High-strength waterproof semitransparent food paper bag body paper and preparation method thereof

A translucent, high-strength technology, applied in the field of paper manufacturing, can solve problems such as poor formability and easy deformation, and achieve the effects of reducing production costs, improving tensile force and formability, and reducing pulp loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

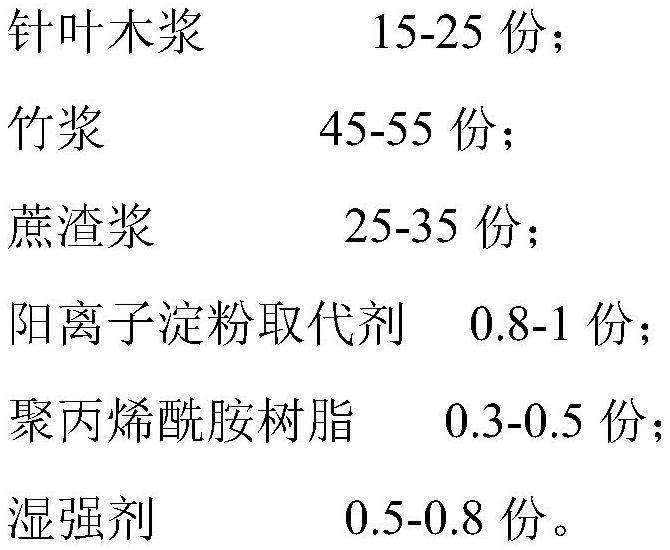

Method used

Image

Examples

preparation example Construction

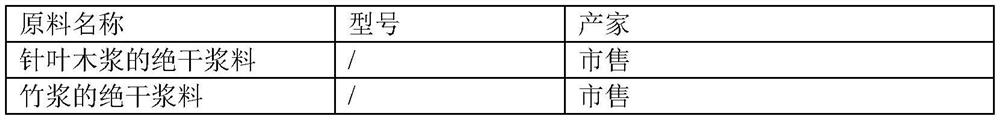

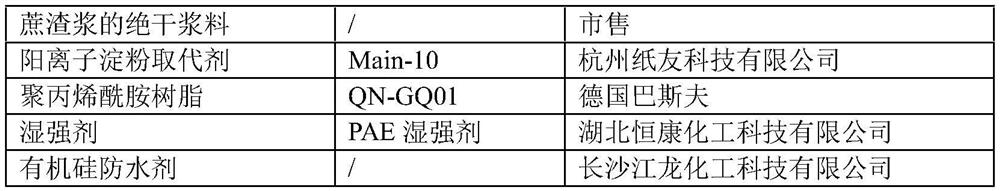

[0045] Examples of Preparation of Raw Materials and / or Intermediates

[0046] The raw material source of following embodiment and preparation is as shown in table 1:

[0047]

[0048]

Embodiment 1

[0051] A high-strength waterproof translucent food paper bag base paper is prepared through the following steps:

[0052] S1, coniferous wood pulp beating;

[0053] Weigh 1000Kg of dry pulp of softwood pulp, add water to adjust the beating concentration of softwood pulp to 3%, add 0.1Kg of beating enzyme, and beat at a beating temperature of 38°C to 75°SR;

[0054] S2, bamboo pulp beating;

[0055] Take by weighing the absolute dry slurry of 1000Kg bamboo pulp, add water to adjust the beating concentration of bamboo pulp to 4.5%, and then beat to 55 ° SR;

[0056] S3, bagasse pulp beating;

[0057] Weigh the dry slurry of 1000Kg bagasse pulp, add water to adjust the beating concentration of bagasse pulp to 4.5%, and then beat to 55 ° SR;

[0058] S4, preparation of high-strength waterproof translucent food paper bag base paper;

[0059] S41, add clear water in the gelatinization tank, keep the rotating speed at 60r / min, slowly add the cationic starch substituting agent, so...

Embodiment 2

[0063] A high-strength waterproof translucent food paper bag base paper is prepared through the following steps:

[0064]S1, coniferous wood pulp beating;

[0065] Weigh 1000Kg of dry pulp of coniferous wood pulp, add water to adjust the beating concentration of coniferous wood pulp to 3.3%, add 0.13Kg of beating enzyme, and perform beating at a beating temperature of 38°C to 75°SR;

[0066] S2, bamboo pulp beating;

[0067] Take by weighing the absolute-dry slurry of 1000Kg bamboo pulp, add water to adjust the beating concentration of bamboo pulp to 4.5-5%, then beating, beating to 55°SR;

[0068] S3, bagasse pulp beating;

[0069] Weigh the dry slurry of 1000Kg bagasse pulp, add water to adjust the beating concentration of bagasse pulp to 4.7%, and then beat to 55 ° SR;

[0070] S4, preparation of high-strength waterproof translucent food paper bag base paper;

[0071] S41. Add clear water into the gelatinization tank, keep the rotating speed at 60r / min, slowly add catio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com