Archaized solid wood composite floor and production process thereof

A solid wood composite floor and production process technology, applied in wood processing appliances, wood veneer bonding, decorative arts and other directions, can solve the problems of many market sales, low competitiveness, single, etc., and achieve the effect of outstanding surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

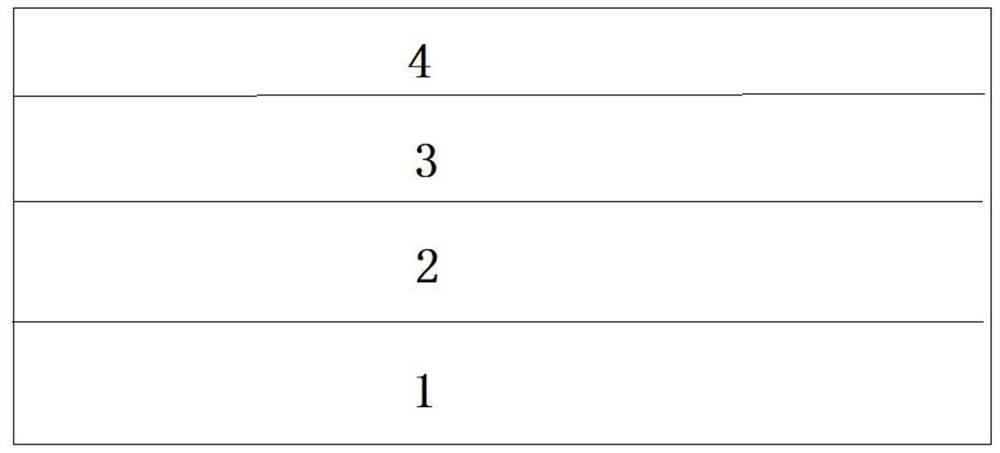

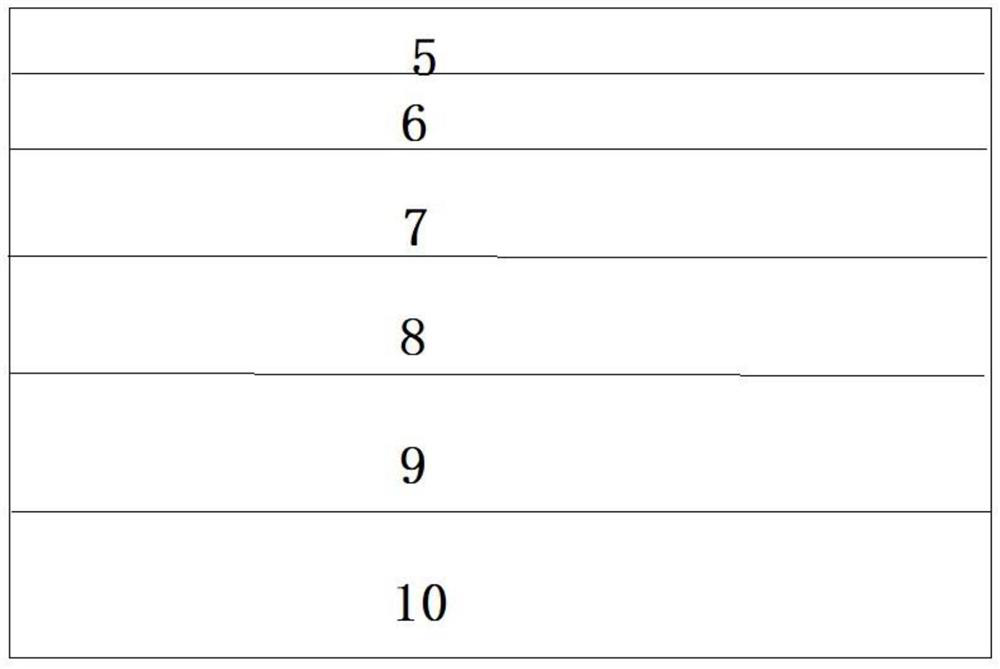

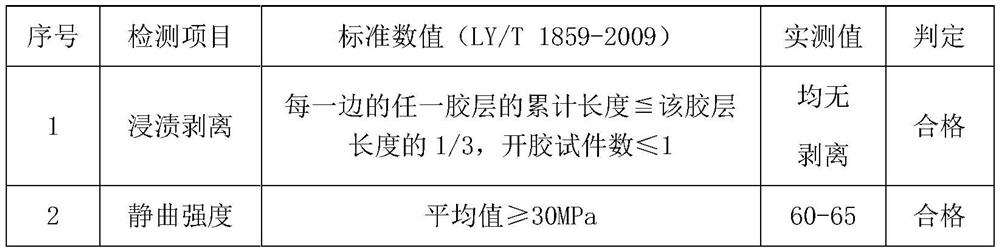

[0032] A kind of antique solid wood composite floor, with a crisscross multi-layer board substrate layer 1 as the main body, the surface layer 2 is attached after the adhesive layer is formed on the surface, and a special antique treatment layer 3 is also provided on the surface layer. The upper layer is the UV paint layer 4, wherein the special antique layer 3 is located between the surface layer 2 and the surface UV paint layer 4, and has a thickness of 0.1 mm. It includes a hand-scraped antique layer 5, a drawing process layer 6, and Zigzag processing layer 7, overcoloring process layer 8, sand mark processing layer 9, and color rubbing processing layer 10. The crisscrossing multilayer board substrate layer 1 is composed of a substrate surface layer, a substrate core layer and a substrate bottom layer, with a thickness of 10 mm; the substrate surface layer and core layer have a thickness of 9 mm, and are made of eucalyptus. The thickness of the base material is 0.6mm, and th...

Embodiment 2

[0034] A kind of antique solid wood composite floor, with a crisscross multi-layer substrate layer 1 as the main body, the surface layer 2 is attached after the adhesive layer is formed on the surface, and a special antique treatment layer 3 is also provided on the surface layer. The upper layer is the UV paint layer 4, wherein the special antique layer 3 is located between the surface layer 2 and the surface UV paint layer 4, with a thickness of 1 mm, and from top to bottom includes the hand-scraped antique layer 5, the drawing process layer 6, and the serrated Texture treatment layer 7, overcoloring process layer 8, sand mark treatment layer 9, and color rubbing treatment layer 10. The crisscrossing multilayer board substrate layer 1 is composed of a substrate surface layer, a substrate core layer and a substrate bottom layer, and has a thickness of 15 mm; the substrate surface layer and core layer have a thickness of 14.5 mm and are made of eucalyptus. The thickness of the b...

Embodiment 3

[0036] A kind of antique solid wood composite floor, with a crisscross multi-layer substrate layer 1 as the main body, the surface layer 2 is attached after the adhesive layer is formed on the surface, and a special antique treatment layer 3 is also provided on the surface layer. The upper layer is the UV paint layer 4, where the special antique layer 3 is located between the surface layer 2 and the surface UV paint layer 4, and has a thickness of 0.5 mm. It includes a hand-scraped antique layer 5, a drawing process layer 6, and Zigzag processing layer 7, overcoloring process layer 8, sand mark processing layer 9, and color rubbing processing layer 10. The crisscross multilayer board substrate layer 1 is composed of a substrate surface layer, a substrate core layer and a substrate bottom layer, and has a thickness of 12.5 mm; the substrate surface layer and core layer have a thickness of 13 mm and are made of eucalyptus. The thickness of the substrate bottom layer is 0.7mm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com