Improved activation liquor for PCB and production technology for generating conductive polymer films in through hole and blind hole of PCB

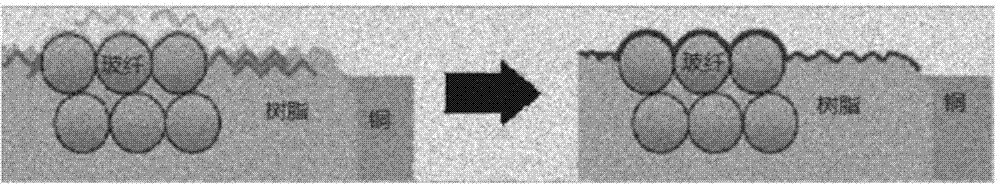

A production process and technology of activation solution, applied in the direction of electrical connection formation and coating of printed components, can solve the problems of unsuitable PCB soft board, high temperature, and high equipment cost, and achieve lower energy consumption, lower activation temperature, and lower energy consumption. consumption and equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

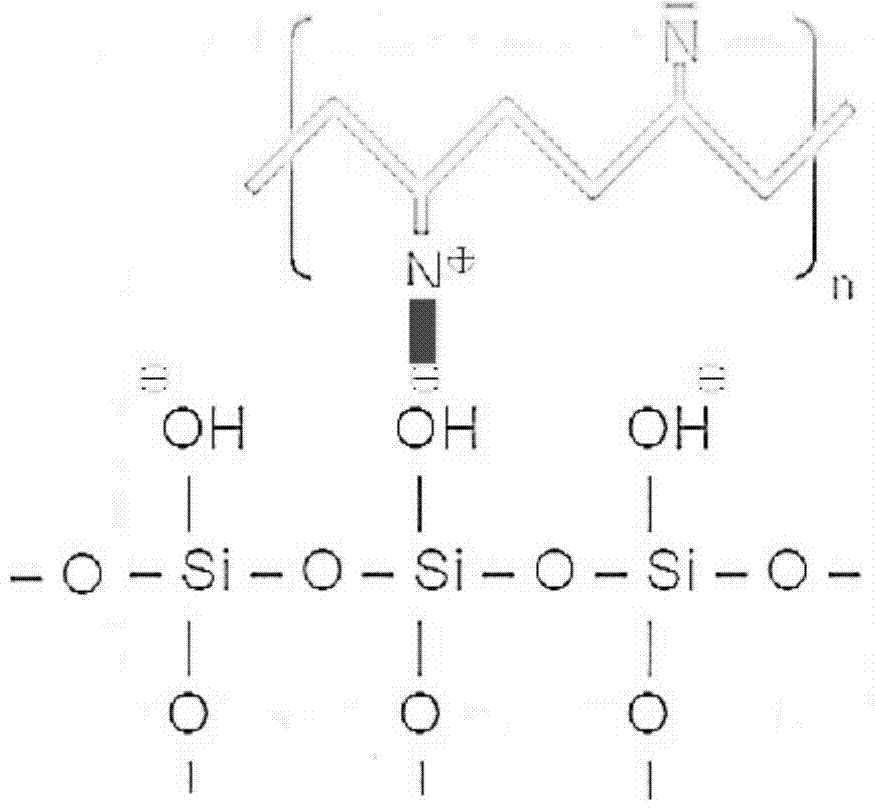

Problems solved by technology

Method used

Image

Examples

Embodiment 1

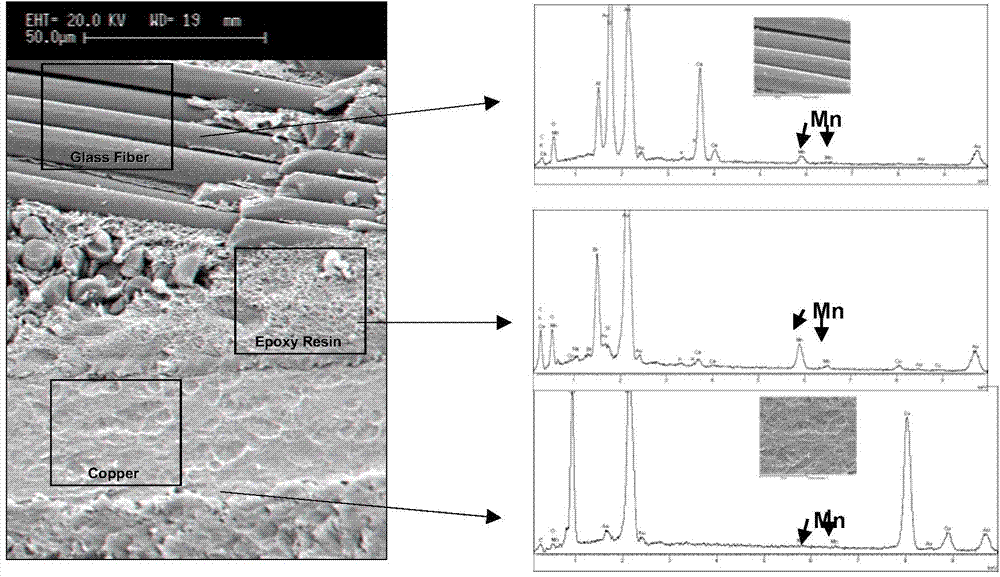

[0049] Rigid plate vertical line Generates a polymer conductive film in a through-hole with a diameter of 250 μm and a depth of 1.6 mm.

[0050] The formula of the improved activating solution is as follows:

[0051]

[0052] The film-forming solution formula is as follows:

[0053]

[0054] Place the PCB in 35mL / L H 2 SO 4 (50% w / w) and 90g / L NaPS, keep warm at 30°C for 1min, and wash with water; then place the PCB in 65mL / L adjustment solution SkyPoly 391C, keep warm at 62°C for 2min, and wash with water; then put the PCB Put it in the activation tank, add the above-mentioned improved activation solution according to the proportion, adjust the pH of the improved activation solution to 6.5 with boric acid, control the temperature of the activation tank at 70°C, keep it warm for 3 minutes, wash with water, and form a manganese dioxide film on the surface of the PCB; Finally, place the PCB in the mixture of the above-mentioned film-forming solutions SkyPoly 396A, SkyPo...

Embodiment 2

[0059] Horizontal line of hard board The production process of the present invention is used to generate a polymer conductive film in a through hole with a diameter of 250 μm and a thickness of 2.4 mm.

[0060] The formula of the improved activating solution is as follows:

[0061] SkyPoly 393C 110m L / L

[0063] Deionized water balance

[0064] The film-forming solution formula is as follows:

[0065]

[0066] Place the PCB in 35mL / L H 2 SO 4(50% w / w) and 90g / L NaPS, keep warm at 30°C for 1min, and wash with water; then place the PCB in 65mL / L adjustment solution SkyPoly 391C, keep warm at 60°C for 1min, and wash with water; then put the PCB Put it in the activation tank, add the above-mentioned improved activation solution according to the proportion, adjust the pH of the improved activation solution to 6 with sulfuric acid, control the temperature of the activation tank to 65°C, keep it warm for 80s, wash with water, and form a manganese...

Embodiment 3

[0070] Horizontal line of hard board The production process of the present invention is used to produce a polymer conductive film in blind holes with a diameter of 100 μm and a depth of 100 μm.

[0071] The formula of the improved activating solution is as follows:

[0072]

[0073] The film-forming solution formula is as follows:

[0074]

[0075] Place the PCB in 35mL / L H 2 SO 4 (50% w / w) and 90g / L NaPS, keep warm at 30°C for 1min, and wash with water; then place the PCB in the adjustment solution SkyPoly 391C, keep warm at 60°C for 3min, and wash with water; then place the PCB in the activation In the tank, add the above-mentioned improved activation solution according to the proportion, adjust the pH of the improved activation solution to 6.5 with phosphoric acid, control the temperature of the activation tank to 75°C, keep it warm for 1min, wash with water, and form a manganese dioxide film on the surface of the PCB; finally the PCB Put it in the mixed solution o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com