Patents

Literature

93results about How to "High degree of molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

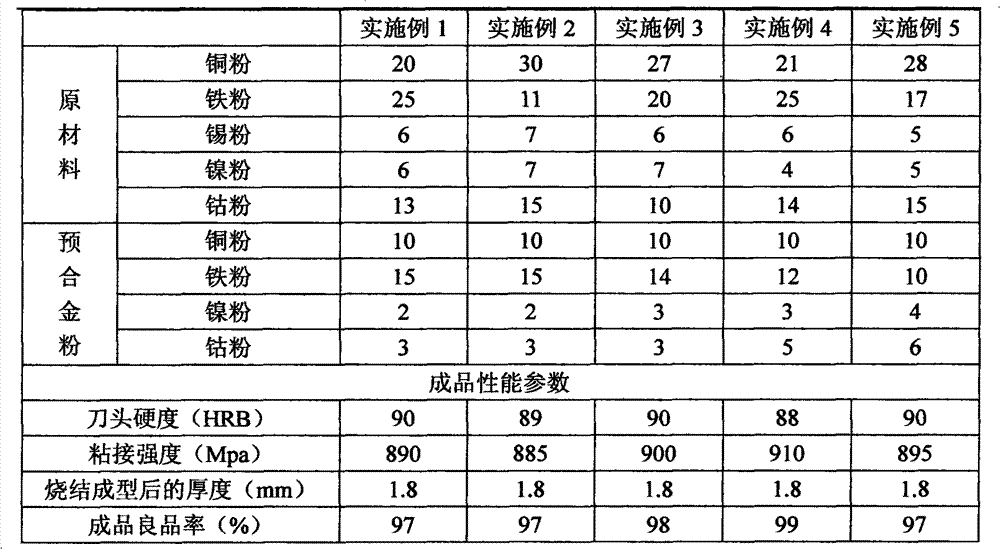

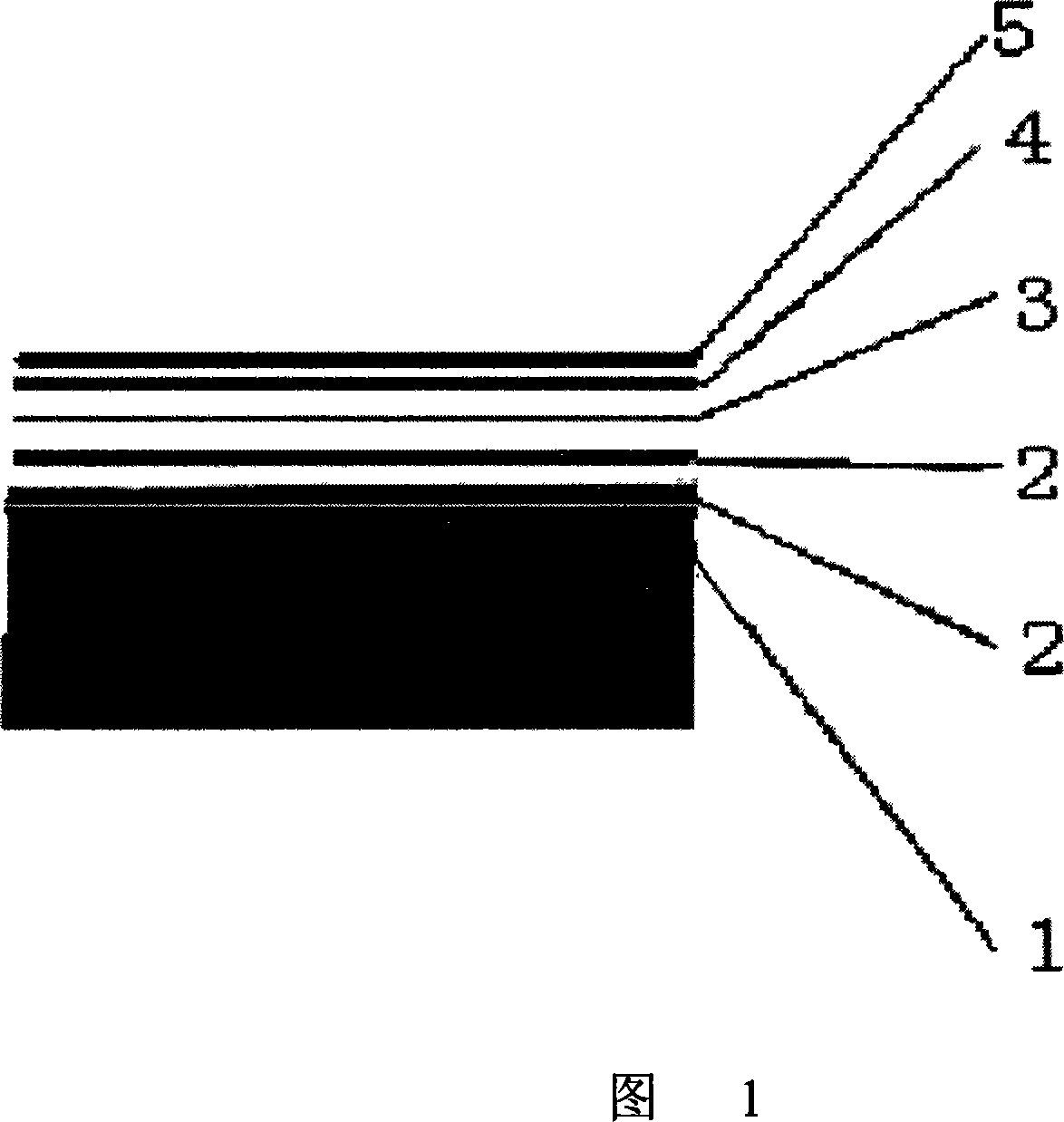

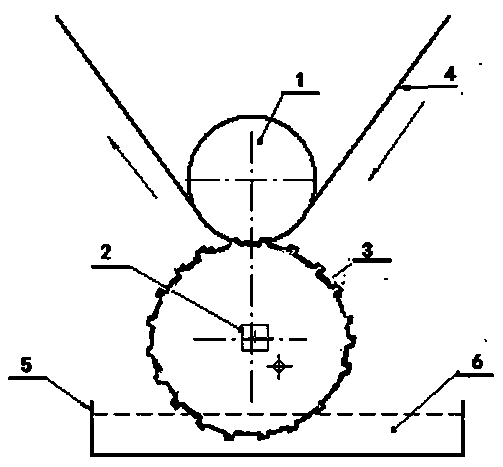

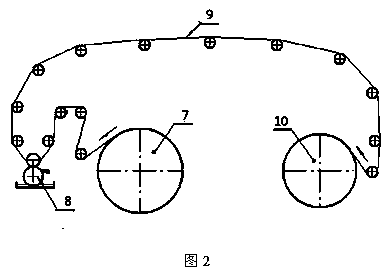

Production process of diamond saw blade formed by compressing granular powders

Disclosed is a production process of a diamond saw blade formed by compressing granular powders. The production process includes steps of using a copper powder, an iron powder, a tin powder, a nickel powder and a cobalt powder as raw materials, adding liquid paraffin for mixing and stirring, and then performing procedure steps of compressing, sintering and post-treating. The production process is characterized in that an agglomerating procedure is performed before a compressing procedure, and the powder raw materials are agglomerated to be granular and then compressed. According to experiments, the production process is obvious in effects, no defect is produced after the compression, and the yield of the finished diamond saw blade can reach above 97%.

Owner:SHIJIAZHUANG XINDA DIAMOND TOOLS CO LTD

Vacuum-coated aluminum paper having false-proof hologram pattern and method for making same

InactiveCN101135124AHigh degree of moldingHigh glossSpecial paperPaper/cardboardAluminum coatingMaterials science

The present invention is vacuum aluminum plating paper with anti-fake holographic pattern and its making process, and belongs to the field of aluminum plating paper making technology. The vacuum aluminum plating paper comprises one paper base and one primary coating, one aluminum coating, one bright coating and one characterized anti-fake holographic pattern layer successively on the paper base. Its making process includes the following steps: sorting paper base, painting the primary coating, vacuum plating aluminum to form the aluminum coating, painting the bright coating, loading the anti-fake holographic pattern layer, rehumidifying, embossing, cutting, printing, etc. The vacuum aluminum plating paper with anti-fake holographic pattern has bright pattern and optional laser anti-fake effect and relatively simple production process.

Owner:YANTAI BOYUAN TECH MATERIALS

Freshwater crayfish feed for improving meat quality and preparation method thereof

InactiveCN105394350ANutritional balanceRich varietyFood processingClimate change adaptationSucroseSaccharum

The invention discloses a freshwater crayfish feed for improving the meat quality. The freshwater crayfish feed is prepared from the following substances in parts by weight: 30 to 40 parts of soybean meal, 10 to 15 parts of corn meal, 8 to 10 parts of tea seed cakes, 6 to 10 parts of bone powder, 8 to 10 parts of mussels meat, 15 to 20 parts of silkworm chrysalis, 3 to 5 parts of smilacina atropurpurea, 4 to 6 parts of vallisneria natans, 2 to 4 parts of potamogeton distinctus, 5 to 8 parts of bentonite, 8 to 10 parts of sugarcane bagasse, 1 to 3 parts of composite vitamin, 1 to 2 parts of amino acid chelate, 3 to 5 parts of a Chinese herbal additive, and 4 to 6 parts of a composite additive. The feed disclosed by the invention is comprehensive and balanced in nutrition; the variety of raw materials is rich, so that the demands of freshwater crayfish in different periods for growth can be met; most of the used raw materials are pure and natural environment-friendly raw materials, and no drugs are retained in the bodies of the freshwater crayfish; the yield can be greatly increased; meanwhile, the freshwater crayfish tastes delicious and is chewy, so that a better breeding benefit is realized.

Owner:袁生咬

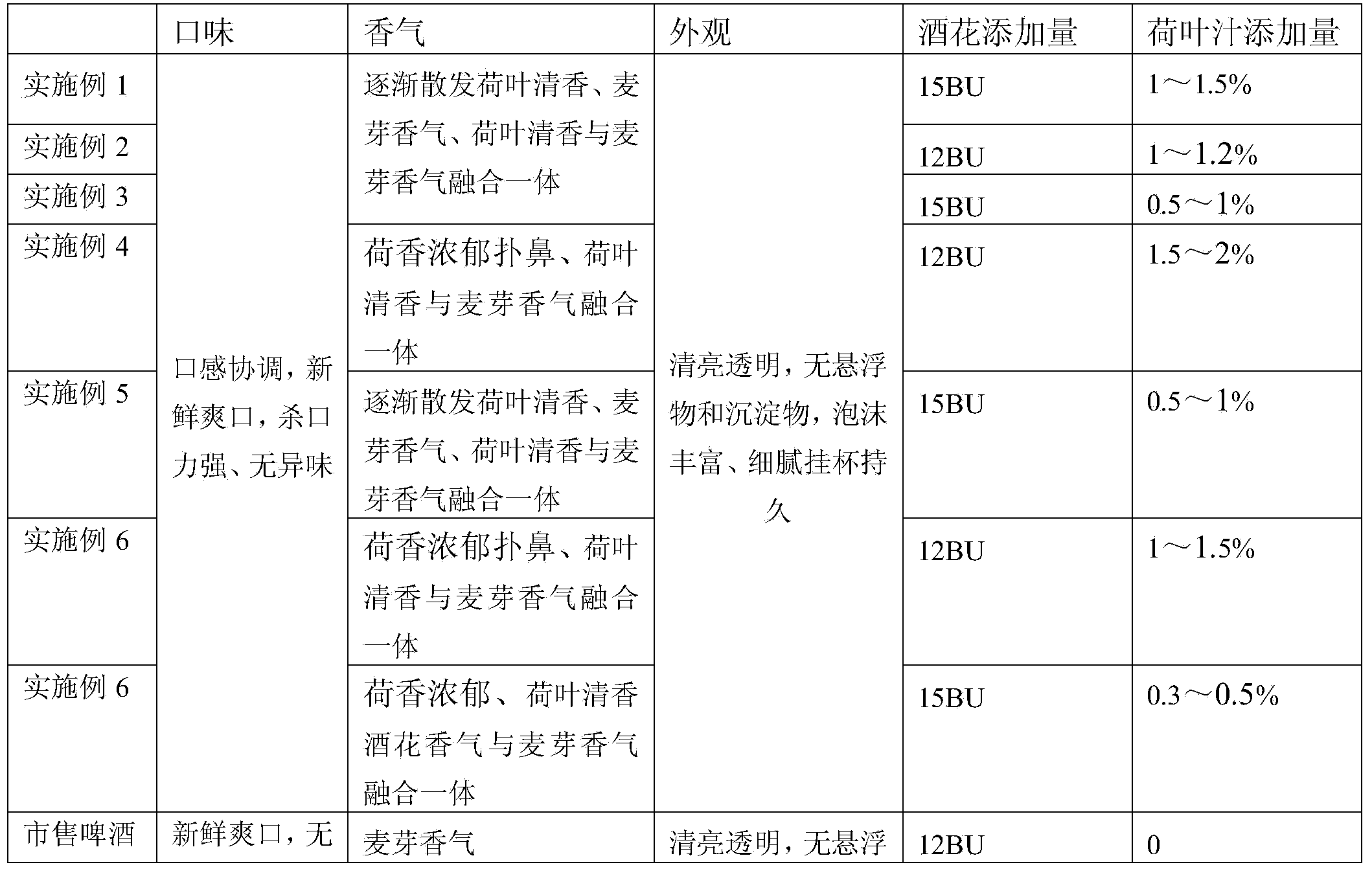

Preparation method for lotus leaf health-care beer

The invention relates to a preparation method for lotus leaf health-care beer. The preparation method comprises the following steps: juicing lotus leaves to obtain lotus leaf juice; mixing and crushing barley malt and wheat malt, and then adding water to obtain mixed mash; saccharifying the mixed mash at the temperature of 44-78DEG C; after the saccharification is ended, filtering, boiling, precipitating, cooling, oxygenating, performing primary fermentation, diacetyl reduction, cooling, post fermentation, post storage and filtering, and operating according to a conventional preparation process of beer fermentation; adding the lotus leaf juice in the boiling process or after post storage and before filtering beer; filling and sterilizing to obtain the lotus leaf health-care beer. According to the preparation method disclosed by the invention, the usage amount of hops is reduced; the stability of wort is improved by using polyphenol in the lotus leaves, so that the forming degree of the beer is improved; the lotus leaf juice is added in the beer during the boiling of the wort or before filtering, so that the faint scent of the lotus leaves and the beer can be better fused together; the prepared lotus leaf health-care beer retains the flavor of fresh malt beer, has faint scent and lotus fragrance of the lotus leaves and has the advantages of pure flavor, freshness, tasty and unique taste; besides, the staying power of beer foam is improved.

Owner:山东巴克斯啤酒有限公司

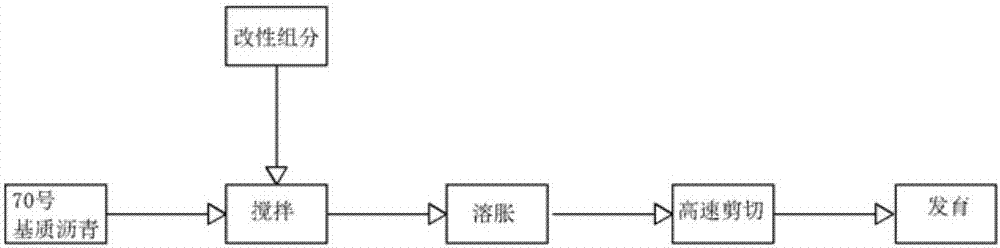

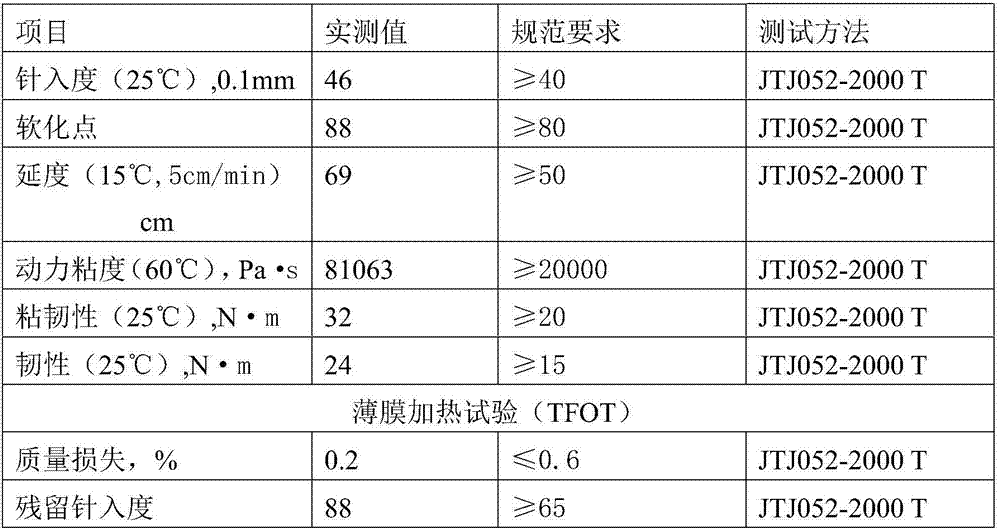

High viscosity modified asphalt formula suitable for drainage asphalt pavement and modifying process thereof

The invention discloses a high viscosity modified asphalt formula suitable for a drainage asphalt pavement. The formula comprises the following components in percentage by weight: 70-85% of #70 matrix asphalt, 3-9% of an SBS modifier, 8-18% of rubber powder, 2-6% of terpene resin, 1-5% of diatomite, 6-15% of asphalt -based carbon fibers for spinning and 2-5% of a warm mixing agent. The high viscosity modified asphalt formula disclosed by the invention is reasonable in step and simple in formula. The viscosity, weather resistance and water stability of the asphalt are remarkably improved. The matrix asphalt is uniformly dispersed, is high in forming degree, is unlikely to age, and is low in sensitivity on environmental temperature.

Owner:CHONGQING ZONJO RENEWABLE RESOURCES DEV CO LTD

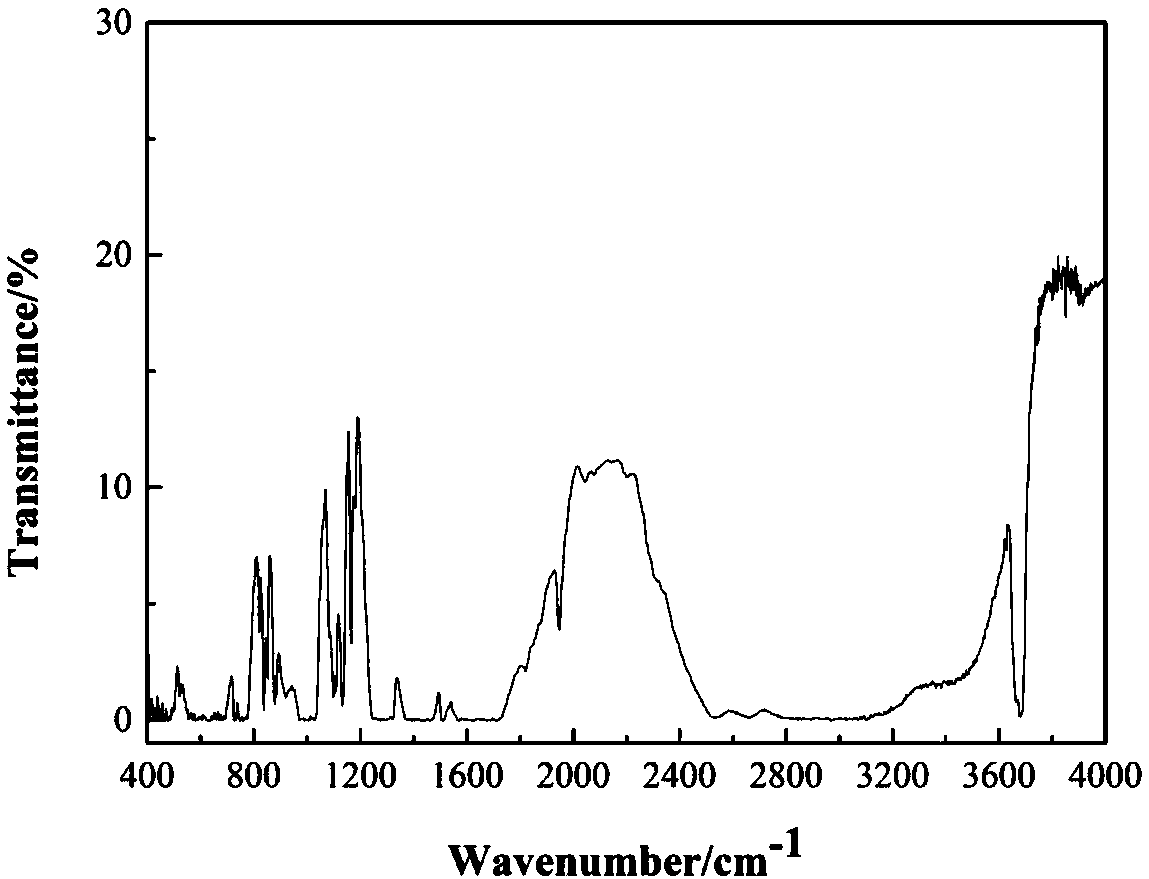

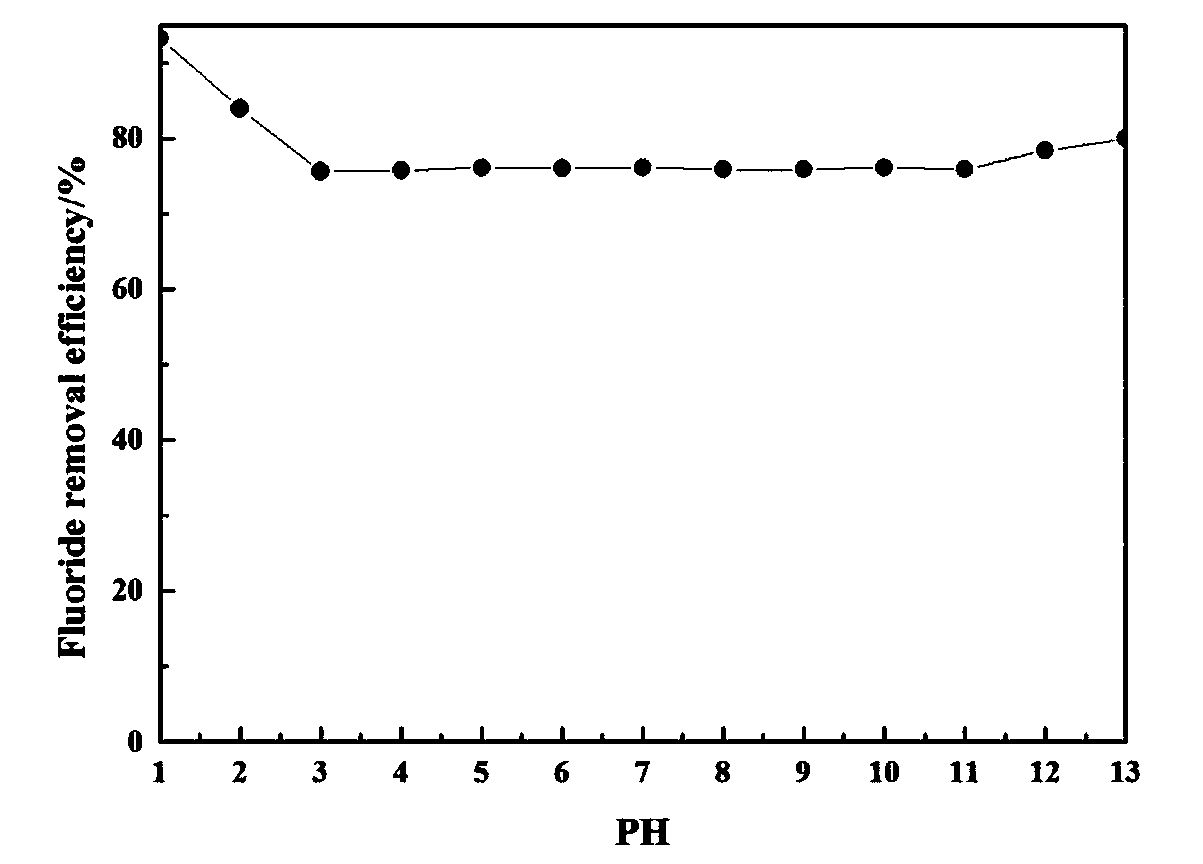

Defective MIL-53 (Al) metal organic framework and preparation method and application thereof

ActiveCN107899559AIncrease profitSynthesis temperature is lowOther chemical processesWater contaminantsOrganic solventMaterial synthesis

The invention belongs to the technical field of material synthesis, and particularly relates to a defective MIL-53 (Al) metal organic framework and a preparation method and application thereof. Metalsalt and an organic ligand are used as raw materials, and by using methanol, ethanol, ethanol and water, N,N-2-methylformamide and the like as organic solvents, linear MIL-53 (Al) is obtained througha reaction at 160-200 DEG C for 12-48 hours. The metal organic framework with large-capacity fluoride removing performance is obtained by adjusting a proper synthesis condition. The preparation methodhas the advantages of high raw material utilization rate, short synthesis time and the like, and a promising synthesis idea is provided for exploring highly-efficient adsorbing material synthesis.

Owner:CENT SOUTH UNIV

Preparation method of aluminum-free transparent laser environmental-protection inner liner for cigarette

ActiveCN104354484AHigh degree of moldingGuaranteed physical propertiesDuplicating/marking methodsPaper coatingPhotogravureAdhesive

The invention discloses a manufacturing method of an aluminum-free transparent laser environmental-protection inner liner for cigarette. The aluminum-free transparent laser environmental-protection inner liner for cigarette comprises paper, a PET film and a waterborne transfer adhesive. According to the manufacturing method, the PET film is molded through a molding press to form a laser pattern with various patterns, and then is combined with paper by the use of the waterborne transfer adhesive; after the PET film is peeled, the laser pattern is transferred to the paper; a layer of transparent medium is plated on the PET film-peeled paper with the laser pattern by the use of a vacuum aluminum plating machine; the transparent medium-plated paper with the laser pattern undergoes water supplement treatment; and a cigarette logo pattern is printed by the use of a photogravure press. By reasonable proportioning and a new technology, the prominent problem that embossing of paper is fuzzy, is easy to bounce back and is not resistant to folding is solved. In comparison with the prior art, the method provided by the invention is environmentally friendly and can be used to maintain original physical properties of paper. By the method, aluminum-free transparent laser environmental-protection inner liner for cigarette has advantages of good flexibility and molding degree, no bouncing-back, folding resistance, clear and accurate printed typeface and the like.

Owner:汕尾高峰科特纸业股份有限公司

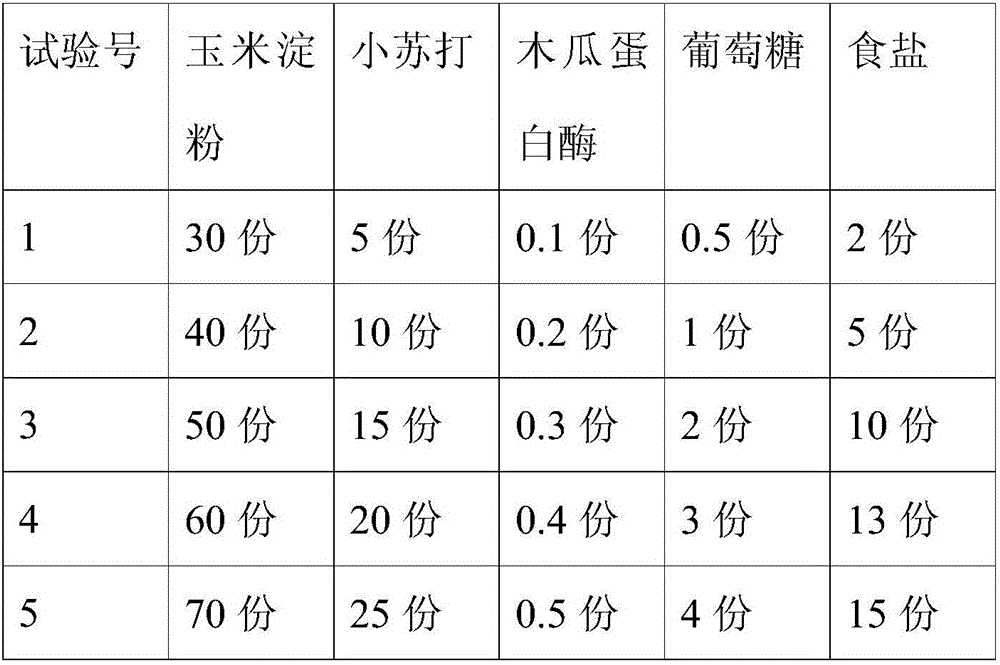

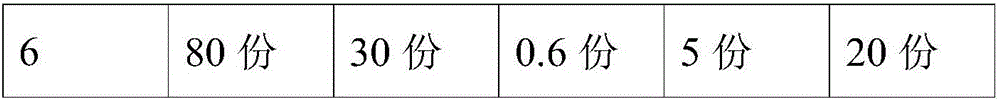

Meat pickling powder and preparation method and use method thereof

The present invention discloses meat pickling powder and a preparation method and a use method thereof. The meat pickling powder comprises corn starch, baking soda, papain, glucose and edible salt. The preparation method comprises the following steps of raw material inspecting and accepting, weighing, mixing and stirring, weighing, packaging and preserving. The use method comprises meat product pickling, pickling material preparing, meat product stirring, and cold storing. The meat pickling powder combines the various raw materials together, utilizes different functions of different accessory materials, can enable the pickled meat products to be fresh and tender, high in shaping degrees, and good in tasty degrees, overcomes the single function of single raw material, reduces the pickling steps, is wide in application ranges, can be used in pickling meat products of beef, mutton, pork, etc., can also be used to pickle edible materials of animal internal organs, etc., has a clear combination method of raw materials in parts by weight, and has theoretical basis and practical application supports.

Owner:成都大龙燚餐饮管理有限公司

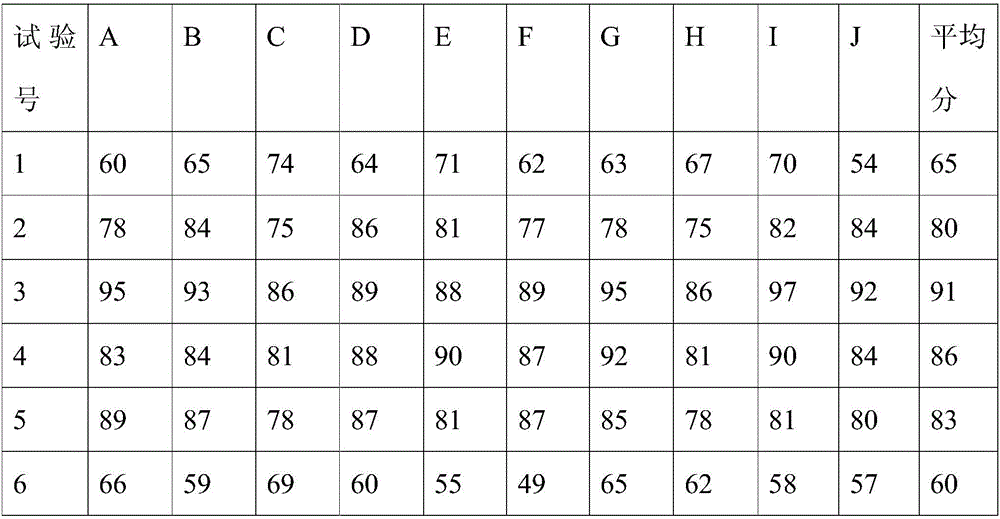

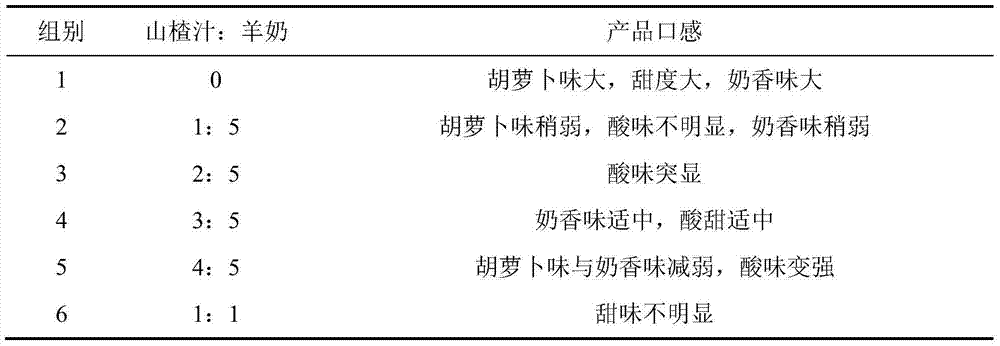

Edible goat milk fruit-vegetable paper and preparation process thereof

ActiveCN104719488AUnique tasteSmooth tasteMilk preparationFood preparationNutritive valuesBeta-Cyclodextrins

The invention discloses edible goat milk fruit-vegetable paper. The edible goat milk fruit-vegetable paper is prepared from the following raw materials in parts by weight: 80-120 parts of goat milk, 60-100 parts of haw juice, 150-170 parts of carrot, 18-22 parts of water, 8-12 parts of a sweetener, 0.1-0.14 part of beta-cyclodextrin, 0.6-1.0 part of a compound stabilizer, 0.08-0.12 part of a colour fixative and 2.3-2.7 parts of honey. The invention further discloses a preparation method of the edible goat milk fruit-vegetable paper. The preparation method comprises the following steps: adding the softened carrot in the goat milk, adequately mixing with the prepared haw juice, then pulping and homogenizing, then adding the stabilizer, a thickener and the colour fixative, mixing and blending, degassing, drying and forming. The abundant nutritive value of the goat milk is adequately utilized, the nutritive value of the carrot and the special health function of haw are achieved, and the goaty flavour of the goat milk is furthest removed; the edible goat milk fruit-vegetable paper is high in stability, convenient to carry and use, and wide in market prospect.

Owner:山东白羚乳业有限公司

Rose flower jelly and preparation method thereof

InactiveCN107692137AThe entrance is moderately sweet and sourHigh degree of moldingFood ingredient functionsVitamin CPetal

The invention provides a rose flower jelly, which is prepared from the following components in parts by weight: 100 to 400 parts of water, 10 to 70 parts of sweetening agent, 0.1 to 6 parts of rosebud, 0.5 to 6 parts of roseleaf, 0.001 to 0.1 part of vitamin C, 0.1 to 10 parts of citric acid, and 0.1 to 10 parts of thickening agent. The invention also provides a preparation method of the rose flower jelly. The rose flower jelly provided by the invention is bright in color, complete in shape, rich in taste, and good in stability, is ideal health-care and snack food, is suitable to be daily taken by consumers, and has a wide market prospect.

Owner:CHENGDU UNIV OF TRADITIONAL CHINESE MEDICINE

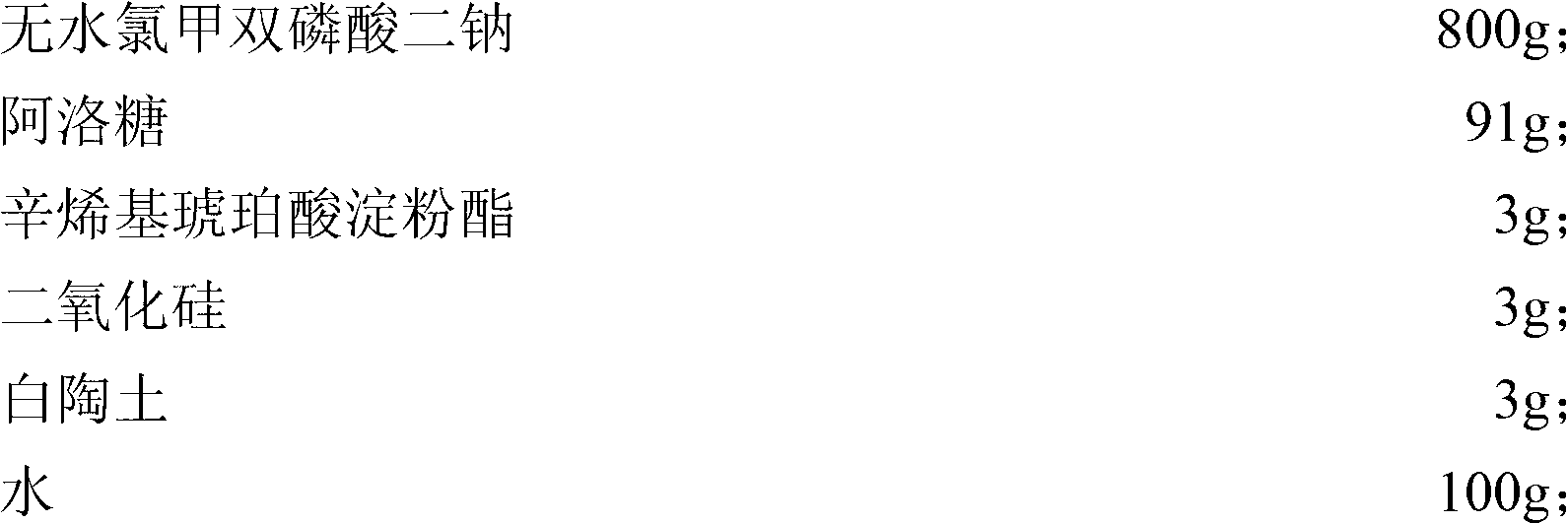

Allose tablet excipient, medicinal tablet and method for preparing medicinal tablet

InactiveCN102697744AImprove emulsion stabilityGood thickening effectOrganic active ingredientsInorganic non-active ingredientsSolubilityOctenyl succinate

The invention discloses an allose tablet excipient. The allose tablet excipient consists of the following components in percentage by weight: 88 to 96 percent of allose, 1 to 5 percent of starch octenyl succinate anhydride, 1 to 5 percent of silicon dioxide and 1 to 5 percent of kaolin, is high in fluidity, molding degree and demoulding performance, and can be directly compressed together with medicines and water to obtain medicinal tablets. The invention also discloses a medicinal tablet. The medicinal tablet consists of the following components in percentage by weight: 75 to 85 percent of medicinal active ingredient, 5 to 15 percent of allose tablet excipient and 5 to 15 percent of water raw material. The allose tablet excipient and the medicinal active ingredient do not have incompatibility and are reacted with each other; and the medicinal tablet is high in dissolvability and fluidity and is suitable for directly compressing various medicines. The invention also discloses a method for preparing the medicinal tablet. The method makes the medicinal tablets easily prepared and is easy to implement, operate and control.

Owner:安吉东来药用辅料有限责任公司

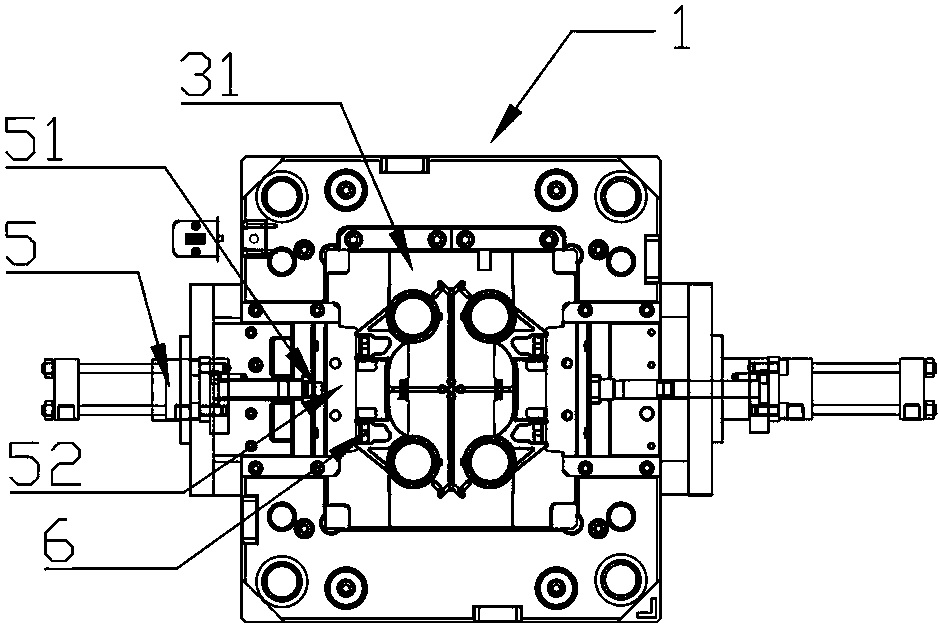

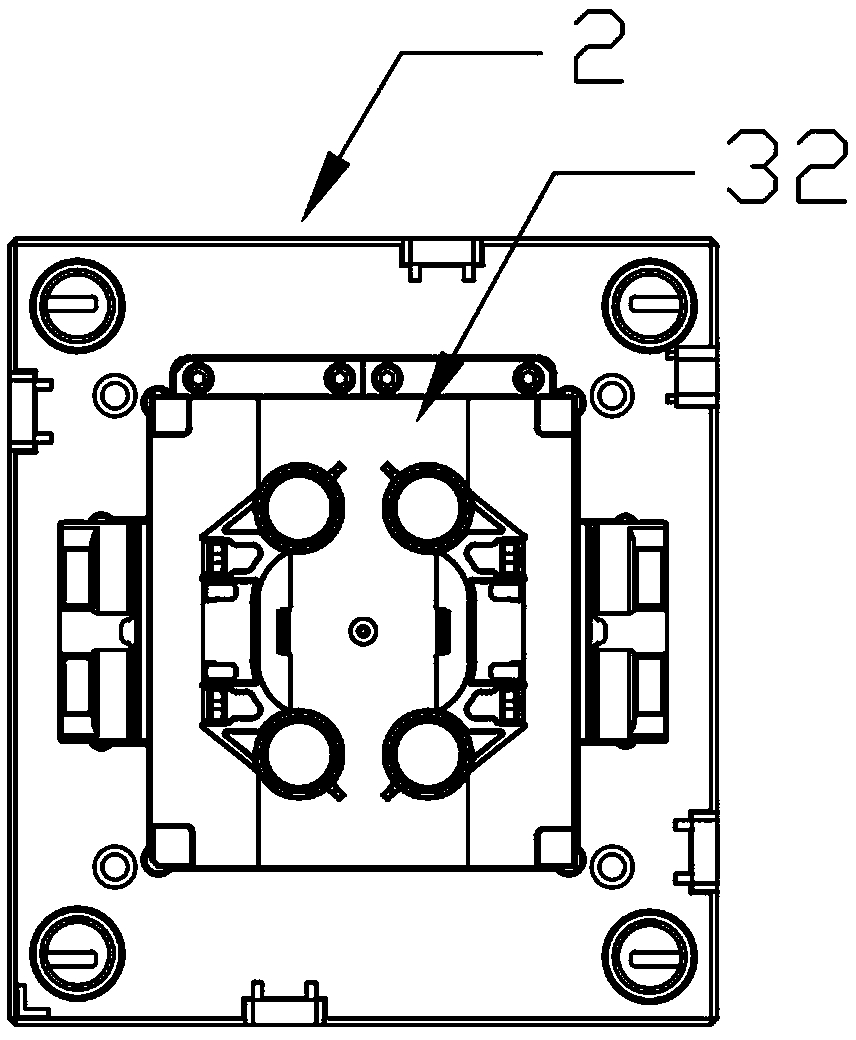

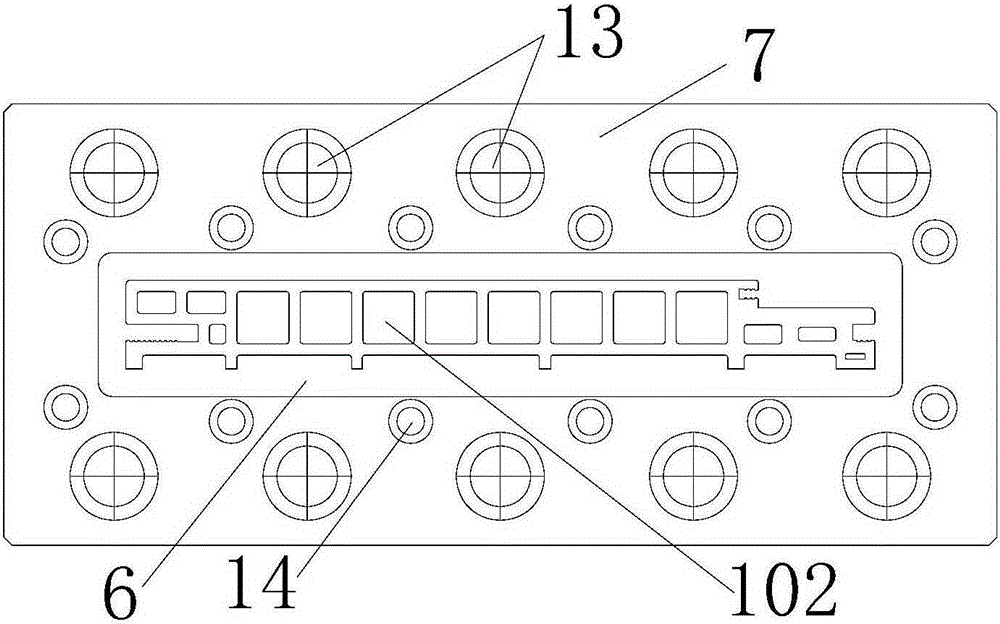

Sliding block injection molding mechanism

InactiveCN103481442AHigh degree of moldingImprove pass rateCoatingsEngineeringInjection molding machine

The invention discloses a sliding block injection molding mechanism. The sliding block injection molding mechanism comprises an injection molding main controller, a lower die base, an upper die base and a withdrawn die jacking mechanism, and the upper die base and the lower die base are jointed in the die closing process to form a die groove corresponding to more than one sliding block. Particularly, an insert module composed of a side pushing air cylinder, a pushing pin and an insert holder is arranged in the position, corresponding an embedding hole of the sliding blocks, of the lower die base; the side pushing air cylinder is fixedly connected to the outer wall of the lower die base; the pushing pin is integrated with the insert holder; the insert holder is separated from the die groove in an opening die state, is loaded with an insert, and is driven by the side pushing air cylinder to move towards the die groove in a closed die state and to ensure that the inset and the embedding hole are integrated. Due to the application of the injection molding mechanism, when the sliding blocks after injection molding are not cooled, the insert is embedded into the embedded hole of the sliding blocks automatically by the insert module, secondary fusing embedding or reassembling in the traditional technology can be omitted, and product forming degree and pass percent are improved. The sliding block injection molding mechanism is fast and convenient to use and low in cost and facilitates mass production.

Owner:SUZHOU INDAL PARK XIELI PLASTIC

High-forming-degree cigarette aluminum-free lining paper

InactiveCN106149474AHigh degree of moldingReduce air permeabilityFlexible coversWrappersSlurryMoisture

The invention provides an aluminum-free inner liner paper with high molding degree for cigarettes. The filler used in it includes bentonite, silicate, gypsum whisker, natural zeolite, diatomaceous earth and talcum powder, and the weight ratio is 2:3. :2:5:4:1, wherein the talcum powder is 270-350 mesh, the bentonite is 500-700 mesh, the silicate is 600-700 mesh, the gypsum whisker is fibrous, and the natural zeolite is 200-400 mesh , diatomite is 300‑500 mesh; the slurry it adopts is the slurry formed by coniferous wood, hardwood, and masson pine according to the ratio of 5:4:7, and its PAE consumption is 0.5%, and the above-mentioned filler is used. The calendering condition of the lining paper is dry and cold calendering, the moisture content of the lining paper is kept between 7-8% before calendering, and the moisture content of the paper after finishing is controlled between 5-6%. The high-formability aluminum-free inner liner paper for cigarettes provided by the present invention has high formability and low air permeability, which is beneficial to maintaining fragrance, moisture and moisture.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

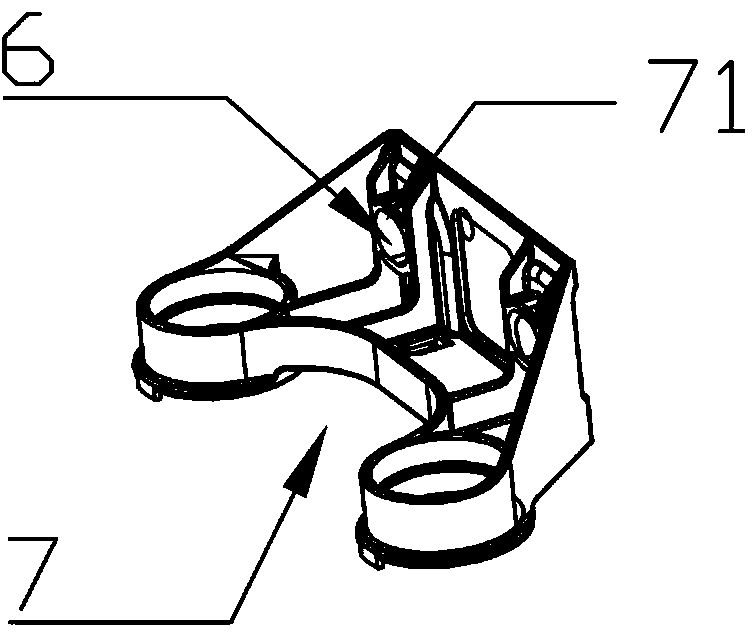

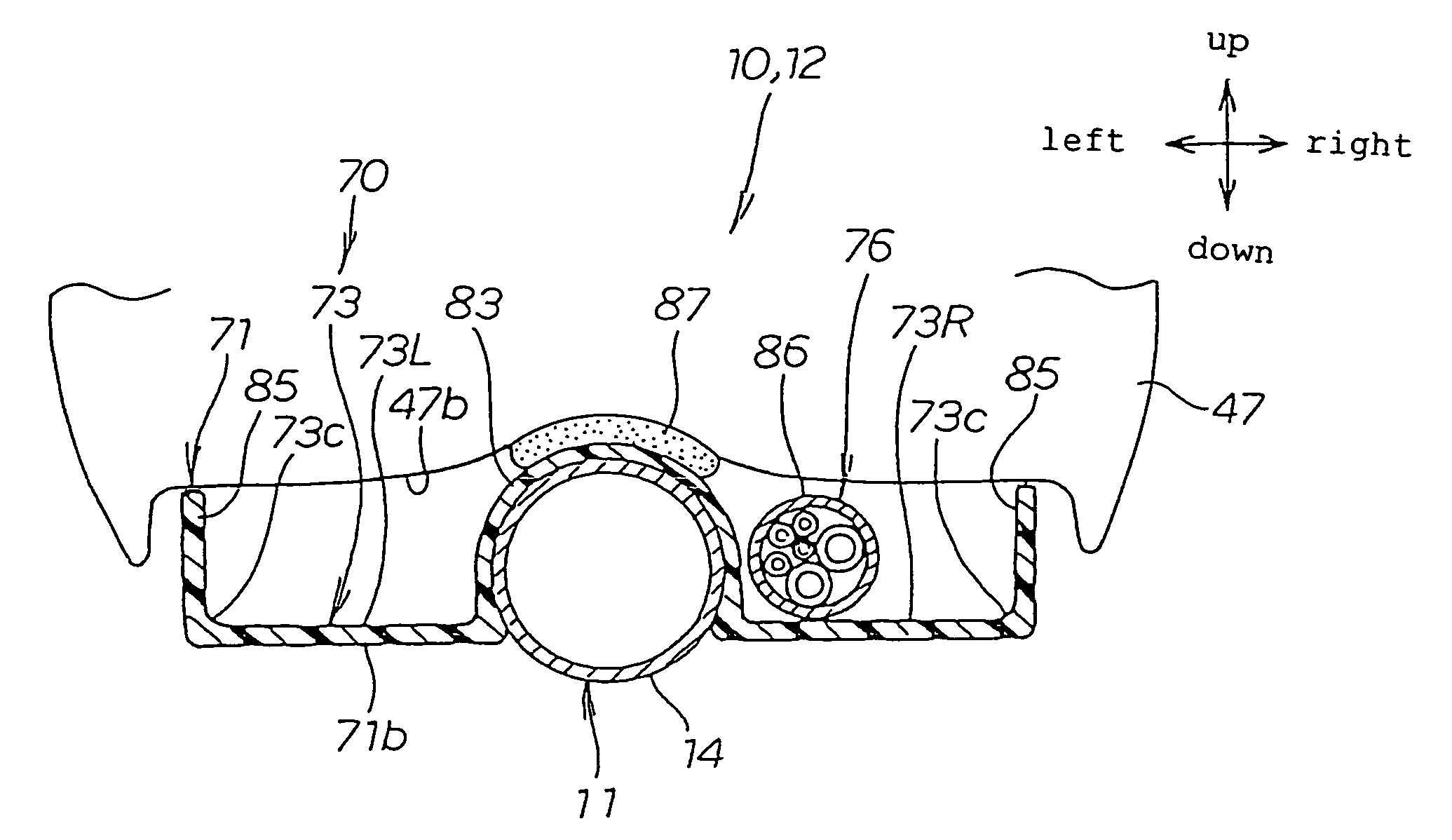

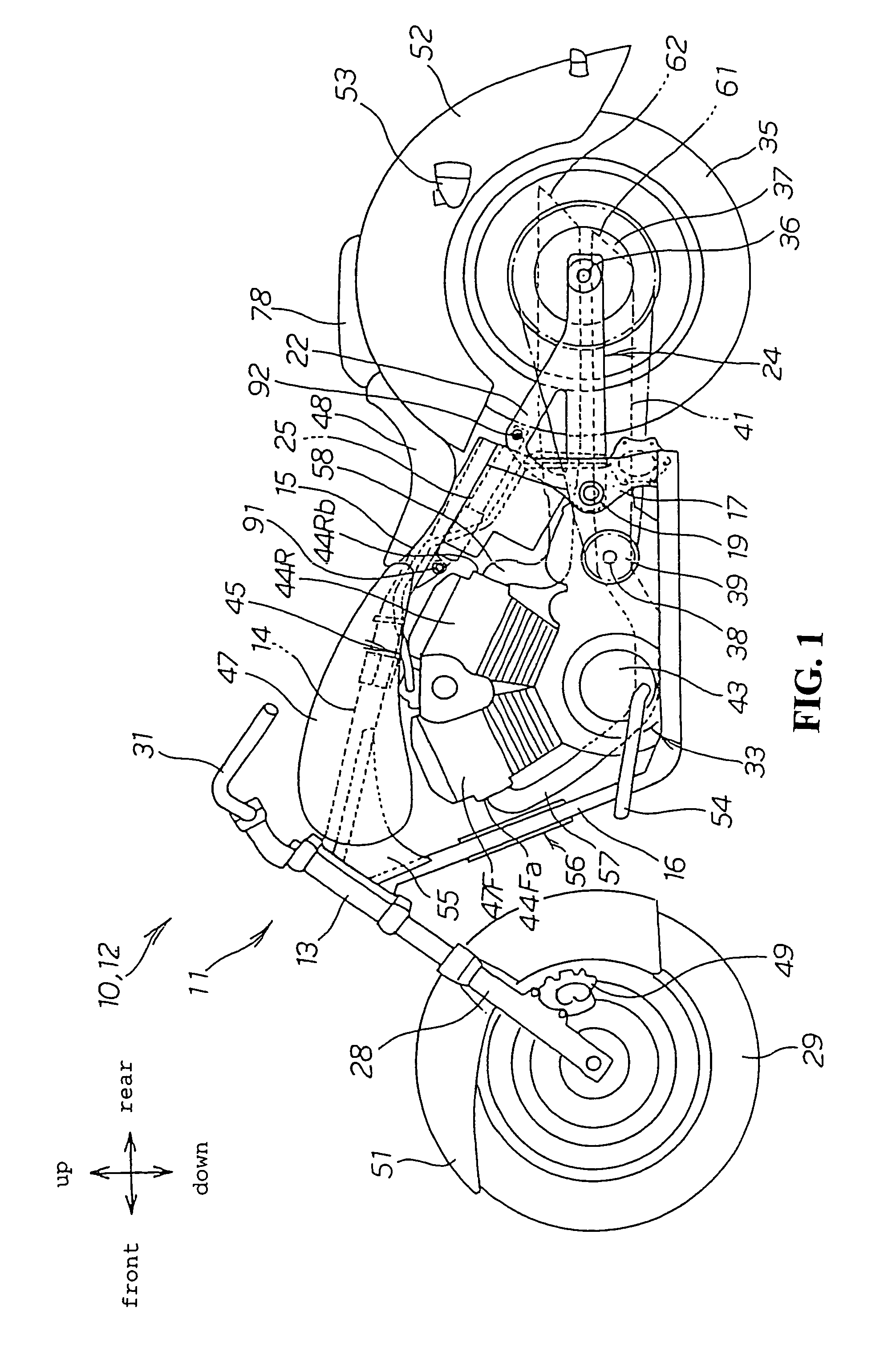

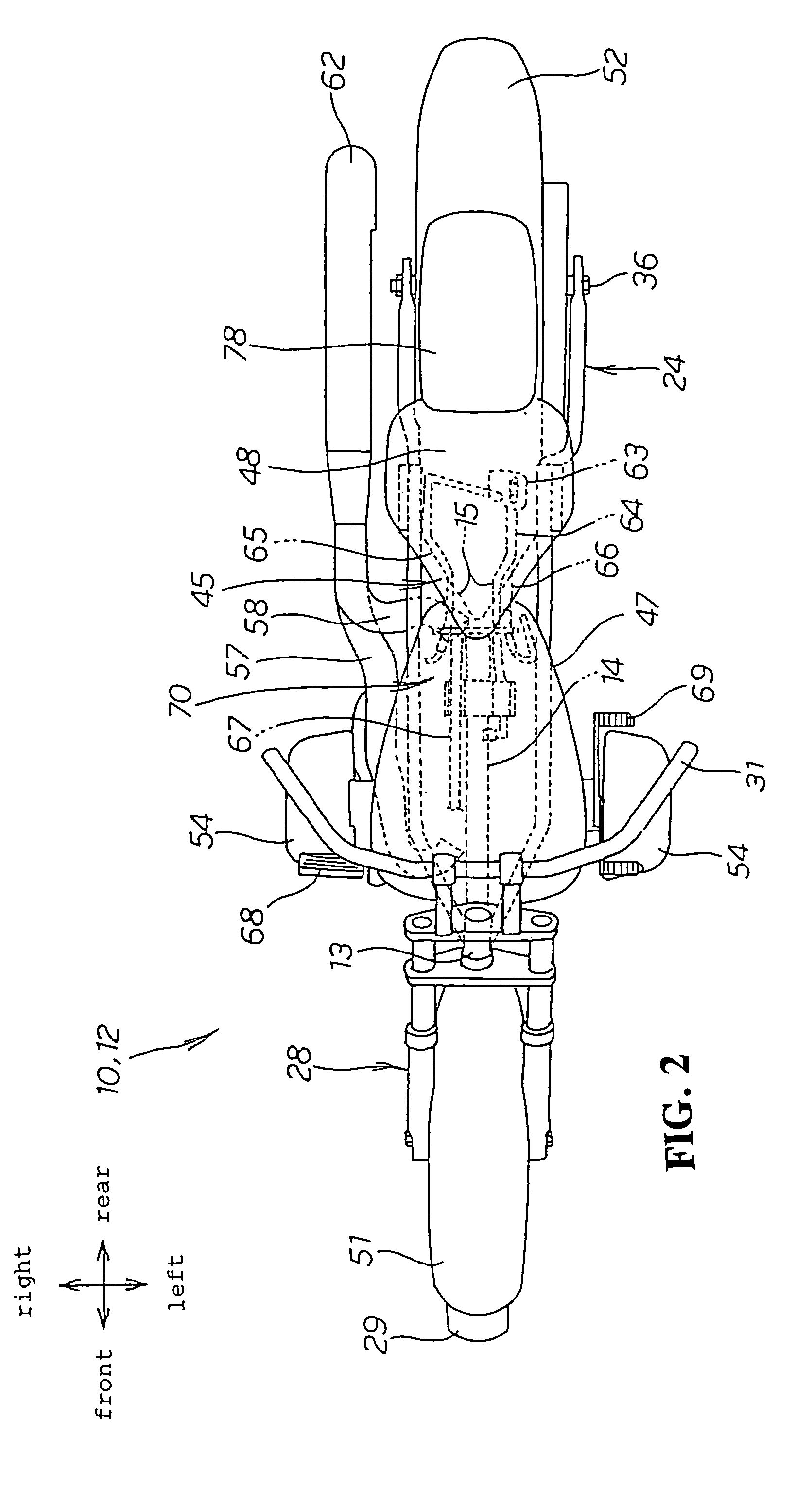

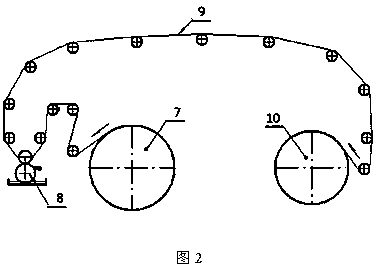

Wire/pipe support device of motorcycle

InactiveUS7686388B2Solve the lack of spaceHigh degree of moldingVehicle seatsOptical signalFuel tankEngineering

The present invention provides a wire / pipe support device of a motorcycle that can possess a sufficient space for accommodating a wire / pipe without increasing the degree of forming of a vehicle body frame. A wire / pipe support device includes a groove-shaped engaging portion that is engaged with a main frame that constitutes a vehicle body frame of a motorcycle and has a lower surface thereof opened. A groove-shaped accommodating portion receives the wire / pipe thereon and has an upper surface thereof opened. The engaging portion is mounted on the vehicle body frame by engaging the engaging portion with the vehicle body frame from above. The wire / pipe is placed on the accommodating portion. The wire / pipe support device is pushed from above by a fuel tank directly or by way of a cushion member thus preventing the floating of the wire / pipe support device from the vehicle body frame and the rotation of the wire / pipe support device about the vehicle body frame.

Owner:HONDA MOTOR CO LTD

Iron-cobalt-copper alloy powder and preparation method thereof

The invention discloses an iron-cobalt-copper alloy powder. The iron-cobalt-copper alloy powder is in a spongy form and is prepared from the following components in percentage by weight: 15+ / -1% of iron, 15+ / -1% of cobalt, and 70+ / -1% of copper; the Fisher particle size of the iron-cobalt-copper alloy powder is 2.0 to 3.0 [mu]m, the oxygen content is less than 0.50%, and apparent density is 1.5 to1.8 g / cm3. According to the iron-cobalt-copper alloy powder preparation method, the yield rate is greater than 92%, the yield rate of a conventional atomizing method is only 60 to 70%, and energy consumption can be greatly reduced; and raw materials namely, cobalt oxide, nanoscale iron powder, and ultrafine copper powder in the production process of the iron-cobalt-copper alloy powder simultaneously infiltrate mutually to form crystals in the high-temperature fusion fission and chemical component decomposition processes; and elements are widely distributed, the porosity is uniform, the compatibility with other metals is improved, and the forming degree and folding resistance of a product are effectively improved, the service life of the product is effectively prolonged, and the using performance of the product is significantly improved.

Owner:江苏萌达新材料科技有限公司

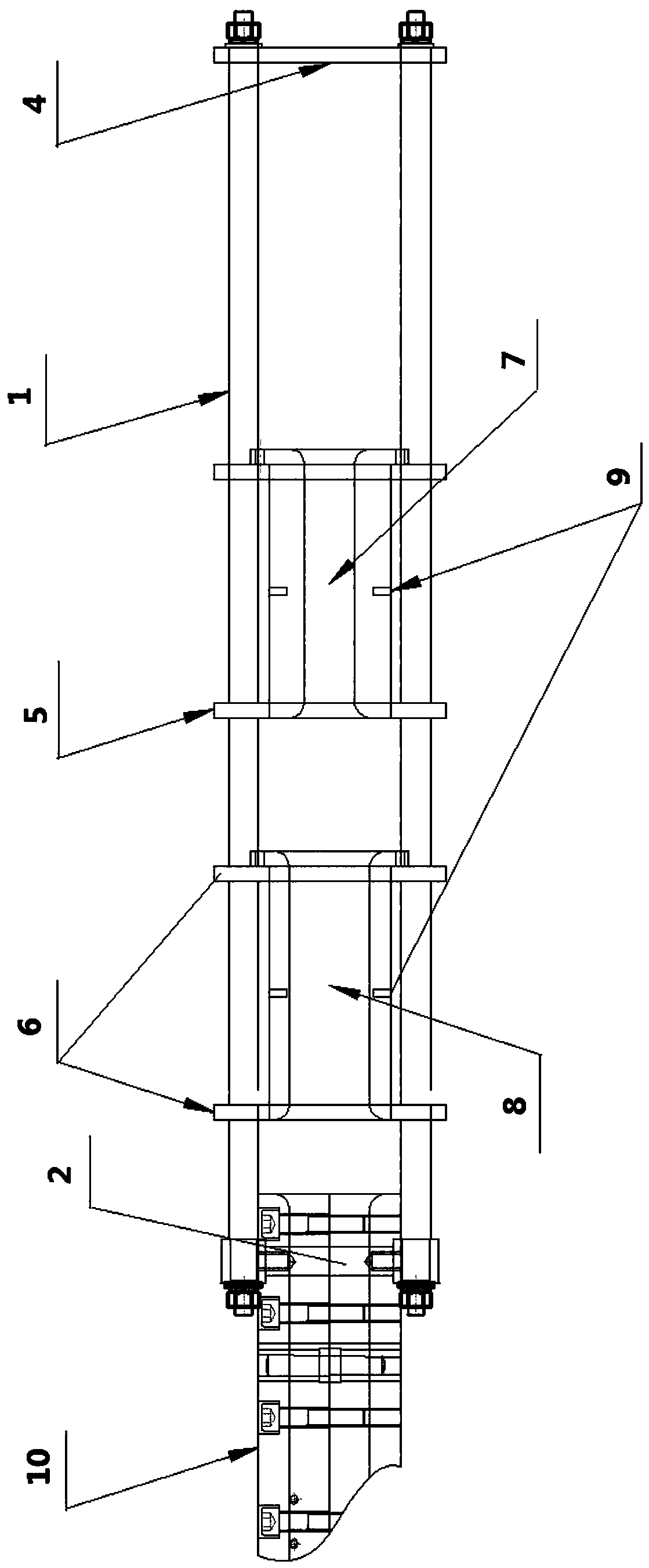

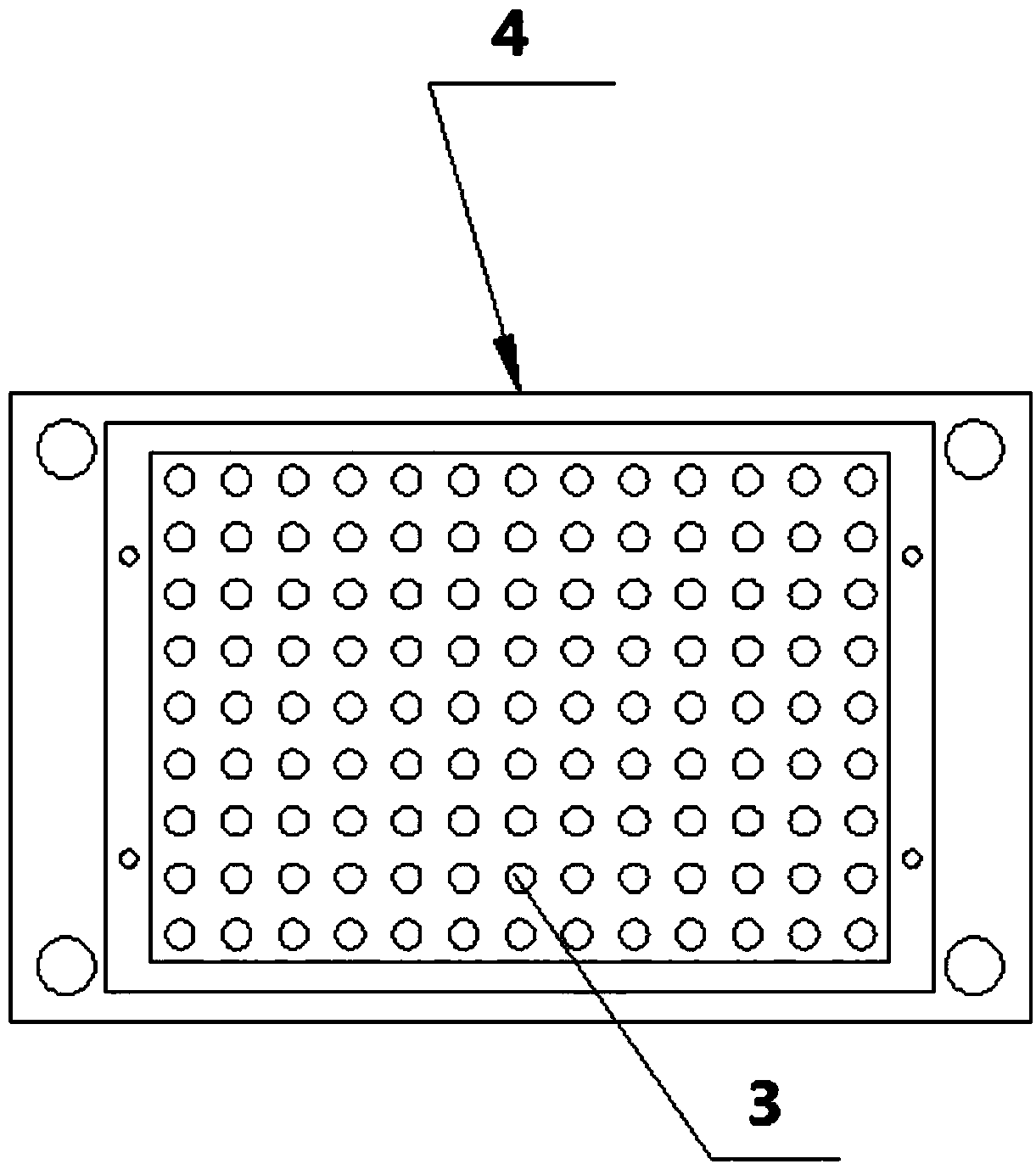

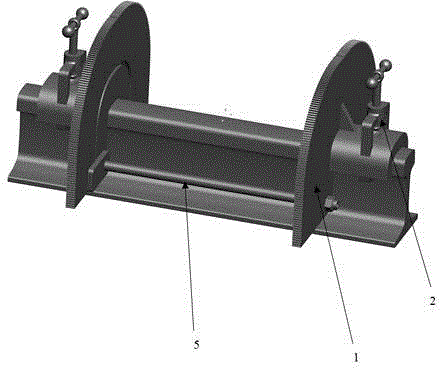

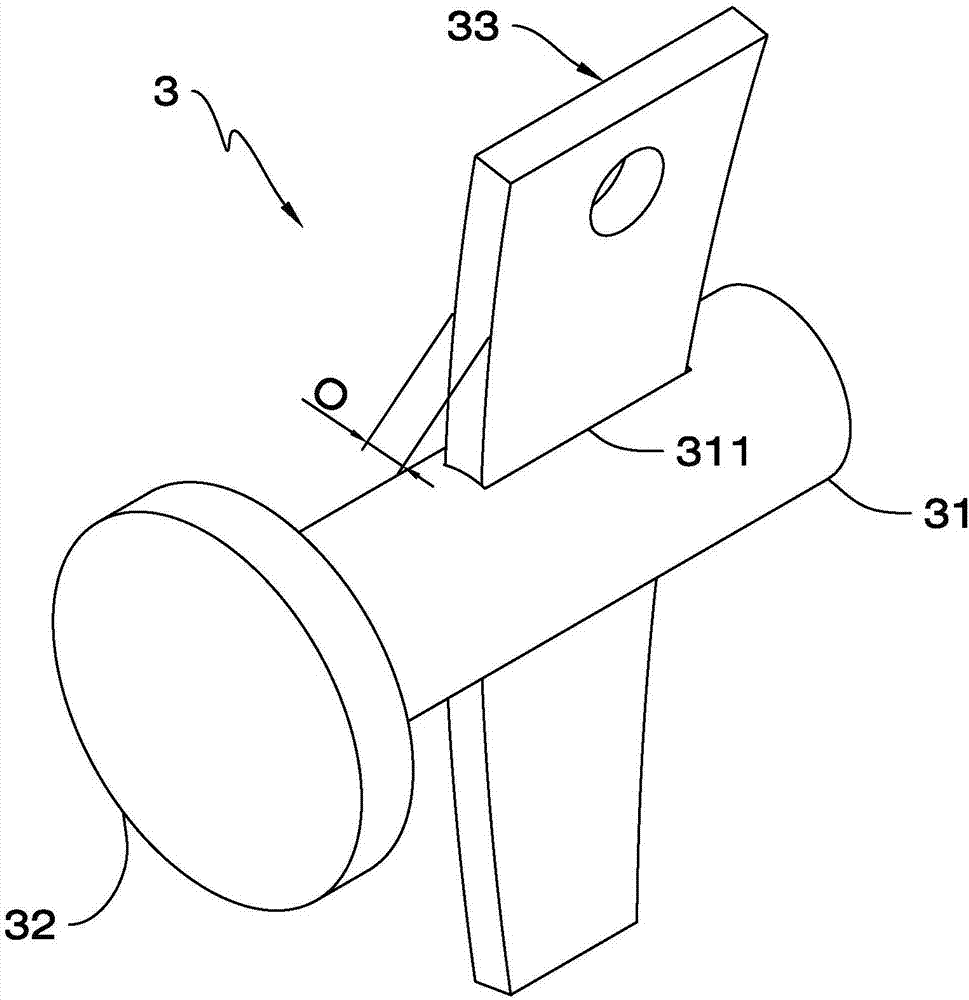

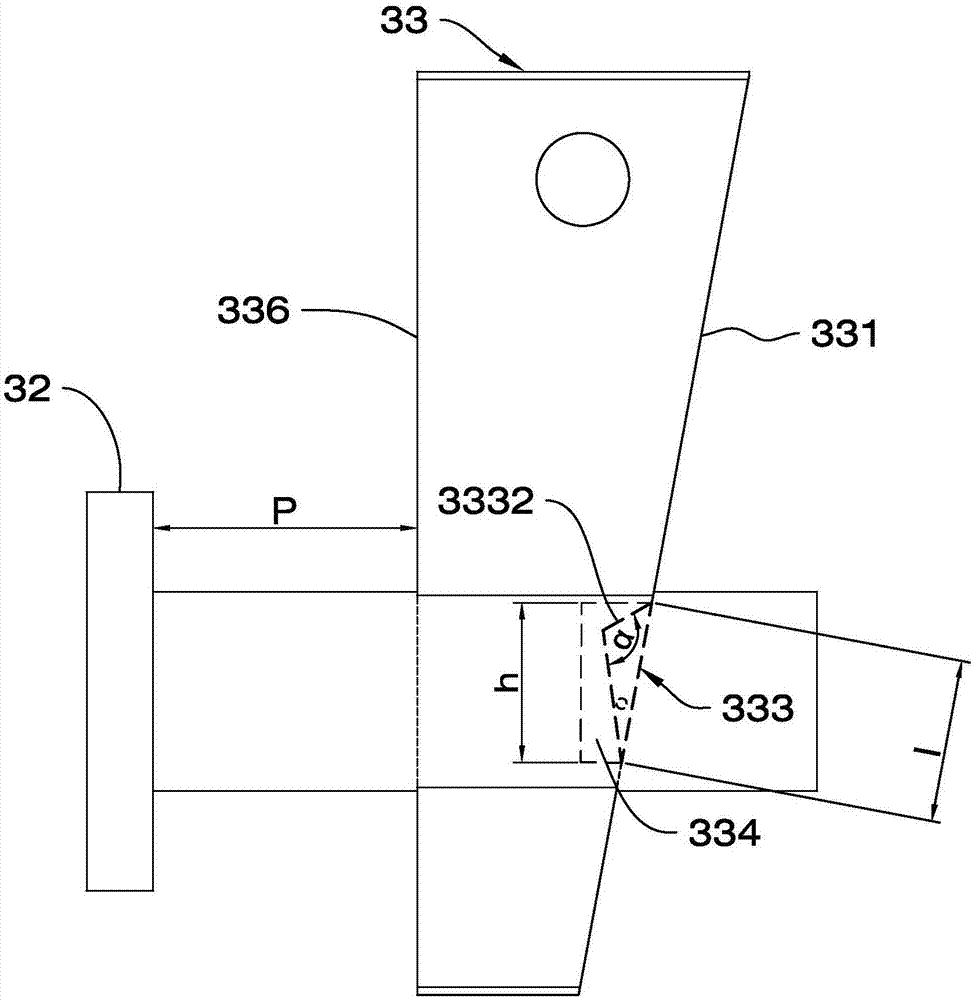

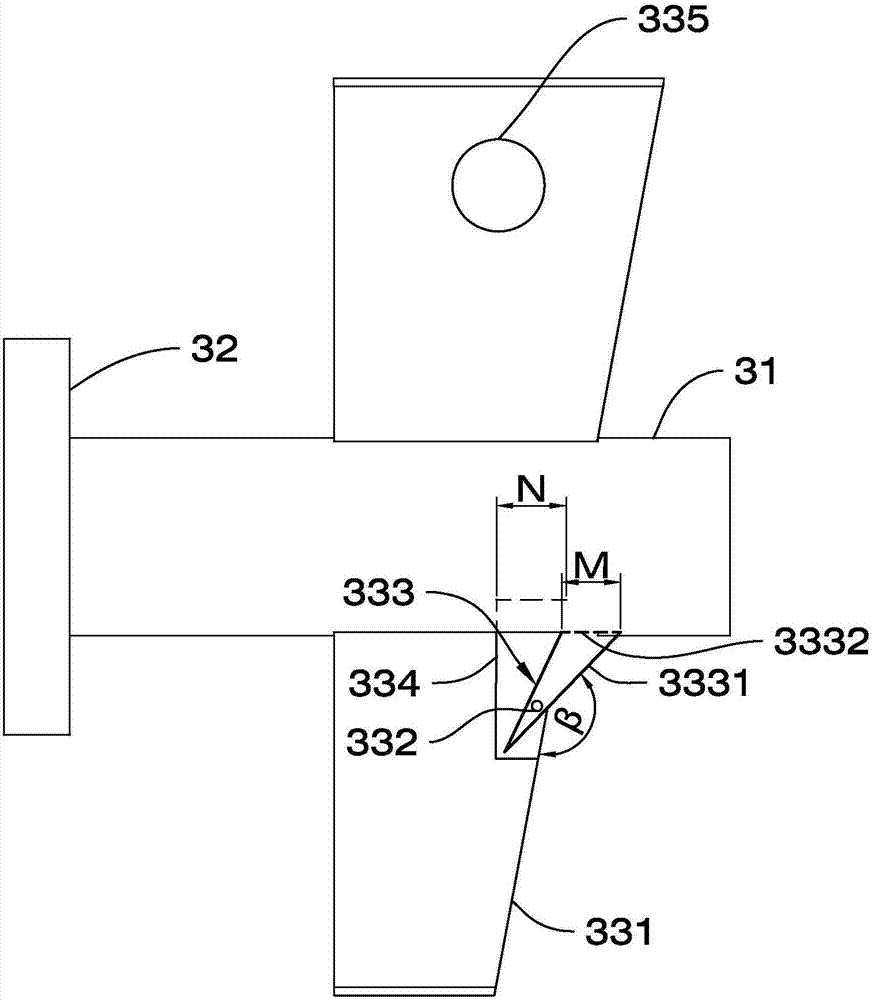

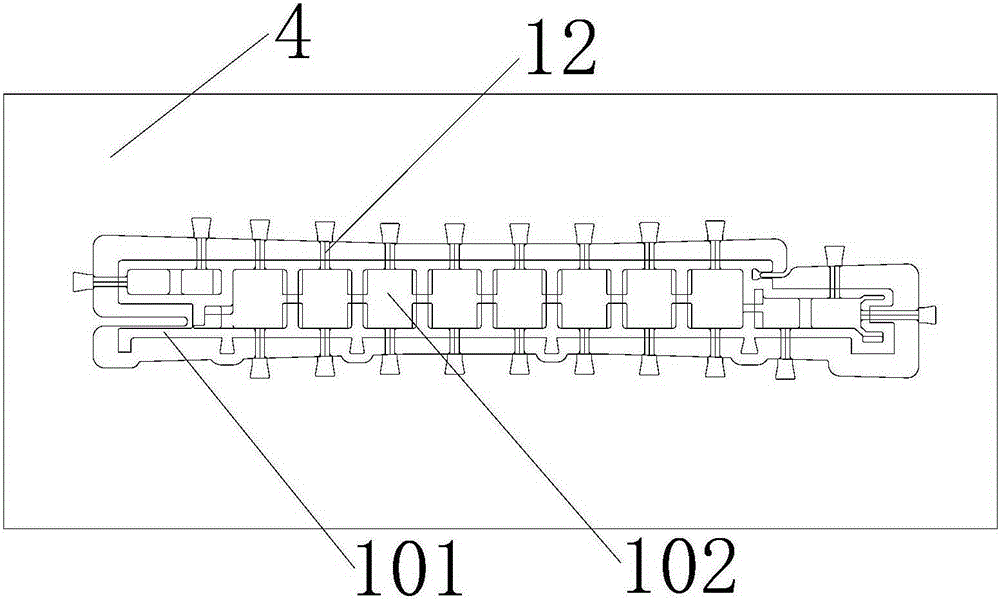

Glass fiber reinforced plastic pultrusion and grading heating pre-forming device and method

The invention relates to a glass fiber reinforced plastic pultrusion and grading heating pre-forming device. The device comprises a supporting frame composed of a plurality of supporting rods, a reaching-in plate, a yarn positioning plate and a pre-heating mold supporting plate are sequentially and fixedly mounted on the supporting frame in the direction of yarn entering, and a plurality of reaching-in holes are distributed on the reaching-in plate and the yarn positioning plate; a second-stage preheating mold is fixed to the pre-heating mold supporting plate, and a first-stage preheating moldis fixedly mounted on the yarn positioning plate; the glass fiber reinforced plastic pultrusion and grading heating pre-forming device is further provided with a fixing connecting piece which comprises a fixing plate and a supporting column for being connected with and supporting the fixing plate, and the supporting frame is fixedly connected to a forming mold through the fixing connecting piece.The invention further provides a grading heating pre-forming method. The glass fiber reinforced plastic pultrusion and grading heating pre-forming device adopts multistage preheating and yarn positioning, the pultrusion speed can be increased, internal and external curing degrees are consistent, the in-mold resistance is reduced, a fiber deviation mold is avoided, and the product shape forming degree is good.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

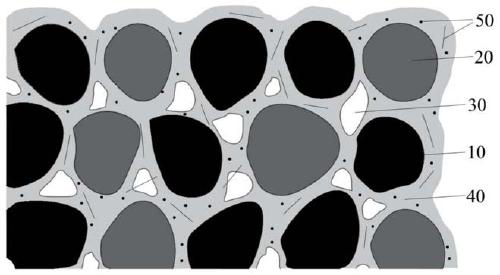

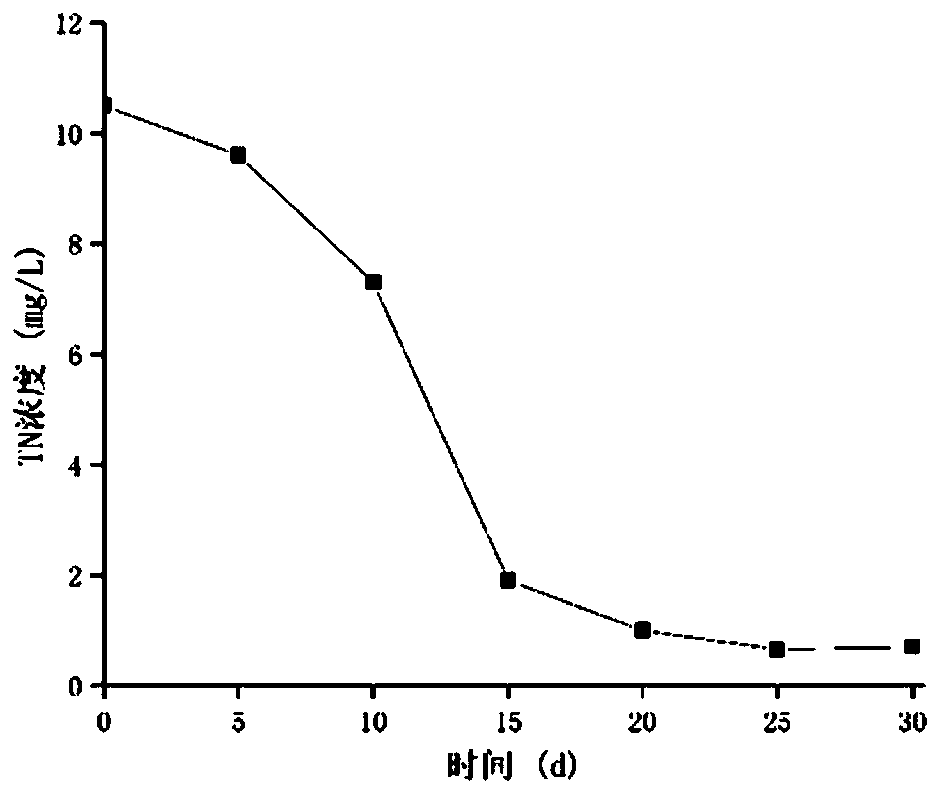

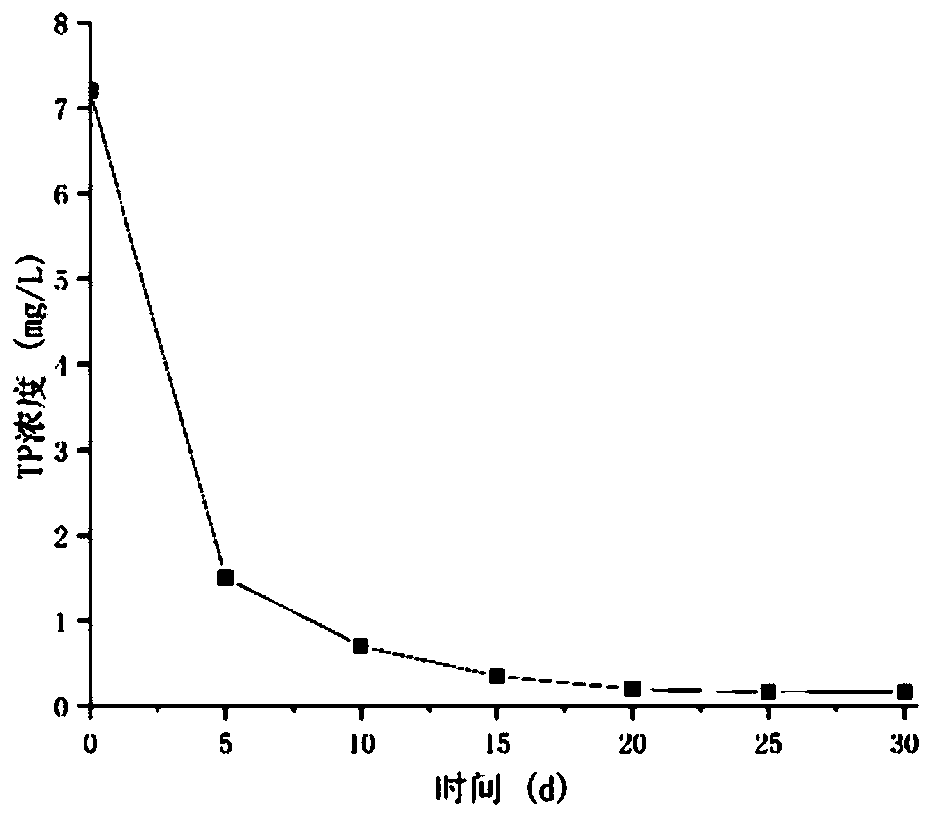

Nitrogen and phosphorus removal ecological permeable material and preparation method thereof

ActiveCN111039620AAvoid hardening and cloggingEfficient removalBreakwatersQuaysNitrogen removalEngineering

The invention discloses a nitrogen and phosphorus removal ecological permeable material and a preparation method thereof, and belongs to the fields of environmental functional materials and water purification. The ecological permeable material comprises a slow-release skeleton structure and permeable holes; the slow-release skeleton structure a skeleton is formed by pyrite particles of which the surfaces are coated with a mixture of a binding material and fiber reinforced ribs and aggregate particles of which the surfaces are coated with a mixture of the binding material and fiber reinforced ribs, the permeable holes are uniformly distributed in the slow-release skeleton structure, and the channels of the holes enable the water permeability coefficient of the ecological permeable materialto be not less than 10 mm / s. The nitrogen and phosphorus removal ecological permeable material has the characteristics of good water permeability, high molding degree, high specific surface area, highstrength, easiness in microbial biofilm formation and the like, can slowly release calcium ions and iron ions to remove phosphorus, realizes autotrophic nitrogen removal, and has a good purificationeffect on pollutants in water, especially total nitrogen and total phosphorus.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

Motor vehicle component made of triple-layer laminated steel

InactiveUS20180222536A1High degree of moldingImprove behaviorUnderstructuresFurnace typesCentral layerAlloy

A motor vehicle component is disclosed. The component is manufactured by hot forming die quenching a sheet metal blank made of a hardenable steel alloy, and the motor vehicle component is made of a triple-layer laminated steel and including a central layer of hardenable steel ally, and the outer layers of a stainless steel alloy.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Casting method of stack sand splicing mold

The invention discloses a casting method of a stack sand splicing mold and belongs to the field of casting. The method comprises: (1) designing castings required to be manufactured, and producing a plurality of intermediate models which are split horizontally; (2) placing the intermediate models into a stack box and pouring sand moldings, opening pouring ports and exhaust ports on the sand molds after drawing, standing for curing, and brushing a layer of charcoal on the surfaces of the sand molds; and (3) stacking the sand molds according to the casting design, aligning the pouring port with the exhaust port, and pouring to prepare the castings. According to the method provided by the invention, because the intermediate molds and stacking sand molds are adopted, the master of accuracy of the castings with complex surfaces is good, and the molding effect of the castings is improved; the surfaces of the castings are more smooth and have high molding degree; and the method can be used for producing large and medium-sized castings, and large processing equipment is not required.

Owner:南京六合金盛机械配件厂

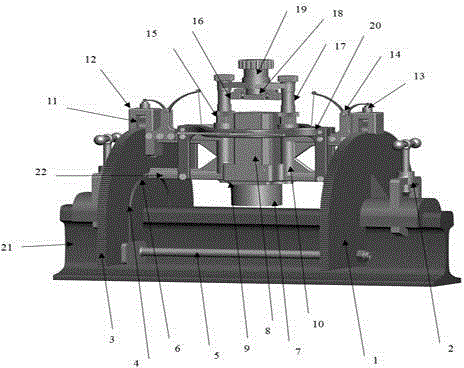

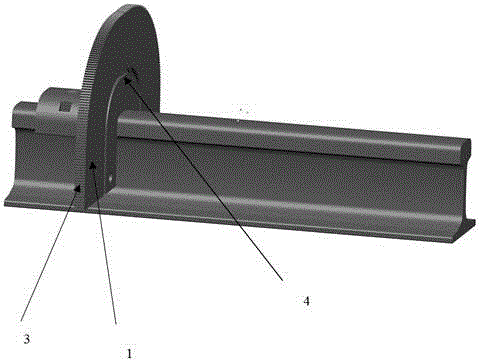

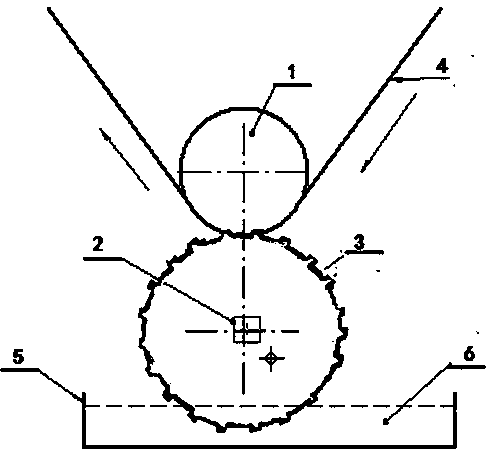

Portable curve-controlled high-precision steel rail profile modeling grinding machine

ActiveCN104929002APrecision grindingPrecise grinding precisionRailway track constructionRail profileElectric machinery

The invention discloses a high-precision profile modeling grinding technology. According to the high-precision profile modeling grinding technology, a steel rail section curve is used for carrying out synchronous amplification to form a running track of a control motor and a running track of a grinding wheel, a steel rail face is compared with a weld joint, and therefore the grinding precision of the grinding wheel is precisely controlled, and a steel rail body is not damaged. Especially, two synchronous running tracks, namely, a grinding wheel moving control guide groove and a motor motion fixed tooth channel, are arranged on a saddle-shaped fixed backer, and the grinding wheel of a grinding machine is controlled to carry out grinding only along the tracks. A motor fixed round guide rod penetrates through a motor moving round guide groove to control the motor to vertically move, and the grinding wheel is made to precisely grind the arc face of a steel rail with a fixed distance always. The grinding technology is high in precision, the profile modeling effect is vivid, and the grinding machine can be dismounted to move, and is light and convenient to carry. The phenomena that the grinding precision of other steel rail grinding machines is insufficient, and produced rail faces protrude and are concave are avoided. The problem that the other grinding machines are large in size, heavy and hard to control is solved, and the grinding machine is ideal high-simulation steel rail grinding equipment.

Owner:刘剑

Production and processing method of organic fertilizer by using livestock and poultry manure

InactiveCN107641051ANo pollution in the processHigh granularityBio-organic fraction processingOrganic fertiliser preparationPoultry manureOrganic fertilizer

The invention discloses a production and processing method of an organic fertilizer by using livestock and poultry manure. The production and processing method has the advantages that the investment cost is low, the structure is simple, the operation is convenient, the production process is continuous and moderate, the production of pollution wastes is avoided, the utilization degree is high, andthe like; the suitability of raw materials is wide, the requirements are low, the matching degree between systems is high, and the link is nature. The prepared fertilizer has the advantages that the forming degree of particle is high, the daily output is high, the efficiency is high, and the clean and environment-friendly effects are realized; after the fertilizer is applied to agricultural products, the high-yield, high-quality and safety effects are realized, the soil can be optimized, the dependency on chemical fertilizer is decreased, and the higher social and economic value is realized.

Owner:安庆市华劲农化有限责任公司

Clamping pin, manufacturing method thereof, aluminum alloy template system using clamping pin and construction method

PendingCN107217846AQuick disassemblyEasy to useAuxillary members of forms/shuttering/falseworksForming/stuttering elementsMaterials scienceAluminium alloy

The invention relates to a clamping pin, a manufacturing method thereof, an aluminum alloy template system using the clamping pin and a construction method, and aims to provide a clamping pin, a manufacturing method thereof, an aluminum alloy template system by the clamping pin and a matched construction method, wherein the clamping pin is simple in structure, convenient to disassemble and assemble and good in fixing effect, and the aluminum alloy template system has high supporting stability. A limit hole is formed in a conical pin body, and a right-angled trapezoid limit piece can enter and exit the limit hole. When the clamping pin is manufactured, the conical pin body and a circular head are firstly formed, the limit hole and the limit piece are formed, the limit piece can enter and exit the limit hole, concrete is poured between an inner template and an outer template of the aluminum alloy template system, and the edges of the inner template and the outer template are connected through the clamping pin and a pull piece. When construction is performed, the inner template and the outer template are firstly arranged, the pull piece is connected with the inner template and the outer template through the clamping pin, the concrete is poured, the clamping pin, the inner template and the outer template are disassembled after the concrete solidifies, and the pull piece positioned outside the concrete is broke off. The clamping pin is simple in structure, convenient to disassemble and assemble and good in fixing effect, the aluminum alloy template system using the clamping pin is high in supporting stability, and the construction method is matched with the system.

Owner:SHANDONG XINHUOXIN MATERIAL TECH CO LTD

Straw briquetting formula and method for preparing same

The invention relates to a straw briquetting formula and a method for preparing the same. The method comprises the following steps: 1) crushing 70 to 90 parts by weight of tobacco straw and 5 to 15 parts by weight of bark, so that the lengths of the tobacco straw and bark are less than 40 mm; 2) mixing the crushed tobacco straw and bark with 5 to 15 parts by weight of clay, putting into a blender, pouring 5 to 12 parts by weight of water into the blender, mixing and stirring until a semi-solidification state is formed; 3) allowing a mixture obtained in step 2) to enter a straw briquetting machine through a feed port to be briquetted, and regulating the pressure to be more than 480 MPa, wherein the straw briquette density is 1.18 g / cm<3>, and the straw briquette curing molding degree is 99%; drying the straw briquette until the straw briquette moisture content is 15 to 20% to obtain a straw briquette. The straw briquetting formula and the method for preparing the same provided by the invention have the characteristics of convenience in transport and storage, high molding degree, small size, good combustibility, avoidance of wasting of resources, reduction in production cost, broad market prospects and the like.

Owner:SHANDONG WEIFANG TOBACCO CO LTD

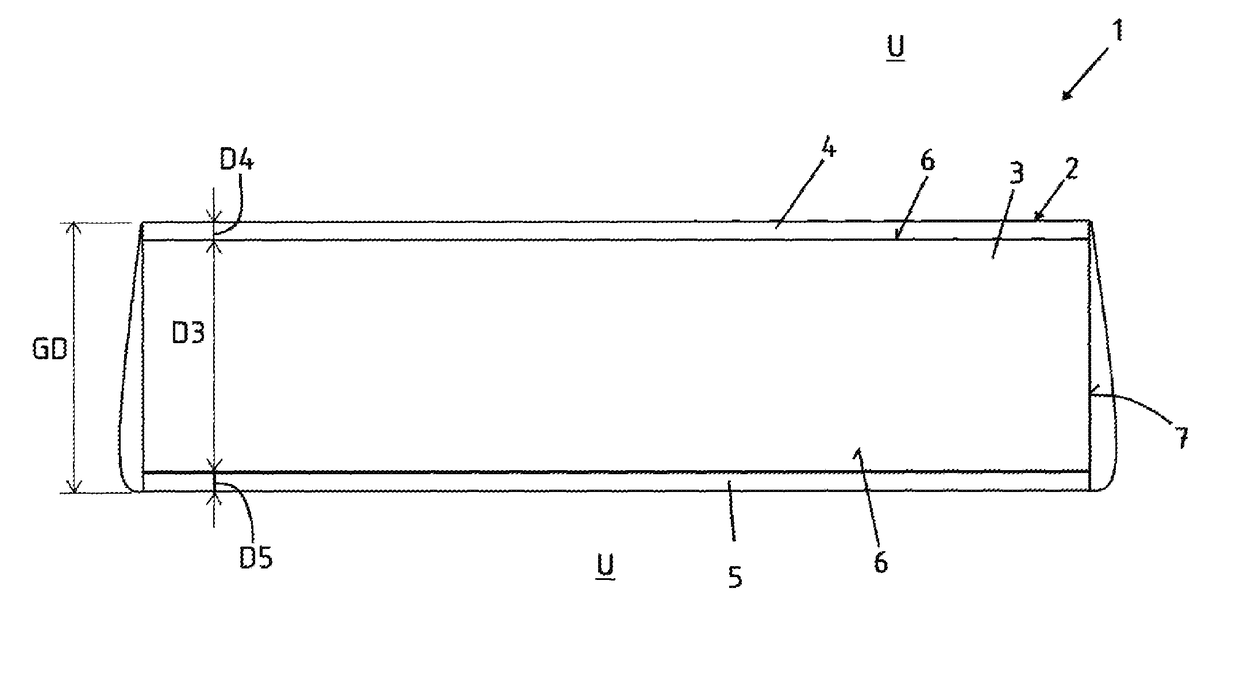

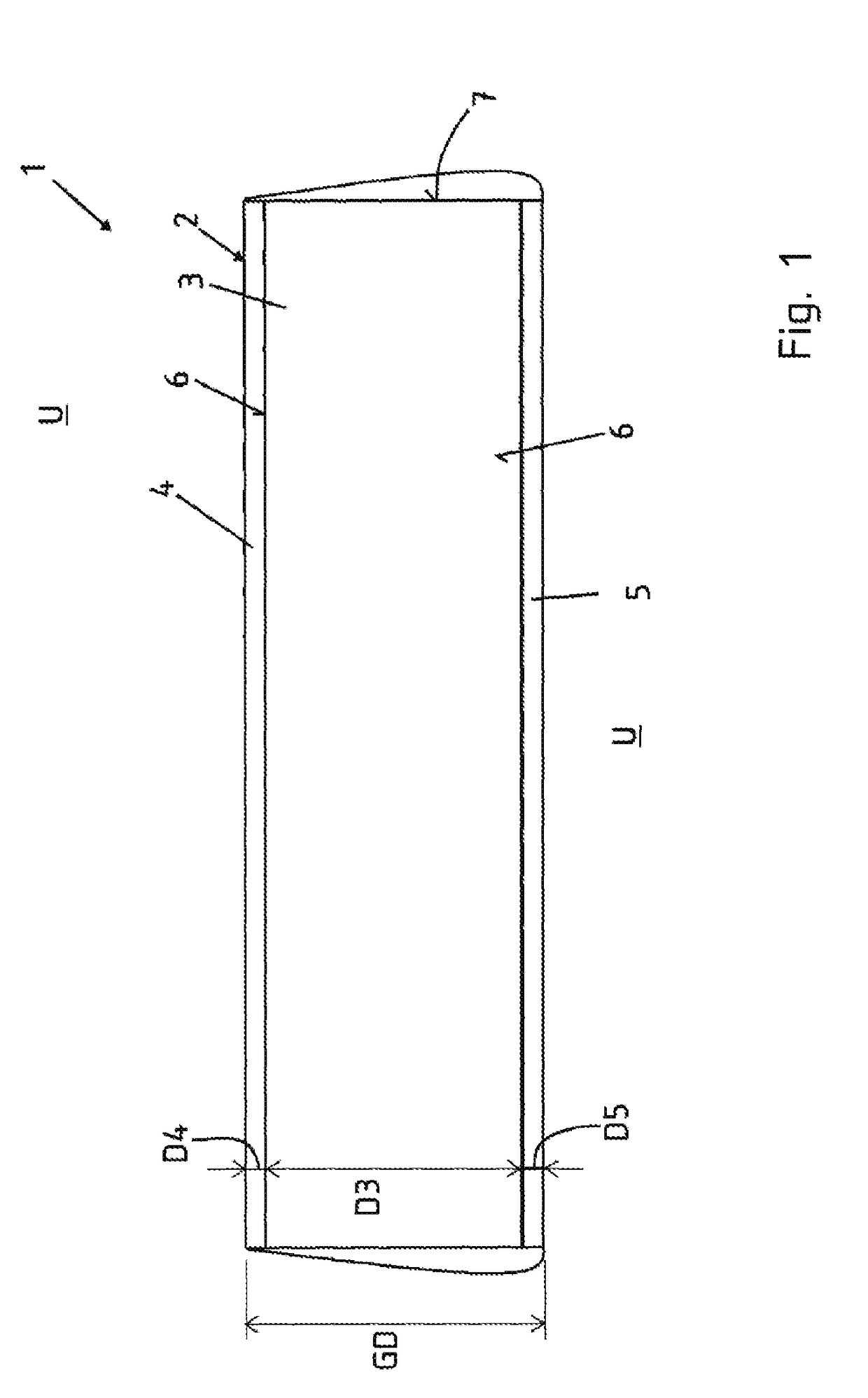

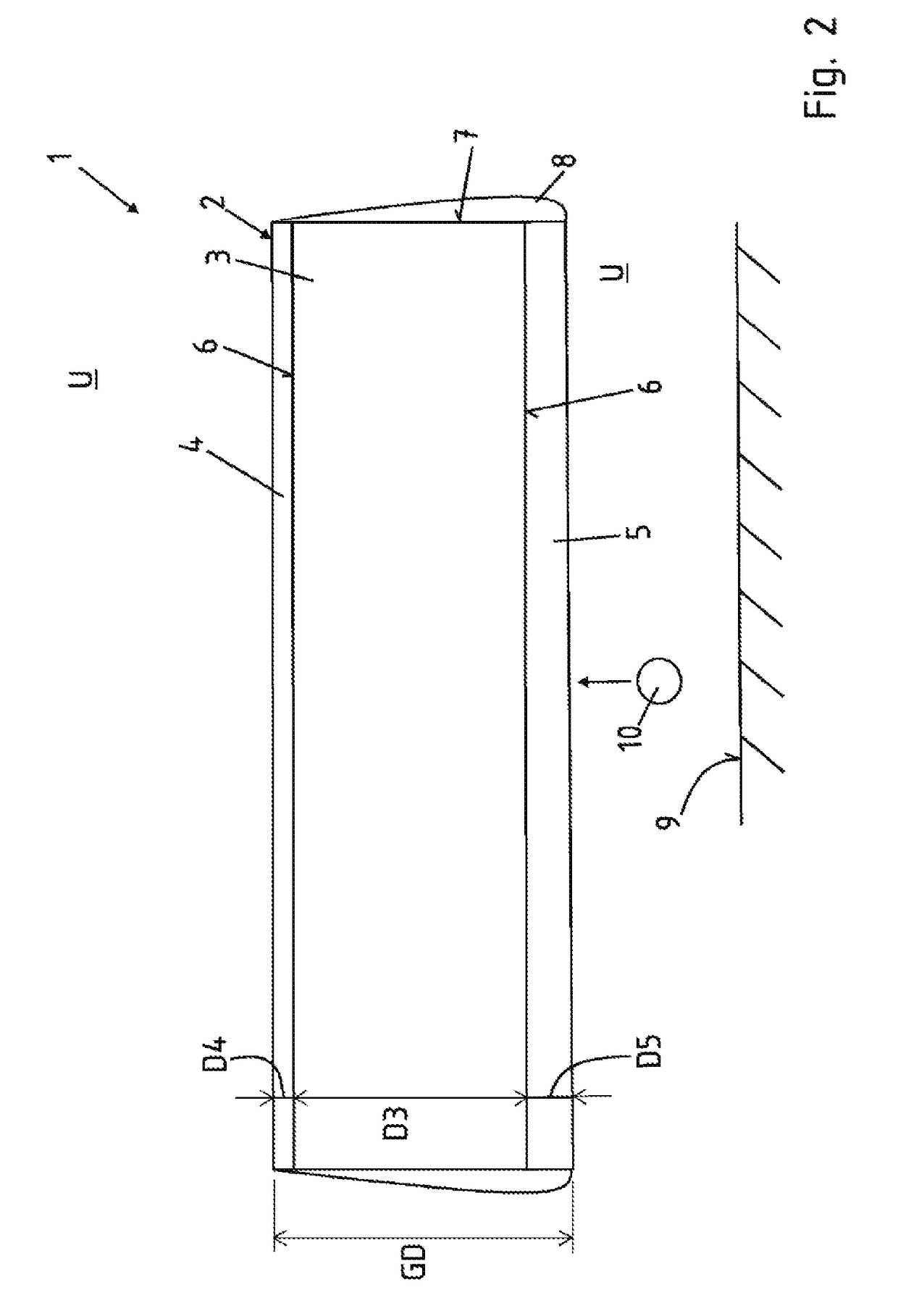

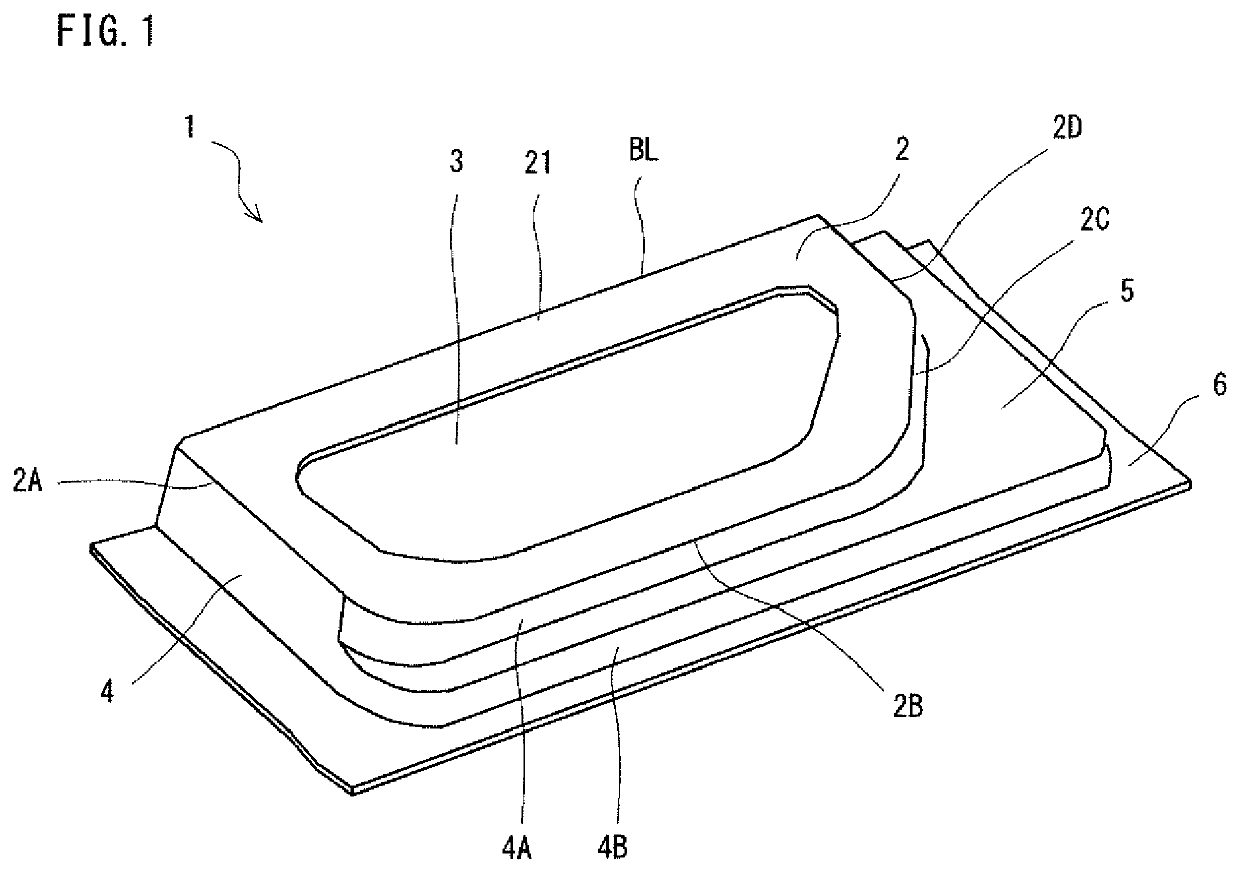

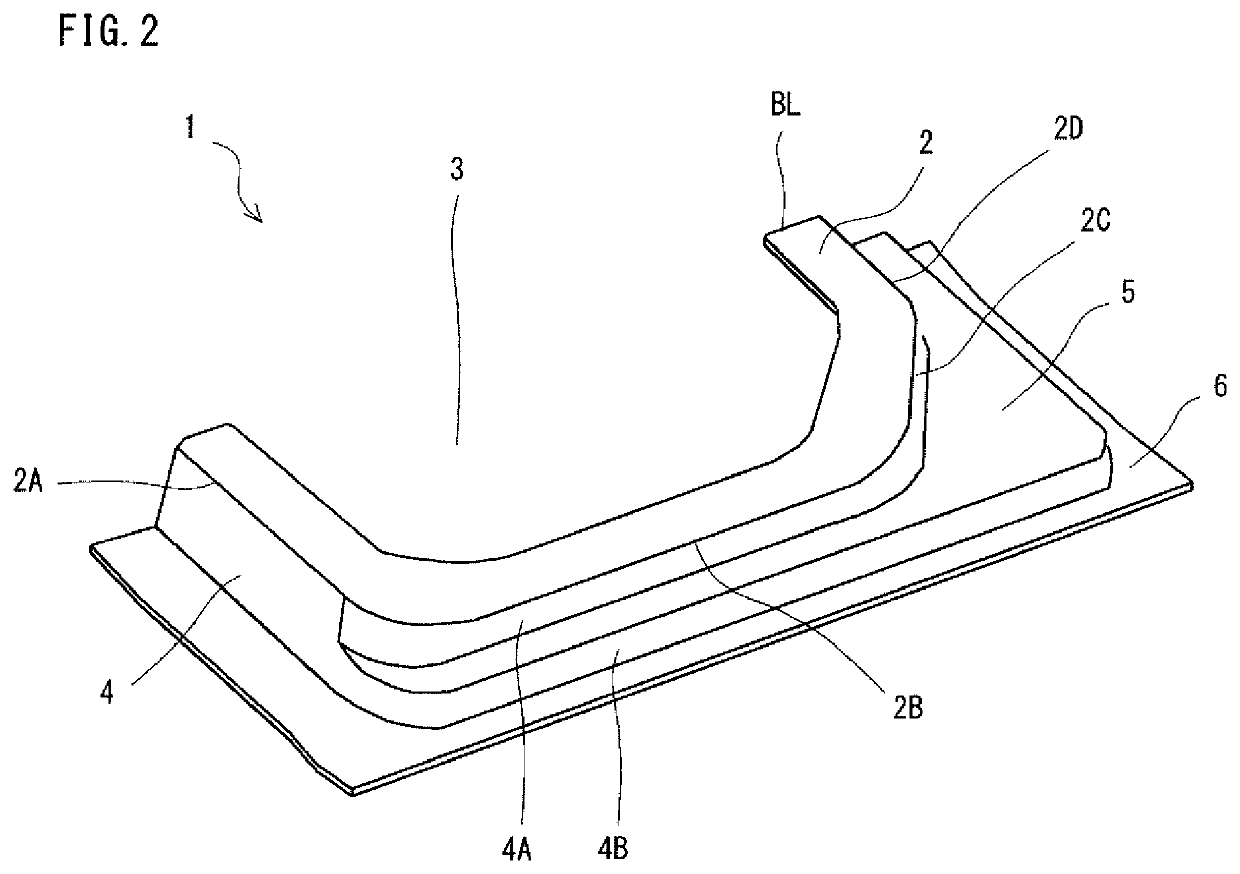

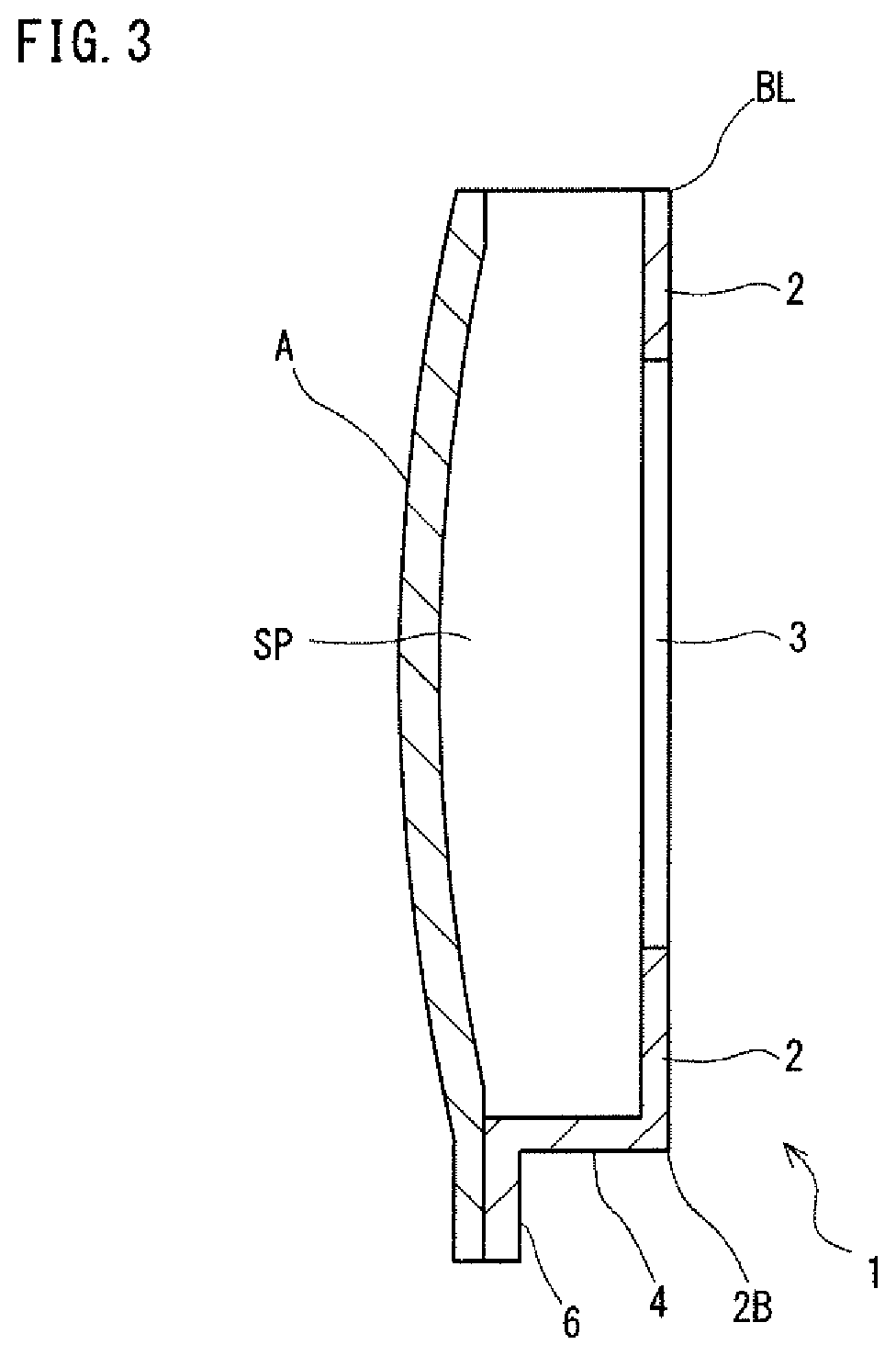

Panel-shaped formed product and method for producing panel-shaped formed product

A panel-shaped formed product made of a metal sheet includes a top panel portion, an opening portion, and a vertical wall portion. The top panel portion is polygonal. The opening portion is provided in the top panel portion. The vertical wall portion extends from at least not less than two adjacent borders among the borders of the top panel portion. At least one pair of each vertical wall portion of pairs of adjacent vertical wall portions of the vertical wall portions has a stepped portion. As a result, the panel shaped formed product has fewer defects such as cracks and wrinkles even when it has a shape that is difficult to form.

Owner:NIPPON STEEL CORP

Modified thermosetting ultrahigh-molecular epoxy resin marine board

The invention relates to a modified thermosetting ultrahigh-molecular epoxy resin marine board which is good in corrosion resistance and weather resistance and high in strength, wherein the performance of the marine board can conform to that of low-carbon steel (such as strength requirement on a steel workpiece Q235 specified by GB / T700-1988Q235). The modified thermosetting ultrahigh-molecular epoxy resin marine board comprises the following components by weight percent: 12-18% of modified thermosetting epoxy resin, 4-6% of hyperbranched solidifying cross-linking agent, 60-86% of fibrous reinforcing materials and 5.5-8.5% of powdered reinforcing material additive. The modified thermosetting ultrahigh-molecular epoxy resin marine board has the advantages that a molecular structure not only contains a large quantity of flexible chain sections to buffer brittleness and hardness of epoxy resin, but also contains an end-capped epoxy group which can participate in curing reaction, and the toughening effect is obvious, so that not only is the bonding strength of a system improved, but also the compression strength and the shearing strength of the materials are improved greatly.

Owner:严小异

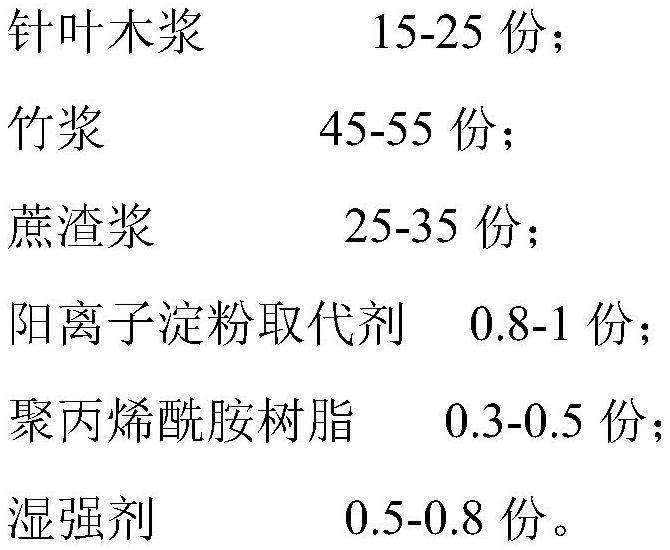

High-strength waterproof semitransparent food paper bag body paper and preparation method thereof

InactiveCN113005806AHigh bursting strengthImproves retention and dehydration speedReinforcing agents additionPaper/cardboardBagasse pulpPolyacrylamide

The invention relates to the technical field of paper leaf manufacturing, and particularly discloses high-strength waterproof semitransparent food paper bag body paper and a preparation method thereof. The preparation method comprises the following preparation steps: S1, weighing absolutely dry pulp of the softwood pulp, adjusting the pulping concentration of the softwood pulp to 3-3.5%, and adding pulping enzyme for pulping; s2, beating bamboo pulp; s3, pulping bagasse pulp; s4, preparing the high-strength waterproof semitransparent food paper bag body paper, wherein s41, uniformly mixing softwood pulp, bamboo pulp and bagasse pulp, and adding a cationic starch substitution agent; s42, adding polyacrylamide resin, stirring for 10-15 minutes, and adding a wet strength agent to obtain a mixture; and S43, after the concentration of the mixture is adjusted to be 2.5-2.8%, subjecting the mixture to screening purification, net forming, squeezing and drying in sequence, and obtaining the high-strength waterproof semitransparent food paper bag body paper . When the bursting strength and the transparency meet the requirements, the molding degree can also meet the requirements.

Owner:福建星城纸业有限公司

Isomaltose hypgather tablet excipient, medicine tablet and preparation method

InactiveCN102671200AImprove emulsion stabilityGood thickening effectPill deliveryPharmaceutical non-active ingredientsIsomaltooligosaccharideMedicine

The invention discloses isomaltose hypgather tablet excipient, which consists of 88 percent to 96 percent of isomaltose hypgather, 1 percent to 5 percent of starch octenyl succinate anhydride, 1 percent to 5 percent of silicon dioxide and 1 percent to 5 percent of porcellanite in percentage by weight, and has the advantages that the mobility is good, the forming degree is good, the demolding performance is good, and isomaltose hypgather tablet excipient can be directly tableted with medicine and water for preparing medicine tablets. The invention also discloses a medicine tablet, which consists of 75 percent to 85 percent of medicine active ingredients, 5 percent to 15 percent of isomaltose hypgather tablet excipient and 5 percent to 15 percent of water raw materials in percentage by weight, wherein the isomaltose hypgather tablet excipient and the medicine active ingredients do not have incompatibility and reaction, in addition, the solvability is good, the flowability is good, and the medicine tablet is suitable for the direct tableting of various kinds of medicine. The invention also discloses a preparation method of the medicine tablet, which has the advantages that the preparation is simple, the implementation is easy, and the operation and the control are easy.

Owner:安吉东来药用辅料有限责任公司

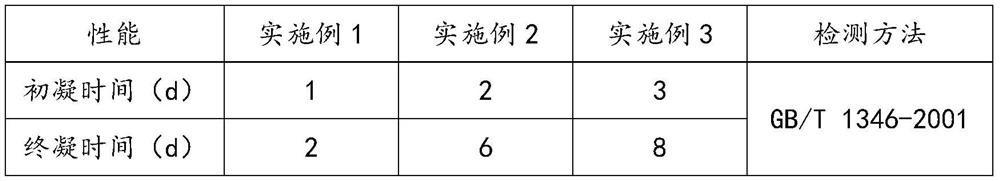

Material for promoting formation of geopolymer in high-humidity environment and preparation method thereof

PendingCN113666655ALow priceWide variety of sourcesSolid waste managementCement productionPhysical chemistryGeopolymer

The invention discloses a material for promoting formation of a geopolymer in a high-humidity environment and a preparation method of the material. The raw materials comprise solid waste, an exciting agent, an additive and water, the solid wastes are industrial solid wastes and comprise fly ash and phosphorus tailing sand; the exciting agent is an alkaline exciting agent and is one of a sodium hydroxide exciting agent, a sodium hydroxide-silica fume composite exciting agent and a water glass exciting agent; the additive is xanthan gum, and the addition amount of the additive is 1% of the solid waste; and the mass ratio (water-solid ratio) of the water to the solid waste is 0.5-0.75. According to the method, the feasibility of preparing a geopolymer grouting filling material from the solid wastes is improved, the problem that the goaf grouting filling material is difficult to form in the actual grouting process is solved, the forming degree of the geopolymer in the high-humidity environment is improved, the final setting time is shortened, the industrial solid wastes can be consumed, and meanwhile, goaf repair treatment is carried out. The raw materials are industrial solid wastes and are low in price and wide in source.

Owner:中能化江苏地质矿产设计研究院有限公司

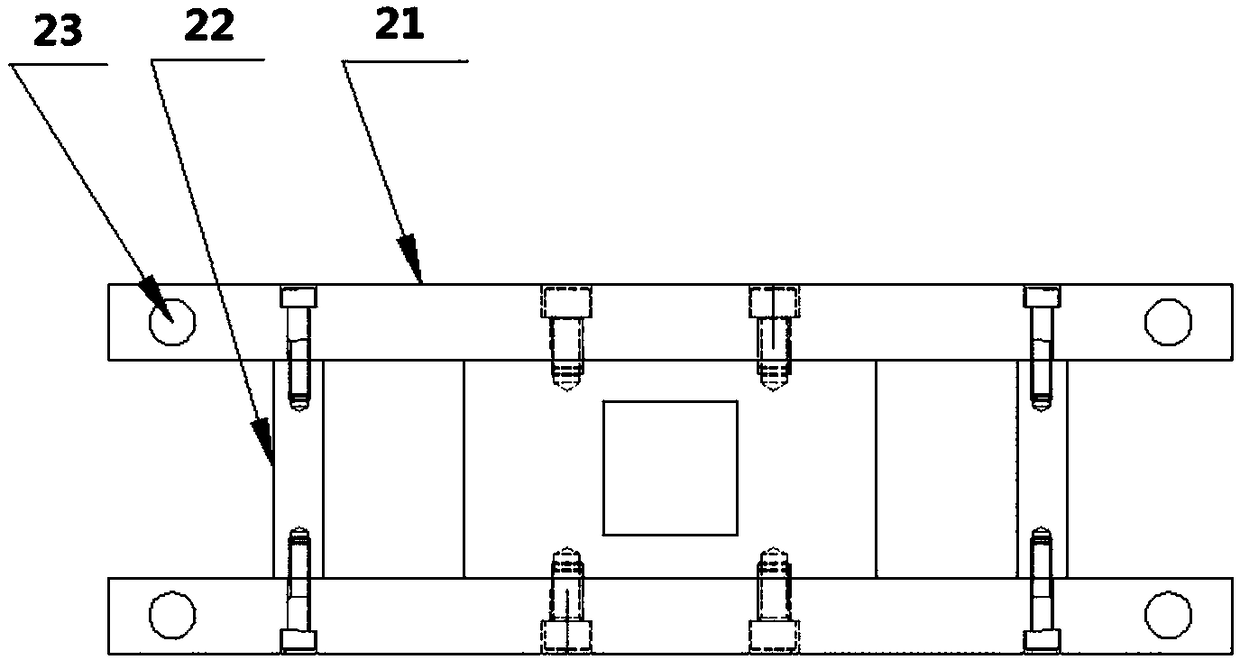

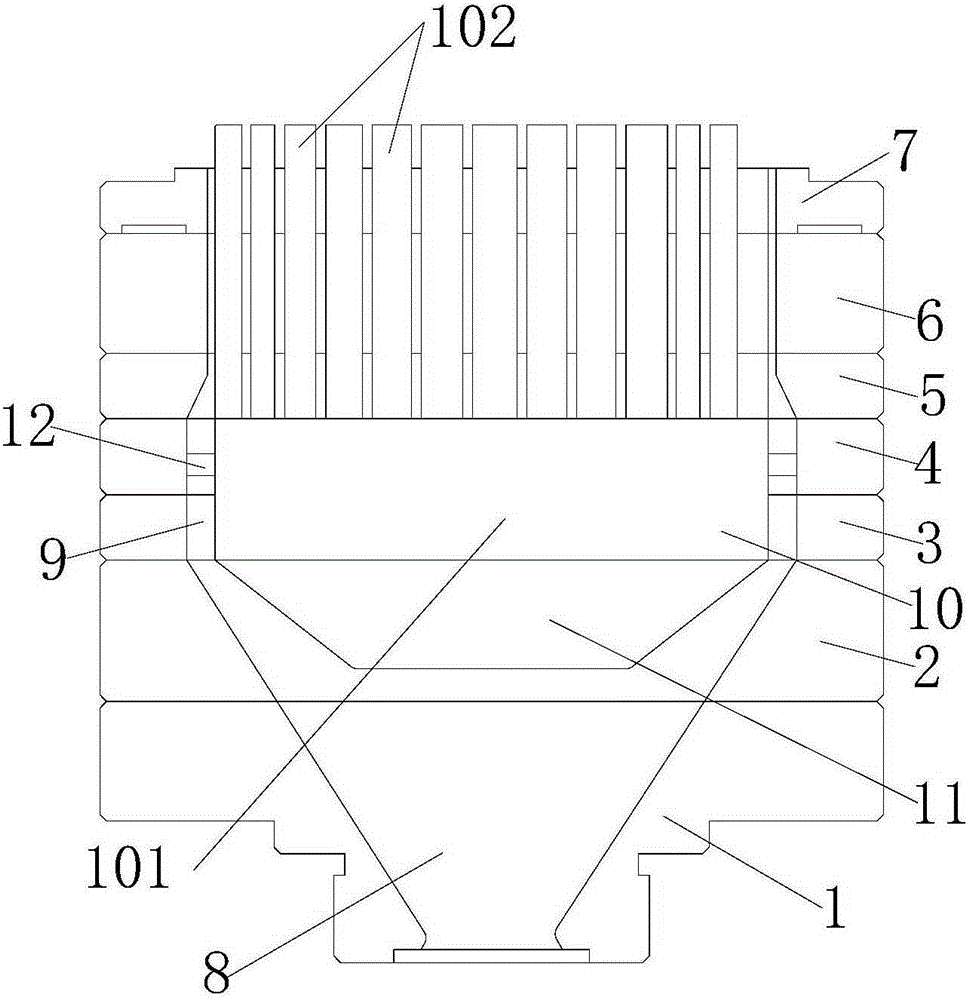

Wood-plastic door pocket extrusion die

The invention discloses a wood-plastic door pocket extrusion die and belongs to the technical field of dies. The die comprises a feed plate, a die body, a filter plate, a support plate, a convergent plate, a die orifice plate and a water cooling plate which are arranged sequentially, wherein the feed plate, the die body, the filter plate, the support plate, the convergent plate, the die orifice plate and the water cooling plate are all provided with internal flow passages, the internal flow passages are combined to form a first die cavity and a second die cavity which are communicated, and a die core is arranged in the second die cavity and extends into the first die cavity to form a shunt column; the inner diameter of the first die cavity and the outer diameter of the shunt column are gradually increased in a feeding direction. According to the invention, the first die cavity and the second die cavity are formed, the die core is arranged in the second die cavity, the shunt column is arranged in the first die cavity, so that pressure of a material in the die is increased, and the forming degree of the material is increased; the inner diameter of the first die cavity and the outer diameter of the shunt column are both increased gradually in the feeding direction, accordingly, the material has higher pressure in the die, the time for bearing higher pressure is prolonged, the forming degree of the material is increased, the quality of a door pocket is improved, and the service life of the door pocket is prolonged.

Owner:HUANGSHI HONGXING PLASTIC MOLD

Cigarette lining paper water supplementing ratio and cigarette lining paper water supplementing preparation method

InactiveCN105507080AHigh degree of moldingGuaranteed physical propertiesPaper coatingPaper/cardboardAcrylic resinProcess engineering

The present invention discloses a cigarette lining paper water supplementing preparation method, wherein paper and a water supplementing solution are provided, and the components of the water supplementing solution comprise 60-80% of purified water, 10-20% of an acrylic resin, and 20-30% of alcohol. The preparation method comprises that the water supplementing solution prepared according to the ratio is poured into a water tank; a coater is opened to drive a mesh water supplementing plate roller to rotate, wherein a concave groove is arranged on the mesh water supplementing plate roller, and with the rotating of the mesh water supplementing plate roller, the concave groove carries the water supplementing solution in the water tank, such that the paper back surface completely contacts the water supplementing solution in the concave groove so as to perform water supplementing; and the paper being subjected to the water supplementing is dried, and the dried paper is coiled by using a paper coiling machine so as to obtain the large coil. According to the present invention, the reasonable ratio and the new process technology are used, such that the problems of unclear emboss, easy bounce, folding intolerance and the like of the environmental-protection paper are solved; and compared with the product in the prior art, the product of the present invention has advantages of original physical property maintaining, good flexibility, good molding, no bounce, folding resistance, clear and accurate printing letter, and the like.

Owner:汕尾高峰科特纸业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com