EPDM/ natural rubber combined ageing-resistant rubber and preparation method thereof

A natural rubber, aging-resistant technology, applied in the production of bulk chemicals, etc., can solve the problems of low heat resistance, low corrosion resistance to acid and alkali, easy aging and deterioration, etc., to meet performance requirements, reduce surface tension, The effect of excellent aging resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

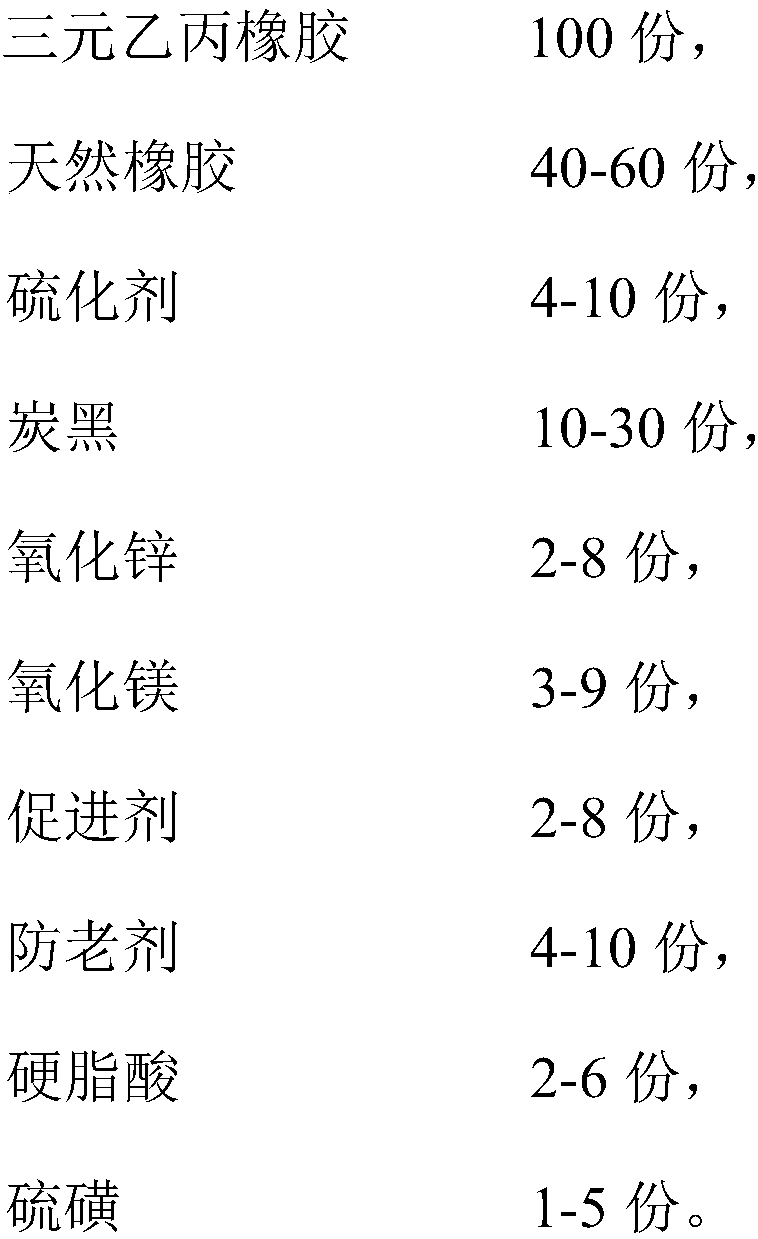

[0025] A kind of EPDM / natural rubber is combined with anti-aging rubber, and described anti-aging rubber is made up of following raw materials in parts by weight:

[0026]

[0027]

[0028] A kind of preparation method of EPDM / natural rubber combined with anti-aging rubber, comprises the following steps:

[0029] (1) Preparation of EPDM masterbatch: Add EPDM to an internal mixer and plasticize at 90°C for 3 minutes, then add stearic acid, zinc oxide and carbon black in turn and mix for 15 minutes to obtain EPDM masterbatch;

[0030] (2) Preparation of natural masterbatch: adding natural rubber to an internal mixer and plasticizing at 70°C for 3 minutes, then adding stearic acid and magnesium oxide in turn to mix for 15 minutes to obtain natural masterbatch;

[0031] (3) EPDM / natural rubber mixing: first add EPDM masterbatch, natural masterbatch, accelerator and anti-aging agent sulfur into the internal mixer for 3 minutes of intensive mixing, then add sulfur for intensiv...

Embodiment 2

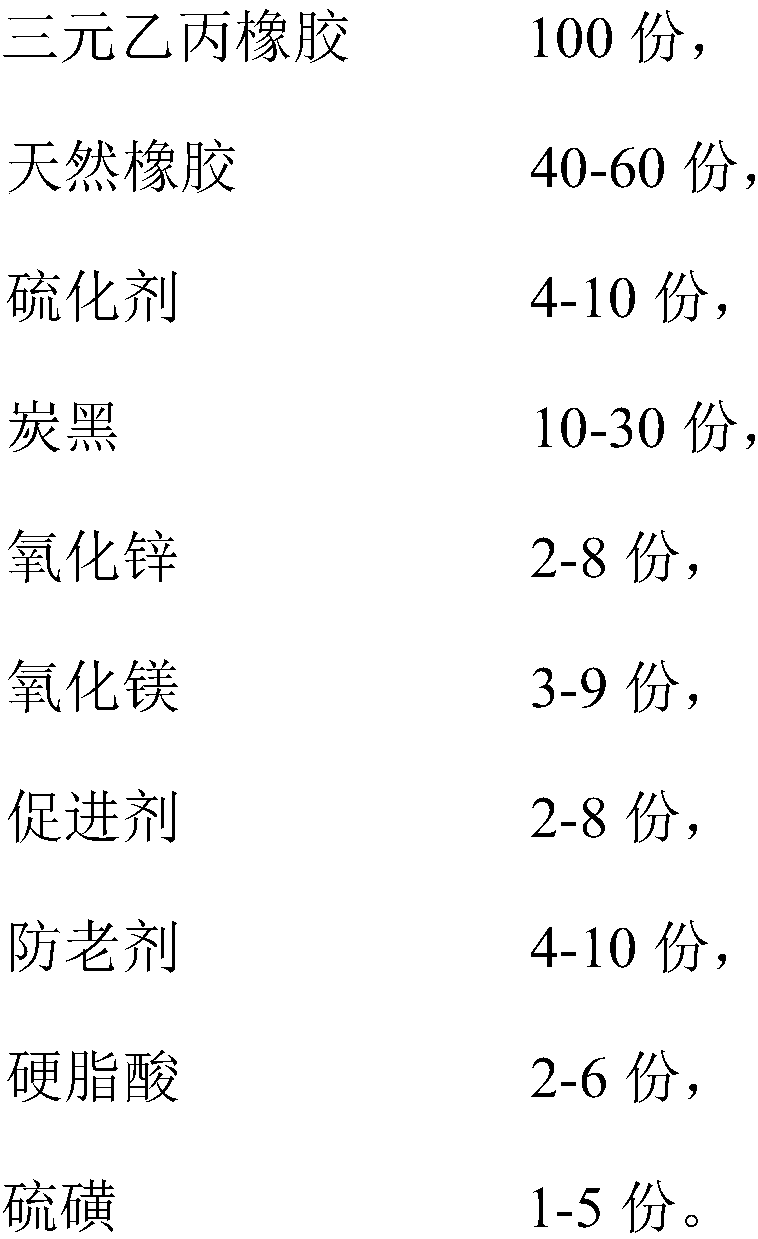

[0034] A kind of EPDM / natural rubber is combined with anti-aging rubber, and described anti-aging rubber is made up of following raw materials in parts by weight:

[0035]

[0036]

[0037] A kind of preparation method of EPDM / natural rubber combined with anti-aging rubber, comprises the following steps:

[0038] (1) Preparation of EPDM masterbatch: Add EPDM to an internal mixer and plasticize at 80°C for 10 minutes, then add stearic acid, zinc oxide and carbon black in turn and mix for 5 minutes to prepare EPDM masterbatch;

[0039] (2) Preparation of natural masterbatch: adding natural rubber to an internal mixer and plasticizing at 60° C. for 10 minutes, then adding stearic acid and magnesium oxide in turn for 5 minutes to prepare natural masterbatch;

[0040] (3) EPDM / natural rubber mixing: first add EPDM masterbatch, natural masterbatch, accelerator and anti-aging agent sulfur into the internal mixer for 1min, then add sulfur for 4min. Extrude and cut into pellets,...

Embodiment 3

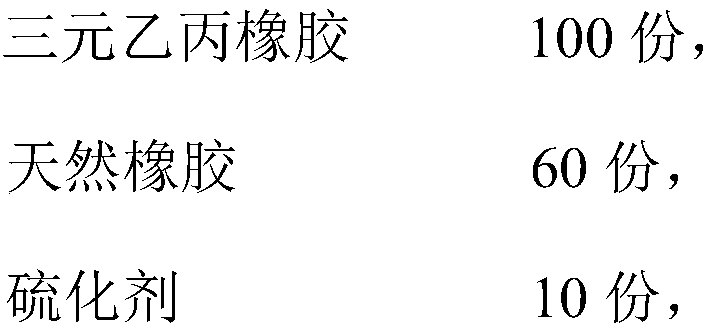

[0043] A kind of EPDM / natural rubber is combined with anti-aging rubber, and described anti-aging rubber is made up of following raw materials in parts by weight:

[0044]

[0045] A kind of preparation method of EPDM / natural rubber combined with anti-aging rubber, comprises the following steps:

[0046] (1) Preparation of EPDM masterbatch: Add EPDM to an internal mixer and plasticize at 85°C for 5 minutes, then add stearic acid, zinc oxide and carbon black in turn and mix for 12 minutes to prepare EPDM masterbatch;

[0047] (2) Preparation of natural masterbatch: add natural rubber to an internal mixer and plasticize at 65°C for 6 minutes, then add stearic acid and magnesium oxide in turn and mix for 11 minutes to obtain natural masterbatch;

[0048] (3) EPDM / Natural Rubber Mixing: First add EPDM masterbatch, natural masterbatch, accelerator and anti-aging agent sulfur into the internal mixer for 2 minutes, and then add sulfur for 10 minutes. Extrude and cut into pellets,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com