran dispersion at 5000 rpm for 2 minutes, then 80 Bake at ℃ for 3h. This is repeated many times until 41 mg of modified superhydrophobic particles are dip-coated on the graphene oxide / melamine foam composite material, a fire detection / early warning composite material3.

[0037] Connect dry batteries, warning lights, and the fire detection / early warning composite 3 prepared in Example 3 through wires, such as figure 1 As shown, a resistance type fire detection / early warning sensor 3 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com