Surface modification liquid for plastic and method of metallizing plastic surface therewith

A surface modification and metallization technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of insufficient catalyst metal adsorption, insufficient surface modification, and small etching roughness. , to achieve the effect of realizing the plating process, the energy cost is favorable, and the bonding is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

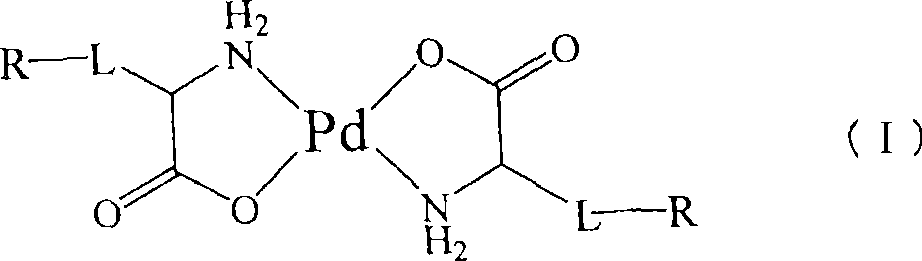

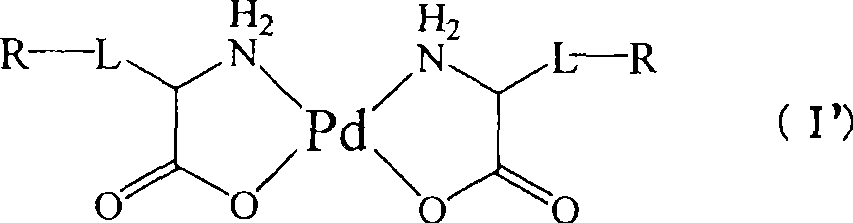

[0035] The palladium complex (I) can be prepared by mixing 1 mol of palladium salt solution with more than 2 mol of basic amino acid aqueous solution at a temperature of about 20°C to 100°C, and after completely dissolving it, the pH value is adjusted to 4.0 to 4.0. 7.5 or so to proceed.

[0036] The palladium complex (I) solution obtained as described above may be a refined product purified by known means, or a powder obtained by concentration and freeze-drying, if necessary.

[0037] The catalyst-imparting treatment liquid can be prepared by adjusting the palladium complex (I) solution prepared as above to a predetermined concentration, or by diluting or dissolving the above-mentioned purified product or powder with water to a predetermined concentration.

[0038] The concentration of the palladium complex (I) solution in the catalyst-imparting treatment liquid is 0.5 mg / L to the saturation concentration of the palladium complex, preferably 1 mg / L to 1000 mg / L in terms of me...

Embodiment 1

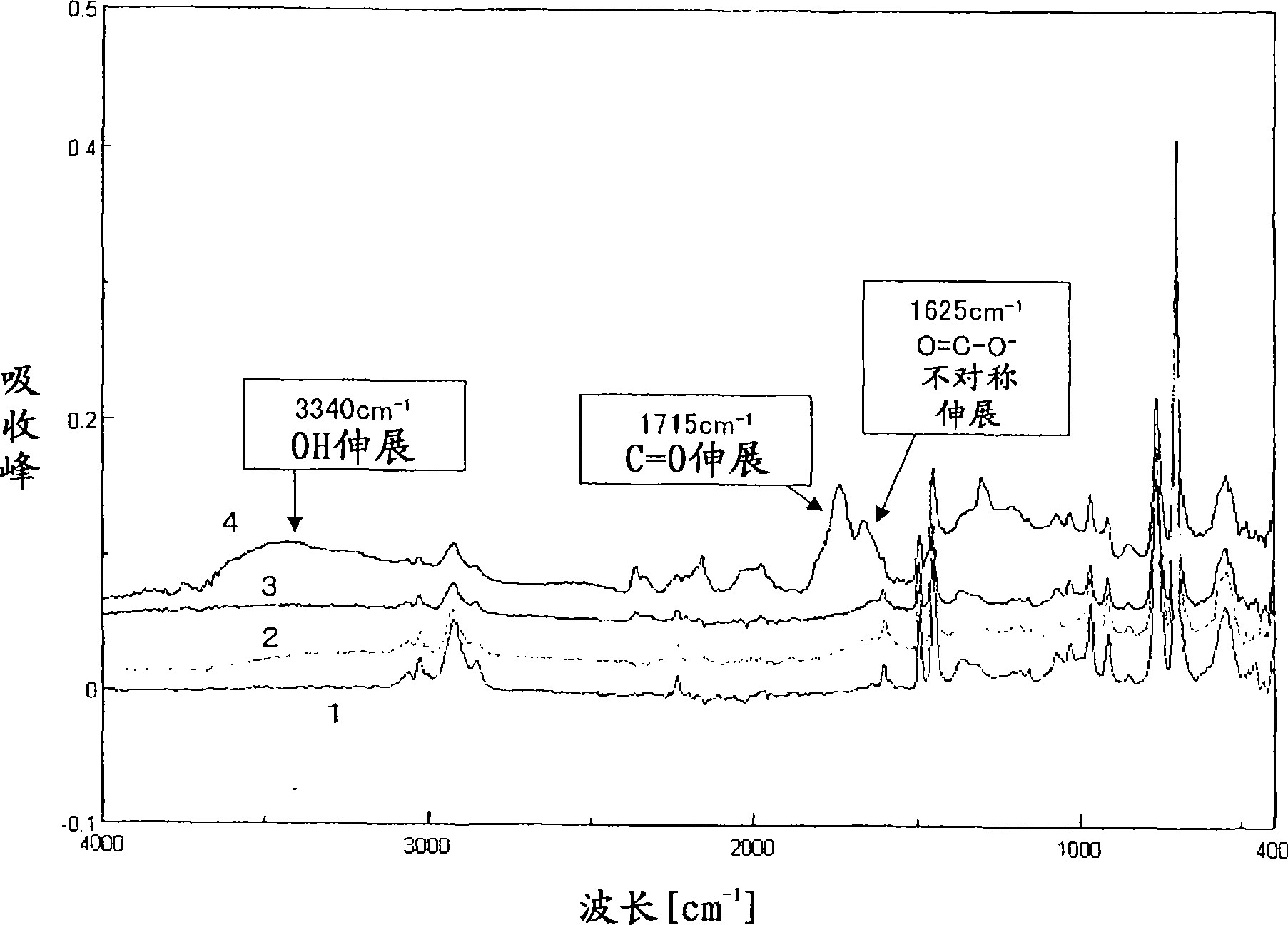

[0049] In the analysis results of FT-IR, it was observed on the surface of the ABS resin molded body treated with a surface modifying liquid containing permanganic acid, phosphoric acid and nitric acid that the 3340cm -1 Nearby peak from hydroxyl, at 1715cm -1 Nearby peak from carbonyl, at 1625cm -1 Nearby peaks originate from carboxyl groups. This result shows that the surface modifying solution strongly modifies the surface of the resin substrate by chemical oxidation. On the other hand, the peaks of these functional groups do not appear on the surface of ABS resin moldings treated with chromic acid / sulfuric acid etching solution and with permanganic acid, phosphoric acid and sulfuric acid etching solution, so it can be confirmed that the improvement of the resin with etching solution The sexual effect is small.

manufacture example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com