Patents

Literature

96 results about "Permanganic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Permanganic acid is the inorganic compound with the formula HMnO₄. This strong oxoacid has been isolated as its dihydrate. It is the conjugate acid of permanganate salts. It is the subject of few publications and its characterization as well as its uses are very limited.

Fire resistant coating for composite steel structure and preparation method thereof

InactiveCN102344726ALow smoke productionDelayed transmissionFireproof paintsEpoxy resin coatingsFoaming agentPermanganic acid

The invention discloses a fire resistant coating for a composite steel structure and a preparation method thereof. The fire resistant coating comprises the following ingredients: organic-inorganic nano hybridized resin, organic resin, ceramic filling material, foaming agent, carbon forming agent, catalyst and ferric permanganate. The fire resistant coating has the advantages of simple and convenient painting, excellent fireproof performance, little smoke generation, large foaming intensity and the like. Generally, the coating is used for brushing 3-5 times, the thickness is controlled to be 0.3-1.8 mm, and the duration of fire resistance can reach to 30-240 min.

Owner:江苏海云花新材料有限公司

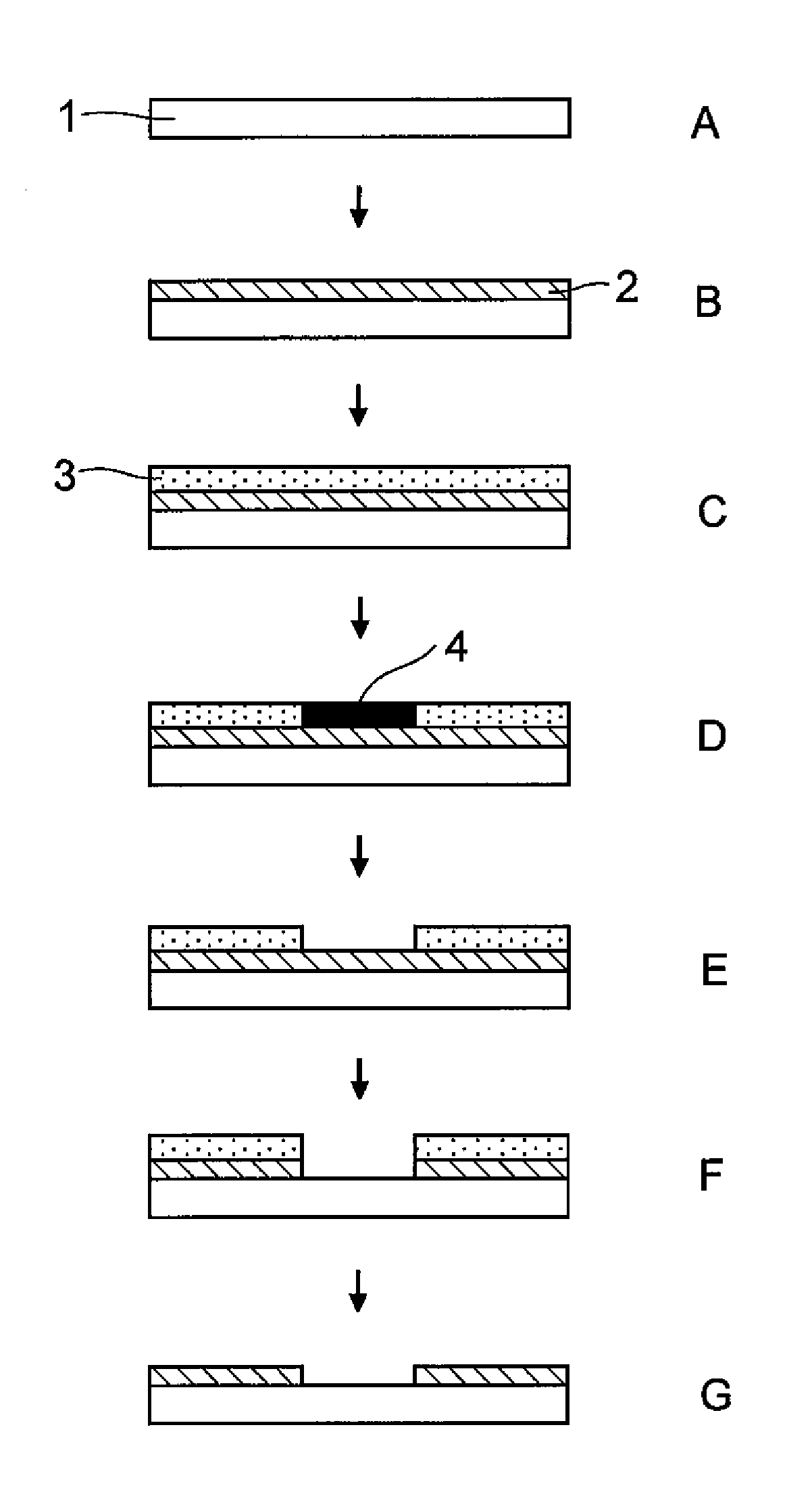

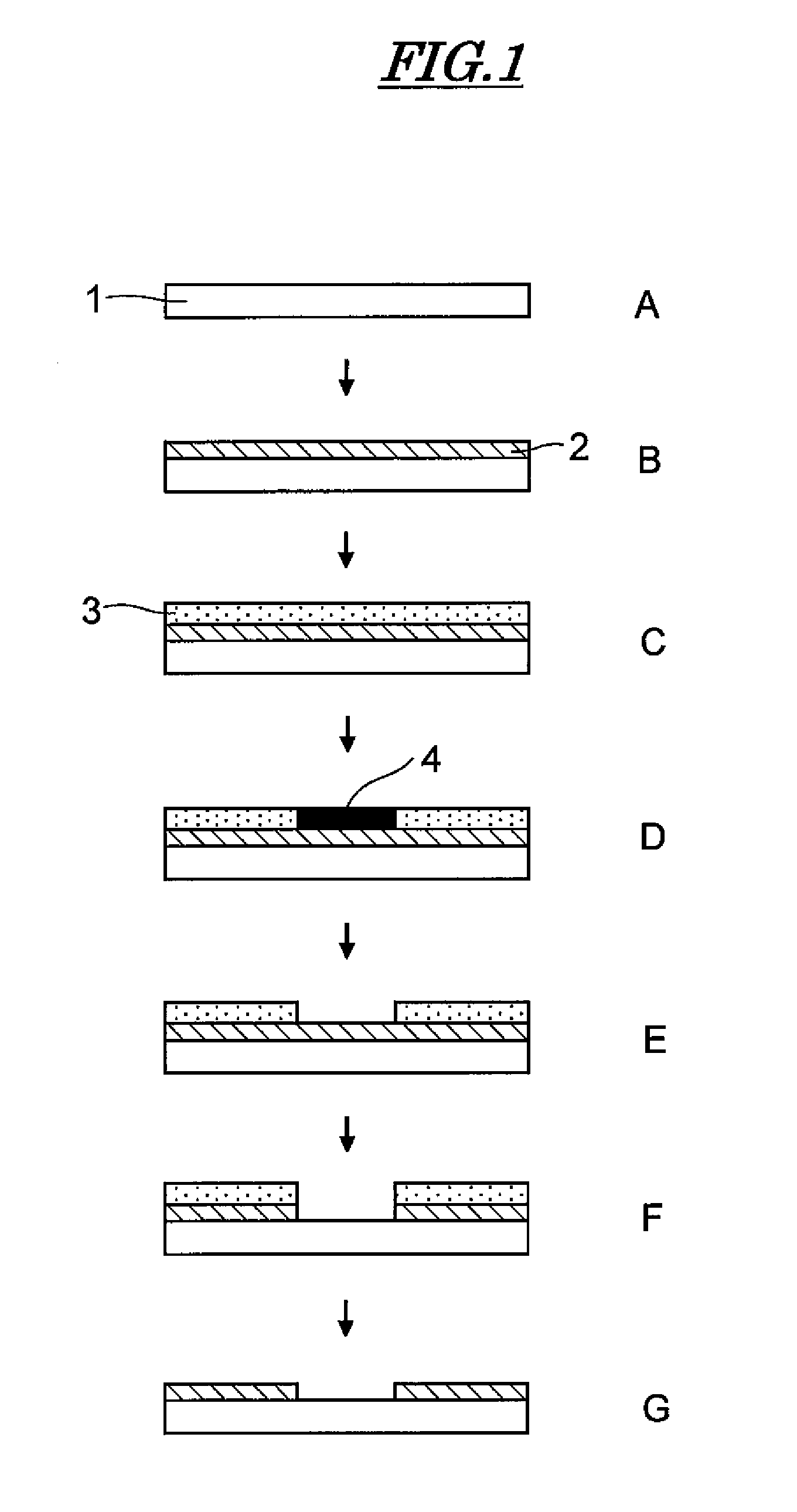

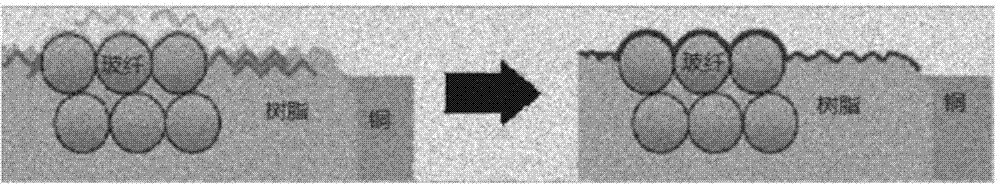

Adhesive film for use in multilayer printed wiring board and method of producing multilayer printed wiring board

InactiveUS20050005437A1Easy to preparePreferable fluidityDecorative surface effectsPrinted circuit secondary treatmentEpoxyThermal dilatation

The present invention provides a laminating method, when a multilayer printed wiring board is produced according to a build-up technique, for easily introducing an insulating layer that, under the lamination conditions, allows filling a resin inside a through hole and / or a via hole simultaneously with laminating a circuit board, is low in the thermal expansion coefficient of a formed insulating layer, and, after roughening a surface of the insulating layer, is excellent in the adhesiveness with a conductor layer that is formed according to plating. The present invention also provides a method of forming the insulating layer; and a method of producing the multilayer printed wiring board; and furthermore an adhesive film that is used in these methods. The laminating method is a method of laminating a circuit board characterized in that the adhesive film formed by laminating a resin composition layer made of the following A layer and B layer on a support base film; Layer A is a layer of a thermosetting resin composition that contains an epoxy resin having two or more epoxy groups in one molecule and an epoxy curing agent, has an inorganic filler content of from 0 to less than 40% by weight, has a cured surface obtained by thermally curing which after roughening with an alkaline permanganic acid solution, allows forming a conductor layer according to the plating, and is solid at ambient temperature, and; Layer B is a layer of a thermosetting resin composition that contains an epoxy resin having two or more epoxy groups in one molecule and an epoxy curing agent, has an inorganic filler content of 40% by weight or more, and is solid at ambient temperature; Layer A is laminated adjacent to the support base film; Layer B layer has a fluidity that allows under lamination conditions the filling of a resin into a through hole and / or a via hole simultaneously with the lamination of the circuit board; and The lamination is carried out while keeping the B layer directly in contact with the circuit board.

Owner:AJINOMOTO CO INC

Method for recovering organic acid and cobalt-manganese metal in terephthalic acid oxidized residues

ActiveCN102503813AOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingMANGANESE ACETATEBenzoic acid

The invention belongs to the technology for recovering organic acid and catalyst from terephthalic acid oxidized residues, which includes the steps of firstly, discharging high-temperature oxidized residues from a pure terephthalic acid (PTA for short) production device, controlling the solid content within the range from 20% to 45% and implementing primary filtering separation within the temperature range from 55 DEG C to 90 DEG C, and directly vending separated solid for manufacturing resin or paint or returning the separated solid to an oxidation reactor for use, wherein primary filtrate is treated according to the process: (I) adding oxalic acid to obtain cobalt-manganese oxalate precipitation, obtaining cobalt-manganese oxalate by means of filtering separation, further cooling the filtrate by means of filtering separation, utilizing the separated solid for extracting benzoic acid and delivering the filtrate to a waste water treating device; or (II) directly cooling the primary filtrate for secondary filtering separation, utilizing the separated solid for extracting benzoic acid, adding oxalic acid into secondary filtrate to obtain cobalt-manganese oxalate precipitation, obtaining cobalt-manganese oxalate by means of filtering separation and delivering the filtrate to a waste water treating device; and secondly, carrying out reaction of the cobalt-manganese oxalate obtained from (I) or (II) with oxidant such as hydrogen peroxide, peroxyacetic acid, bromine, manganate, permanganic acid, manganese dioxide or / and hydrobromic acid, utilizing cobalt acetate aqueous liquor, cobalt bromide aqueous liquor, manganese acetate aqueous liquor, manganese bromide aqueous liquor, acetic acid or / and pure water as dissolvent, then carrying out reaction of the cobalt-manganese oxalate with metallic cobalt, metallic manganese or / and hydrobromic acid after the cobalt-manganese oxalate is completely dissolved, and obtaining homogeneous phase liquor containing cobalt-manganese bromide ions by means of purification and filtration, wherein the mixed liquor can be directly mixed with cobalt acetate, manganese acetate, cobalt bromide, manganese bromide, acetic acid or water to serve as oxidation catalyst for the terephthalic acid.

Owner:浙江上虞利星化工有限公司

Preparation method of 4,4'-(Hexafluoroisopropylidene) diphthalic anhydride

ActiveCN101696199AOvercoming the Factors Affecting Industrial Safety ProductionHigh yieldOrganic chemistryAlkyl transferO-Xylene

The invention discloses a preparation method of 4,4'-(Hexafluoroisopropylidene) diphthalic anhydride (6-FDA), belonging to the technical field of liquid crystal materials. The main technical scheme is achieved as follows: o-xylene and 2,2-dichloro-hexafluoropropane undergo alkylation reaction in an ionic liquid under the catalytic action of Lewis acids (AlCl3, ZnCl2) to obtain 4,4'-(Hexafluoroisopropylidene) di(2-xylene); then the 4,4'-(Hexafluoroisopropylidene) di(2-xylene) is oxidized by permanganic acid TEBA triethylbenzylammonium salts to obtain 4,4'-(Hexafluoroisopropylidene) diphthalandione; and finally, the 4,4'-(Hexafluoroisopropylidene) diphthalandione is dehydrated by acetic oxide to obtain the 4,4'-(Hexafluoroisopropylidene) diphthalicanhydride (6-FDA). The preparation method has the advantages of mild reaction condition, less three-waste emission and high yield.

Owner:天津众泰材料科技有限公司

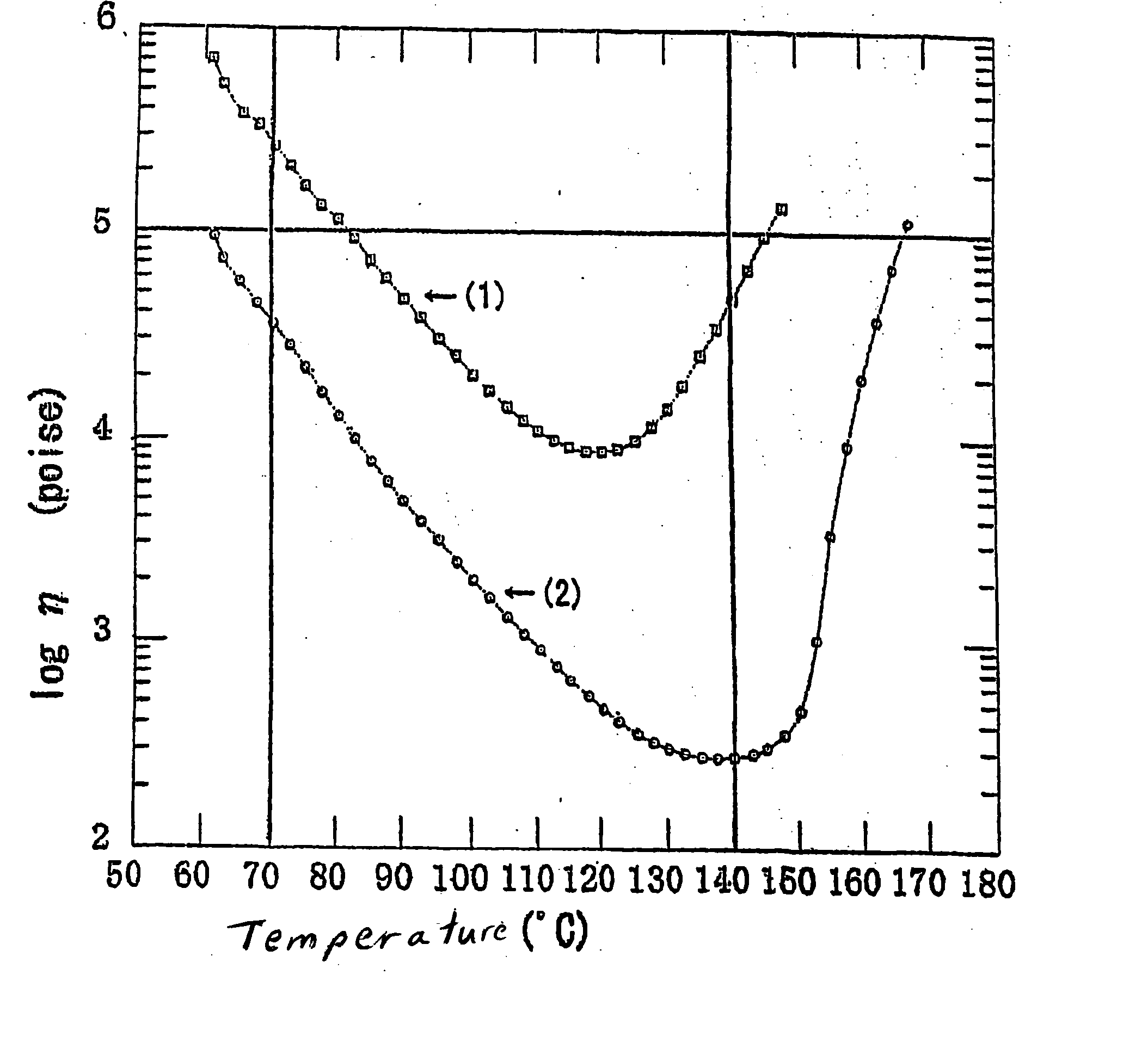

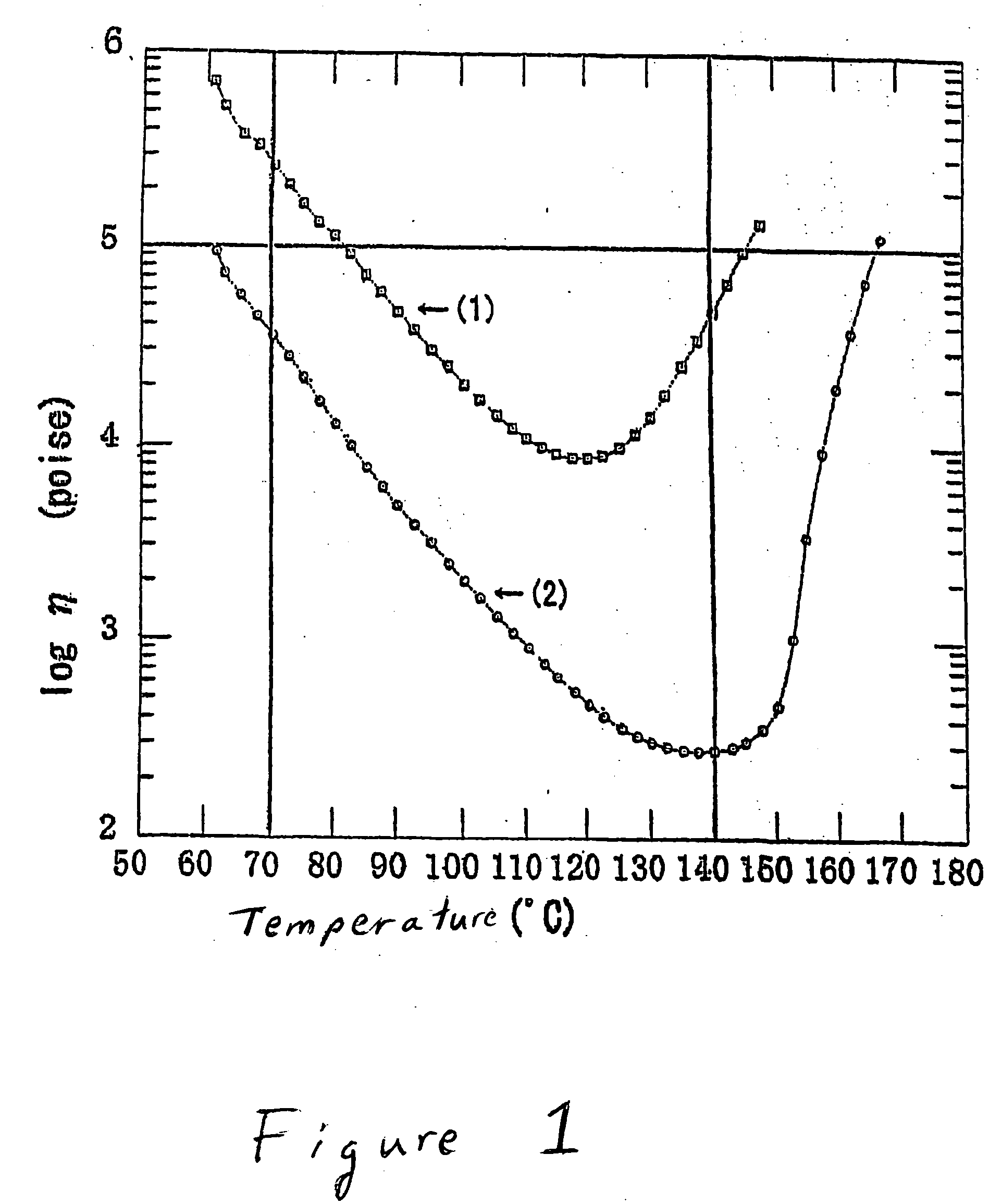

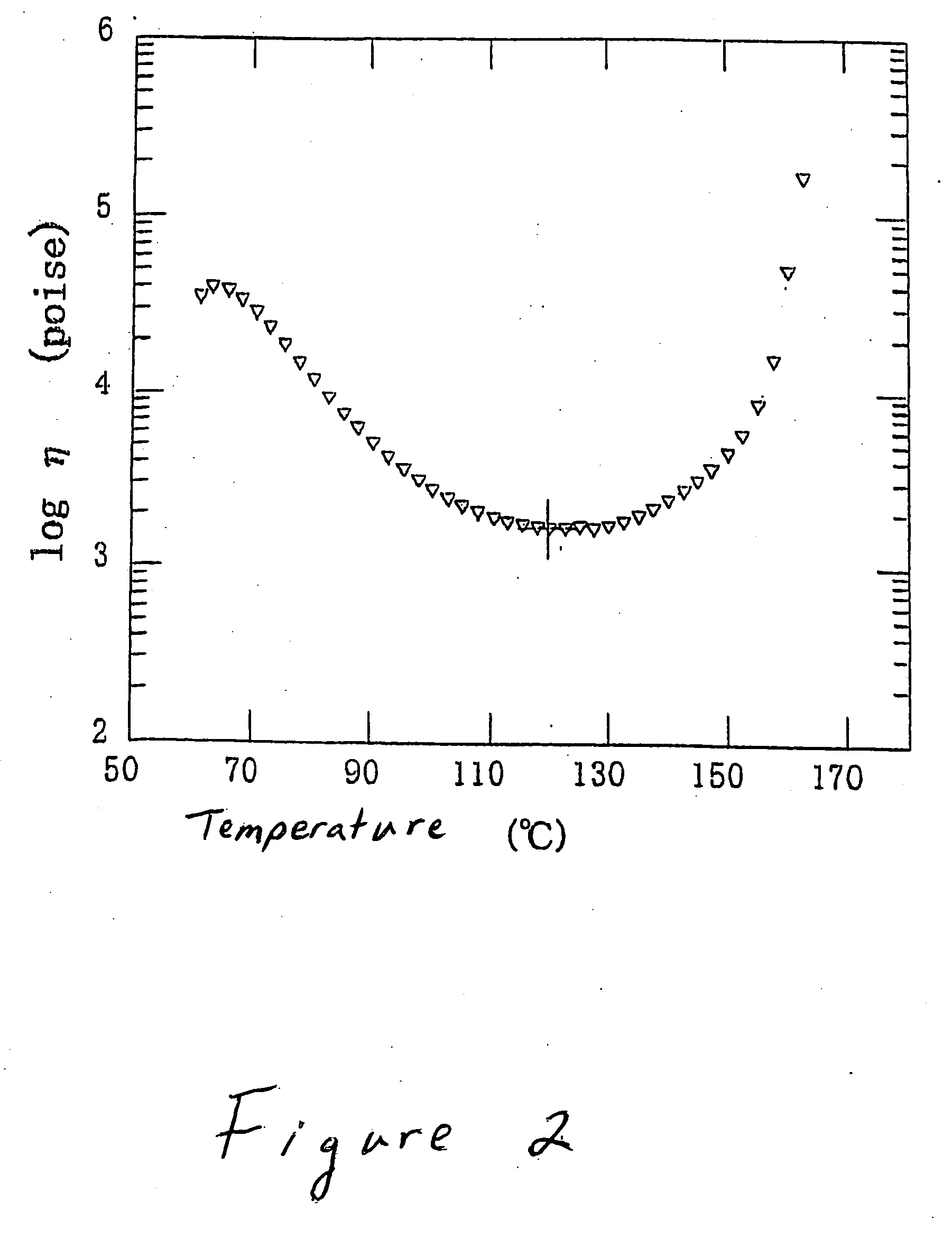

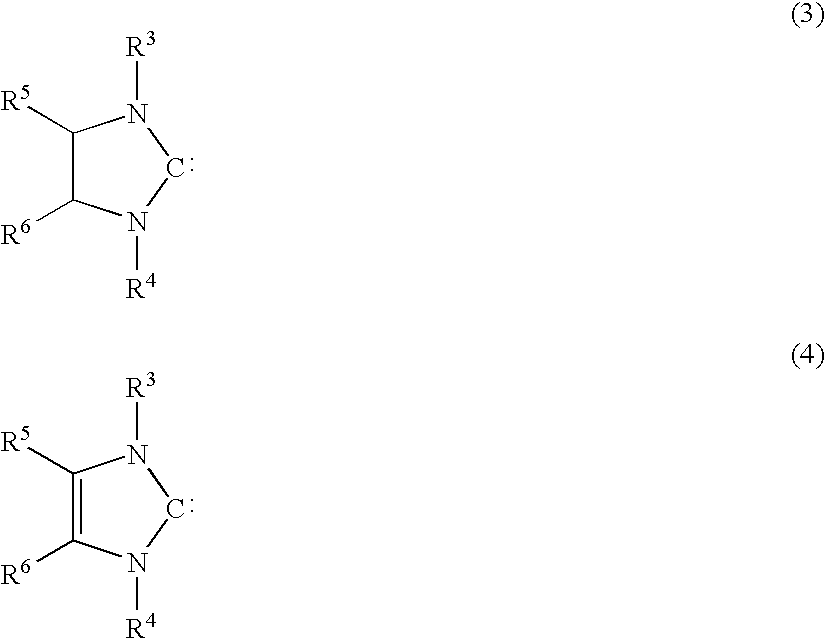

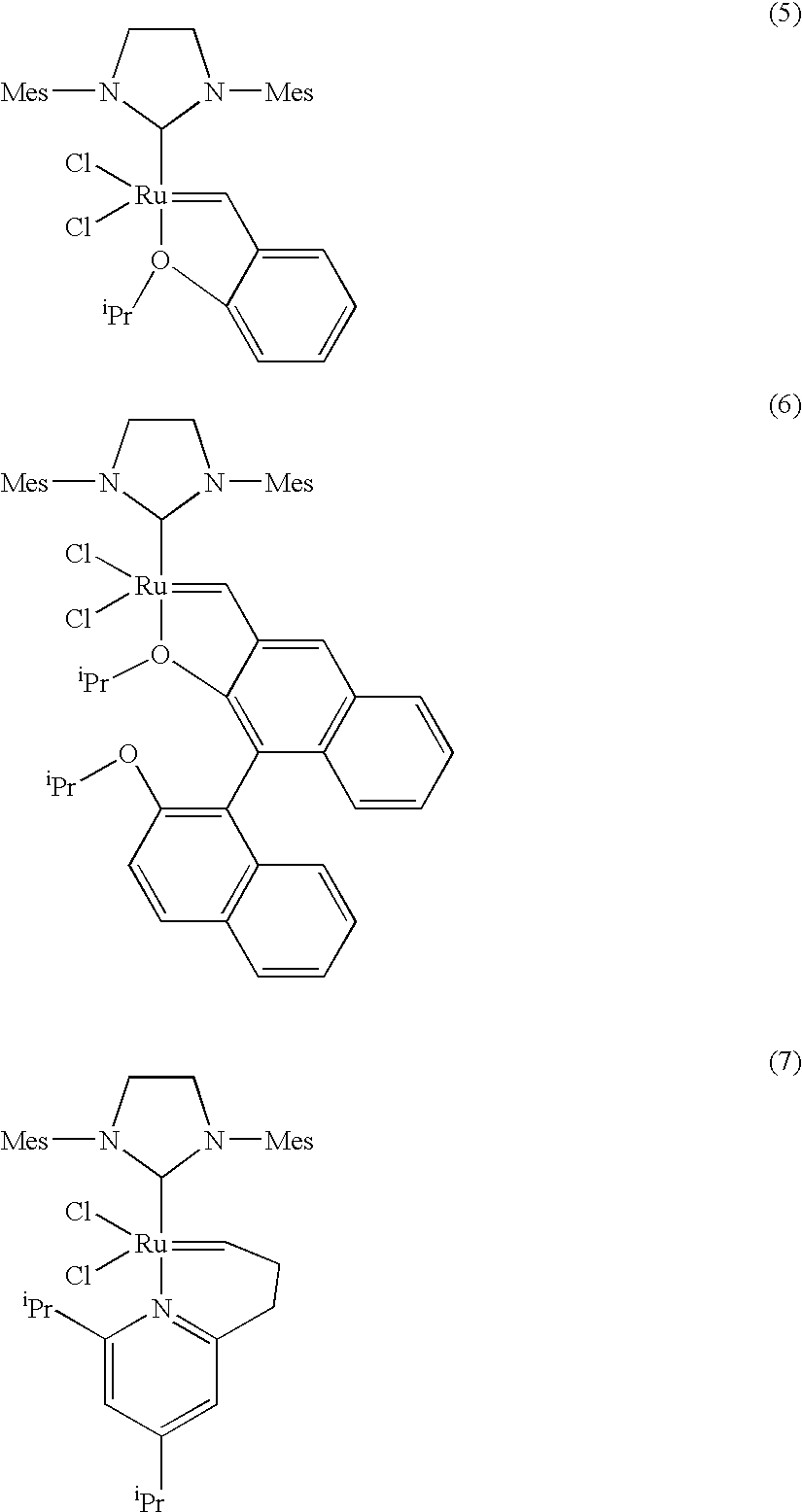

Multilayer body and method for producing same

InactiveUS20060154099A1Improve adhesionReduce the amount of solutionSynthetic resin layered productsPretreated surfacesPermanganic acidBulk polymerization

A laminated body is disclosed which is excellent in adhesion between a molded product and a plating layer. A laminated body containing a plating layer formed on its surface of a molded product obtained by bulk polymerization of a cyclic olefin monomer in the presence of an inorganic filler by using a ruthenium catalyst. A method for producing a laminated body containing a plating layer formed on its surface, which comprises the steps of: the step of obtaining a molded product by bulk polymerization of a cyclic olefin monomer in the presence of an in organic filler by using a ruthenium catalyst; the step of etching the surface of the molded product with a permanganic acid compound; the step of applying a plating catalyst thereon; and the step of electroless plating the surface of the molded product.

Owner:ZEON CORP

Etching liquid for conductive polymer, and method for patterning conductive polymer

InactiveUS20100089872A1Improve etching effectDecorative surface effectsPrinted circuit aspectsHydrogen halidePermanganic acid

The object is to provide an etching liquid for a conductive polymer having excellent etching capability toward a conductive polymer, and a method for patterning a conductive polymer employing the etching liquid for a conductive polymer. The conductive etching liquid of the present invention is selected from the group consisting of (1) an etching liquid comprising greater than 0.5 wt % but no greater than 70 wt % of (NH4)2Ce(NO3)8 or at least 0.5 wt % but no greater than 30 wt % of Ce(SO4)2, (2) an etching liquid comprising greater than 0.5 wt % but no greater than 30 wt % of (NH4)4Ce(SO4)4, (3) an etching liquid comprising a hypochlorous acid salt aqueous solution having an effective chlorine concentration of at least 0.06 wt % and a pH of greater than 3 but less than 8, (4) an etching liquid comprising nitrosyl chloride which comprises at least 5 wt % of hydrochloric acid and at least 20 wt % of nitric acid, a (hydrochloric acid concentration+0.51×nitric acid concentration) value being no greater than 35 wt %, and a (hydrochloric acid concentration+0.5×nitric acid concentration) value being at least 30 wt %, (5) an etching liquid comprising at least 3 wt % but no greater than 40 wt % of a bromic acid compound and at least 4 wt % of an inorganic acid, (6) an etching liquid comprising at least 6 wt % but no greater than 40 wt % of a chloric acid compound and at least 7 wt % of a hydrogen halide, (7) an etching liquid comprising at least 0.001 wt % but no greater than 20 wt % of a permanganic acid compound, and (8) an etching liquid comprising at least 3 wt % but no greater than 30 wt % of a hexavalent chromium compound.

Owner:TSURUMISODA +1

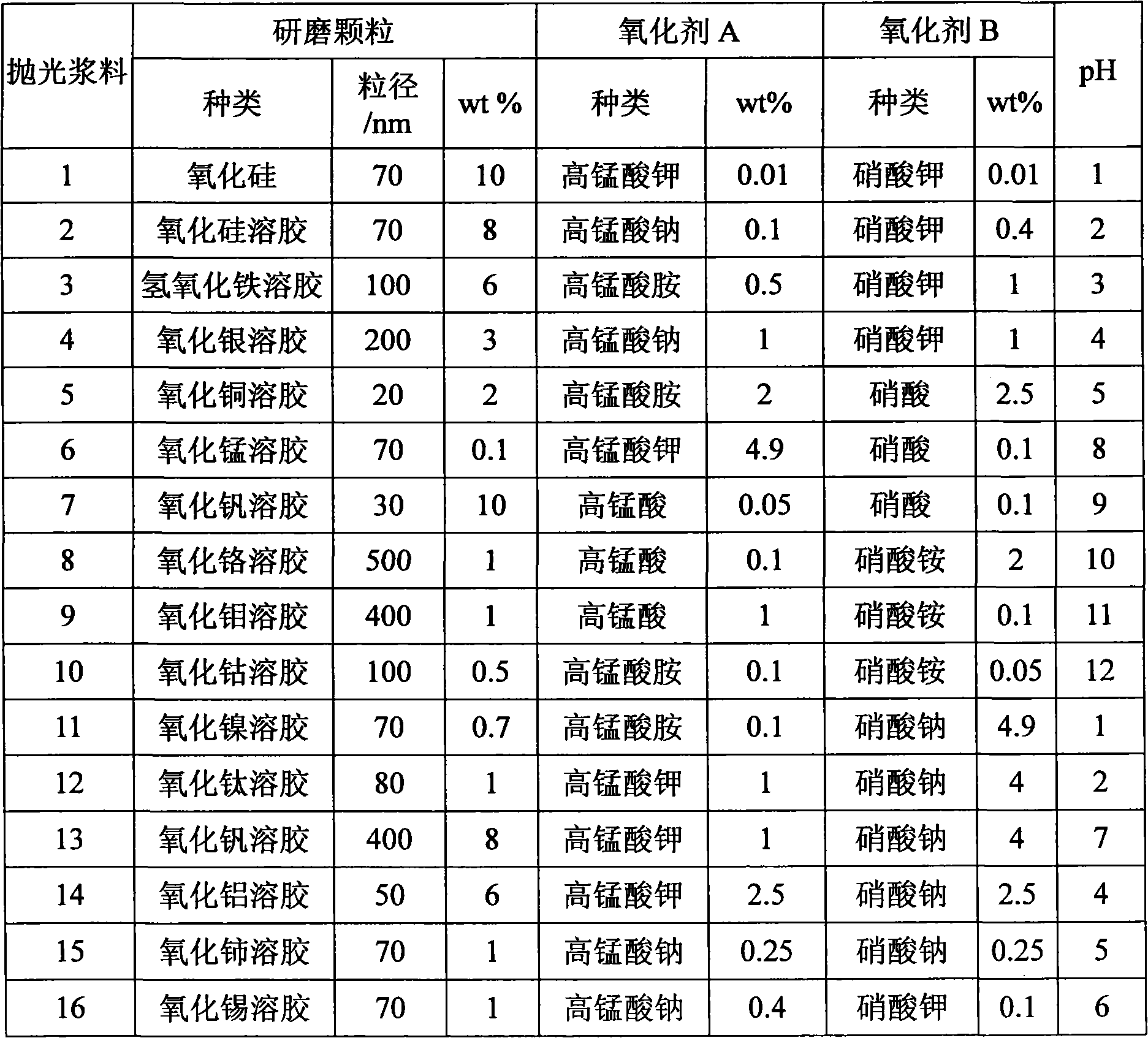

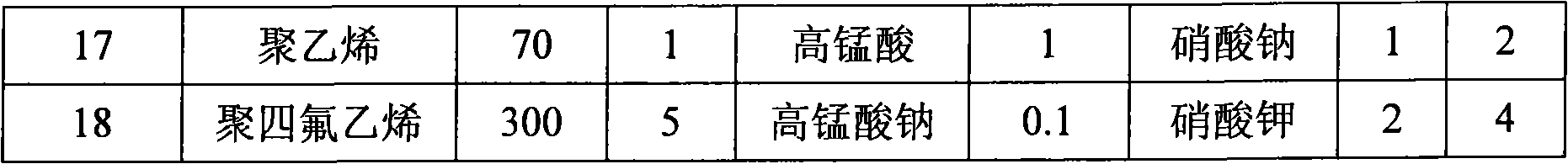

Chemical mechanical polishing sizing agent

InactiveCN101684393AIncrease the absolute removal rateReduce pinhole corrosionPolishing compositions with abrasivesDielectricPermanganic acid

The invention discloses a chemical mechanical polishing sizing agent comprising oxidant containing two groups of oxidants, wherein one group is selected from one or a plurality of permanganate and soluble salt thereof, and the other group is selected from one or a plurality of nitric acid and soluble salt thereof. The chemical mechanical polishing sizing agent of the invention increases the absolute removal speed of metal by mutual action of oxidant permanganic acid radical and bitrate radical as well as abrasive particles, improves selection ratio of relative removal speed of dielectric, canlower metal pinhole corrosion, lowers dielectric corrosion produced in the metal planarization process, obviously lowers defects and improves product yield.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Surface modification liquid for plastic and method of metallizing plastic surface therewith

InactiveUS20090176022A1Improve wettabilityImprove adsorption capacityPretreated surfacesLiquid/solution decomposition chemical coatingPermanganic acidPhosphoric acid

A surface modification liquid for plastic that in pretreatment for metallization of a plastic surface by metal plating, solves the problems of etching treatment with the use of conventional etching liquid containing chromic acid, etc. There is provided a surface modification liquid for plastic characterized by containing permanganic acid, phosphoric acid and nitric acid.

Owner:EBARA-UDYLITE CO LTD

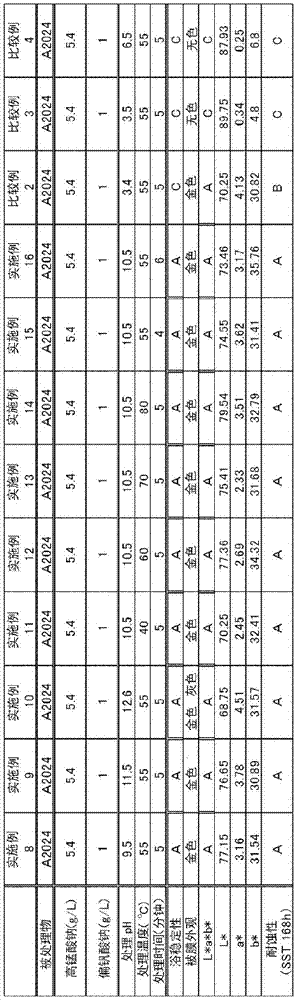

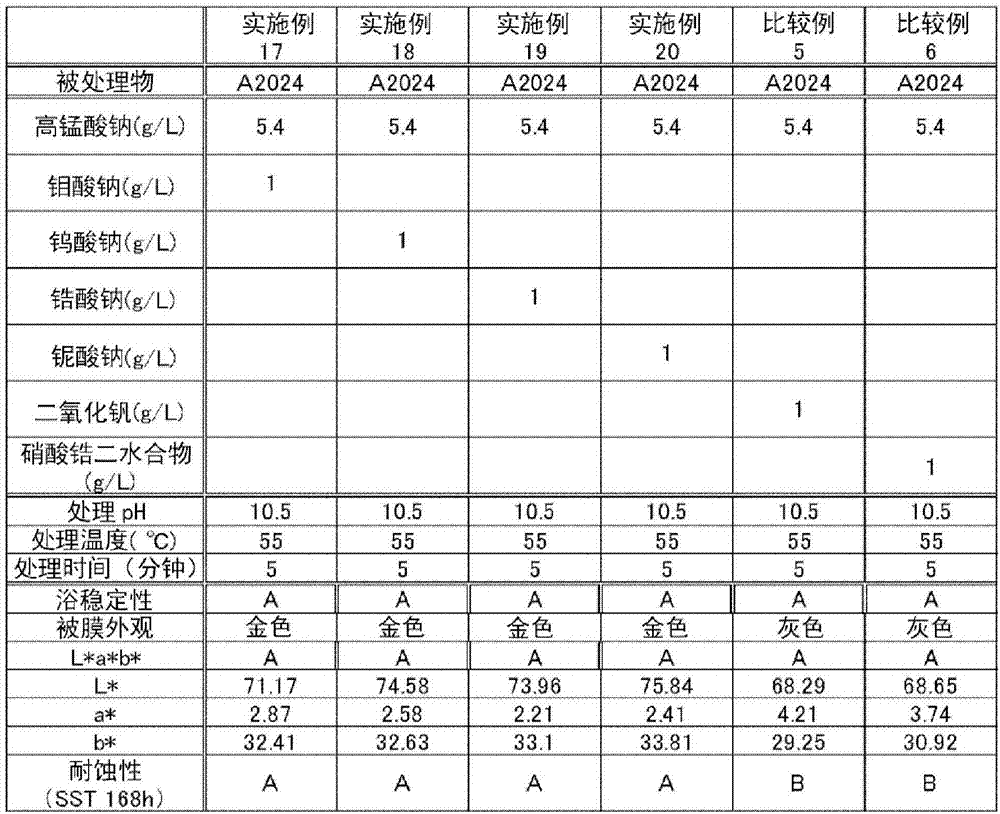

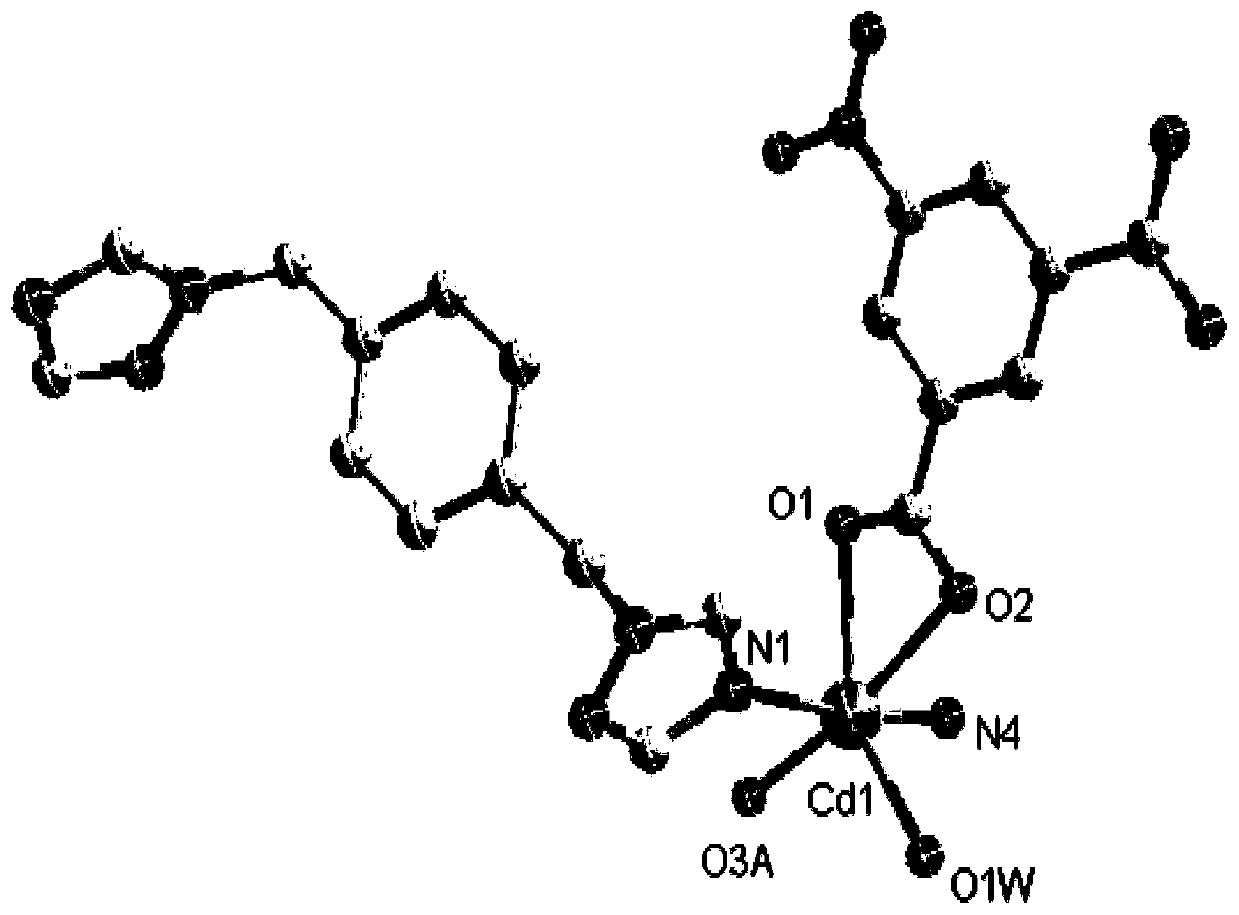

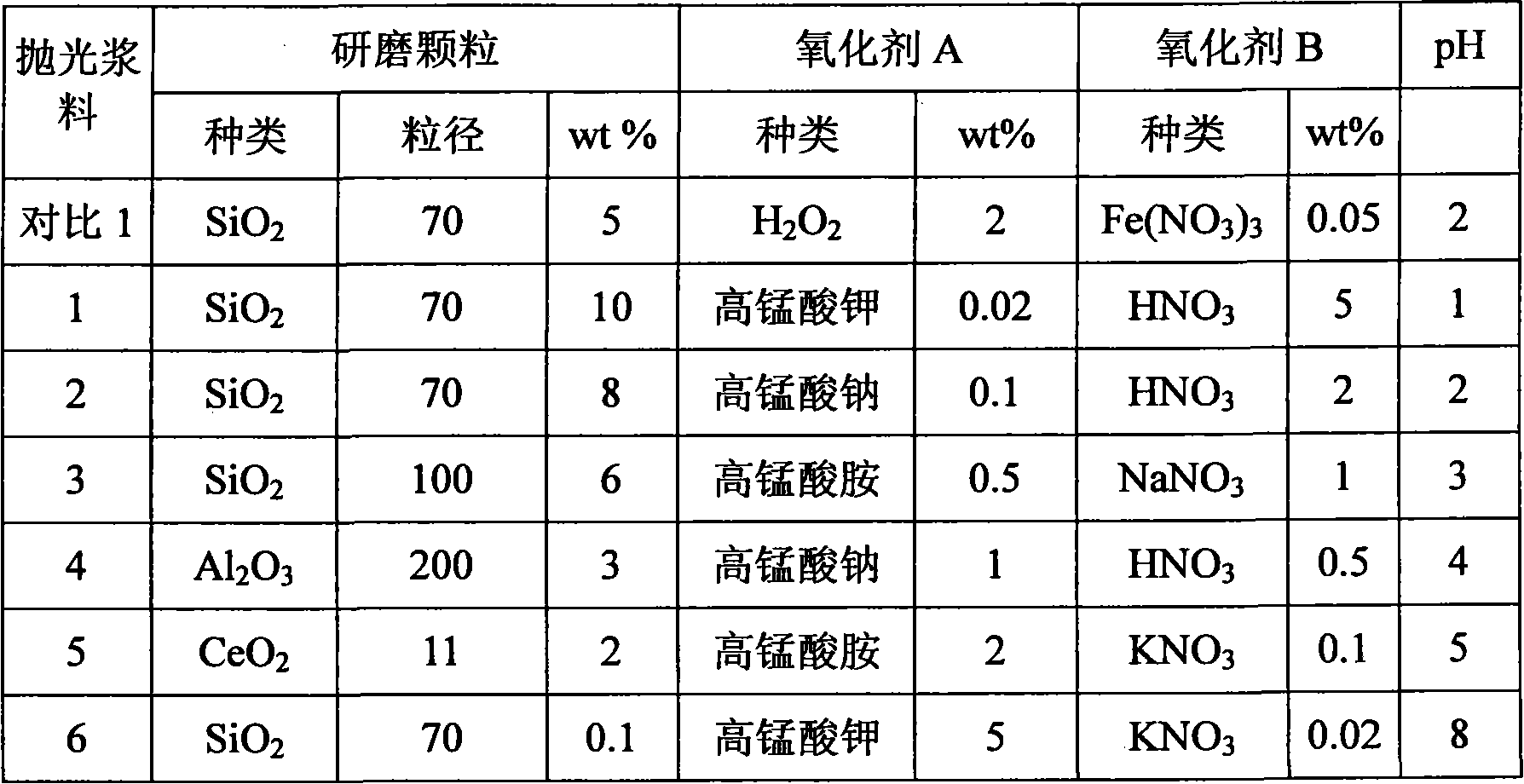

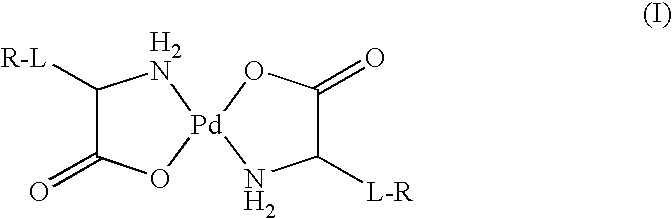

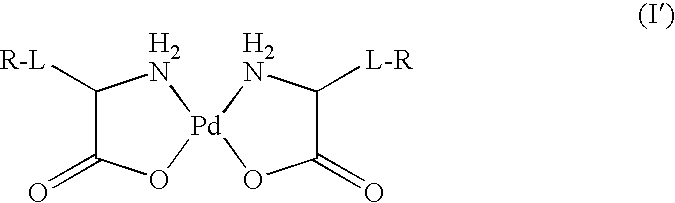

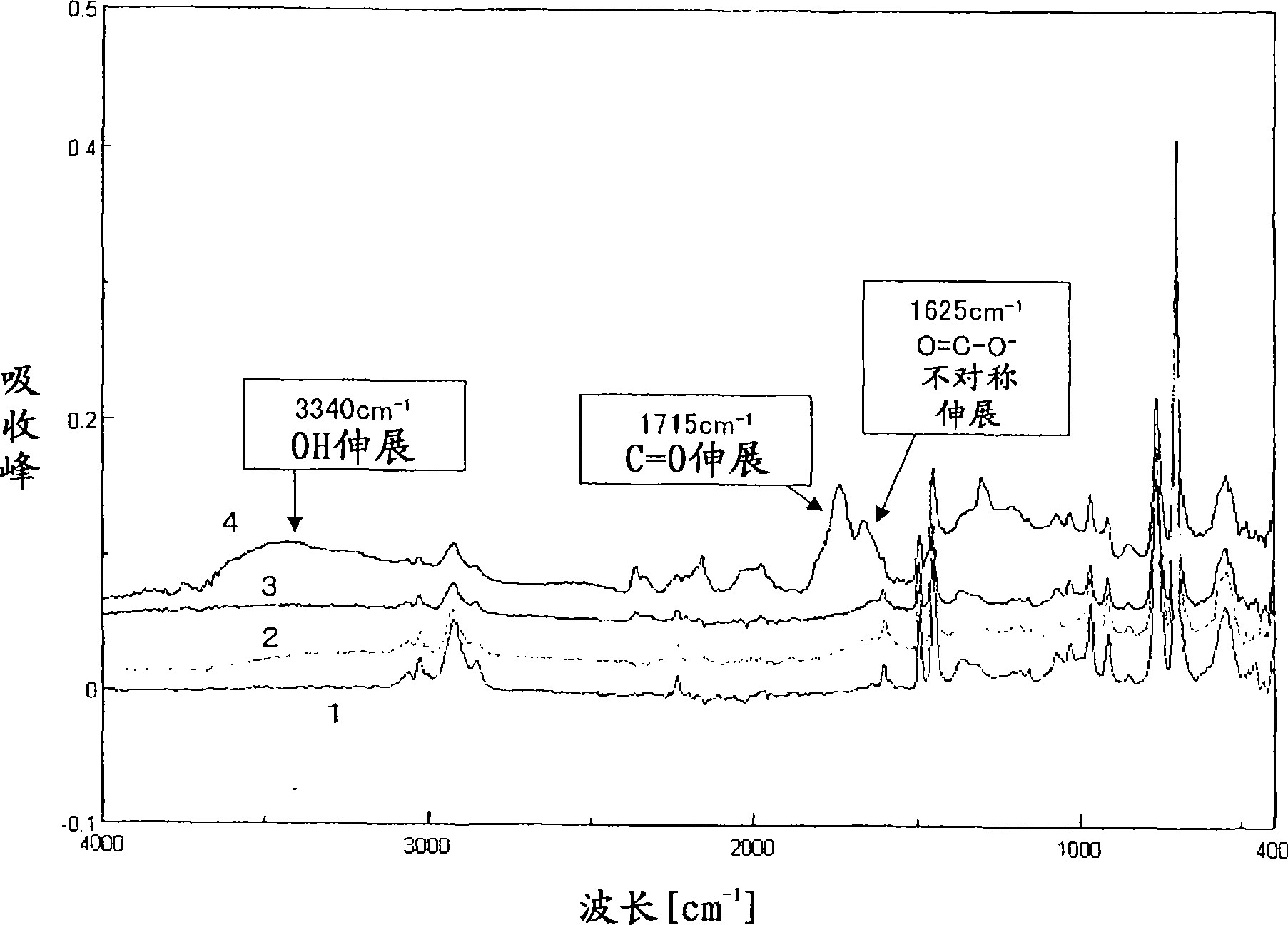

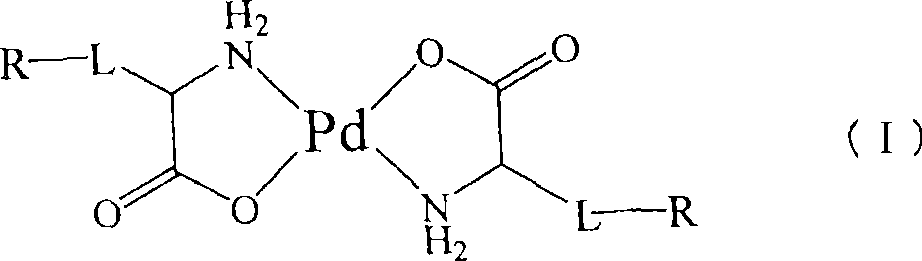

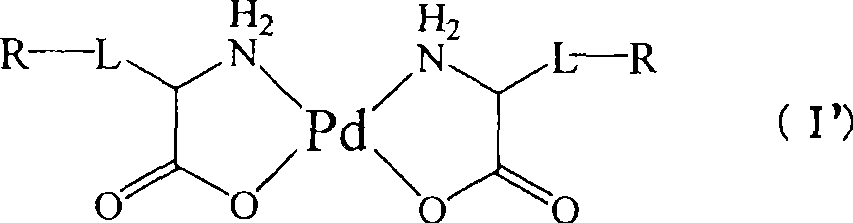

Preparation of light-emitting crystal material {[Cd2(tpphz)(bdc)([mu]2-OAc)2].tpphz.2H2O}n for rapid and high-sensitivity detection of permanganate ions

ActiveCN110655529AIncrease in sizeQuality improvementFluorescence/phosphorescenceLuminescent compositionsPermanganic acidPhenazine

The invention discloses preparation of a light-emitting crystal material {[Cd2(tpphz)(bdc)([mu]2-OAc)2].tpphz.2H2O}n for rapid and high-sensitivity detection of permanganate ions. The preparation method comprises: adding tetrapyrido[3,2-a:2',3'-c:3'',2''-h:2''',3'''-j]phenazine, cadmium nitrate and terephthalic acid into water,stirring in N,N-dimethylacetamideto obtain a stable suspension, puttingthe suspension into a closed reaction kettle, carrying out a heating reaction, slowly cooling to a room temperature, filtering, washing, and drying to obtain the light-emitting crystal material. According to the invention, with the preparation method, the light-emitting crystal material {[Cd2(tpphz)(bdc)([mu]2-OAc)2].tpphz.2H2O}n for rapid and high-sensitivity detection of permanganate ions is obtained.

Owner:JIANGNAN UNIV

Conductive powder plated by electroless plating and process for producing the same

ActiveCN101415863ALiquid/solution decomposition chemical coatingSuperimposed coating processPermanganic acidMicroparticle

Provided is a conductive powder plated by electroless plating which, even when composed of fine particles having an average particle diameter of, in particular, 20 mu m or smaller, has excellent deposit adhesion imparted thereto without using chromic acid, which is causative of environmental pollution, permanganic acid, etc. and a process for industrially advantageously producing the powder. The conductive powder plated by electroless plating is characterized by comprising a core powder coated with a melamine resin and a metallic coating film deposited thereon by electroless plating.The process is characterized by comprising: a step in which a core powder is brought into contact with an initial condensate for a melamine resin and the initial condensate is polymerized to obtain a core powder coated with a melamine resin; a step in which a noble metal is deposited on the surface of the core powder coated with the melamine resin; and a step in which the core powder having the noble metal deposited thereon is plated by electroless plating.

Owner:NIPPON CHECMICAL IND CO LTD

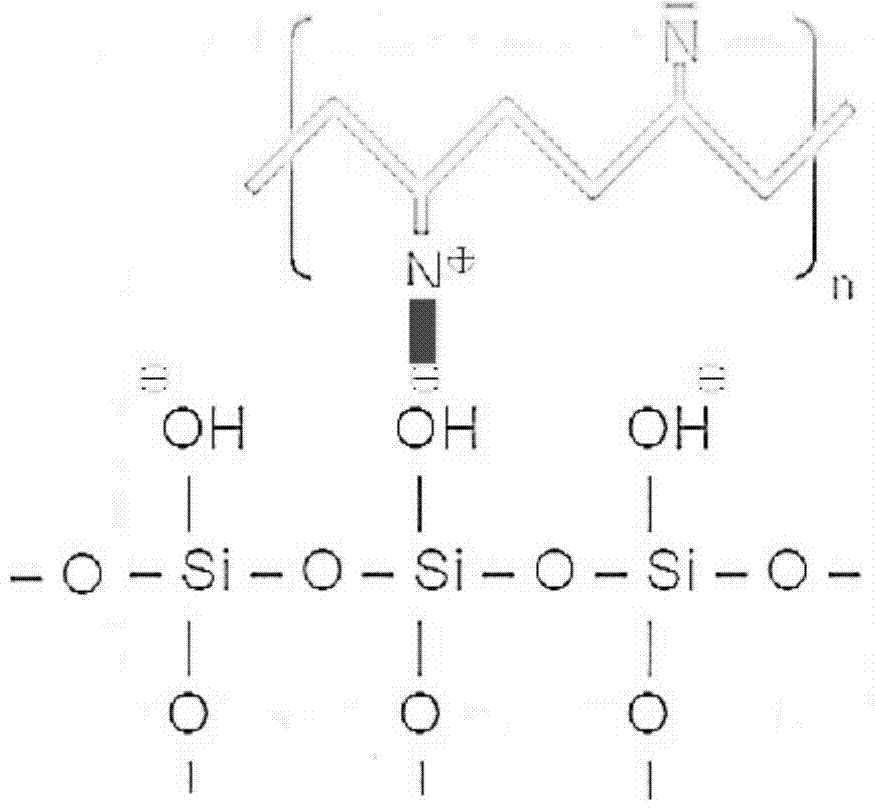

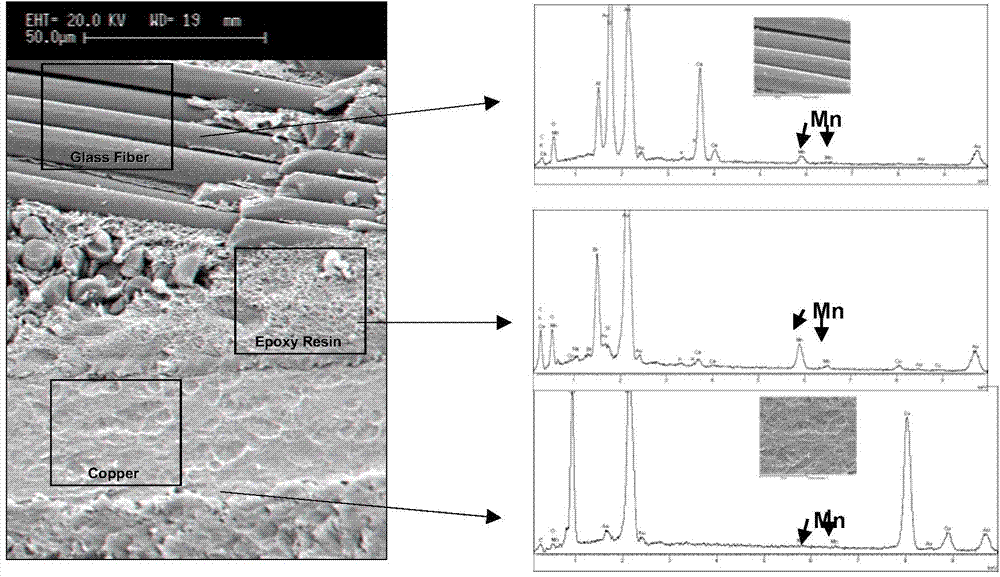

Method for electroplating metal on surface of insulating base material

ActiveCN108977862AImprove surface propertiesImprove bindingPrinted circuit manufactureConductive polymerWater soluble

The invention relates to a method for electroplating metal on the surface of an insulating base material. The method comprises the following steps that the surface of the insulating base material makes contact with a water-soluble anionic compound, so that a modified surface is produced; the modified surface makes contact with an aqueous solution containing permanganate ions, so that a manganese dioxide adsorption layer is formed on the modified surface; a conducting polymer layer is formed on the surface of the manganese dioxide adsorption layer; and electroplating is carried out on the surface of the conducting polymer layer, and thus a metal layer is formed. According to the method, the anionic compound is deposited on the surface of the insulating base material so as to form a coatinglayer tightly combined with the surface of the base material, after the modification and adsorption, an even film with a certain thickness is formed on the surface, thus, under the metal electroplating liquid and electroplating condition are the same, the deep plating capacity and dispersing capacity of the electroplating liquid can be greatly improved, the obtained metal plating layer has the characteristics of being flat, even and good in backlighting effect, and the hole breakout phenomenon and the phenomenon that certain parts of the electroplating metal layer in holes are too thin are avoided.

Owner:GUANGDONG TONESET SCI & TECH

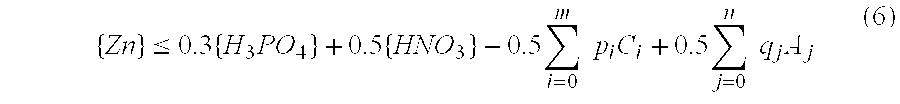

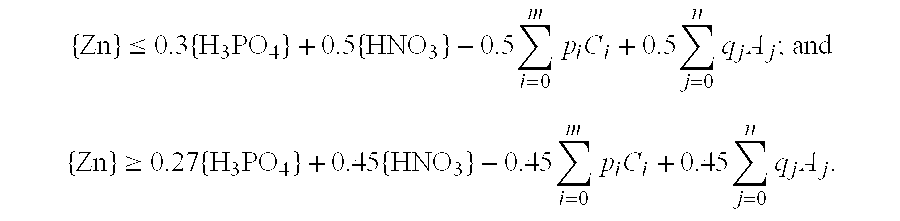

Nonsludging zinc phosphating composition and process

InactiveUS7422629B1Electrolytic inorganic material coatingOther chemical processesPhosphoric Acid EstersElectrolysis

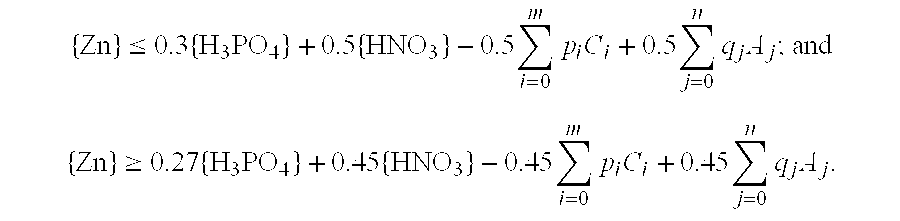

Electrolysis using a suitable electrolyte provides a completely nonsludging zinc phosphate conversion coating process that produces a high quality conversion coating in a very short time. The suitable electrolyte contains at least water, dissolved nitric acid, and dissolved zinc cations and optionally also contains m chemically distinct species of cations other than zinc and n chemically distinct species of anions other than anions derivable by ionization of phosphoric and nitric acids, each of m and n independently being zero or a positive integer. Preferably, the liquid composition contains as additive at least one selection from nitrous acid, permanganic acid, peroxysulfuric acid, hydrogen peroxide, chloric acid, perchloric acid, nitrobenzenesulfonic acid, hydroxylamine, starch / phosphoric acid esters, fluorine compounds, and salts of the preceding; and / or the metal substrate is subjected to cathodic electrolysis after the workpiece has been brought into contact with a weakly basic aqueous colloidal solution that contains titanium oxide, titanium hydroxide, and zinc phosphate.

Owner:HENKEL KGAA

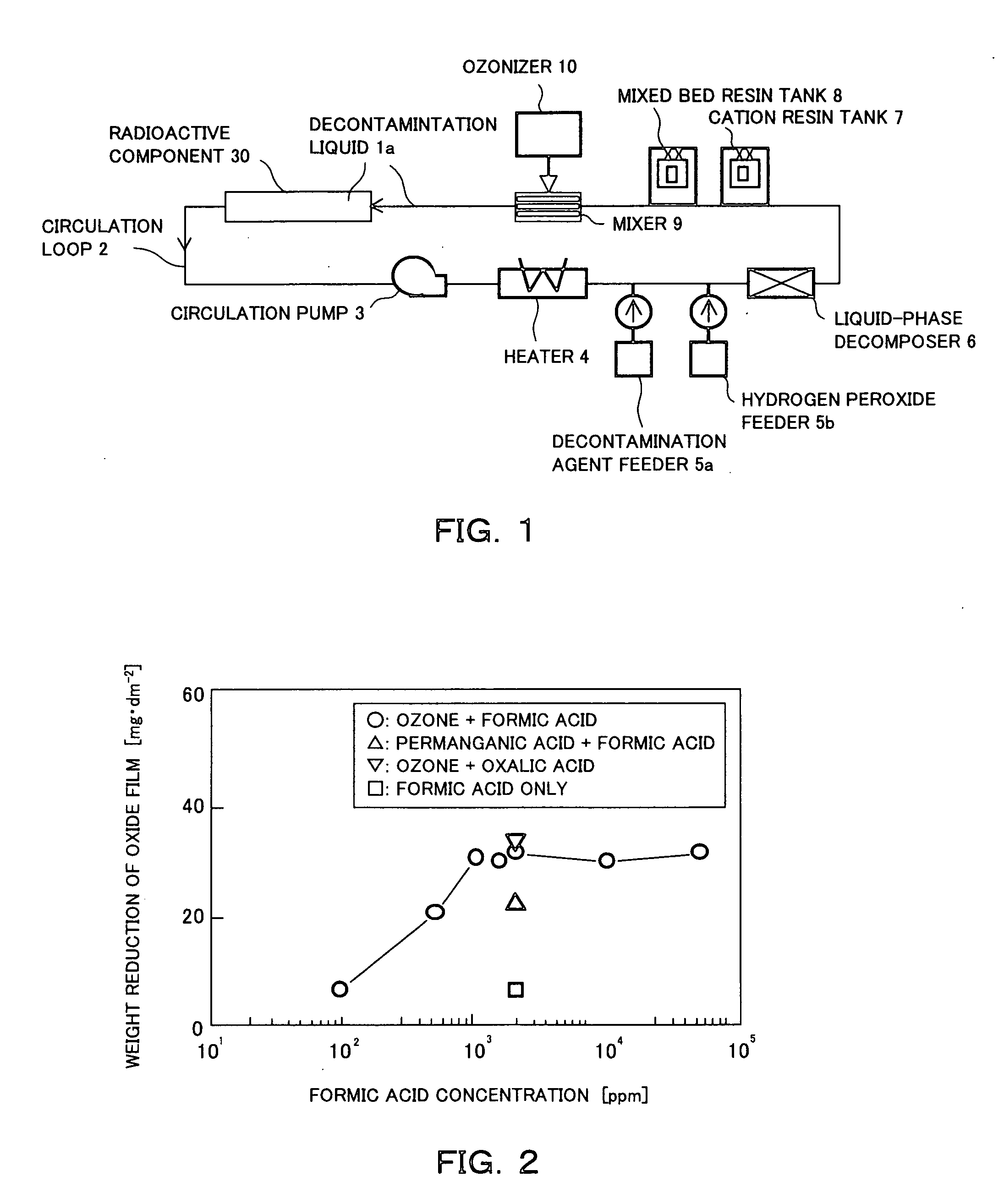

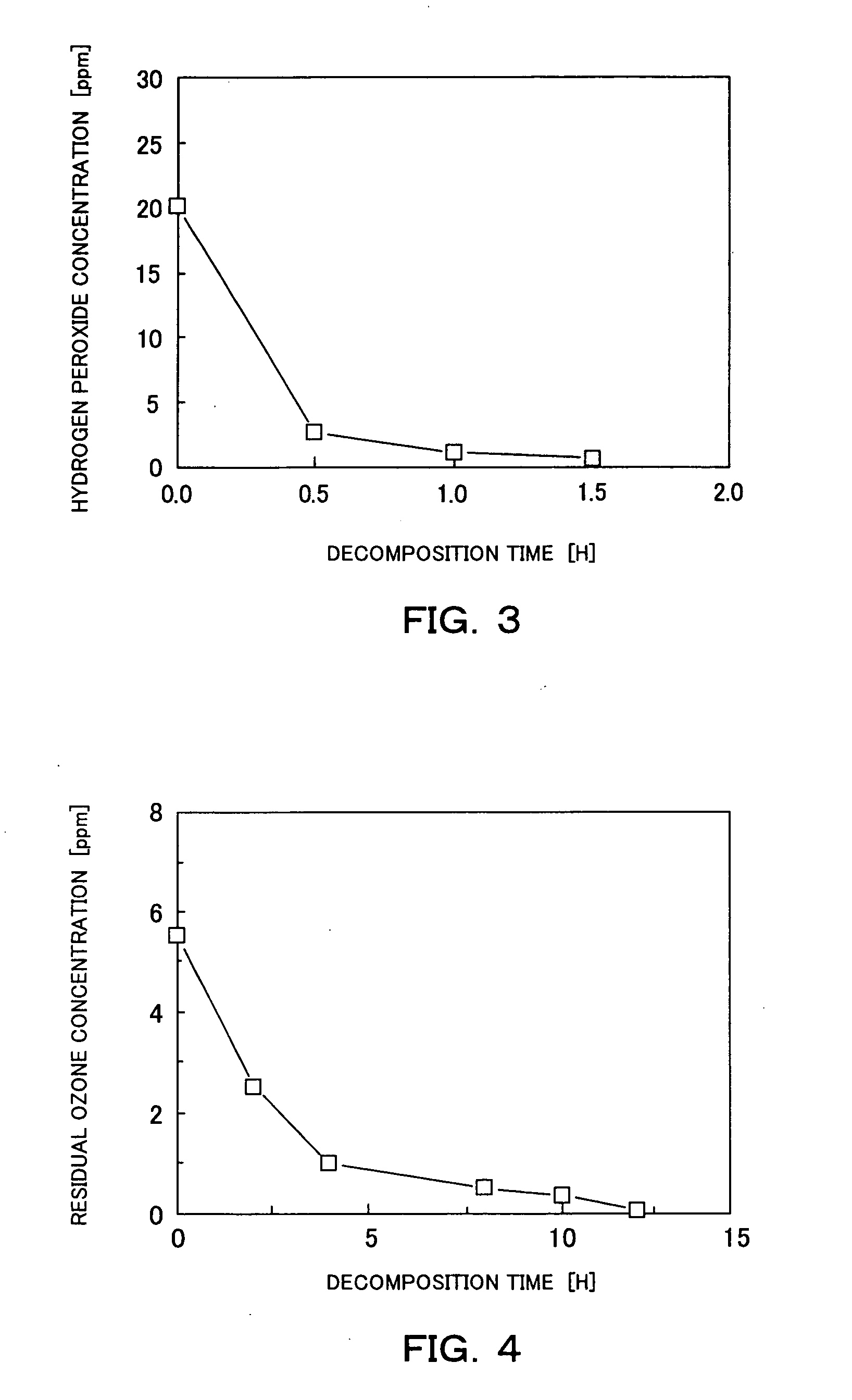

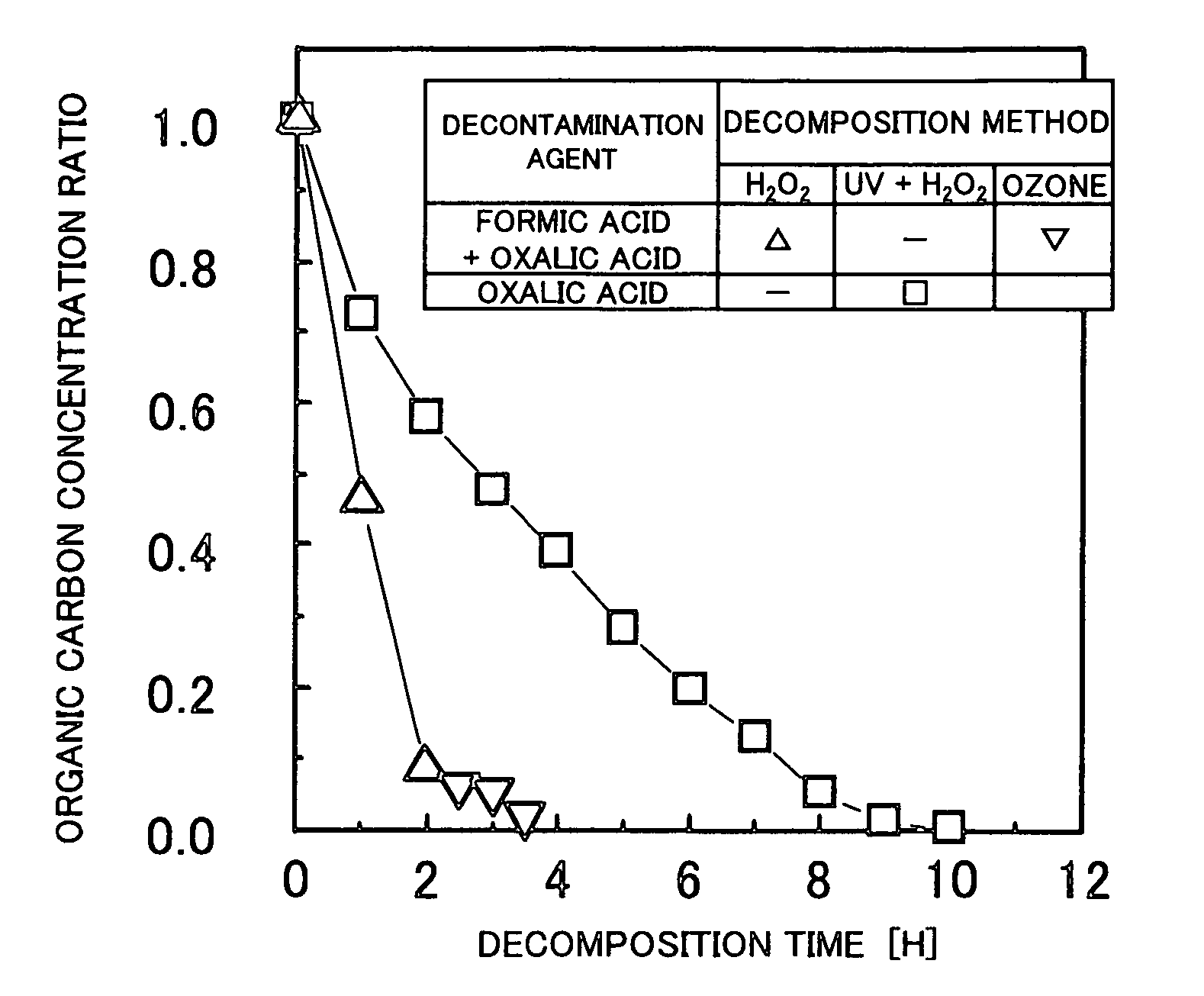

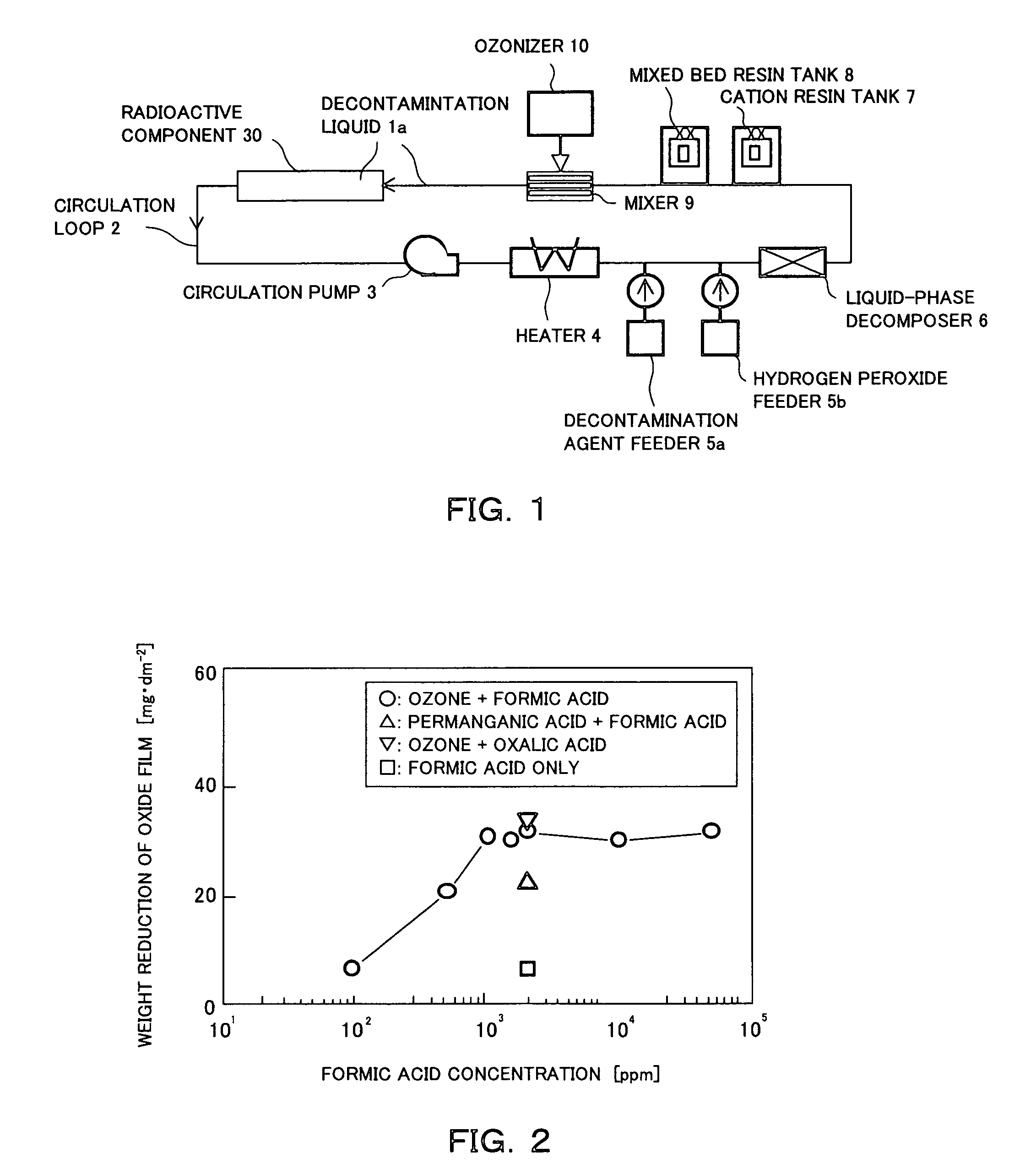

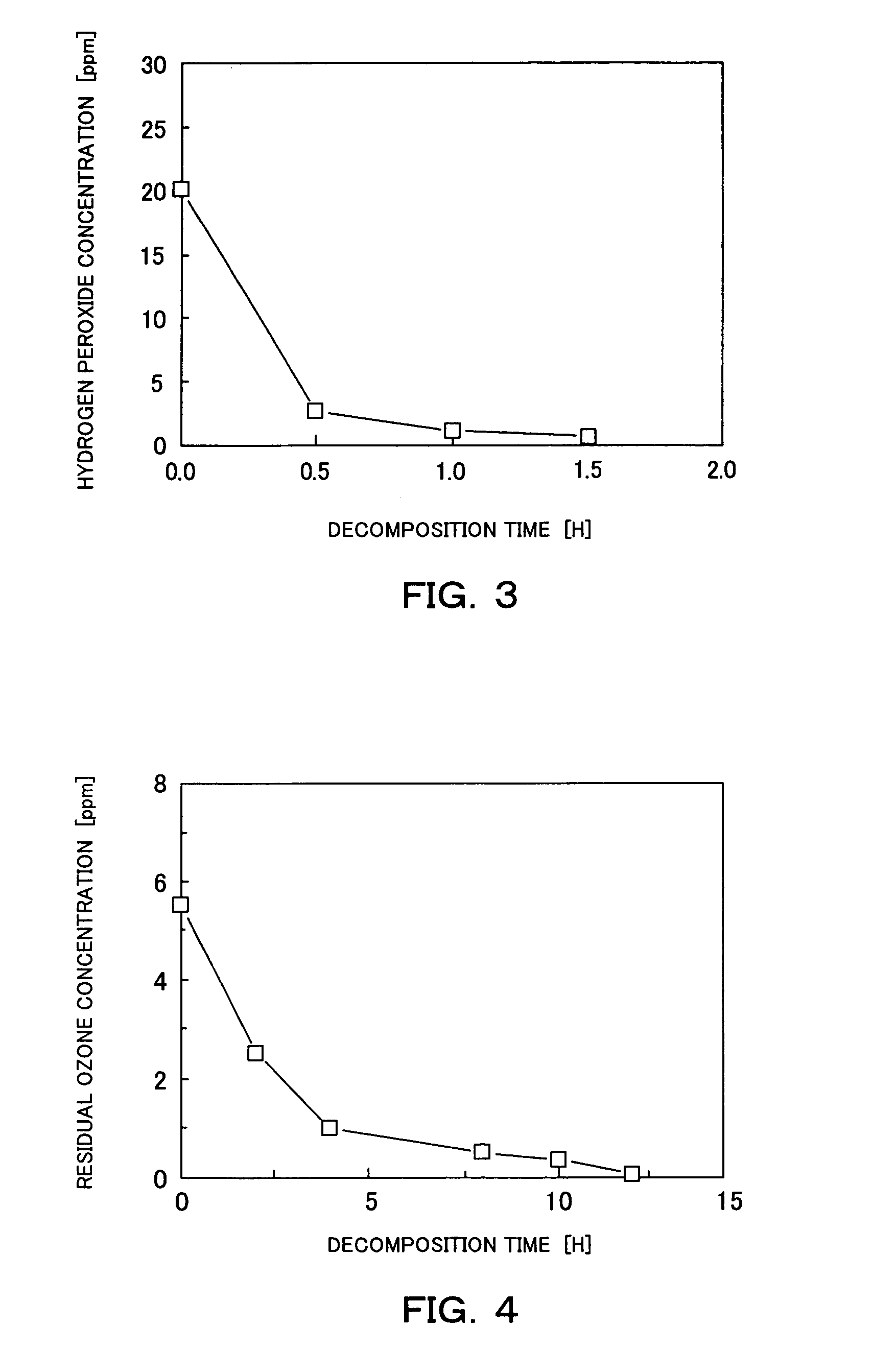

System and method for chemical decontamination of radioactive material

InactiveUS20060167330A1StepHigh dissolution rateNuclear engineering problemsDisinfectionOXALIC ACID DIHYDRATEPermanganic acid

A method for chemically decontaminating radioactive material. The method includes reducing-dissolving step for setting surface of radioactive material in contact with reducing decontamination liquid including mono-carboxylic acid and di-carboxylic acid as dissolvent; and oxidizing-dissolving step for setting the surface of the radioactive material in contact with oxidizing decontamination liquid including oxidizer. The method may include repeated pairs of steps, each pair including the reducing-dissolving step and the oxidizing-dissolving step. The mono-carboxylic acid may include formic acid, and the di-carboxylic acid includes oxalic acid. The oxidizer may be ozone, permanganic acid or permanganate.

Owner:KK TOSHIBA

Preparation method of aluminum alloy cobalt salt chemical conversion coating treating fluid

The invention relates to a preparation method of aluminum alloy cobalt salt chemical conversion coating treating fluid, belonging to the field of aluminum alloy surface treatment. A porous chemical conversion coating formed by treating aluminum alloy through treating fluid has the characteristics of no chromium, environment friendliness, and good corrosion resistance property, and the like, the treating fluid is prepared from cobalt salt, oxidant, ligand and water, wherein per liter of cobalt salt chemical conversion treating fluid contains the following compositions by weight: 20-50g of cobalt salt, 1-50g of an oxidant, and 2-7g of ligand, and the PH value of the treating fluid ranges from 3 to 4; the cobalt salt is selected from one or two of cobalt-nitrate hydrate and cobalt-chloride hydrate; the oxidant is selected from one or more of lithium permanganate, sodium permanganate, ammonia permanganate and calcium permanganate; and the ligand is selected from one or two of sodium nitrite or sodium acetate.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

System and method for chemical decontamination of radioactive material

InactiveUS7087120B1StepAmount of generated secondary waste is comparatively smallNuclear engineering problemsNuclear engineering solutionsPermanganic acidRadioactive agent

A method for chemically decontaminating radioactive material. The method includes reducing-dissolving step for setting surface of radioactive material in contact with reducing decontamination liquid including mono-carboxylic acid and di-carboxylic acid as dissolvent; and oxidizing-dissolving step for setting the surface of the radioactive material in contact with oxidizing decontamination liquid including oxidizer. The method may include repeated pairs of steps, each pair including the reducing-dissolving step and the oxidizing-dissolving step. The mono-carboxylic acid may include formic acid, and the di-carboxylic acid includes oxalic acid. The oxidizer may be ozone, permanganic acid or permanganate.

Owner:KK TOSHIBA

Visual type harmful gas remover and preparing method

InactiveCN100563793CPowerful captureEasy to useDispersed particle separationPermanganic acidPhosphate

A visible harmful gas eliminating agent and its preparation method are obtained by treating a porous carrier with permanganate under alkaline conditions. The porous carrier can be solid silica gel with good adsorption function, molecular sieve, zeolite, alumina, calcium chloride, powder, regular or irregular particles, or filter paper. Permanganate is an alkali metal salt of permanganate, and potassium permanganate is the best. Alkaline conditions are provided and maintained by potassium hydroxide, sodium hydroxide, bicarbonate, phosphate, borate or ammonium chloride-ammonia solution. The present invention can capture, adsorb and eliminate various volatile and reducing harmful substances. Gases, and show noxious gas removal results by a clear, regular color change from red to brown.

Owner:无锡优胜美迪环保科技有限公司

Improved activation liquor for PCB and production technology for generating conductive polymer films in through hole and blind hole of PCB

ActiveCN104744974AStrong oxidation abilityLow costCoatingsPrinted element electric connection formationPermanganic acidConductive polymer

The invention discloses improved activation liquor for a PCB. The improved activation liquor for the PCB comprises 1-100g / L of a compound or a mixture containing permanganic acid radical ions, 0.1-20g / L of a compound or a mixture containing at least one of ferrous ion, ferric ion and ammonium ion and the balance of deionized water. The improved activation liquor for the PCB contains one or at least two of ferrous ion, ferric ion and ammonium ion, so that an activation reaction can be carried out at low temperature, and energy consumption is reduced compared with the traditional technological conditions; meanwhile, activating treatment requirements of a hard board and a flexible board can be met at the same time, and the problems that an activation tank needs to be prepared from a high-temperature-resistant and strong-oxidation-resistant material as the traditional activation liquor has strong oxidizing property and equipment cost is high can be solved. The activation liquor is improved, so that the energy consumption is reduced, the equipment cost is reduced, and product application range is expanded.

Owner:GUANGDONG SKYCHEM TECH LTD

Surface modification liquid for plastic and method of metallizing plastic surface therewith

InactiveCN101400823AImprove wettabilityLarge adsorption capacityLiquid/solution decomposition chemical coatingPermanganic acidPhosphoric acid

A surface modification liquid for plastic that in pretreatment for metallization of a plastic surface by metal plating, solves the problems of etching treatment with the use of conventional etchant containing chromic acid, etc. There is provided a surface modification liquid for plastic characterized by containing permanganic acid, phosphoric acid and nitric acid.

Owner:EBARA-UDYLITE CO LTD

Broad-spectrum efficient disinfectant and preparation method thereof

The invention relates to the technical field of disinfection appliances and the field of chemical engineering cleaning and particularly relates to a broad-spectrum efficient disinfectant and a preparation method of the road-spectrum efficient disinfectant. The broad-spectrum efficient disinfectant comprises the following components in parts by weight: 10-80 parts of peroxosulfuric acid or permanganic acid, 5-50 parts of salt, 5-30 parts of acid and 3-20 parts of a cosolvent. The preparation method comprises the steps of adding the weighed components into a solid grinding machine and a stirring machine, and carrying out stirring and uniform mixing. The broad-spectrum efficient disinfectant prepared by virtue of the preparation method has bacteriocidal spectra of active oxygen and active chlorine, can kill the vast majority of pathogenic microorganisms, can be applied to environmental sterilization, air sterilization, body surface sterilization, wall and floor sterilization, public health place sterilization, farm sterilization and cultivation place sterilization and can further be applied to sterilization and derusting of medical instruments and production equipment.

Owner:张卢军

Method for manufacturing multilayer circuit board

InactiveUS20030021889A1Increase resistanceEasy to useVacuum evaporation coatingSputtering coatingPermanganic acidEngineering

A method for manufacturing a multilayer circuit board, in which adhesion between electrical insulating layer and a conductive layer is high and the patternability is also excellent, is provided. The method for manufacturing the multilayer circuit board comprises a step of; 1) bringing the surface of the electrical insulating layer produced by setting a setting resin composition containing an alicyclic olefin polymer or an aromatic polyether polymer into contact with a permanganic acid compound or a plasma, 2) dry-plating the surface and then wet- or dry-plating the surface, 3) dry-plating the surface several times and then wet-plating the surface, or 4) plating the surface and then annealing it, so as to form a conductive layer.

Owner:ZEON CORP

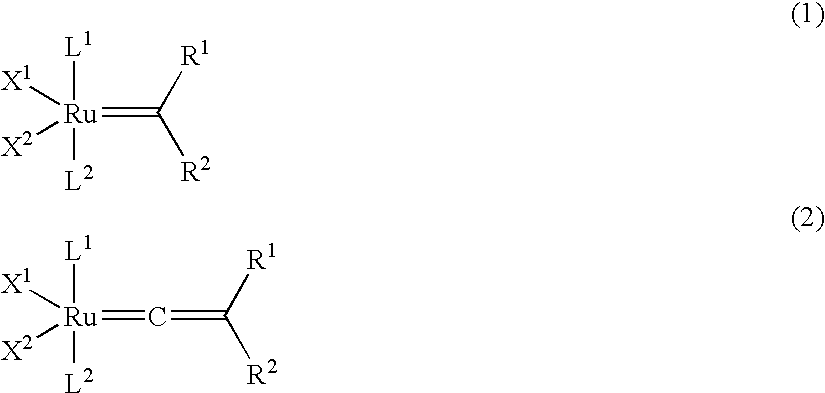

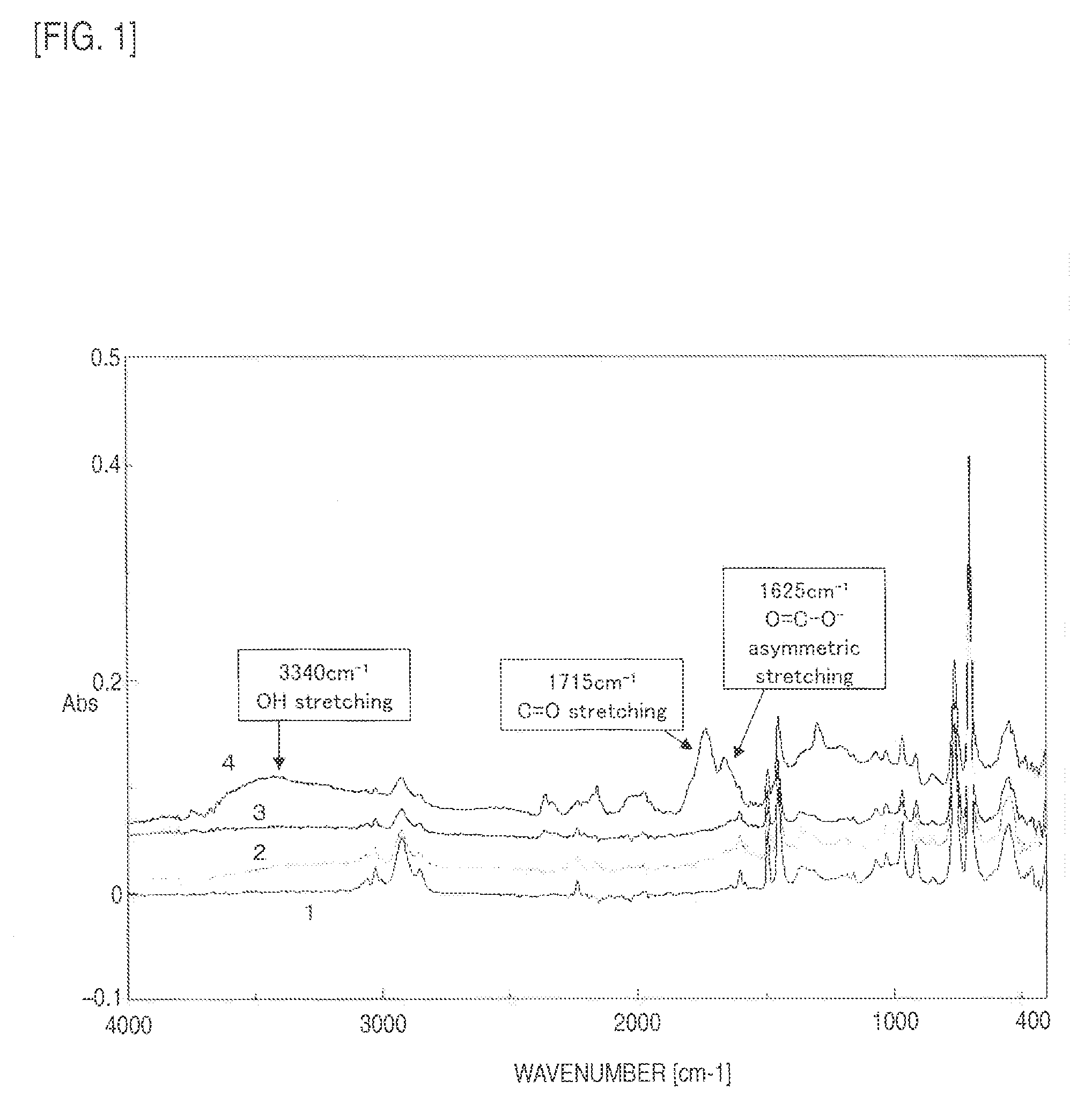

Cluster compounds containing [Mn3SrO4] and [Mn4SrO4] core structures, preparation method and application thereof

ActiveUS20200290031A1Electrolysis componentsOrganic-compounds/hydrides/coordination-complexes catalystsPermanganic acidPtru catalyst

[Mn3SrO4] cluster compounds are synthesized in a single step from raw materials consisting of simple and inexpensive Mn2+, Sr2+ inorganic compounds and carboxylic acids by using permanganate anion as oxidant. This step can be followed by the synthesis of asymmetric biomimetic water splitting catalyst [Mn4SrO4] cluster compounds in the presence of water. The [Mn4SrO4] cluster compound can catalyze the splitting of water in the presence of an oxidant to release oxygen gas. The neutral [Mn3SrO4](R1CO2)6(R1CO2H)3 cluster compound can serve as precursors for the synthesis of biomimetic water splitting catalysts, and can be utilized in the synthesis of different types of biomimetic water splitting catalysts. [Mn4SrO4](R1CO2)8(L1)(L2)(L3)(L4) cluster compounds can serve as artificial water splitting catalysts, can be utilized on the surface of an electrode or in the catalyzed splitting of water driven by an anoxidant.

Owner:INST OF CHEM CHINESE ACAD OF SCI

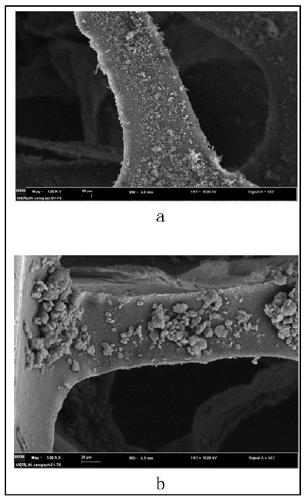

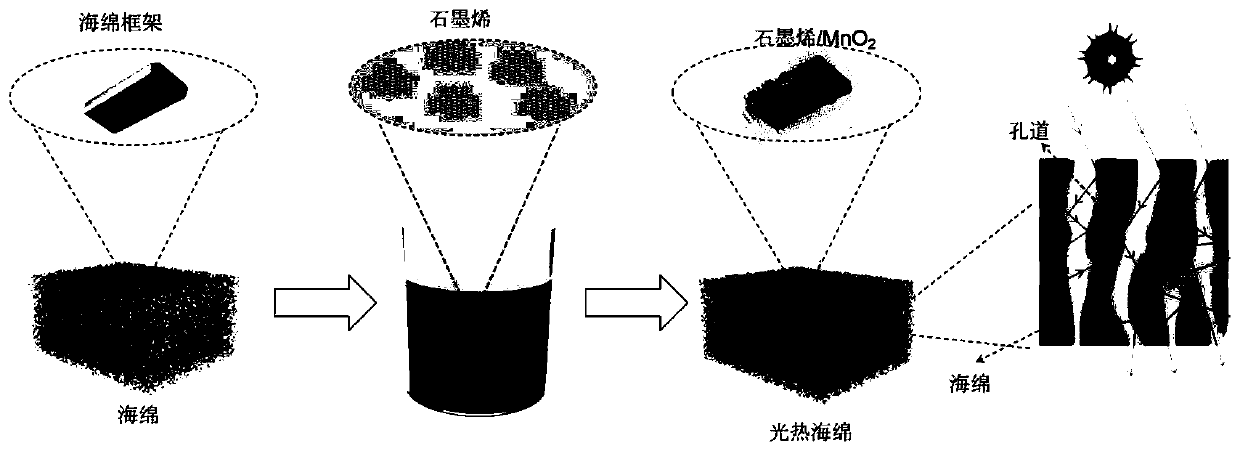

Photothermal sponge, and preparation method and application thereof

InactiveCN110256721ASimple preparation processReduce manufacturing costChemical industryDispersed particle separationPermanganic acidReaction temperature

The invention relates to a photothermal sponge, a preparation method thereof and an application thereof in air purification. The method comprises the following steps: 1) dissolving a graphene material in water, and carrying out ultrasonic treatment to prepare a graphite dispersion solution with a certain concentration; 2) immersing the porous sponge in the graphite dispersion solution, and carrying out ultrasonic treatment to absorb the graphite dispersion solution; and 3) continuously adding permanganic acid or permanganate to the solution, controlling the concentration of the permanganate, the reaction temperature and the reaction time, and drying the obtained sample to obtain the sample. 1) the preparation method of the synthesized photothermal sponge has the advantages of simple preparation process, low production cost, and easiness in large-scale production; 2) the photothermal sponge has an excellent characteristic of adsorbing toluene in indoor air, and can be reused; and 3) the porous structure of the sponge can enhance the scattering and absorption of light in pores, so solar energy is efficiently utilized, and heat is rapidly produced.

Owner:WUHAN UNIV OF TECH

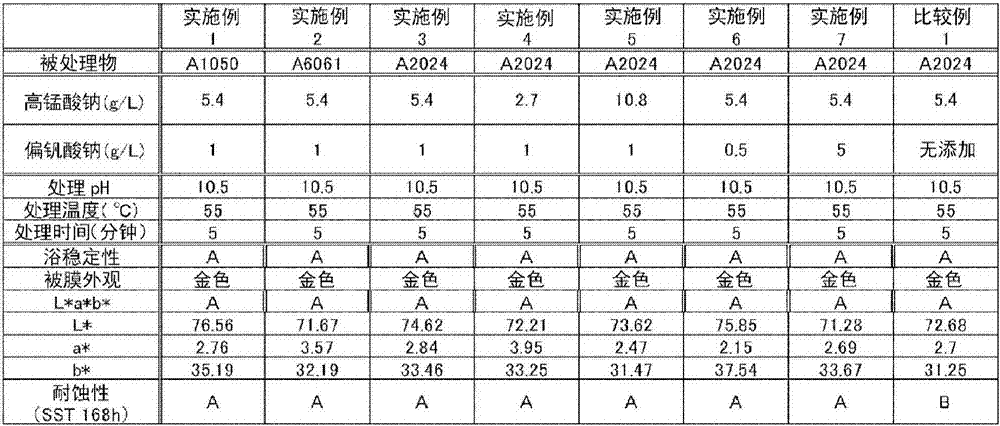

Chemical conversion solution for aluminum or aluminum alloy, chemical conversion method, and chemical conversion film

InactiveCN107250435AImprove securityImprove corrosion resistanceMetallic material coating processesPermanganic acidOxygen

The present invention addresses the problem of providing a chemical conversion surface treatment solution capable of forming a chemical conversion film with excellent corrosion resistance and design on an article, in which the surface portion comprises aluminum or an aluminum alloy, using a process similar to conventional chemical conversion without using components that have high environmental impact such as hexavalent chromium, trivalent chromium, or fluorine. The present invention relates to a chemical conversion solution for aluminum or aluminum alloy comprising an aqueous alkaline solution that contains a permanganic acid compound and at least one kind of metal oxygen acid compound selected from a group consisting of vanadic acid compounds, molybdic acid compounds, tungstic acid compounds, zirconic acid compounds and niobic acid compounds.

Owner:OKUNO CHEM IND CO LTD

Bistriazole ligand-regulated cadmium 5-nitroisophthalate complex, preparation method thereof, and application of complex as fluorescent probe

ActiveCN110878102AImprove thermal stabilityStrong and stable fluorescenceOrganic chemistry methodsFluorescence/phosphorescenceFluoProbesBenzene

The invention discloses a bistriazole ligand-regulated cadmium 5-nitroisophthalate complex, a preparation method thereof, and an application of the complex as a fluorescent probe. The complex has a 4-linked three-dimensional triple penetration dmp topological network structure, and the chemical expression of the complex is [Cd(5-NO2IP)(BTB)(H2O)]n. The preparation method is characterized in that the complex is prepared by a hydrothermal reaction of 5-nitroisophthalic acid, an inorganic base, 1,4-bis(1,2,4-triazol-1-methyl)benzene and a cadmium salt. The preparation method has the advantages ofsimple process, convenience in operation, and high yield; and the prepared bistriazole ligand-regulated cadmium complex has stable fluorescence properties and good thermal stability, and can be usedfor detecting Fe (III) ions and permanganate ions at the same time.

Owner:HENGYANG NORMAL UNIV

Preparation method for preparing high-purity vanadium from acidic high-manganese vanadium-containing leached solution

The invention discloses a preparation method, in particular discloses a preparation method for preparing high-purity vanadium by using an acidic high-manganese vanadium-containing leaching solution, and belongs to the technical field of metallurgical production technology. The invention provides a method for preparing high-purity vanadium by using an acidic high-manganese vanadium-containing leaching solution with low production cost and good preparation effect. The preparation method first removes impurity manganese under strong alkaline conditions, then precipitates and washes the vanadium precipitates under strong acidic conditions, and finally calcines the vanadium precipitates to obtain the high-purity vanadium.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Etching solution, and method for metallization of plastic surface employing the method

InactiveCN101680093AEasy to modifyImprove stabilityLiquid/solution decomposition chemical coatingSurface treatment compositionsPolymer sciencePermanganic acid

Disclosed is an etching solution which is highly effective for modifying various plastic materials, has high bath stability, and can be used for the metallization of a plastic surface on an industrialscale. The etching solution comprises a permanganic acid salt and a periodic acid salt or a salt thereof, and has a pH value of 2.0 or lower.

Owner:EBARA-UDYLITE CO LTD

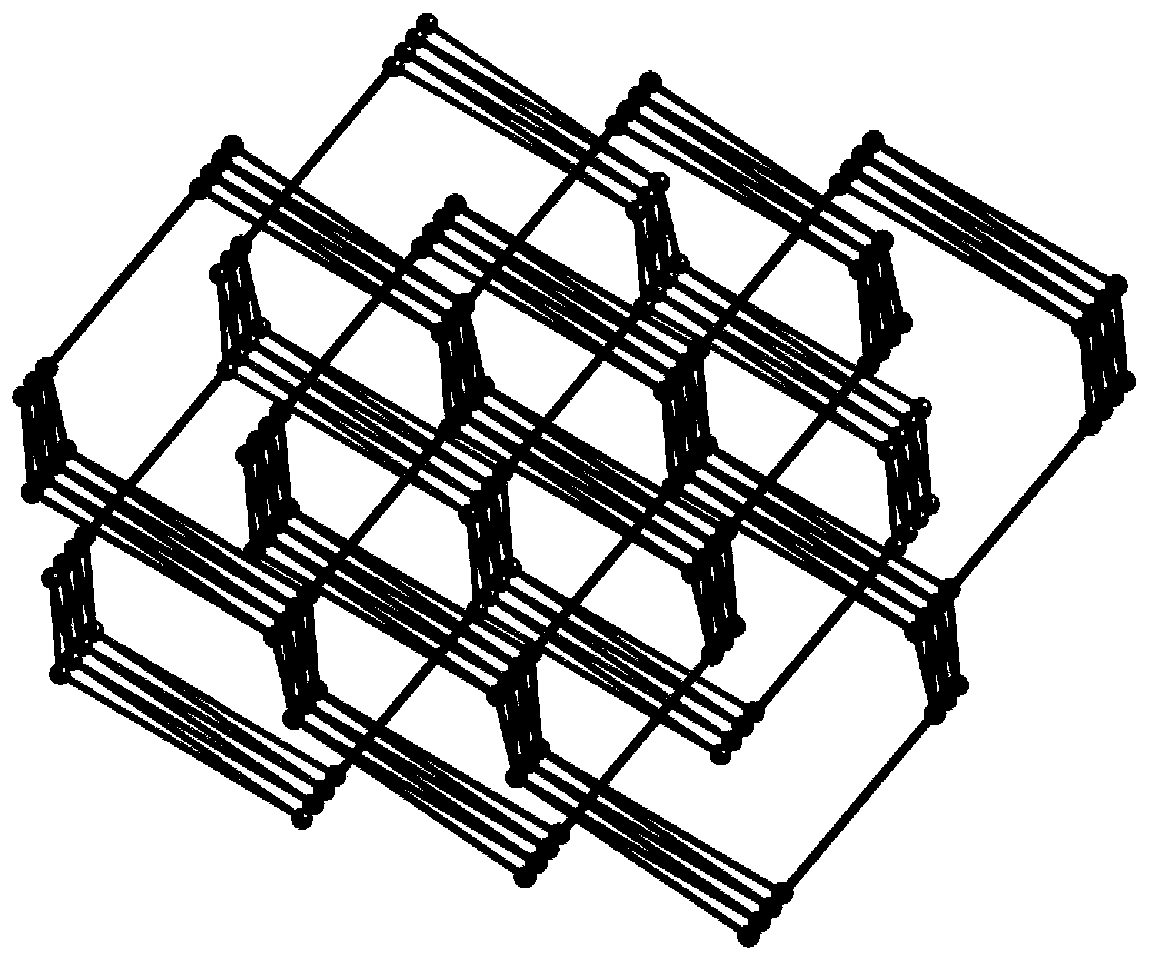

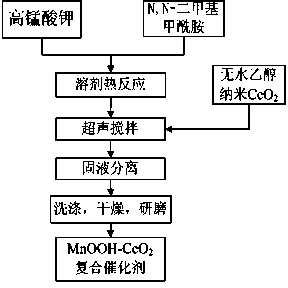

MnOOH nanorod denitration catalyst and preparation method thereof

InactiveCN103831096AGood denitrification rateIdeal denitrification rateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPermanganic acid

The invention discloses a MnOOH nanorod denitration catalyst and a preparation method thereof. The catalyst comprises a MnOOH nanorod and CeO2 attached to the MnOOH nanorod. The preparation method comprises the following steps: carrying out a solvothermal reaction on potassium permanganate and N,N-dimethyl formamide at the temperature of 100-200 DEG C for 2-4 hours to obtain the MnOOH nanorod; adding absolute ethyl alcohol and nanometer CeO2 particles into the reacted solution, and ultrasonically stirring for 3-5 hours, so that the nanometer CeO2 particles are fully loaded to the MnOOH nanorod; and performing solid-liquid separation on the impregnated product, and washing and drying to obtain the MnOOH-CeO2 composite catalyst. The preparation method is simple in process and simple and convenient to operate, industrial production is conveniently realized, the catalyst does not have toxicity and is high in safety, and harm of the used catalyst to the environment is reduced.

Owner:CHONGQING UNIV

Method for plating metal on surface of insulating base material

InactiveCN108601235AImprove surface propertiesImprove bindingPrinted circuit manufacturePermanganic acidConductive polymer

The invention relates to a method for plating a metal on the surface of an insulating base material. The method comprises the following steps: alternately touching the surface of the insulating base material with polycations and polyanions to produce a modified surface; touching the modified surface with an aqueous solution containing permanganate ions to form a manganese dioxide adsorption layeron the modified surface; forming a conductive polymer layer on the surface of the manganese dioxide adsorption layer; and performing plating on the surface of the conductive polymer layer to form a metal layer. According to the method, by means of the alternate deposition of the polycations and polyanions on the surface of the insulating base material to form a firmly combined coating layer withthe surface of the base material, after a thin film with a certain thickness is uniformly formed on the surface by means of the modification and adsorption, under the same metal plating solution and plating conditions, the deep plating ability and the dispersing ability of the plating solution are greatly improved, the obtained metal plating layer has the characteristics of flatness, uniformity and good backlight effect, and the phenomena of hole breakage and that the Plating metal layer at a certain site in the hole is too thin are avoided.

Owner:GUANGDONG GUANGHUA SCI TECH +1

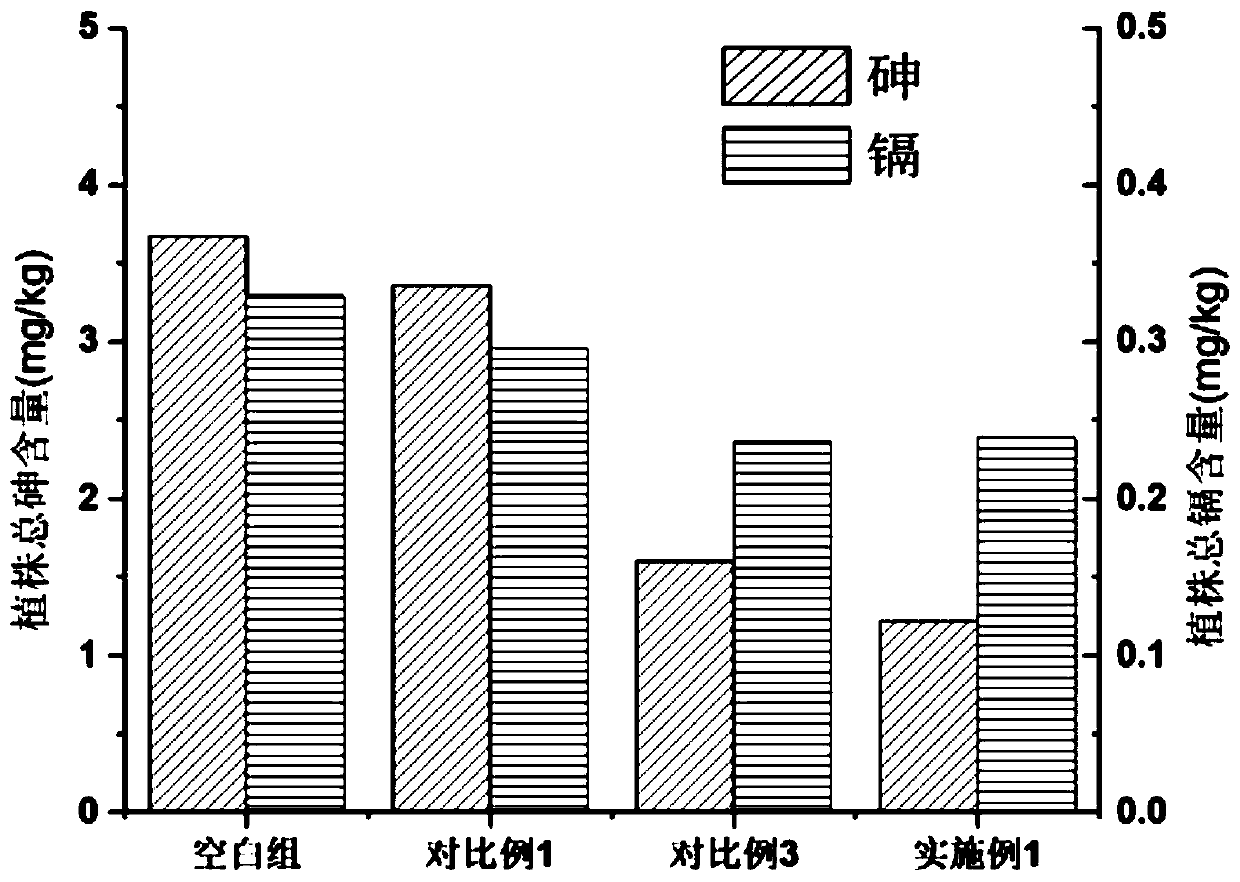

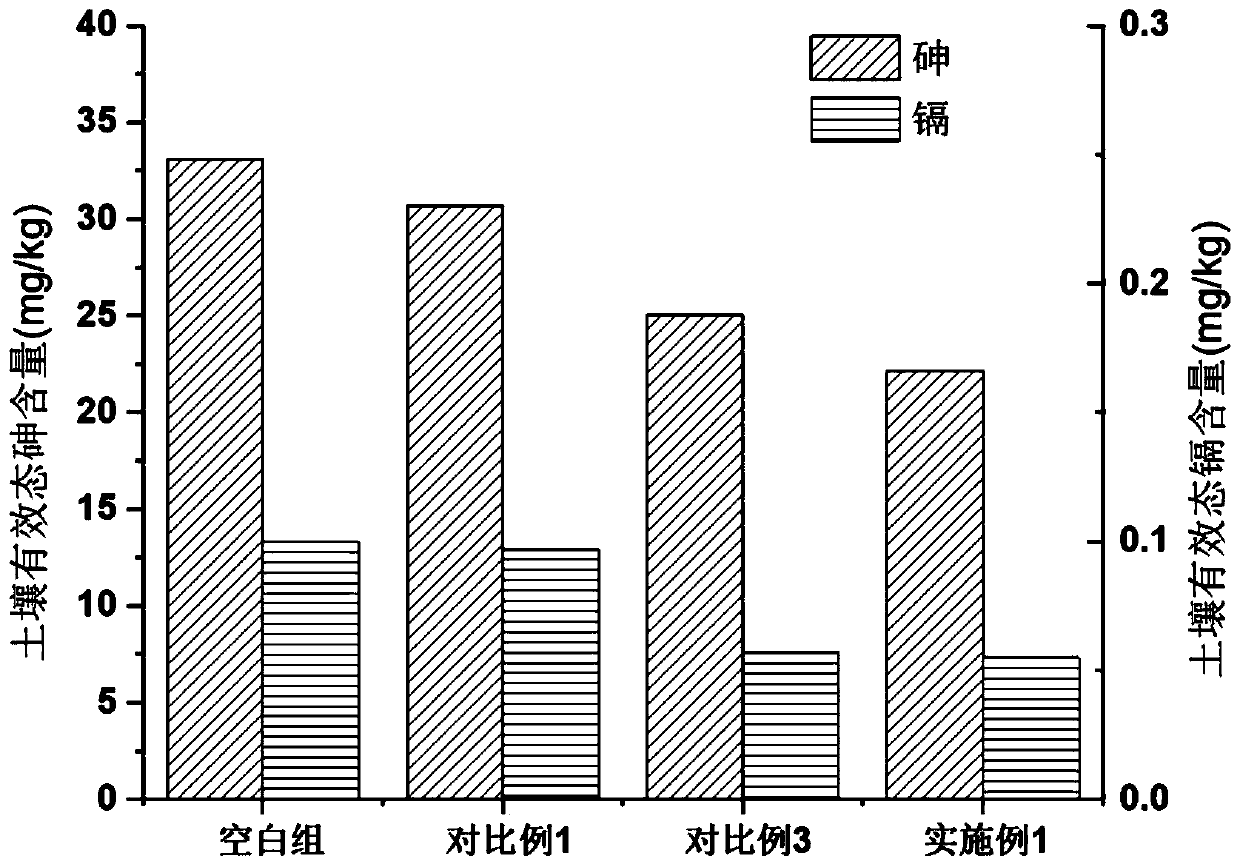

Method for treating soil cadmium-arsenic combined pollution by using multifunctional manganese-based material

InactiveCN111282985AReduce oxidation rateReduced release rateAgriculture tools and machinesContaminated soil reclamationPermanganate saltPermanganic acid

The invention belongs to the technical field of environmental protection, and particularly discloses a method for treating soil cadmium-arsenic combined pollution by using a multifunctional manganese-based material. The method specifically comprises the steps: uniformly mixing the multifunctional manganese-based material with cultivated land soil; a preparation method of the multifunctional manganese-based material is prepared by the following steps: uniformly mixing a potassium permanganate aqueous solution with zeolite, and stirring to obtain a turbid liquid; heating the turbid liquid for reaction, drying to obtain a manganese-based material after the reaction is finished, and compounding the manganese-based material with limestone to obtain the multifunctional manganese-based material.According to the invention, permanganate is loaded on a zeolite mineral material, so that the oxidation and release rate of permanganate is reduced, and the long-term effect of permanganate in soil arsenic oxide and cadmium and arsenic immobilization is improved; Mn<2+> ions can also improve the antagonism of crops such as rice and the like on cadmium, and remarkably reduce the absorption of cropssuch as rice and the like on cadmium and the toxic action of cadmium on rice.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

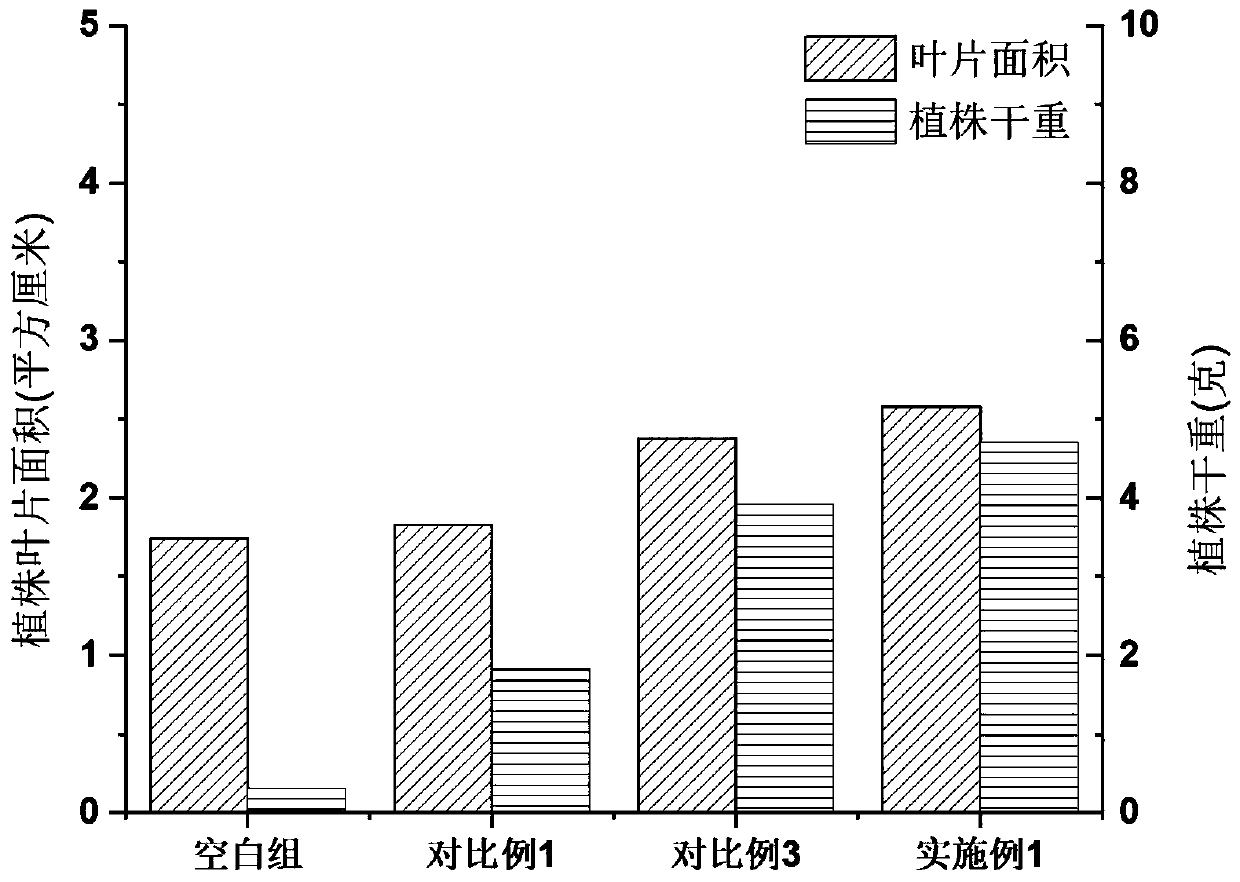

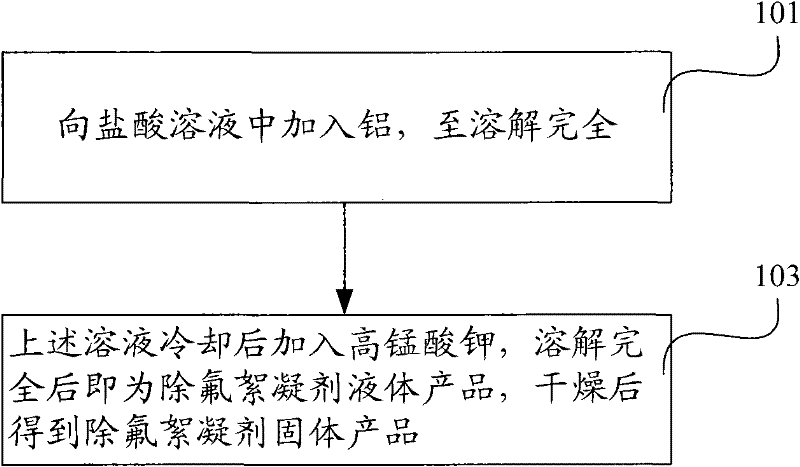

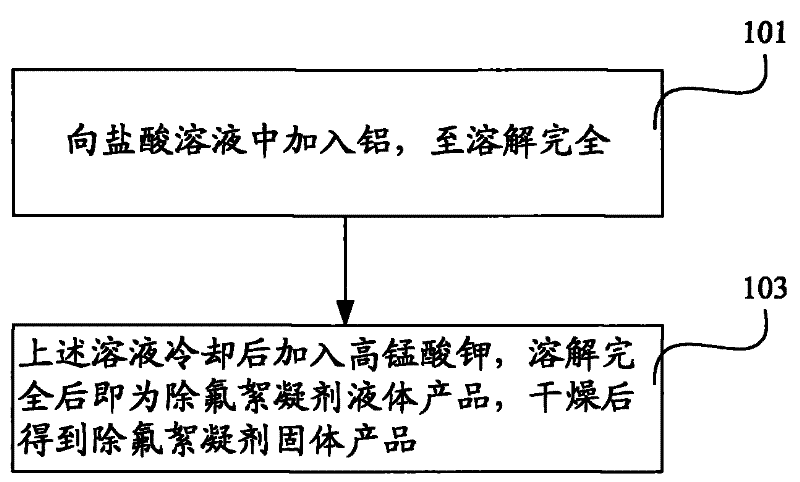

Defluorination flocculant and preparation method thereof

InactiveCN102234150AEfficient removalReduce pollutionWater contaminantsEnergy based wastewater treatmentPermanganic acidLiquid state

The invention discloses a defluorination flocculant and a preparation method thereof. The defluorination flocculant is characterized in that: the defluorination flocculant mainly comprises a permanganic acid composite salt with hydroxy groups; the permanganic acid composite salt has a solid state and a liquid state; the solid permanganic acid composite salt is purple in color and granular in state, and does not air-slake and deteriorate; and the liquid permanganic acid composite salt is aubergine in color. The invention also provides the preparation method of the defluorination flocculant. The defluorination flocculant and the preparation method thereof which are adopted in the invention allow F<-> in waste water containing fluorine to be effectively removed, so the pollution of the polysilicon solar cell industry to environment is reduced.

Owner:BAODING KAISIDA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation of light-emitting crystal material {[Cd2(tpphz)(bdc)([mu]2-OAc)2].tpphz.2H2O}n for rapid and high-sensitivity detection of permanganate ions Preparation of light-emitting crystal material {[Cd2(tpphz)(bdc)([mu]2-OAc)2].tpphz.2H2O}n for rapid and high-sensitivity detection of permanganate ions](https://images-eureka.patsnap.com/patent_img/539562a1-0deb-4e53-8f2f-0f7bf3b13024/RE-HDA0002269020590000011.png)

![Preparation of light-emitting crystal material {[Cd2(tpphz)(bdc)([mu]2-OAc)2].tpphz.2H2O}n for rapid and high-sensitivity detection of permanganate ions Preparation of light-emitting crystal material {[Cd2(tpphz)(bdc)([mu]2-OAc)2].tpphz.2H2O}n for rapid and high-sensitivity detection of permanganate ions](https://images-eureka.patsnap.com/patent_img/539562a1-0deb-4e53-8f2f-0f7bf3b13024/RE-HDA0002269020590000012.png)

![Preparation of light-emitting crystal material {[Cd2(tpphz)(bdc)([mu]2-OAc)2].tpphz.2H2O}n for rapid and high-sensitivity detection of permanganate ions Preparation of light-emitting crystal material {[Cd2(tpphz)(bdc)([mu]2-OAc)2].tpphz.2H2O}n for rapid and high-sensitivity detection of permanganate ions](https://images-eureka.patsnap.com/patent_img/539562a1-0deb-4e53-8f2f-0f7bf3b13024/RE-HDA0002269020590000021.png)

![Cluster compounds containing [Mn3SrO4] and [Mn4SrO4] core structures, preparation method and application thereof Cluster compounds containing [Mn3SrO4] and [Mn4SrO4] core structures, preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/7625b4fd-512b-407c-90cd-52124ef33130/US20200290031A1-D00001.png)

![Cluster compounds containing [Mn3SrO4] and [Mn4SrO4] core structures, preparation method and application thereof Cluster compounds containing [Mn3SrO4] and [Mn4SrO4] core structures, preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/7625b4fd-512b-407c-90cd-52124ef33130/US20200290031A1-D00002.png)

![Cluster compounds containing [Mn3SrO4] and [Mn4SrO4] core structures, preparation method and application thereof Cluster compounds containing [Mn3SrO4] and [Mn4SrO4] core structures, preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/7625b4fd-512b-407c-90cd-52124ef33130/US20200290031A1-D00003.png)