Preparation method of aluminum alloy cobalt salt chemical conversion coating treating fluid

A technology of conversion treatment and cobalt salt chemistry, applied in the coating process of metal materials, etc., can solve problems such as unsuitable for large-scale use, strong pungent smell, and complicated preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

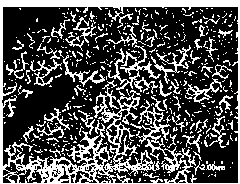

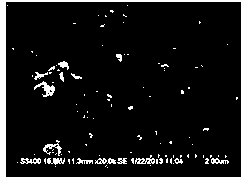

Image

Examples

Embodiment 1

[0040] 1060 aluminum alloy surface cobalt salt chemical transformation method, comprises the following steps:

[0041] (1) Aluminum alloy surface pretreatment process

[0042] First put the 1060 aluminum alloy sample into the degreasing agent to remove the oil stains during surface machining, and the soaking time is 10 minutes;

[0043] After washing with water, put it into an alkaline solution at 70°C for 40 seconds to remove the thin natural oxide layer on the surface. Each liter of alkaline solution is composed of 10g sodium carbonate and 25g sodium hydroxide; after washing with water, put it into a 25% volume percent dilute nitric acid solution Soak for 40s to neutralize; finally wash with water.

[0044] (2) Configuration of cobalt salt chemical conversion treatment solution: every liter of cobalt salt chemical conversion treatment solution contains 30g cobalt chlorate hydrate, 2g lithium permanganate, 2g sodium permanganate, 3g ligand sodium nitrite, the pH of the treat...

Embodiment 2

[0047] A method for chemical conversion of cobalt salt on the surface of 2117 aluminum alloy, comprising the following steps:

[0048] (1) Aluminum alloy surface pretreatment procedure is the same as embodiment 1

[0049] (2) Configuration of cobalt salt chemical conversion treatment solution: every liter of cobalt salt chemical conversion treatment solution contains 30g cobalt chlorate hydrate, 6g lithium permanganate, 6g sodium permanganate, 3g ligand sodium nitrite, the pH of the treatment solution The value is 3.

[0050] (3) The cobalt salt chemical conversion treatment on the surface of the aluminum alloy is to put the pretreated sample into the cobalt salt chemical conversion treatment solution prepared at 50°C for 20 minutes, take it out, wash it with running water, and then ultrasonically clean it with water for 5 minutes. drying.

Embodiment 3

[0052] 7050 aluminum alloy surface cobalt salt chemical transformation method, comprises the following steps:

[0053] (1) Aluminum alloy surface pretreatment process

[0054] First put the 7050 aluminum alloy sample into the degreasing agent to remove the oil stains during surface machining, and the soaking time is 20 minutes;

[0055] After washing with water, put it into an alkaline solution at 60°C for 30 seconds to remove the thin natural oxide layer on the surface. Each liter of alkaline solution is composed of 20g sodium carbonate and 15g sodium hydroxide; after washing with water, put it into a 35% volume percent dilute nitric acid solution Soak for 30s to neutralize; finally wash with water.

[0056] (2) Configuration of cobalt salt chemical conversion treatment solution: per liter of cobalt salt chemical conversion treatment solution contains, 20g cobalt chlorate hydrate, 10g cobalt nitrate hydrate, 20g lithium permanganate, 10g sodium permanganate, 3g ligand nitrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com