Sliding block injection molding mechanism

A technology of injection molding and sliding blocks, which is applied in the direction of coating, etc., can solve the problems of time-consuming, high process cost, and low pass rate, and achieve low cost, improve product forming degree and pass rate, and facilitate mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Aiming at the shortcomings of traditional injection molds in finished inserts, the present invention proposes an innovative improvement plan. By introducing air cylinders into the traditional mold combination to form insert modules and electrification control, the injection molding products The integrated production of inserts provides a practical technical solution.

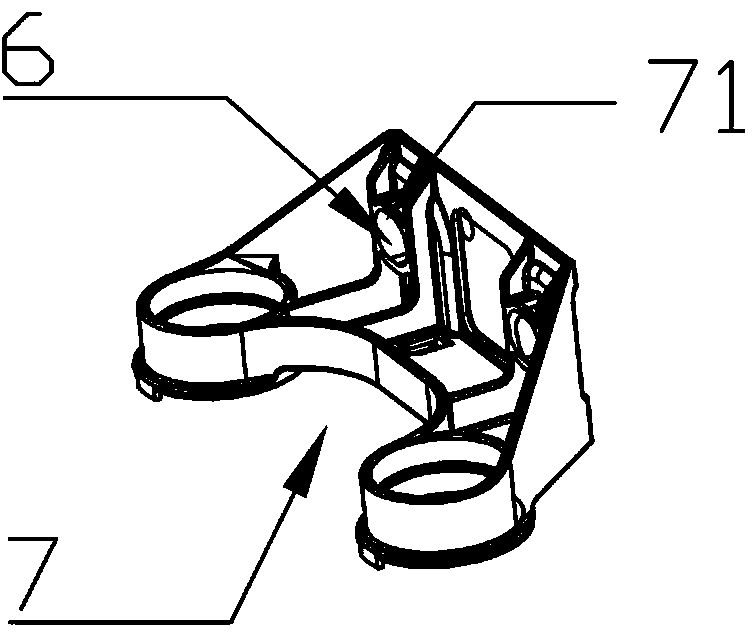

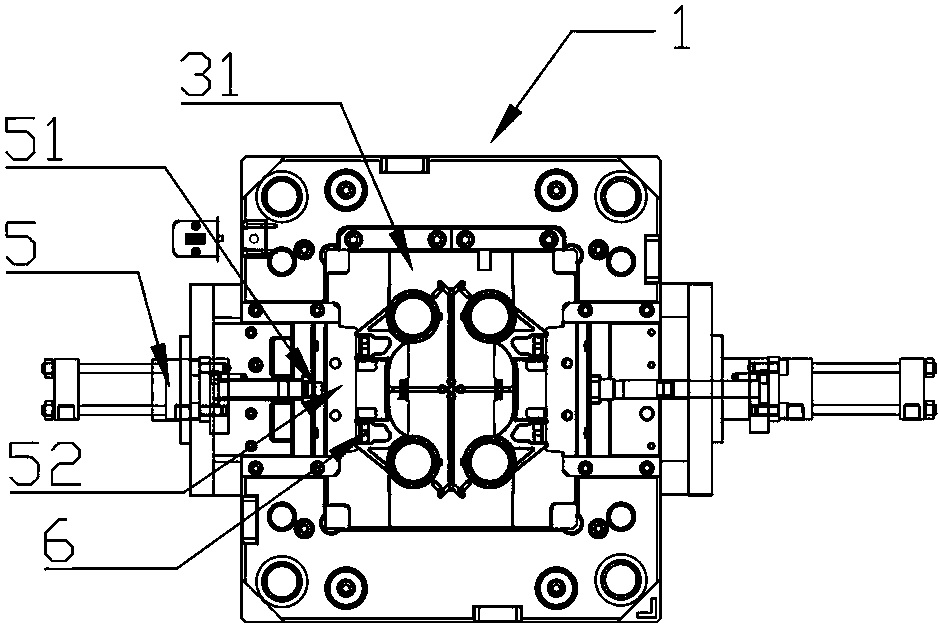

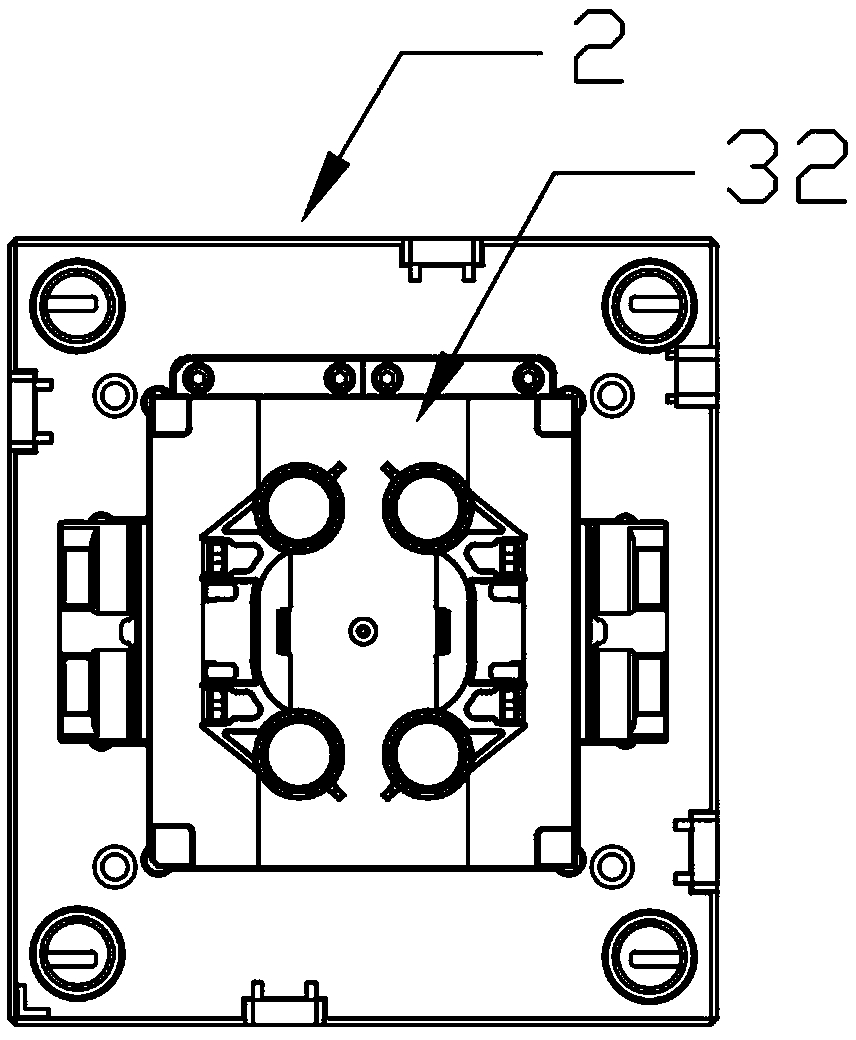

[0015] Such as Figure 2 to Figure 4 As shown, it is a schematic diagram of the structure of each part of the injection molding mechanism of the slider of the present invention, including an injection molding master controller, a lower mold base 1, an upper mold base 2 and a mold ejection lifting mechanism 4, and the lower mold base 1 is set There is a lower mold core 31, and the upper mold base 2 is provided with an upper mold core 32, and the upper and lower mold bases are joined into mold grooves corresponding to more than one slide block 7 when the mold is closed. As an innovative feature, the inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com