Anti-extrusion signal cable

A signal cable and anti-extrusion technology, which is applied in the field of anti-extrusion signal cables, can solve the problems of being easily extruded, pulled, and lost, and achieve the effects of enhanced anti-extrusion ability, reduced shielding ability, and good tensile ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

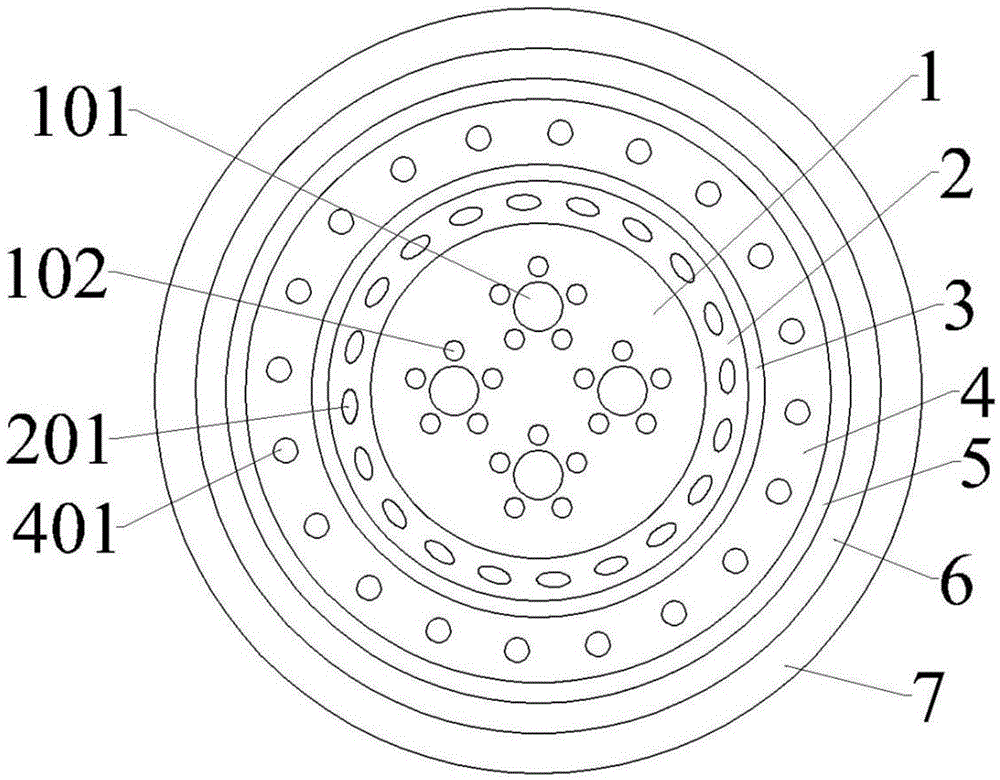

[0030] Such as figure 1 As shown, an anti-extrusion signal cable, including:

[0031] A cable core, which includes an insulator 1 and a plurality of wire cores, the interior of the insulator 1 is provided with a plurality of first through holes 101 and a plurality of second through holes 102 in the axial direction, and each first through hole 101 is surrounded by Surrounded by three second through holes 102, the plurality of wire cores are respectively placed in the plurality of first through holes 101, and for each wire core, it includes a conductor, a polyester tape covering the conductor And the copper wire braid covering the polyester tape, the material of the insulator 1 is polyethylene with a density of 0.920 g / cubic centimeter;

[0032] The inner sheath 2, which covers the cable core, has a plurality of third through holes 201 in the inner sheath 2 along the axial direction, and the material of the inner sheath 2 has a density of 0.934 g / cm3 polyethylene;

[0033] Sh...

example 2

[0043] Such as figure 1 As shown, an anti-extrusion signal cable, including:

[0044] A cable core, which includes an insulator 1 and a plurality of wire cores, the interior of the insulator 1 is provided with a plurality of first through holes 101 and a plurality of second through holes 102 in the axial direction, and each first through hole 101 is surrounded by Surrounded by 6 second through holes 102, the plurality of wire cores are respectively placed in the plurality of first through holes 101, and for each wire core, it includes a conductor, a polyester tape covering the conductor And the copper wire braid covering the polyester tape, the material of the insulator 1 is polyethylene with a density of 0.923 grams / cubic centimeter;

[0045] The inner sheath 2, which covers the cable core, is provided with a plurality of third through holes 201 along the axial direction inside the inner sheath 2, and the material of the inner sheath 2 has a density of 0.936 grams / cubic cent...

example 3

[0056] Such as figure 1 As shown, an anti-extrusion signal cable, including:

[0057] A cable core, which includes an insulator 1 and a plurality of wire cores, the interior of the insulator 1 is provided with a plurality of first through holes 101 and a plurality of second through holes 102 in the axial direction, and each first through hole 101 is surrounded by Surrounded by five second through holes 102, the plurality of wire cores are respectively placed in the plurality of first through holes 101, and for each wire core, it includes a conductor, a polyester tape covering the conductor And the copper wire braid covering the polyester tape, the material of the insulator 1 is polyethylene with a density of 0.921 g / cubic centimeter;

[0058] The inner sheath 2, which covers the cable core, has a plurality of third through-holes 201 in the inner sheath 2 along the axial direction, and the material of the inner sheath 2 has a density of 0.935 g / cubic centimeter polyethylene; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com