Wool felt doll and making method thereof

A production method and wool felt technology, applied in dolls, toys, entertainment and other directions, can solve problems such as unsuitable dolls, sponge damage, and incision lengthening, and achieve mass production, strong anti-extrusion ability, and simple processing and molding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

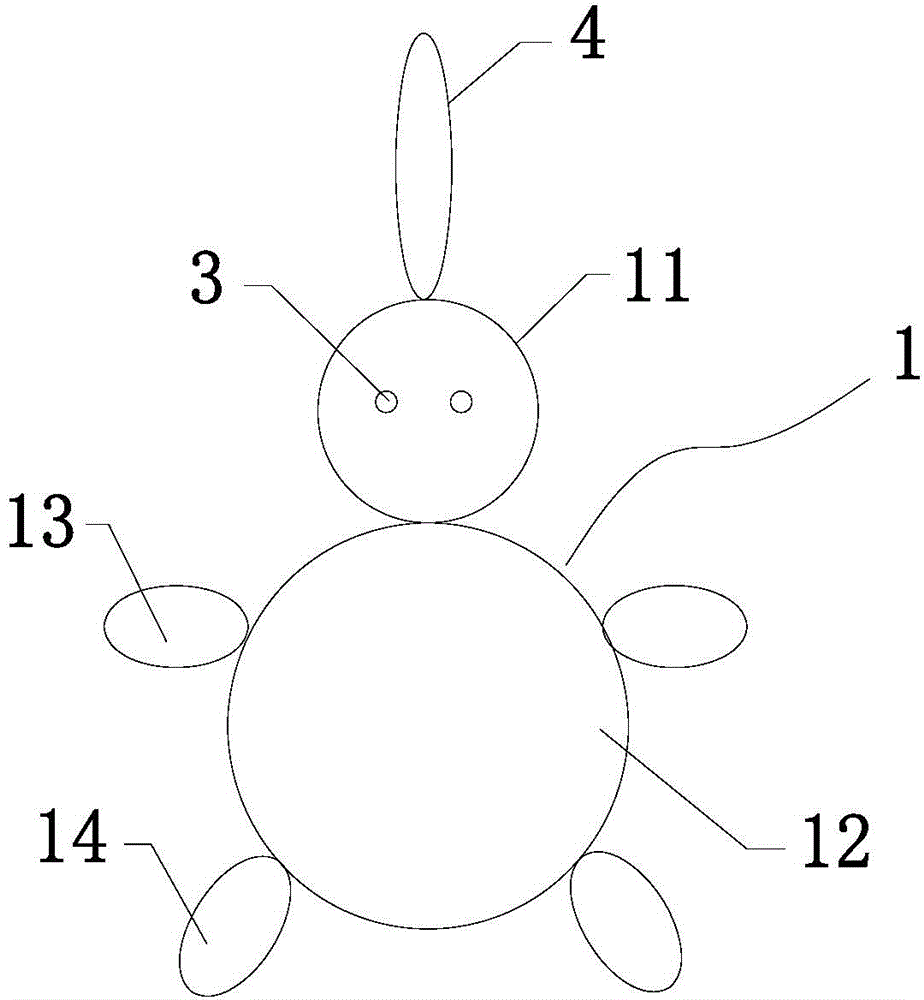

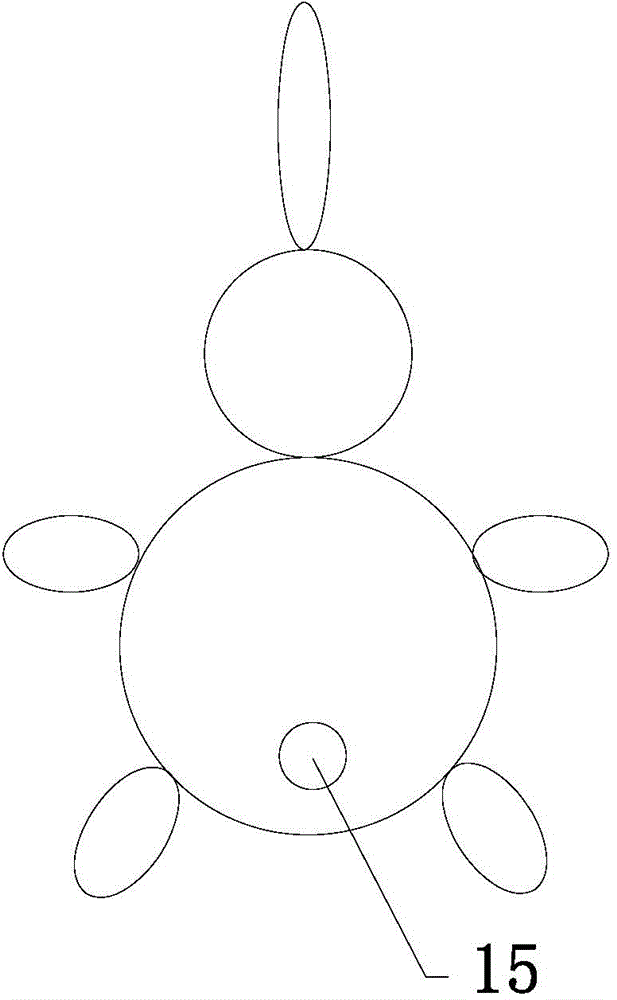

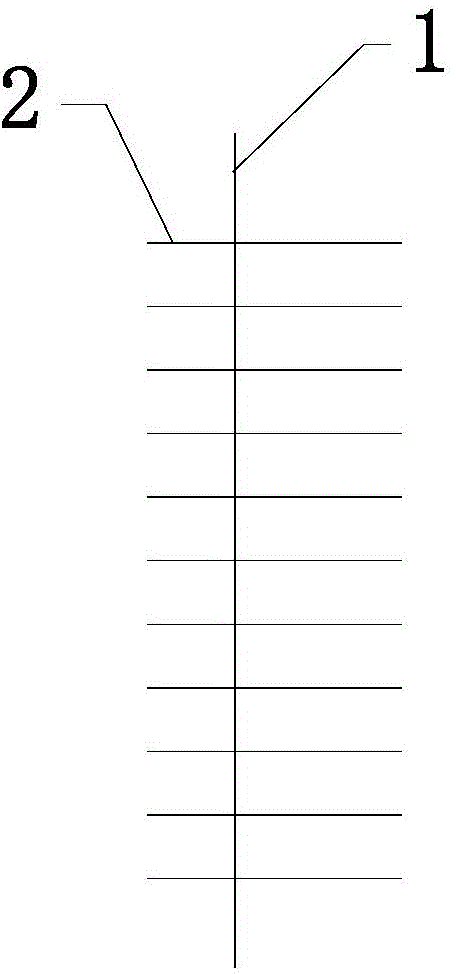

[0031] The present invention as Figures 1 to 3 It can be seen from the figure that the wool felt doll includes a doll body 1 made of polyurethane sponge, wool 2 and eye parts 3; the wool 2 covers the surface of the doll body 1, and the wool 2 is pierced into the doll with a needle It is fixed in the main body 1. Wherein, the doll body 1 includes a head 11, a torso 12, a pair of hands 13, a pair of feet 14 and a tail 15; the head 11 is installed on the top of the torso 12, and the eye parts 3 are installed on the head. On the head 11, the top of the head 11 is provided with a suspension ring 4; the hands 13 are respectively installed on both sides of the upper part of the trunk 12; the feet 14 are respectively installed on both sides of the lower part of the trunk 12; the tail 15 is installed On the back of the lower part of the tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com