Rubber compound for rubber for coating chemical fiber bleaching rubber roll

A chemical fiber and covering rubber technology is applied in the field of rubber covering rubber for chemical fiber bleaching rubber rollers, which can solve the problems of difficult forming of rubber rollers and high Mooney viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

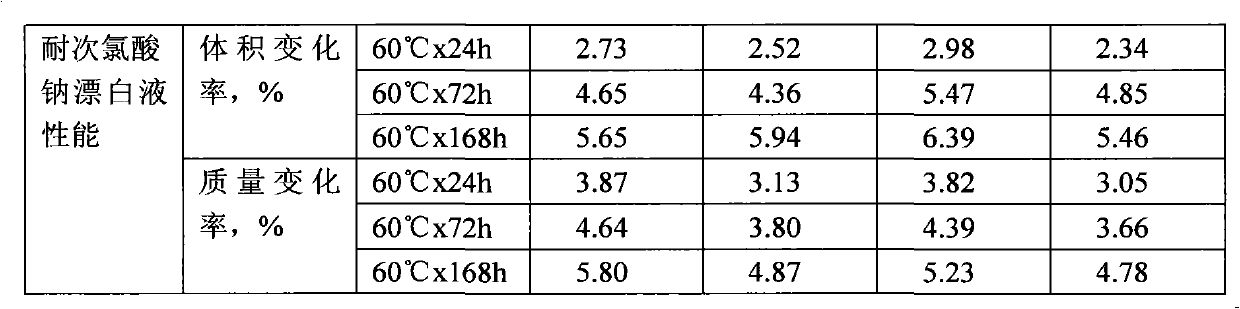

Embodiment 1-3 and comparative example l

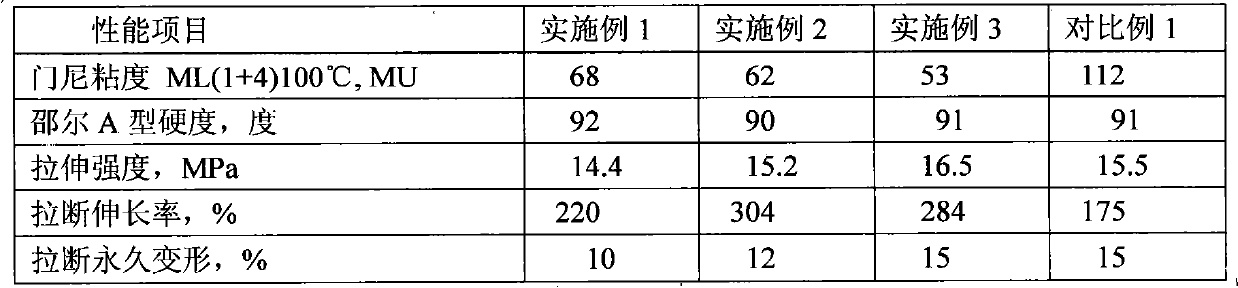

[0035] The sizing formula of embodiment 1-3 and comparative example 1 and the mass proportioning of various raw materials are listed in table 1.

[0036] Table 1

[0037] raw material

Example 1

Example 2

Example 3

Comparative example 1

EPDM Rubber (4045)

100

100

100

100

10

10

10

10

10

10

10

10

3

3

3

3

Antiaging agent(2246)

1.5

1.5

1.5

1.5

Tackifying resin (H-501)

3

3

3

3

Tackifying Resin (SP 1077)

6

6

6

6

Silica (T-150)

80

80

50

80

Silica (A-200)

30

8

8

8

8

Titanium dioxide

20

20

20

20

Qi polyester (12-I)

8

8

8

Liquid ethylene propylene rubber (CP 80)

10 ...

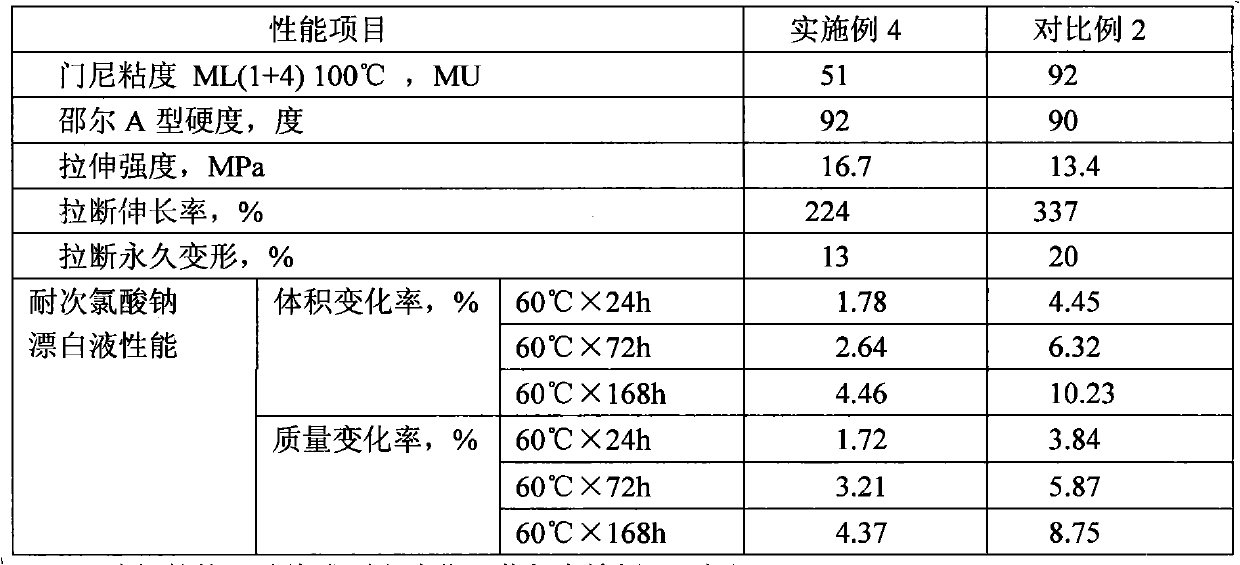

Embodiment 4

[0047] The sizing material formula of embodiment 4 and the quality proportioning of various raw materials are as follows:

[0048] EPDM rubber (4725P) 100

[0050] Magnesium oxide 10

[0051] stearic acid 3

[0052] Antiaging agent (2246) 1.5

[0053] Tackifying resin (H-501) 3

[0054] Tackifying resin (SP1077) 6

[0055] Silica (T-150) 75

[0056] Silane coupling agent (Si-69) 6

[0057] Titanium dioxide 20

[0058] Polyester (12-I) 8

[0059] Liquid polybutadiene resin (Ricon 153) 15

[0060] Paraffin oil (6035) 20

[0061] Accelerator CZ 1.6

[0062] Accelerator DM 0.5

[0063] Accelerator BZ 0.8

[0064] Accelerator TMTD 0.7

[0065] Accelerator DPTT 0.7

[0066] sulfur 6

[0067] Dicumyl peroxide 0.8

[0068] The preparation process of the sizing material in Example 4 is the same as that of Examples 1-3, with the differences: ①The roll temperature of the open rubber mixing machine is 60-70°C; ②The liquid material is replaced with s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mooney viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com