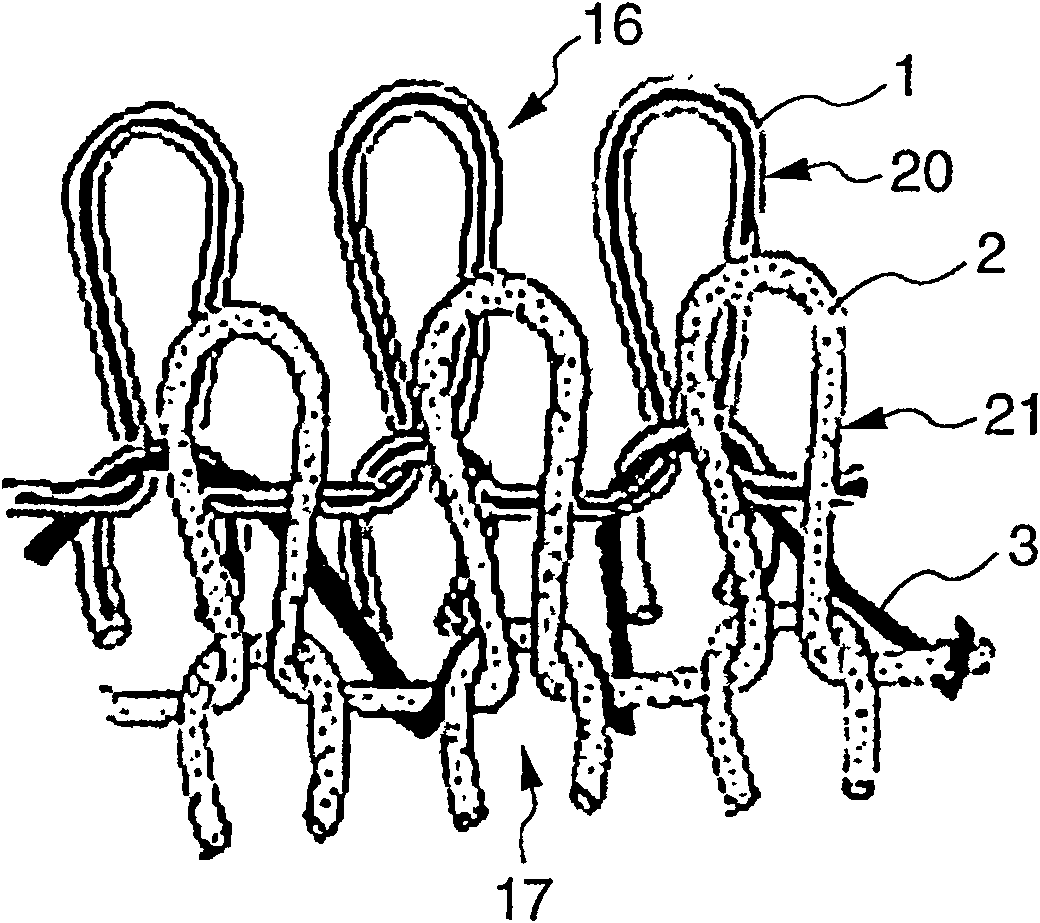

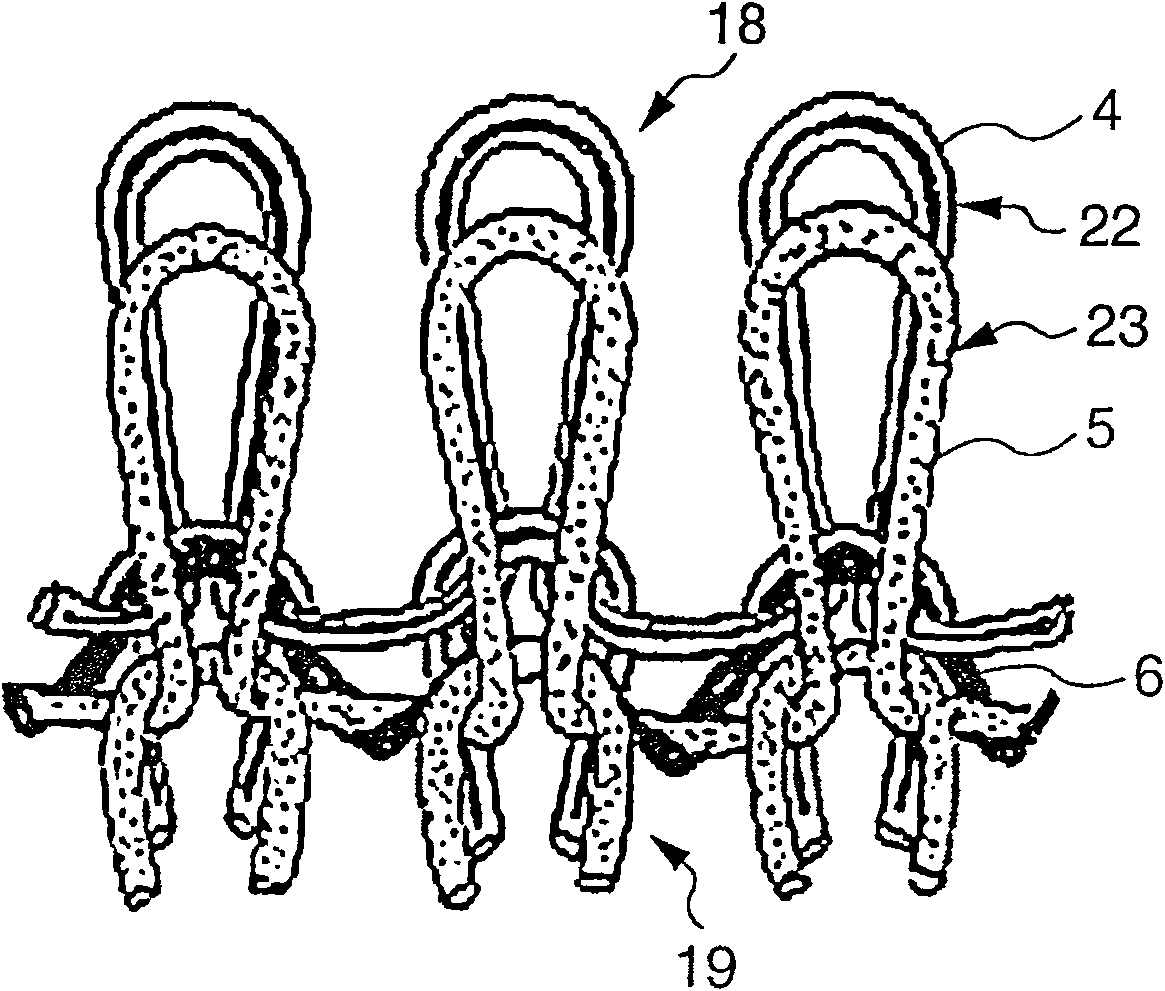

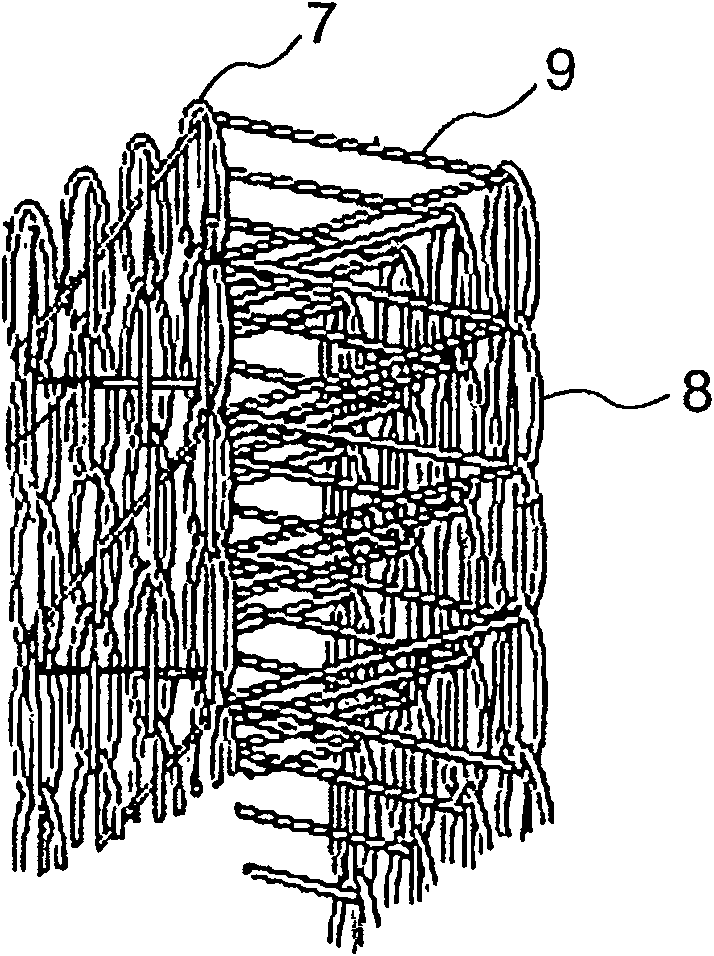

Elastic knitting fabric having multilayer structure and method for producing the fabric

A multi-layer structure, knitted fabric technology, applied in the direction of knitting, weft knitting, warp knitting, etc., can solve the problems of unsatisfactory balance, uncontrolled curl, troublesome and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] A kind of polyester fiber false twist processing yarn (Technofine Manufactured by Asahi Kasei Co., Ltd.) is used as the yarn of the front and back bottom knitting fabrics of three-dimensional knitted fabrics to make the knitted fabrics form jersey stitches. A bare filament of 155 dtex polyurethane-based elastic fibers (by Roica Manufactured by Asahi Kasei Co., Ltd.) is used as the yarn that connects the front and back bottom knitted fabrics.

[0128] Link knitting was performed with all the needle operations of a 60-hole double-sided double-needle circular knitting machine (V-LEV6 type, manufactured by Fukuhar Works Co., Ltd.) with a row pitch of 28 and a diameter of 30 inches to obtain a unit Circular knitted fabric with the distance between patterns set to 4 mm. At this time, the loop length of the bare polyurethane-based elastic fiber was 800 cm, and the loop length of the knitted fabric constituting the front and back bottom knitted fabric was 827 cm. As a result...

Embodiment 2

[0132] The inner and outer bottom knitted fabrics of the three-dimensional knitted fabric are knitted in the same manner as in Example 1. A kind of bare silk (Roica Manufactured by Asahi Kasei Co., Ltd.) is used as the yarn that connects the front and back bottom knitted fabrics. At this point, link knitting is done by all knitting needles. The obtained knitted fabric is processed in the same operation flow as in Example 1. In this case, the technical parameters and weaving characteristics of weaving are shown in Table 1 and Table 2.

[0133] The obtained three-dimensional knitted fabric had a thickness of 3.12 mm, a compressibility of 55%, a recovery rate of 99.4%, an air permeability of 0.41, and a good touch. This three-dimensional knitted fabric is ideal for interior linings such as shoes, as well as materials such as bed linens.

Embodiment 3

[0135] Knitting was performed in the same manner as in Example 2, except that connection was performed using 1 / 2 of the knitting needles as connection knitting. In this case, the technical parameters and weaving characteristics of weaving are shown in Table 1 and Table 2.

[0136] The obtained three-dimensional knitted fabric had a thickness of 3.00 mm, a compressibility of 60%, a recovery rate of 97.4%, an air permeability of 0.55, and a good touch. This three-dimensional knitted fabric is ideal for interior linings such as shoes, as well as materials such as bed linens.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com