Material for promoting formation of geopolymer in high-humidity environment and preparation method thereof

A geopolymer and environmental technology, applied in the field of geopolymer preparation and application, can solve the problems of low temperature, high humidity in goaf, poor molding, etc., and achieve the advantages of improving molding degree, reducing environmental harm and improving environmental protection benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

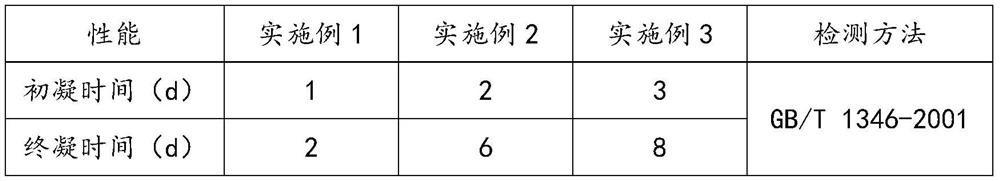

[0027] This example discloses a material for promoting the formation of geopolymers in a high-humidity environment and a preparation method thereof, and the initial setting and final setting times of the geopolymers are measured.

[0028] Geopolymer materials include: fly ash, phosphorus tailings sand, alkali activator and water, wherein the alkali activator is sodium hydroxide, the water-solid ratio is 0.5, water and sodium hydroxide (as Na 2 O meter) the mol ratio is 20.

[0029] The preparation method of geopolymer comprises the steps:

[0030] S1. Dry the fly ash and phosphorous tailings at 105°C for 12 hours to remove moisture;

[0031] S2. cooling, crushing and pulverizing the dried raw materials to 200 mesh, weighing 250g each of fly ash and phosphorus tailing sand, weighing 55.56g sodium hydroxide, adding 250g water to dissolve;

[0032] S3. Mix the above-mentioned fly ash, phosphorus tailings sand and sodium hydroxide solution, add 5g of xanthan gum and stir for 10m...

Embodiment 2

[0034] This example discloses a material for promoting the formation of geopolymers in a high-humidity environment and a preparation method thereof, and the initial setting and final setting times of the geopolymers are measured.

[0035] Geopolymer materials include: fly ash, phosphorus tailings sand, alkali activator and water, wherein the alkali activator is sodium hydroxide and silica fume, the water-solid ratio is 0.5, water and sodium hydroxide (as Na 2 O) molar ratio of 25, silica fume (SiO 2 In terms of) and sodium hydroxide (as Na 2 O meter) the molar ratio is 2.

[0036] The preparation method of geopolymer comprises the steps:

[0037] S1. Dry the fly ash and phosphorous tailings at 105°C for 12 hours to remove moisture;

[0038] S2. cooling, crushing and pulverizing the dried raw materials to 200 mesh, weighing 250g each of fly ash and phosphorus tailings sand;

[0039] S3. Weigh 44.44g of sodium hydroxide and 66.67g of silica fume, add 250g of water to dissolv...

Embodiment 3

[0042] This example discloses a material for promoting the formation of geopolymers in a high-humidity environment and a preparation method thereof, and the initial setting and final setting times of the geopolymers are measured.

[0043] Geopolymer material comprises: fly ash, phosphorus tailings sand, alkali activator and water, wherein the original water glass used for preparing alkali activator is 3.3 mold, and water-solid ratio is 0.5, and water and sodium hydroxide (as Na 2 O meter) the mol ratio is 25, and the required modulus of preparation water glass activator is 2.

[0044] The preparation method of geopolymer comprises the steps:

[0045] S1. Dry the fly ash and phosphorous tailings at 105°C for 12 hours to remove moisture;

[0046]S2. cooling, crushing and pulverizing the dried raw materials to 200 mesh, weighing 250g each of fly ash and phosphorus tailings sand;

[0047] S3. Take by weighing 239.37g of industrial-grade water glass solution of 3.3 molds, 17.19g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com