Water-locking sponge as well as preparation method and application thereof

A water sponge and sponge technology, applied in the field of porous materials, can solve the problems of lack of prevention of bacterial growth, skin regeneration, secondary injury of wound surface, increase wound stimulation, etc., achieving strong adjustability, high universality, and improved water retention. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

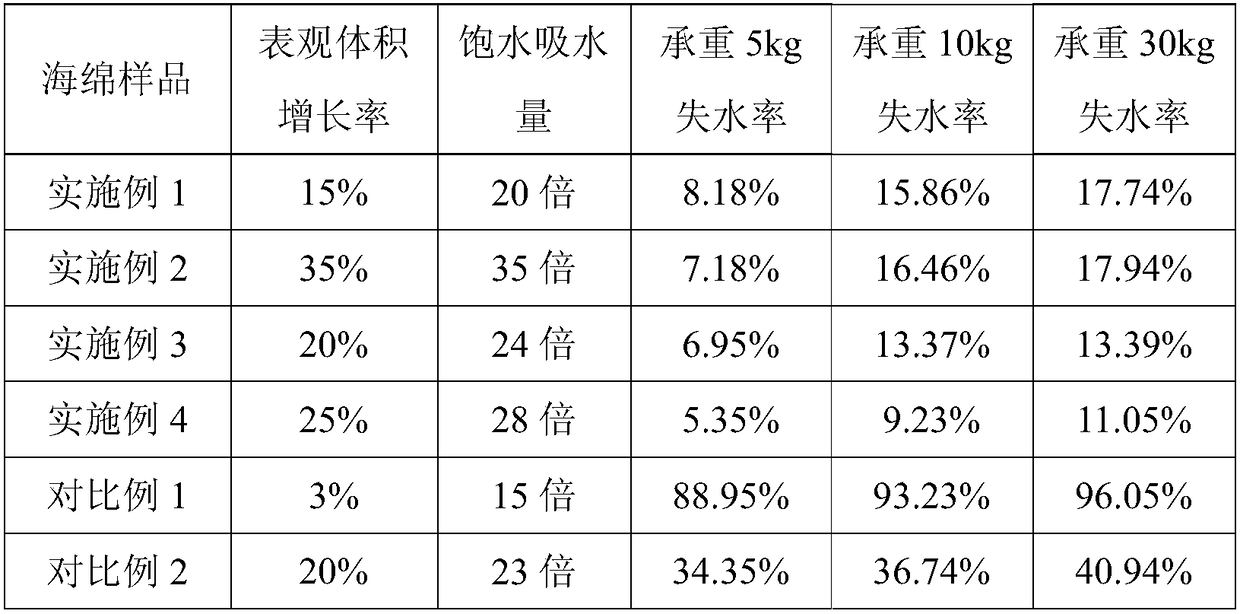

Examples

Embodiment 1

[0029] A water-locking sponge, including a polyester sponge and a 30-mesh sodium polyacrylate water-absorbing resin filled in the pores of the sponge in granular form, and the apparent density of the water-absorbing resin in the water-locking sponge is 5kg / m 3 .

[0030] Its preparation method is as follows:

[0031] (1) mixing the foaming resin and the foaming aid to obtain a foaming mixture;

[0032] (2) Dispersing the dried water-absorbing resin with a particle size of 30 meshes in the foaming mixture obtained in step (1), the water-absorbing resin accounting for 20 wt% of the foaming mixture obtained in step (1);

[0033] (3) Foaming the mixture obtained in step (2) to obtain a water-locking sponge.

Embodiment 2

[0035] A water-locking sponge, comprising a polyester sponge and 200-mesh polyacrylamide and 170-mesh sodium polyacrylate water-absorbing resin (mass ratio 1:1) filled in the pores of the sponge in granular form, and the water-absorbing resin in the water-locking sponge The apparent density is 30g / m 3 .

[0036] Its preparation method is as follows:

[0037] (1) mixing the foaming resin and the foaming aid to obtain a foaming mixture;

[0038] (2) Dispersing the dried water-absorbing resin with a particle size of 200 mesh in the foaming mixture obtained in step (1), the water-absorbing resin accounting for 60 wt% of the foaming mixture obtained in step (1);

[0039] (3) Foaming the mixture obtained in step (2) to obtain a water-locking sponge.

Embodiment 3

[0041]A water-locking sponge, comprising a polyether sponge and a 140-mesh polyoxyethylene water-absorbing resin filled in the internal pores of the sponge in granular form, and the apparent density of the water-absorbing resin in the water-locking sponge is 15g / m 3 .

[0042] Its preparation method is as follows:

[0043] (1) mixing the foaming resin and the foaming aid to obtain a foaming mixture;

[0044] (2) Dispersing the dried water-absorbing resin with a particle size of 100 mesh in the foaming mixture obtained in step (1), the water-absorbing resin accounting for 40 wt% of the foaming mixture obtained in step (1);

[0045] (3) Foaming the mixture obtained in step (2) to obtain a water-locking sponge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com