Thermoplastic polyolefin impermeable composite material and preparation method thereof

A technology of thermoplastic polyolefin and composite materials, which is applied in the field of anti-seepage materials, can solve problems such as insufficient flexibility, and achieve the effects of simple processing technology, long service life and high hydrostatic pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

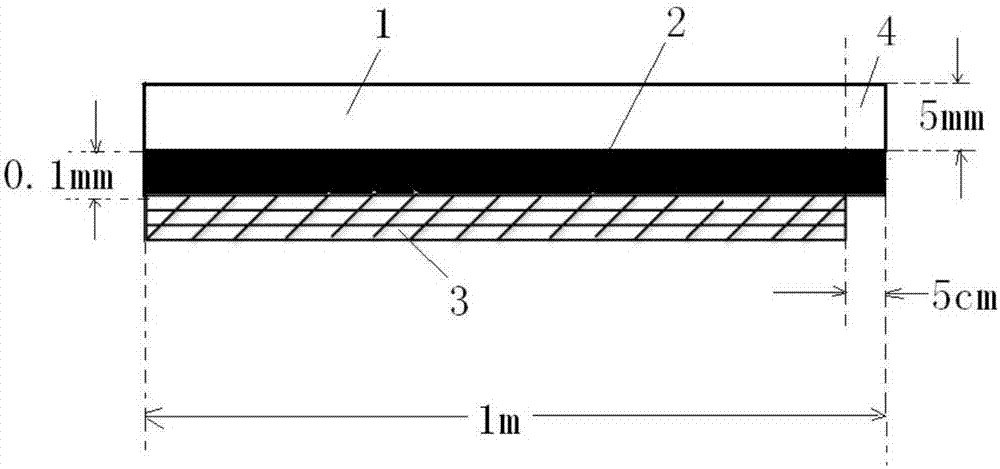

[0035] This embodiment provides a thermoplastic polyolefin anti-seepage composite material, such as figure 1 As shown, it includes a thermoplastic polyolefin composite layer and a geotextile layer 3; the thermoplastic polyolefin composite layer includes a cross-laminated polyolefin layer 2 and a thermoplastic polyolefin layer 1.

[0036] The thermoplastic polyolefin composite layer of the present embodiment has a width of 1m, and the geotextile layer 3 has a grammage of 100g / m 2 non-woven polypropylene geotextile, one end of the geotextile layer 3 is 5 cm away from the edges of the two ends of the thermoplastic polyolefin layer as the lap edge 4.

[0037] The preparation method of the thermoplastic polyolefin anti-seepage composite material of the present embodiment is as follows:

[0038] (1) Place the raw material of the cross-laminated polyolefin layer 2 in the first screw extruder unit and the second screw extruder, and at a screw speed of 100 rpm, the melt extrusion widt...

Embodiment 2

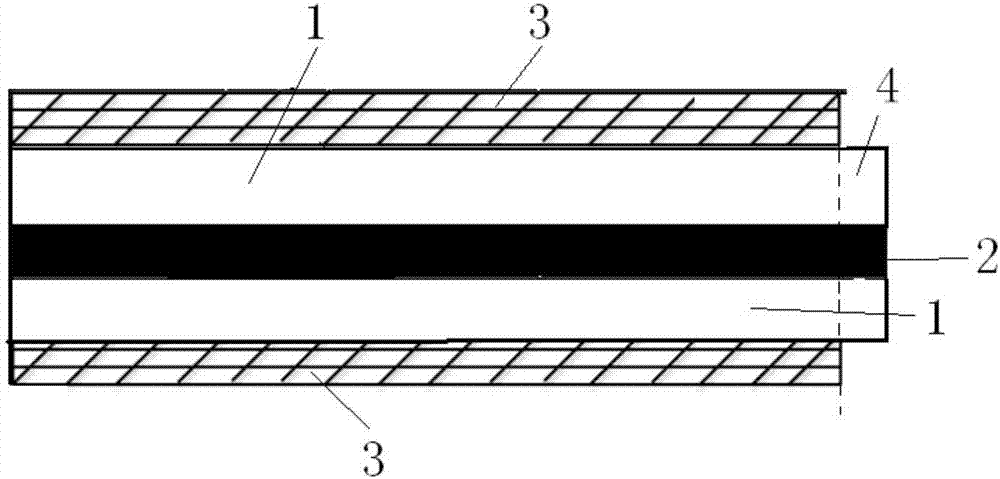

[0045] This embodiment provides a thermoplastic polyolefin anti-seepage composite material, such as figure 2 As shown, it includes a thermoplastic polyolefin composite layer and upper and lower geotextile layers 3; the thermoplastic polyolefin composite layer includes a cross-laminated polyolefin layer 2 and a thermoplastic polyolefin layer 1, and the infrared absorption spectrum of the thermoplastic polyolefin layer picture see Figure 4 .

[0046] The upper floor geotextile layer 3 of the present embodiment is the grammage 500g / m 2 The non-woven needle-punched polyester geotextile, the lower geotextile layer 3 is 1000g / m 2 The spun polypropylene long-fiber geotextile; the thermoplastic polyolefin composite layer has a thickness of 2.5mm and a width of 2m;

[0047] The preparation method of the thermoplastic polyolefin anti-seepage composite material of the present embodiment is as follows:

[0048] (1) Place the raw material of the cross-laminated polyolefin layer 2 in ...

Embodiment 3

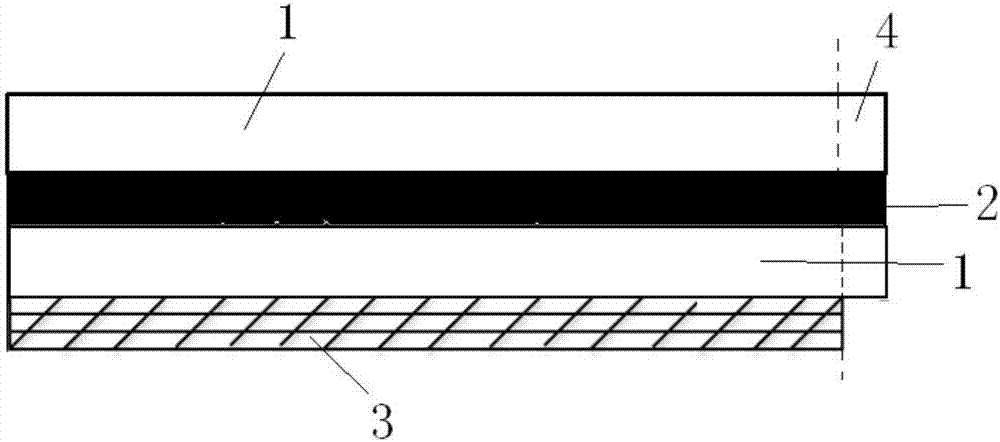

[0054] This embodiment provides a thermoplastic polyolefin anti-seepage composite material, which includes a thermoplastic polyolefin composite layer and a geotextile layer 3 ; the thermoplastic polyolefin composite layer includes a cross-laminated polyolefin layer 2 and a thermoplastic polyolefin layer 1 .

[0055] The thermoplastic polyolefin composite layer of the present embodiment has a width of 2m, and the geotextile layer 3 has a grammage of 1000g / m 2 A non-woven needle-punched polyester geotextile, and the two ends of the geotextile layer 3 are 15 cm away from the edge of one end of the thermoplastic polyolefin layer as the overlapping edge 4.

[0056] The preparation method of the thermoplastic polyolefin anti-seepage composite material of the present embodiment is as follows:

[0057] (1) The raw material of the cross-laminated polyolefin layer 2 is placed in the first screw extruder unit, the screw speed is 400 revolutions / min, and the polyolefin film with a width o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com