Super-hydrophobic organic silicon aerogel as well as normal-temperature and normal-pressure drying preparation method and application thereof

An atmospheric drying and super-hydrophobic technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems that airgel does not have hydrophobic function, the cost of preparation process is high, and needs further improvement, etc., to achieve Good for large-area preparation, excellent superhydrophobic and lipophilic properties, and excellent compression recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

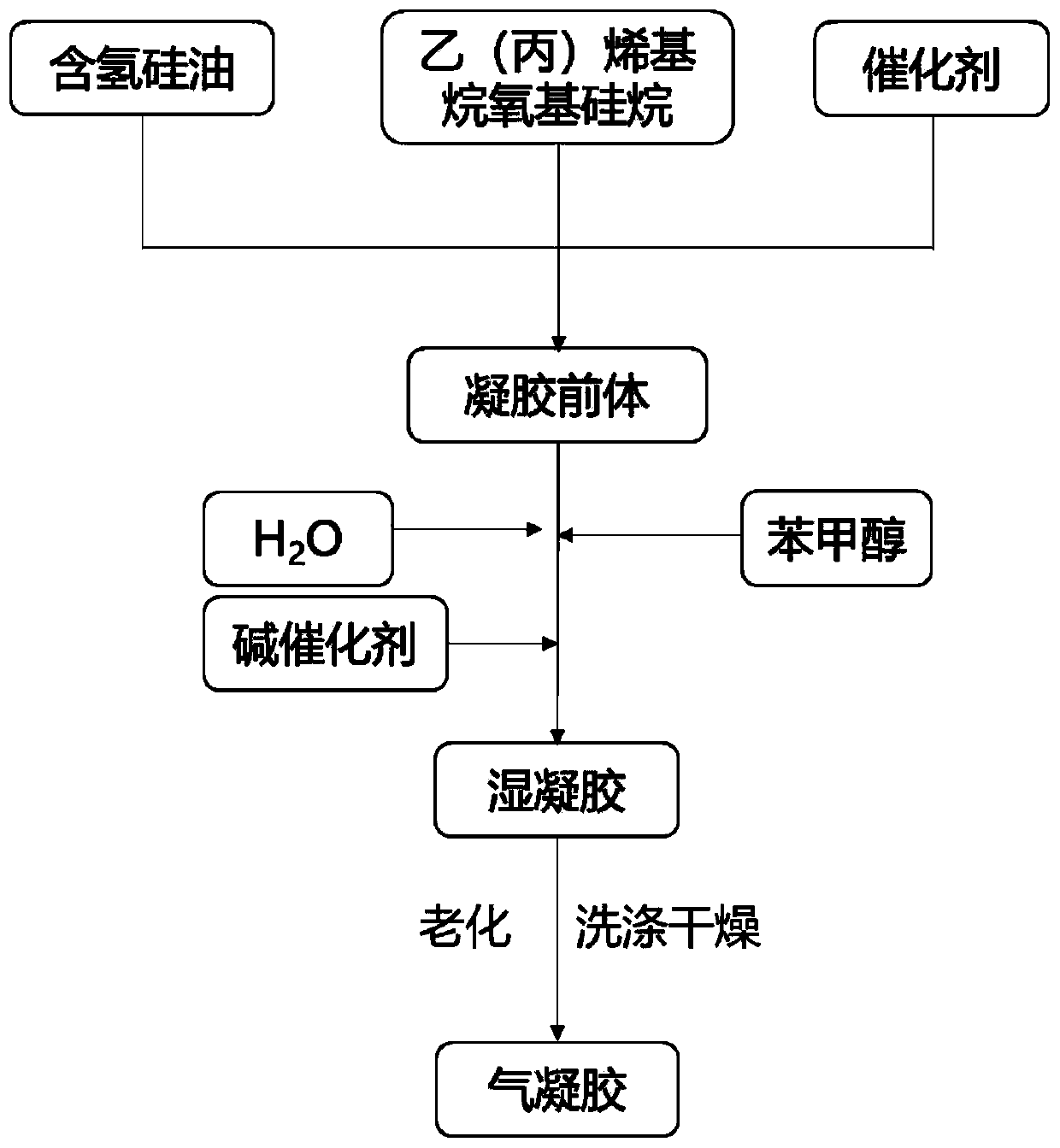

[0045] The process flow of the normal temperature and pressure drying preparation method of the superhydrophobic organosilicon aerogel of the present invention is as follows figure 1 shown, including steps:

[0046] (1) After mixing hydrogen-containing silicone oil, component A and catalyst, heat at 40-70°C to obtain a gel precursor; the component A is vinylalkoxysilane and / or propenylalkoxysilane;

[0047] (2) Adding an organic solvent (such as benzyl alcohol), water and an alkali catalyst to the gel precursor, stirring evenly, and keeping it warm at 70-90° C. to obtain a wet gel;

[0048] (3) Wash the wet gel with a washing solvent to remove the original solvent and unreacted molecules, then wash the wet gel again with a low surface energy solvent, and finally dry at normal temperature and pressure to obtain the superhydrophobic silicone airgel.

Embodiment 1

[0050] (1) Add 2.6g of hydrogen-containing silicone oil with a hydrogen content of 0.75wt%, 3.1g of vinylmethyldimethoxysilane and 0.2g of catalyst into the container and stir evenly, and put it in an oven at 50°C for 20min to allow the reaction fully carried out.

[0051] (2) Cool the reactant obtained in step (1) to room temperature, add 1.2g of water, 60g of benzyl alcohol and 0.2g of tetramethylammonium hydroxide, stir well and put it into an oven at 80°C for gel aging for 2 days.

[0052] (3) Replace the gel obtained in step (2) in isopropanol solvent for 3 times, each time for 8 hours, to replace unreacted molecules, and then replace it with n-hexane solvent for 3 times, each time for 8 hours, after the replacement is completed The superhydrophobic silicone airgel can be obtained by drying at normal temperature and pressure.

[0053] The density of the superhydrophobic silicone airgel obtained in Example 1 is 78 mg cm -3

[0054] figure 2 It is a photo of the airgel...

Embodiment 2

[0060] (1) Add 2.0g of hydrogen-containing silicone oil with a hydrogen content of 1.0wt%, 3.1g of vinylmethyldimethoxysilane and 0.2g of catalyst into the container and stir evenly, and put it in an oven at 50°C for 20min to allow the reaction fully carried out.

[0061] (2) Cool the reactant obtained in step (1) to room temperature, add 1.2g of water, 60g of benzyl alcohol and 0.3g of tetramethylammonium hydroxide, stir well, and put it into an oven at 80°C for gel aging for 2 days.

[0062] (3) See step (3) in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com