Door frame, preparation method of door frame, and molding press door comprising door frame

A door frame and molding technology, applied in the direction of door leaves, windows/doors, manufacturing tools, etc., can solve the problems of limited strength of molded doors, resistance to impact and extrusion, complex processing procedures, etc., to avoid glue connection or nailing, Enhance the overall strength, the effect of a stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

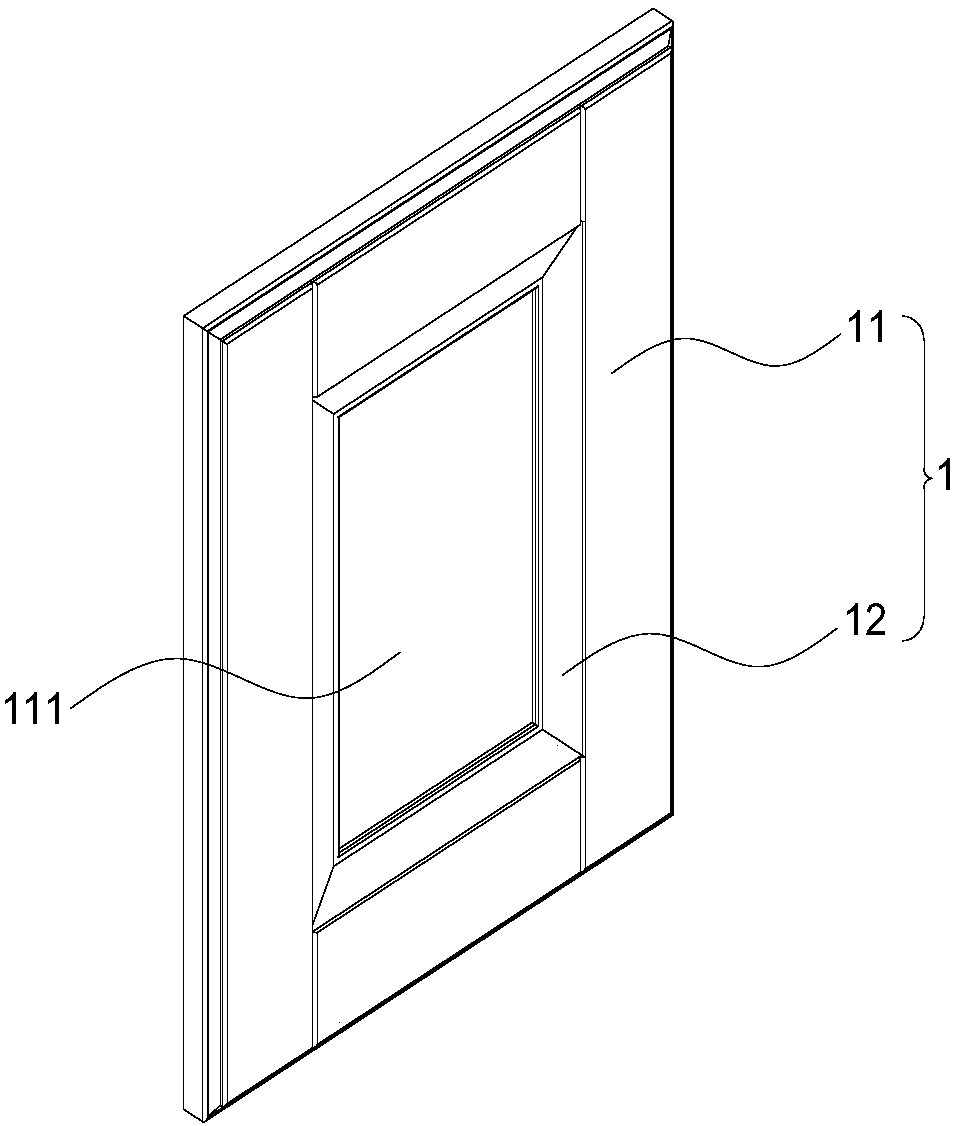

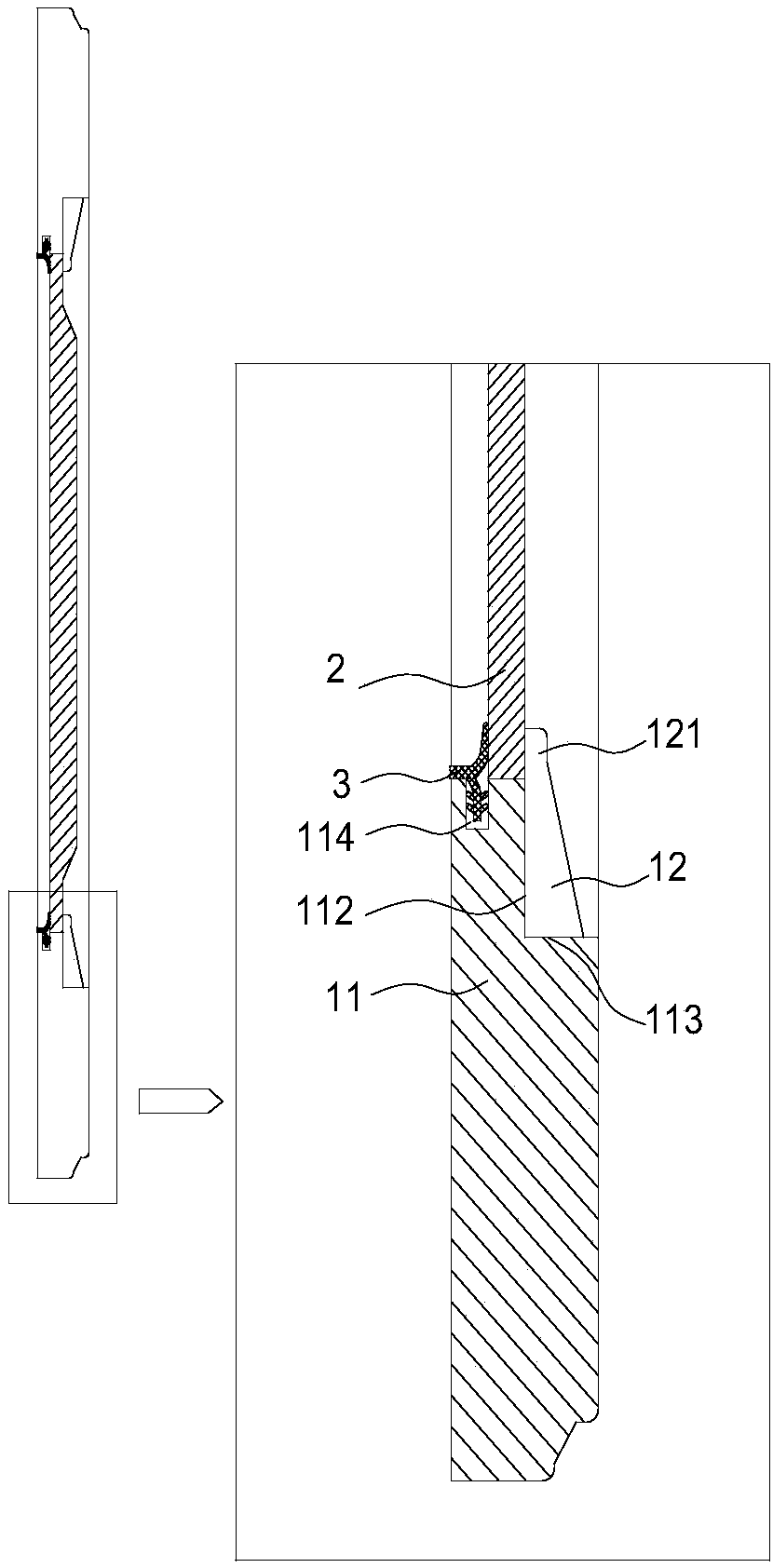

[0038] like Figure 1-2 Shown is a door frame 1 of the present invention. The door frame 1 includes a door frame main body 11 and a frame 12. The middle part of the door frame main body 11 is provided with a rectangular opening 111 matching the size of the rectangular door core 2. Rectangular and right-angled groove around the rectangular opening 111 ("right-angled groove" here means that the periphery of the rectangular opening 111 towards the outer side of the door is a rectangular concave position, and the rectangular concave position surrounds the rectangular opening 111), the right angle The cross-section of the groove is L-shaped, and the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com