Method for plating chrome on surface of thin plate

A surface chrome plating and thin plate technology, which is applied in the field of chrome plating on the surface of thin plates, can solve the problems of high investment, high production costs, and high pressure on environmental protection and emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] Concrete steps and process parameters of the embodiments of the present invention are as follows:

[0100] 1. Alkaline washing

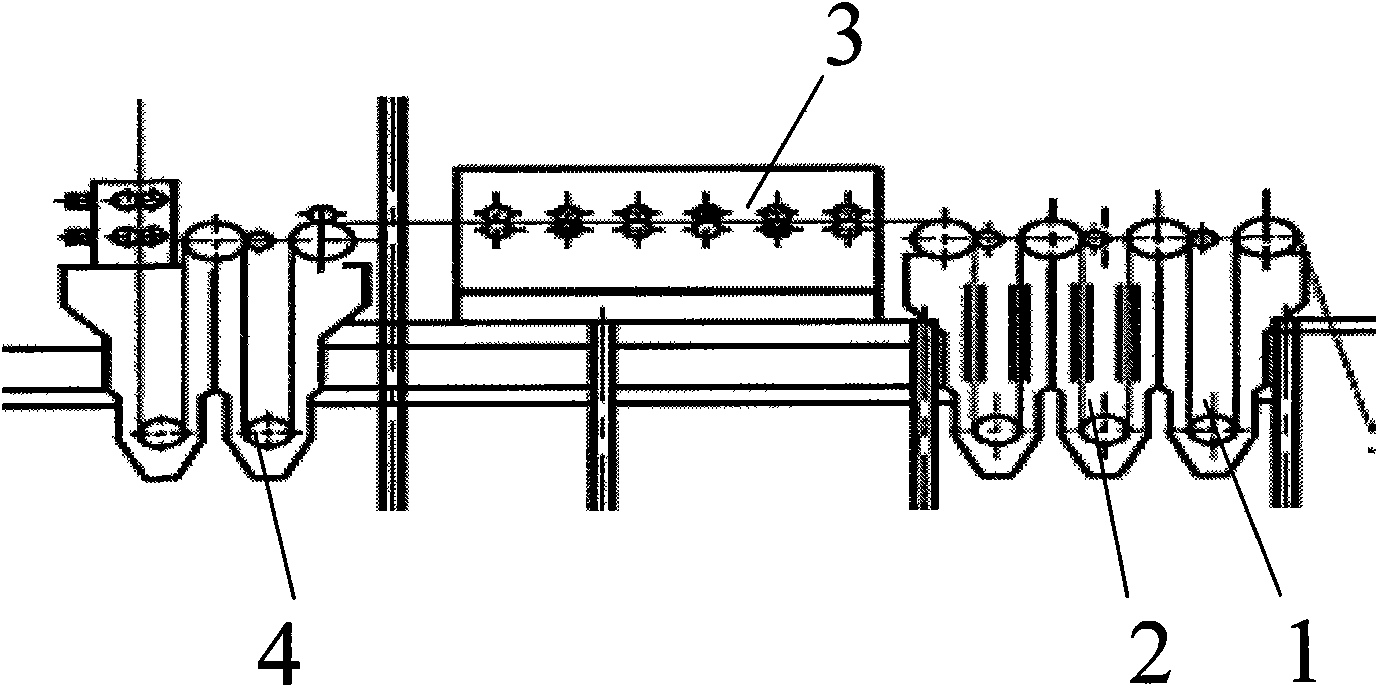

[0101] Such as figure 2 As shown, the equipment makes the strip pass through the solution to remove the oil and dirt adhering to the surface of the strip. It includes a pre-soak tank 1, which soaks the strip for preliminary degreasing; The electrodes on both sides of the middle strip are used for degreasing; one scrubbing tank 3 is used for physical degreasing; two rinsing tanks 4 are sprayed with high-temperature water to remove the lye on the surface of the strip.

[0102] 1. Alkali leaching

[0103] Alkali concentration: active alkali 35g / l

[0104] Solution temperature: 45°C

[0105] Additive: Electrolytic cleaning additive 25 (low temperature cleaning agent);

[0106] 2. Electrolytic cleaning

[0107] Liquid: active alkali

[0108] Temperature: 45°C

[0109] Concentration: 35g / L

[0110] Power supply: 8.0KA, 30V, 2 sets

[0111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com