Patents

Literature

73results about How to "Solve difficult molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weight-losing meal replacing biscuit and making method thereof

ActiveCN102100241ASolve difficult moldingEasy to dry and shapeDough treatmentBakery productsFiberPolyphenol

The invention relates to a weight-losing meal replacing biscuit and a making method thereof, and belongs to the technical field of nutrition and food science. A high-protein high-fiber netlike stereo structure is formed by a low-temperature baking technology so as to solve the problems that the high-protein high-fiber biscuit is difficulty shaped, is not dried thoroughly and is burned in baking; the biscuit has more balanced nutritional structure, prolongs the emptying time of the stomach, eliminates hunger and hidden hunger, and ensures the weight losing effect; by adding unique stachyose, the biscuit has excellent effects on the aspects of improving the intestinal environment and preventing constipation; and apple polyphenol and collagen have the effect of beautifying the skin and can relieve the universal skin nutrition problem in the weight losing process, so that the weight losing process is more health and effective.

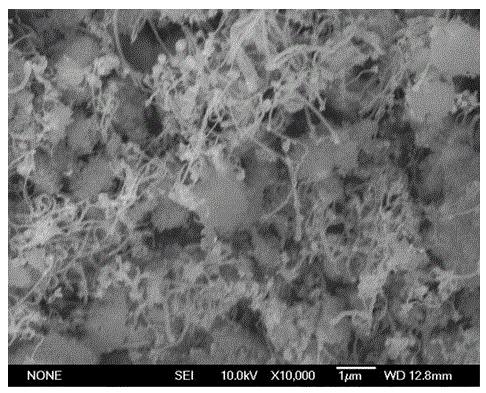

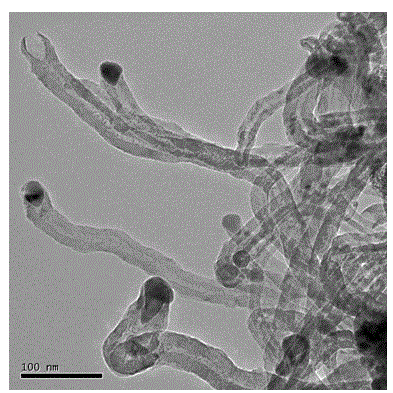

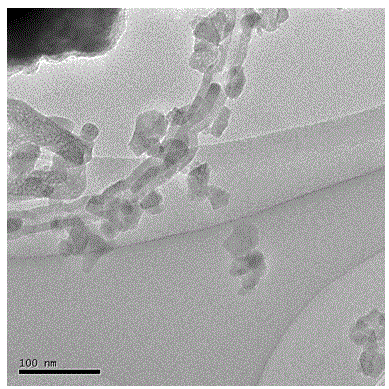

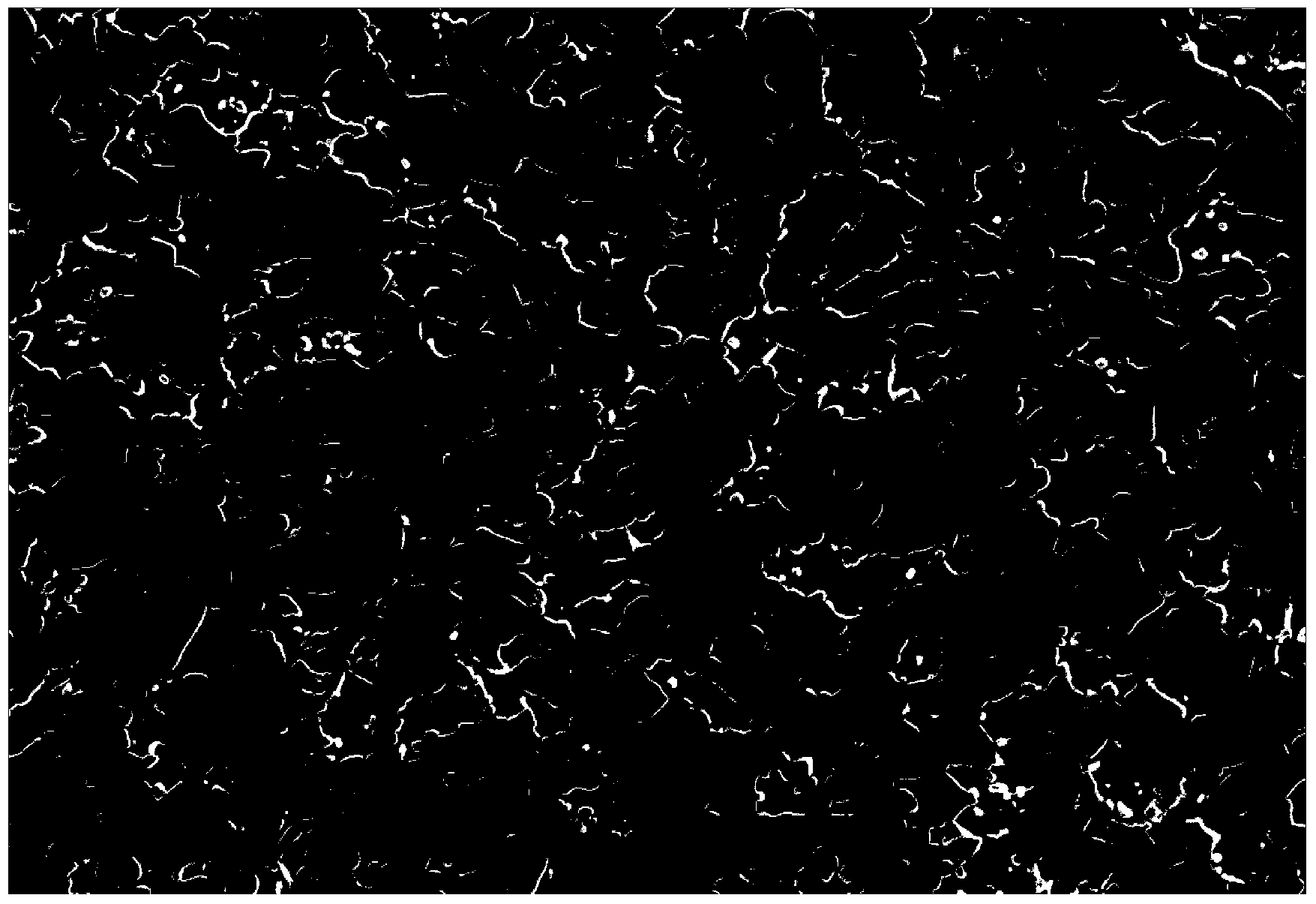

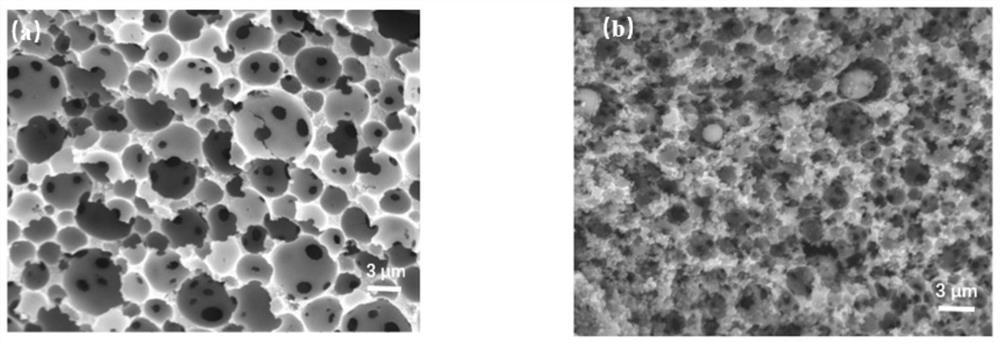

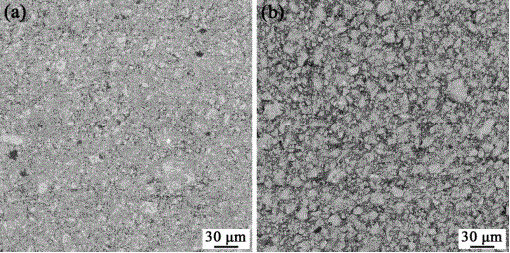

Preparation method of carbon nanotube reinforced hydroxyapatite composite material

The invention discloses a preparation method of a carbon nanotube reinforced hydroxyapatite composite material, relating to a composite material for prosthesis materials. According to the preparation method, a carbon nanotube is synthesized in hydroxyapatite powder, the carbon nanotube is subjected to surface modification by using hydroxyapatite, and the carbon nanotube reinforced hydroxyapatite composite material is further prepared. The preparation method comprises the following steps of: firstly preparing carbon nanotube-hydroxyapatite powder from nickel carbonate and the hydroxyapatite powder, then preparing hydroxyapatite-modified carbon nanotube-hydroxyapatite powder, and finally preparing the carbon nanotube reinforced hydroxyapatite composite material. The preparation method disclosed by the invention overcomes the defects that the carbon nanotube is difficult to disperse in a hydroxyapatite matrix, the wettability and the interfacial strength between the carbon nanotube and the hydroxyapatite matrix are low, the hydroxyapatite powder of which the surface is loaded with the carbon nanotube is difficult to form and the biocompatibility of the composite material is poorer in the prior art.

Owner:HEBEI UNIV OF TECH

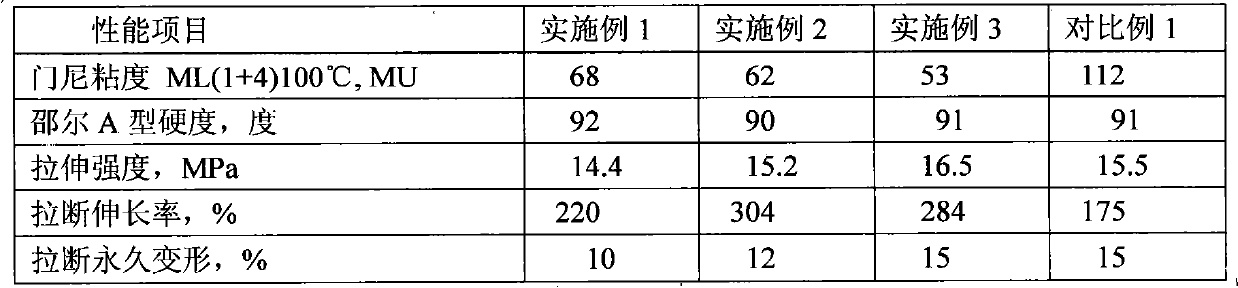

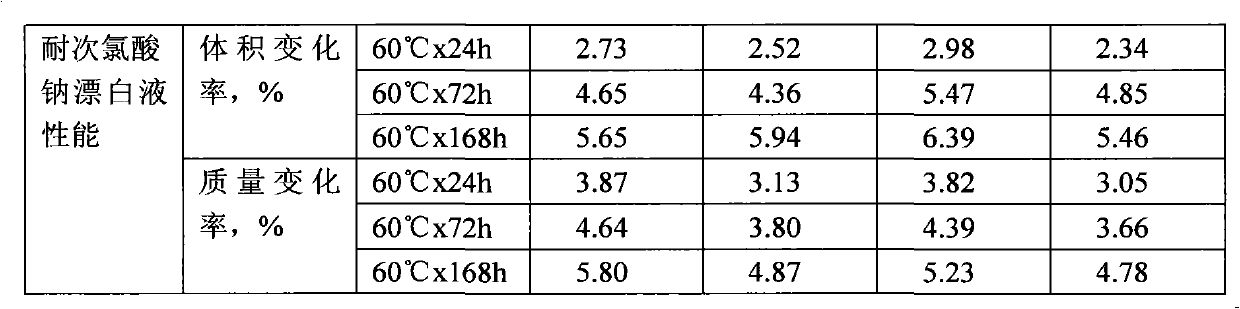

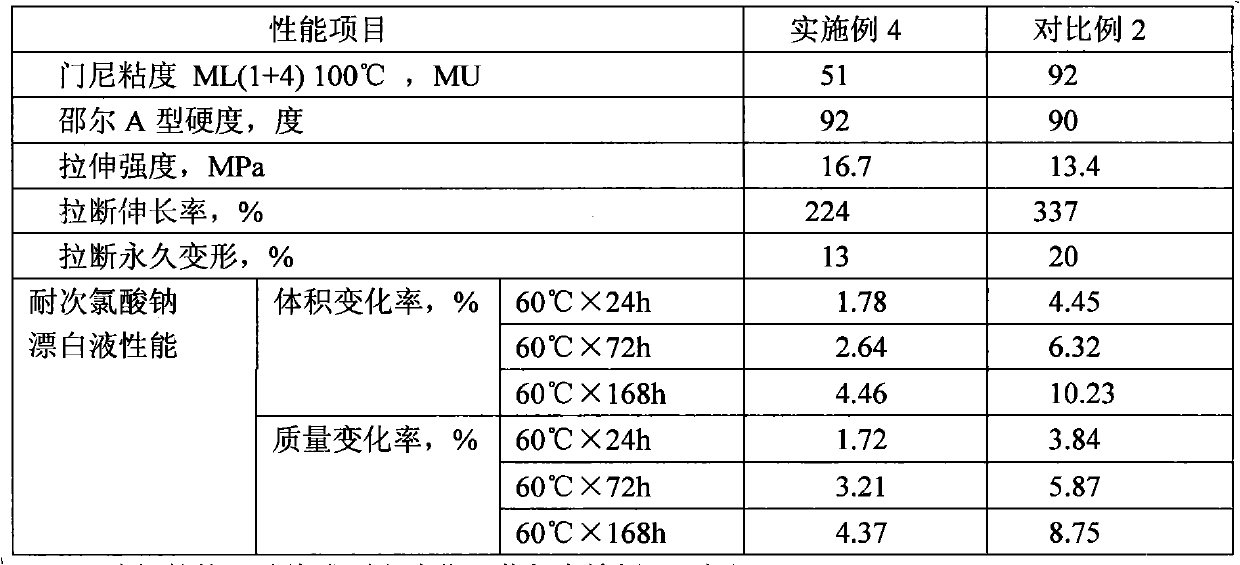

Rubber compound for rubber for coating chemical fiber bleaching rubber roll

The invention relates to a rubber compound for a rubber for coating a chemical fiber bleaching rubber roll. The rubber compound comprises ethylene propylene diene monomer, white carbon black, paraffin oil, polymeric liquid plasticizers (such as oligomer esters, liquid ethylene propylene methylene and liquid high vinyl polybutadiene), sulfur, accelerating agents, dicumyl peroxide and other auxiliaries. The rubber compound has the characteristics of high hardness (the Shore A hardness is 90-95 degrees), white color, excellent bleaching liquid sodium hypochlorite resistance, good processability and suitability for covering and forming on a rubber roll extrusion and winding covering machine.

Owner:河北春风银星胶辊股份有限公司

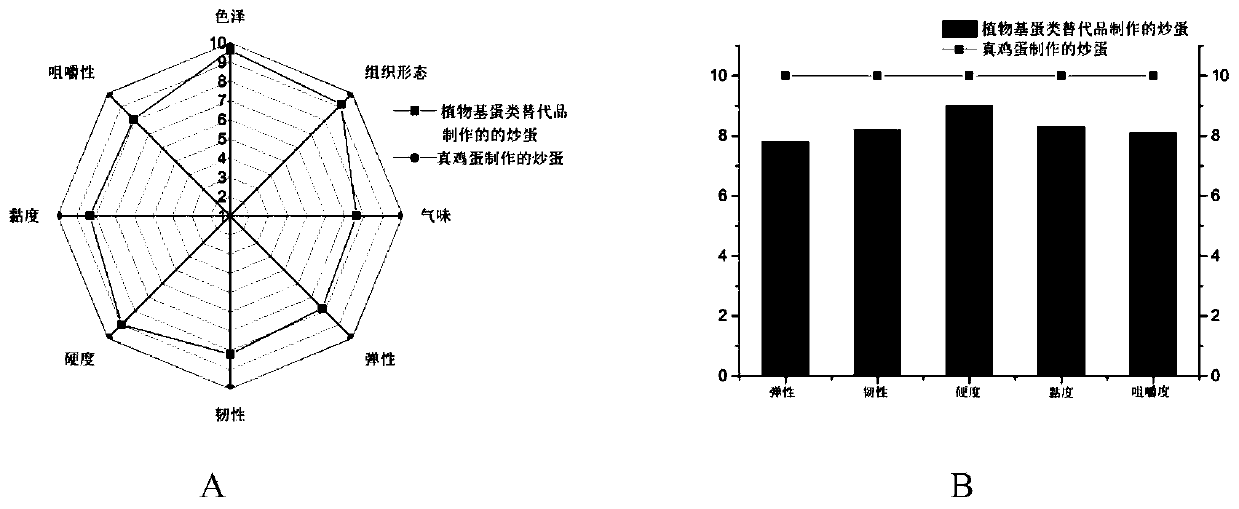

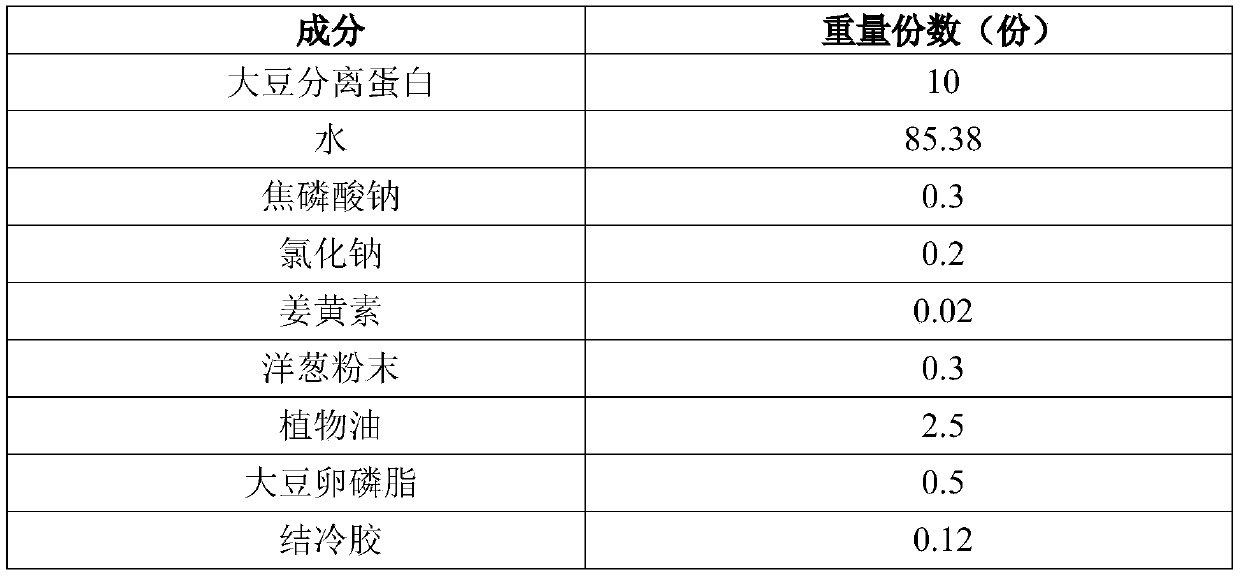

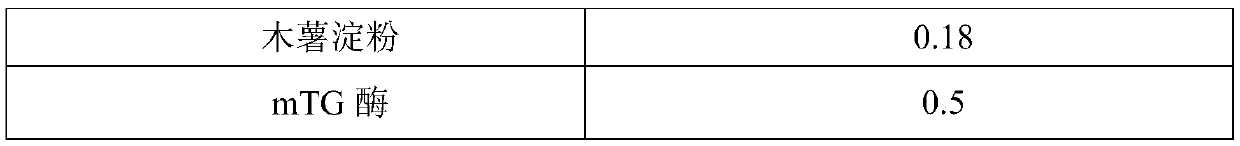

Method for preparing egg substitute based on soy isolate protein and product

ActiveCN111436576AImprove gel qualityStructural solutionClimate change adaptationFood ingredientsBiotechnologyVegetable oil

The invention discloses a method for preparing an egg substitute based on soy isolate protein and a product. The method comprises the following steps of mixing soy isolate protein with water, sequentially adding salt, pigment and flavoring agent, and carrying out shearing, stirring and mixing separately; then adding vegetable oil and soya bean lecithin, and carrying out emulsification reaction through shearing and stirring; adding a hydrophilic polysaccharide substance thereto, wherein the hydrophilic polysaccharide substance is a mixture of gellan gum and cassava starch; adding mTG enzyme, and continuously stirring at the temperature of 45-55 DEG C; and carrying out enzyme deactivation treatment to obtain the egg substitute. The gel quality of the soy isolate protein in the heating process is improved by adding the hydrophilic polysaccharide substance which comprises the gellan gum and the cassava starch, and the problems of loose structure and difficulty in forming of a plant proteingel product are solved under the specific temperature condition by utilizing the covalent cross-linking effect of the mTG enzyme and the soy isolate protein; and the invention provides a novel egg substitute and a processing technology thereof.

Owner:ZHEJIANG UNIV OF TECH

Light forsterite heat insulating brick and method of manufacturing the same

InactiveCN101497527AReduce molding pressureHigh porosityGlass furnace apparatusBrickVolumetric Mass Density

The invention relates to a lightweight forsterite insulating brick and a manufacturing method thereof. The invention adopts a technical proposal that the insulating brick is prepared from the following raw materials in portion by weight: 60 to 70 portions of forsterite sand of 1 to 0.5 millimeter, 15 to 25 portions of magnesite of 1 to 0.5 millimeter, 5 to 15 portions of magnesite powder of less than or equal to 0.088 millimeter, and 5 to 10 portions of SiO2 micro powder of less than or equal to 2mu m; and the adding amount of a bonding agent is 5 to 15 percent of the gross weight of the raw materials. The lightweight forsterite insulating brick has the advantages of small volume weight, low heat conduction coefficient, good heat insulation effect, and high normal pressure strength. The manufacturing method adopts a hydraulic press to mold, not only can solve the problems such as difficult molding and uneven density of green bricks, is easy to strip a mold, does not need to cut a finished product, simultaneously reduces energy consumption, saves resource, reduces discharge of pollutants, and protects environment.

Owner:营口青花耐火材料股份有限公司

Honeycomb low-temperature SCR denitration catalyst and preparation method thereof

ActiveCN109529813ASolve difficult moldingCalcination temperature is lowDispersed particle separationCatalyst activation/preparationPolyethylene oxideWater vapor

The invention relates to a honeycomb low-temperature SCR denitration catalyst and a preparation method thereof, and belongs to the technical field of flue gas denitration. The preparation method comprises the following steps: A, mixing: 100 parts by weight of titanium-molybdenum powder, 8-20 parts by weight of carboxymethyl cellulose, 5-10 parts by weight of polyethylene oxide, 5-7.5 parts by weight of silicon dioxide powder, 5-7.5 parts by weight of silica sol, 7-18 parts by weight of wood pulp, 25-50 parts by weight of glass fiber, 50-80 parts by weight of deionized water, 5-15 parts by weight of an ammonium metavanadate solution, 10-20 parts by weight of an ammonium metatungstate solution, 30-55 parts by weight of ammonia water and 10-20 parts by weight of lactic acid are added into a mixer to be fully mixed; water vapor in the mixer is pumped after the mixing, and the molybdenum content of the titanium-molybdenum powder is greater than or equal to 7%; B, molding; C, drying; and D,calcination. By the preparation method, the energy consumption is reduced, and the denitration efficiency of the obtained honeycomb low-temperature SCR denitration catalyst at the temperature of 160 to 250 DEG C reaches 83% and above.

Owner:HUADIAN QINGDAO ENVIRONMENTAL TECHNOLOCY CO LTD

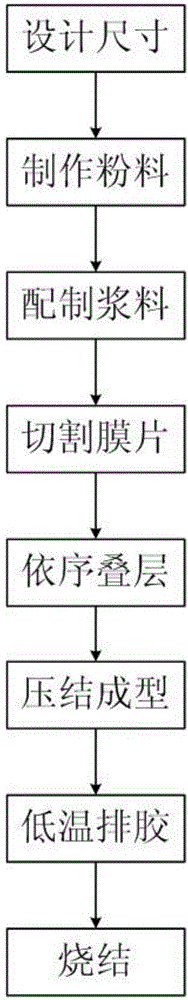

Method for molding coaxial dielectric filter green body

The invention discloses a method for molding a coaxial dielectric filter green body. The method comprises the following steps: preparing a ceramic-based diaphragm, and cutting; disassembling the device structure into a group of plane figures from the vertical plane of a laminating direction according to the thickness of the diaphragm, and performing pattern transfer on the cut diaphragm; laminating the pattern transferred diaphragm in sequence until the total thickness of the diaphragm reaches a set device thickness, and heating and pressurizing the layered diaphragms to form a molded ceramic blank; degreasing and sintering the molded ceramic blank body to obtain the required ceramic device green body. According to the process, the problem that a complex ceramic device is hard to mold and limited in application can be solved, the thought of integral molding assisted by later process, which is followed by a traditional method is bypassed, the problems of low yield, poor operability, low flexibility, high broken rate of filter green bodies, offset out of control of a coupling structure, reduced bandpass filtering capability and the like are solved, and preparation of the ceramic device green body with complicated structure can be effectively realized.

Owner:HUAZHONG UNIV OF SCI & TECH

High-titanium-carbide steel bond hard alloy mold material

The invention discloses a high-titanium-carbide steel bond hard alloy mold material which comprises 55-65 wt% of titanium carbide and 35-45 wt% of iron-base binding phase. The iron-base binding phase comprises 0.2-0.6% of C, 1.5-4% of Cr, 0.8-1.8% of Mn, 2.0-4.0% of Mo, 2-8% of Ni, 0.5-2.0% of Cu, 0-1.01% of alloy additive and the balance of Fe. The preparation method comprises the following steps: thoroughly mixing the raw material powders according to the optimized proportion to obtain a mixed powder, and carrying out wet milling, filtration, drying, cold isostatic compaction, vacuum sintering and heat treatment to obtain the required mold material. The high-titanium-carbide steel bond hard alloy only adopts the normalizing heat treatment, the hardness reaches higher than HRA87, and the strength is high and satisfies the service performance of normal-temperature and high-temperature mold materials.

Owner:LAIWU JINWEI NEW MATERIALS

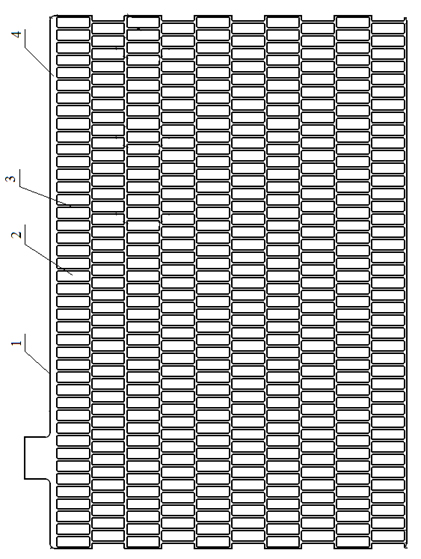

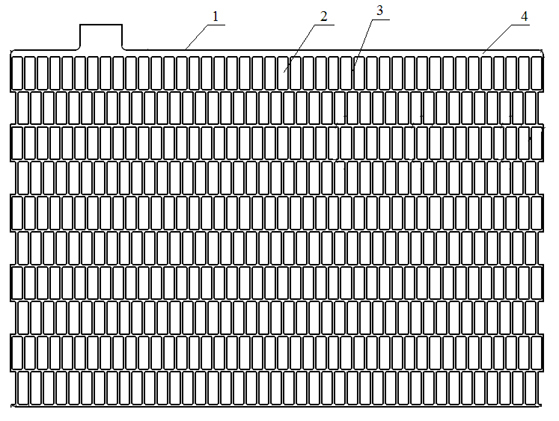

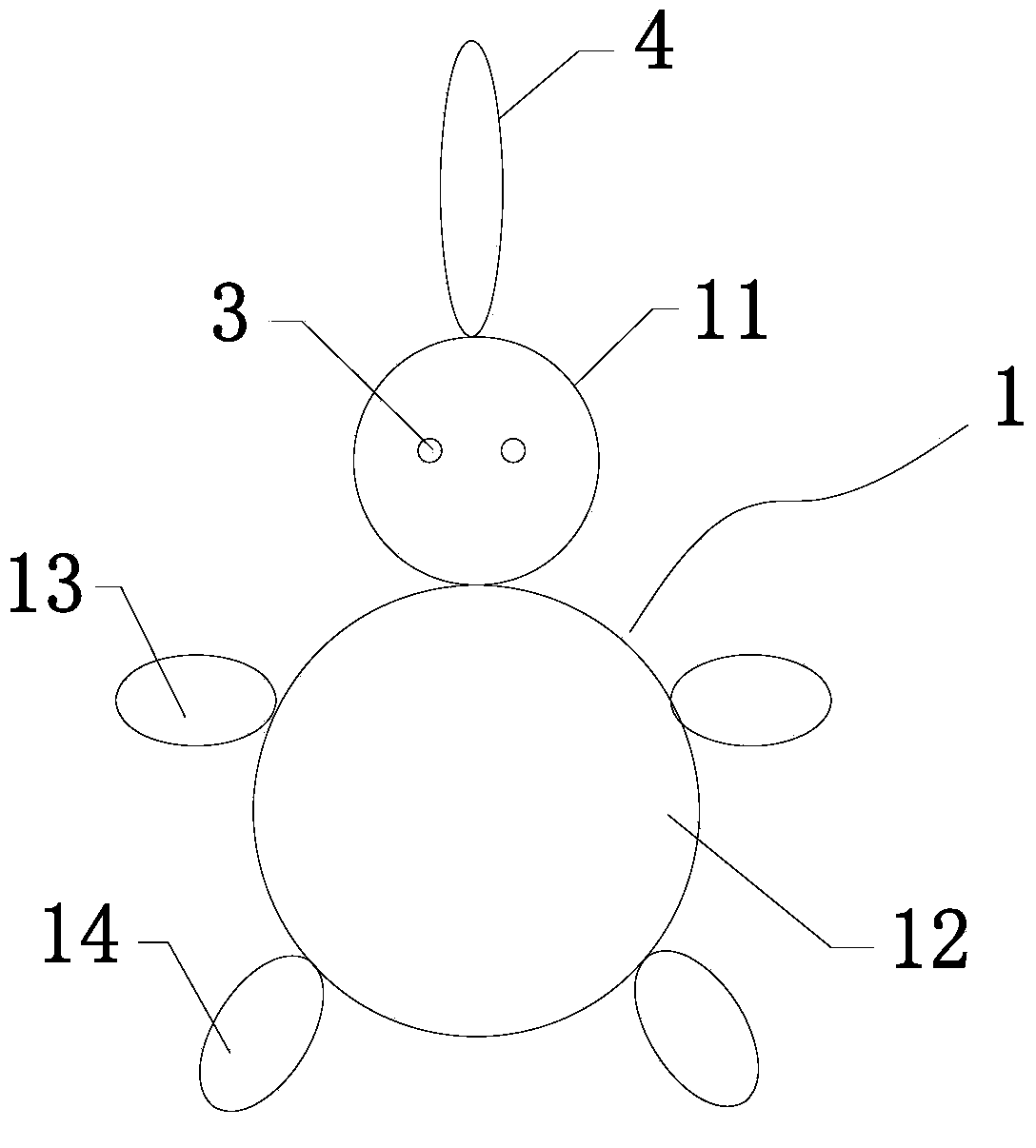

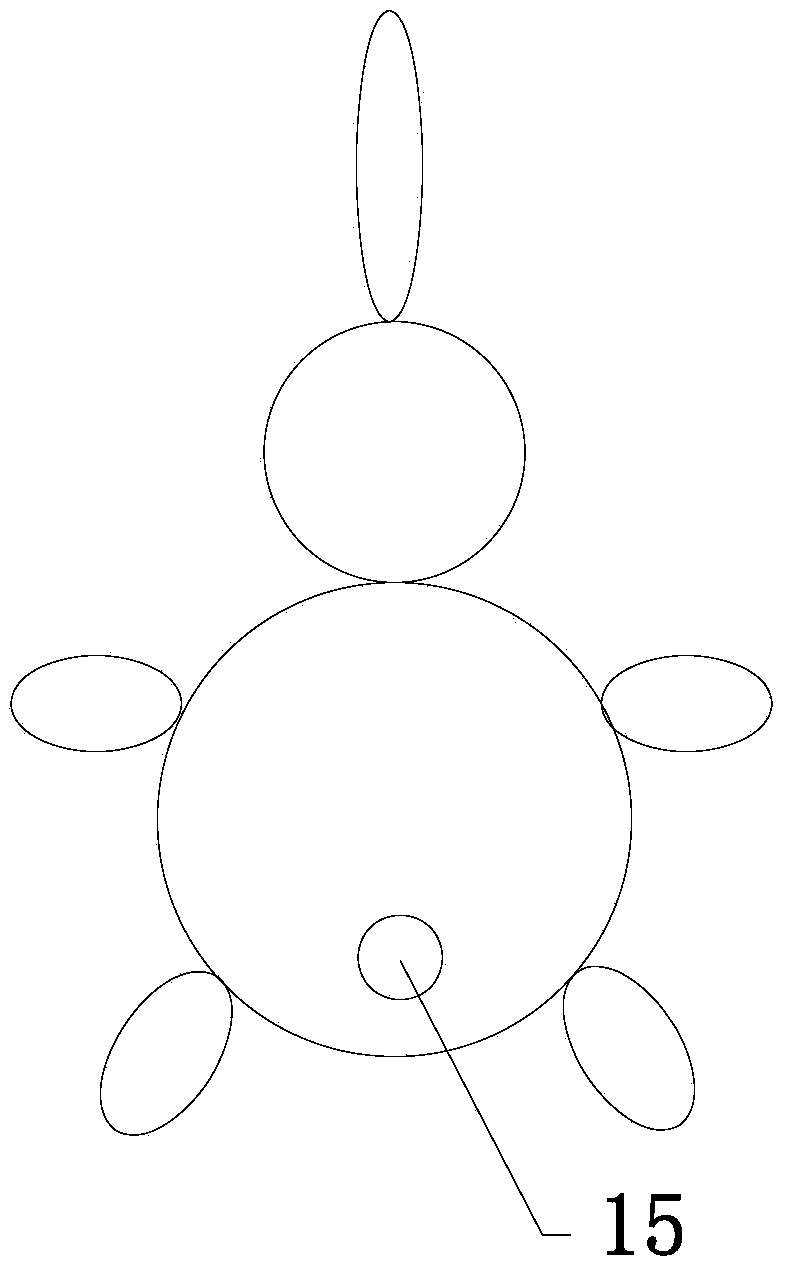

Technology for forming maintenance-free lead-acid battery pole plates

InactiveCN102034974ASmall thickness toleranceIncrease productivityLead-acid accumulator electrodesSpecific energyMaterials science

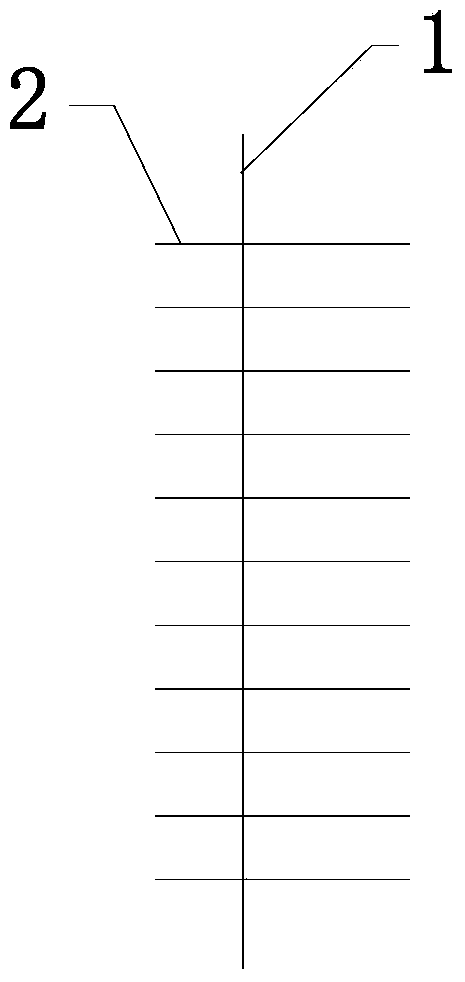

The invention discloses a technology for forming maintenance-free lead-acid battery pole plates, comprising the following steps: (1) heating to melt an alloy lead liquid in a melting furnace; (2) casting the alloy lead liquid into lead strips by using a casting machine; (3) winding the lead strips by using a winder; (4) delivering the lead strips to a stamping machine and stamping the lead strips into plate grid strips (1), wherein uniform rectangular holes (2) are formed in the middle of each plate grid strip (1), ribs (3) are arranged among the holes (2), and edge and corner lead strips (4) used for cutting plugs are arranged on two sides of each plate grid strip; (5) winding the plate grid strips by using the winder; and (6) coating the plate grid strips by using a plate coating machine and splitting the plate grid strips by using a plate splitting mold to form lead-acid battery pole plates. The technology for forming maintenance-free lead-acid battery pole plates during lead-acid battery production can improve the service life, the quality and the specific energy of a lead-acid battery.

Owner:JIANGSU LEOCH BATTERY

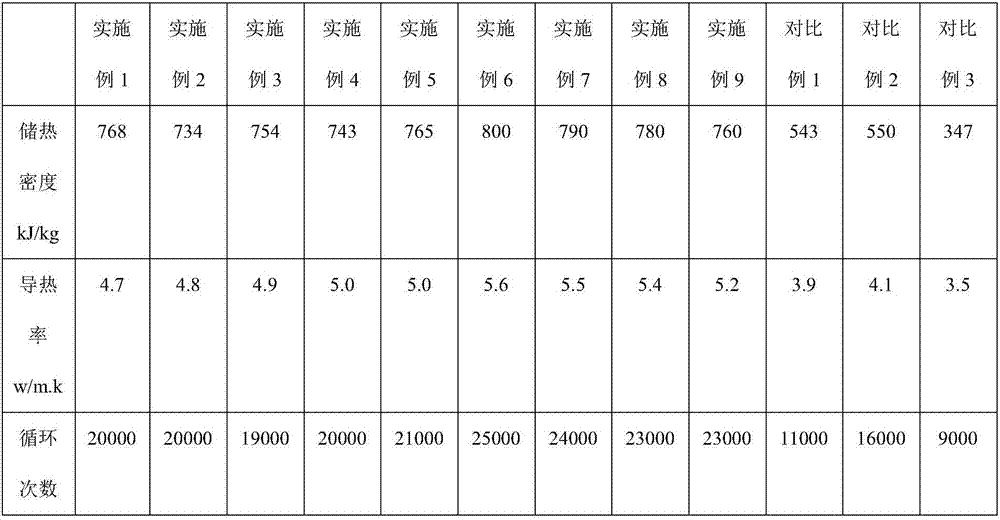

A phase-change heat storage material and a preparing method thereof

ActiveCN107337436AHigh heat storage densityImprove thermal conductivityGranularityHeat storage material

A phase-change heat storage material is provided. The phase-change heat storage material includes carbonate and a ceramic matrix. The granularity of the carbonate is 2-10 [mu]m, and the granularity of the ceramic matrix is 1-10 [mu]m. The phase-change heat storage material has a high heat storage density and high thermal conductivity, the heat storage density of the material can be 700 kJ / kg or above, and the thermal conductivity of the material can be 4.5 w / m.k or above. The number of times of cyclic use of the material is greatly increased and can be 19000 or above.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

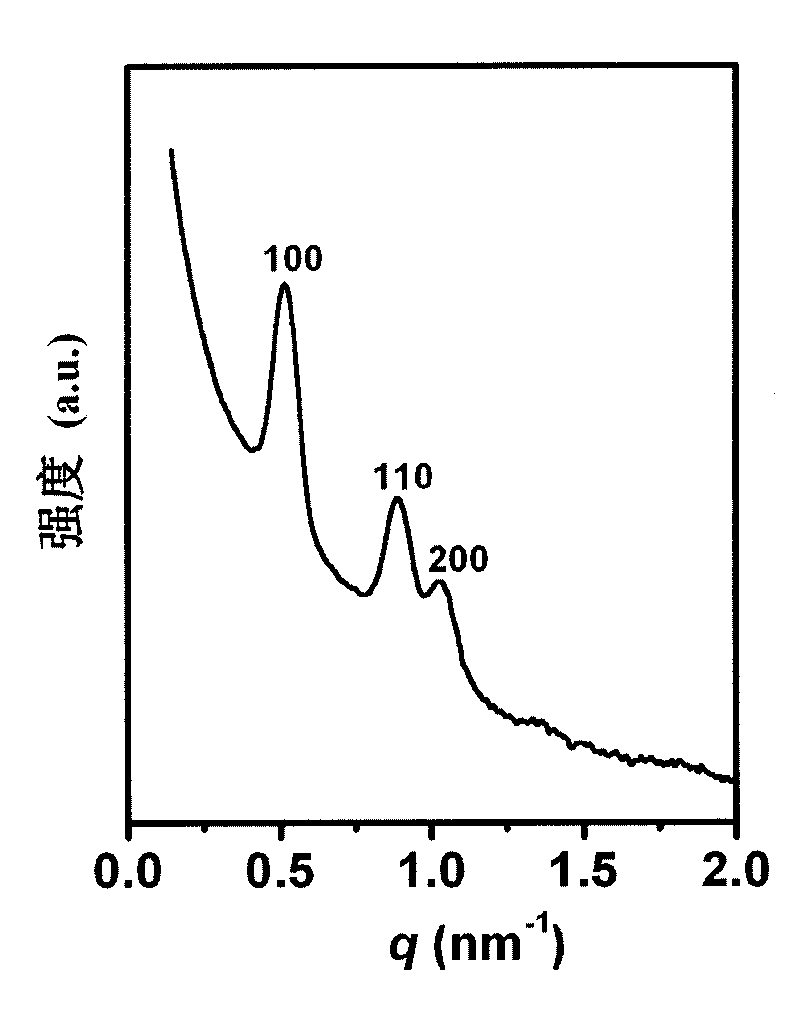

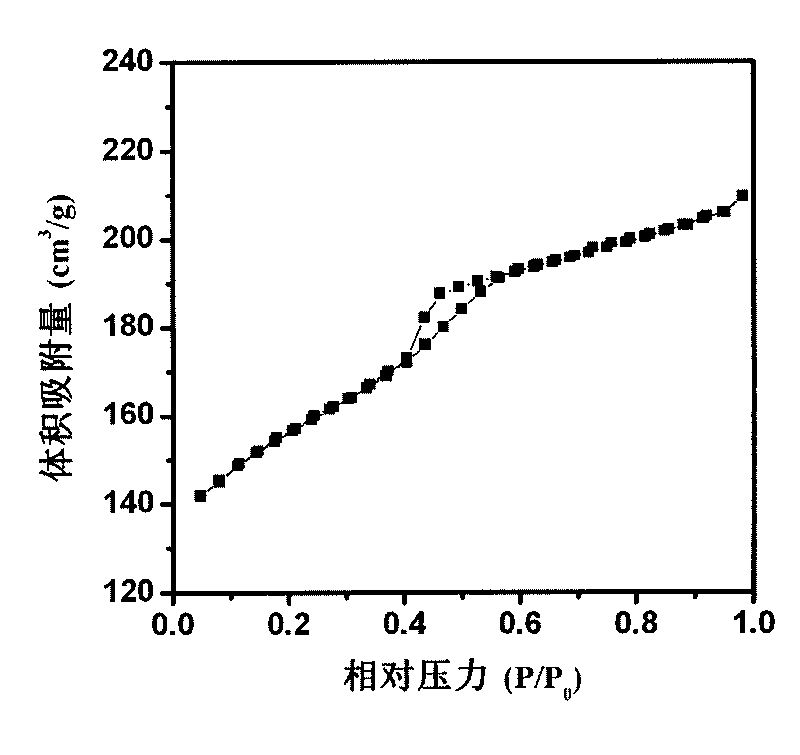

Polymer composite with plasticity, ordered mesoporous polymer of multi-level structure and ordered mesoporous carbon material

The invention relates to the material field and provides a polymer composite with plasticity. The polymer composite with plasticity and with plasticine characteristic is synthesized through evaporation-induced self-assembly of a solvent by mixing a mixed surfactant and an organic polymer. The polymer composite is further roasted and the surfactant is removed to obtain an ordered mesoporous polymer of multi-level structure, and the ordered mesoporous polymer is carbonized at high temperature to obtain an ordered mesoporous carbon material of multi-level structure. Being plastic, the shape of the polymer composite is not damaged before and after roasting, the mesoporous polymers and carbon materials of different shapes can be obtained after carrying out post-forming on the polymer composite, and the macro shapes of the mesoporous polymers and carbon materials are not damaged. The obtained carbon materials have the characteristics of open multi-level pore channel structures, high specific surface, large pore volume, uniform mesopore diameter and the like.

Owner:SHANGHAI NORMAL UNIVERSITY

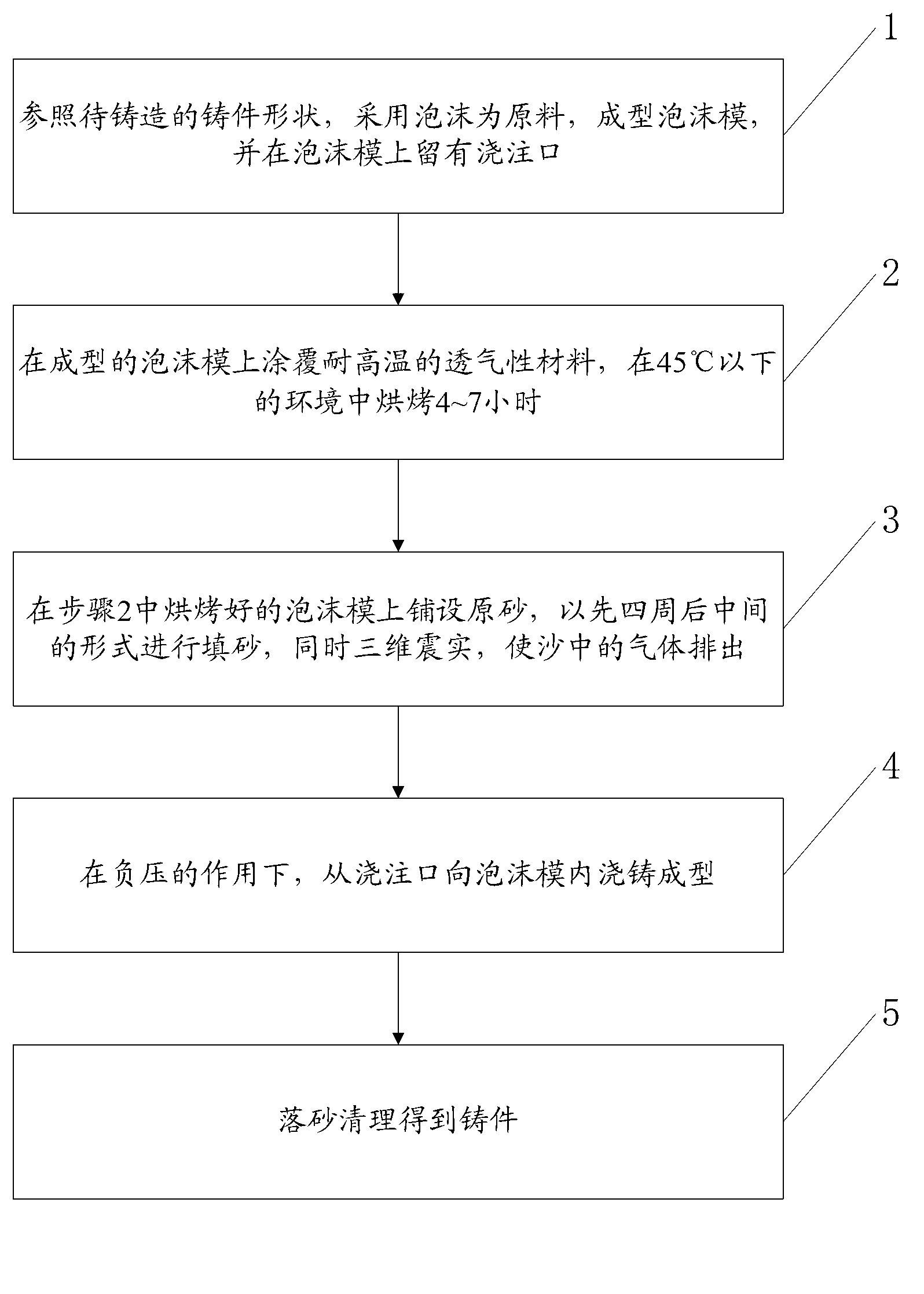

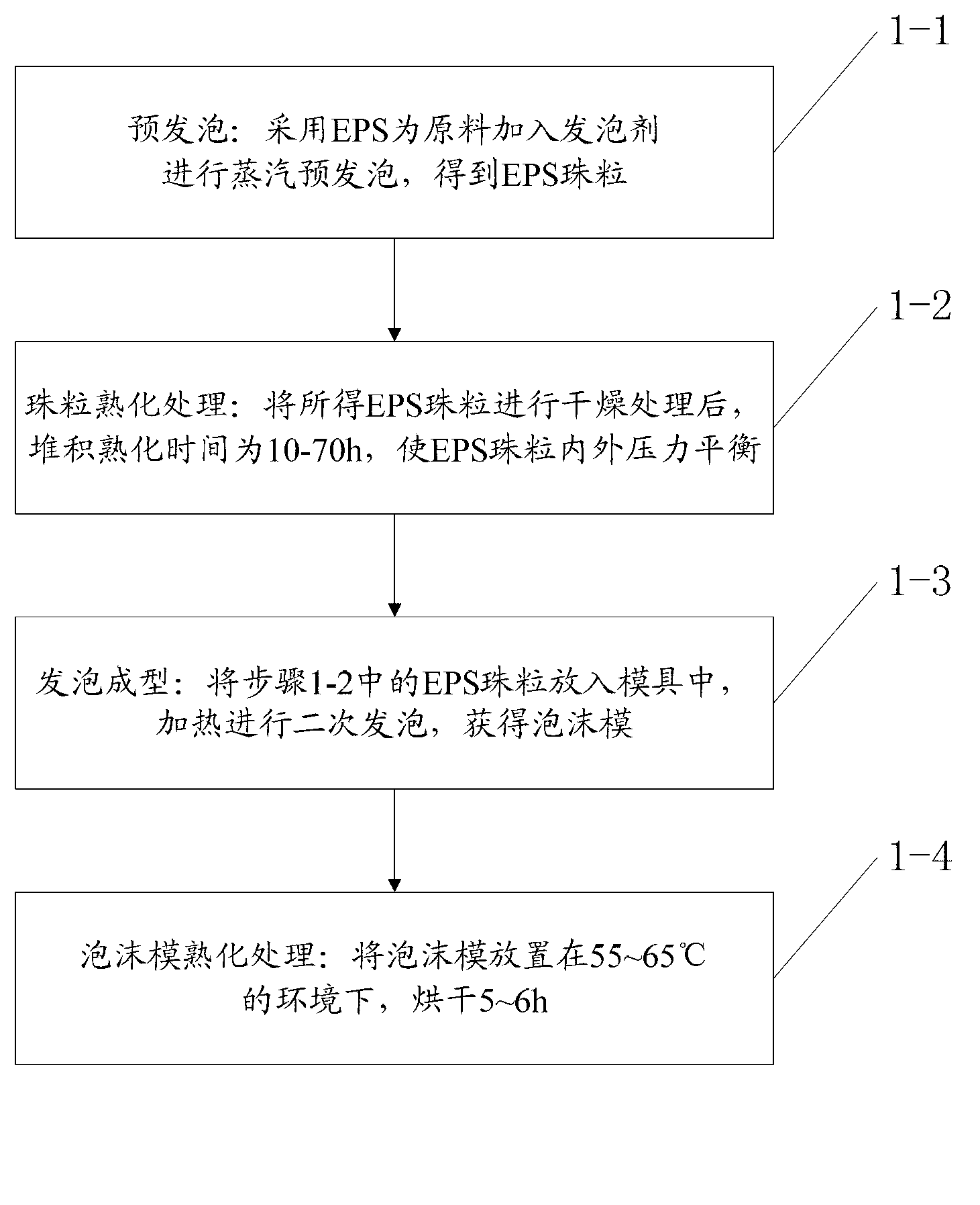

Lost foam casting method

InactiveCN103008548AImprove processing plasticityImprove processing efficiencyFoundry mouldsFoundry coresDie castingCasting mold

The invention discloses a lost foam casting method comprising the steps of 1. taking foam as a material, molding a foam die which is the same as a cast in shape, preserving a sprue gate on the foam die; 2. coating a high-temperature-resistant poromeric material on the foam die, and baking for 4-7 hours in the environment below 45 DEG C; 3. paving roughing sand on the foam die, carrying out three-dimensional ramming filling from the periphery to the middle so as to discharge gas in the sand; 4. casting inwards from the sprue gate under the effect of negative pressure; and 5. cleaning shakeout to obtain the cast. The foam die is taken as a casting mold, so that on one hand, the problem that the metal die casting mold is difficult to process is solved; and on the other hand, the problem that the sand die casting mold is not easy to mold is solved. The foam die can be produced by batch due to the plasticity that the foam die is easy to process. Therefore, the casting mold is high in processing efficiency, and the material and device costs in the molding process of the foam die are low. Thus, the production cost also can be effectively reduced in comparison with the entire casting process.

Owner:ANYUE COUNTY JINLONG MACHINERY MFG

Plant-based composition and application thereof

PendingCN112155114AFibrousSolve difficult moldingProteins working-up by texturisingVegetable proteins working-upEngineeringProcess engineering

The invention relates to a plant-based composition and application thereof, and belongs to the technical field of soyabean product processing. The plant-based composition is prepared from 150-180 parts of soybean wiredrawing protein, 8-10 parts of soybean protein isolate and 1.8-2.2 parts of glutamine transaminase, the cylindrical wiredrawing protein with the model number of 910B is selected, firstly, filament removal treatment is carried out through a plastic blade, and then baking treatment at the temperature of 90-110 DEG C is carried out for 20-40 min for assistance, so that it is guaranteed that the moisture content of the soybean wiredrawing protein is 58%-60%. A hamburger meat pie is prepared by adding other corresponding auxiliary materials into the plant-based composition, bakingis carried out for 1 hour at 55 DEG C for assistance based on a traditional process, then, steaming is carried out for 15 minutes at 85-95 DEG C, and finally the meat pie with the diameter of 6-8 cm and the thickness of 1-2 cm is obtained through preparation. The combination of the formula and the process can effectively solve the problem that a traditional plant-based meat pie is difficult to form in the cooking process due to adoption of colloid, and finally, the effects that various materials are bonded together and cannot be loosened in the cooking process are achieved.

Owner:SICHUAN NANXI HUIJI FOOD +1

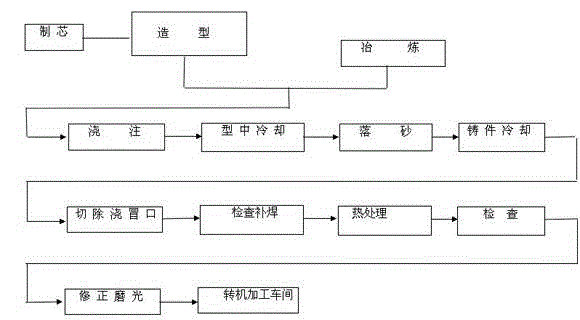

A casting method of an ultrafine high-nickel-content air tube

InactiveCN104525869AAvoid problemsQuality improvementFoundry mouldsFoundry coresMaterials scienceMetal

The invention discloses a casting method of an ultrafine high-nickel-content air tube. The method comprises following four steps: core preparing, moulding, pouring and sand knock-out. The method is mainly characterized in that: a pouring process of the method adopts a top pouring manner, a product is turned transversely by 90 degrees and poured, the problem that high-nickel-content tubes having a diameter of 26 mm, an inner diameter of 14 mm and a wall thickness of 4 mm are difficult to cast and mould is overcome by controlling the pouring temperature, speed and time, a process yield of the method is high, moulding operation is convenient, the consumption amount of metal liquids is small, the production cost is reduced, and requirements on the large-scale production efficiency are satisfied.

Owner:西峡飞龙特种铸造有限公司

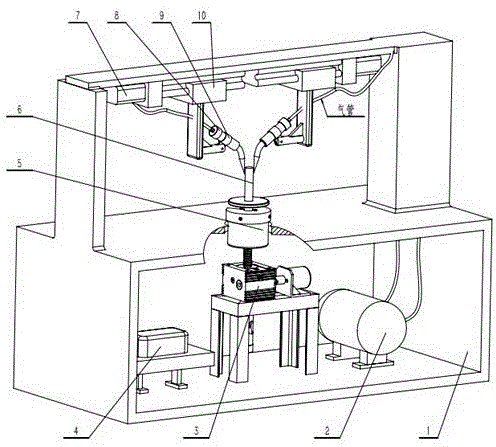

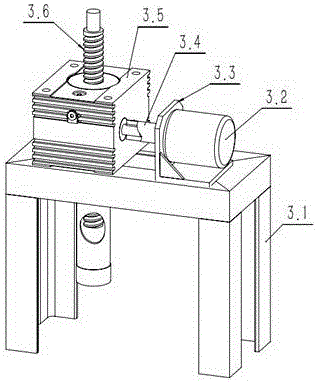

Rotary type tubular tissue biological 3D printing device and method thereof

InactiveCN104999668AAdjust position differencesImprove printing efficiencyAdditive manufacturing apparatusAutomatic controlEngineering

The invention discloses a rotary type tubular tissue biological 3D printing device and a method thereof. The rotary type tubular tissue biological 3D printing device comprises a rack bed body, an air source, a lifting mechanism assembly, a controller, a rotary connecting tray assembly, a spray head drive assembly and the like, wherein under the control of the controller, an air pressure spray head moves to the position of a cylindrical bracket; an air source is used for supplying air to the air pressure spray head by virtue of an air tube for pressing out a biological material, and a motor b of the rotary connecting tray assembly drives a rotary tray to carry out rotary motion; after the rotary tray rotates by one circle, pneumatic spray heads move by a specified distance in a radial direction to print a next position. When one layer is printed, a motor a drives the lifting mechanism assembly to control the rotary connecting tray assembly to move downwards, so that printing of a tubular tissue is realized. By increasing the group number of the pneumatic spray heads, the printing of the tubular tissue with a heterostructure can be realized. The rotary type tubular tissue biological 3D printing device is simple and delicate in structural concept, liable to realize automatic control, and capable of printing various materials, so that the printing efficiency is improved; and the problem that the tubular tissue is not liable to print and form is effectively solved.

Owner:ZHEJIANG UNIV

Mutual-nested topology pipeline type structure and overall forming method

ActiveCN108481767AGuaranteed integritySolve molding problemsBranching pipesTubular articlesEngineeringUltimate tensile strength

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Pine pollen tablets and preparation method thereof

InactiveCN102028136ASolve difficult moldingImprove performanceFood shapingFood preparationSulfatePine pollen

The invention discloses pine pollen tablets and a preparation method thereof. The pine pollen tablets are prepared from the following components serving as raw materials in percentage by weight: 15 to 80 percent of pine pollen, 12 to 36 percent of dextrin, 3 to 15 percent of calcium sulfate, 4 to 50 percent of solution of gelatin, 0.5 to 3 percent of talcpowder and 0.2 to 1.0 percent of magnesium stearate. The pine pollen tablets are prepared by the following steps of: sieving the raw materials, mixing, palletizing by using the gelatin and tabletting. By changing the raw material formula in the conventional production process, the problem that the pine pollen tablets are not easily to be shaped is solved, and products do not contain sugar. The pine pollen tablets prepared by the method have stable performance and are suitable for large-scale production, and the product quality meets the requirements of Pharmacopoeia of People's Republic of China.

Owner:昆明振华制药厂有限公司

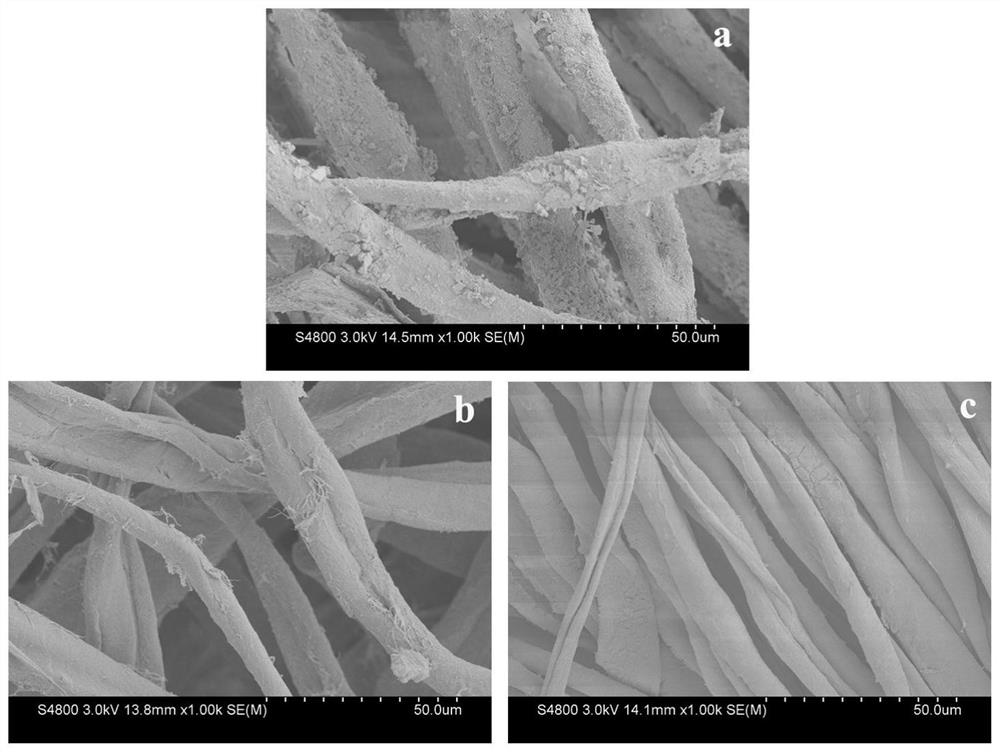

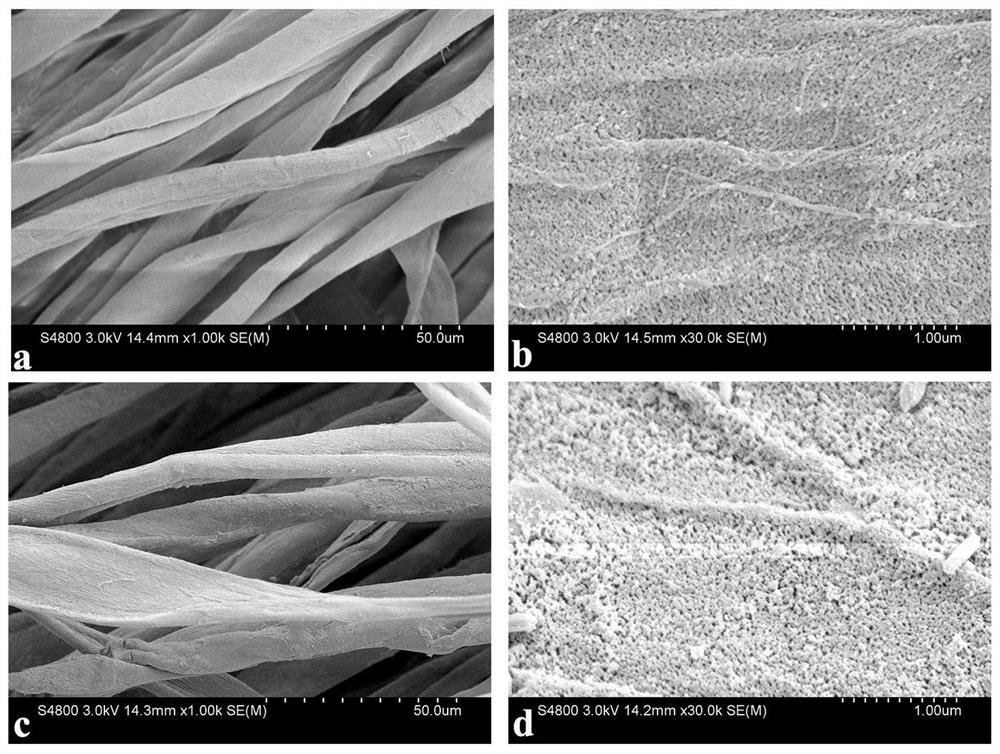

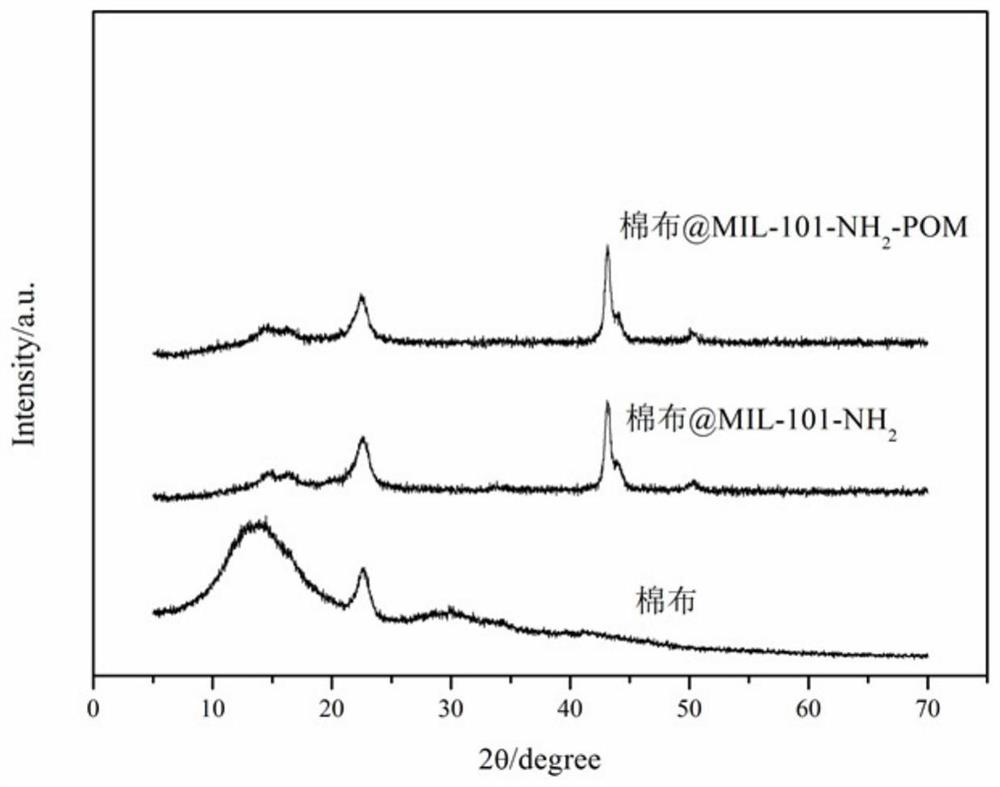

MOF-based cotton cloth immobilized polyacid catalytic material as well as preparation method and application thereof

PendingCN112517078AEffective fixed loadSolve difficult moldingOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsPolymer scienceCotton cloth

The invention relates to the technical field of desulfurization catalytic materials, in particular to an MOF-based cotton cloth immobilized polyacid catalytic material and a preparation method and application thereof.The MOF-based cotton cloth immobilized polyacid catalytic material is prepared from MOF-based cotton cloth and Keggin type phosphorus molybdenum tungsten type polyacid immobilized onthe MOF-based cotton cloth; the MOF-based cotton cloth is cotton cloth and an MOF material growing on the cotton cloth. According to the prepared MOF-based cotton cloth polyacid catalytic material, the problem that the MOF-based polyacid catalytic material is not easy to form can be solved, the preparation process is simple, the prepared MOF-based cotton cloth polyacid desulfurization catalytic material has a good desulfurization effect when used in a gasoline and diesel oil simulation system, and the desulfurization rate of the prepared cotton cloth @MIL-101-NH2-POM can reach up to 100%. Whenthe cotton cloth-coated @MIL-101-NH2-POM is repeatedly used for 12 times, the desulfurization rate of the cotton cloth-coated @MIL-101-NH2-POM can still reach 96%.

Owner:CHANGAN UNIV

Wear-resisting high-temperature-resistant high molecular material formula

InactiveCN106543543ASolve the problem of large linear expansion coefficientFix stability issuesPolymer scienceTemperature resistance

The invention discloses a wear-resisting high-temperature-resistant high molecular material formula. The material is prepared from the following raw materials in parts by weight: 100 parts of ultra high molecular weight polyethylene, 2 to 3 parts of graphene, 3 to 4 parts of talcum powder, 1 to 2 parts of glass beads, 2 to 5 parts of silicon dioxide and 4 to 5 parts of accessory ingredient. According to the formula provided by the invention, the raw materials including the graphene, the talcum powder, the glass beads, the silicon dioxide and the like are used for performing reinforcing and modifying treatment on the ultra high molecular weight polyethylene to improve the mechanical performance of the same, the prepared material does not only have the own excellent performance of the ultra high molecular weight polyethylene, and the indexes of hardness, toughness, high-temperature resistance, wear resistance and the like of the prepared material are all improved, devices for a pump and a valve made from the modified ultra high molecular weight polyethylene material are long in service life and safe and reliable in fireproof performance.

Owner:江苏环宇纺织科技有限公司

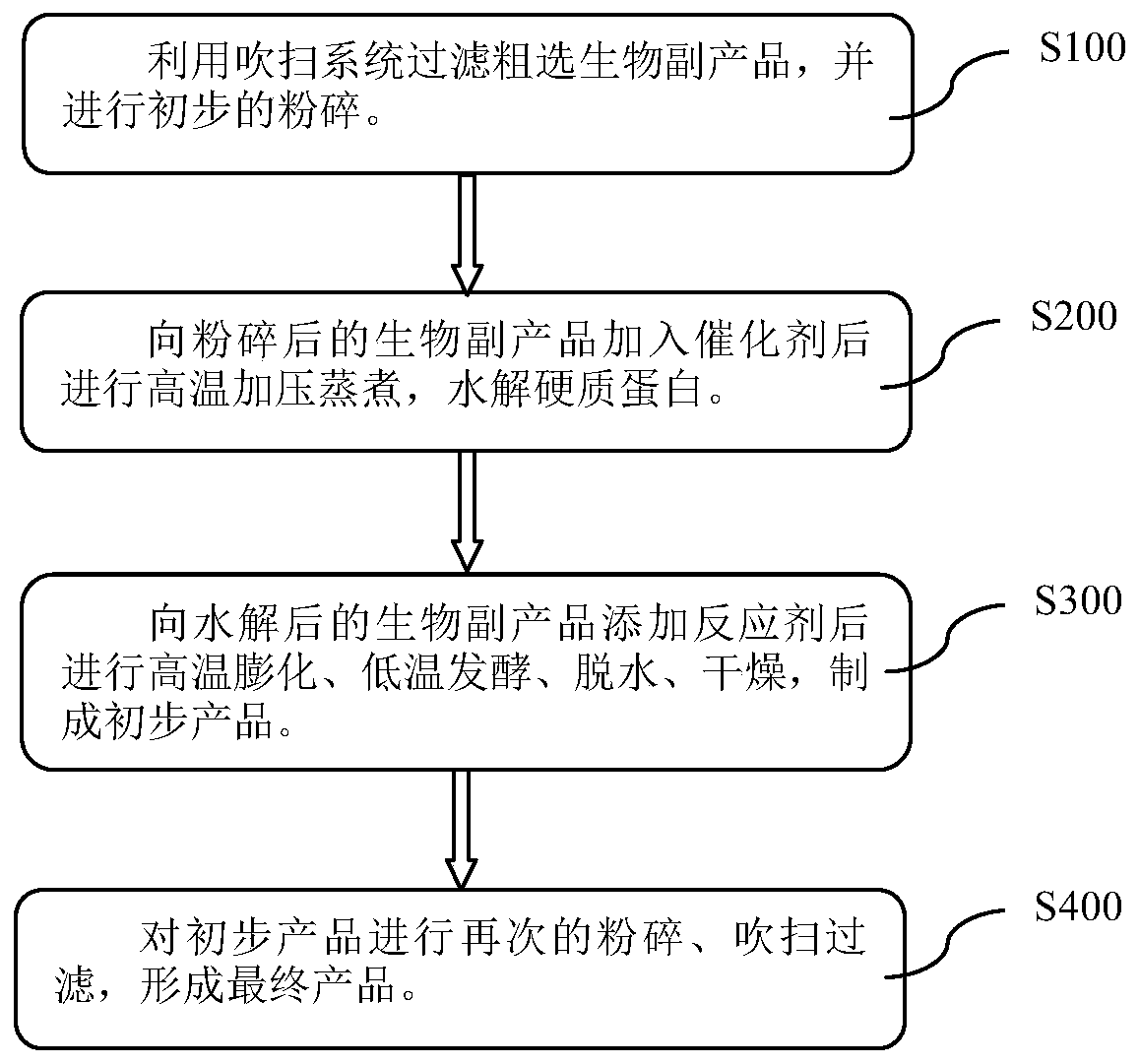

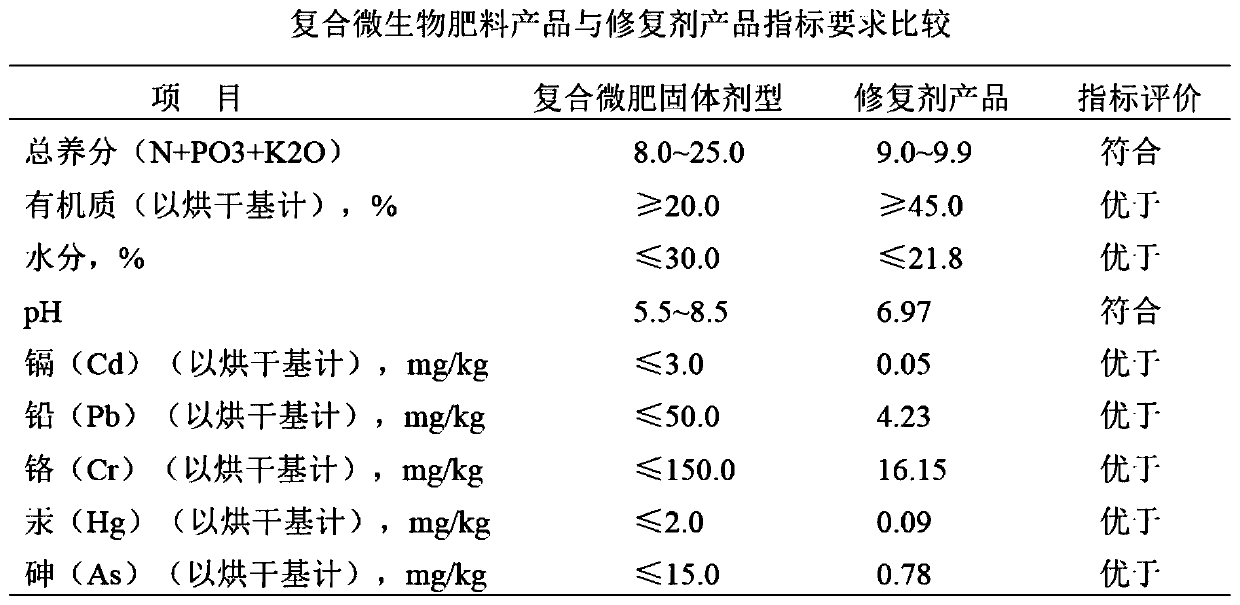

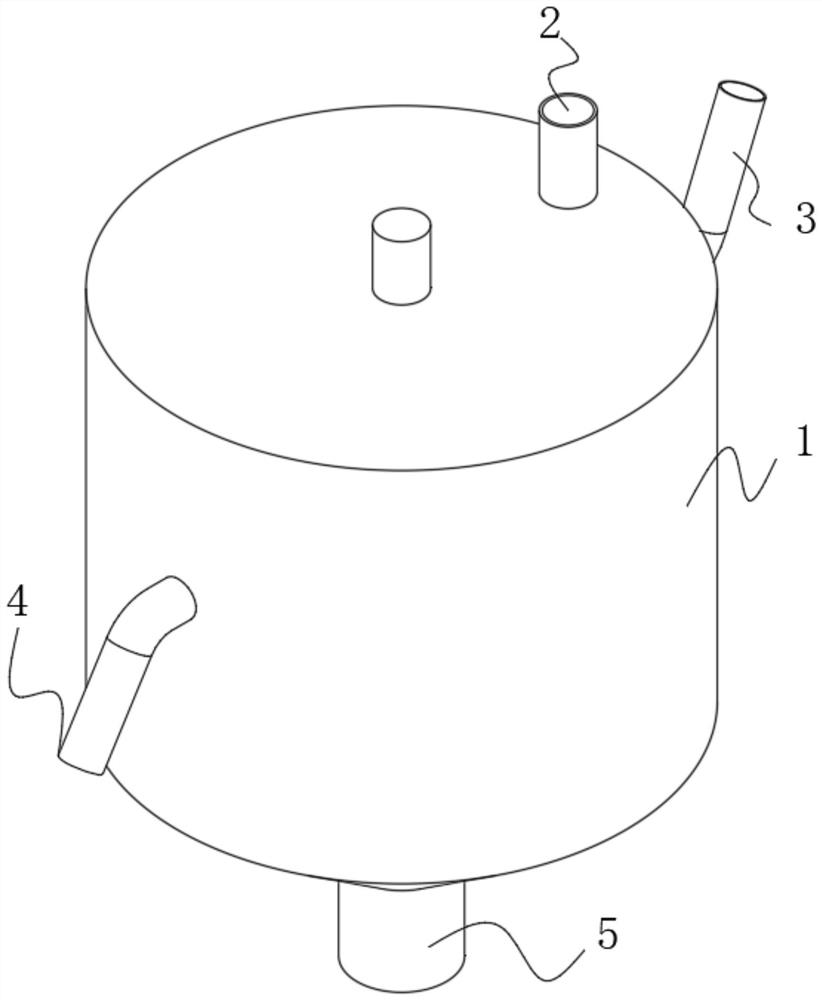

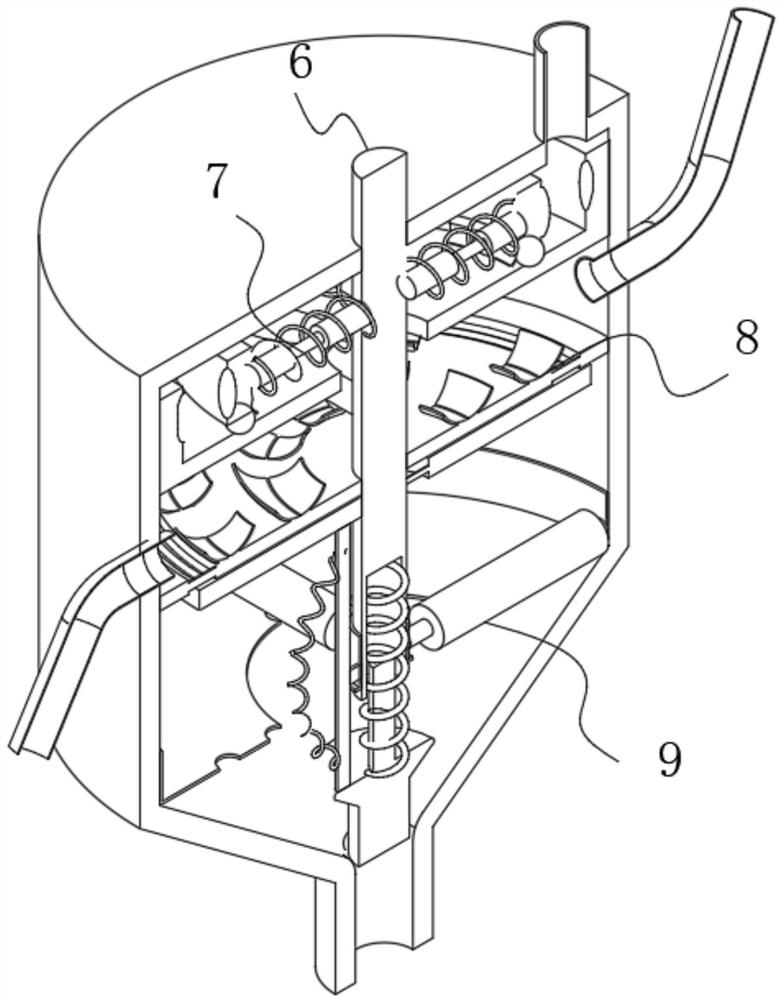

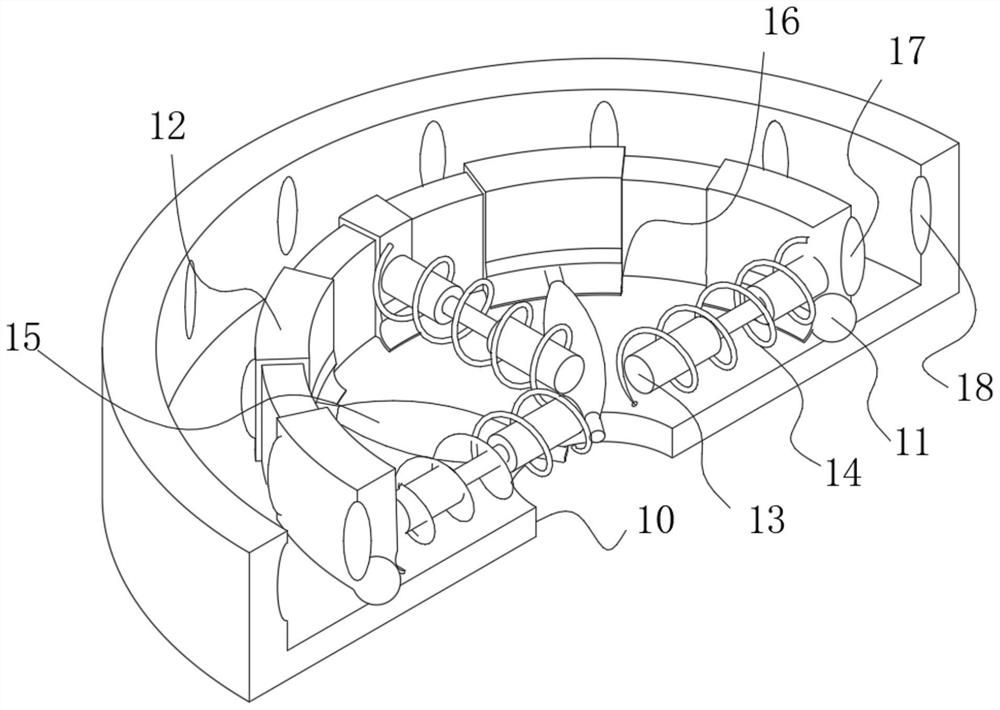

Preparation method and expansion preparation device of soil heavy metal repair agent

ActiveCN109929563AStabilization/immobilization effect is firmImprove fertilityAgriculture tools and machinesOrganic fertilisersSoil heavy metalsHigh pressure

The embodiment of the invention discloses a preparation method of a soil heavy metal repair agent. The preparation method comprises the steps that a biological by-product is roughly screened and crushed; after a catalyst is added, high-temperature pressurized digesting is conducted; after a reaction agent is added, high-temperature expansion, low-temperature fermentation, dehydrating and drying are conducted, and thus a preliminary product is prepared; and the preliminary product is crushed again and subjected to purging filtering, and thus a final product is formed. An expansion preparation device of the soil heavy metal repair agent comprises a high-pressure compartment provided with a feeding inlet and a discharging outlet, and a material flat-crushing mechanism mounted in the high-pressure compartment, a fluidifying material-transferring bed is arranged between the material flat-crushing mechanism and the feeding inlet, the discharging outlet is connected with an expansion cavity,the side wall of the near-bottom of the high-pressure compartment is connected with a steam generating device through an air delivery pipeline, the top of the high-pressure compartment is connected tothe steam generating device through a circulating pipeline, and a pressure relief valve is arranged on the circulating pipeline. The soil heavy metal repair agent has a long-term stable passivation repair effect, secondary pollution is avoided, soil fertility can be increased, and phytonutrients are formed advantageously.

Owner:北京贵清科技有限公司

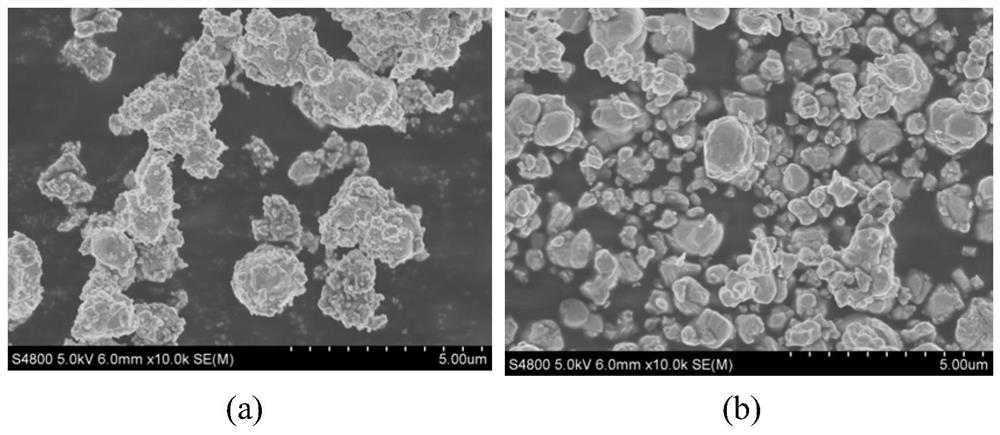

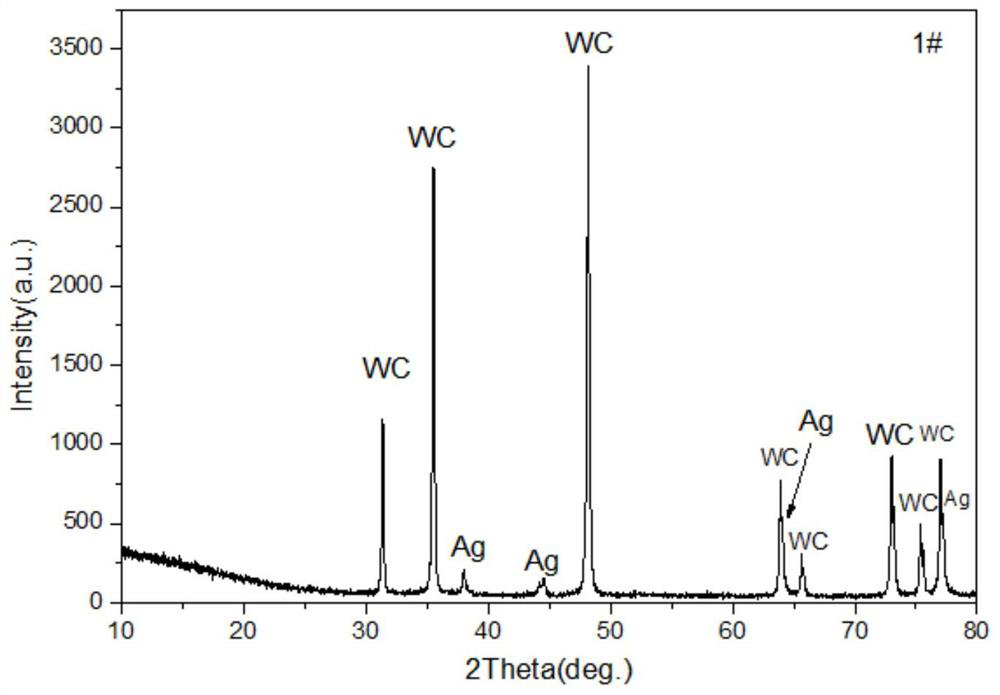

Preparation method of silver tungsten carbide contact material

PendingCN112170861AEvenly distributedSolve difficult moldingTransportation and packagingMetal-working apparatusAqueous solutionSilver nitrate

The invention discloses a preparation method of a silver tungsten carbide contact material. The preparation method comprises a step of obtaining a pressed blank, and is characterized in that the stepof obtaining the pressed blank comprises the following procedures: soaking tungsten carbide powder with a silver nitrate solution, drying an obtained mixed material, carrying out thermal decompositionreaction, crushing, reducing, and pressing obtained silver tungsten carbide mixed powder to obtain the pressed blank, wherein the silver nitrate solution is a silver nitrate aqueous solution. The method is simple in process, short in production period and low in forming difficulty, and the obtained contact is more uniform in metallographic structure, higher in density and hardness and lower in resistivity.

Owner:桂林金格电工电子材料科技有限公司

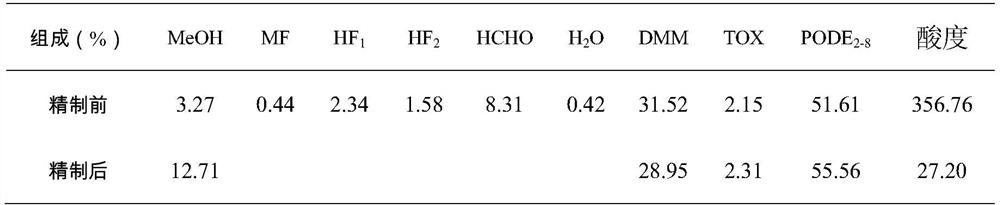

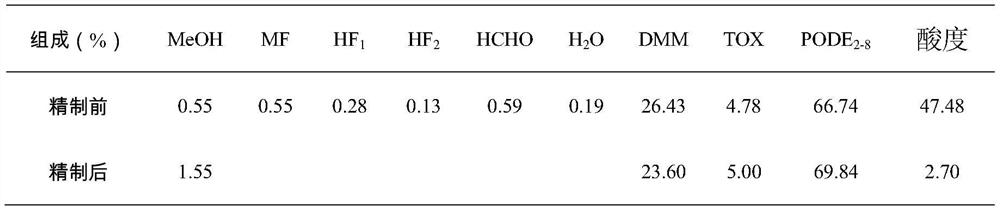

Refining process of polyoxymethylene dimethyl ether condensation product

ActiveCN111689840AReduce consumptionHigh activityOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystHydrolysis

The invention discloses a refining process of a polyoxymethylene dimethyl ether condensation product. The process includes: carrying out hydrolysis reaction on water, formaldehyde and formic acid in acondensation equilibrium product under the action of a catalyst, enabling the produced active hydrogen to reduce unhydrolyzed formaldehyde and methyl formate into methanol under the action of the catalyst, thus reaching the multi-effect refining purpose of aldehyde removal, deacidification, degreasing and dehydration of a condensation equilibrium product, and sending the refined product to a subsequent separation unit. According to the invention, the chemical characteristics of a small amount of water, formaldehyde, formic acid and methyl formate in the condensation equilibrium product are skillfully utilized, a hydrolysis reduction reaction network is formed under the action of a catalyst, formaldehyde, formic acid, methyl formate and water in the condensation equilibrium product react with one another to generate methanol which is easy to separate, and the catalytic refining process achieves multi-effect refining of aldehyde removal, deacidification and dehydration on a polyoxymethylene dimethyl ether condensation product.

Owner:DONGFANG HONGSHENG NEW ENERGY APPL TECH RES INST +1

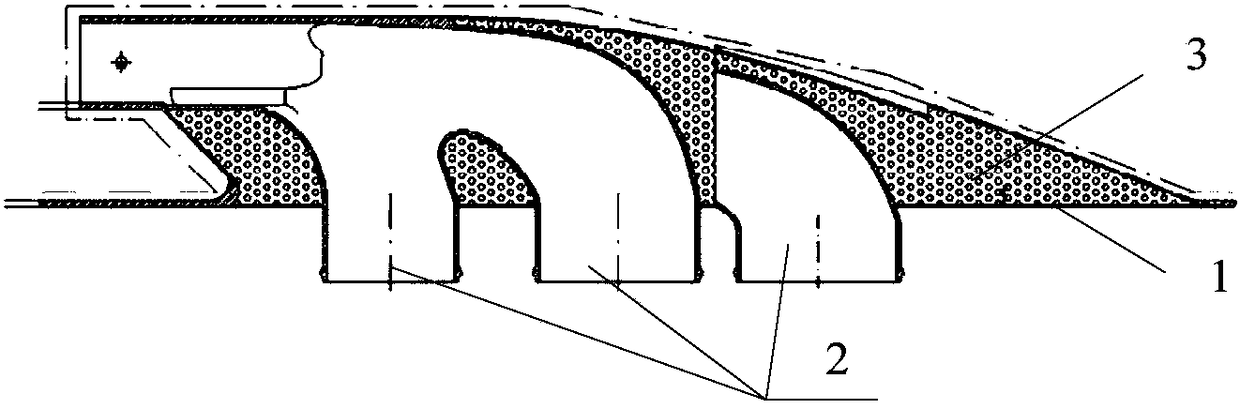

Double-runner sand core of heat-resisting steel spiral case as well as producing method and locating method of sand core

ActiveCN109128011AImprove liquidityEasy to fillFoundry mouldsFoundry coresMetallurgyMaterials science

The invention discloses a double-runner sand core of a heat-resisting steel spiral case as well as a producing method and a locating method of the sand core. The sand core is prepared from the following raw materials in percentage by weight: 78 to 85 percent of ceramsite sand, 9 to 15 percent of soldering iron sand, 2 to 3 percent of polyethylene resin, 1.0 to 1.5 percent of calcium stearate and 1.8 to 3.0 percent of a curing agent. The double-runner sand core disclosed by the invention has no batch seam burrs and has a smooth and compact surface; the problem that the sand core of the double-runner heat-resisting steel spiral case is difficult to form because of a thin wall of a runner is solved.

Owner:西峡飞龙特种铸造有限公司

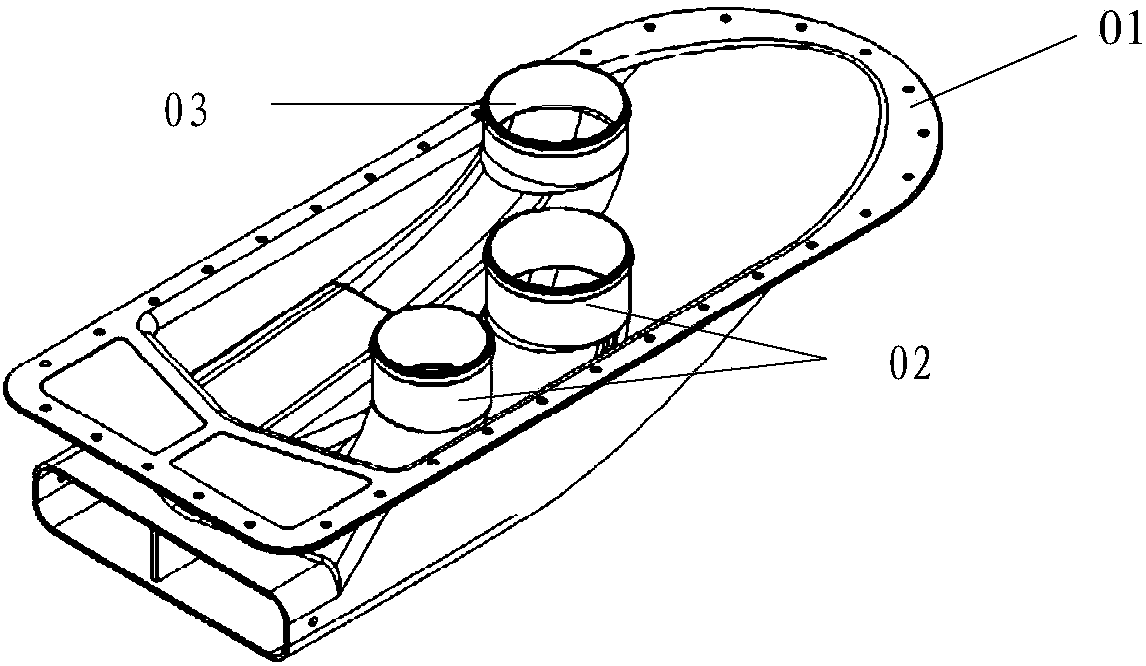

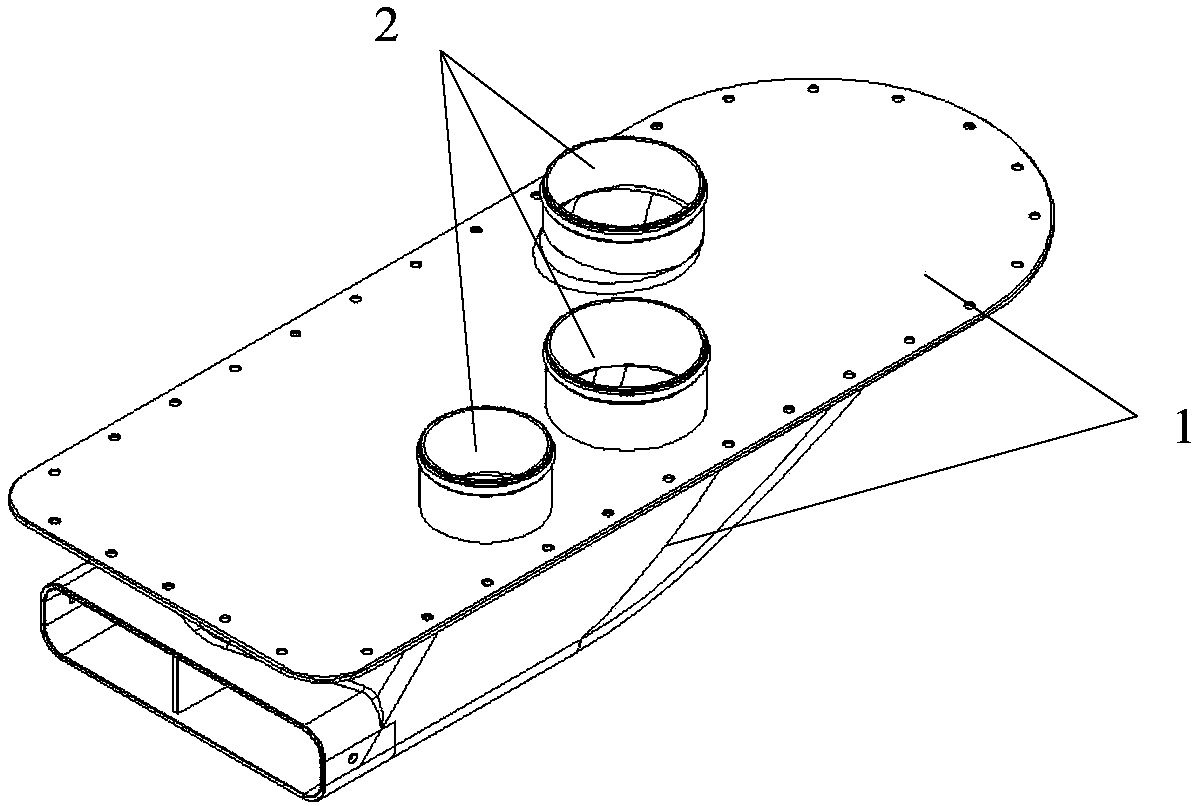

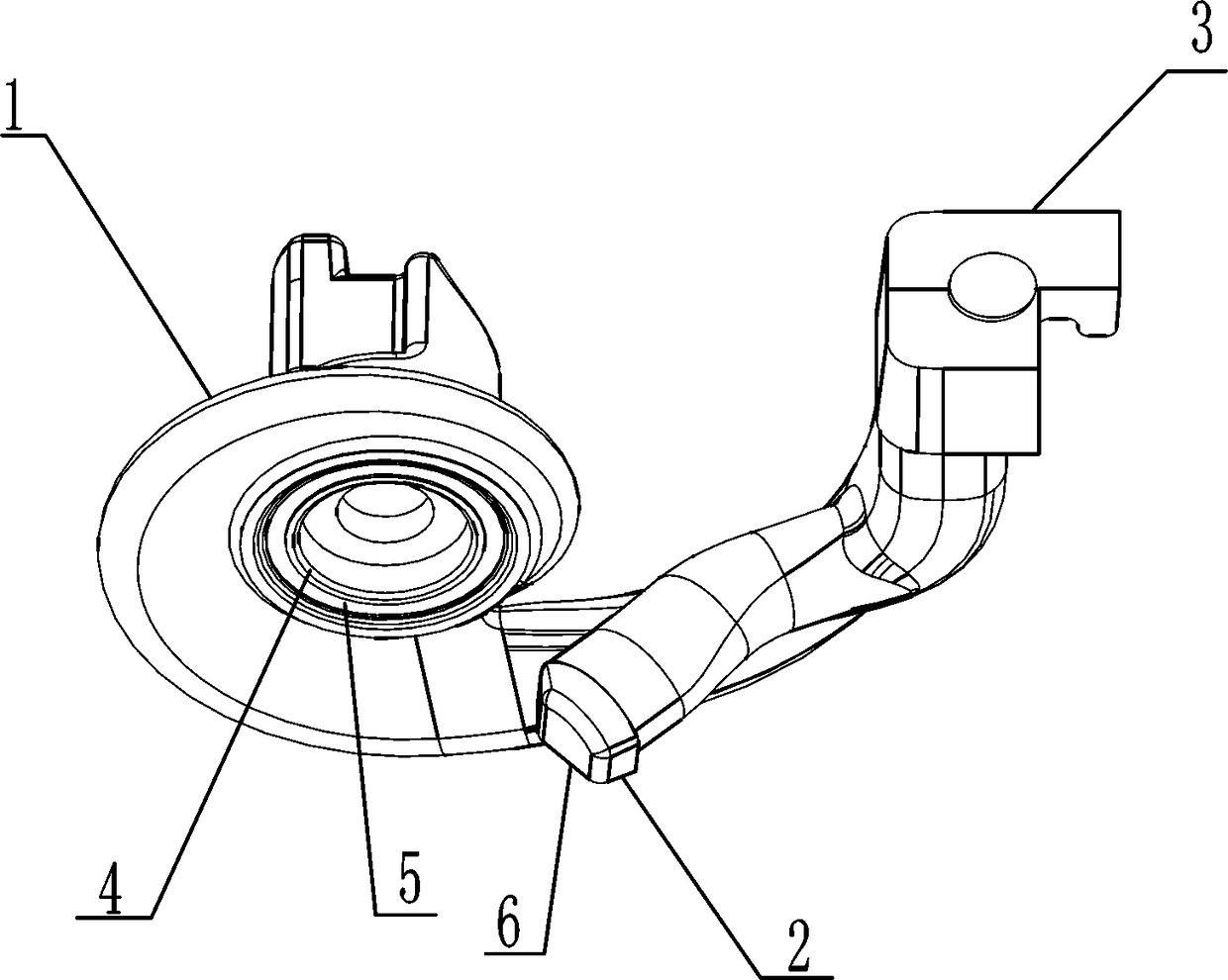

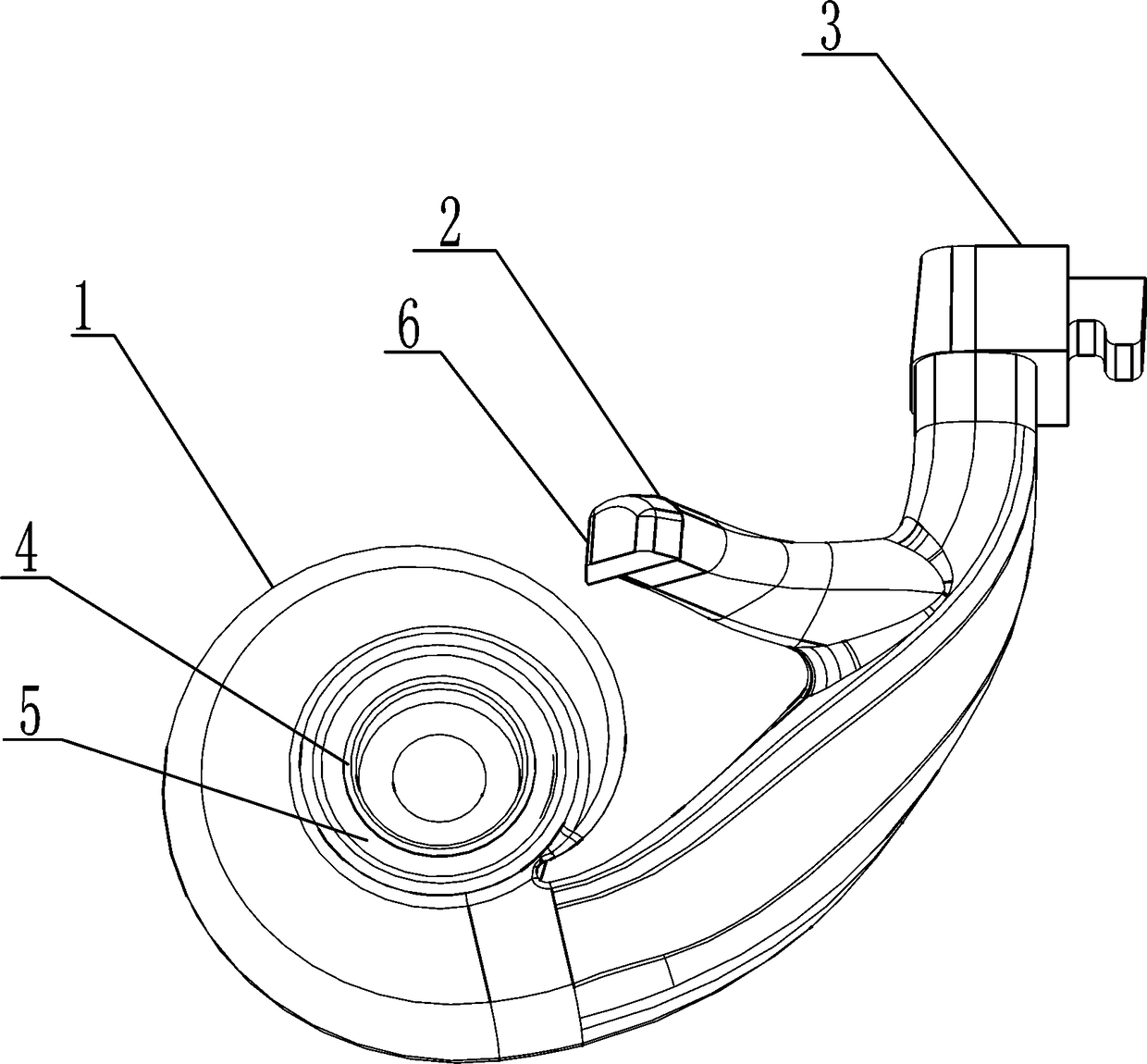

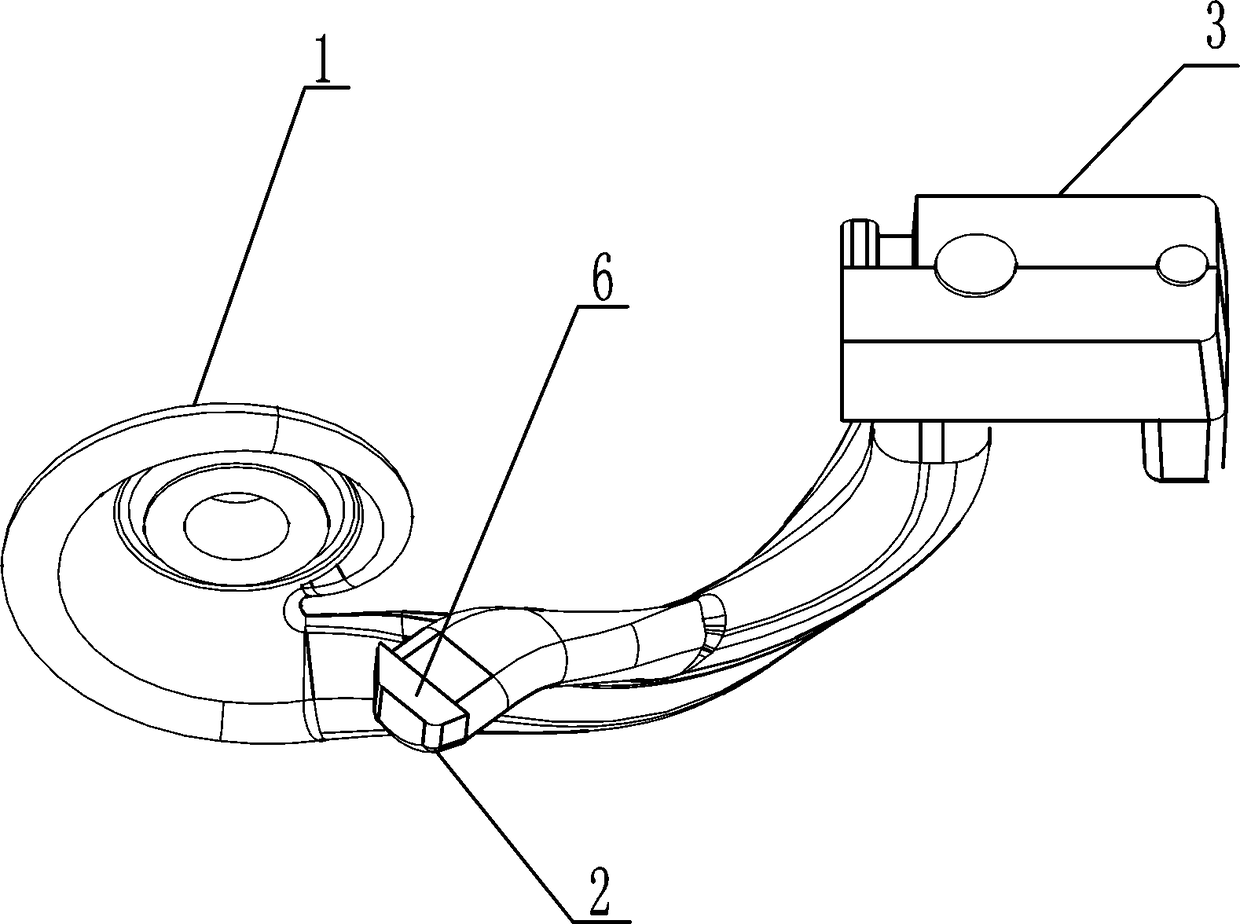

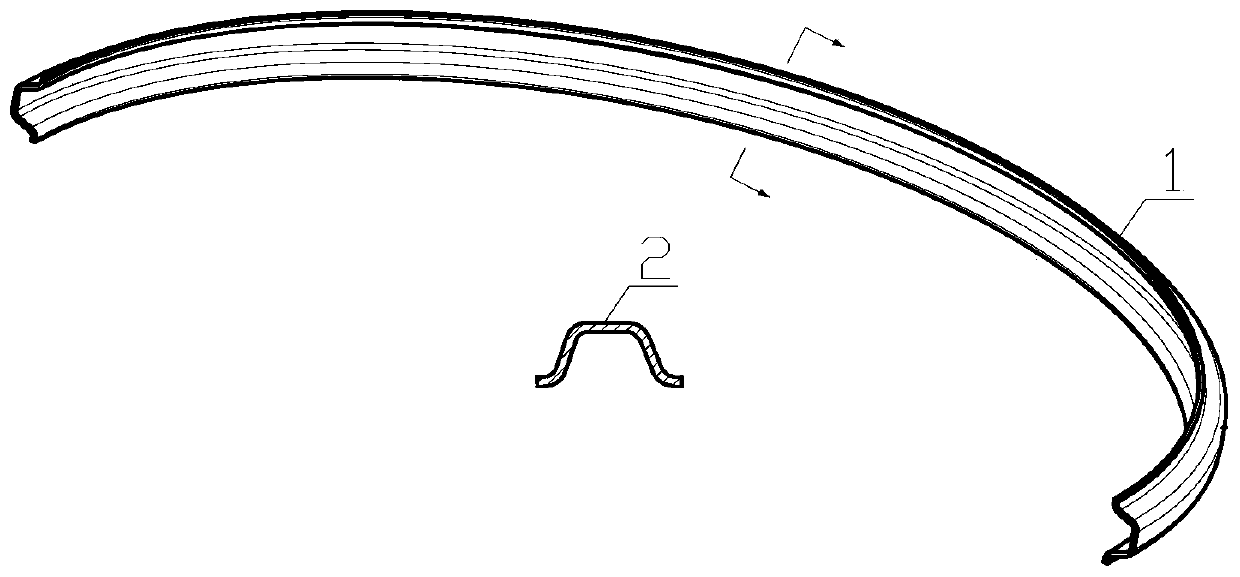

Roll bending forming die and forming method of large-curvature semi-arc-shaped pipe orifice reinforcing part

InactiveCN110639988ASimple structureSimple and convenient installation methodEngineeringStructural engineering

The invention discloses a roll bending forming die and a forming method of a large-curvature semi-arc-shaped pipe orifice reinforcing part. The forming die comprises a forming cam, a forming concave wheel and a driven concave wheel; the forming cam, the forming concave wheel and the driven concave wheel are respectively mounted on three different rollers of an asymmetric three-axis roller bendingmachine; during forming, blank positioning is carried out firstly, then the relative position relation between the forming cam, the forming concave wheel and the driven concave wheel is set, then thethree-axis roll bending device is used for forming, and finally, the pipe orifice reinforcing part passes between the three synchronous rotating rollers and continuously generates axial and longitudinal plastic bending deformation, so that the required cross-sectional shape and the radian shape are obtained.

Owner:XIAN AIRCRAFT IND GROUP

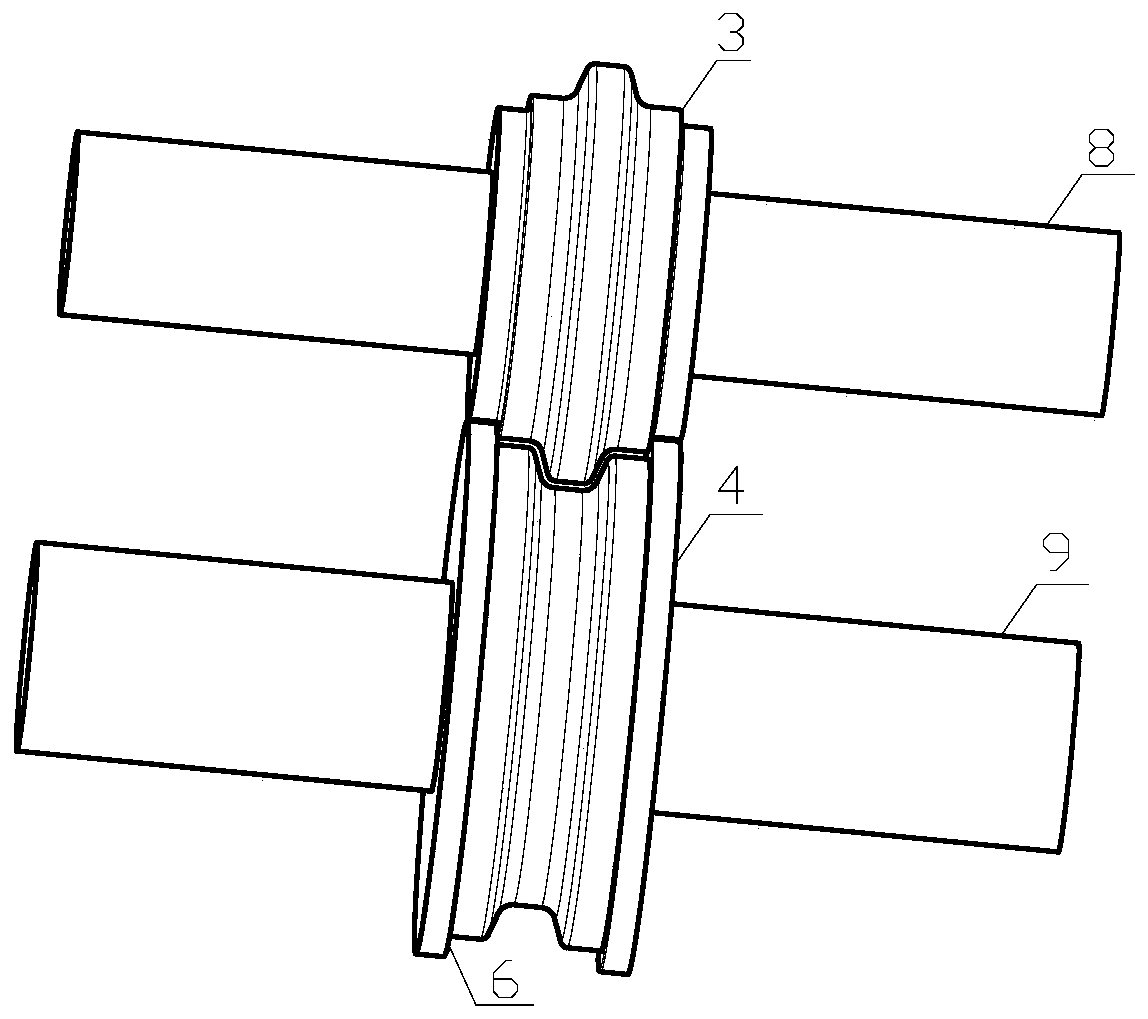

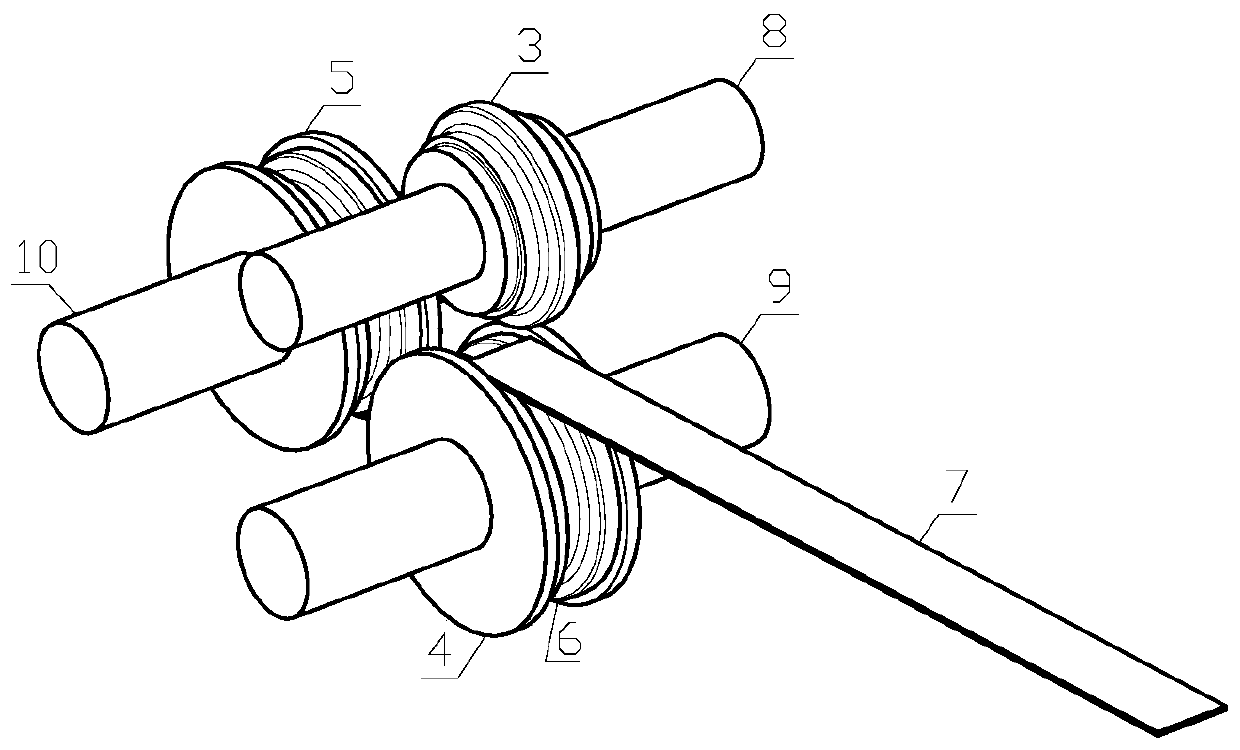

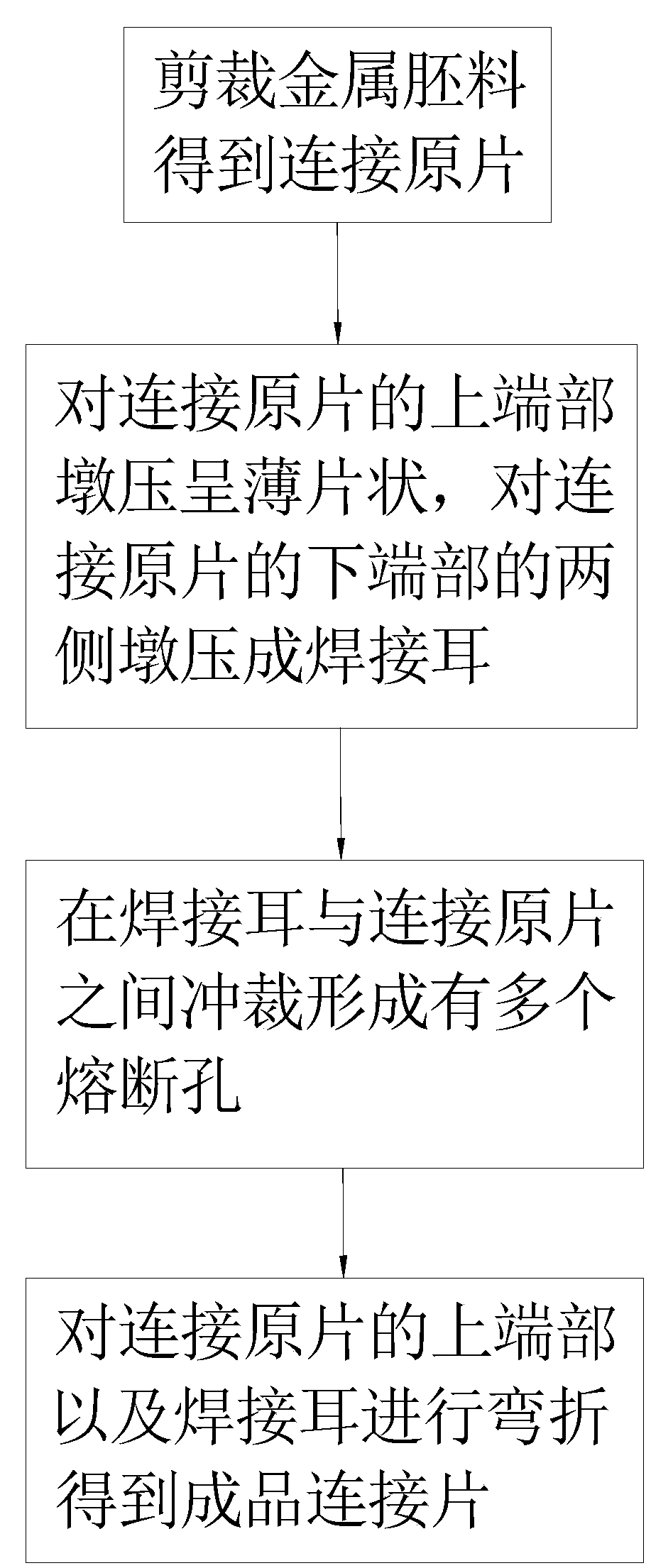

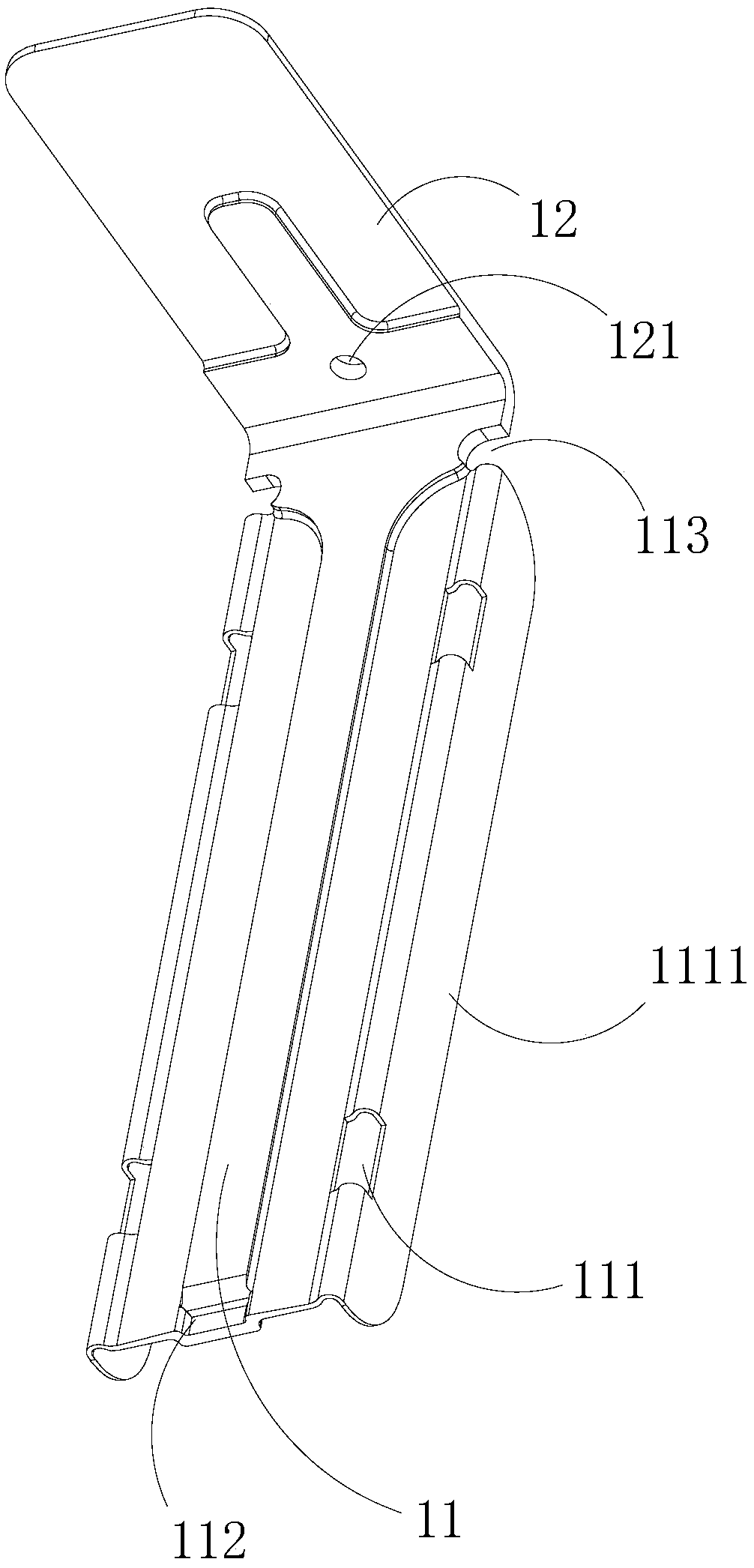

Forming technology of side-welding connecting piece

The invention relates to the technical field of batteries, discloses a forming technology of a side-welding connecting piece, and provides a stamping die. The stamping die comprises a pier press die,a blanking die and an edge bending die. The forming technology comprises the following steps that (1) a metal blank material is cut into a plurality of connecting raw pieces; (2) the upper end of eachconnecting raw piece is processed by the pier press die in a pier press mode to be in a sheet shape, and the two sides of the lower end of each connecting raw piece are processed in a forging and pressing mode to form welding lugs; (3) fusing holes are formed in the bending positions between the welding lugs on the two sides and each connecting raw piece in a blanking mode by the use of the blanking die; and (4) the upper end of each connecting raw piece is bent by the edge bending die to form a conducting strip, a welding piece is formed at the lower end of each connecting raw piece, and thecorresponding welding lugs on the two sides are bent in the positive direction. Due to the fact that the two sides of the lower end of each connecting raw piece are processed in a pier press mode, the portions of connection between the welding lugs and the connecting raw pieces can be thinned, the welding lugs can be conveniently bent, the bending forming technology of the welding lugs is simpler, the material waste is reduced, and the efficiency is higher.

Owner:SHENZHEN RED FAIRY PRECISION TECH CO LTD

Leather leftover material secondary compression utilization equipment

ActiveCN113617793AIncrease the crushing areaBroken fastSolid waste disposalTextile disintegration and recoveryWaste recoveryWaste material

The invention belongs to the field of leather solid waste recovery, and particularly relates to leather leftover material secondary compression utilization equipment which comprises a machine body. A feeding pipe is fixedly connected to the upper surface of the machine body, and a water inlet pipe is arranged at the bottom end of the feeding pipe. According to the leather leftover material secondary compression utilization equipment, through the arrangement of a cleaning mechanism, when crushed materials fall to the upper surface of a partition plate, a water inlet pipe injects water, a transmission shaft drives a rolling shaft to rotate, and a rotating disc does circular motion with the transmission shaft as the circle center along the upper surface of the partition plate; under the driving of the rotating disc, an arc-shaped plate continuously stirs the materials, and a rotating plate is matched, so that the outer surfaces of the materials and the outer surfaces of brush strips make contact and friction faster and more sufficiently, and the cleaning speed and the cleaning effect are improved; and one part of water flow with impurities flows out of a blow-off pipe, and the other part of water flow with the cleaned materials falls down from a screen, so that the problem that when traditional leather is recycled, due to the fact that the number of impurities in the materials is large, the utilization rate is low is solved.

Owner:江门市普德再生资源科技有限公司

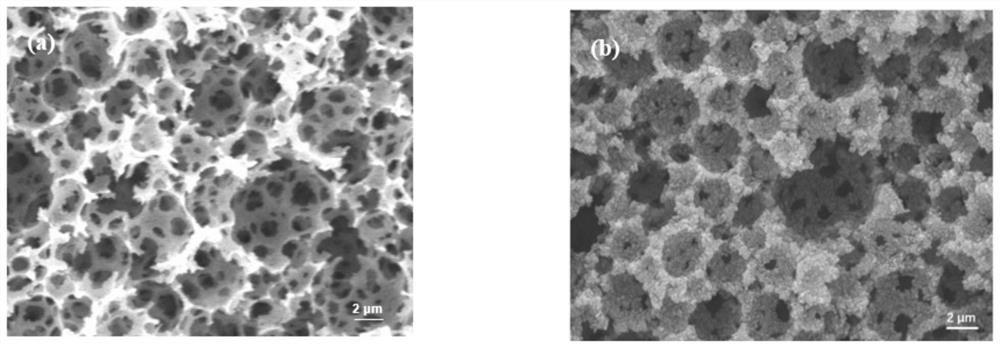

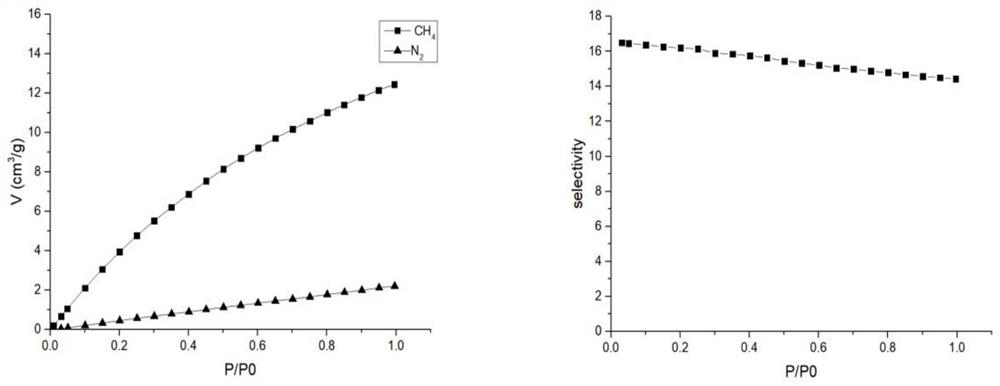

Composite material for separating CH4 gas and preparation method thereof

PendingCN111889078AImprove protectionHigh hydrothermal stabilityGas treatmentOther chemical processesMicrosphereMetal-organic framework

The invention discloses a composite material for separating CH4 gas, and belongs to the technical field of adsorption separation. The composite material reserves the gas adsorption separation capability of metal organic framework materials (MOFs) in performance. After the MOFs material is compounded with the porous polymer material polyacrylate microspheres (PGT) and polyacrylamide microspheres (PAM), the problems that the MOFs material is difficult to form and the separation efficiency is reduced after the MOFs material is formed are solved. Meanwhile, the material has better hydrothermal stability and wear resistance, is an efficient composite material for gas separation, and has important industrial value in the aspects of enrichment and utilization of methane in low-concentration coalbed methane and removal of nitrogen and carbon dioxide from natural gas.

Owner:青岛创启汇能新材料科技有限公司

Wool felt doll and making method thereof

The invention discloses a wool felt doll and a making method thereof. The wool felt doll comprises a doll body, wool and decorating parts, wherein the doll body is made of polyurethane sponge. The surface of the doll body is covered with the wool, and the wool penetrates into the doll body through a needle and is fixed. The decorating parts are installed on the doll body. The wool felt doll is high in density, easy to machine and shape, and high in extrusion resisting capability, and has the advantages of being soft, distinct in detail, vivid and the like after being shaped. Obviously, the problem that an existing wool felt doll is difficult to shape is solved, the characteristic that the wool felt doll is soft is also kept, and meanwhile the problem that wool felt dolls are difficult to produce on a large scale is solved. More importantly, the polyurethane sponge is environmentally friendly and nontoxic, namely the wool felt doll made of the polyurethane sponge is suitable for people at all ages, and there is no need to worry that the wool felt doll causes harm to the human body. Besides, the wool felt doll can be manually made in a DIY mode, and requirements of more users are met.

Owner:涂雄

Material for promoting formation of geopolymer in high-humidity environment and preparation method thereof

PendingCN113666655ALow priceWide variety of sourcesSolid waste managementCement productionPhysical chemistryGeopolymer

The invention discloses a material for promoting formation of a geopolymer in a high-humidity environment and a preparation method of the material. The raw materials comprise solid waste, an exciting agent, an additive and water, the solid wastes are industrial solid wastes and comprise fly ash and phosphorus tailing sand; the exciting agent is an alkaline exciting agent and is one of a sodium hydroxide exciting agent, a sodium hydroxide-silica fume composite exciting agent and a water glass exciting agent; the additive is xanthan gum, and the addition amount of the additive is 1% of the solid waste; and the mass ratio (water-solid ratio) of the water to the solid waste is 0.5-0.75. According to the method, the feasibility of preparing a geopolymer grouting filling material from the solid wastes is improved, the problem that the goaf grouting filling material is difficult to form in the actual grouting process is solved, the forming degree of the geopolymer in the high-humidity environment is improved, the final setting time is shortened, the industrial solid wastes can be consumed, and meanwhile, goaf repair treatment is carried out. The raw materials are industrial solid wastes and are low in price and wide in source.

Owner:中能化江苏地质矿产设计研究院有限公司

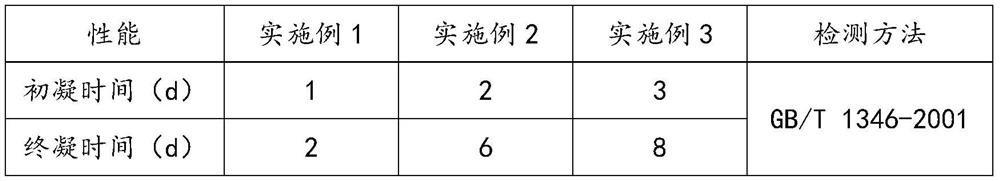

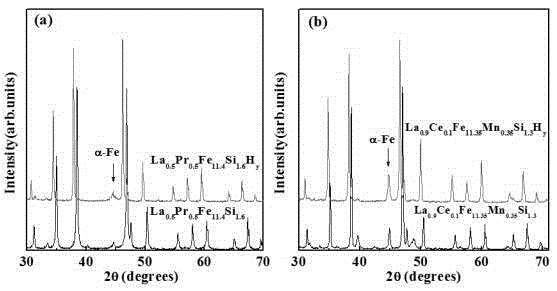

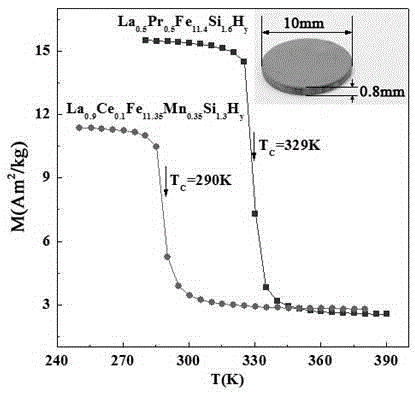

High atmospheric pressure synthetic method for flaky La(Fe, Si)13-based hydride block with efficient room temperature magnetic refrigeration performance

InactiveCN105314598ASolve difficult moldingEfficient room temperature magnetic refrigeration performanceMultiple metal hydridesHydrogen atmosphereFree cooling

The invention belongs to the field of new function materials and provides a high atmospheric pressure synthetic method for a flaky La(Fe, Si)13-based hydride block with efficient room temperature magnetic refrigeration performance. According to the method, a La(Fe, Si)13-based compound with a NaZn13 structure is smashed before being placed in a high atmospheric pressure heat treatment device, and subjected to hydrogen absorption in a hydrogen atmosphere before being cooled to the room temperature, and then a saturated hydrogen absorption hydride is obtained; the saturated hydrogen absorption hydride is pressed into a flake, sintered and cooled naturally, and then the flaky hydride block is obtained. By the adoption of the method, the problem of hard molding to the La(Fe, Si)13-based hydride in practical application is solved, and a flaky La(Fe, Si)13-based magnetic refrigeration working medium with efficient room temperature magnetic refrigeration performance and capable of being used at a driving magnetic cold-accumulation refrigerator can be obtained.

Owner:SHENYANG LIGONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com