Patents

Literature

40results about How to "Good paint adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

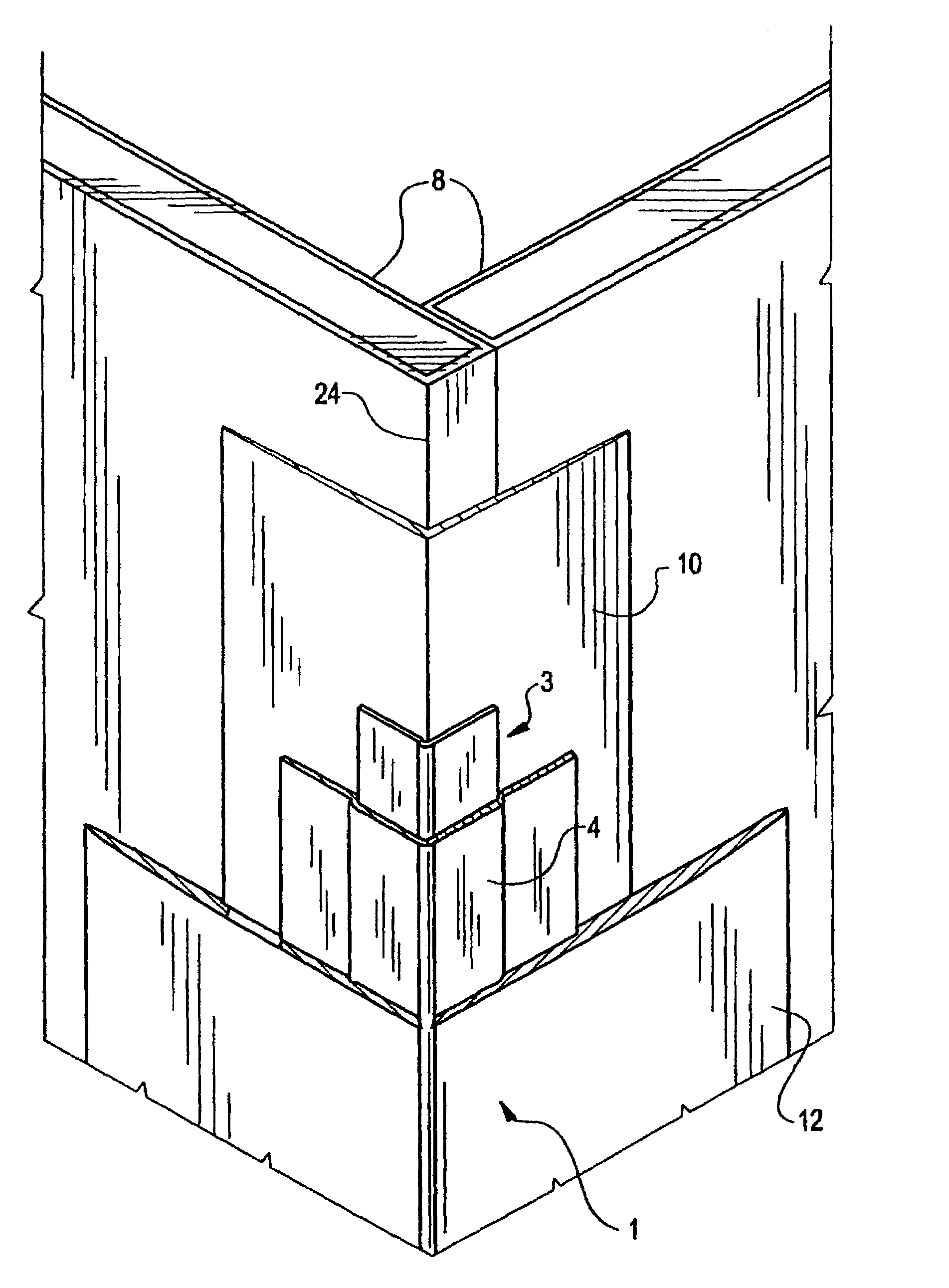

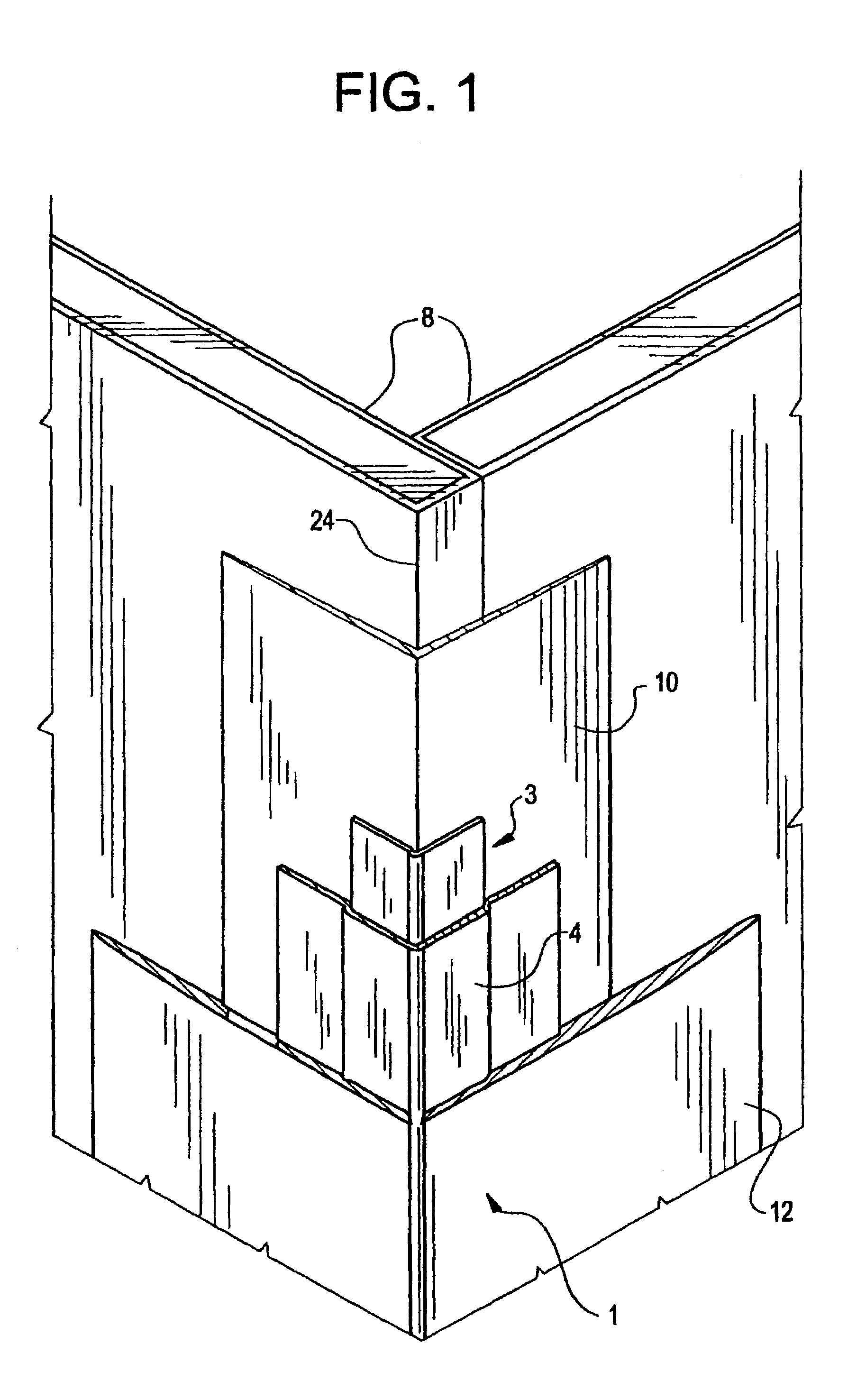

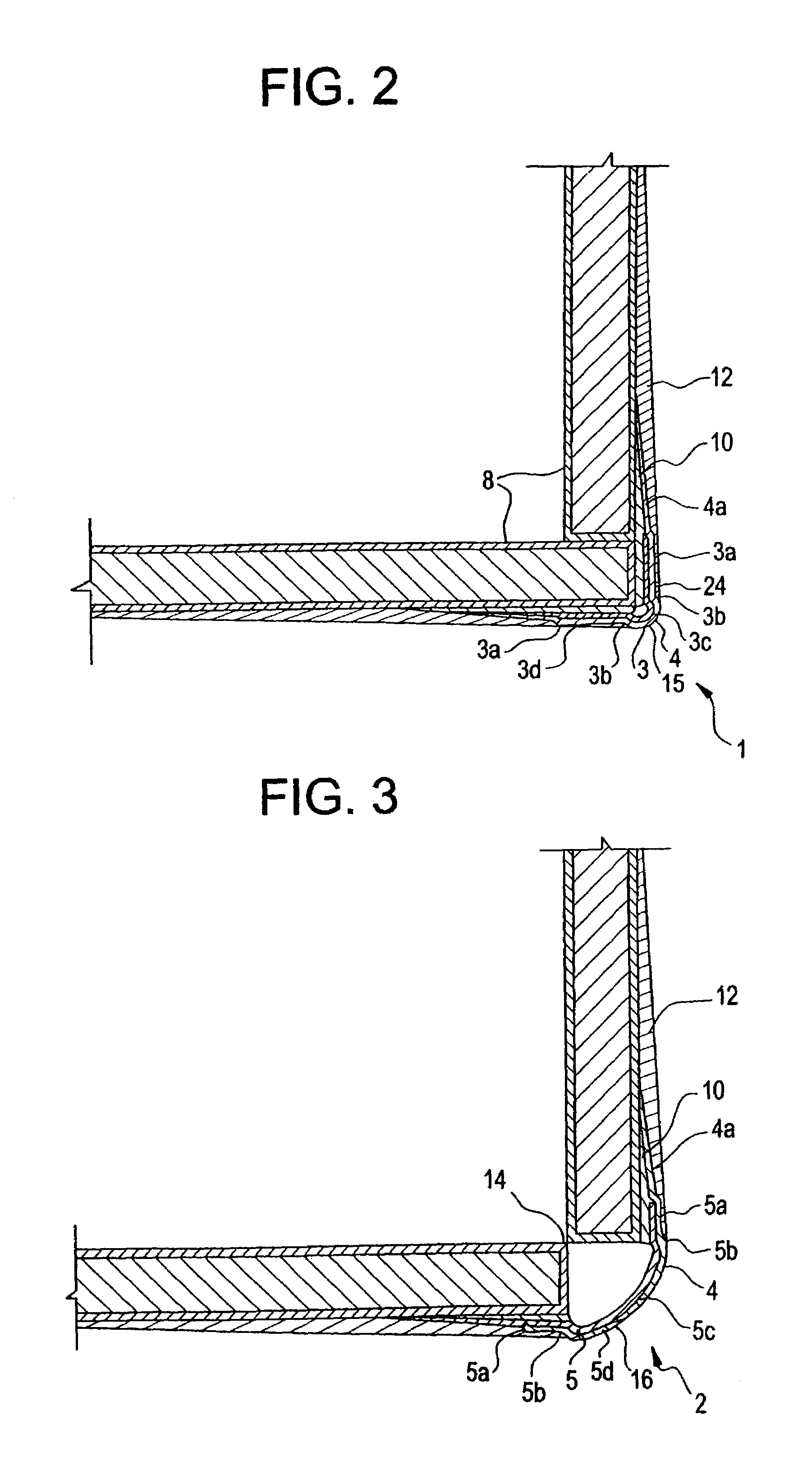

Paper and paperbead for protecting drywall corners

ActiveUS7214434B2Improve adhesionResistant to scuffingNon-fibrous pulp additionNatural cellulose pulp/paperJoint compoundUltimate tensile strength

The present invention relates to drywall corner beads, particularly drywall corner beads having an outer paper layer, and paper therefor. The improved paperbead includes an elongated core having an outer surface. A paper strip is bonded to the outer surface of the core. The paper is impregnated on one side with a polymer, preferably latex, that penetrates only about half the thickness of the paper. The other side of the paper is roughened to improve adhesiveness to joint compounds. The latex impregnated side of the paper maintains increased strength making the paper resistant to scuffing while at the same time, the roughened side of the paper improves its adhesiveness to joint compounds.

Owner:BAILEY METAL PROD +1

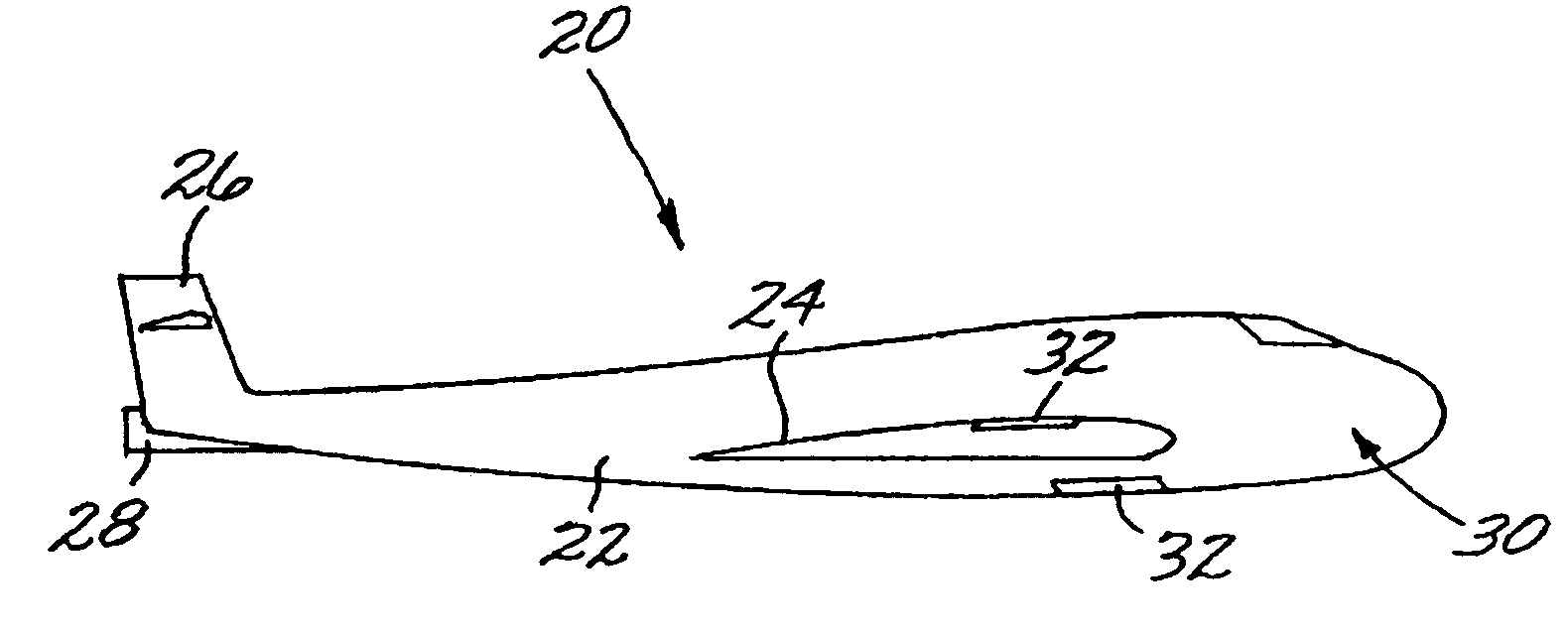

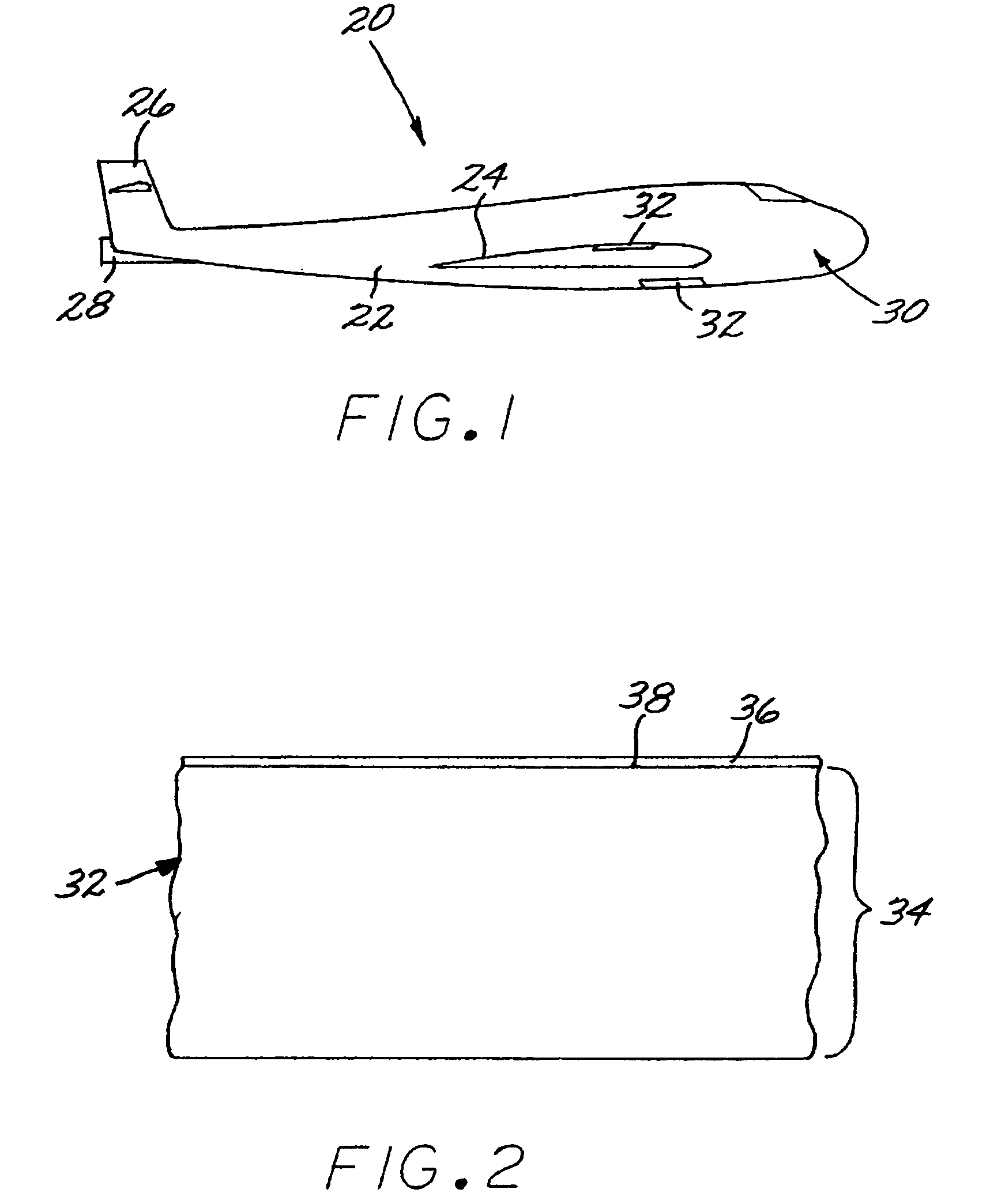

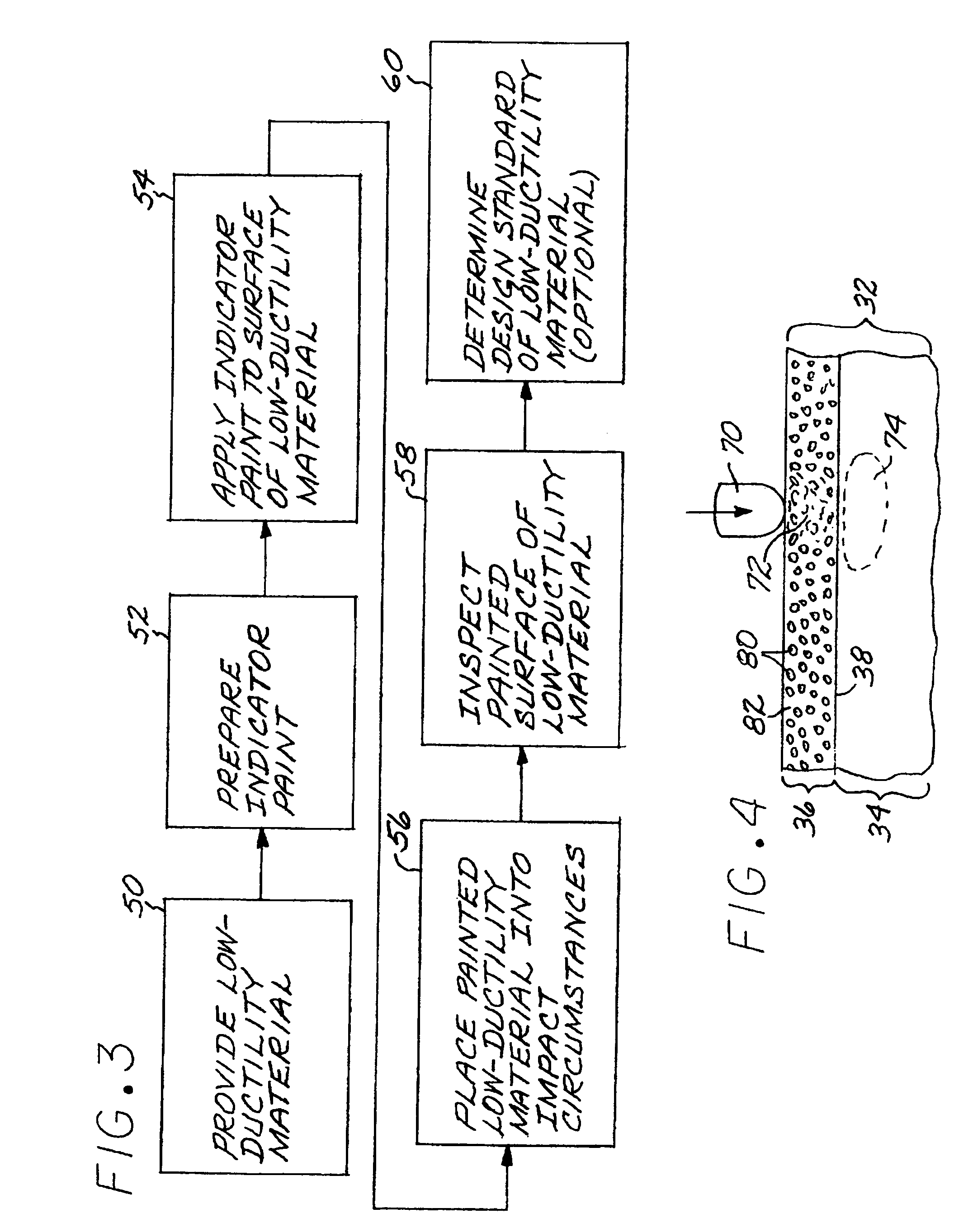

Approach for indicating the occurrence of a mechanical impact on a material, such as a low-ductility composite material

ActiveUS7647809B1Easy to detectImprove inspection techniqueAcceleration measurementApparatus for force/torque/work measurementMechanical impactMaterials science

A method of indicating the presence of mechanical impact is used with a low-ductility material, such as a composite material, having a tensile elongation to failure of less than about 2 percent. The method includes preparing an indicator paint having an impact-sensitive component that produces a visible change when subjected to a mechanical impact, applying the indicator paint to the surface of the low-ductility material, placing the low-ductility material having the indicator paint thereon into circumstances where it may be subject to the mechanical impact, and thereafter inspecting the low-ductility material having the indicator paint thereon for the presence of the visible change. The method may be used to establish design criteria for the low-ductility material by establishing an impact-effect threshold value from the step of inspecting, and determining a design limit for the low-ductility material responsive to the impact-effect threshold value. One result of the using the present approach is to reduce the structural weight by reducing the barely visible impact damage design factor.

Owner:SPECTRUM AERONAUTICAL

Composition and process for treating surfaces or light metals and their alloys

InactiveUS6485580B1Excellent corrosion resistanceExcellent paint adhesionSolid state diffusion coatingCorrosion resistantConversion coating

Owner:NIHON PARKERIZING

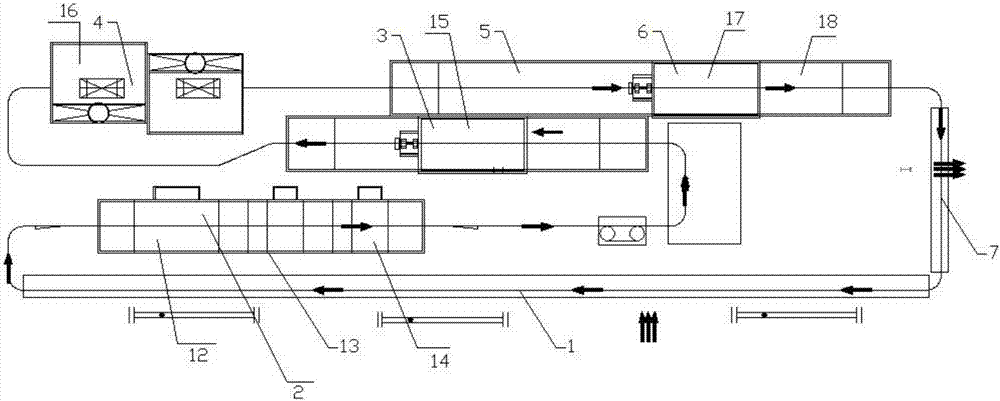

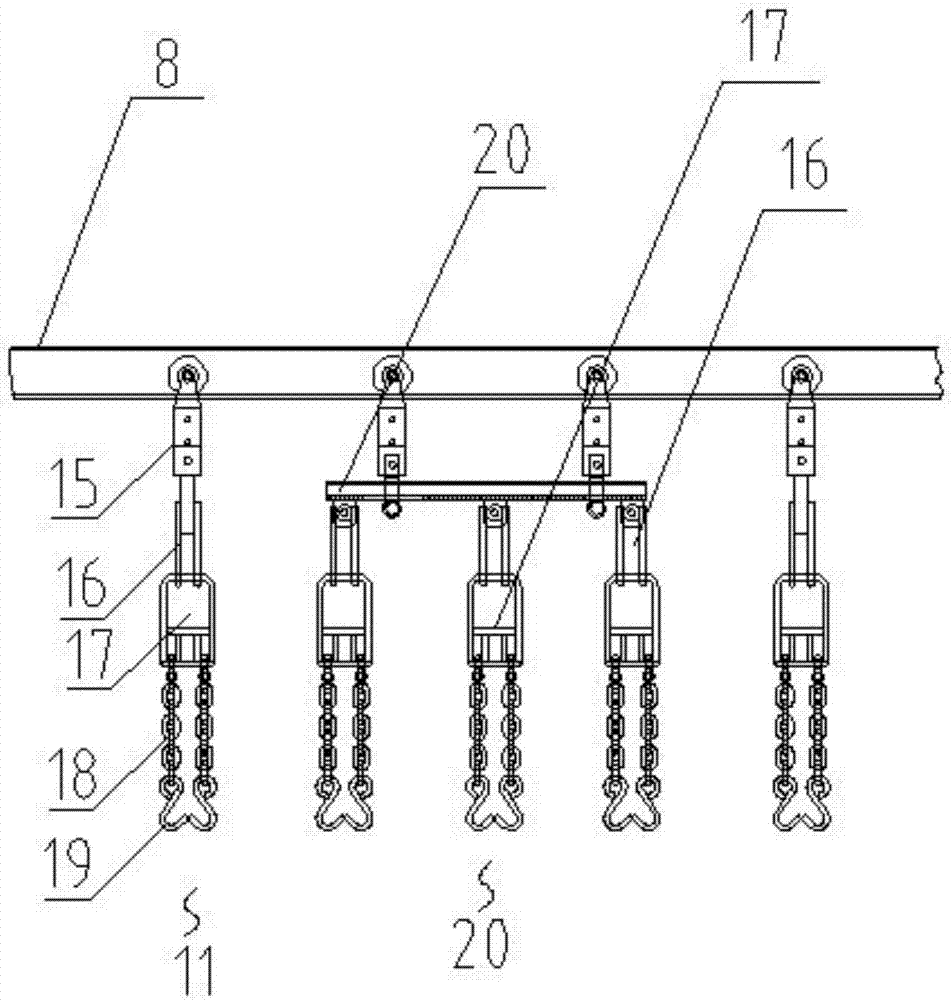

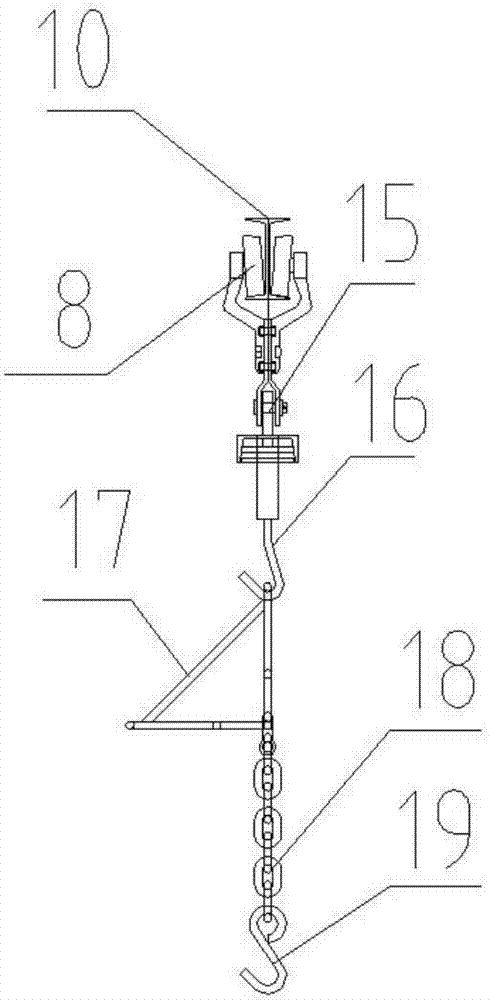

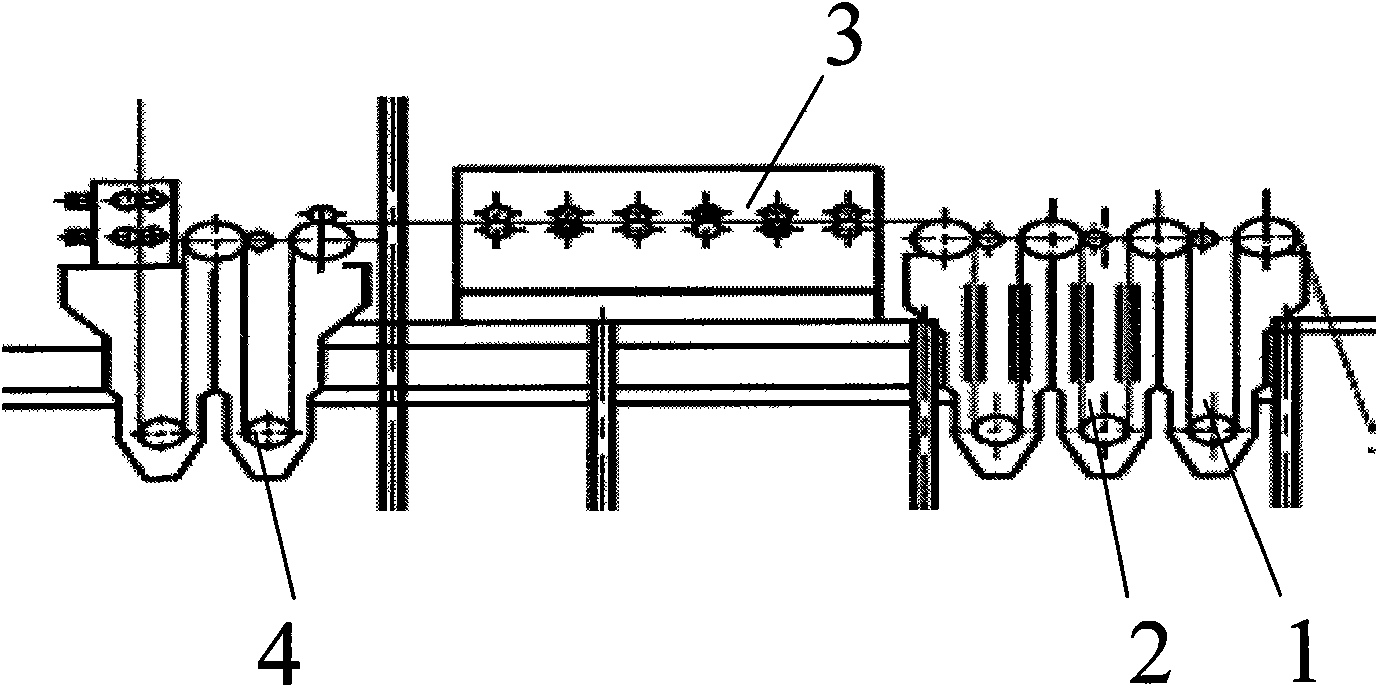

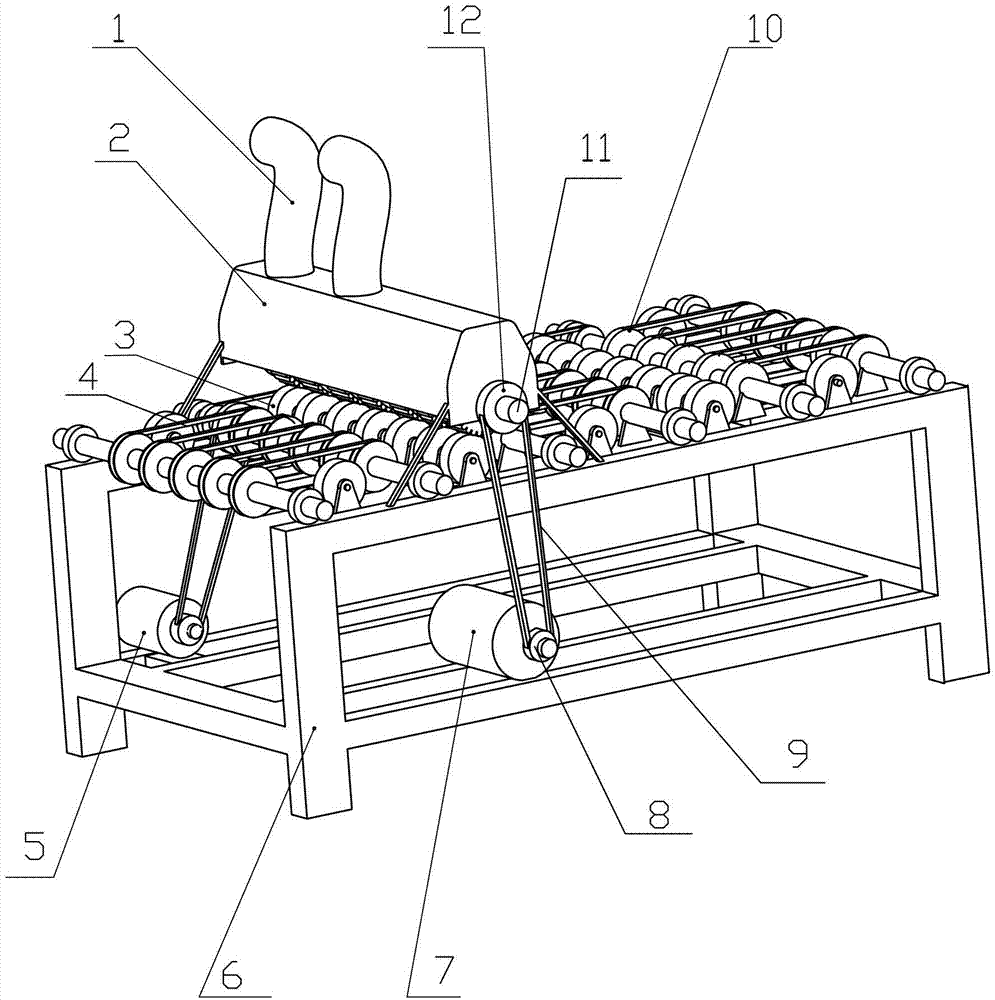

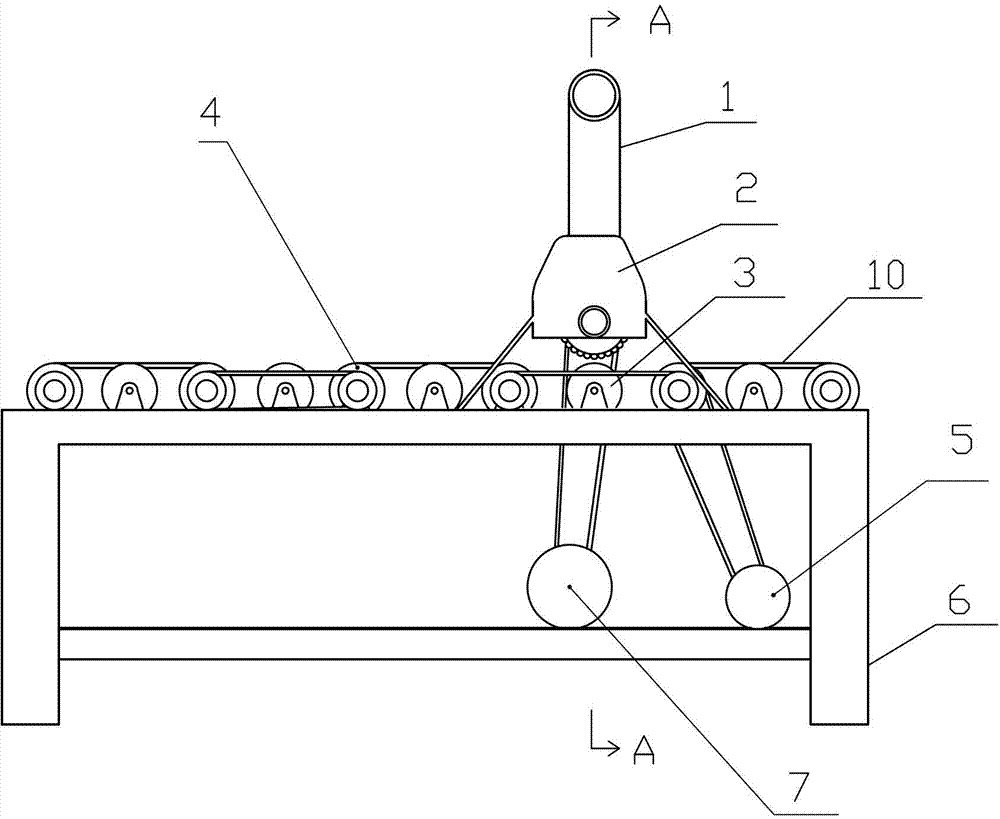

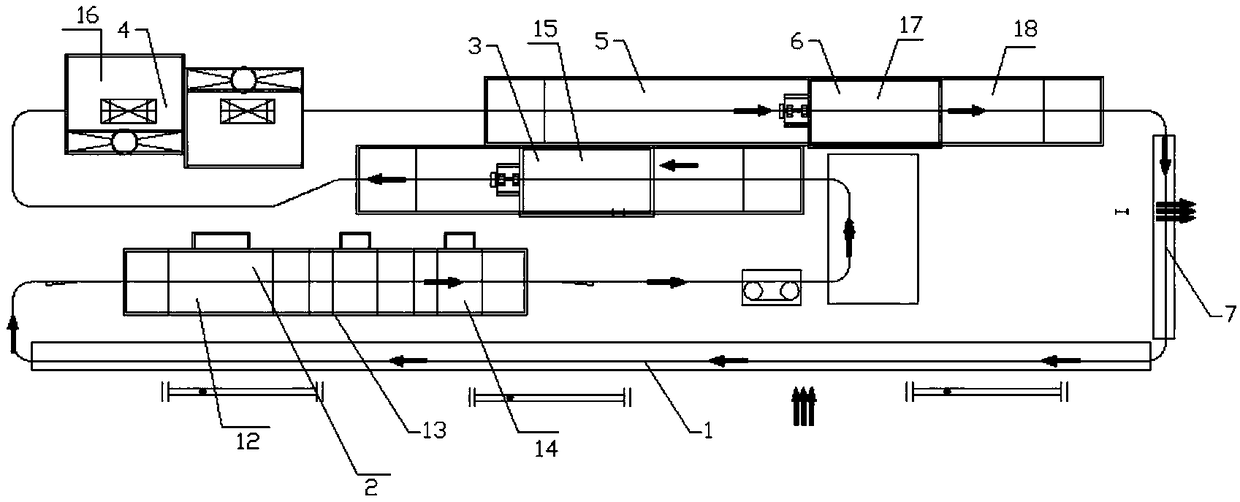

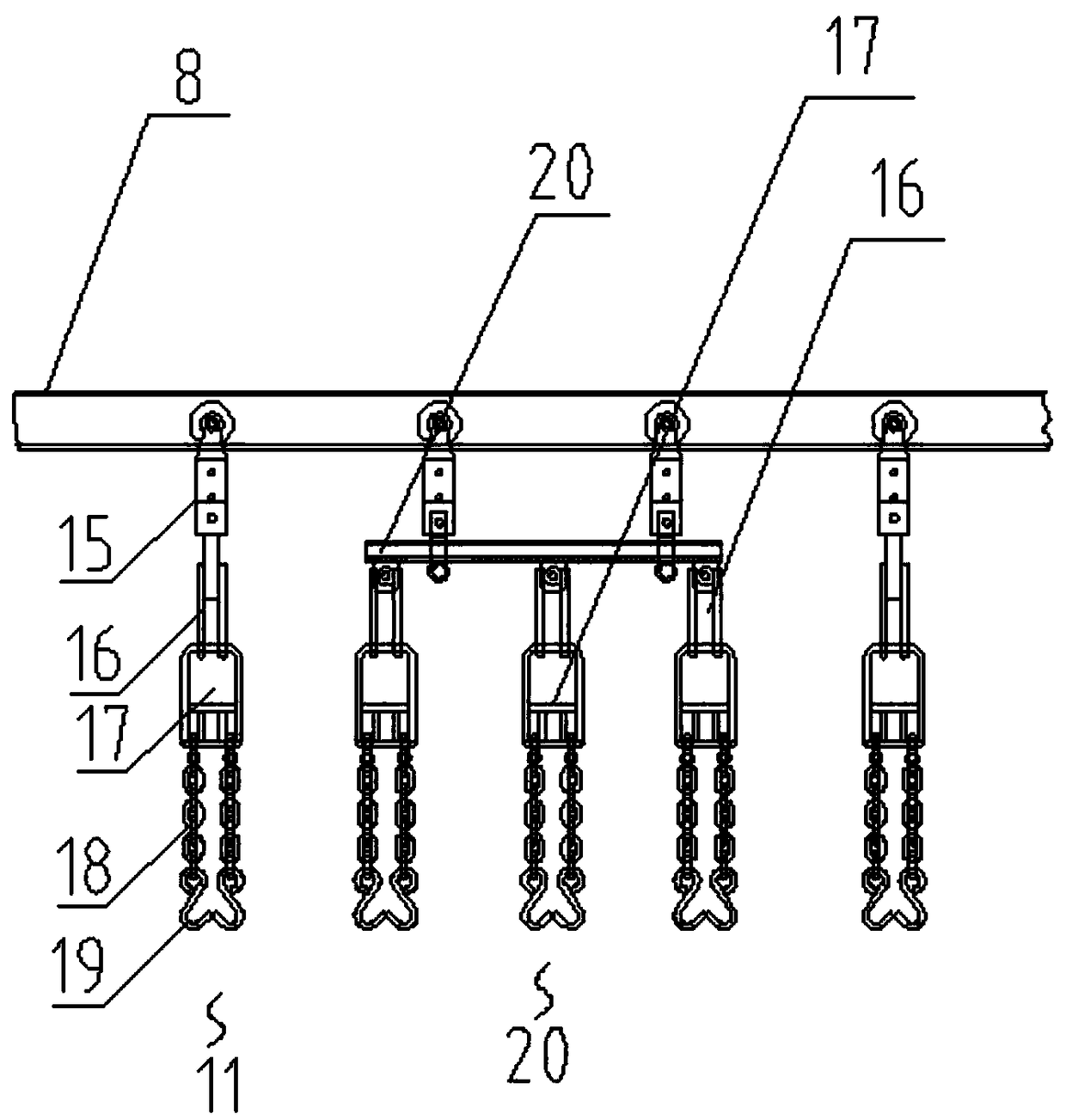

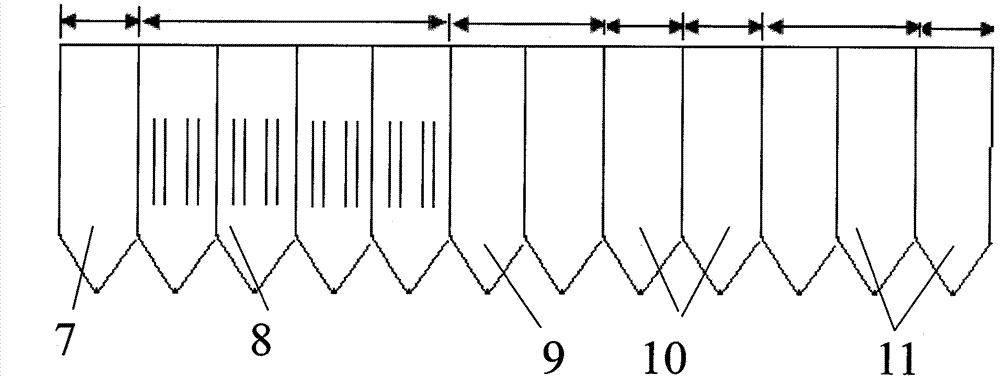

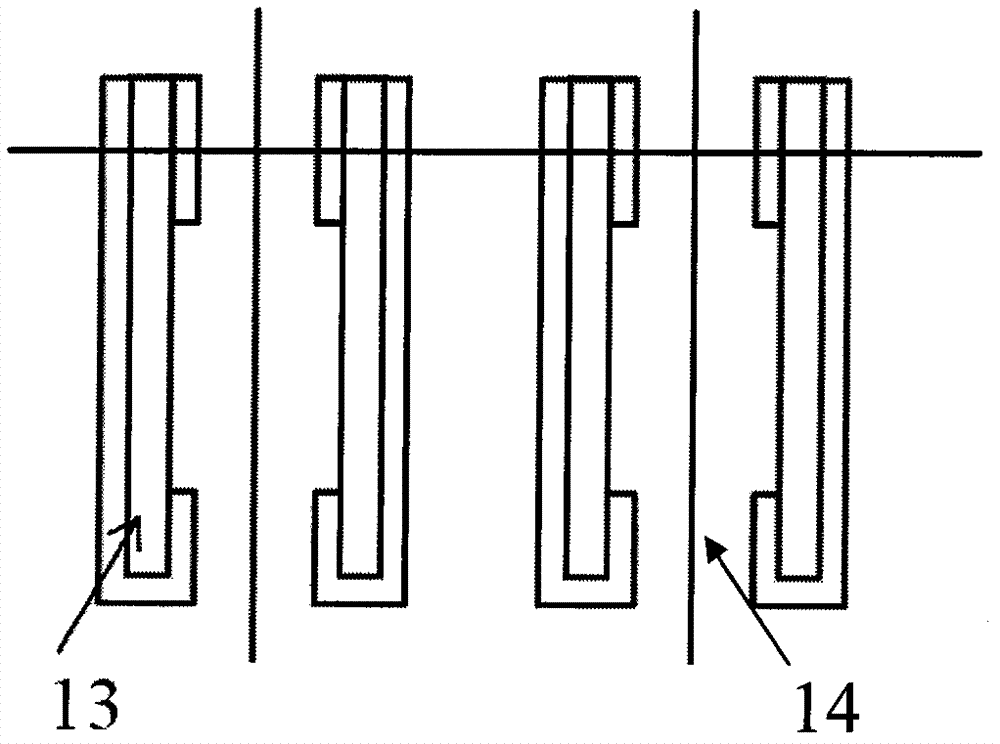

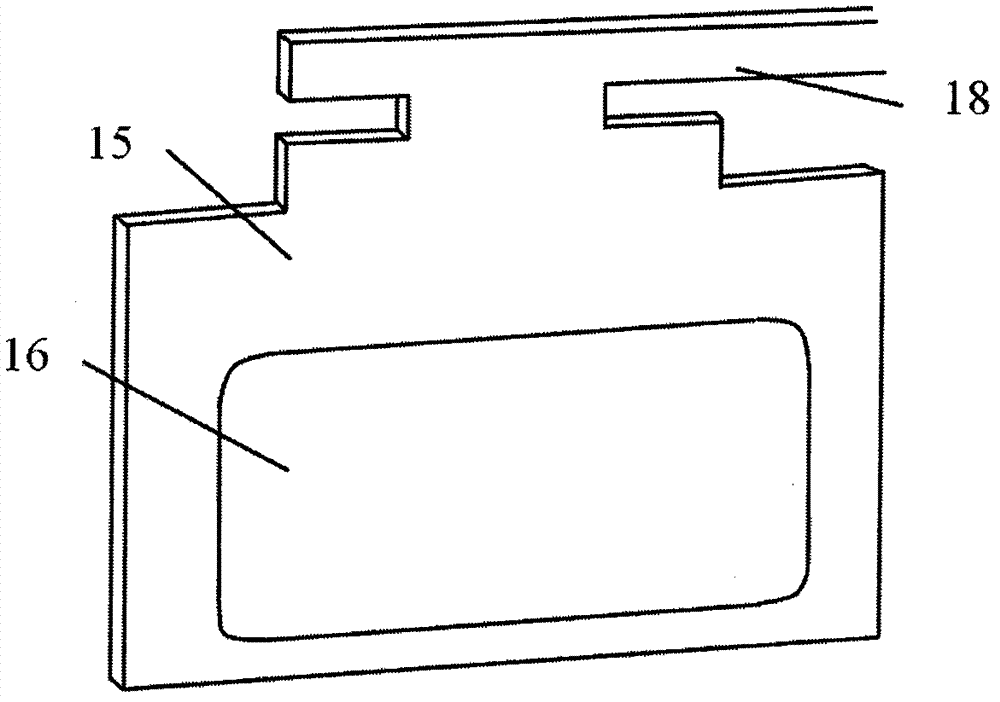

Agricultural equipment gearbox coating line and coating method thereof

ActiveCN107138335AEfficient removalReduce pollutionSpraying apparatusPretreated surfacesAgricultural engineeringElectric machinery

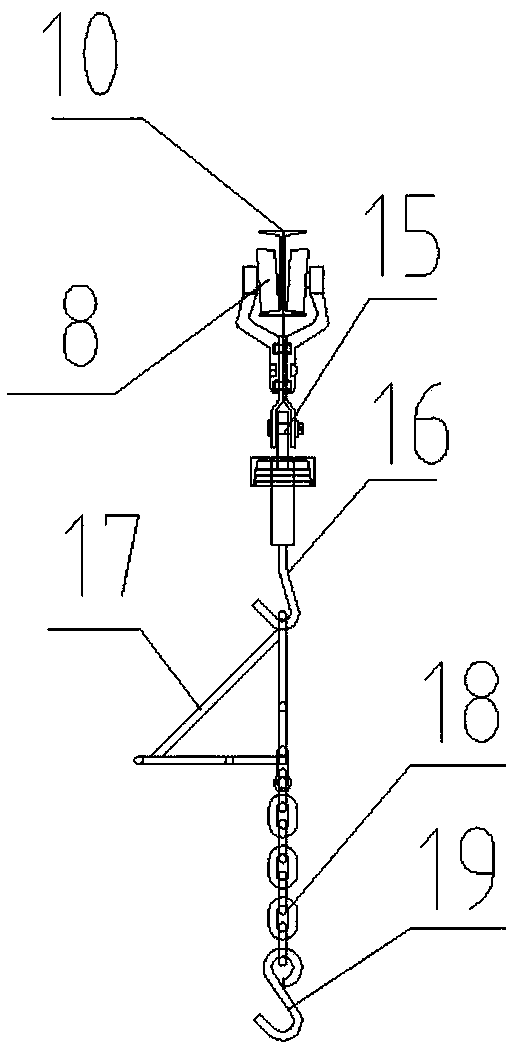

The invention discloses an agricultural equipment gearbox coating line which comprises a line feeding area, a washing area, a drying area, a paint spraying area, a levelling area, a finishing coat drying area, a line discharging area, a rail, a coating assembly line chain, a plurality of lifting appliance assemblies and a drive motor, wherein the line feeding area, the washing area, the drying area, the paint spraying area, the levelling area, the finishing coat drying area and the line discharging area are sequentially connected; the rail is fixedly arranged at the top of the entire agricultural equipment gearbox coating line; the coating assembly line chain is connected with the drive motor; the coating assembly line chain is connected with the rail; driven by the drive motor, the coating assembly line chain moves along the rail; the lifting appliance assemblies are fixed on the coating assembly line chain; and gearboxes are lifted through the lifting appliance assemblies at the line feeding area. The agricultural equipment gearbox coating line is reasonable in structure, light and convenient to operate, excellent in coating effect and high in paint adhesive force, and the agricultural equipment gearbox coating line and a coating method thereof can meet the using requirements.

Owner:山东卫禾传动股份有限公司

Quaternary Ammonium Salts as a Conversion Coating or Coating Enhancement

InactiveUS20110100512A1Improve adhesionGood paint adhesionSolid state diffusion coatingAnti-corrosive paintsGlycolatesQuaternary ammonium cation

Disclosed are quaternary ammonium salts containing non-halogen anions such as carbonates, bicarbonates, phosphates, glycolates and mixtures thereof as conversion coatings or additives imparting anti-corrosive properties to paints. The invention relates to a method for inhibiting the corrosion of metal surfaces by applying a composition containing one or more quaternary ammonium carbonate or bicarbonate. The disclosure is also directed to anti-corrosive coatings for metal substrates containing these compounds and to metal substrates having these anticorrosive coatings.

Owner:LONZA INC

A Method for the Manufacture of a Phosphatable Part Starting from a Steel Sheet Coated with a Metallic Coating Based on Aluminum

ActiveUS20180216218A1Easy to implementGood paint adhesionHot-dipping/immersion processesFurnace typesSheet steelZinc

A method for the manufacture of a hardened part coated with a phosphatable coating is provided. The method includes providing a steel sheet pre-coated with a metallic coating including from 4.0 to 20.0% by weight of zinc, from 1.0 to 3.5% by weight of silicon, optionally from 1.0 to 4.0% by weight of magnesium, and optionally additional elements chosen from Pb, Ni, Zr, or Hf, the content by weight of each additional element being less than 0.3% by weight, the balance being aluminum and unavoidable impurities and residuals elements. The steel sheet is cut to obtain a blank, the blank is thermally treated at a temperature between 840 and 950° C. to obtain a fully austenitic microstructure in the steel, the blank is transferred into a press tool and hot-formed to obtain a part. The part is cooled to obtain a martensitic or martensitic-bainitic microstructure or made of at least 75% of equiaxed ferrite, from 5 to 20% of martensite and bainite in amount less than or equal to 10%.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Method for plating chrome on surface of thin plate

The invention discloses a method for plating chrome on a surface of a thin plate. The method comprises the following steps: 1) alkali washing, including alkali liquor leaching, electrolysis washing and alkali washing; 2) pickling, including electrolysis pickling and acid washing; 3) electroplating, including chromeplating and washing; and 4) oiling. The method sufficiently utilizes the performance advantage of CrO3+NH4 plating solution, optimizes the pre-treatment pickling process and electroplating parameters, particularly controls the solution concentration of alkali washing and pickling, strictly controls the current efficiency of an electroplating section and the electroplating concentration, overcomes the defects in the tradition process, generates compact metal chrome and chromic oxide layers on the surface of strip steel, realizes one-step production of an electrolytic chromium steel plate the strip steel surface of which is plated with optimally combined metal chromium and chromic oxide so as to obtain the excellent chromeplated plate with bright and uniform plating layer. Meanwhile, the method saves energy consumption, reduces pressure environment-friendly emission, reduces cost for production and maintenance, and creates a condition for improving the chromeplated plate, thus having excellent popularization and application prospect.

Owner:BAOSHAN IRON & STEEL CO LTD

Composite material comprising ethylene/propylene copolymer and method for preparing the same

A composite material, including between 30 and 94 percent by weight of a polymer mixture of polyethylene or polypropylene, polyolefin elastomer, and sorbitol; between 5 and 60 percent by weight of a reinforcing agent; between 0 and 40 percent by weight of a strengthening agent; between 0.1 and 1 percent by weight of a disproportionation agent; between 0.1 and 1 percent by weight of a coupling agent; between 0.1 and 1 percent by weight of an antioxidant; between 0.1 and 1 percent by weight of an anti-aging agent; between 0.1 and 1 percent by weight of an ultraviolet absorber; between 0.1 and 1 percent by weight of a lubricant; and between 0.1 and 1 percent by weight of triethyl aluminum. A method for preparing the composite material includes separately mixing components, combining them in a twin screw extruder, and extruding and granulating the combined mixture.

Owner:GUANGZHOU LEVE LIGHTING

Polyolefin-based thermoplastic polymer composition

InactiveUS7834093B2Increase surface polarityGood paint adhesionBathing devicesLight therapyPolyolefinPolymer chemistry

Disclosed herein is a polyolefin-based thermoplastic polymer composition, in which an acrylate copolymer phase obtained by absorbing an alkyl acrylate monomer, an alkyl methacrylate monomer, a polar group-containing acrylate monomer and a polymerization initiator into a polyolefin matrix and then polymerizing the monomers is dispersed in a polyolefin phase. The thermoplastic polymer composition has excellent surface polarity leading to excellent paint adhesion.

Owner:AXIAMATERIALS

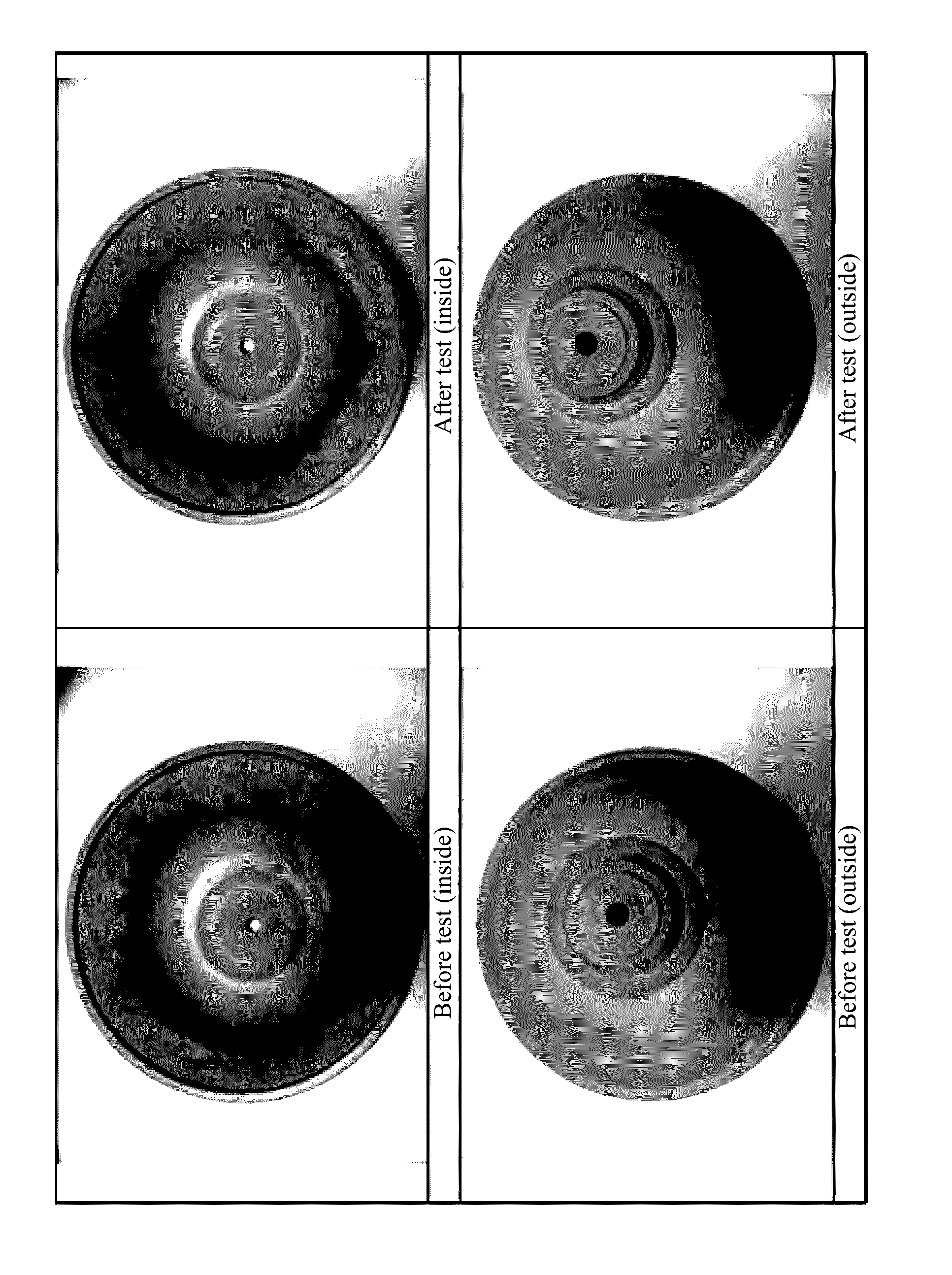

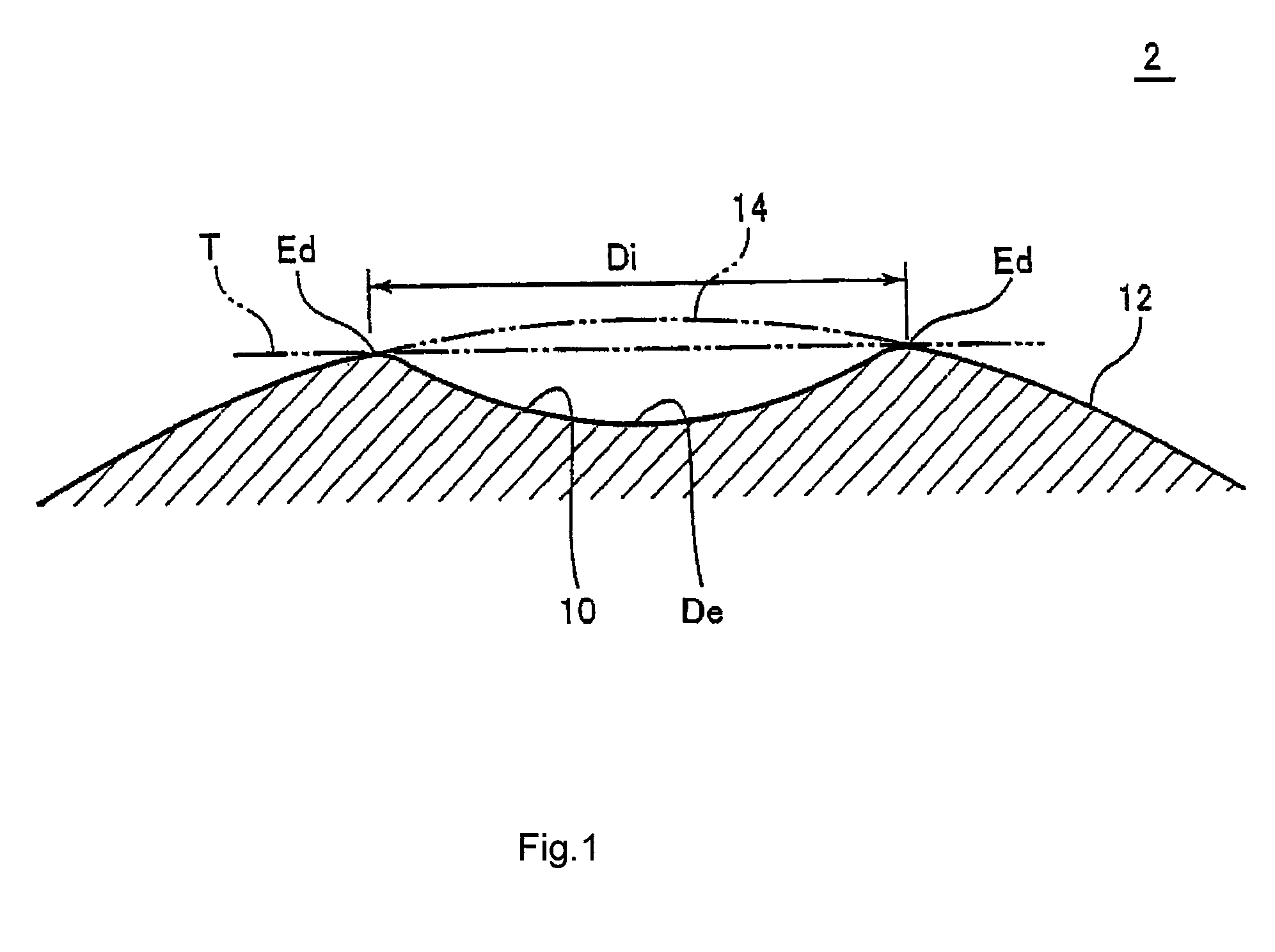

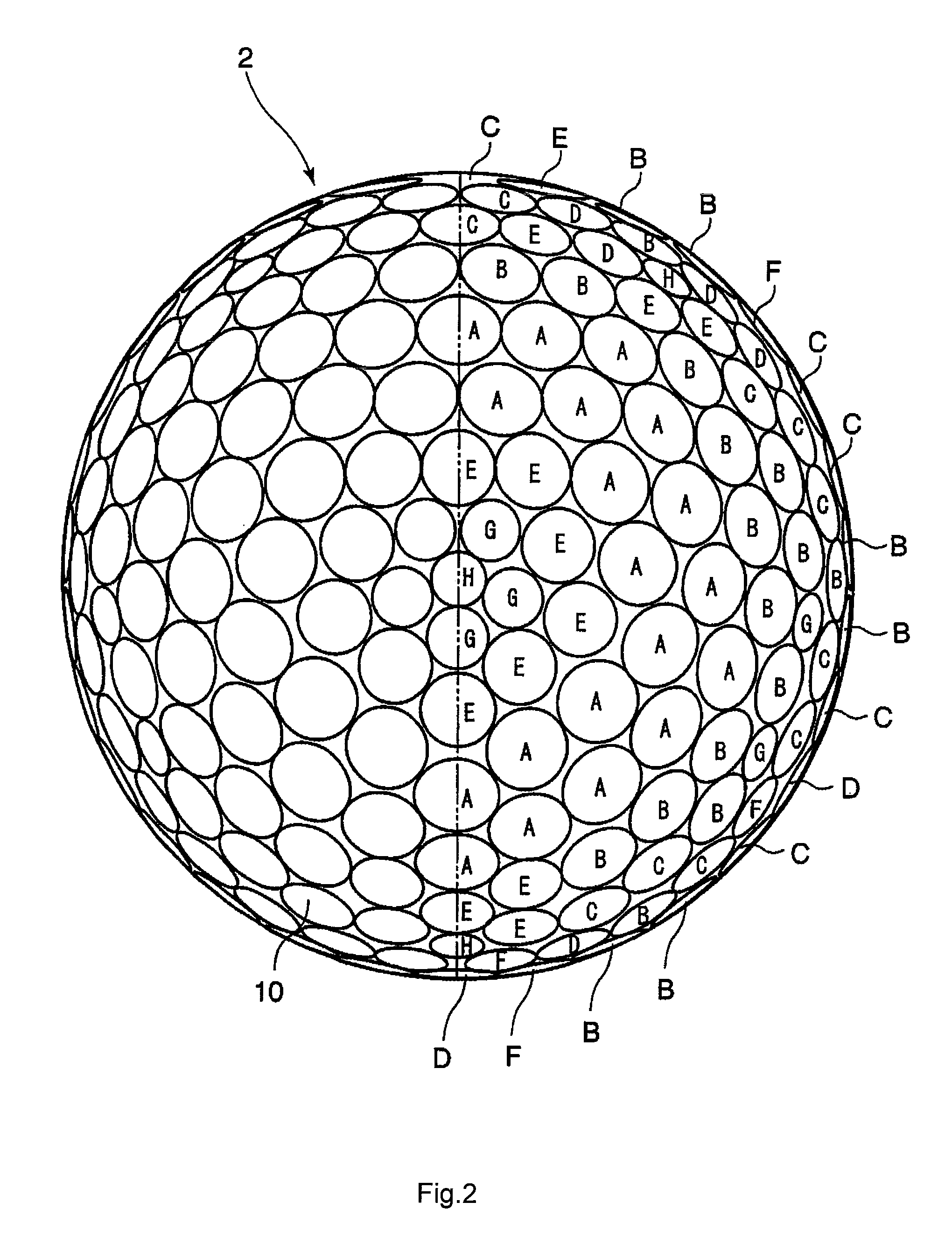

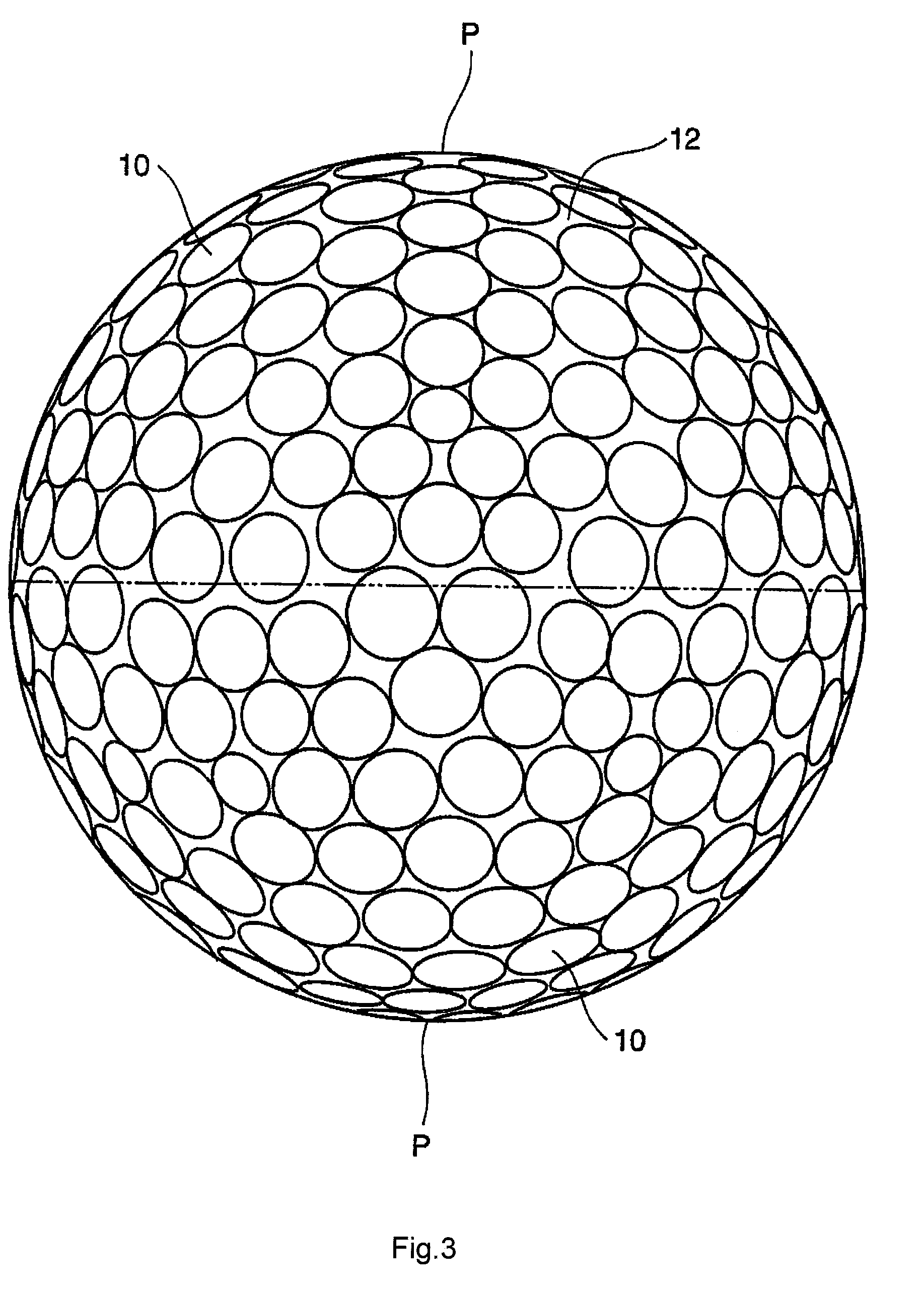

Coated one-piece golf ball

The present invention provides a coated one-piece golf ball having excellent adhesion of a paint layer to a golf ball body and good appearance. The present invention relates to a coated one-piece golf ball comprising a golf ball body formed by vulcanizing and press-molding rubber composition, and a clear paint layer formed on the golf ball body, wherein the rubber composition comprises not less than 0.5 and less than 2.0 parts by weight of titanium oxide, based on 100 parts by weight of base rubber, and the clear paint comprises 0.1 to 2.0 parts by weight of fluorescent brightener, based on 100 parts by weight of resin solid content.

Owner:SUMITOMO RUBBER IND LTD

Quaternary ammonium salts as a conversion coating or coating enhancement

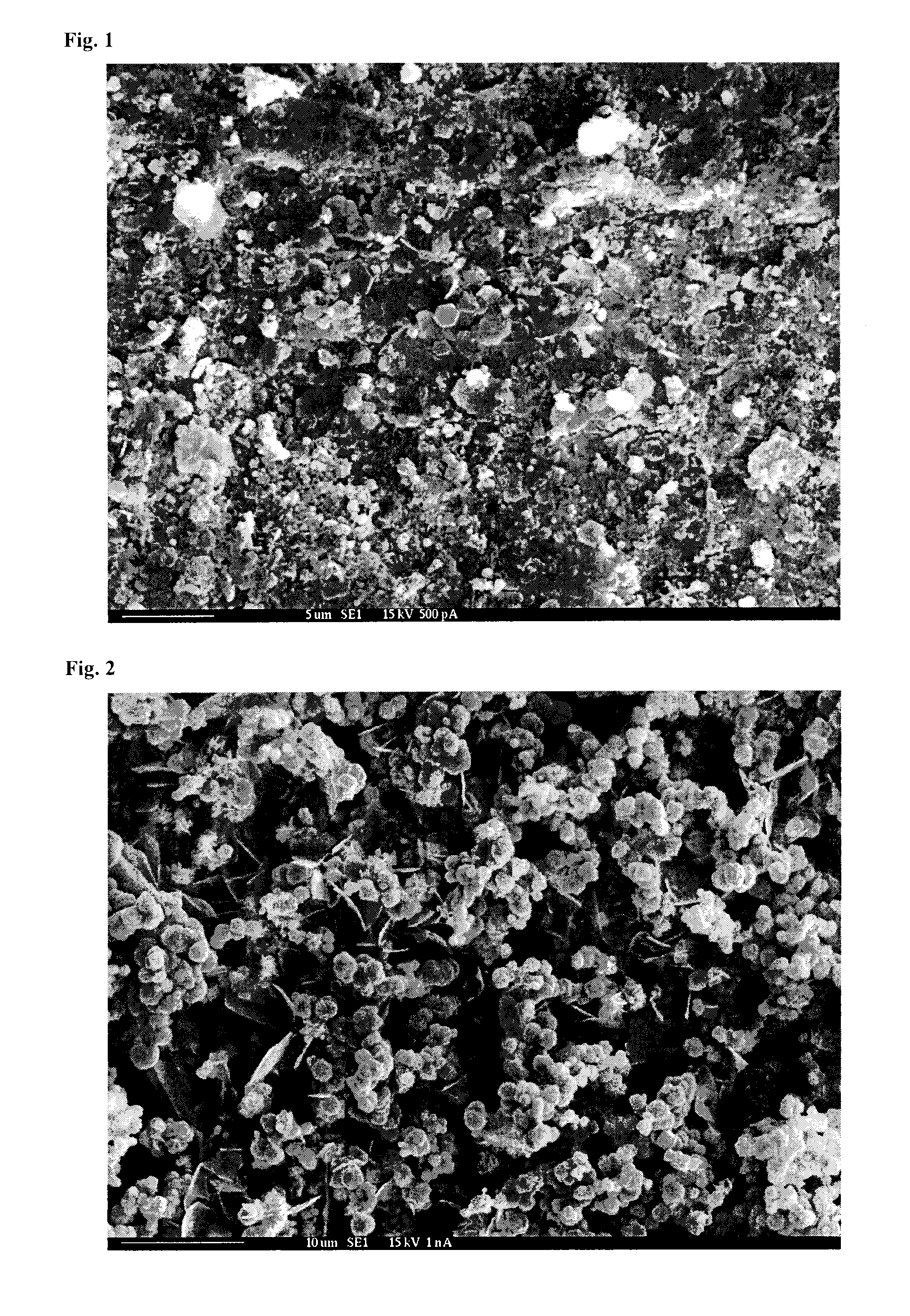

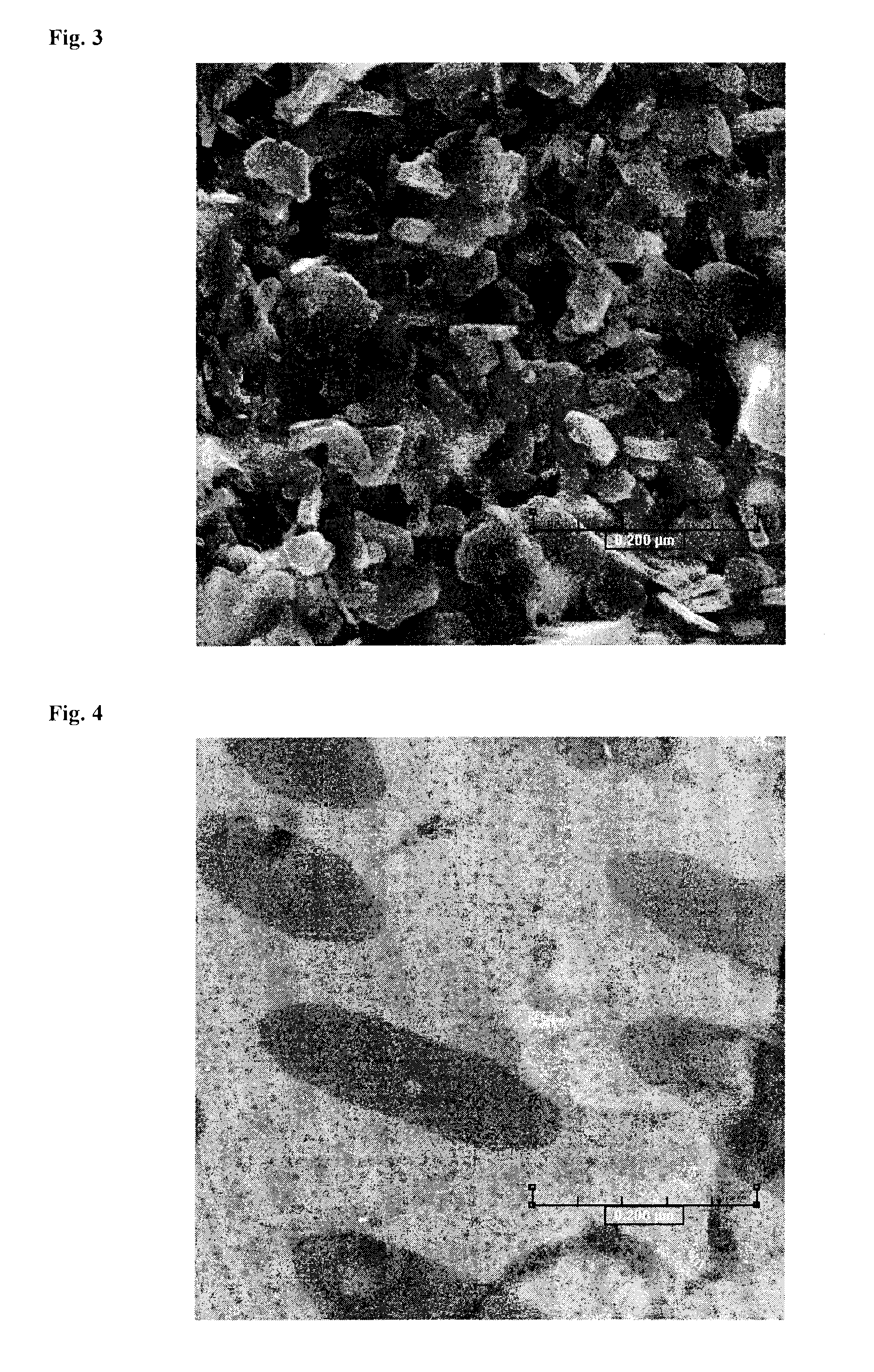

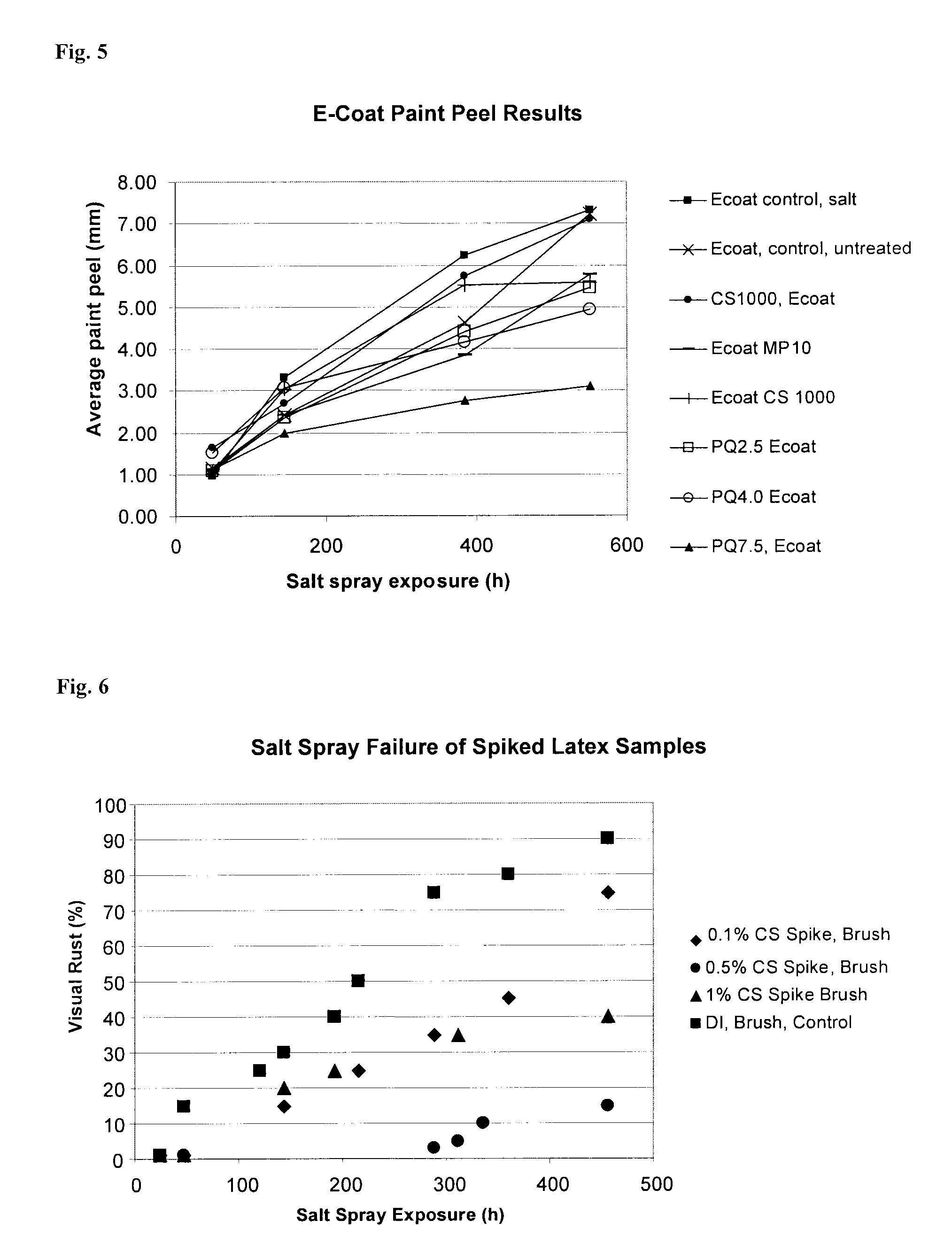

InactiveUS20060151071A1Improve adhesionGood paint adhesionAnti-corrosive paintsMetallic material coating processesGlycolatesHalogen

Disclosed are quaternary ammonium salts containing non-halogen anions such as carbonates, bicarbonates, phosphates, glycolates and mixtures thereof as conversion coatings or additives imparting anti-corrosive properties to paints. The invention relates to a method for inhibiting the corrosion of metal surfaces by applying a composition containing one or more quaternary ammonium carbonate or bicarbonate. The disclosure is also directed to anti-corrosive coatings for metal substrates containing these compounds and to metal substrates having these anticorrosive coatings.

Owner:LONZA INC

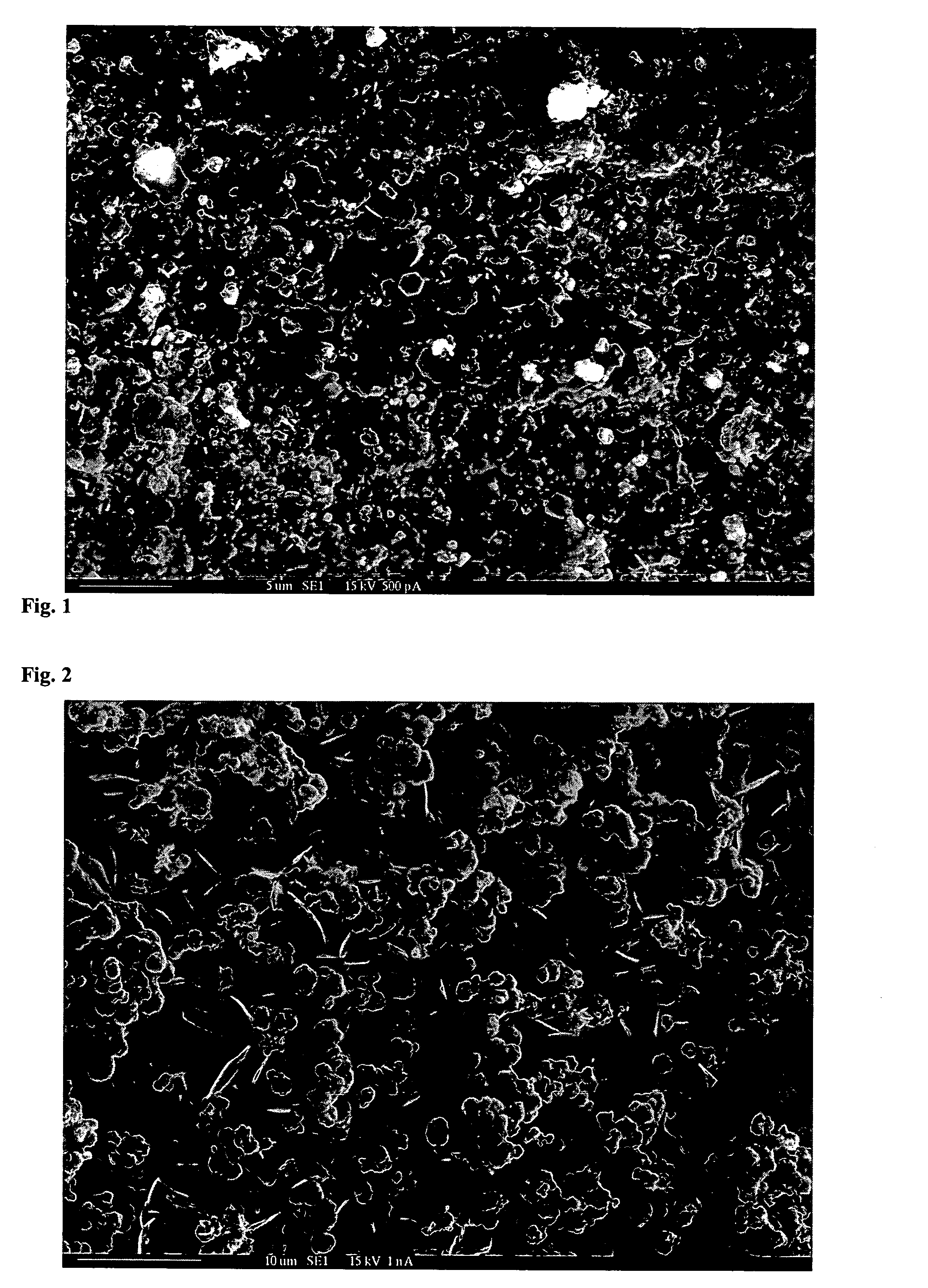

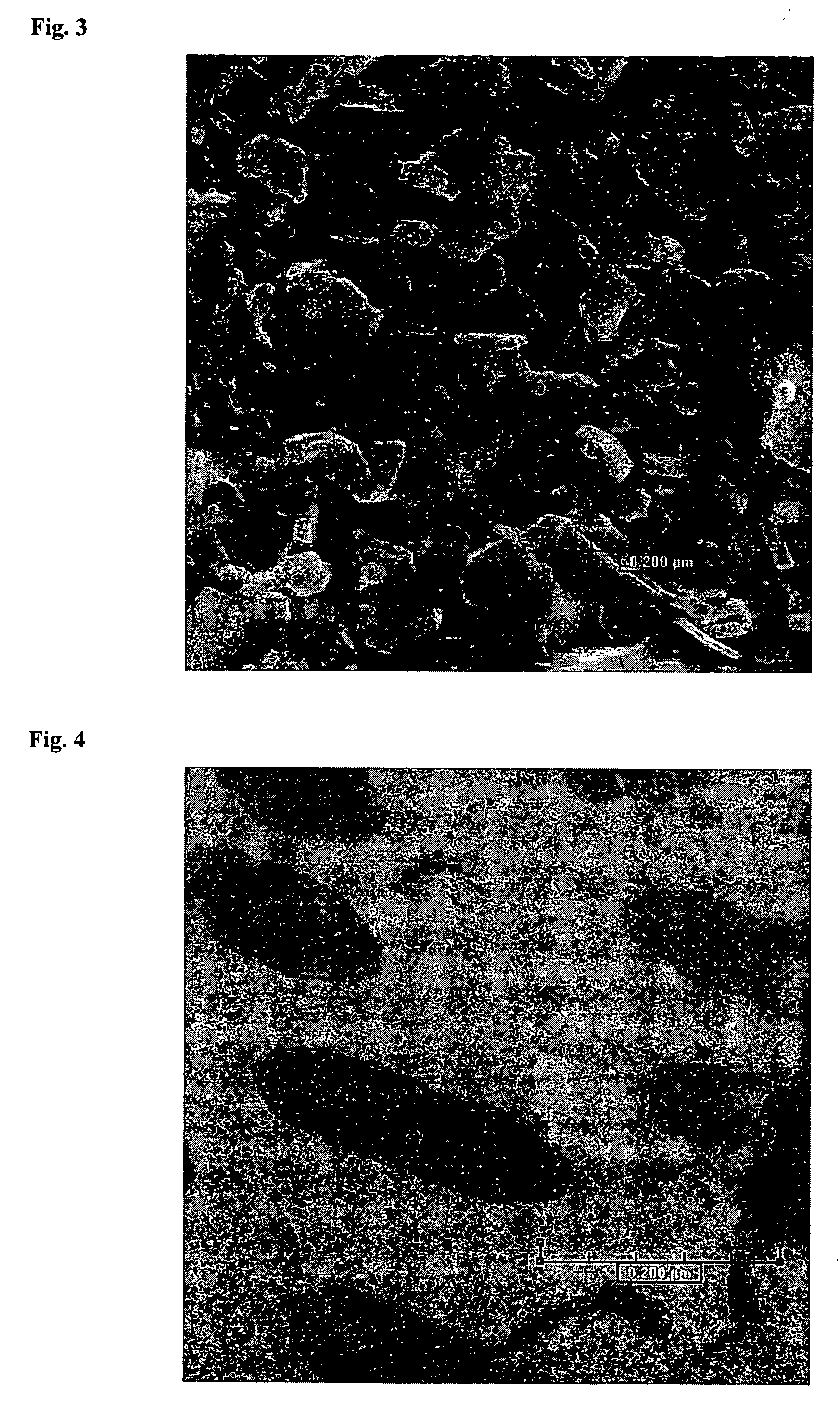

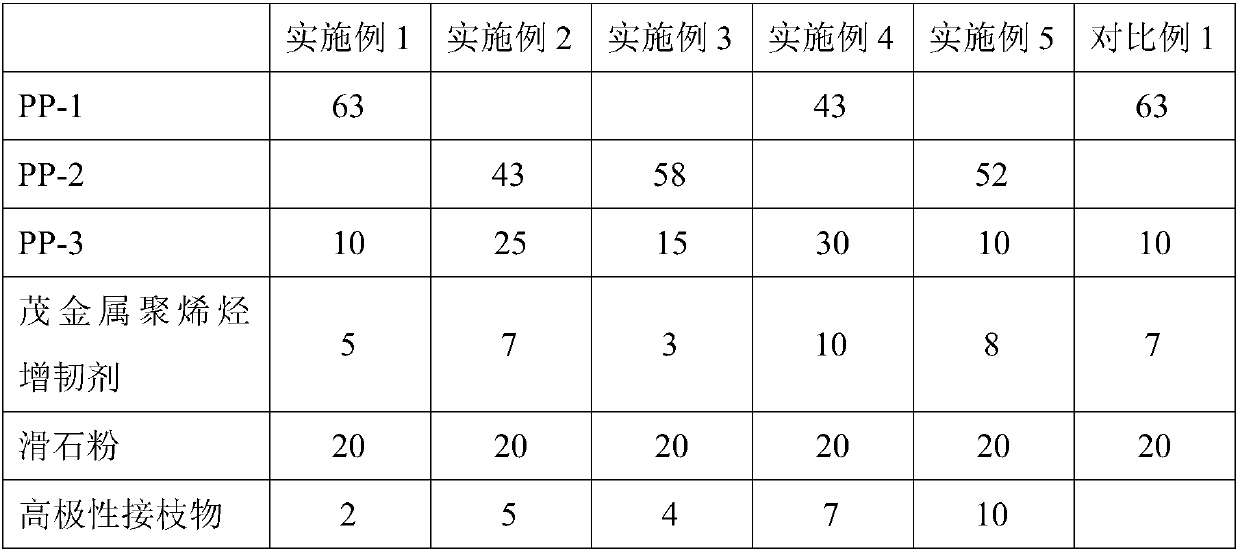

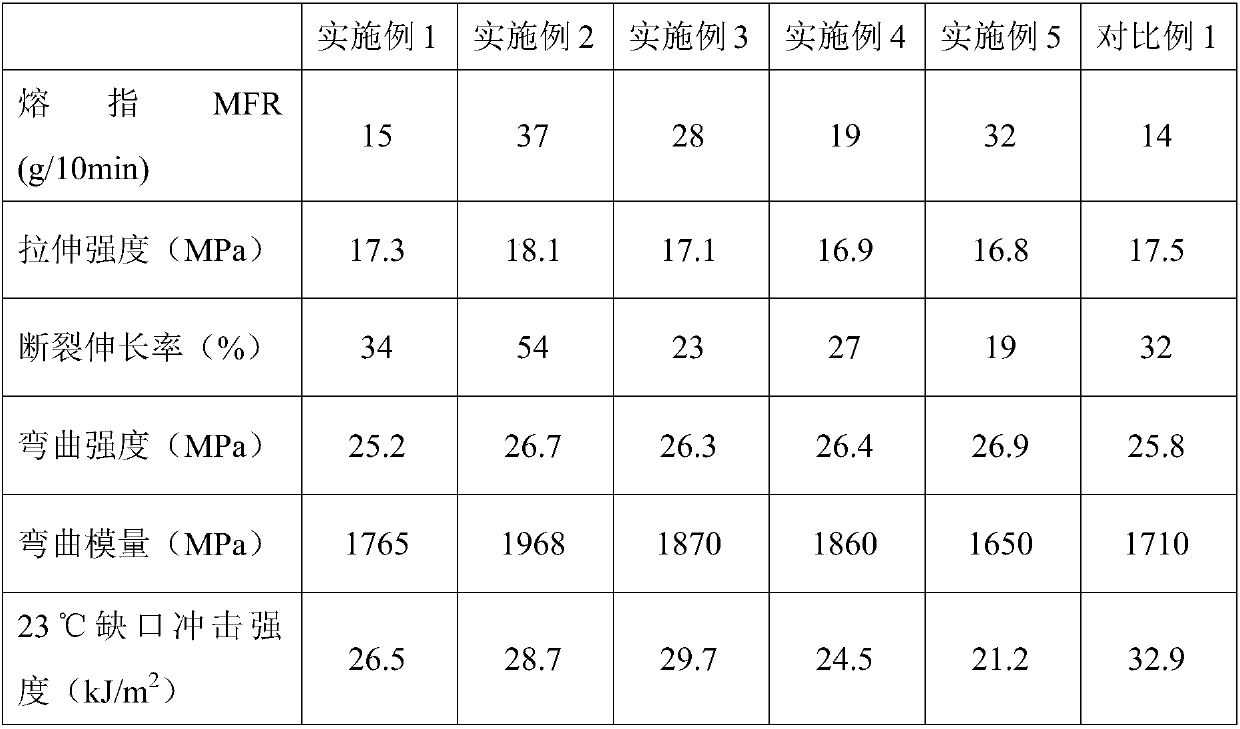

Polypropylene composite material for automobile sprayed exterior trimming parts and preparation method thereof

InactiveCN107641256AHigh-volume production featuresLow modification costPolypropylene compositesPolyolefin

The invention discloses a polypropylene composite material for automobile sprayed exterior trimming parts. The polypropylene composite material is prepared from the following raw materials in percentage by mass: 30 to 70 percent of high-impact-resistance co-polypropylene, 10 to 30 percent of high-melt-flow-index high-rigidity homo-polypropylene, 3 to 10 percent of metallocene polyolefin tougheningagent, 5 to 20 percent of talc powder and 2 to 10 percent of high-polarity graft. The invention further discloses a preparation method of the polypropylene composite material. According to the polypropylene composite material for automobile sprayed exterior trimming parts and the preparation method thereof disclosed by the invention, a high-polarity modified polymer is prepared through online melting chemical grafting; moreover, through a two-stage extruding granulator, secondary real-time melt blending of a high-activity and high-polarity modified polymer is realized, significant increase ofthe surface polarity of the obtained polypropylene composite material is ensured, and the adhesion and aging resistance of paint-coated parts are improved.

Owner:中广核俊尔(上海)新材料有限公司

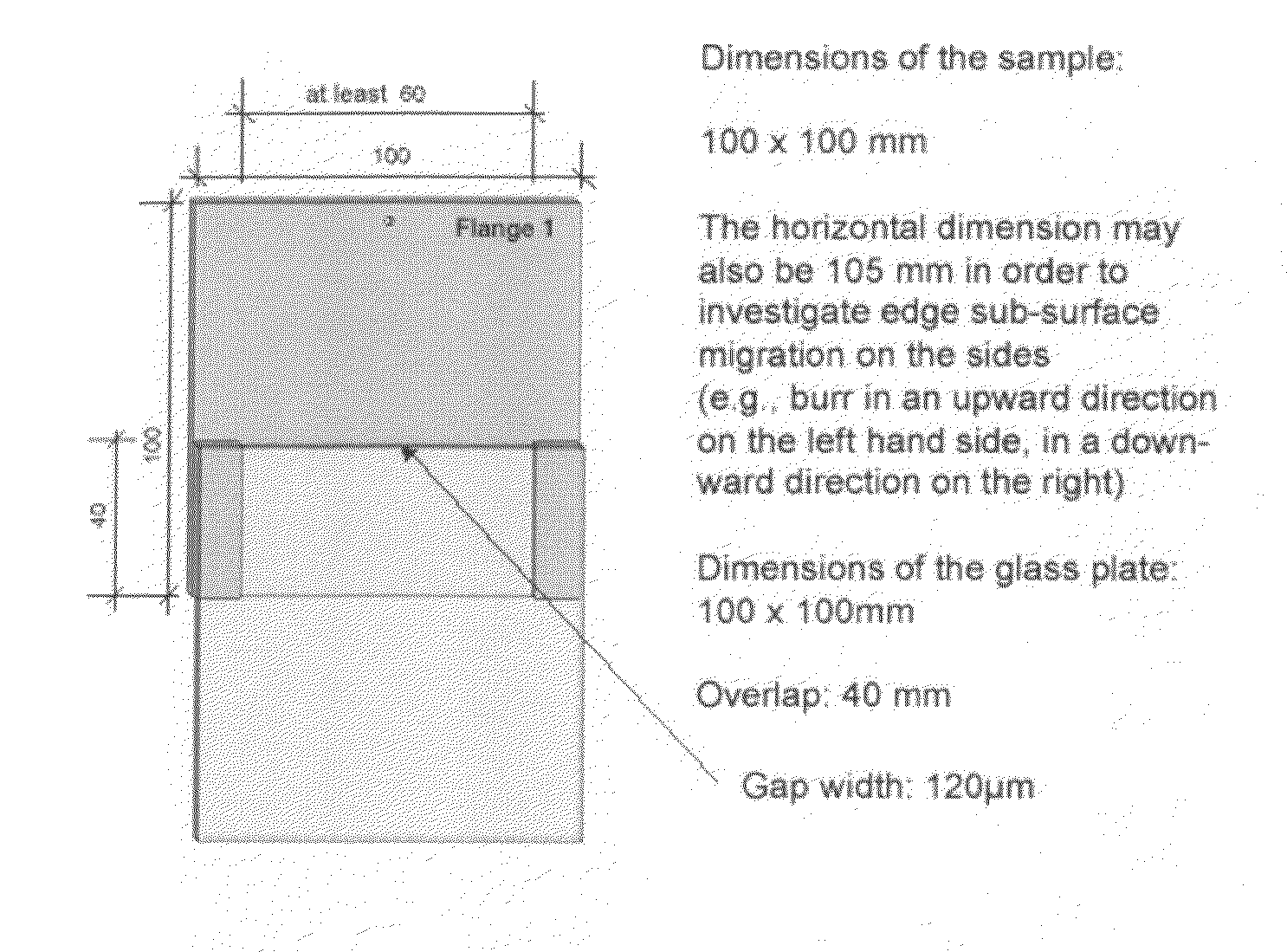

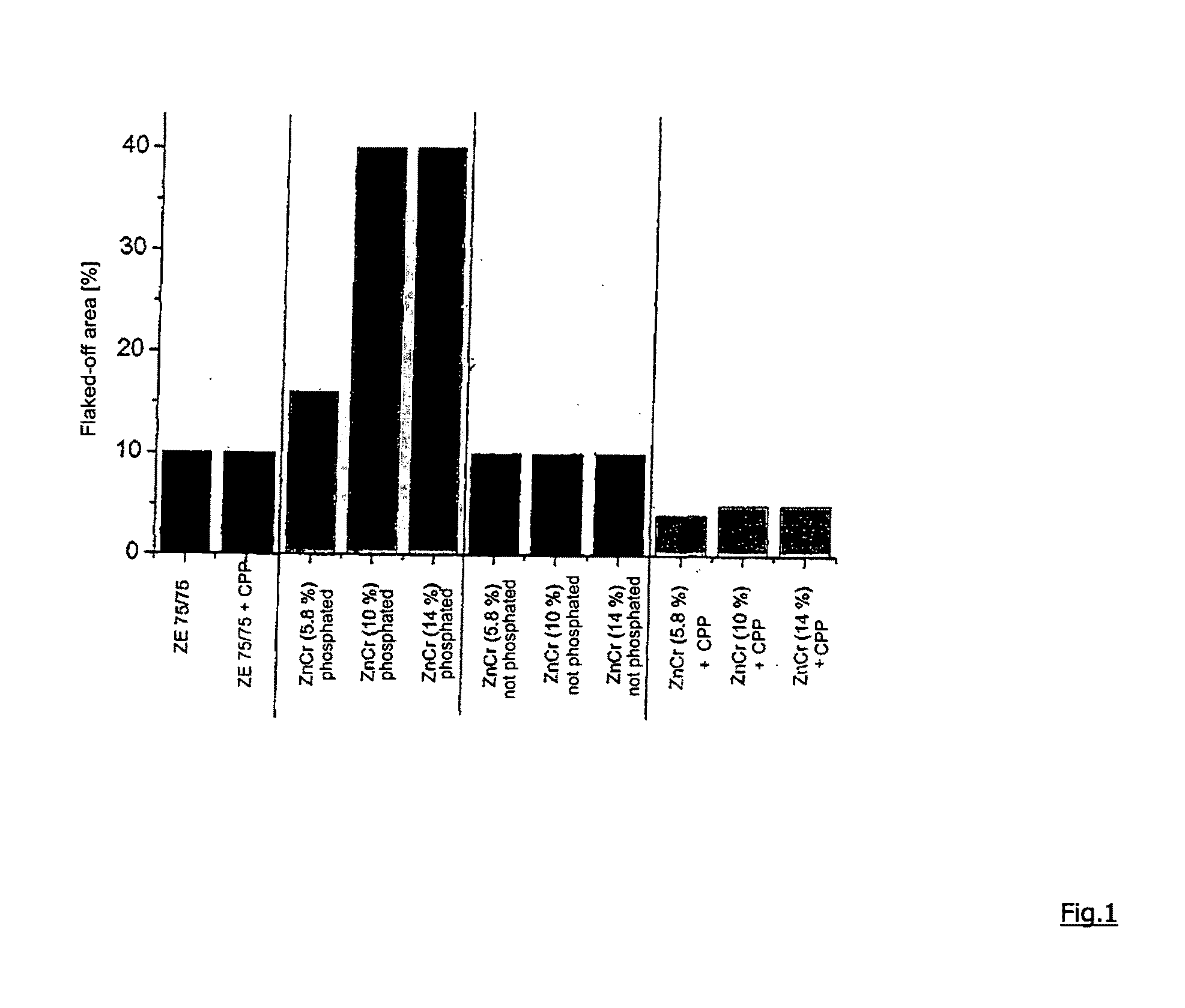

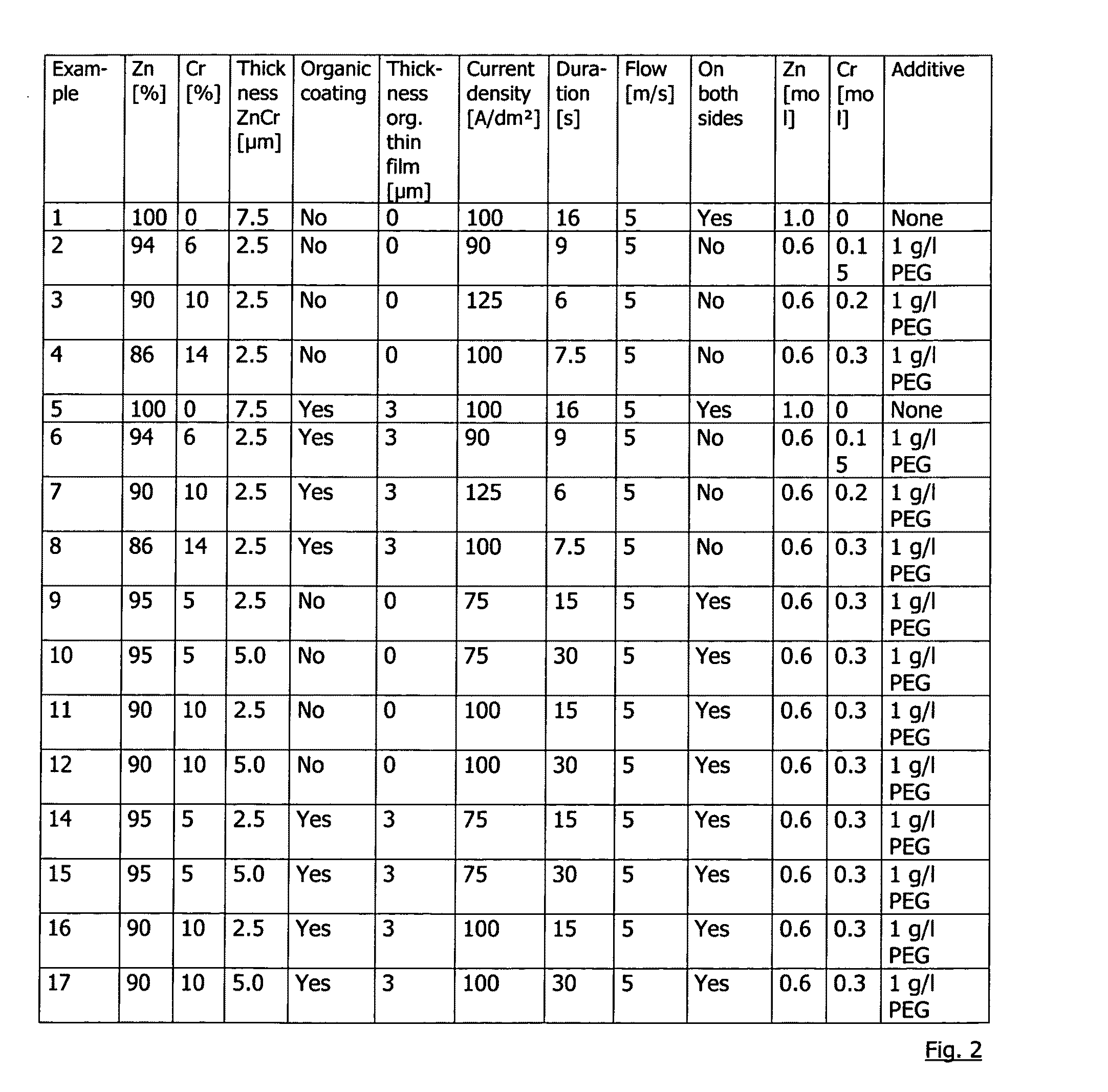

Corrosion protective layer with improved characteristics

InactiveUS20100068555A1Good paint adhesionImprove mechanical propertiesLiquid surface applicatorsAnti-corrosive paintsThin layerSynthetic resin

The invention relates to a corrosion-protective layer for protecting steel substrates from corrosion, comprising a zinc-chromium layer applied on the steel substrate by electrolytic joint deposition of zinc and chromium ions, and a chromate-free organic thin layer applied thereon, substantially comprising synthetic resins, and to a method for improving the paint adhesion of a zinc-chromium corrosion-protective layer.

Owner:VOESTALPINE STAHL GMBH

Electric conductive oxidation technique for automobile aluminum part

ActiveCN105442018AImprove anti-corrosion performanceImprove wear resistanceSurface reaction electrolytic coatingWear resistanceOxidative treatment

The invention discloses an electric conductive oxidation technique for an automobile aluminum part. The technique comprises the steps of deoiling, cleaning through clear water for multiple times, acid cleaning, an electric conductive oxidation process, drying and storage. Firstly, the aluminum alloy workpiece is subjected to deoiling treatment and then cleaned through the flowing clear water for multiple times, acid is adopted for initial surface treatment, and then an oxidation pond is energized for oxidation treatment, so that the corrosion resistance and abrasion resistance of the aluminum alloy workpiece are improved; a good coated film layer is formed on the surface of the workpiece, the adhesive force of spray paint is good, the corrosion resistance effect is good, an oxidization agent is free of pollution and environmentally friendly after the treatment, raw materials are simple, and the cost is low.

Owner:ANHUI BOWEI CHANGAN ELECTRONICS

Non-slip wear-resistant floor coating and preparation method

The invention discloses a non-slip wear-resistant floor coating and a preparation method, and belongs to the technical field of decorative coatings. The coating comprises modified polyacrylic resin, silicone acrylic emulsion, titanium dioxide, lime powder, paste attapulgite clay, alumina, filler, defoamer and pigment. The preparation method includes the following steps: firstly adding the modified polyacrylic resin and water to a reaction kettle, adding the paste attapulgite clay, the alumina and the titanium dioxide after heating and stirring, mixing and reacting for 1-2h, then adding the silicone acrylic emulsion for ultrasonic treatment for 20-30min, adding the lime powder, filler and defoamer with stirring and shearing for 5-10min, and adding the pigment into the mixture prior to mixing evenly to obtain the coating. The coating has good non-slip performance, greatly improves use safety for users, and has good wear resistance, good coating adhesiveness and high use value.

Owner:温州月煌科技有限公司

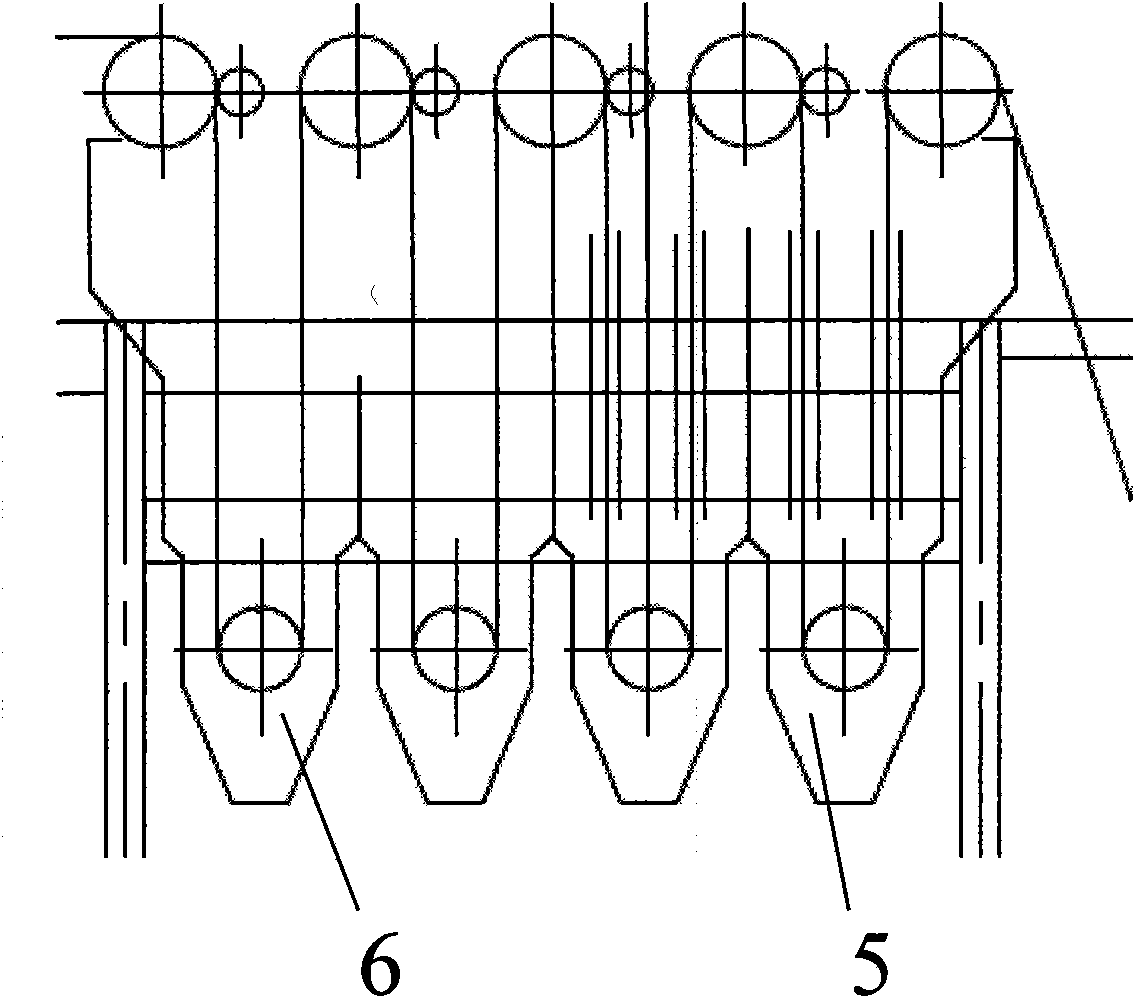

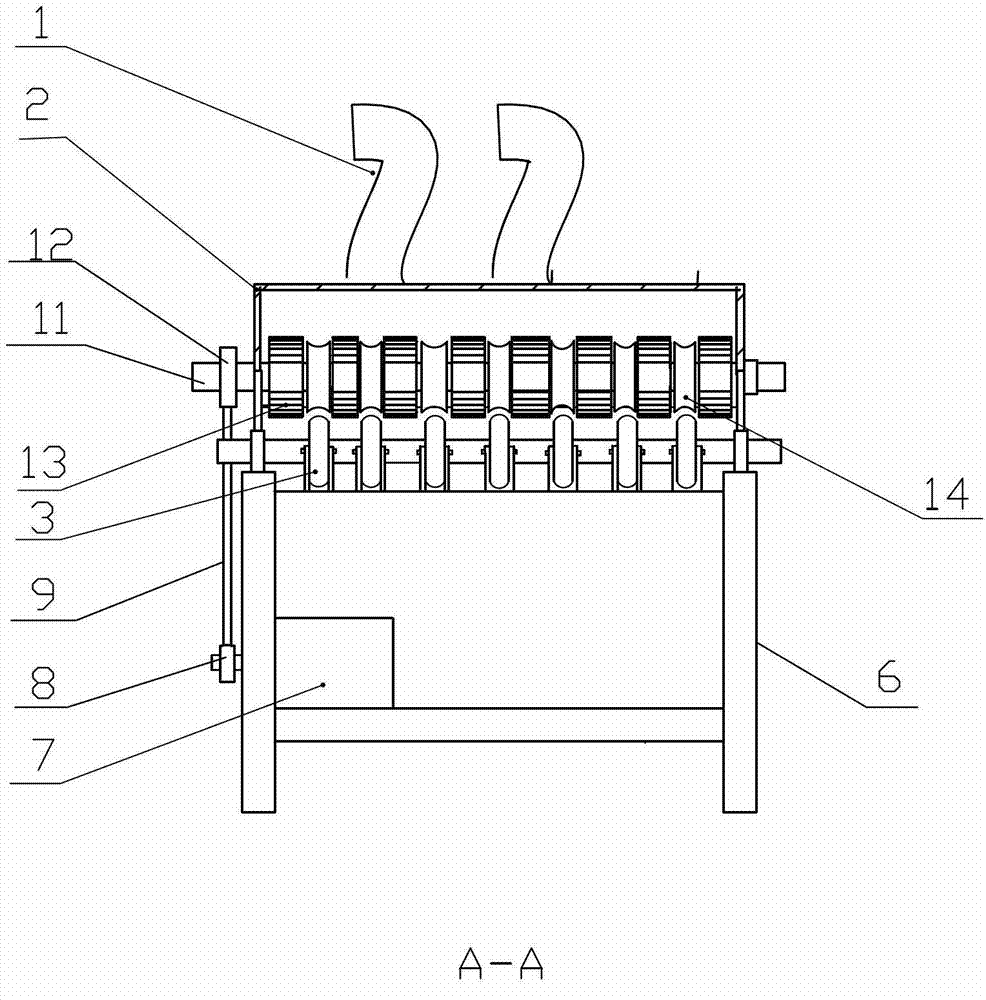

Surface polisher for contour plates

InactiveCN103240649AGood paint adhesionEasy to useGrinding drivesPlane surface grinding machinesUltimate tensile strengthMechanical engineering

The invention discloses a surface polisher for contour plates, and belongs to a polishing device. The surface polisher structurally comprises a frame, a polishing mechanism and conveying mechanisms; the polishing mechanism and the conveying mechanisms are arranged on the upper portion of the frame; the conveying mechanisms include a front conveying mechanism and a rear conveying mechanism; the polishing mechanism is arranged between the front conveying mechanism and the rear mechanism which are both connected with a conveying motor; and multiple supporting rollers are arranged on the lower portion of the polishing mechanism. Compared with the prior art, the surface polisher for the contour plates has the advantages that labor intensity of operators is reduced, working efficiency is improved, paint adhesion of the contour plates is good, service life is prolonged, convenience in use is realized, and the like. Therefore, the surface polisher has good popularization and application values.

Owner:JINAN TONEC ENERGY SAVING

Archaized solid wood composite floor and production process thereof

PendingCN111749425ANo pollution in the processSave resourcesNatural patternsWood veneer joiningSolid woodAdhesive

The invention belongs to the technical field of building materials, and relates to an archaized solid wood floor, in particular to an archaized solid wood composite floor. A crisscross multilayer board base material layer is taken as a main body, the surface of the multilayer board base material layer is coated with adhesive to form a bonding layer, a surface layer is attached, a special archaizedprocessing layer is further arranged on the surface layer, and the uppermost layer is a UV paint layer. The special archaized layer is located between the surface layer and the surface UV paint layer, the thickness of the special archaized layer is between 0.1 mm and 1 mm, and the special archaized layer comprises a hand scraping archaized layer, a wire drawing process layer, a sawtooth grain treatment layer, a color coating process layer, a sand mark treatment layer and a color wiping treatment layer from top to bottom. The present invention also discloses a production process. According tothe archaized solid wood composite floor, the natural texture and the natural color of the wood are retained, the production process is simple, no distortion is lost in the texture pattern, the floorhas good visual characteristics through post-processing, and has relatively high paint adhesion and the like, and the physical and mechanical properties of the produced archaized floor meet the requirements of various indexes.

Owner:圣象地板(句容)有限公司

Method of making a golf ball

InactiveUS20020100993A1Good paint adherenceGood thickness uniformityPretreated surfacesAuxillary shaping apparatusProduction rateEngineering

Owner:SUMITOMO RUBBER IND LTD

Environmental-friendly heat-insulating self-cleaning weatherable floor paint and preparation method thereof

InactiveCN108342140AGood stabilityNot easy to fadeFireproof paintsAntifouling/underwater paintsEmulsionPolyolefin

The invention discloses an environmental-friendly heat-insulating self-cleaning weatherable floor paint and a preparation method thereof. The paint comprises, by weight, 50-60 parts of acrylic hydroxyemulsion, 15-25 parts of silicon acrylic emulsion, 20-30 parts of compound resin, 8-10 parts of pigment filler, 20-30 parts of ore powder, 7-11 parts of heat-insulating additive, 3-5 parts of coupling agent, 6-8 parts of nano additive, 10-14 parts of flame-retardant smoke inhibitor, 2-4 parts of processing agent and 1-2 parts of polyolefin wax. The paint has the advantages of being low in thermalconductivity, good in heat-insulating effect, better in waterproofing and skid resisting performance, fine, good in adhesive force, good in leveling property, excellent in touch feeding, good in stability, compact in surface, stain resistant and excellent in self-cleaning performance, and the paint has a certain sterilizing and mildew proofing performance; components of raw materials of the paintare safe and reliable, free from toxin and have no harm, the raw materials are easy to obtain, the cost of the paint is lower, the process is simple and clear, the process is easy to operate, and theindustrialized production is easy to achieve, so that the paint has higher practical value and better application prospects.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

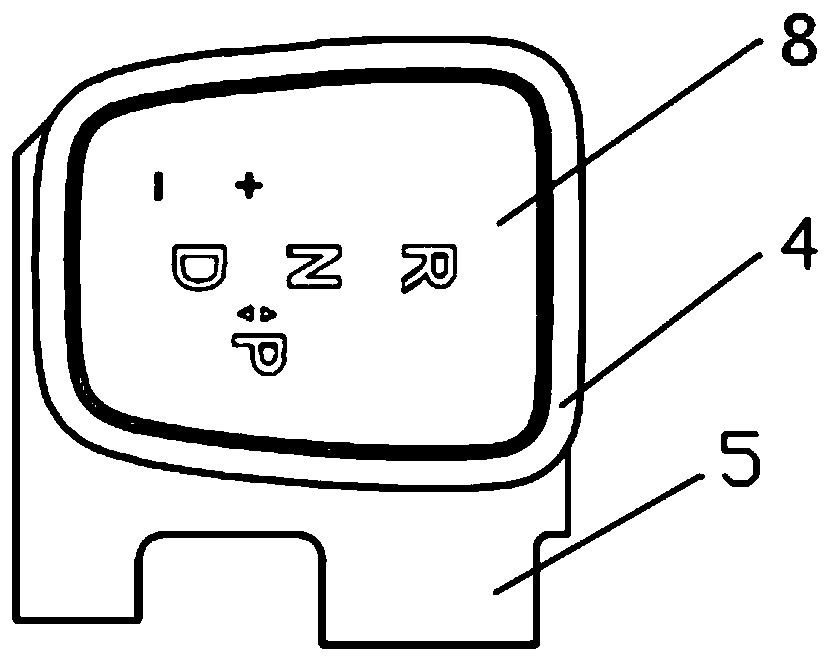

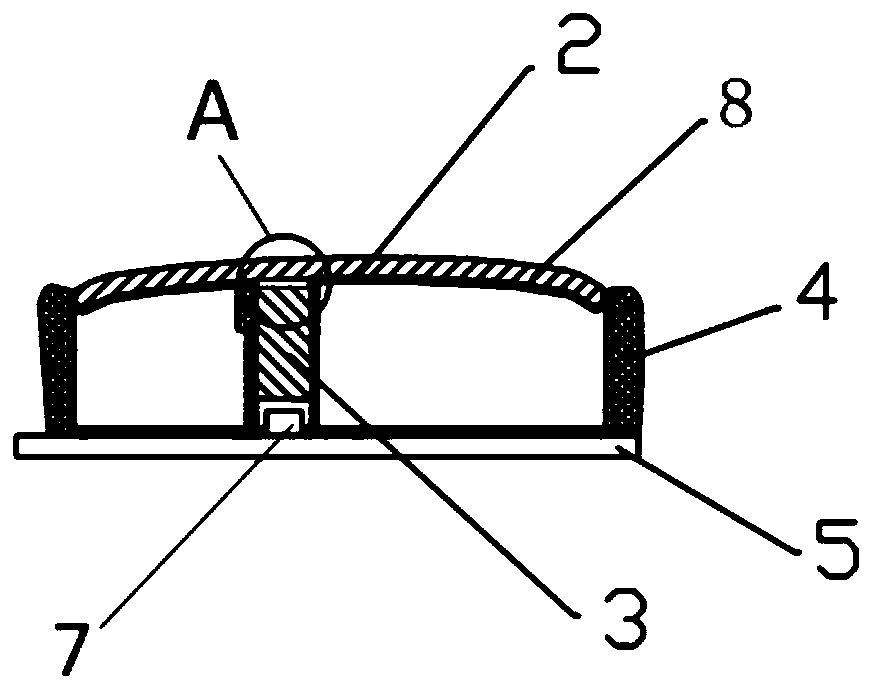

Dark-surface light-transmitting automobile electronic gear position indication panel and manufacturing method thereof

ActiveCN110660340AGood for clear displayGood light transmissionIlluminated signsLight guideBlack paint

The invention relates to a dark-surface light-transmitting automobile electronic gear position indication panel and a manufacturing method thereof. The gear position indication panel comprises a fixedblock, a transparent panel arranged at the top of the fixed block, a black paint layer arranged between the transparent panel and the fixed block, a light-emitting LED circuit board arranged at the bottom of the fixed block and a light guide block embedded in the fixed block; and the black paint layer comprises a plurality of characters of black paint and highlight black paint located on the peripheries of the characters of black paint. The manufacturing method comprises the following steps: 1) preparing the transparent panel; 2) spraying the highlight black paint at the bottom of the transparent panel; 3) engraving a gear position character area on the highlight black paint; 4) printing the characters of black paint in the gear position character area; and 5) assembling the transparent panel, the fixed block, the light-emitting LED circuit board and the light guide block together to obtain the gear position indication panel. Compared with the prior art, the gear position indication panel in the invention has the advantages that the structure is simple, the manufacturing method is convenient and fast, the problem that gear position characters are not clearly displayed can be effectively solved, and a good application prospect is achieved.

Owner:上海子元汽车零部件有限公司

Surface treatment agent, surface treatment method, and surface treated metal material

ActiveUS20180187312A1Improve corrosion resistanceGood paint adhesionElectrophoretic coatingsSuperimposed coating processWater solubleSurface finishing

A surface treatment agent which is chromate-free and which can impart excellent coating adhesion and corrosion resistance to a metal material (in particular, a metal material treated with a phosphate), a surface treatment method that uses the surface treatment agent, and a surface treated metal material that is treated using the method are provided. The agent is for a metal material and contains a water-soluble ethylene glycol monoalkyl ether. It is preferable for this surface treatment agent to contain at least one type of metal compound selected from among a water-soluble vanadium compound, a water-soluble titanium compound, a water-soluble zirconium compound and a water-soluble hafnium compound.

Owner:NIHON PARKERIZING

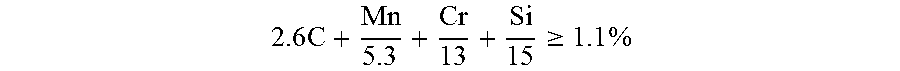

Method for the manufacture of a phosphatable part starting from a steel sheet coated with a metallic coating based on aluminum

ActiveUS11414737B2Easy to implementHigh coverage rateHot-dipping/immersion processesFurnace typesMetal coatingThermoforming

A method for the manufacture of a hardened part coated with a phosphatable coating is provided. The method includes providing a steel sheet pre-coated with a metallic coating including from 4.0 to 20.0% by weight of zinc, from 1.0 to 3.5% by weight of silicon, optionally from 1.0 to 4.0% by weight of magnesium, and optionally additional elements chosen from Pb, Ni, Zr, or Hf, the content by weight of each additional element being less than 0.3% by weight, the balance being aluminum and unavoidable impurities and residuals elements. The steel sheet is cut to obtain a blank, the blank is thermally treated at a temperature between 840 and 950° C. to obtain a fully austenitic microstructure in the steel, the blank is transferred into a press tool and hot-formed to obtain a part. The part is cooled to obtain a martensitic or martensitic-bainitic microstructure or made of at least 75% of equiaxed ferrite, from 5 to 20% of martensite and bainite in amount less than or equal to 10%.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Ground skid-resistant coating for bathroom and preparation method thereof

InactiveCN107418429AAvoid falling off, etc.Extended service lifeEmulsion paintsEmulsionDefoaming Agents

The invention discloses a ground skid-resistant coating for a bathroom. The coating contains the following raw materials in parts by weight: 60-80 parts of modified epoxy resin, 20-30 parts of silicone acrylic emulsion, 2-10 parts of talcum powder, 12-18 parts of titanium dioxide, 15-20 parts of lime powder, 15-22 parts of paste type attapulgite, 2-4 parts of O-diphenylsulfonic acid, 1-10 parts of nano materials, 9-15 parts of aluminium oxide, 17-25 parts of filler, 3-8 parts of a defoaming agent and 1-3 parts of pigment. The ground skid-resistant coating for the bathroom, provided by the invention, has good waterproof and skid resistant performances, and the use safety of a user is greatly improved, so that the potential safety hazard caused by slipping due to slip ground when people shower in the bathroom can be avoided.

Owner:合肥聪亨新型建材科技有限公司

A kind of agricultural equipment gearbox coating line and its coating method

ActiveCN107138335BEfficient removalReduce pollutionPretreated surfacesCoatingsAgricultural engineeringElectric machinery

The invention discloses an agricultural equipment gearbox coating line which comprises a line feeding area, a washing area, a drying area, a paint spraying area, a levelling area, a finishing coat drying area, a line discharging area, a rail, a coating assembly line chain, a plurality of lifting appliance assemblies and a drive motor, wherein the line feeding area, the washing area, the drying area, the paint spraying area, the levelling area, the finishing coat drying area and the line discharging area are sequentially connected; the rail is fixedly arranged at the top of the entire agricultural equipment gearbox coating line; the coating assembly line chain is connected with the drive motor; the coating assembly line chain is connected with the rail; driven by the drive motor, the coating assembly line chain moves along the rail; the lifting appliance assemblies are fixed on the coating assembly line chain; and gearboxes are lifted through the lifting appliance assemblies at the line feeding area. The agricultural equipment gearbox coating line is reasonable in structure, light and convenient to operate, excellent in coating effect and high in paint adhesive force, and the agricultural equipment gearbox coating line and a coating method thereof can meet the using requirements.

Owner:山东卫禾传动股份有限公司

High corrosion resistant surface treated magnesium alloy product and its Manufacturing process

InactiveCN1238556CImprove coating adhesionEquivalent to finish adhesionMetallic material coating processesSodium acetateAcetic acid

Disclosed is a method for processing high corrosion resistance surface treated magnesium alloy product, the surface of an aluminum-containing magnesium alloy is subjected to chemical treatment for 0.3 to 10 min with a treating solution in which the concentration of the water soluble salt of permanganic acid or manganic acid is >= 2 g / L expressed in terms of the content of KMnO4 and also less than the solubility thereof, the concentration of the water soluble salt of phosphoric acid is 0.05 to 100 g / L expressed in terms of the content of Na3PO4, the concentration of acetic acid is 0.05 to 100 ml / L, the concentration of sodium acetate is 0.05 to 50 g / L, pH is <= 7, and solution temperature is 288 to 368 K, and the high corrosion resistance surface treated magnesium alloy product is obtained by the producing method. A magnesium alloy product having a high corrosive resistance surface produced according to the present invention has a Mn adhesion of 100 to 600 mg / m2, P adhesion of < 200 mg / m2, CH3COO-adhesion of 0.01 to 1000 mg / m2.

Owner:MITSUI MINING & SMELTING CO LTD

Golf ball

InactiveUS8450425B2Increase repulsionImprove liquidityGolf ballsSolid ballsDivalent metal ionsEngineering

Owner:SUMITOMO RUBBER IND LTD

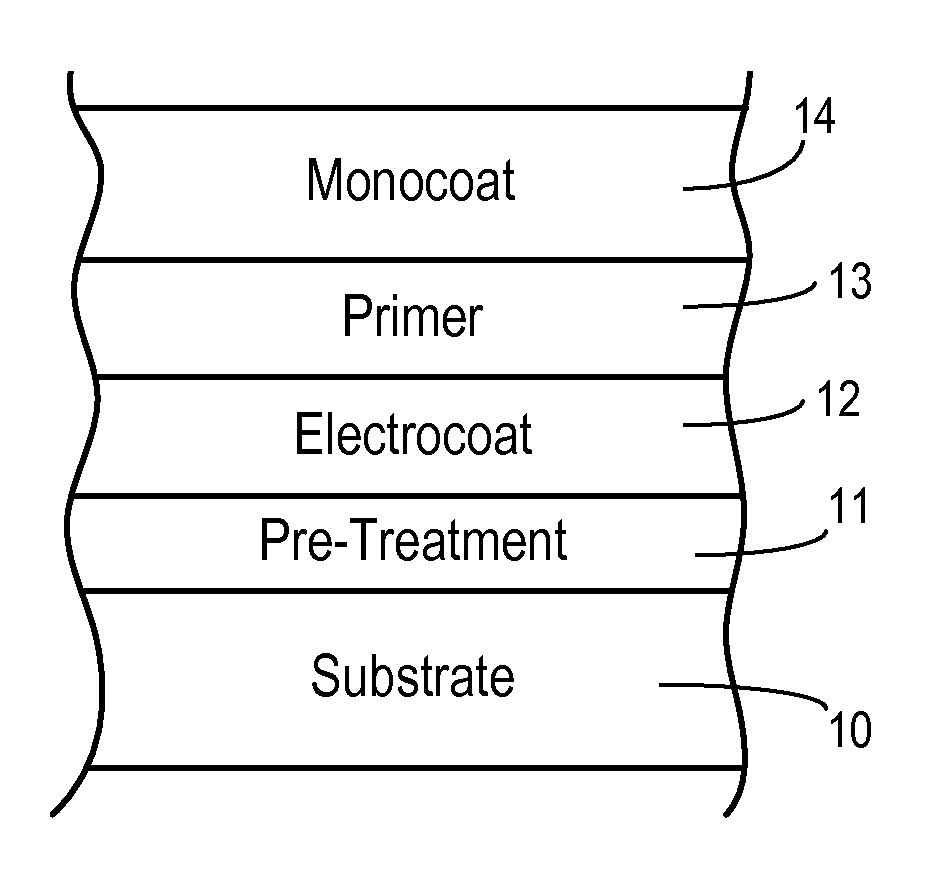

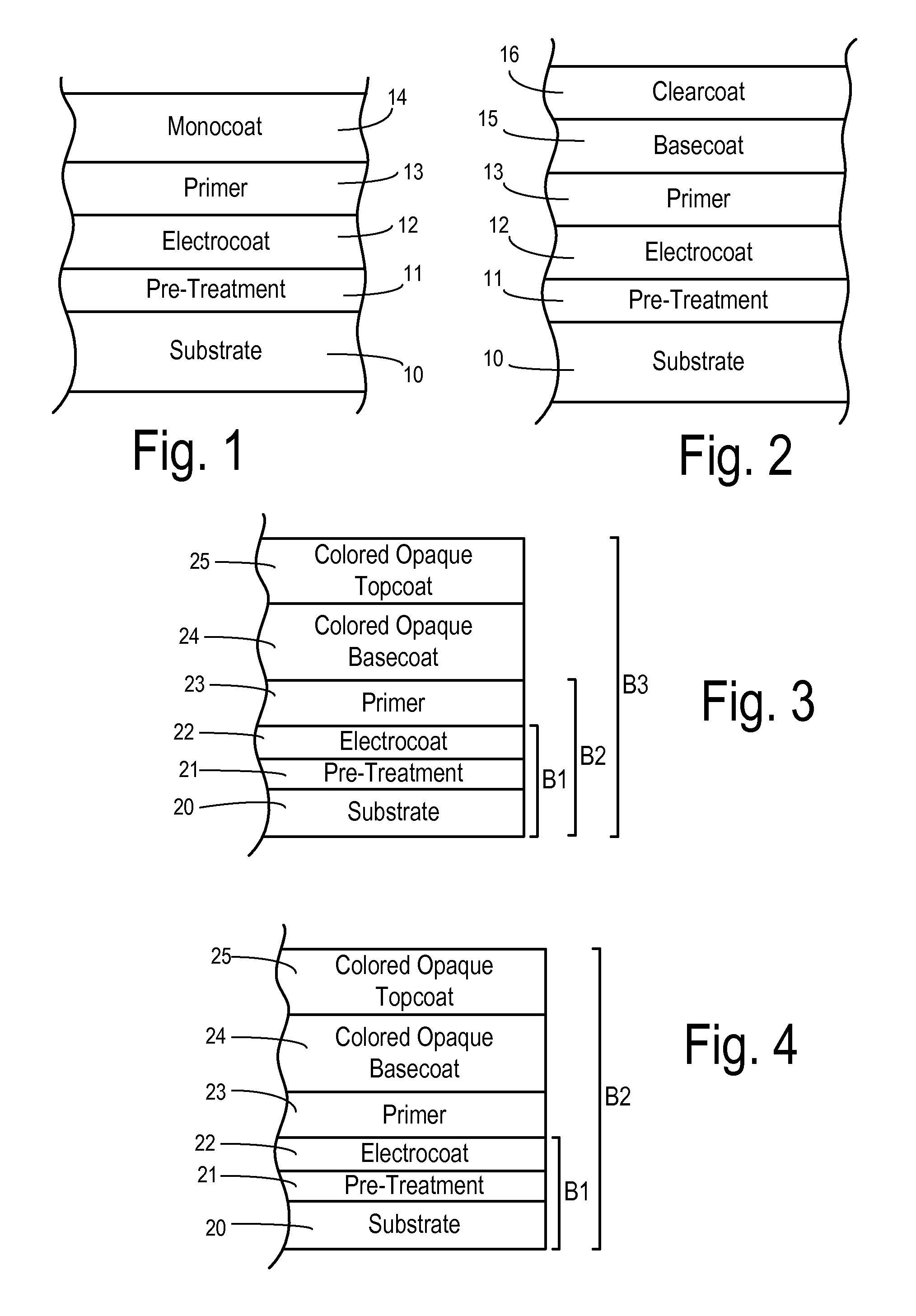

Automotive paint system for bright and vibrant colors

InactiveUS20130209761A1Good paint adhesionImprove the immunityLayered productsElectrostatic spraying apparatusAutomotive paintUltraviolet

A painted substrate forms at least a portion of an exterior body panel of a vehicle. A pre-treatment layer, and electrocoat layer, and a primer layer overlie the substrate. A colored, opaque basecoat layer overlies the primer layer and is comprised of polymeric resin and a first coloring agent. The basecoat layer is formulated to provide near ultraviolet light blocking. A colored, opaque topcoat layer overlies the basecoat layer and is comprised of polymeric resin and a second coloring agent having substantially the same color as the first coloring agent. The topcoat layer is formulated to provide a glossy appearance, chemical resistance, and scratch resistance. The topcoat layer is also formulated to provide ultraviolet blocking and paint-chip resistance greater than the ultraviolet blocking and paint-chip resistance of the basecoat layer.

Owner:FORD GLOBAL TECH LLC

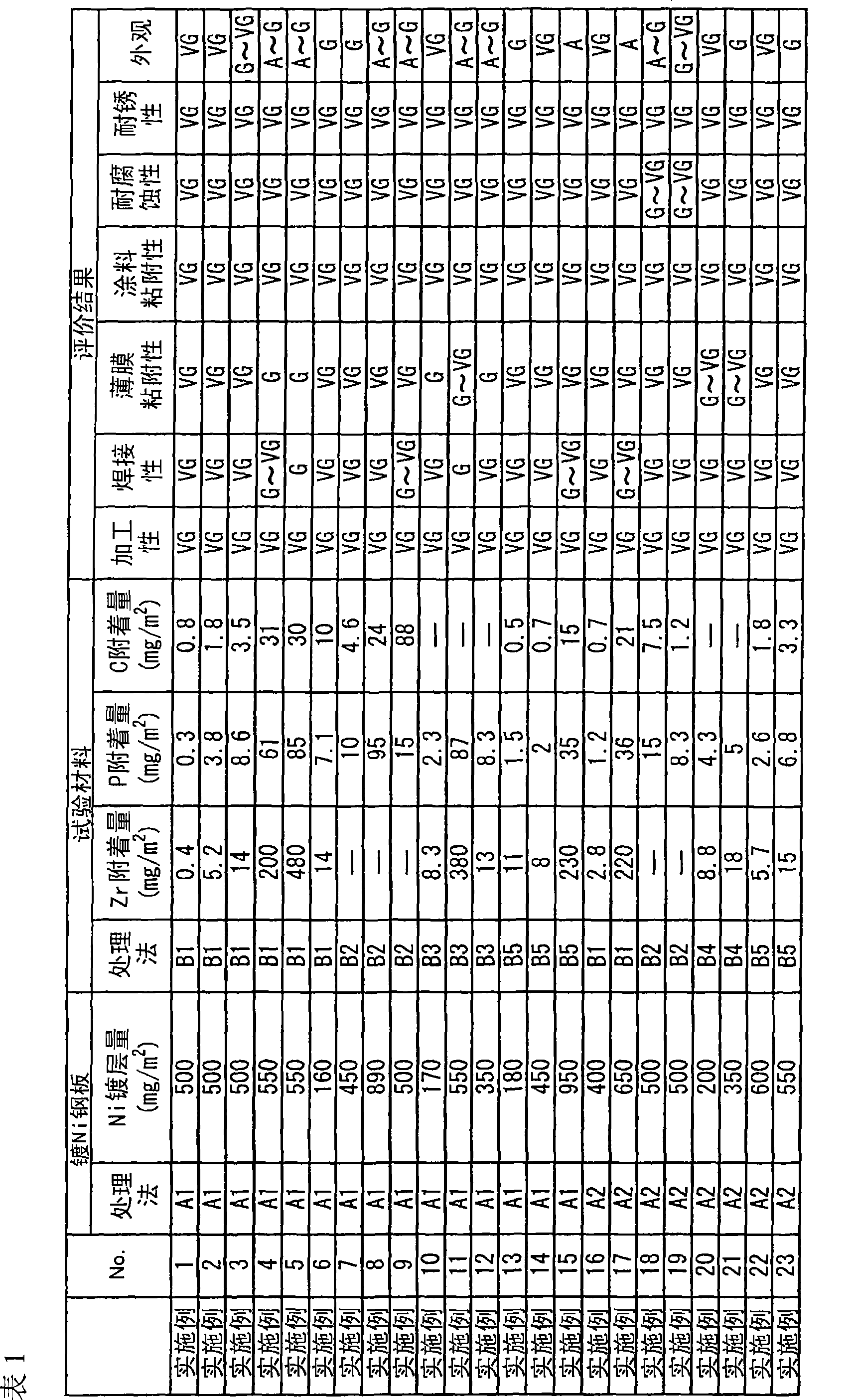

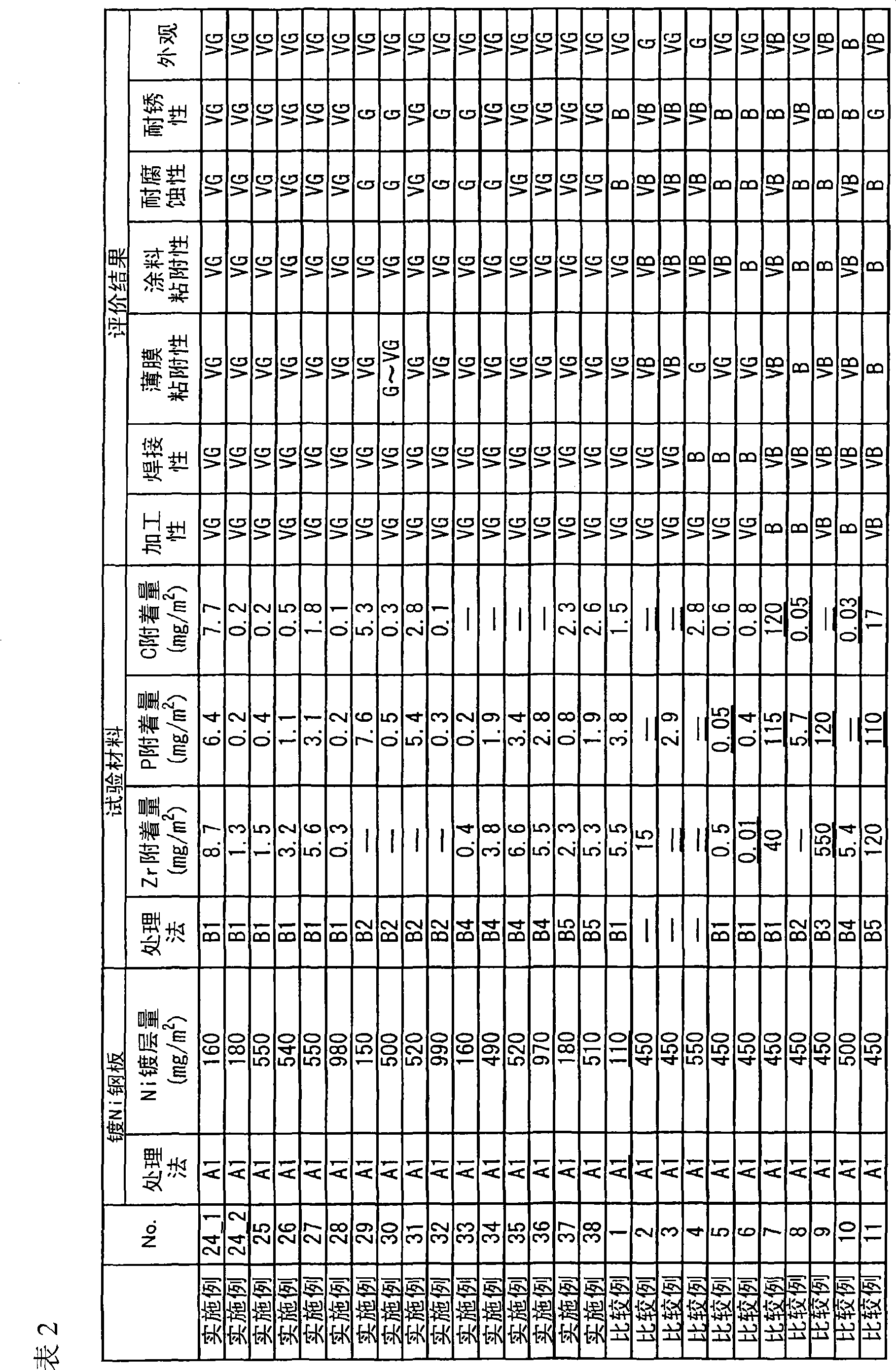

Steel plate for container, and method for production thereof

ActiveCN101466872BImprove adhesionGood lookingElectrolytic inorganic material coatingPhosphatisationO-Phosphoric AcidElectrolysis

The invention provides a steel plate for container and a manufacturing method thereof. A steel substrate has on at least one surface thereof a Ni plating layer containing 150 mg / m<2> to 1,000 mg / m<2> of Ni. A phosphoric acid coating of 0.1 mg / m<2> to 100 mg / m<2> in terms of P content and at least one of a Zr coating of 0.1 mg / m<2> to 500 mg / m<2> in terms of Zr content and a phenol resin coating of 0.1 mg / m<2> to 100 mg / m<2> in terms of C content are formed on the Ni plating layer by a cathode electrolytic treatment.

Owner:NIPPON STEEL CORP

Method for plating chrome on surface of thin plate

The invention discloses a method for plating chrome on a surface of a thin plate. The method comprises the following steps: 1) alkali washing, including alkali liquor leaching, electrolysis washing and alkali washing; 2) pickling, including electrolysis pickling and acid washing; 3) electroplating, including chromeplating and washing; and 4) oiling. The method sufficiently utilizes the performance advantage of CrO3+NH4 plating solution, optimizes the pre-treatment pickling process and electroplating parameters, particularly controls the solution concentration of alkali washing and pickling, strictly controls the current efficiency of an electroplating section and the electroplating concentration, overcomes the defects in the tradition process, generates compact metal chrome and chromic oxide layers on the surface of strip steel, realizes one-step production of an electrolytic chromium steel plate the strip steel surface of which is plated with optimally combined metal chromium and chromic oxide so as to obtain the excellent chromeplated plate with bright and uniform plating layer. Meanwhile, the method saves energy consumption, reduces pressure environment-friendly emission, reduces cost for production and maintenance, and creates a condition for improving the chromeplated plate, thus having excellent popularization and application prospect.

Owner:BAOSHAN IRON & STEEL CO LTD

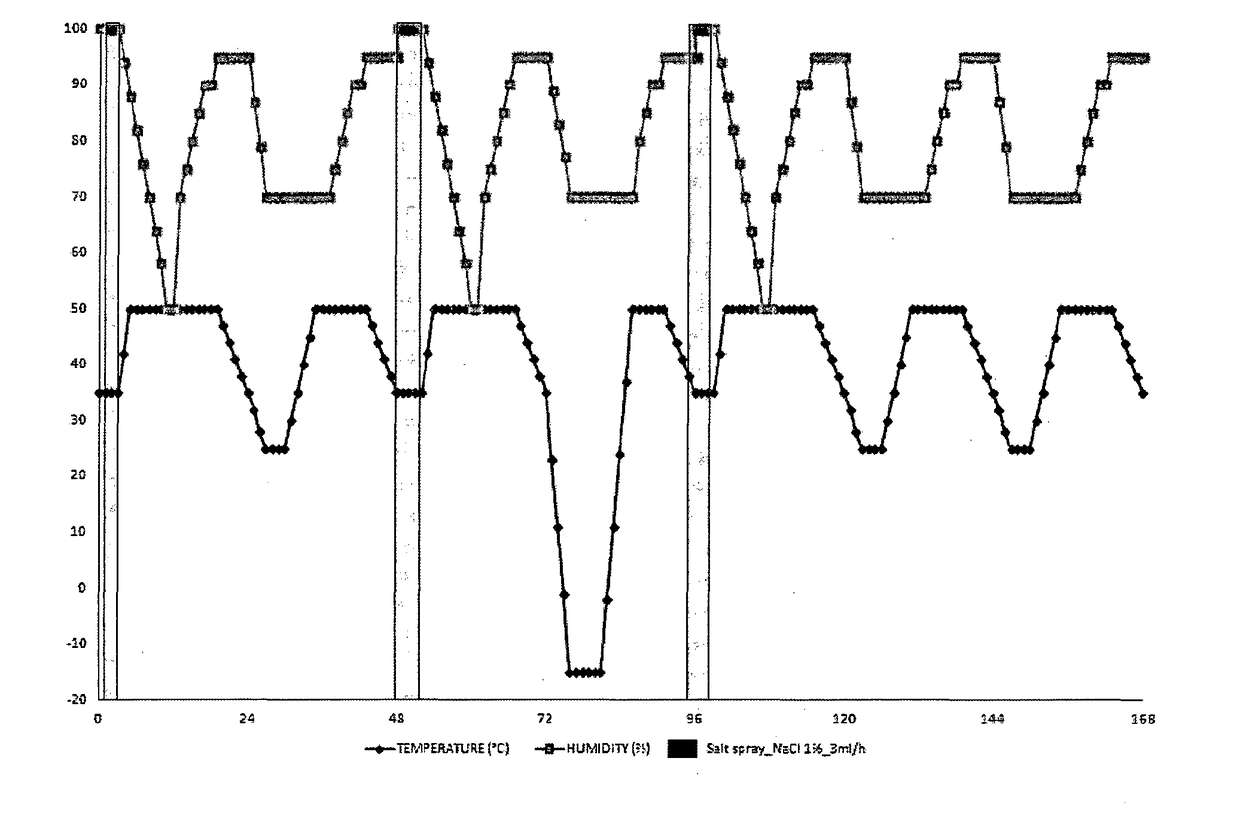

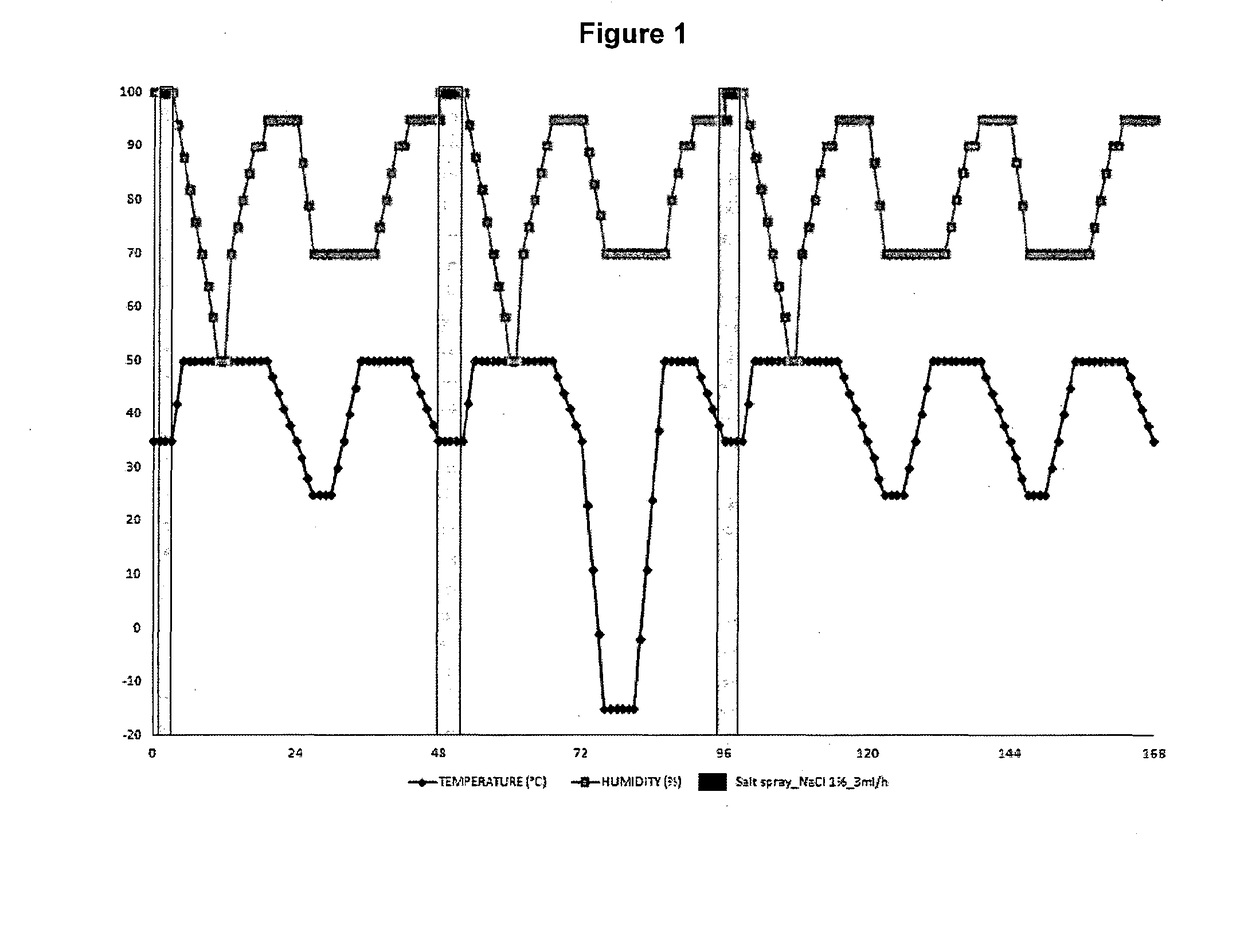

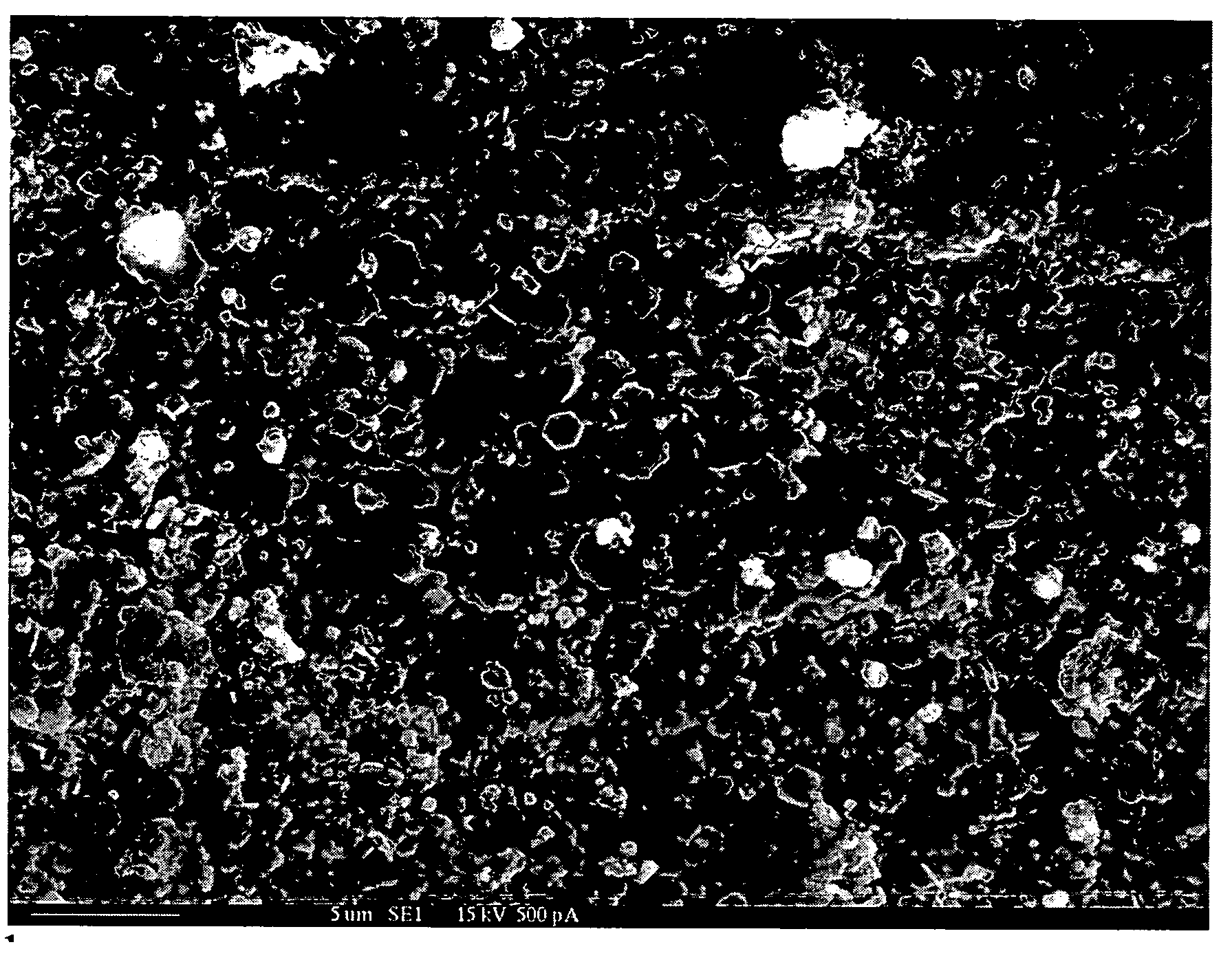

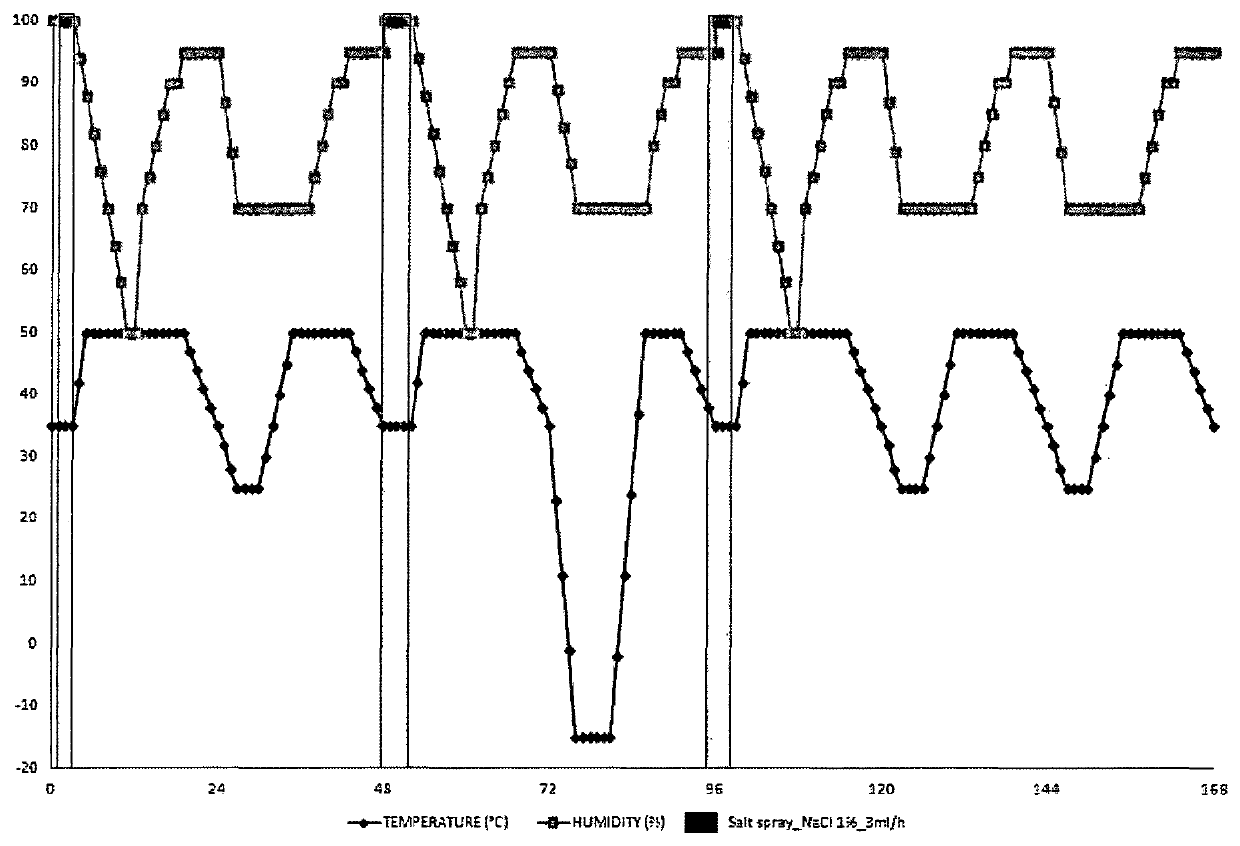

Development of a sol-gel anticorrosion treatment

ActiveUS20190085175A1Easily visible to naked eyeImprove corrosion resistanceLiquid surface applicatorsAnti-corrosive paintsNanowireAlcohol

The invention relates to a process for treating a metal alloy part, characterized in that it comprises the following steps: —producing a stock formulation by mixing, in equal molar parts of silicon, an alcoholic solution of hydrolysed epoxysilane and an alcoholic solution of hydrolysed aminosilane, —mixing the stock formulation with a suspension comprising conductive nanowires in an amount by weight of between 0.1% and 10% relative to the total weight of the stock formulation in order to obtain a dilute formulation, and —depositing the dilute formulation on the part in order to obtain the coating.

Owner:SAFRAN +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com