Patents

Literature

67results about How to "Strong extrusion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biology base polymer aerogel oil absorption material and preparation method thereof

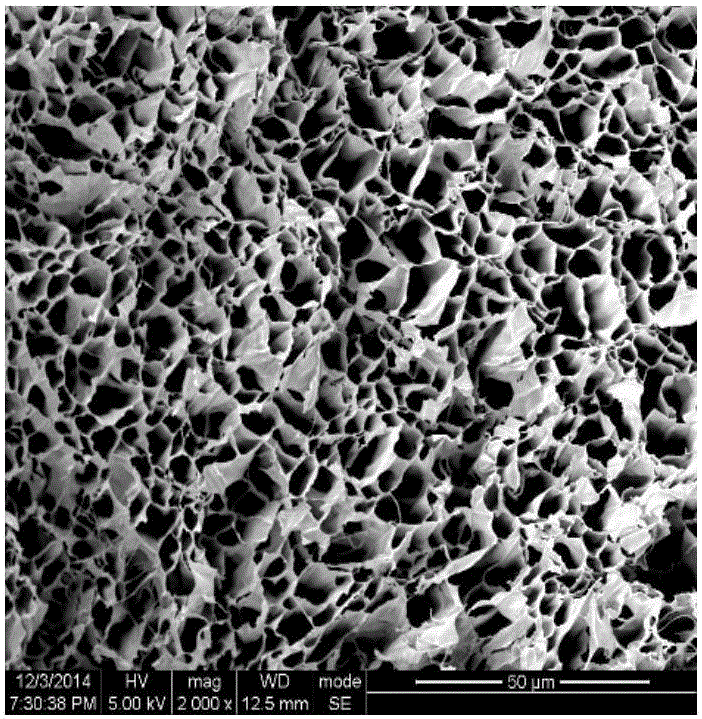

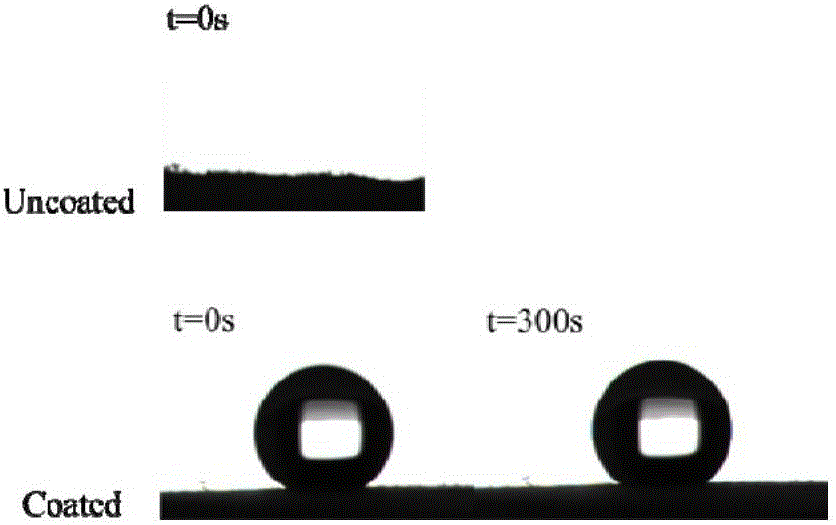

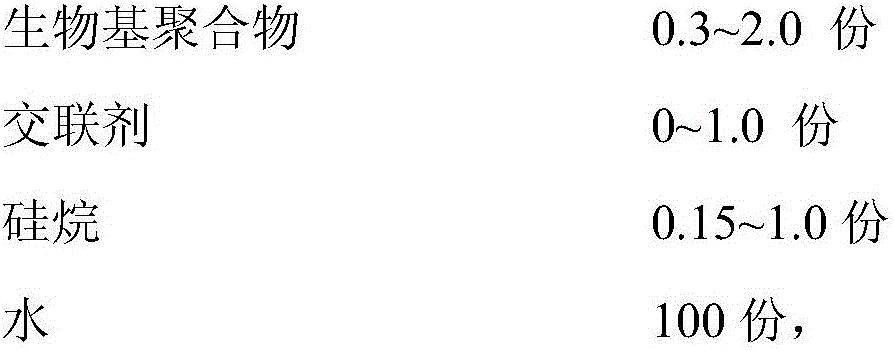

The invention discloses a biology base polymer aerogel oil absorption material. The oil absorption material is prepared by the following steps: at first, crosslinking biology base polymers by a crosslinking agent, to obtain a precursor liquid, then freeze-drying the precursor liquid to obtain aerogel, and finally grafting silane onto the aerogel surface to obtain the hydrophobic biology base polymer aerogel oil absorption material. The density of the oil absorption material is 3.8 to 23.1 kg / m3. The water contact angle is at least 117.8 degrees. The adsorption capacities on gasoline, paraffin oil, chloroform, and crude oil are 30.5-109.0 g / g, 33.2-131.2 g / g, 58.2-163.0 g / g, and 24.7-95.8 g / g. After 50 times of gasoline adsorption-extrusion circulation, the retention rate of adsorption capacity is 43 to 99%. The disclosed aerogel oil absorption material has the advantages of large oil absorption capacity and high oil absorption efficiency. Moreover, the oil absorption material can be repeatedly used by simply extruding the oil absorption material, while a high retention rate of adsorption capacity can be maintained. At the same time, the raw material sources are wide, the raw materials are cheap and easily available, the preparation is simple, the technology is matured, the method is environment-friendly, and the requirements of sustainable development can be met.

Owner:SICHUAN UNIV

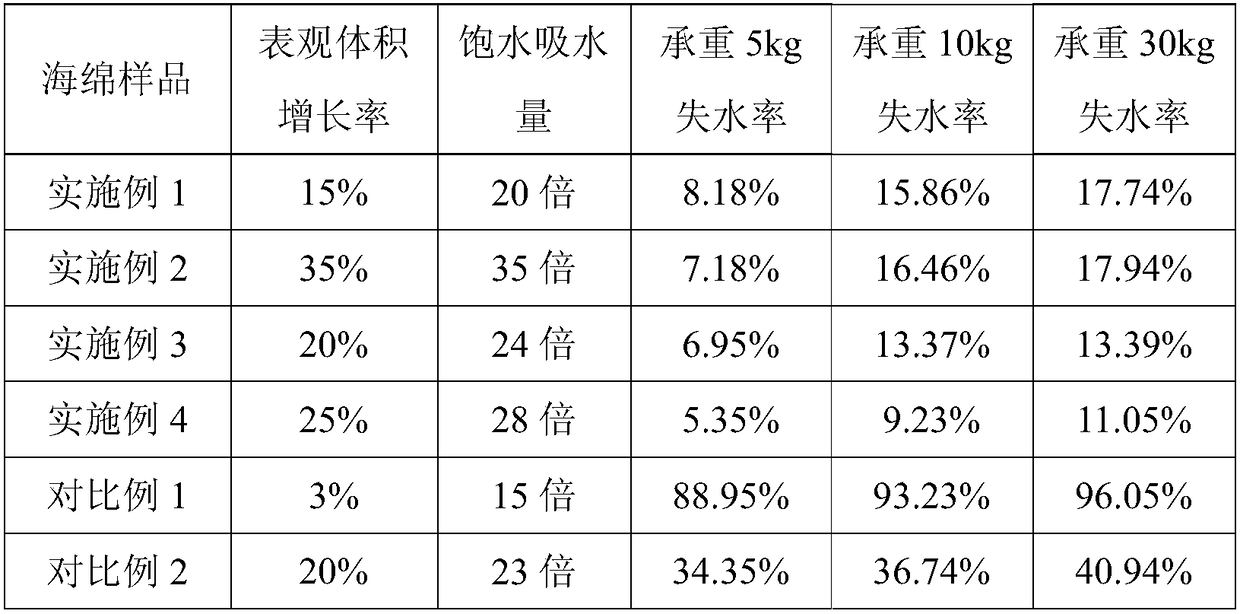

Water-locking sponge as well as preparation method and application thereof

The invention relates to a water-locking sponge as well as a preparation method and application thereof. The water-locking sponge comprises sponge and a water-absorbing resin filled in a foam skeletonof the sponge. The preparation method comprises the following steps: (1) mixing foaming resin and a foaming assistant to obtain a foaming mixture; (2) dispersing dry water-absorbent resin in the foaming mixture obtained in step (1); and (3) foaming the mixture obtained in step (2) to obtain the water-locking sponge. The water-locking sponge provided by the invention integrates the advantages of sponge and water-absorbing resin, achieves the effect that one plus one is greater than two, obtains a composite water-locking sponge with a high water-locking rate, and has strong extrusion resistance. The preparation method of the water-locking sponge has strong operability, strong adjustability and high universality.

Owner:SHANGHAI GEL KING INSULATION PROD +1

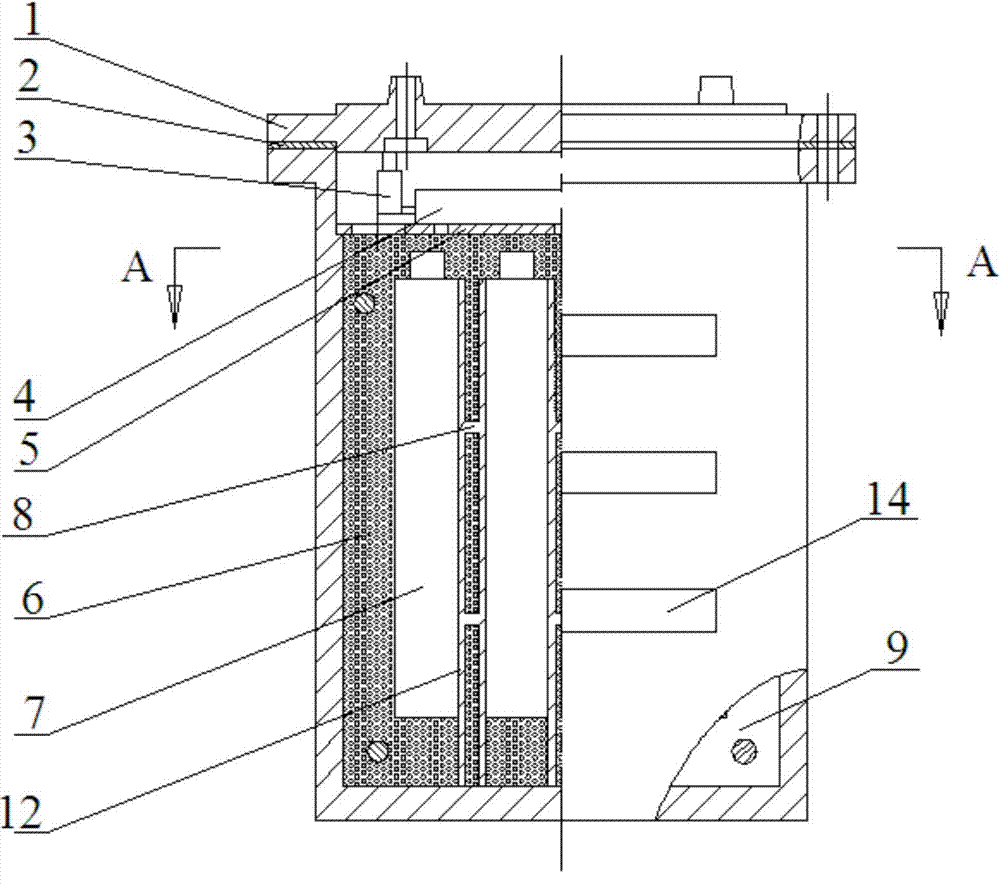

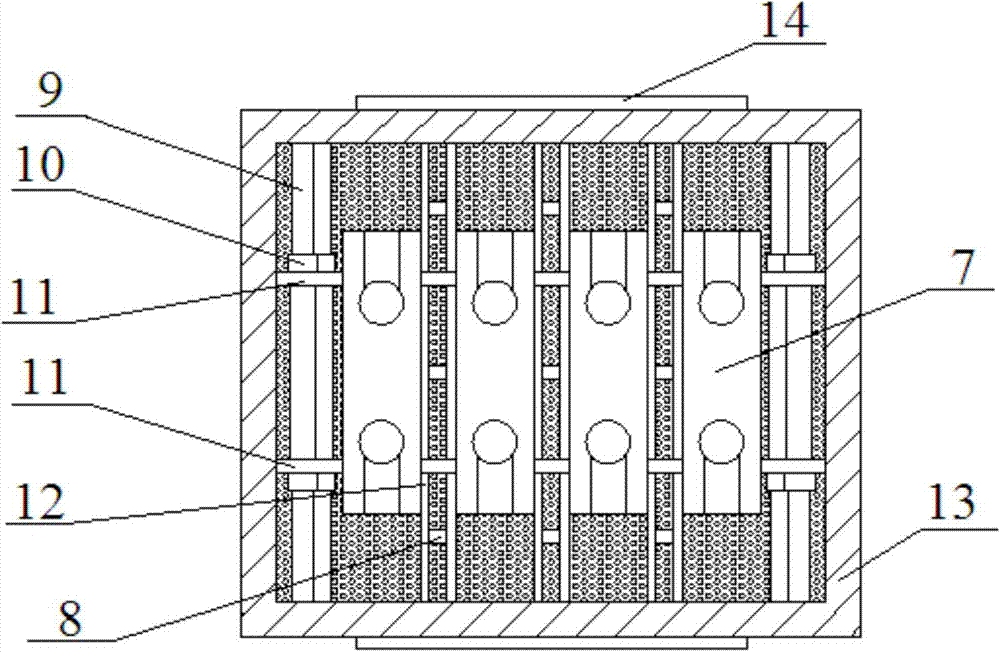

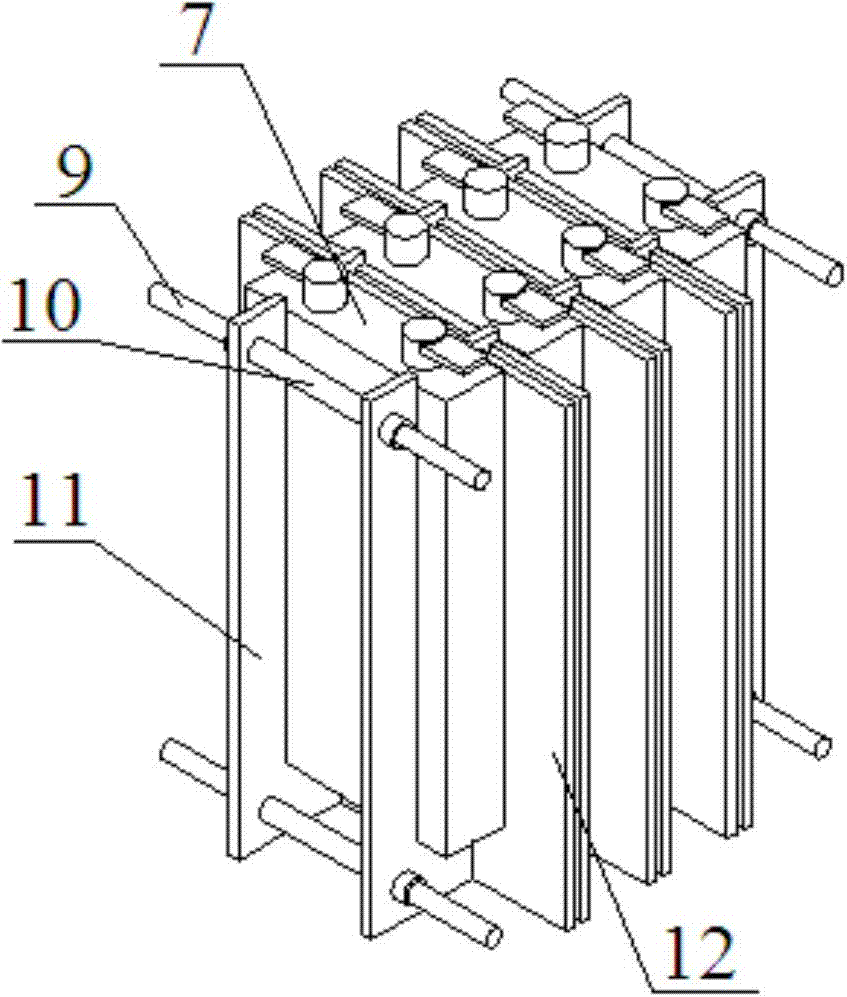

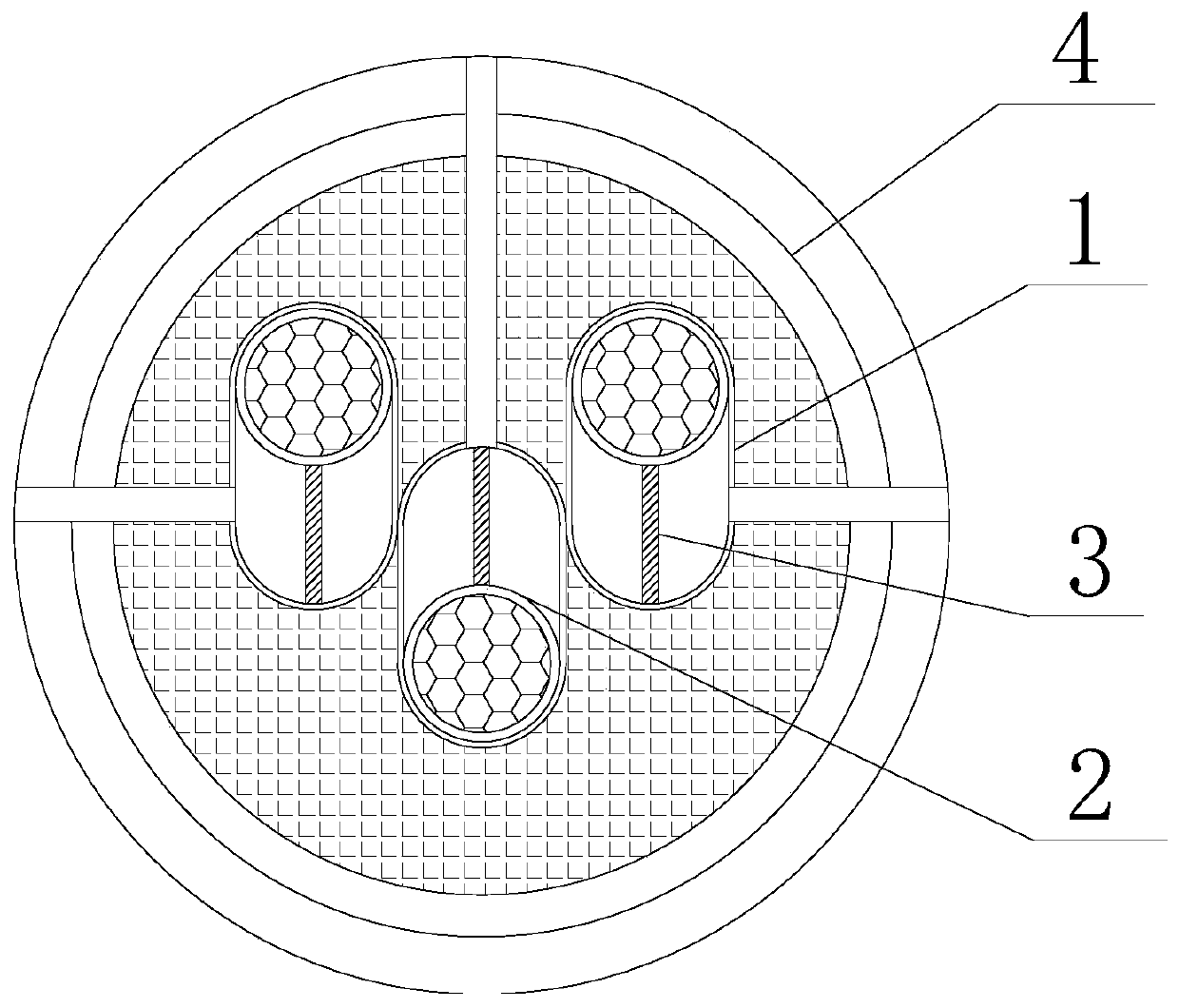

Lithium battery module for replacing lead-acid storage battery of automobile

ActiveCN103500807AImprove securityReduce volumeCell component detailsSecondary cells servicing/maintenanceElectrical batteryEngineering

The invention relates to a lithium battery module for replacing a lead-acid storage battery of an automobile. The lithium battery module comprises an upper cover, a shell, a seal grid plate, lithium batteries, insulated phase-change materials, a battery fixedly-held assembly, heat-conducting rib plates, a battery protection plate and a self-restoring circuit protector, wherein the upper cover and the shell are mechanically connected to form a seal cavity, the seal grid plate is arranged in the shell and divides the seal cavity into an upper-half seal cavity and a lower-half seal cavity, the insulated phase-change materials are filled in the lower-half seal cavity, multiple lithium batteries are fixedly connected through the battery fixedly-held assembly and are arranged in the insulated phase-change materials, the heat-conducting rib plates are arranged between each two adjacent lithium batteries, and the battery protection plate and the self-restoring circuit protector are arranged in the upper-half seal cavity; a circuit is mounted in the upper-half seal cavity, one end of the circuit penetrates through the seal grid plate and is connected with the electrodes of the lithium batteries, and the other end of the circuit is connected with an external pole column through the upper cover. Compared with the prior art, the lithium battery module has the advantages of long service life, good power property, small volume, high integration and the like.

Owner:TONGJI UNIV

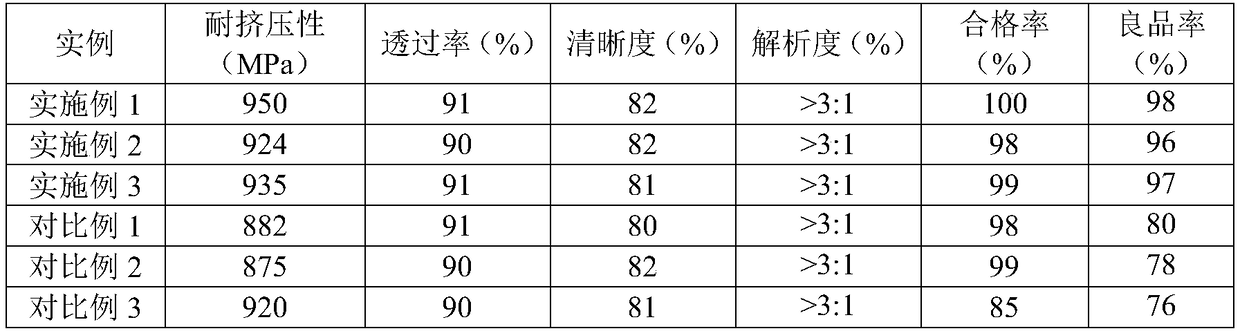

3D (three-dimensional) glass processing technology

InactiveCN109206002AImprove pass rateAvoid temporary blindnessGlass reforming apparatusGlass tempering apparatusEtchingMobile phone

The invention provides a 3D (three-dimensional) glass processing technology. According to the technology, 2D (two-dimensional) glass is subjected to the steps of cutting, CNC (computer numerical control) outline processing, hot bending shaping, strengthening, transfer printing, laser irradiation, AG (anti-glare) etching and the like, finally a 3D (three-dimensional) glass finished product is prepared, and therefore the problems of oxidization, glare, hook surface decoration and the like in the hot bending shaping process of glass in the processing and manufacturing process of 3D (three-dimensional) glass can be solved, meanwhile, the manufactured 3D (three-dimensional) glass product is excellent in performance and low in cost, and the application in the mobile phone industry, the computerindustry, the digital industry and optical lenses can be realized.

Owner:江苏优视光学科技有限公司

Auxiliary constant-temperature battery box

ActiveCN102751451AImprove efficiencyStrong extrusion resistancePrimary cell maintainance/servicingSecondary cellsBoiling pointWorking temperature

The invention relates to an auxiliary constant-temperature battery box. The battery box comprises an outer shell, an inner shell, a polar column cover, a low-boiling-point medium, a heating plate and a cooling plate, wherein the inner shell is arranged inside the outer shell; a sealed cavity is formed between the outer shell and the inner shell; the polar column cover is arranged inside the inner shell; the low-boiling-point medium is arranged in the sealed cavity; the heating plate and the cooling plate are respectively arranged at the bottom and the top of the outer shell; and when the temperature of a battery pack in the battery box needs to be reduced or raised, the battery box changes the phase of the low-boiling-point medium through the heating plate or the cooling plate, so that the aim of maintaining the constant temperature of the battery pack in the battery box is achieved. Compared with the prior art, the auxiliary constant-temperature battery box has the advantages of high efficiency, capability of effectively adjusting the working temperature of the battery pack, simple structure and the like.

Owner:HUIZHOU BNET TECH CO LTD

Anti-compression suspension cable

InactiveCN106340345AStrong extrusion resistanceSo as not to damageFloating cablesInsulated conductorsElectrical conductorIsoetes triquetra

The invention provides the following technical proposal of an anti-compression suspension cable comprising a primary conductor, air bags, secondary conductors and a cable main body. The top end of the cable main body is connected with a clamping slot through a fixing block; both sides of the cable main body are provided with air charging pipes. One end of each air charging pipe is provided with an air valve. One side of each air charging pipe is provided with an air bag. The central position inside the cable main body is provided with an equilateral triangle shaped anti-tensile core. And the three corners of the equilateral triangle shaped anti-tensile core are provided with the secondary conductors. The central position of the equilateral triangle shaped anti-tensile core is penetrated by the primary conductor. The surface of the equilateral triangle shaped anti-tensile core is coated with a spinning layer. According to the invention, the anti-compression suspension cable is provided with a rubber buffer layer, enabling the cable to have a better anti-extrusion capability. At the same time, even extruded, irreversible deformation does not occur to the cable, nor does the damage. Therefore, the service lifetime of the cable is lengthened.

Owner:LEIYANG XINGYU WIRE & CABLE CO LTD

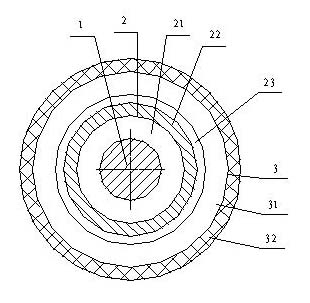

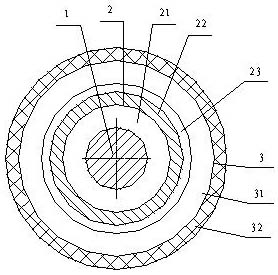

Cable for hybrid power vehicle

ActiveCN102005258AMeet high configuration requirementsCompact structureNon-insulated conductorsFlexible cablesAviationElectrical conductor

The invention relates to a cable for a hybrid power vehicle, which comprises a conductor, an insulating layer and a sheath sequentially, wherein the insulating layer comprises a temperature-resistant insulating layer, a reinforced insulating layer and a bonded insulating layer, and the sheath comprises an inner sheath and an outer sheath. The cable of the invention overcomes the defects that the functions of the current cable can not meet the configuration requirements of vehicles for executing special tasks, the structure and the service life are unsatisfactory, and the like; the cable is suitable for electric power and signal transmission of various hybrid power engineering equipment, transport vehicles, new energy hybrid power vehicles and the vehicles for executing special tasks; and the cable can also be used for electric power and signal transmission of electrical equipment in high-temperature or special environments for ships, smelting, power generation, oil production, aerospace and the like.

Owner:湖南华菱线缆股份有限公司

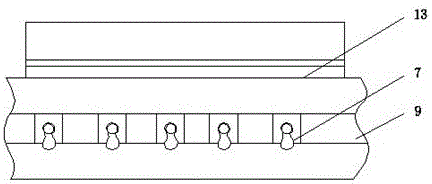

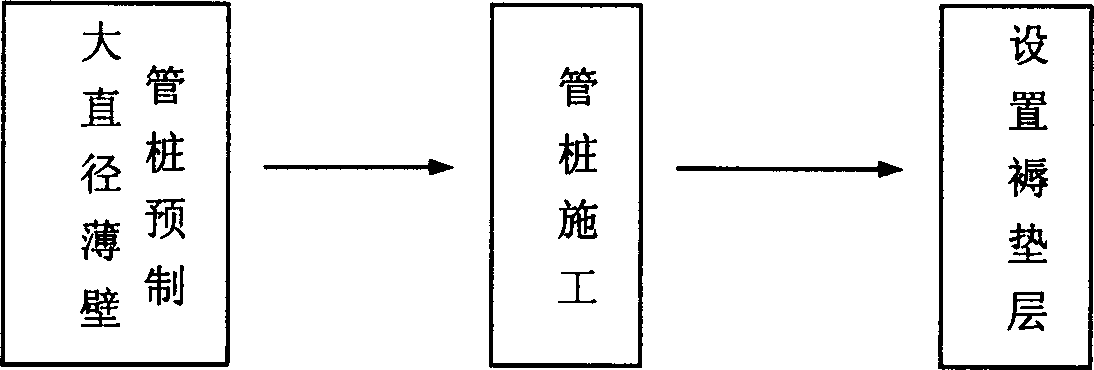

Method of reinforcing soft base using large diameter thin wall pipe pole composite ground

InactiveCN1556283AReduce penetration resistanceFast constructionBulkheads/pilesDistortionThin walled

The method includes following steps: (1) prefabricating big and thin wall pipe piles; (2) according to designed reinforcing requirement, punching or pressing the said prefabricated pipe piles into base of foundation in soft clay by using construction machinery; (3) setting mattress layer on top of pipe piles to assort with distortion and stress of pile ground. Advantages are convenient construction, low cost, fast, adjusting distortion of pile ground so as to ensure piling quality and suit reinforcing base of foundation in soft clay.

Owner:GUANGDONG PROVINCE HANGSHENG CONSTR GRP

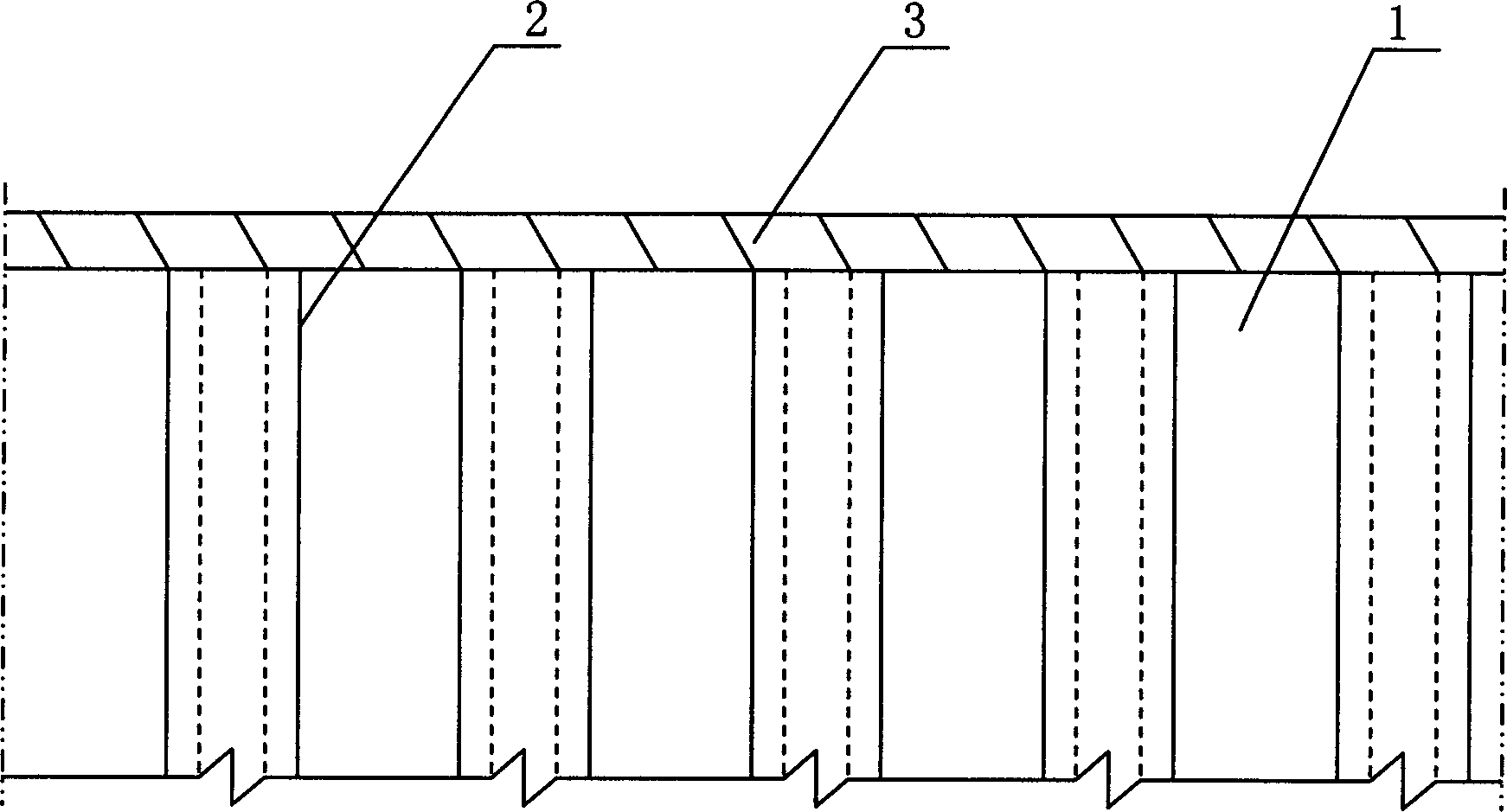

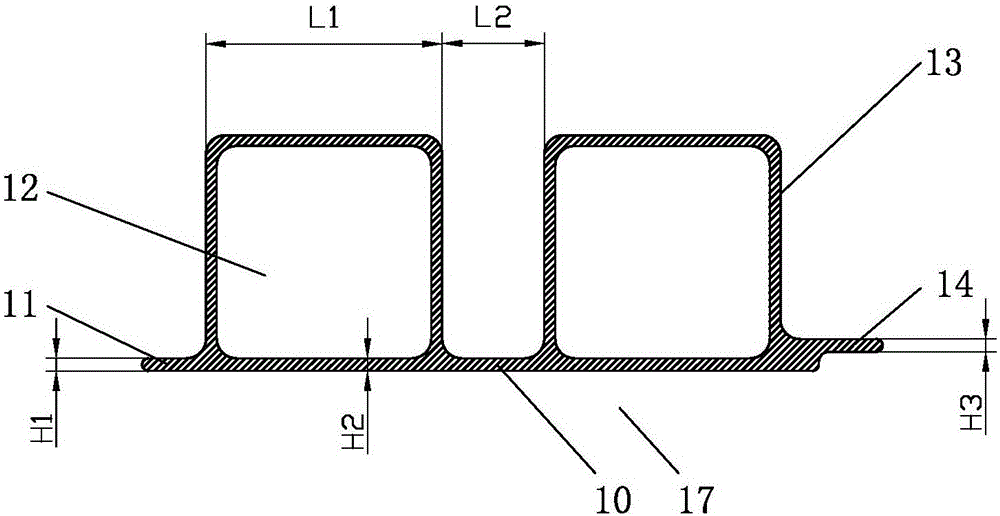

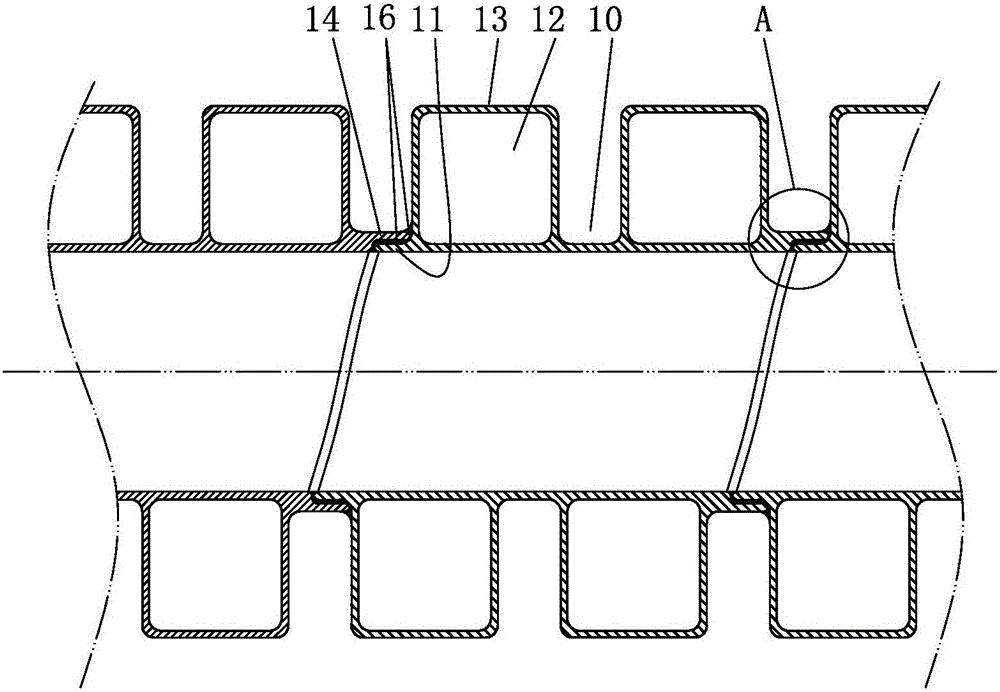

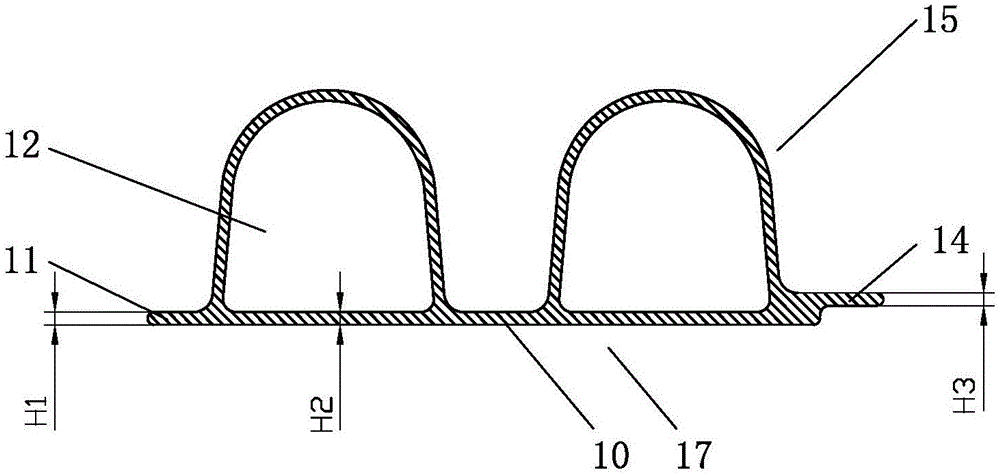

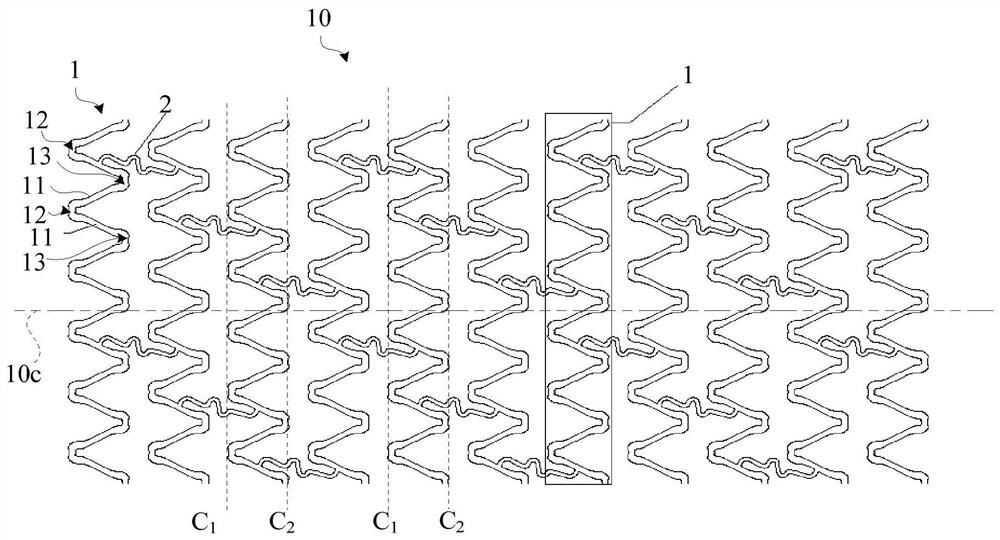

Frame-shaped spiral winding plastic pipe as well as production equipment and production process thereof

InactiveCN106287009AImprove performanceLow costRigid pipesTubular articlesConductor CoilMechanical engineering

The invention belongs to the technical field of municipal drainage and sewage discharging pipelines, and relates to a frame-shaped spiral winding plastic pipe as well as production equipment and a production process thereof. More than one hollow rectangular pipe or hollow arched pipe is transversely formed on an external surface of a plastic tape of the frame-shaped spiral winding plastic pipe at intervals, wherein the top surface of the arched pipe is in smooth transition, a connecting edge is arranged at one side of the frame-shaped spiral winding plastic pipe, and an upper surface of an edge at the other side extends outwards to form a fastening edge, so as to form strip profiles, and the frame-shaped spiral winding plastic pipe is formed by adhering and connecting the strip profiles through a hot melt adhesive after spiral winding. The production equipment comprises an extruding machine, a profile mould, a shaping mould, a cooling and shaping platform, a traction machine, a winding mechanism, a carrying platform and a pipe cutting saw. The production process comprises the following steps: shaping the strip profiles, winding the strip profiles in a spiral manner, and adhering and connecting the strip profiles through the hot melt adhesive to form a pipe. The frame-shaped spiral winding plastic pipe as well as the production equipment and the production process thereof disclosed by the invention have the following advantages: material cost and equipment manufacturing cost are lowered while performance of the pipe is improved, the product is safe and reliable, and the frame-shaped spiral winding plastic pipe can meet the requirement on long-term use, and is applicable to producing large-diameter municipal drainage and sewage discharging pipelines.

Owner:何周富 +1

Process for producing rare earth copper alloy

The invention relates to a process for producing a rare earth copper alloy. The process comprises the following steps: adding and refining an alloy element in a melting pot, and degassing by using a hexachloroethane degassing agent; standing for 50 minutes, then injecting into a second pot, adding rare earth, and then degassing and removing slag. The process particularly comprises the following steps: (1) heating and cleaning a melting furnace device; (2) weighing 1000 kg of copper ingots, and preheating; (3) after the copper ingots are melted and the temperature of the melting furnace is increased to 1100-1200 DEG C, adding manganese chloride, then increasing the temperature of the melting furnace to 1300-1400 DEG C, and installing a mechanical stirring device for stirring; (4) adding a fusing agent; and (5) degassing, and then manually removing the slag. The rare earth copper alloy produced through the process disclosed by the invention has excellent abrasion resistance and anti-extrusion capacity, is a high-quality choice of an automobile king pin bushing material, is simple in production process, and is easy to popularize, and the utilization ratio of rare earth resources is increased.

Owner:NANTONG ZHIBANG NEW MATERIAL TECH

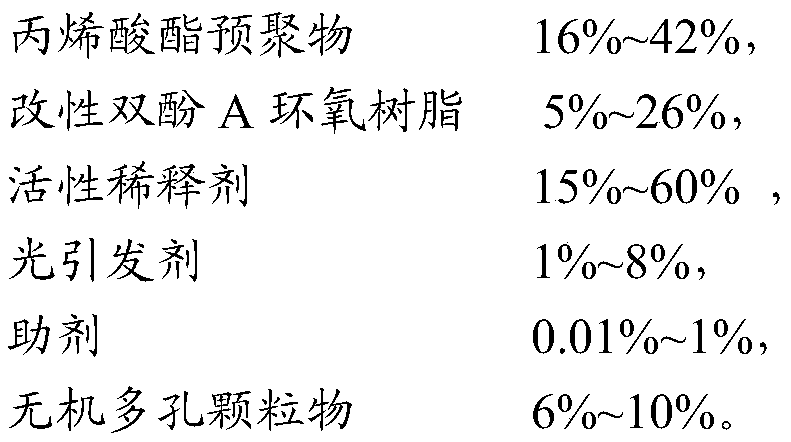

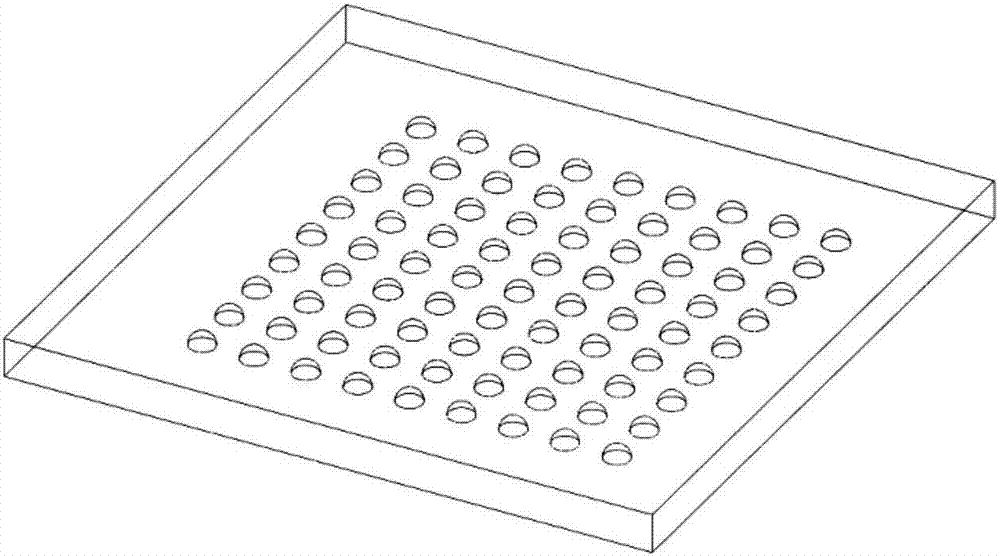

UV glue for package and preparation method thereof

InactiveCN110408350AStrong water vapor adsorption capacityStrong oxygen adsorption functionNon-macromolecular adhesive additivesEster polymer adhesivesParticulatesPolymer science

The invention relates to the field of display technology, in particular to UV glue for package and a preparation method thereof. The UV glue for package is prepared from an acrylic ester prepolymer, modified bisphenol-A epoxy resin, a reactive diluent, a photoinitiator, an addition agent, and inorganic porous particulate matter.

Owner:合肥派森新材料技术有限公司

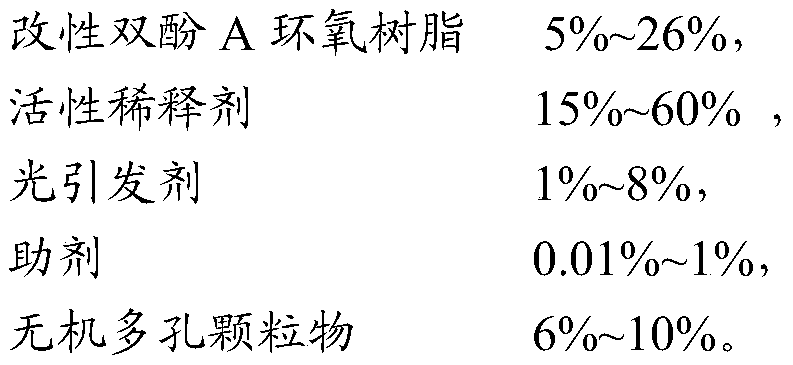

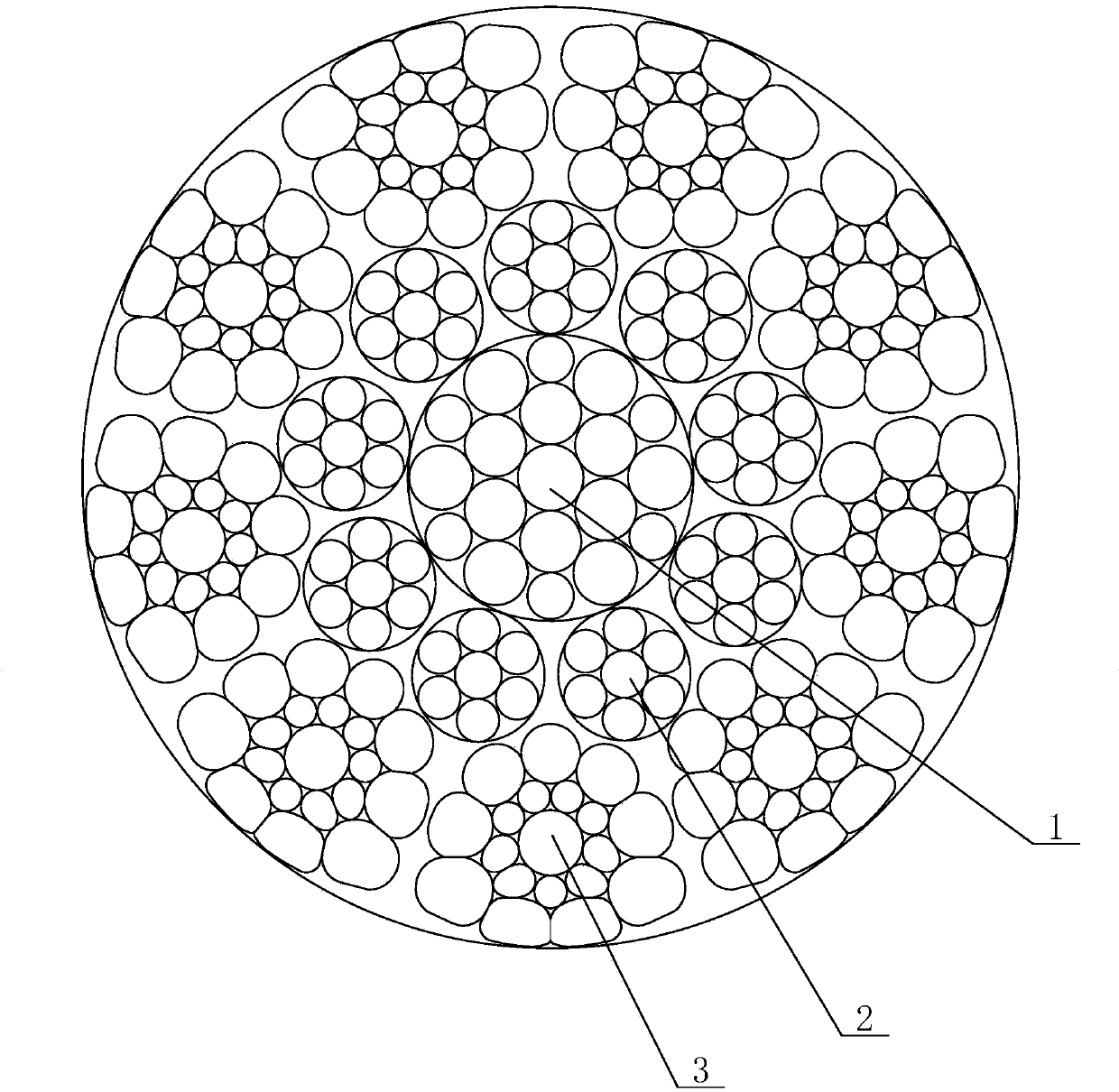

Double-compaction steel wire rope for harbour machinery and manufacturing method of double-compaction steel wire rope

InactiveCN103757952AHigh breaking forceStrong wear resistanceRope making machinesLoad resistanceEngineering

The invention discloses a double-compaction steel wire rope for harbour machinery. The double-compaction steel wire rope comprises a steel core center strand, six steel core outer-layer strands and six outer-layer strands, the steel core outer-layer strands symmetrically wrap and twist the steel core center strand to form a steel core, the outer-layer strands symmetrically wrap and twist the steel core, a steel wire rope is a compaction rope, strands in the rope are in face contact, each outer-layer strand is a compaction strand, and steel wires in each strand are in face contact. Structure of the rope strands is in face contact through die extrusion, and the steel wire rope after being compacted is in face contact with a pulley, so that the double-compaction steel wire rope has ultrahigh breaking force and high wear resistance, extruding resistance and impact load resistance. Compared with those of steel wire ropes identical with the double-compaction steel wire rope in diameter and strength, bearing capacity is improved by 20%, and wear resistance is improved by about 25%; service life of the double-compaction steel wire rope is long, and correspondingly, running cost of the harbour machinery is reduced.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

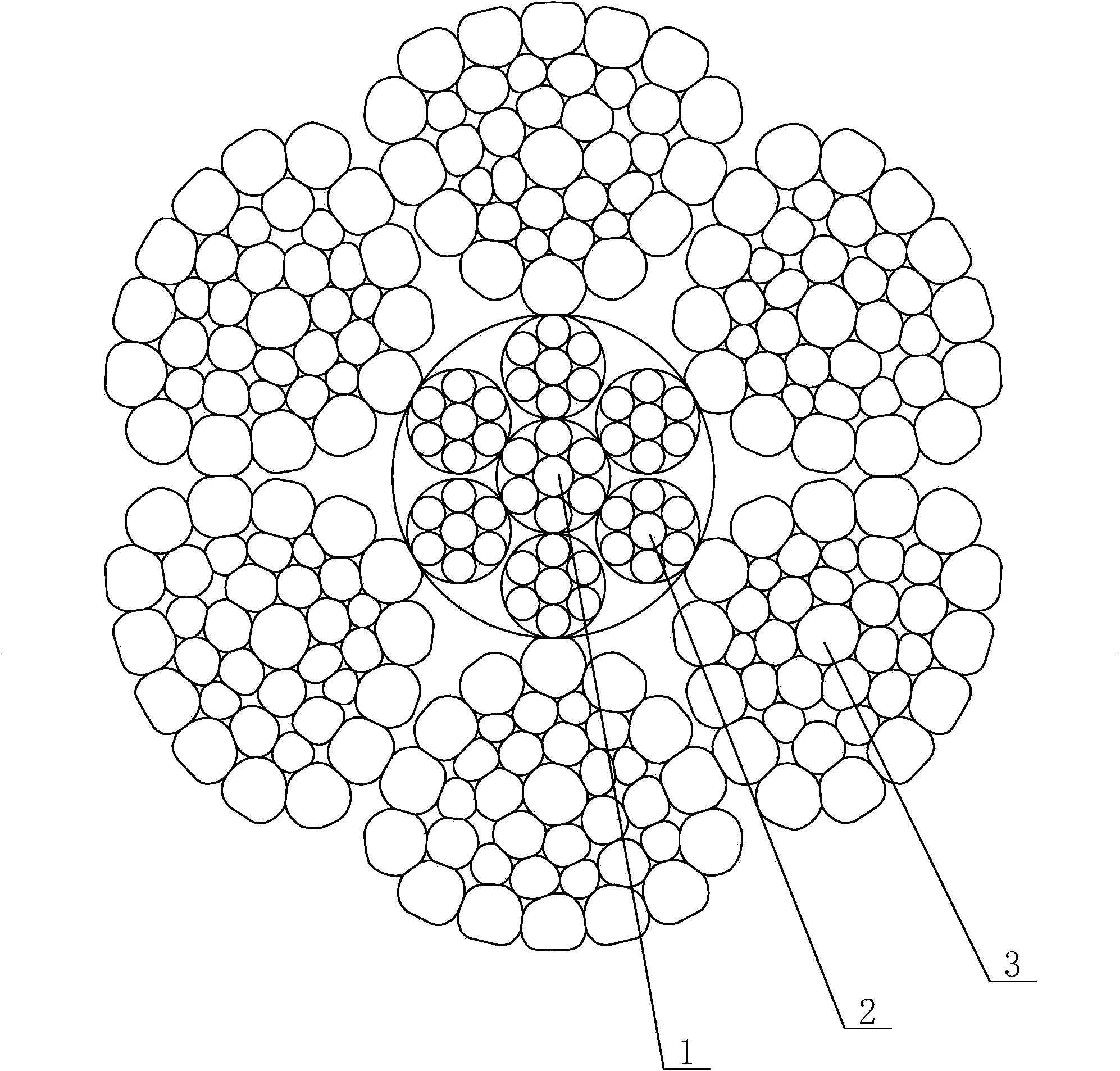

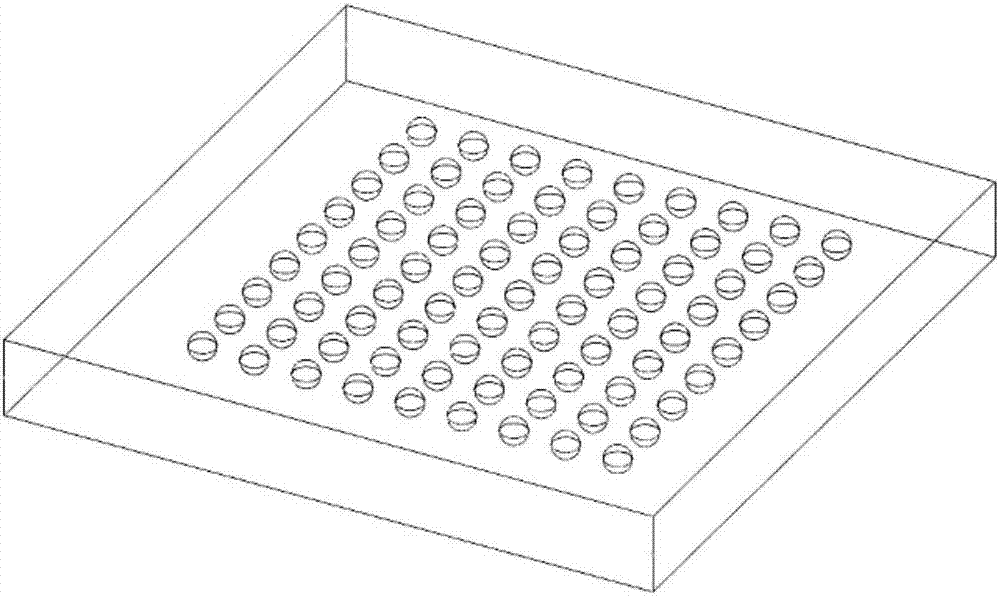

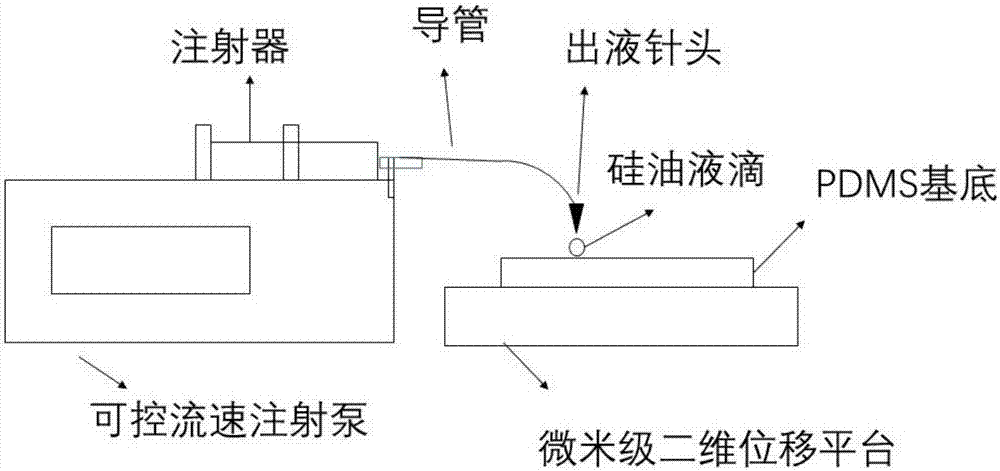

Manufacturing method for controllable focal length liquid lens array

The invention relates to a manufacturing method for a controllable focal length liquid lens array. By controlling the mass of silicon oil dropped in a silica gel substrate, the refraction surface curvature and the lens focal length of a single microlens are controlled. By controlling the temperature in the experiment process, plano-convex or convexo-convex lens shapes are manufactured. By displacing a platform, the arrangement and the number of microlenses in the array are controlled. The manufacturing method is more suitable for preparation of the liquid microlens array of a larger area. The manufacturing period is short, the manufacturing cost is low and the manufacturing method is simple. The finished product of the invention is strong in anti-extruding performance and controllable in focal length, the array is structured. The method achieves the controllable lens focal length, the rapid response speed and the excellent imaging quality. The method can be widely applied in the fields of photovoltaic cells, microfluidic devices, three-dimensional imaging, monomolecular imaging, artificial compound eyes and optical coupling devices.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

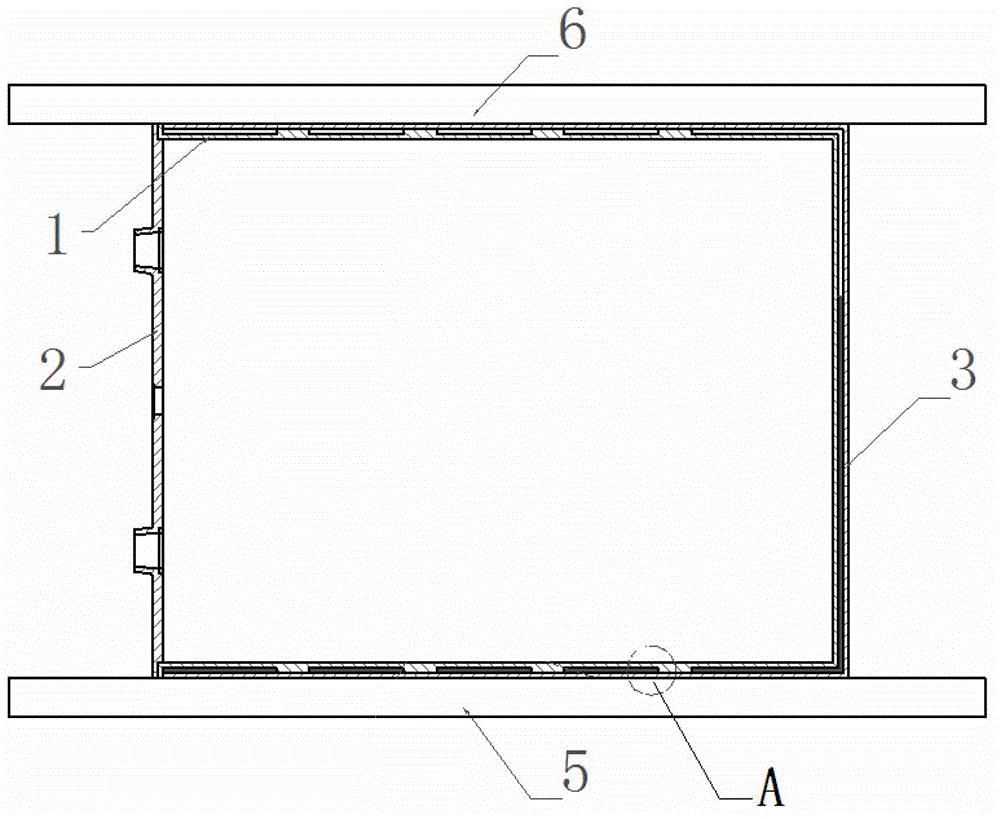

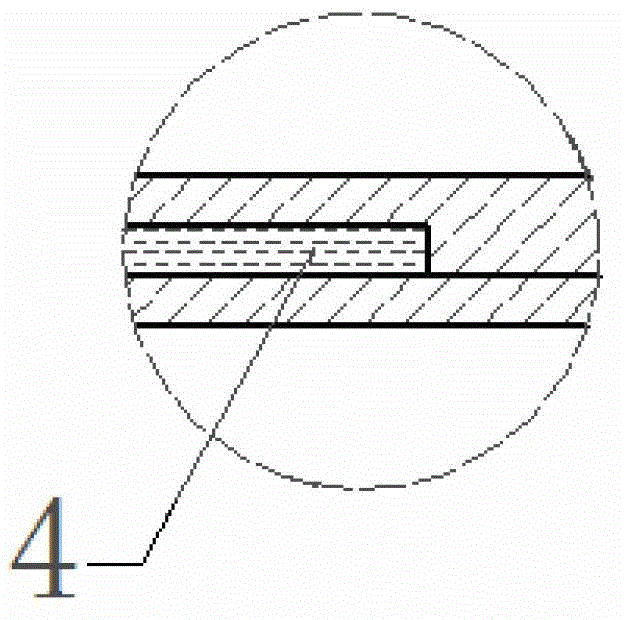

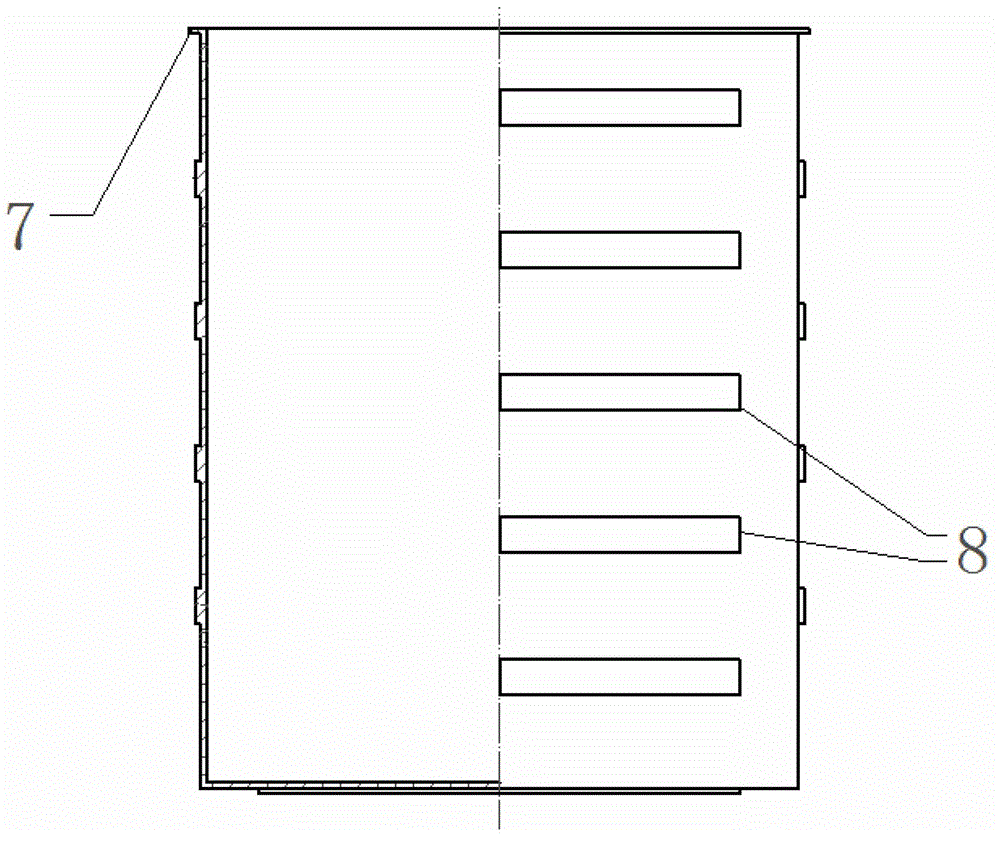

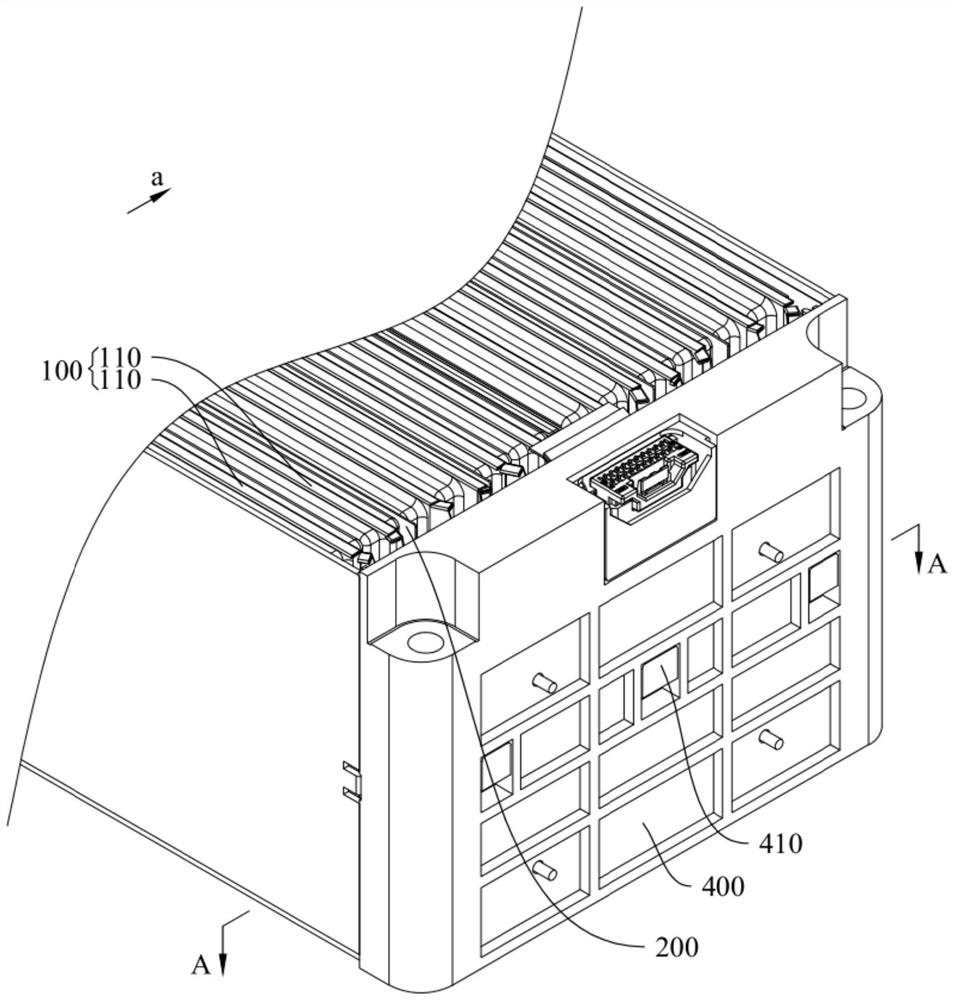

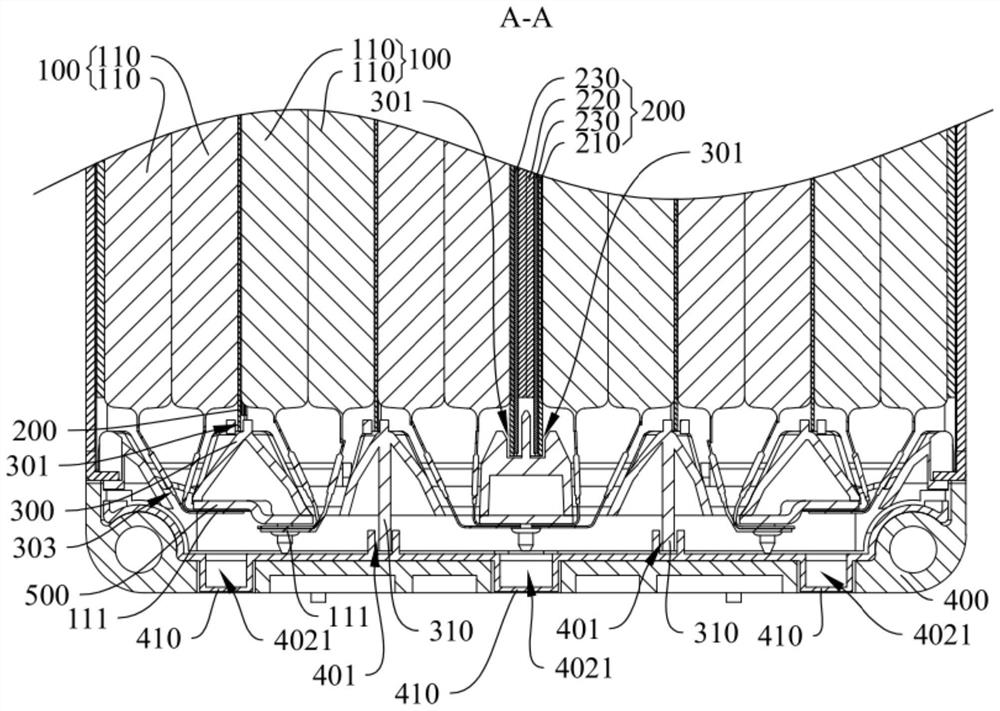

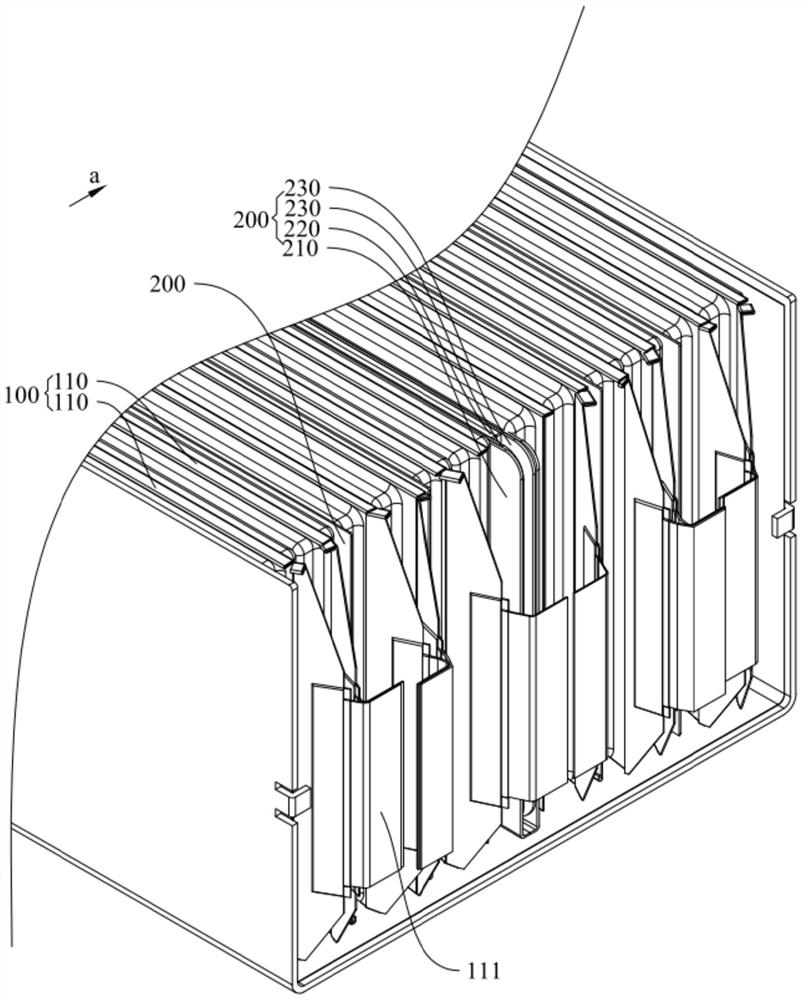

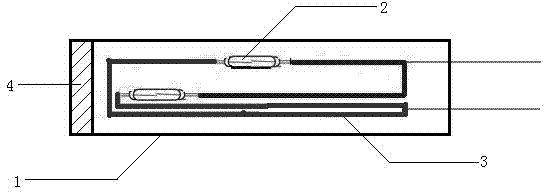

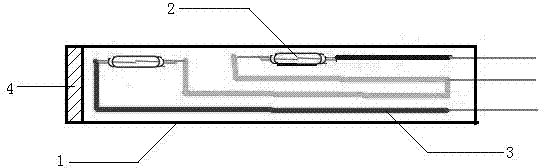

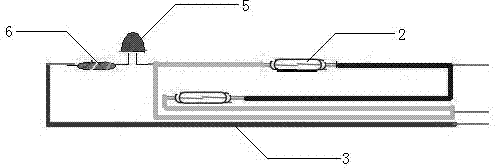

Battery module and battery pack

PendingCN112510322AStrong extrusion resistanceThermal runaway spreads slowlyCell seperators/membranes/diaphragms/spacersBattery isolationStructural engineeringMechanical engineering

The invention relates to the field of batteries, and provides a battery module and a battery pack. The battery module comprises a plurality of battery core assemblies, at least one spacing structure and at least one tab bracket, wherein the plurality of battery core assemblies are arranged in an array along the thickness direction, each battery core assembly comprises at least one battery core unit, the spacing structures are arranged between two adjacent battery core assemblies, the end portions of the spacing structure are convexly arranged relative to the end surfaces of the battery core units, the tab bracket is arranged at one ends of the plurality of battery core assemblies, at least one first inserting groove is formed in one side, facing the spacing structure, of the tab bracket, and the first inserting groove is matched with the end portion of the spacing structure in an inserting manner. Based on the structure, when the tab bracket is extruded, the tab bracket extrudes the spacing structure which is matched with the first inserting groove in an inserting manner, but does not directly extrude the battery core assembly, so that the spacing structure can bear a relatively large extrusion force, and the battery core assembly only needs to bear a relatively small extrusion force so as to reduce the extrusion degree of the tab bracket on the battery core assembly.

Owner:SHANGHAI CENAT NEW ENERGY

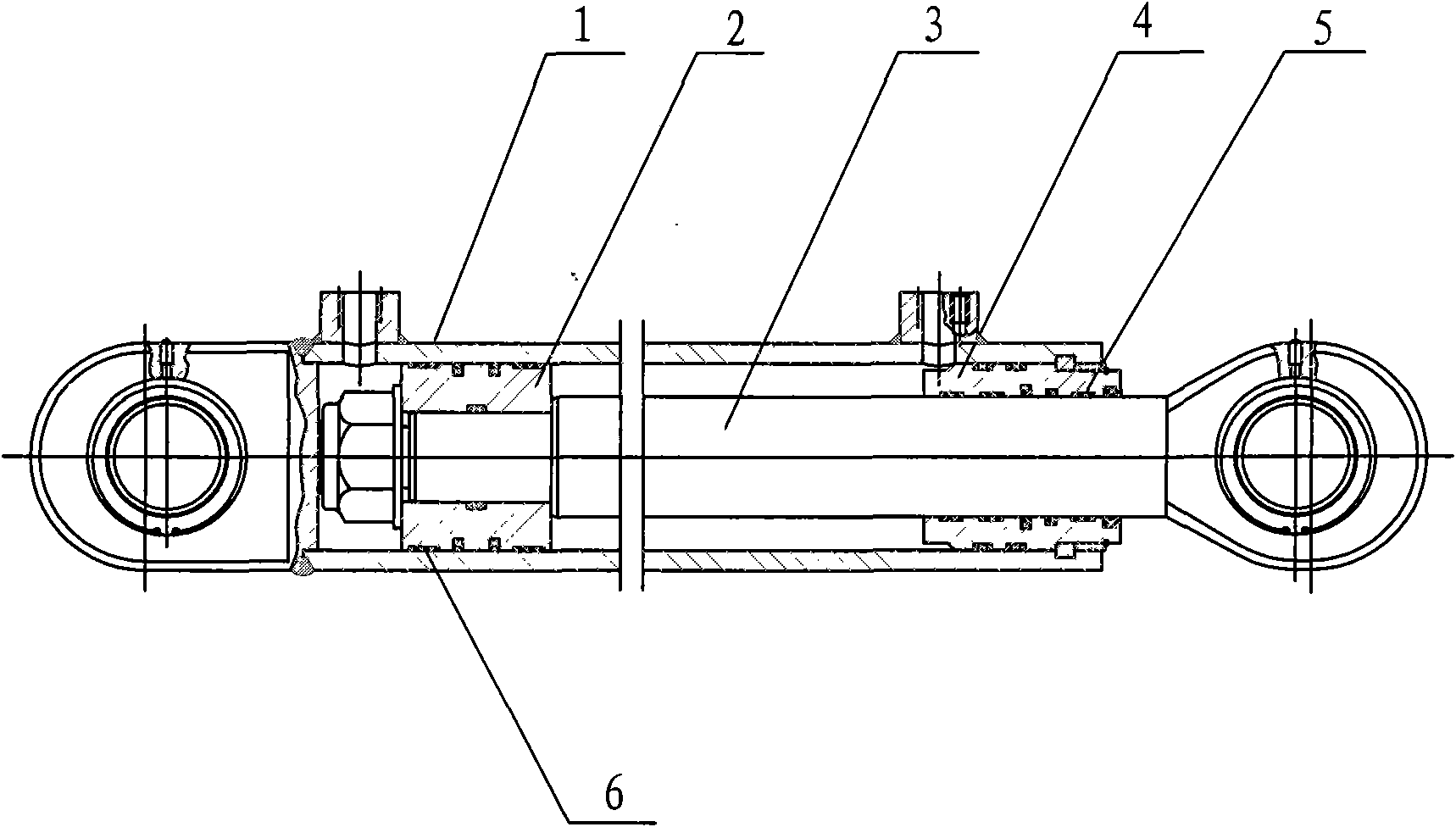

High-strength engineering machinery hydraulic cylinder

InactiveCN101655117AExtended service lifeSolve technical problems with short service lifeEngine sealsCylindersIntermediate frequencySteel ball

The invention discloses a high-strength engineering machinery hydraulic cylinder, which comprises a cylinder body. A piston rod and a guiding support ring are arranged in the cylinder body, a piston is arranged on the piston rod, and an oil inlet pipe interface and an oil return pipe interface are arranged on the cylinder body; the cylinder body is made of 27 SiMn alloy steel material, the pistonrod is made of SiCr-440 material, the surfaces of the cylinder body and the piston rod are quenched at intermediate frequency, and then the surface of the piston rod is plated with hard chromium and polished to Ra 0.08 mum; the piston consists of a floating buffer plunger piston and a floating buffer sleeve; the buffer plunger piston is limited by a steel ball; two lip-shaped seals are arranged onthe piston rod, and lubricant is filled between the two lip-shaped seals; two ends of the piston are provided with pollution-receiving rings of which thicknesses are 4 millimeters; and the guiding support ring is a DU composite material sliding bearing. The high-strength engineering machinery hydraulic cylinder solves the technical problem of short service life of the hydraulic cylinder in the prior art, can bear 30MPa high pressure when in use, and is an ideal engineering machinery hydraulic cylinder; and the surface of the hydraulic cylinder is not easy to be damaged.

Owner:SHANDONG ZHONGLI HYDRAULIC TECH

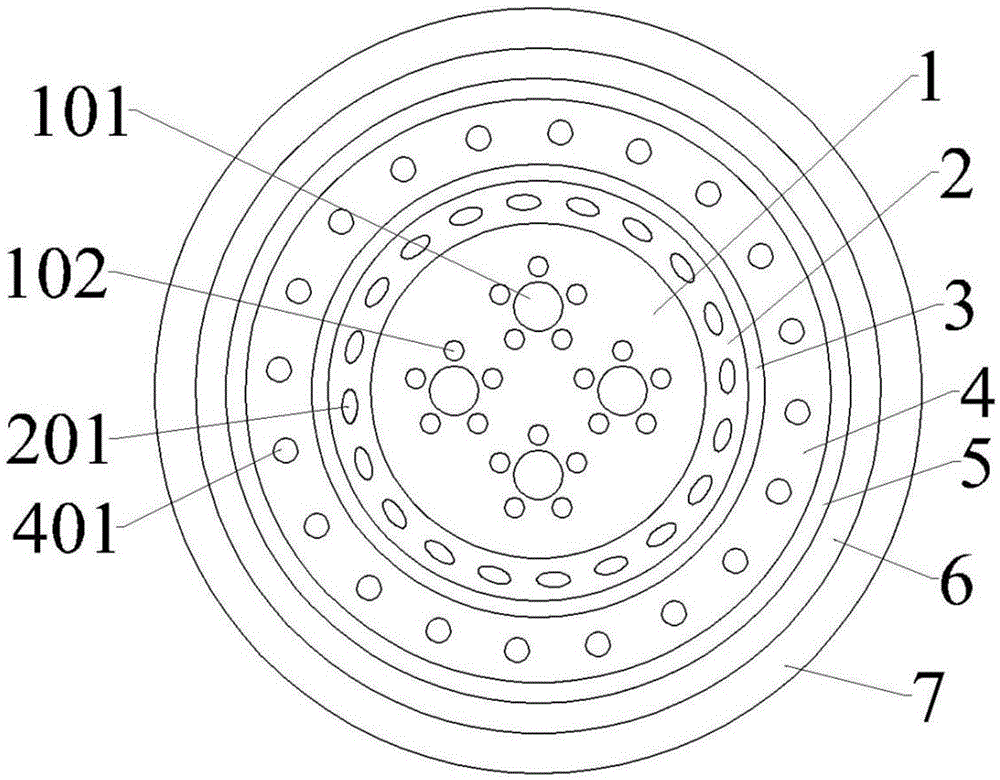

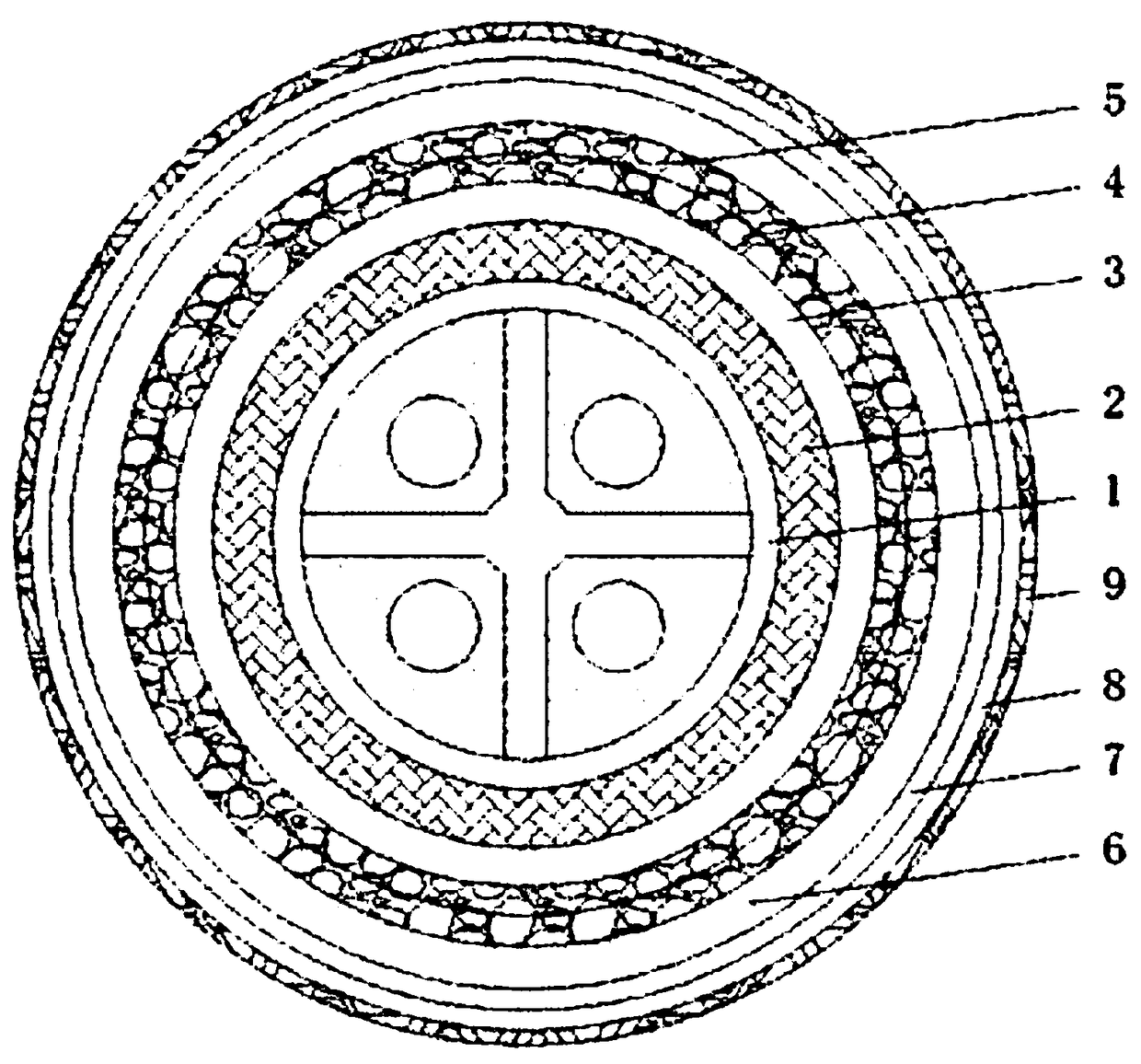

Anti-extrusion signal cable

ActiveCN105655021AWaterproofFlame retardantQuad constructionsPlastic/resin/waxes insulatorsPolyesterElectrical conductor

The invention discloses an anti-extrusion signal cable comprising a cable core, an internal protection layer, a shielding layer, an intermediate protection layer, a reinforcing layer, a protection layer and an external protection layer. The cable core comprises an insulator and multiple wire cores. The internal part of the insulator is provided with multiple first through holes and multiple second through holes along an axial direction. Each first through hole is surrounded by 3-6 second through holes. The multiple wire cores are respectively arranged in the multiple first through holes. Each wire core comprises a conductor, a polyester tape which wraps the conductor and a copper wire braiding layer which wraps the polyester tape. The internal part of the internal protection layer is provided with multiple third through holes along the axial direction. The internal part of the intermediate protection layer is provided with multiple fourth through holes along the axial direction. The signal cable has the properties of being waterproof and moisture-proof, flame-retardant and fireproof, anti-interference and anti-extrusion.

Owner:ZHEJIANG LANTIAN CABLES MFG

Double-compacted parallel laid wire rope for telescopic boom

InactiveCN103741530AImprove carrying capacityExtended service lifeTextile cablesLoad resistanceEngineering

The invention discloses a double-compacted parallel laid wire rope for a telescopic boom. The double-compaction parallel laid wire rope comprises a center strand, nine inner strands and nine outer strands, the nine inner strands are symmetrically laid outside the center strand in a wrapping manner, the nine outer strands are symmetrically laid in grooves in the surfaces of the inner strands in a wrapping manner, the wire rope is a compacted rope, the strands in the rope are in surface contact, the outer strands are compacted strands, and steel wires in the outer strands are in surface contact. Due to the fact that the structures of the rope strands are in surface contact via being extruded by a die and the compacted wire rope is also in surface contact with a pulley contact surface, the double-compacted parallel laid wire rope for the telescopic boom has ultrahigh breaking force, high abrasion resistance, crumpling resistance and impact load resistance. Bearing capacity of the wire rope is 20% higher than that of wire ropes with same diameter and strength, abrasion resistance is improved by 25% approximately, service life of the wire rope is long, and operation cost of a telescopic boom crane is reduced correspondingly.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

Casting mould frame

The invention belongs to the technical field of sand mould casting, and specifically discloses a casting mould frame. The casting mould frame comprises a frame body and a moulding sand layer located in the frame body, wherein a cooling pool is arranged on the frame body; a pipeline penetrating through the moulding sand layer is arranged on the frame body; the two ends of the pipeline are communicated with the cooling pool respectively; the outer wall of the pipeline located in the moulding sand layer is coated with a layer of epoxy resin; and a lead block is embedded on the wall of the pipeline. The casting mould frame disclosed by the invention has a function of accelerating cooling of liquid metals in a mould cavity.

Owner:YONGCHUAN DISTRICT CHONGQING HUAYI MACHINERY CASTING CO LTD

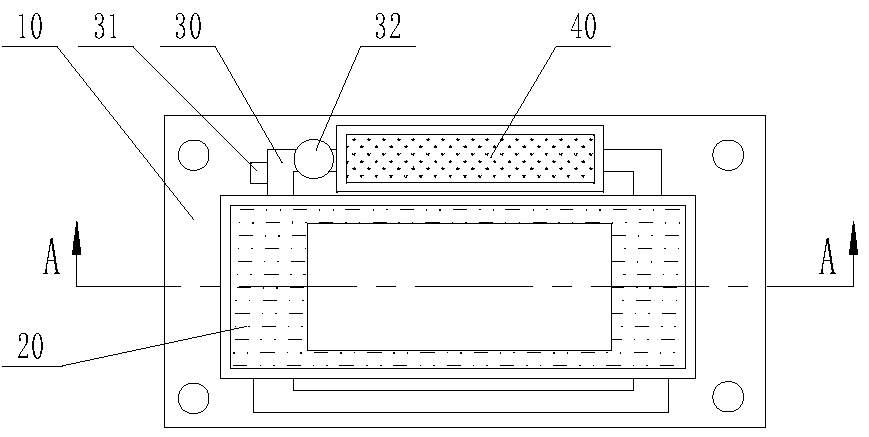

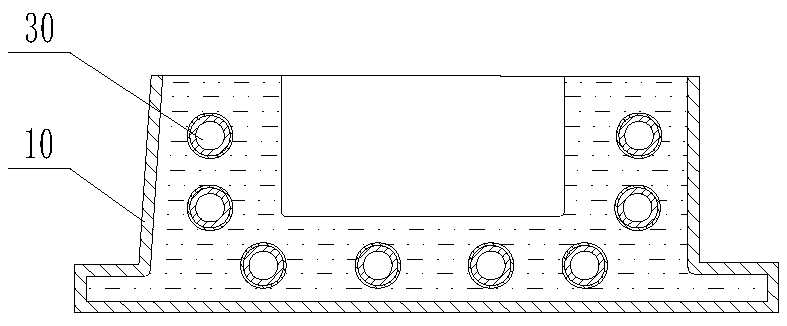

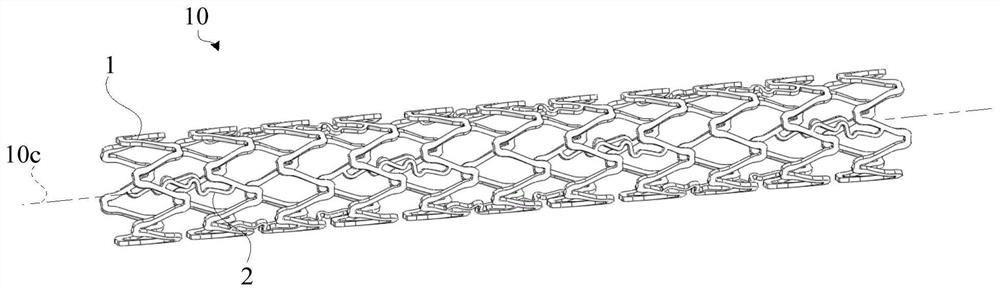

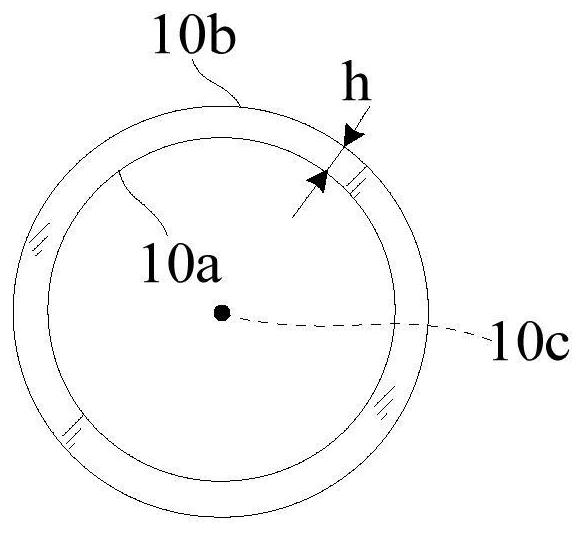

Stent

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

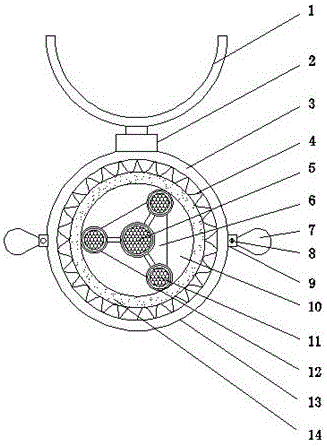

Visual magnetically-controlled switch

InactiveCN104779115AStrong extrusion resistanceNot easy to break and damageMagnetic movement switchesEngineeringOrganic glass

The invention relates to a visual magnetically-controlled switch. The visual magnetically-controlled switch comprises an outer tube, two reed switches and leads, wherein the outer tube is a transparent organic glass tube with two ends sealed, and the outer tube is filled with epoxy resin; the two reed switches are connected with the leads respectively and mutually connected in the outer tube. The switch has the inner visual performance and can perform visual operation, so that the switch state is distinguished more conveniently, and hidden danger is discovered more directly; the switch is free of rust, easy to dismount and high in seal and waterproof performance and has very high applicability to severe environments of shafts under mines; the magnetizing range is wide, the detection accuracy and the action sensitivity are high, and the detection error probability is greatly decreased; the switch is simple to produce, short in molding cycle and low in production cost.

Owner:NANJING MEISHAN METALLURGY DEV +1

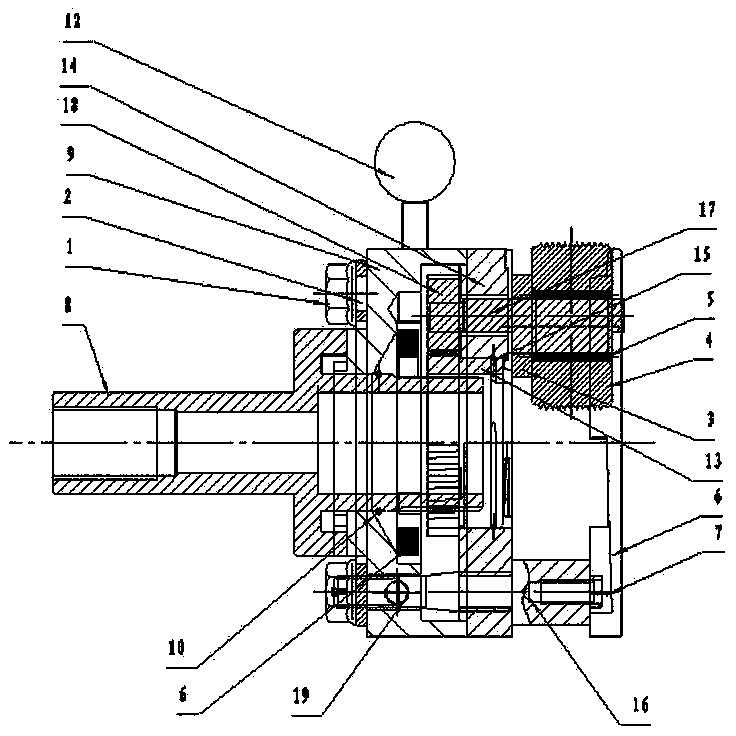

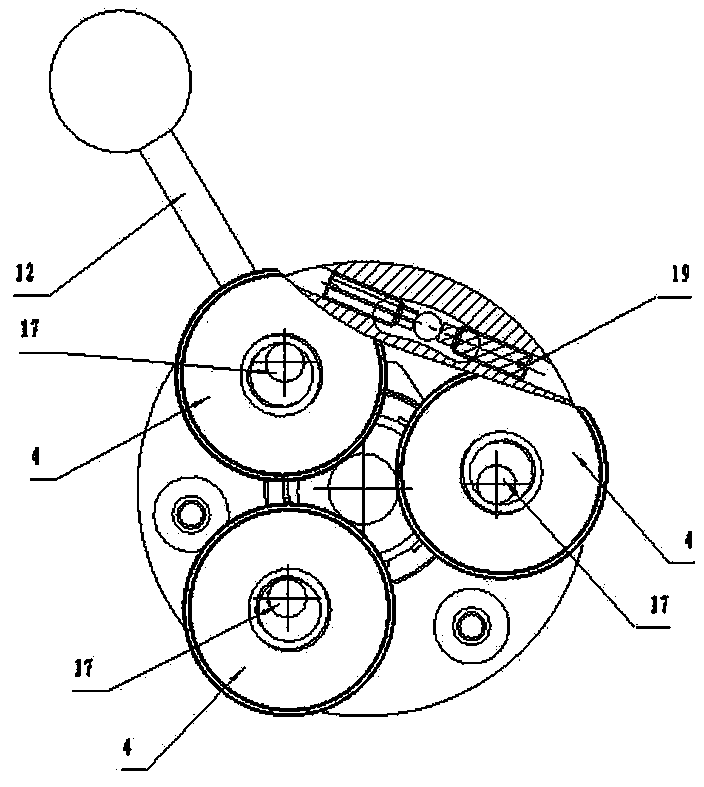

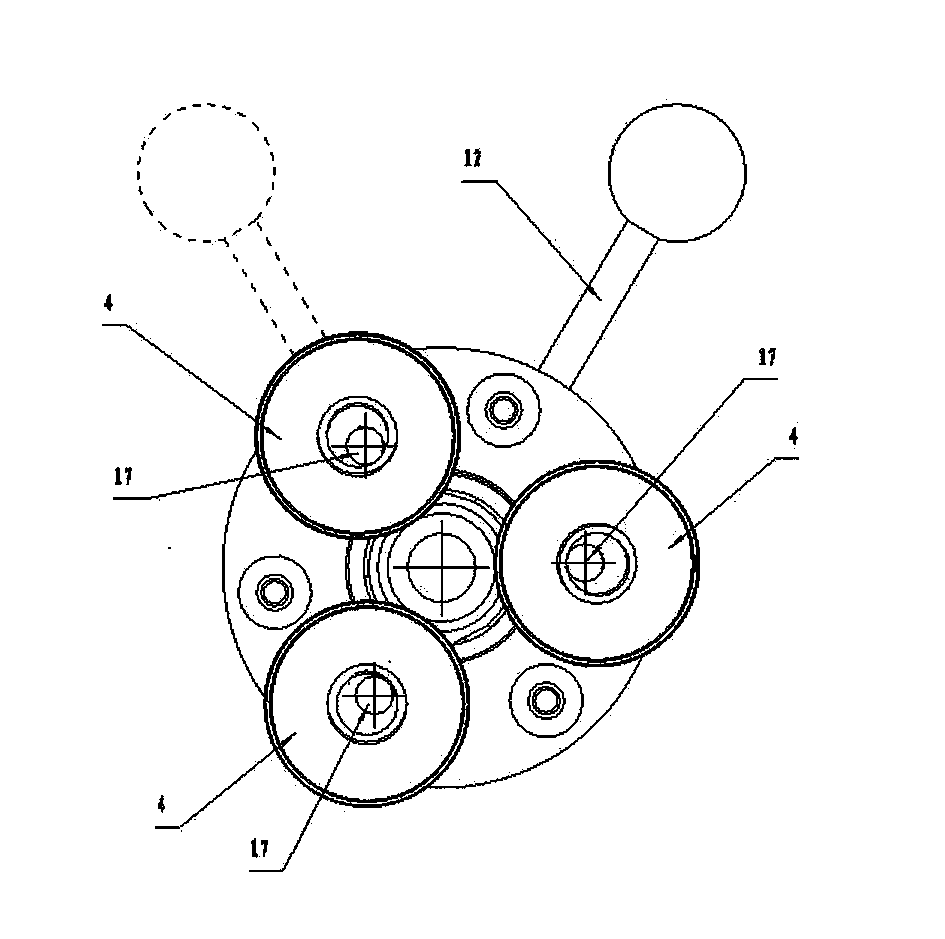

Rolling tool for axial external threads

InactiveCN103611856AImprove processing efficiencyImprove thread strengthScrew-threads articlesEngineeringUltimate tensile strength

The invention relates to a rolling tool for axial external threads. The rolling tool comprises a base and is characterized in that the base comprises a first component, a second component, a lock nut, a rear cover plate, a thread rolling wheel washer, a thread rolling wheel, a rolling pin, an outer fixing cover plate and an Allen screw. The first component comprises an outer splined shaft, a thread size adjusting cover, an outer splined shaft retainer ring, a volute spring and a reset handle. The second component comprises a transmission large gear, a rolling wheel mounting block, a transmission large gear retainer spring, a connecting rod, an eccentric shaft and a transmission small gear. The outer splined shaft of the first component is nested onto splines of the transmission large gear of the second component. The connecting bar penetrating the rear cover plate is fixedly connected through the lock nut. The outer edge of the eccentric shaft is sequentially sleeved with the thread rolling wheel washer, the rolling pin and the thread rolling wheel. The outer fixing cover plate is fixed to the connecting bar through the Allen screw. The rolling tool has the advantages that high thread strength of threaded connectors can be ensured, the surface of the threaded connectors is smooth, and threaded connectors are high in compression resistance and long in service lives.

Owner:SICHUAN KESDA AUTOMOBILE BRAKE SYST GRP

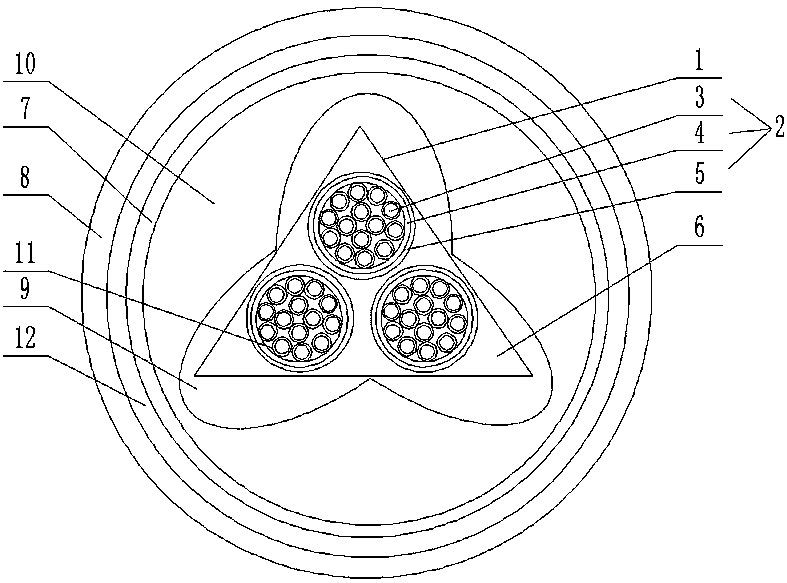

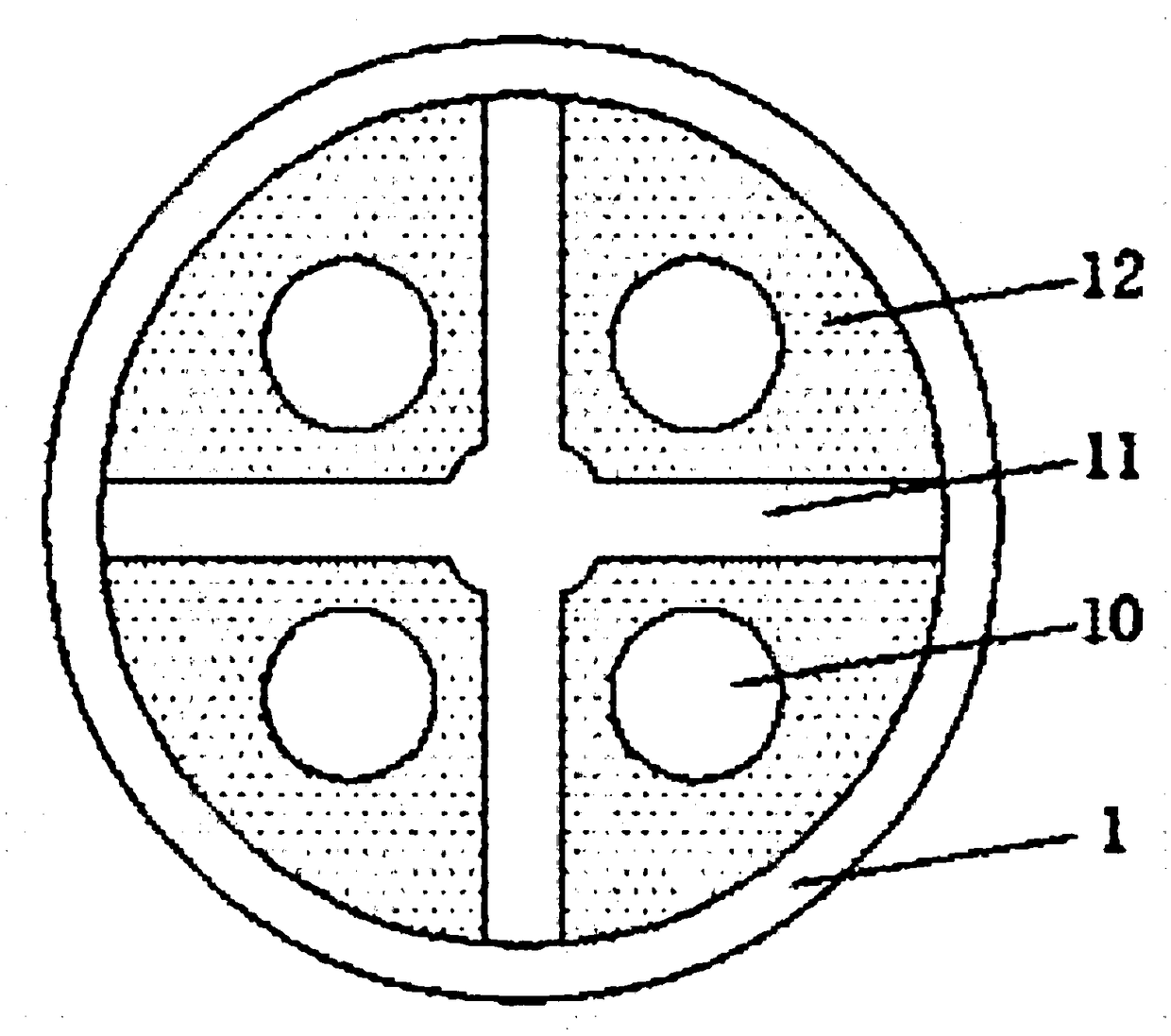

A deep earth load-bearing detection cable

PendingCN109003697AAvoid squeezingStrong extrusion resistanceNon-insulated conductorsPlastic/resin/waxes insulatorsEngineeringCopper

The invention discloses a deep earth bearing detection cable. The invention comprises a triangular skeleton, a plurality of cable core units are arranged in the triangular skeleton, and the cable coreunit comprises copper strands, an insulating layer and an inner shielding layer arranged in order from the inside to the outside. A water-proof layer is filled between the cable core unit and the cable core unit and between the cable core unit and the triangular skeleton, and an outer shielding layer and an armor layer are sleeved on the outer ring of the triangular skeleton in order. The three end corners of the triangular skeleton are all provided with semi-elliptical cushions, which are made of polyurethane material, and the three semi-elliptical cushions are end-to-end connected and located between the triangular skeleton and the outer shielding layer, and a silicon rubber elastic layer is also arranged between the semi-elliptical cushion and the outer shielding layer. When the invention is extruded in the use process, the invention will produce certain elastic deformation to buffer the extruded force; At that same time, the triangular skeleton can effectively prevent the cable core unit from bee extruded, and the invention has strong extrusion resistance and long service life.

Owner:山东希尔电缆有限公司

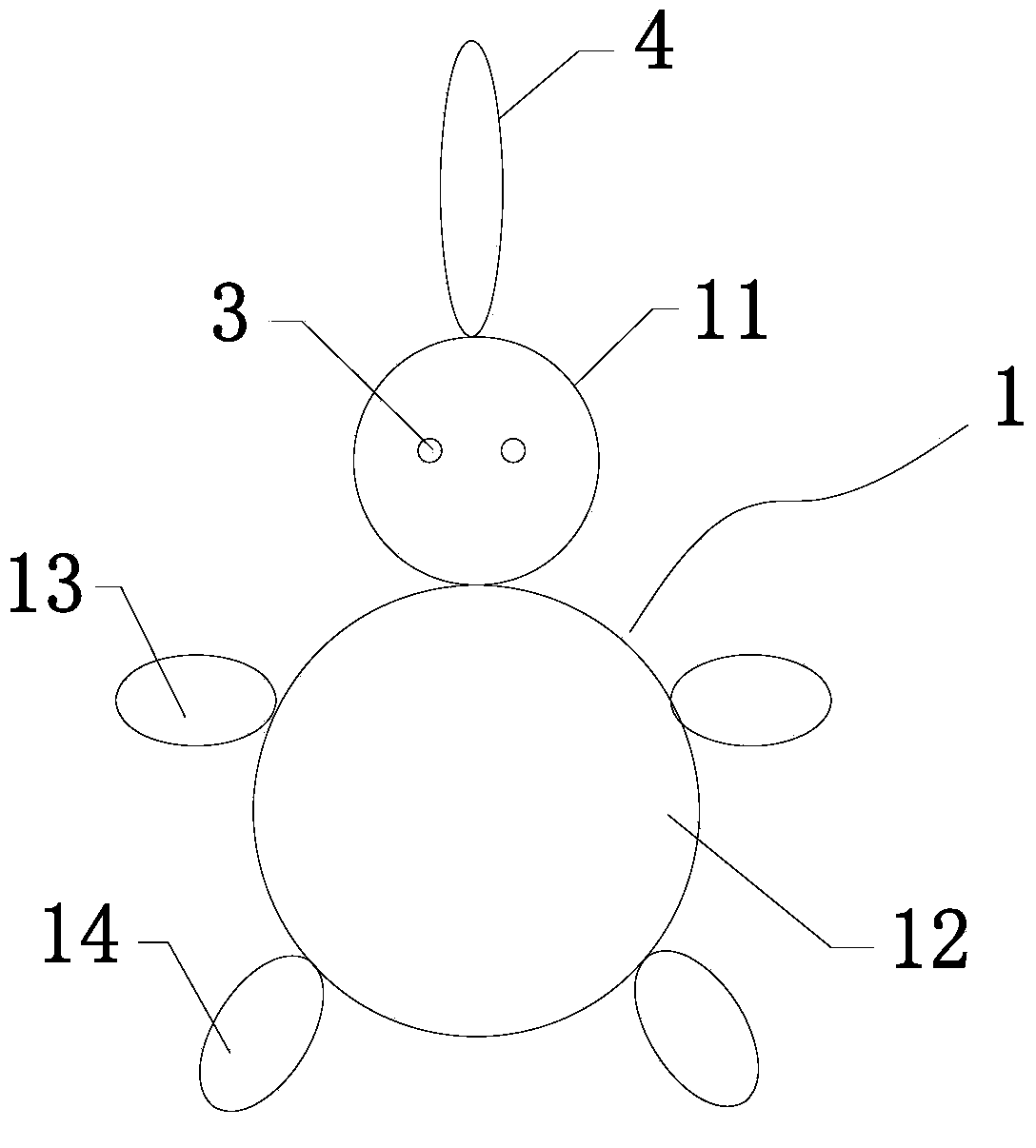

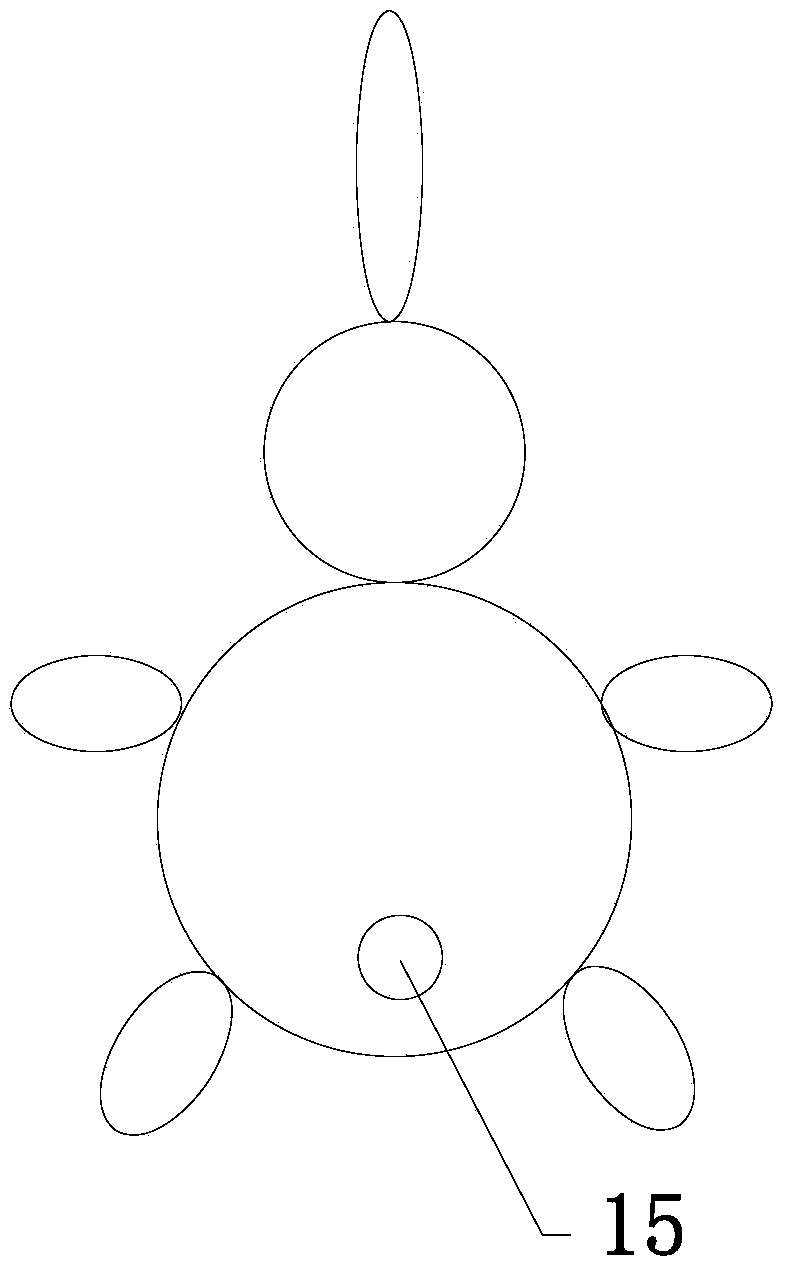

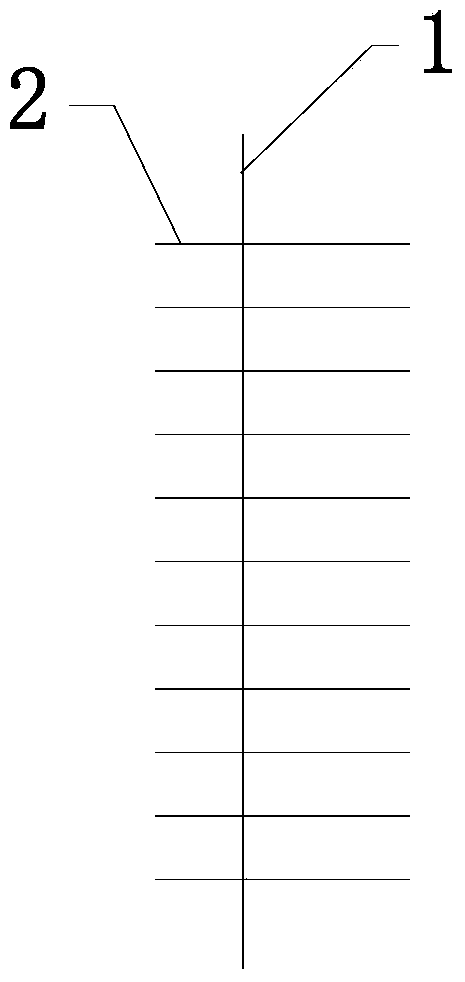

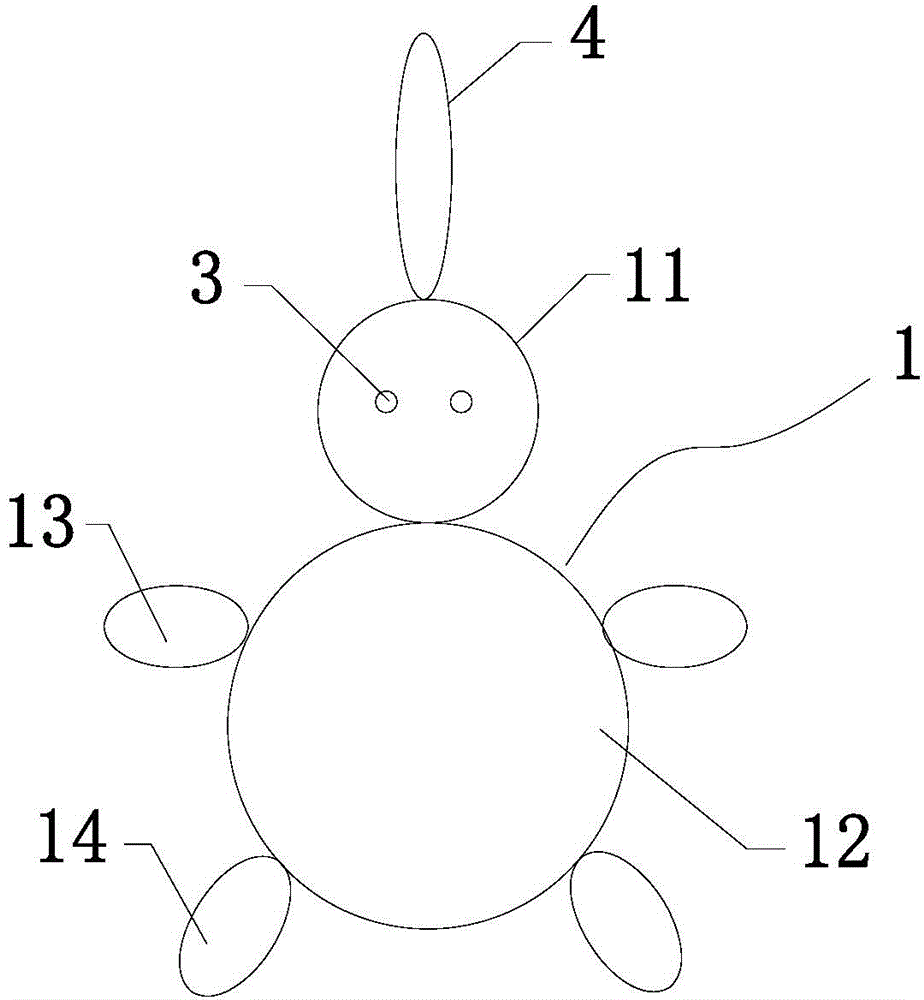

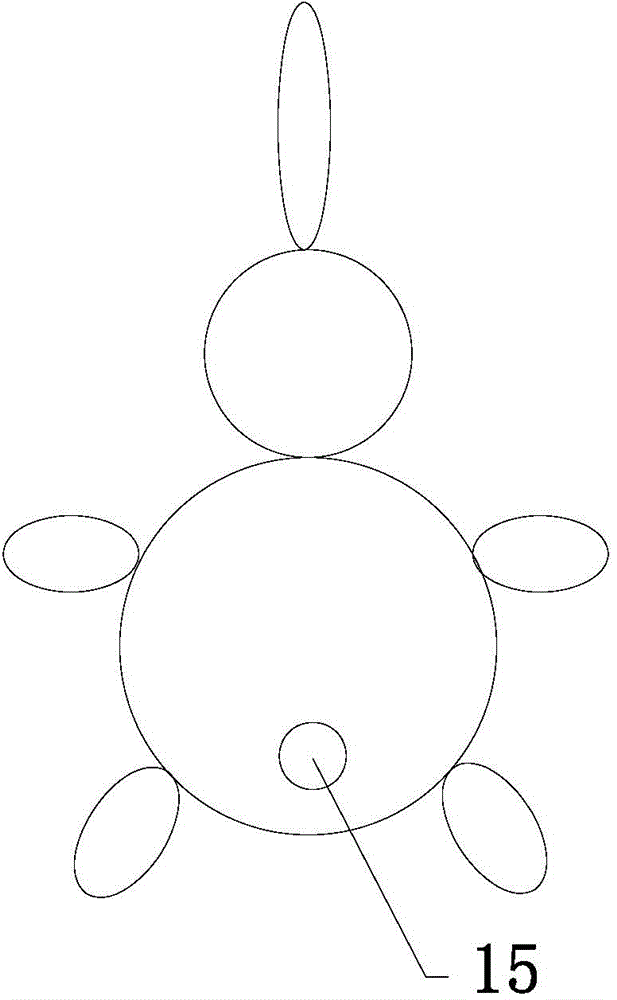

Wool felt doll and making method thereof

The invention discloses a wool felt doll and a making method thereof. The wool felt doll comprises a doll body, wool and decorating parts, wherein the doll body is made of polyurethane sponge. The surface of the doll body is covered with the wool, and the wool penetrates into the doll body through a needle and is fixed. The decorating parts are installed on the doll body. The wool felt doll is high in density, easy to machine and shape, and high in extrusion resisting capability, and has the advantages of being soft, distinct in detail, vivid and the like after being shaped. Obviously, the problem that an existing wool felt doll is difficult to shape is solved, the characteristic that the wool felt doll is soft is also kept, and meanwhile the problem that wool felt dolls are difficult to produce on a large scale is solved. More importantly, the polyurethane sponge is environmentally friendly and nontoxic, namely the wool felt doll made of the polyurethane sponge is suitable for people at all ages, and there is no need to worry that the wool felt doll causes harm to the human body. Besides, the wool felt doll can be manually made in a DIY mode, and requirements of more users are met.

Owner:涂雄

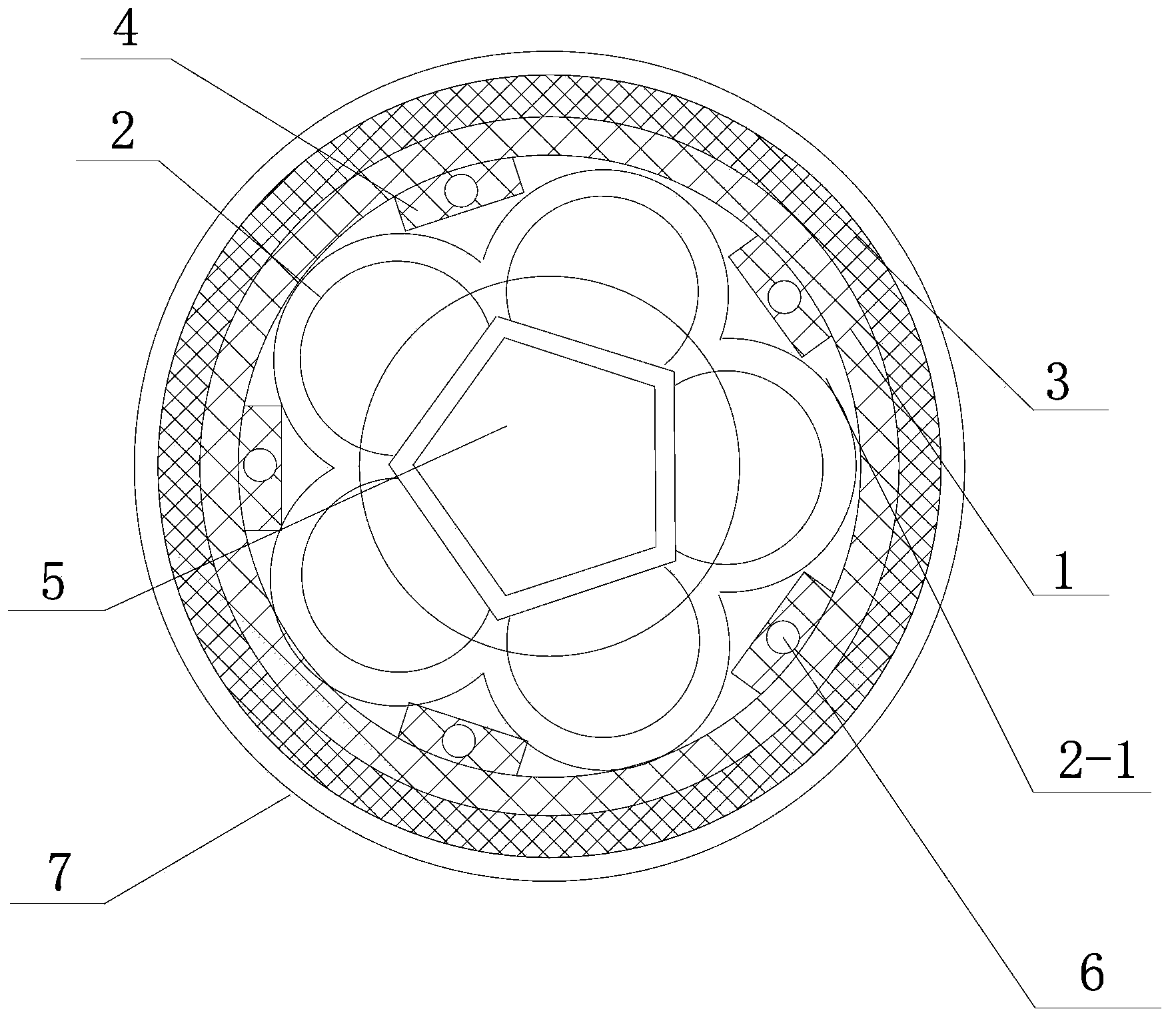

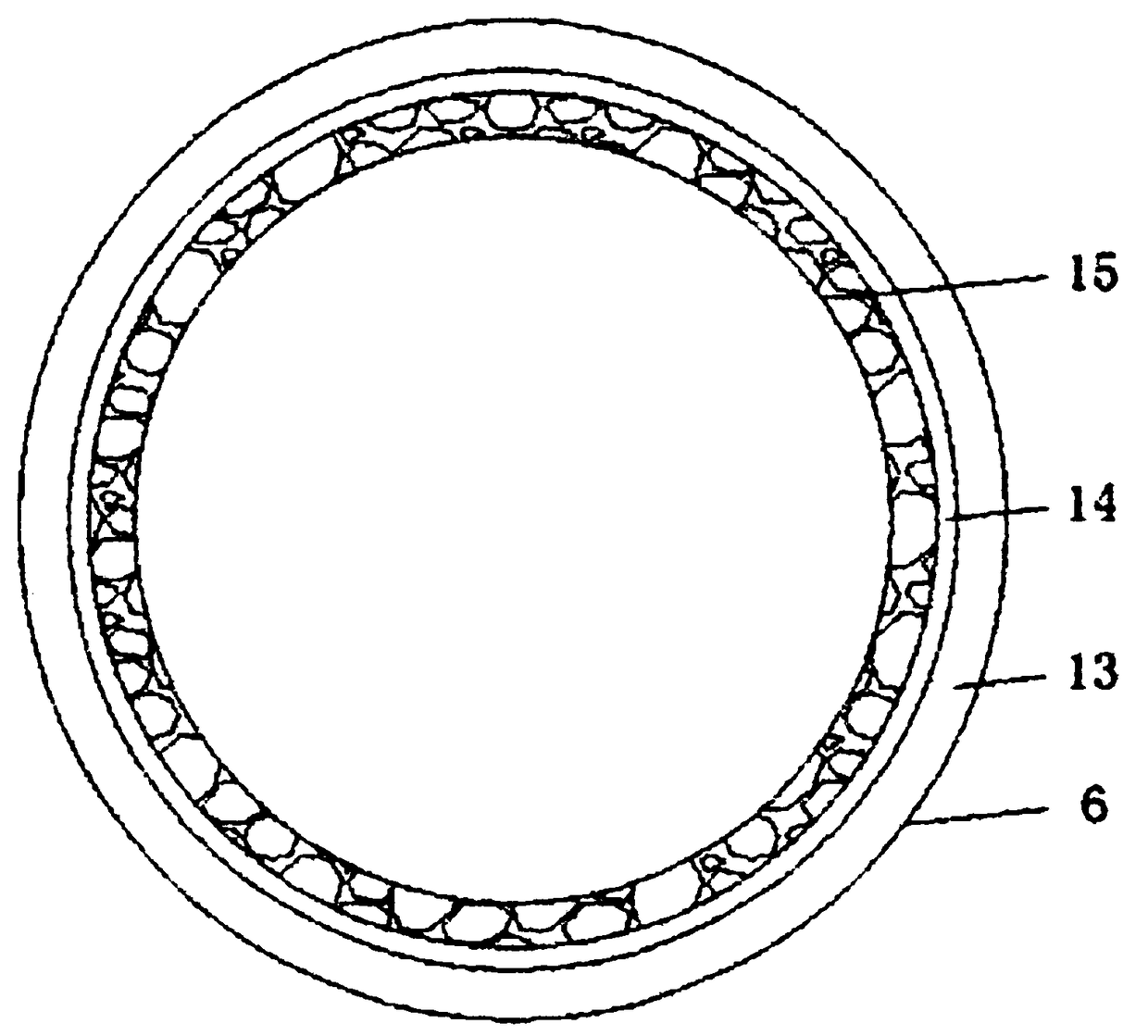

Pressure-tolerant communication perforated pipe

InactiveCN103515912AEasy to fixStrong extrusion resistanceCable installations in surface ductsCable installations in underground tubesWaste management

The invention relates to a pressure-tolerant communication perforated pipe. According to the perforated pipe, the problem that a secondary pipe and a main pipe of a present communication perforated pipe are not firmly connected and materials are wasted is solved. The pressure-tolerant communication perforated pipe comprises a main pipe, secondary pipes, a connector and positioning pins. The secondary pipes include five circular pipes with equal diameters. Centers of the five circular pipes with equal diameters are at the same circumference, and two adjacent circular pipes are tangent to each other and are integrated as a whole. A centre hole encircled by the five circular pipes has a regular pentagon structure. The secondary pipes are arranged in the main pipe. The connector is arranged at the end portion of the main pipe. Location holes are disposed along the axial direction of the connector, the main pipe and the secondary pipes. The positioning pins pass through the location holes to connect the connector, the main pipe and the secondary pipes together. According to the pressure-tolerant communication perforated pipe provided by the invention, the secondary pipes and the main pipe are connected fixedly and firmly. The pressure-tolerant capability of the perforated pipeline is strong.

Owner:江苏易成电力器材有限公司

High-strength optical cable for network equipment

InactiveCN109188633AStrong extrusion resistanceIncrease usage intensityFibre mechanical structuresEpoxyFiber

The invention relates to a high-strength optical cable for network equipment. The optical cable comprises an optical cable main body, a reinforced steel wire layer, an outer sheath protecting sleeve,wire cores and reinforced supporting rods, wherein the reinforcing supporting rods are arranged inside the optical cable main body; the wire cores are arranged inside the optical cable main body on one sides of the reinforced supporting rods; the optical cable main body between the wire cores is filled with epoxy resin; the reinforced steel wire layer is arranged on the outer side of the optical cable main body; an insulating layer is arranged on the outer side of the reinforced steel wire layer; a first electromagnetic shielding layer is arranged on the outer side of the insulating layer; a second electromagnetic shielding layer is arranged on the outer side of the first electromagnetic shielding layer; the first and second electromagnetic shielding layers are formed by weaving fabrics with electromagnetic shielding functions; the fabrics comprise fabric bodies; the fabric bodies are polyester fibers; and Cu-Cu composite films are arranged on the surfaces of the fabric bodies.

Owner:广州一源贸易有限公司

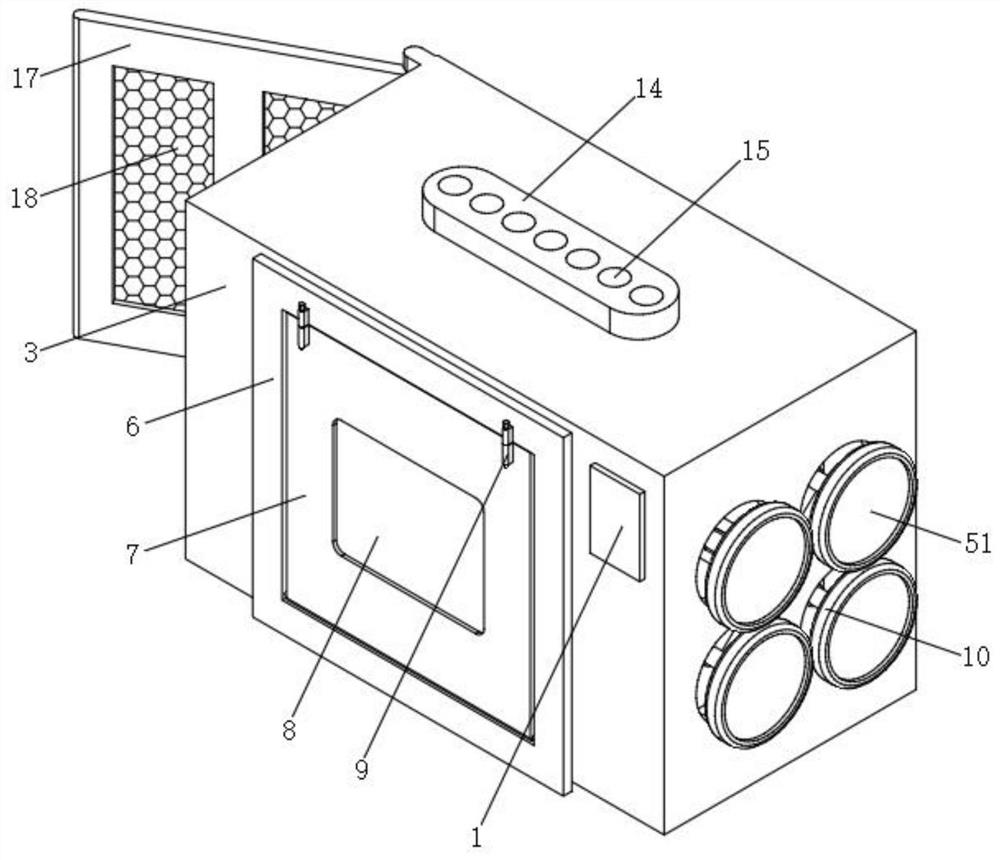

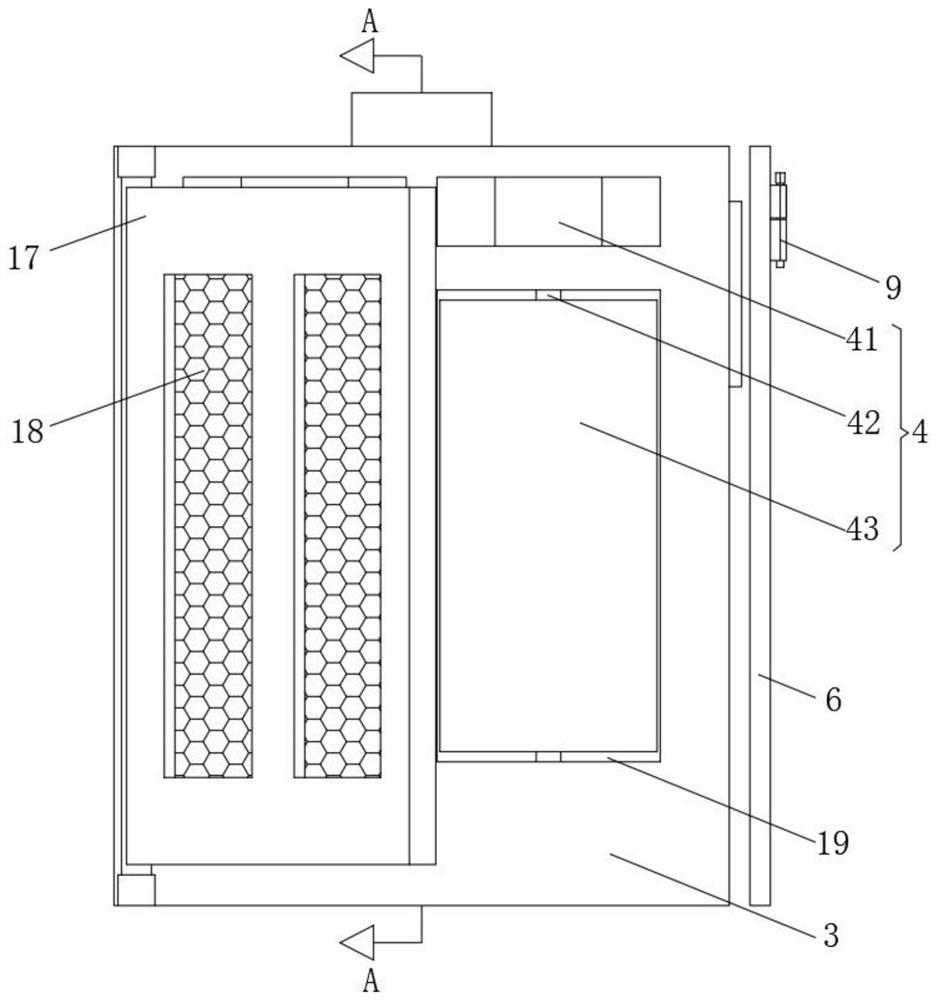

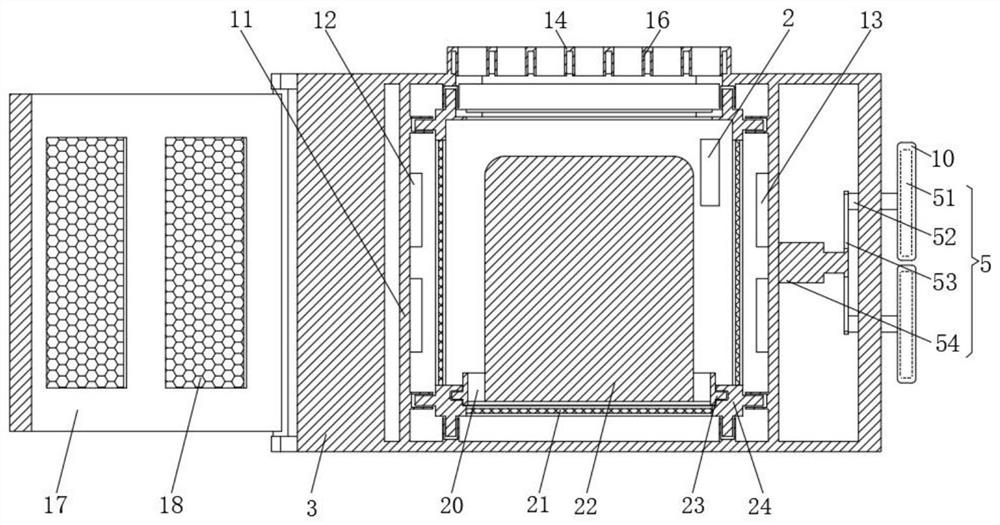

Maintenance-free heat dissipation type intelligent circuit breaker

InactiveCN111653961AImprove extrusion resistanceImprove impact resistanceSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsStructural engineeringMoisture sensor

The invention discloses a maintenance-free heat dissipation type intelligent circuit breaker. The intelligent circuit breaker comprises a box body, a front door, an air inlet control mechanism and anair outlet control mechanism. Two partition plates are installed between the inner walls of the box body in parallel; an air inlet fan is mounted on the partition plate on the left side; an air outletfan is mounted on the partition plate on the right side; a concentric-square-shaped plate is mounted between the two partition plates; a mounting base is mounted at the bottom end of the concentric-square-shaped plate; punching screen plates are installed on the side faces of the box body; a circuit breaker body is fixedly installed on the mounting base; an air inlet is formed in the left end ofthe box body; an air outlet is formed in the right end of the box body; a temperature and humidity sensor is installed on the inner wall of the box body; a wire penetrating base is installed at the top end of the box body; and a wire hole is formed in the top end of the wire penetrating base. The front door is fixed to the front side face of the box body through screws, and a sealing plate is hinged to the front side face of the front door. The circuit breaker is good in anti-collision and anti-extrusion performance and high in safety, and is provided with a heat dissipation mechanism.

Owner:JIANGSU SHILIN ELECTRIC EQUIP

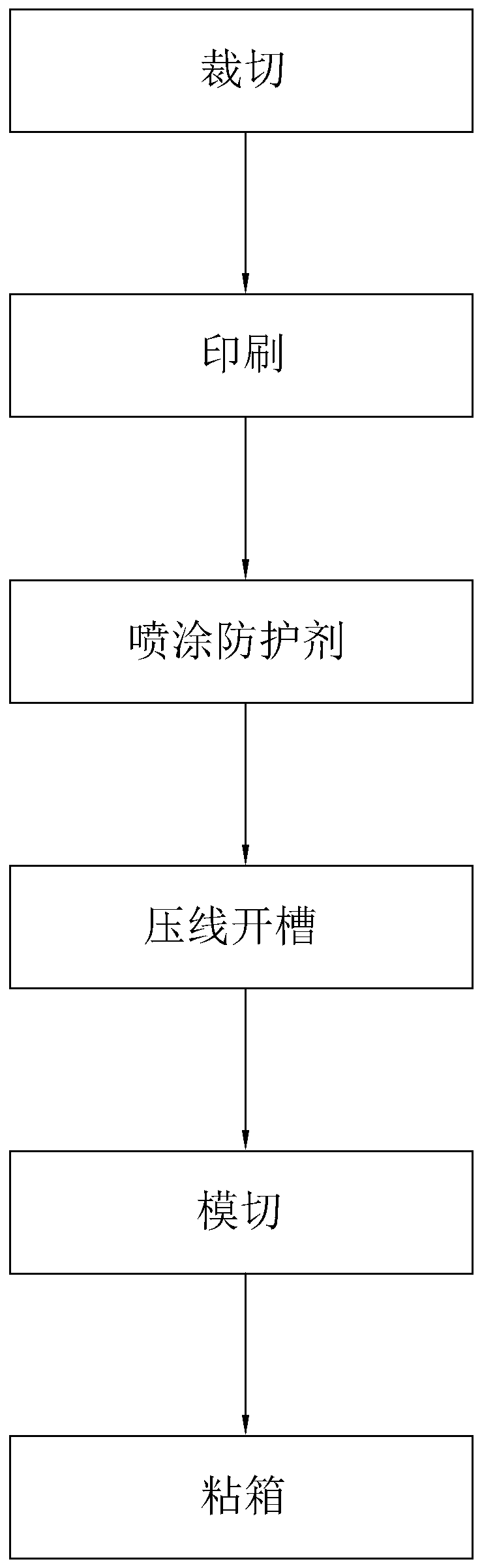

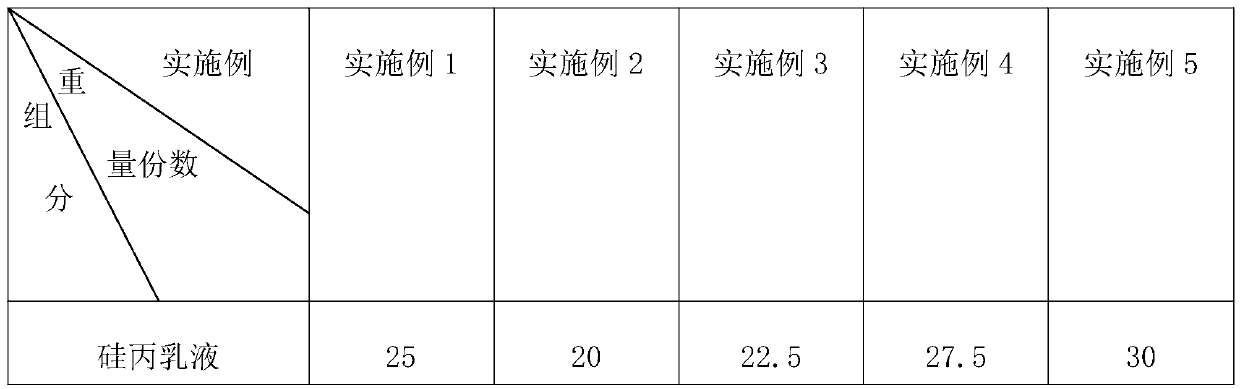

Production and processing technology of corrugated carton

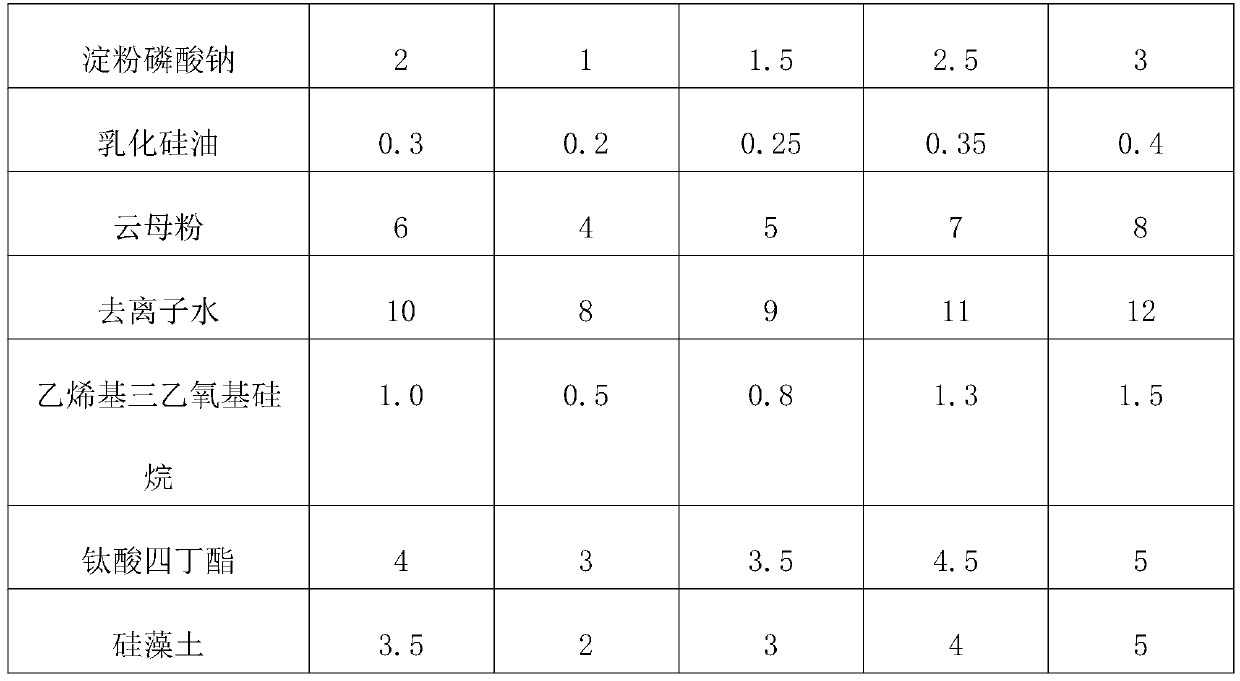

InactiveCN111058333AImprove protectionImprove stain resistanceNon-fibrous pulp additionFlexible coversVinyltriethoxysilaneCarton

The invention discloses a production and processing technology of a corrugated carton, which relates to the technical field of corrugated paper product processing, and solves the problem that the overall quality of the corrugated carton is greatly reduced due to the fact that printed corrugated paper is easy to stain and damage in the subsequent processing process, and the production and processing technology comprises the following steps: step 1, cutting; step 2, printing; 3, spraying a protective agent; 4, pressing lines and slotting; step 5, die cutting; and step 6, box sticking; wherein the protective agent in the step 3 is prepared from the following components in parts by weight: 20 to 30 parts of a silicone acrylic emulsion; 1-3 parts of a thickening agent; 0.2 to 0.4 part of a defoaming agent; 4-8 parts of a wear-resistant filler; 8 to 12 parts of deionized water; 0.5 to 1.5 parts of vinyl triethoxy silane; 3 to 5 parts of tetrabutyl titanate; 2-5 parts of diatomite. Accordingto the production and processing technology of the corrugated carton, in the actual application process, printed patterns are not prone to being stained and damaged, and the overall quality of the corrugated carton can be guaranteed.

Owner:上海赛尔印刷包装材料有限公司

A compact, crush-resistant cable

ActiveCN108091430BCompact structureStrong extrusion resistanceInsulated cablesInsulated conductorsElastic componentLong axis

The invention discloses a structurally-compact anti-extrusion cable. The structurally-compact anti-extrusion cable comprises a cable core and an outer structural layer wrapping the outer periphery ofthe cable core; the cable core comprises elastic tubes, wire cores, elastic components and a wrapping layer; a plurality of elastic tubes are provided; the elastic tubes are sequentially distributed according to an order; the cross-section of each elastic tube is in the shape of an oblong hole; any two adjacent elastic tubes are arranged in a staggered manner at different heights along the long axis direction of the elastic tubes; the number of the wire cores is consistent with the number of the elastic tubes; the wire cores are arranged in the elastic tubes in a one-to-one corresponding manner; the number of the elastic components is consistent with the number of the elastic tubes; the elastic components are arranged in the elastic tubes in a one-to-one corresponding manner; when the elastic components are in natural states, any two adjacent wire cores are located at one side where the two adjacent wire cores are far away from each other; and the wrapping layer wraps the outer circumference of the elastic tubes. The structure of the structurally-compact anti-extrusion cable of the invention is simple and compact, and the cable can have strong anti-extrusion ability in any direction.

Owner:GUANGDONG YUANGUANG CABLE IND

Wool felt doll and making method thereof

The invention discloses a wool felt doll and a making method of the wool felt doll. The wool felt doll comprises a doll body made of polyurethane sponge, wool and a decorating part, wherein the surface of the doll body is covered with the wool, and the wool is punctured into the doll body through a needle to be fixed; the decorating part is installed on the doll body. The doll is high in density, easy to process and form and high in anti-extruding capacity, and the formed doll has the advantages of being soft in hand feeling, clear in detail, lifelike and the like; obviously, the doll solves the problem that an existing wool felt doll is difficult to form, keeps the characteristic that the wool felt doll is soft, and meanwhile solves the problem that wool felt dolls are difficult to produce on a large scale, more importantly, the polyurethane sponge is environmentally friendly and nontoxic, in other words, the wool felt doll made of the polyurethane sponge is suitable for people of all ages, and a user does not need to worry about harm to a body. Besides, the doll can be made in a manual DIY mode, and requirements of more using groups are met.

Owner:涂雄

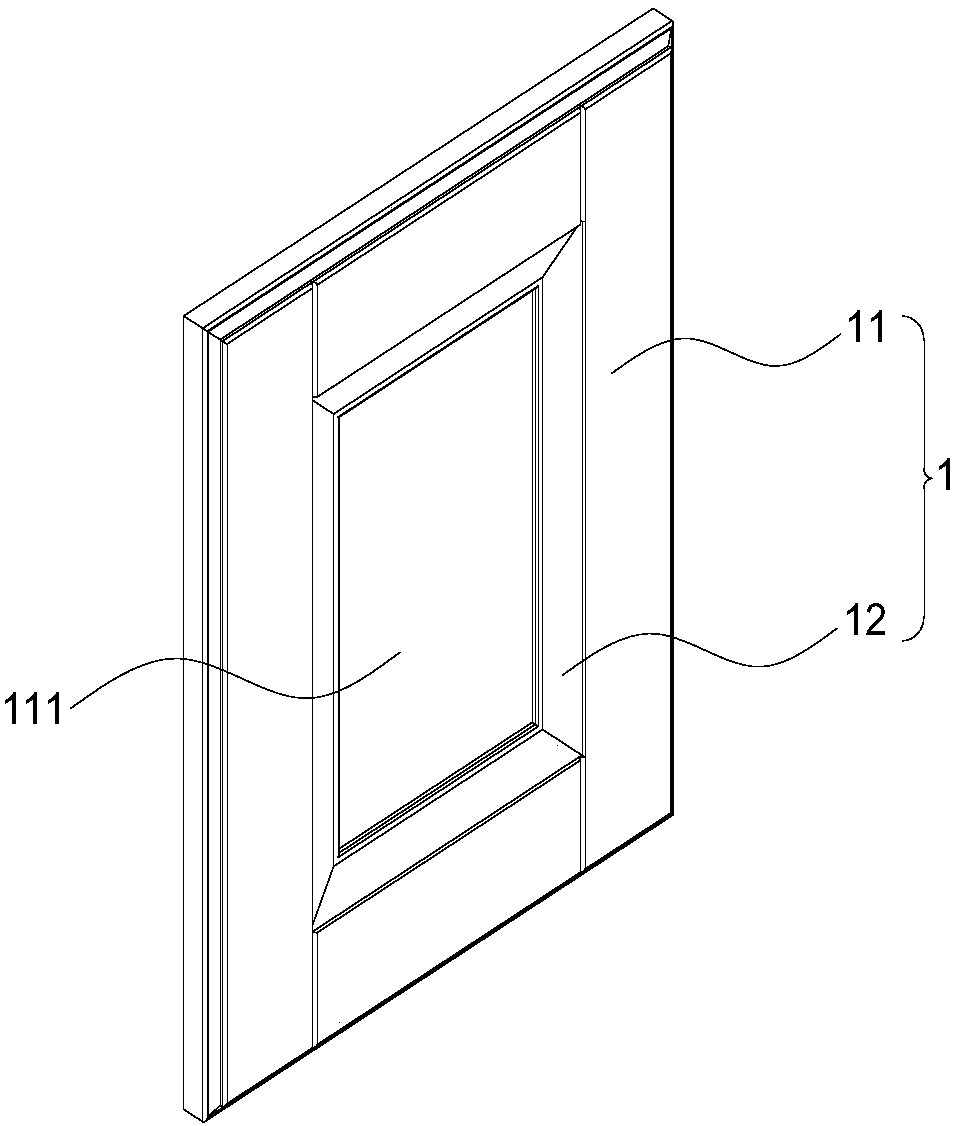

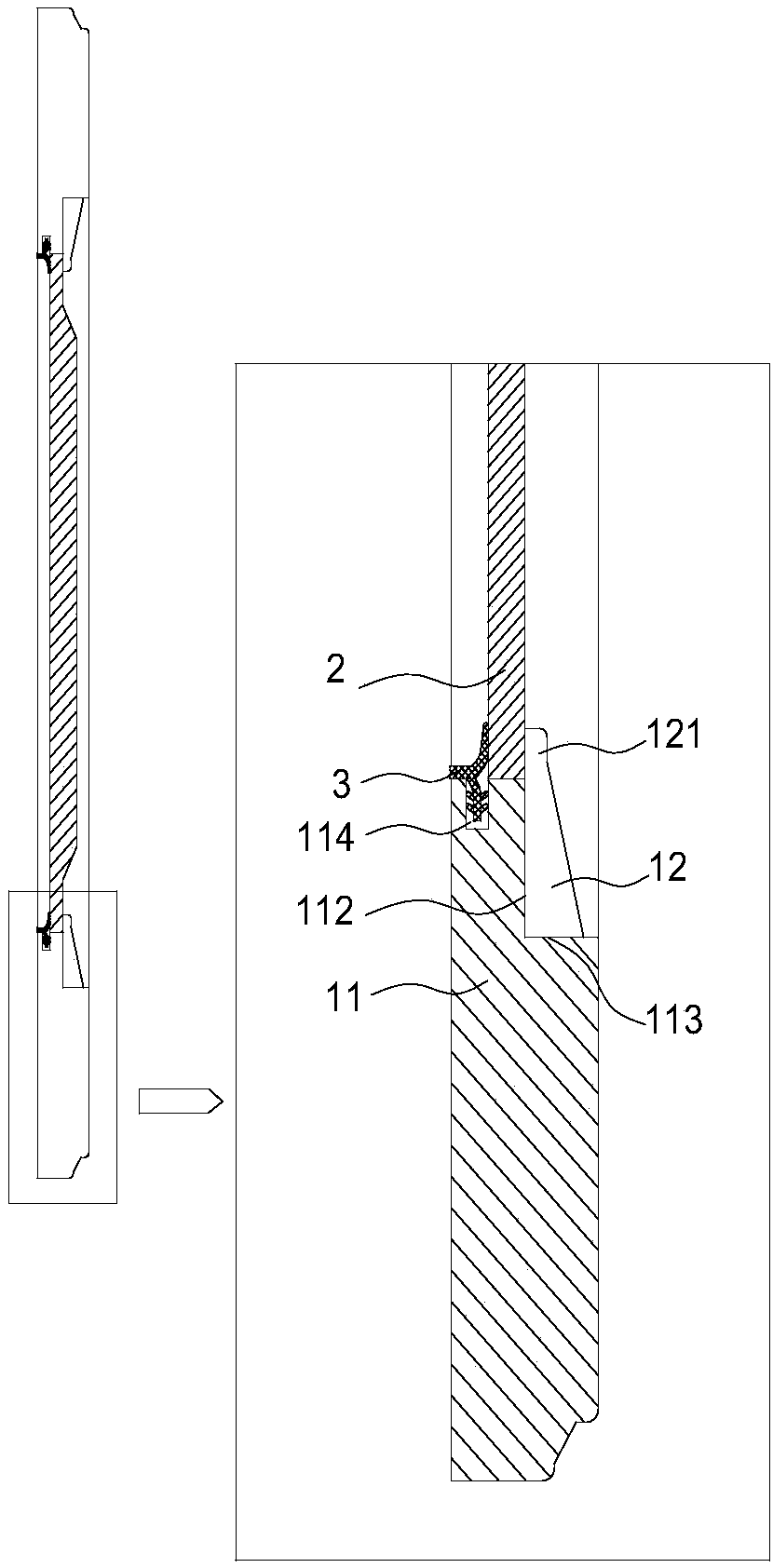

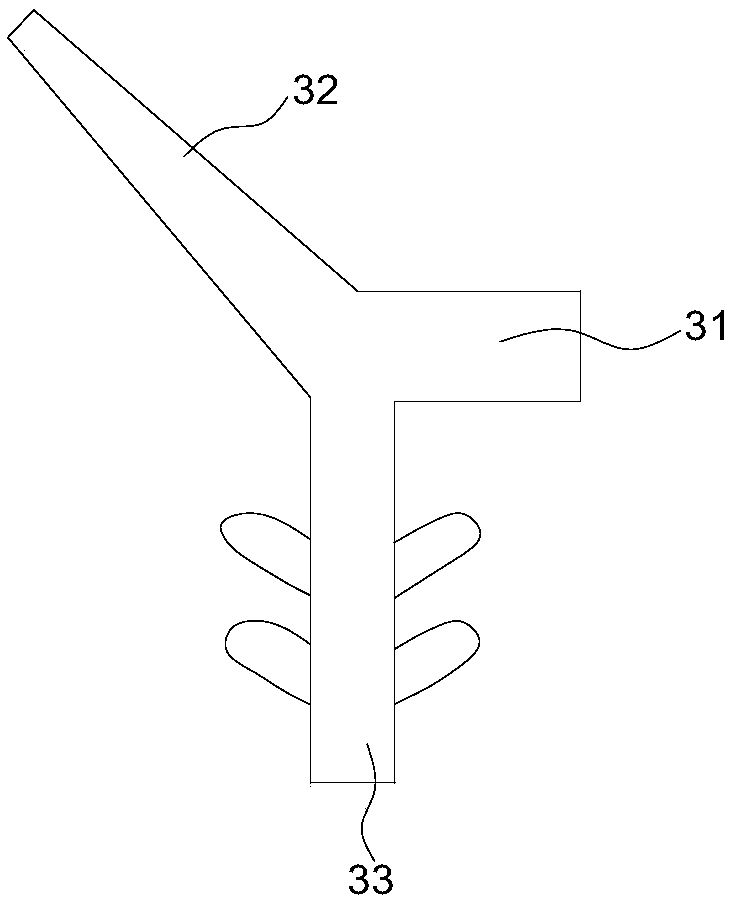

Door frame, preparation method of door frame, and molding press door comprising door frame

InactiveCN108316821AImprove stabilityHigh strengthWood working apparatusDoor leavesEngineeringElectrical and Electronics engineering

The invention discloses a door frame and further discloses a molding press door and a preparation method of the molding press door. The door frame comprises a door frame main body and a side frame. Arectangular opening with the size being matched with that of a rectangular door core is formed in the middle of the door frame main body, and a rectangular right-angle groove surrounding the rectangular opening is formed in the obverse side of the door frame main body. The cross section of the right-angle groove is in an L shape, and the right-angle groove comprises a horizontal groove face parallel to the obverse side of the door frame main body and a vertical groove face perpendicular to the obverse side of the door frame main body. The horizontal groove face is covered with the side frame,and the side frame extends out of the horizontal groove face towards rectangular opening to form an abutting-joint part. The thickness of the side frame is smaller than or equal to the height of the vertical groove face. The molding press door formed by assembling the door frame is overall flat and smooth, the stability and strength of the molding press door are enhanced, and the impact-resistantand extruding-resistant properties of the molding press door are also enhanced.

Owner:SUOFEIYA HOME COLLECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com