Chemical conversion solution for aluminum or aluminum alloy, chemical conversion method, and chemical conversion film

A technology of chemical conversion treatment and aluminum alloy, which is applied in the direction of coating, etc., can solve the problems of no chemical conversion treatment film tone, no effect of low corrosion resistance alloy aluminum, etc., and achieve high safety and low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A plate of A1050 (0.5×50×100 mm in size) was used as a treatment object (test piece), and the following pretreatment was performed.

[0059] 3.0% by mass of alkali degreasing agent "Top Al Clean 101" (trade name, manufactured by Okuno Pharmaceutical Co., Ltd.) was heated to 55° C., and the test piece was immersed for 1 minute for degreasing treatment, and then washed with water for 30 seconds. Moreover, the 7.0 mass % sodium hydroxide aqueous solution was heated to 55 degreeC as needed, the said test piece was immersed for 1 minute, it etched, and thereafter, it washed with water for 30 seconds. Next, the above-mentioned test piece was immersed in 10.0% by mass of a stain remover "Top desmat N-20" (Top desmat N-20 trade name, manufactured by Okuno Pharmaceutical Co., Ltd.) for about 30 to 60 seconds to carry out stain removal. Remove, then wash with water for 30 seconds.

[0060] On the other hand, 1 g / L of sodium metavanadate was added and mixed to deionized water hea...

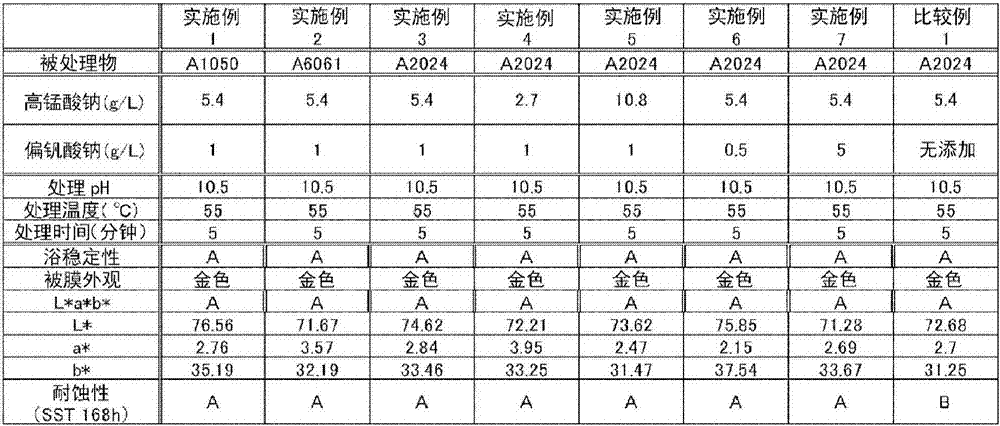

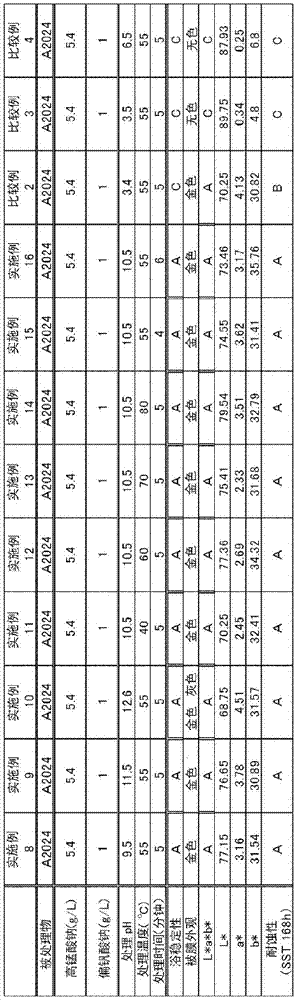

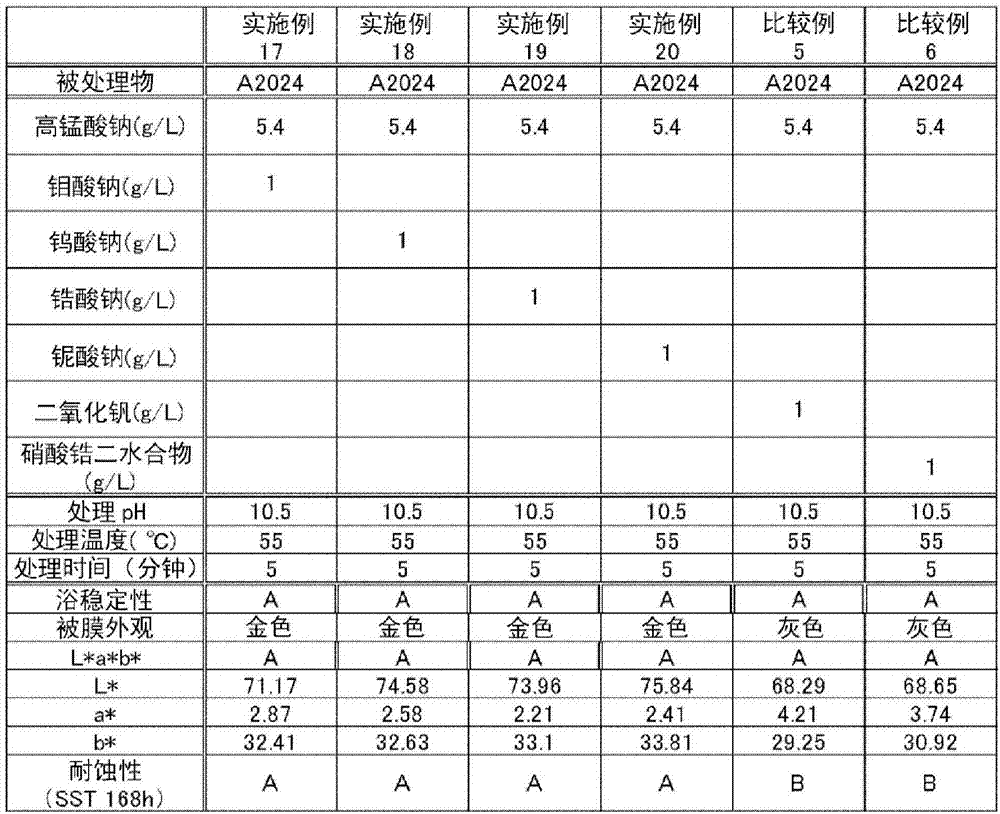

Embodiment 2~20 and comparative example 1~8

[0064] A chemical conversion treatment liquid containing the components described in Tables 1 to 4 was prepared, and the chemical conversion treatment was performed under the conditions described in Tables 1 to 4 using the test piece described in Tables 1 to 4 that had been subjected to the same pretreatment as in Example 1. For each test piece after the chemical conversion treatment, the film appearance and corrosion resistance were evaluated according to the following method, and the bath stability was also evaluated according to the following method. These results are shown in Tables 1-4.

[0065] (bath stability)

[0066] After each chemical conversion treatment liquid was prepared, it was left to stand for 30 days, and the state of the chemical conversion treatment liquid was observed and evaluated according to the following criteria.

[0067] A...No aggregation or precipitation occurs

[0068] C...aggregate or precipitate produced

[0069] (film appearance)

[0070] By...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com