A kind of polyaniline/graphene/polyvinyl alcohol composite gel and preparation method thereof

A technology of graphene composite and polyvinyl alcohol, which is applied in the field of new materials and supercapacitors, can solve the problems of reduced specific surface area, reduced performance of composite materials, and difficult processing, and achieves mild reaction conditions, adjustable component content, and reaction Effects in simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of polyaniline / graphene / polyvinyl alcohol composite gel, its preparation method comprises the steps:

[0025] 1) Disperse 0.1g of graphene oxide and 0.1g of p-phenylenediamine in 150mL of N,N-dimethylformamide, react at 100°C for 18 hours, centrifuge, wash and dry to obtain aniline-containing oxide Graphene;

[0026] 2) Disperse 0.06 g of graphene oxide containing aniline groups and 0.06 g of aniline in 20 mL of water, and conduct a hydrothermal reaction at 180 ° C for 18 hours to obtain a polyaniline / graphene composite gel;

[0027] 3) Immerse 0.15 g of the obtained polyaniline / graphene composite gel in a polyvinyl alcohol solution with a volume of 30 mL and a concentration of 20 mg / mL at 80 ° C, and then cycle freezing and thawing at -50 ° C and room temperature for 10 times to obtain polyaniline / graphene / polyvinyl alcohol composite gel.

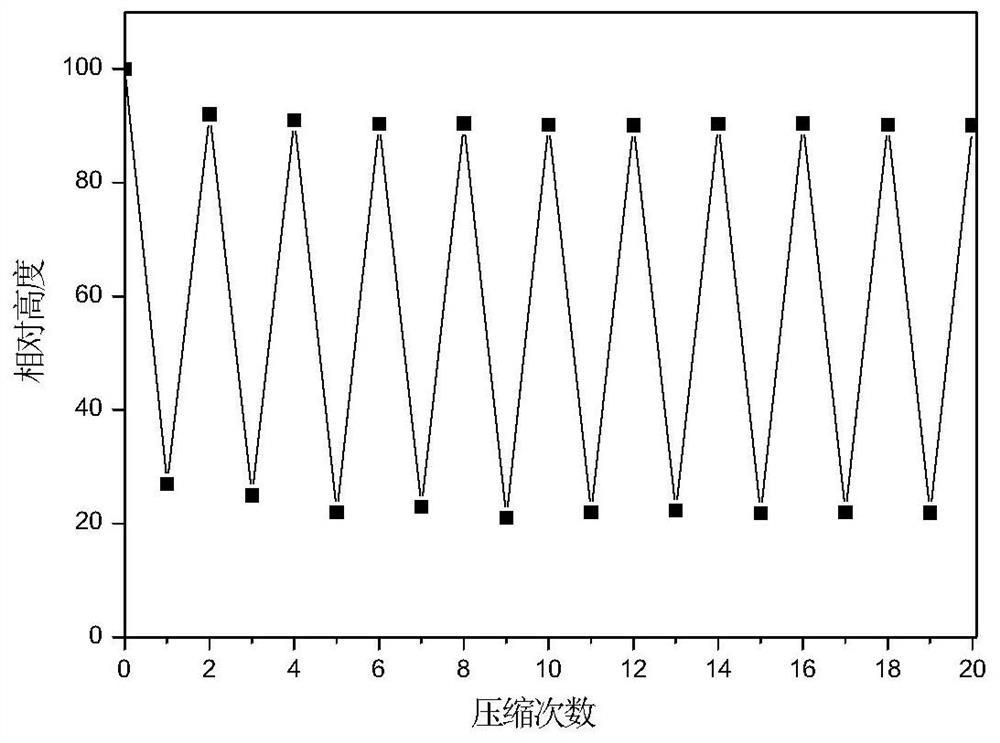

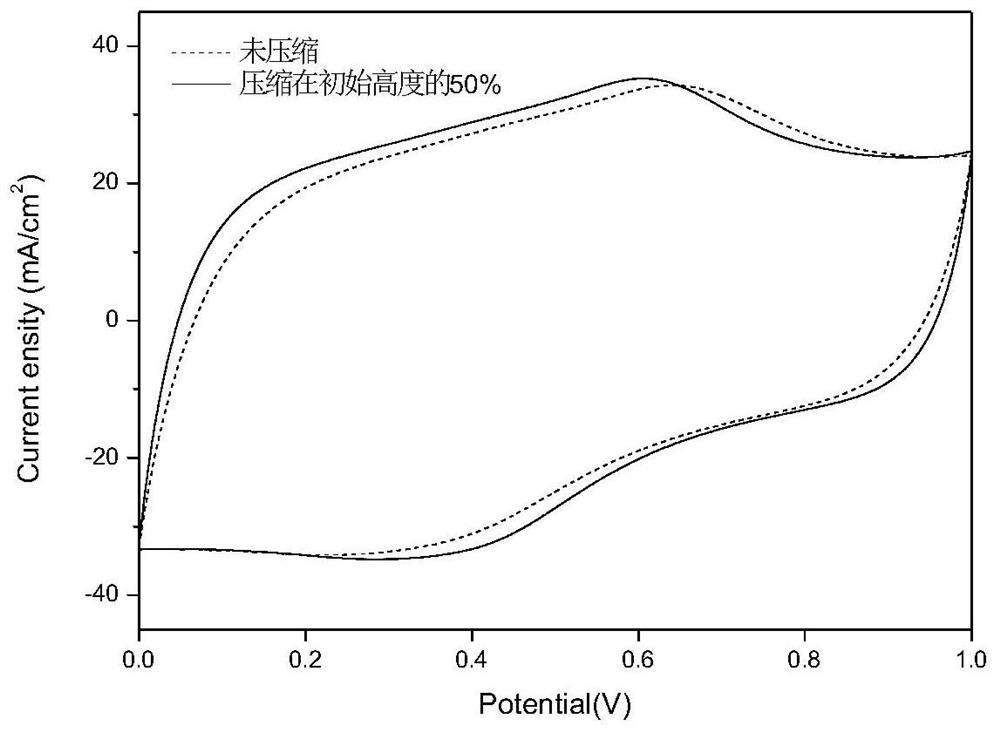

[0028] figure 1 It is the test result of the height retention of the composite gel obtained in this embodiment after be...

Embodiment 2

[0030] A kind of polyaniline / graphene / polyvinyl alcohol composite gel, its preparation method comprises the steps:

[0031] 1) Disperse 0.15g of graphene oxide and 0.2g of p-phenylenediamine in 200mL of N,N-dimethylformamide, react at 105°C for 24 hours, centrifuge, wash and dry to obtain aniline-containing oxide Graphene;

[0032] 2) Disperse 0.1 g of graphene oxide containing aniline groups and 0.15 g of aniline in 30 mL of water, and conduct a hydrothermal reaction at 165 ° C for 20 h to obtain a polyaniline / graphene composite gel;

[0033] 3) Immerse 0.2 g of the obtained polyaniline / graphene composite gel in a polyvinyl alcohol solution with a volume of 35 mL and a concentration of 50 mg / mL at 85 ° C, and then cycle freezing and thawing at -30 ° C and room temperature for 5 times to obtain polyaniline / graphene / polyvinyl alcohol composite gel.

Embodiment 3

[0035] A kind of polyaniline / graphene / polyvinyl alcohol composite gel, its preparation method comprises the steps:

[0036] 1) Disperse 0.35g of graphene oxide and 0.4g of p-phenylenediamine in 350mL of N,N-dimethylformamide, react at 105°C for 30 hours, centrifuge, wash, and dry to obtain aniline-containing oxide Graphene;

[0037] 2) Disperse 0.15 g of graphene oxide containing aniline groups and 0.2 g of aniline in 40 mL of water, and conduct a hydrothermal reaction at 195 ° C for 12 hours to obtain a polyaniline / graphene composite gel;

[0038] 3) Immerse 0.35 g of the obtained polyaniline / graphene composite gel in a polyvinyl alcohol solution with a volume of 40 mL and a concentration of 100 mg / mL at 90 ° C, and then cycle freezing and thawing at -30 ° C and room temperature for 12 times to obtain polyaniline / graphene / polyvinyl alcohol composite gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com