Visual magnetically-controlled switch

A technology of magnetic control switch and reed switch, which is applied in the direction of magnetic switch, magnetic/electric field switch, electric switch, etc., which can solve the problems of normal production and operation constraints, short service life, and easy corrosion of industrial and mining enterprises, and reduce detection operations Quantity and cost of material and spare parts, detection error probability reduction, and strong sealing and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

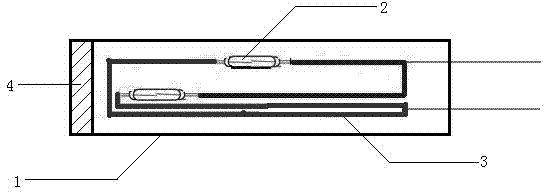

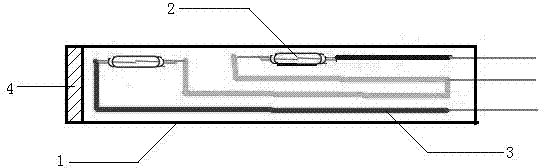

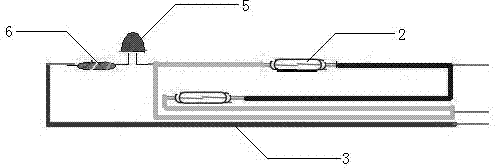

[0036] Such as figure 1 Shown is a schematic diagram of the structure of the reed switch in the present invention when it is connected in parallel, which is used to detect the magnetic control switch for the parking position of the hoist, so as to prevent abnormal operation caused by undetected; the present invention is a visible magnetic control switch, including an external tube Shell 1, reed switch 2 and wire 3.

[0037] The outer casing 1 is a transparent plexiglass tube filled with epoxy resin; one end of the outer casing 1 is sealed with a rubber insulating self-adhesive tape 4 , and the other end is sealed with epoxy resin.

[0038] The number of reed swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com