Portable curve-controlled high-precision steel rail profile modeling grinding machine

A portable, high-precision technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of rail surface bulge and depression, large size of grinding machine, insufficient grinding accuracy, etc., to achieve accurate grinding, ensure driving safety, imitation. shape effect realistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

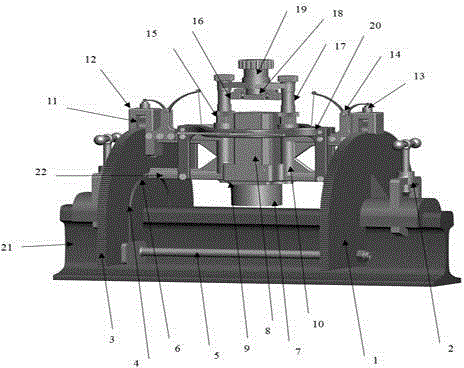

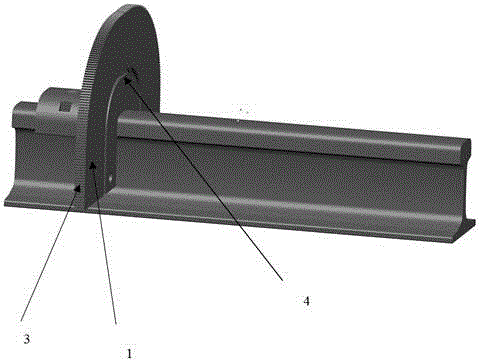

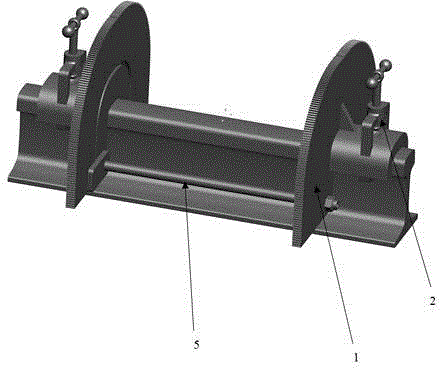

[0021] The specific implementation components of the present invention are in figure 1 It is shown in: saddle-type fixed bracket backing 1, hanging bolt mechanism 2, gear slideway 3, curved track groove 4, backing connecting rod 5, motor moving bracket bearing head 6, grinding wheel 7, motor 8, motor fixing bracket cylinder Type guide rod 9, motor mobile bracket cylindrical guide groove 10, motor fixed bracket mobile gear 11, mobile gear fixing device 12, mobile gear positioning device 13, gear fixed adjustment device 14, grinding depth precision control device 15, grinding accuracy Control the mobile slideway 16, the circular guide groove 17 on the top of the motor fixed bracket, the mobile connection device 18 of the motor fixed bracket, the motor moving up and down the control adjustment device 19, the motor mobile handrail 20, and the steel rail 21.

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com