Nano zero-valent iron with montmorillonite serving as carrier, and preparation method and application thereof

A nano-zero-valent iron and montmorillonite technology, applied in the field of nanomaterials, can solve the problems of underutilized surface, reduced reactivity and utilization efficiency, underutilized and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

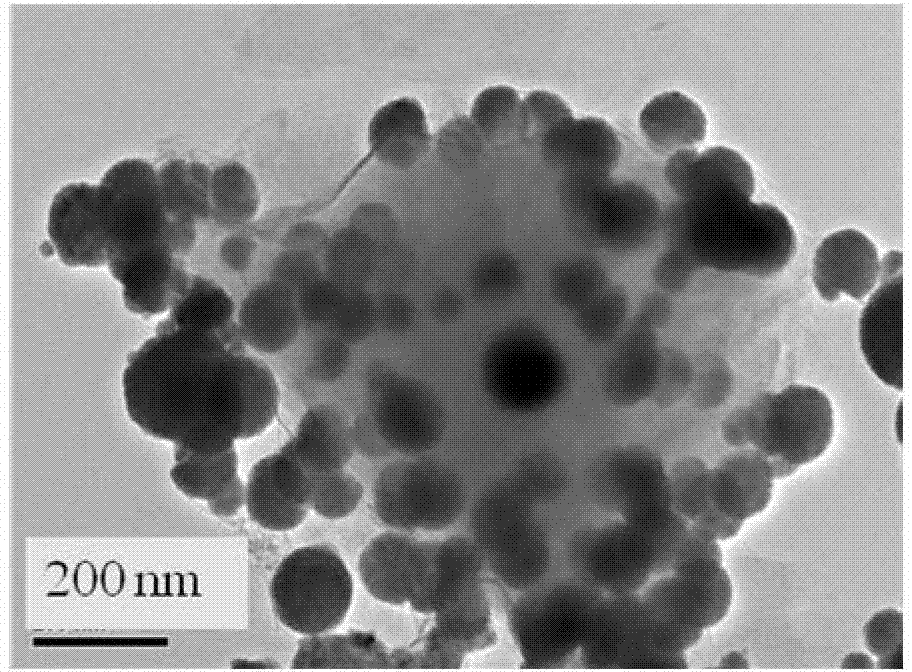

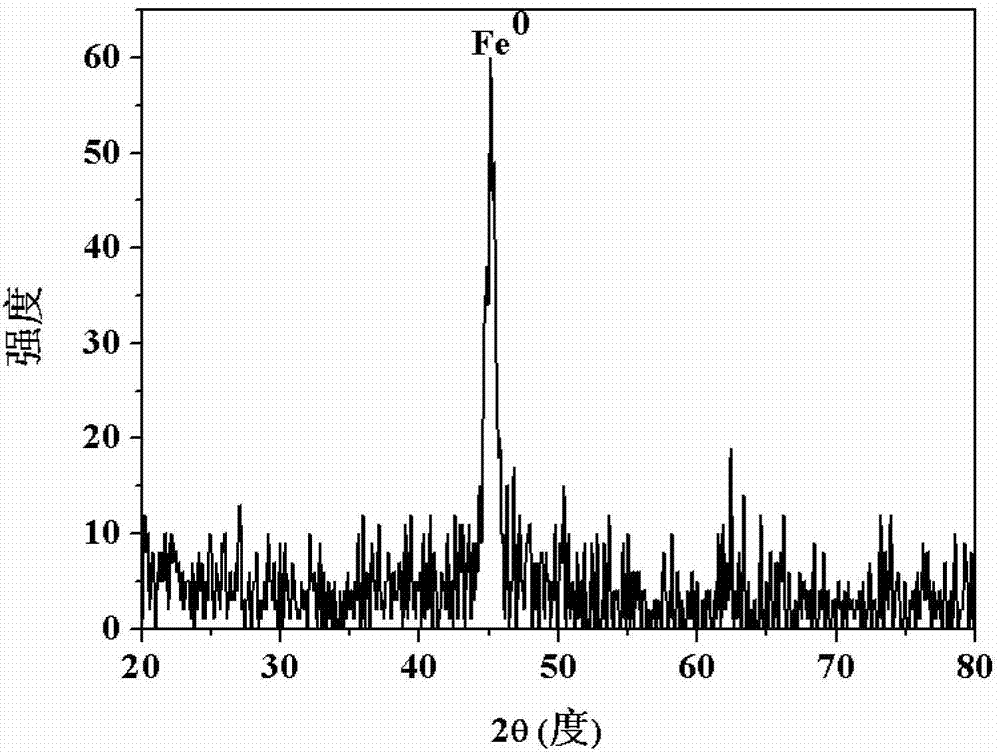

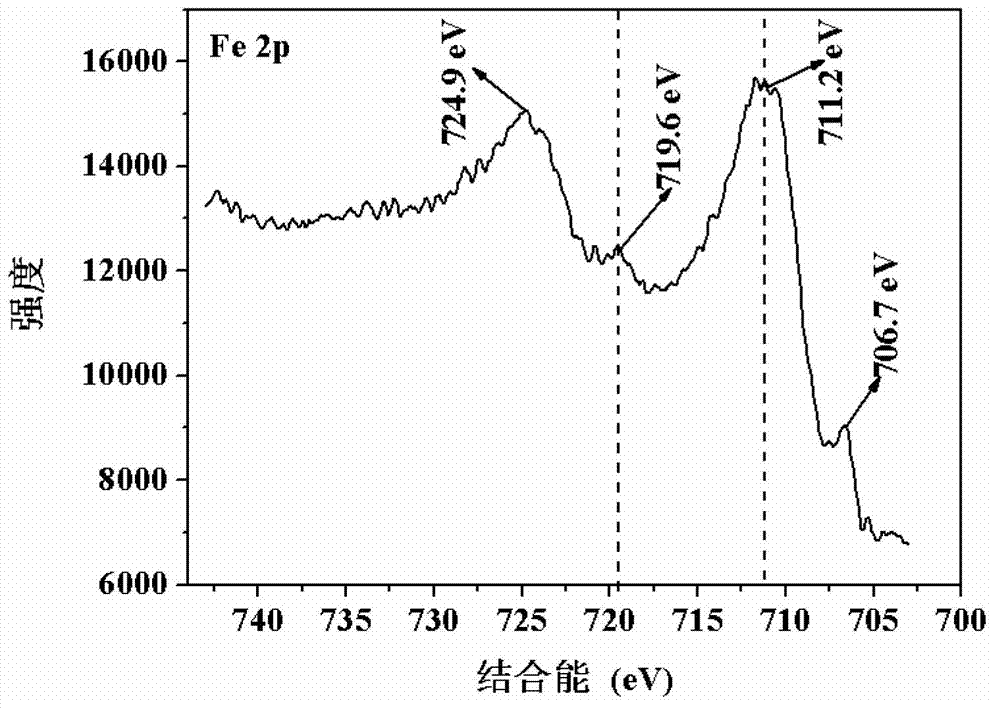

[0045] Preparation of nanometer zero-valent iron with montmorillonite as carrier:

[0046] (1) Ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) 20 g was dissolved in 100 mL of deionized water, and 0.7 g of soluble starch, 50 mL of absolute ethanol and 4 g of montmorillonite particles were added to the ferrous sulfate heptahydrate solution to obtain a mixed solution;

[0047] (2) Ultrasonic disperse the mixed solution at 250W for 12min, then pass argon gas into the mixed solution at 0.6mL / min and stir at 1050r / min for 5h to obtain the precursor solution;

[0048] (3) Dissolve 9g of sodium borohydride in 100mL of deionized water, pass argon gas into the precursor solution at 0.6mL / min and stir at 1050r / min, and at the same time, dissolve the obtained sodium borohydride solution at 0.005mL / s Add at a high speed, and then stir for 1 hour after the addition, separate the black product obtained from the reaction from the liquid phase, wash the black product alternately with deionized...

Embodiment 2

[0054] First prepare potassium saturated montmorillonite particles:

[0055] Pour 250 mL of 0.5 mol / L KCl solution into a bottle containing 20 g of montmorillonite, shake and mix at 180 rpm in a shaking box for 9.5 hours, centrifuge at 4000 rpm in a centrifuge for 25 minutes, and pour out the supernatant;

[0056] Add 250 mL of 0.5 mol / L KCl solution to the solid particles in the lower layer, shake and mix at 180 rpm for 9.5 hours in a shaking box, centrifuge at 4000 rpm for 25 minutes in a centrifuge, repeat 3 times, and obtain pre-potassium saturated montmorillonite;

[0057] Add 250mL of deionized water to the obtained pre-potassium saturated montmorillonite, shake and mix it at 180rpm in a shaking box for 9.5h, then centrifuge at 4000rmp in a centrifuge for 25 minutes, and repeatedly centrifuge and wash until it is washed with 0.2mol / L AgNO 3 The solution does not detect Cl in the centrifuged supernatant - After freeze-drying, the obtained solid is potassium-saturated mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com