Patents

Literature

106results about How to "Highlight individuality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Subject color matching method and mobile terminal

InactiveCN103927102AMeet individual needsHighlight individualityImage analysisInput/output processes for data processingPersonalizationGamut

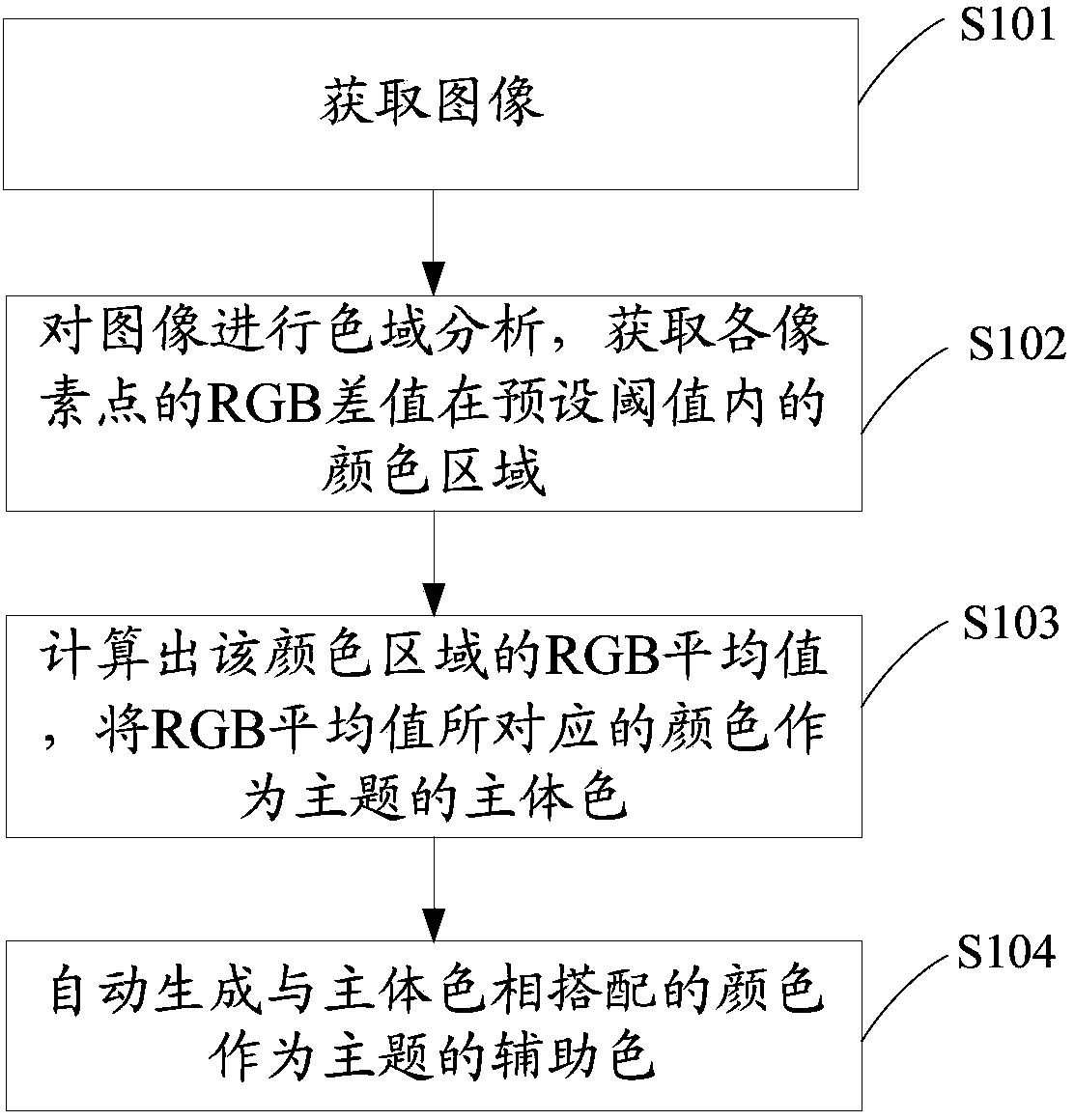

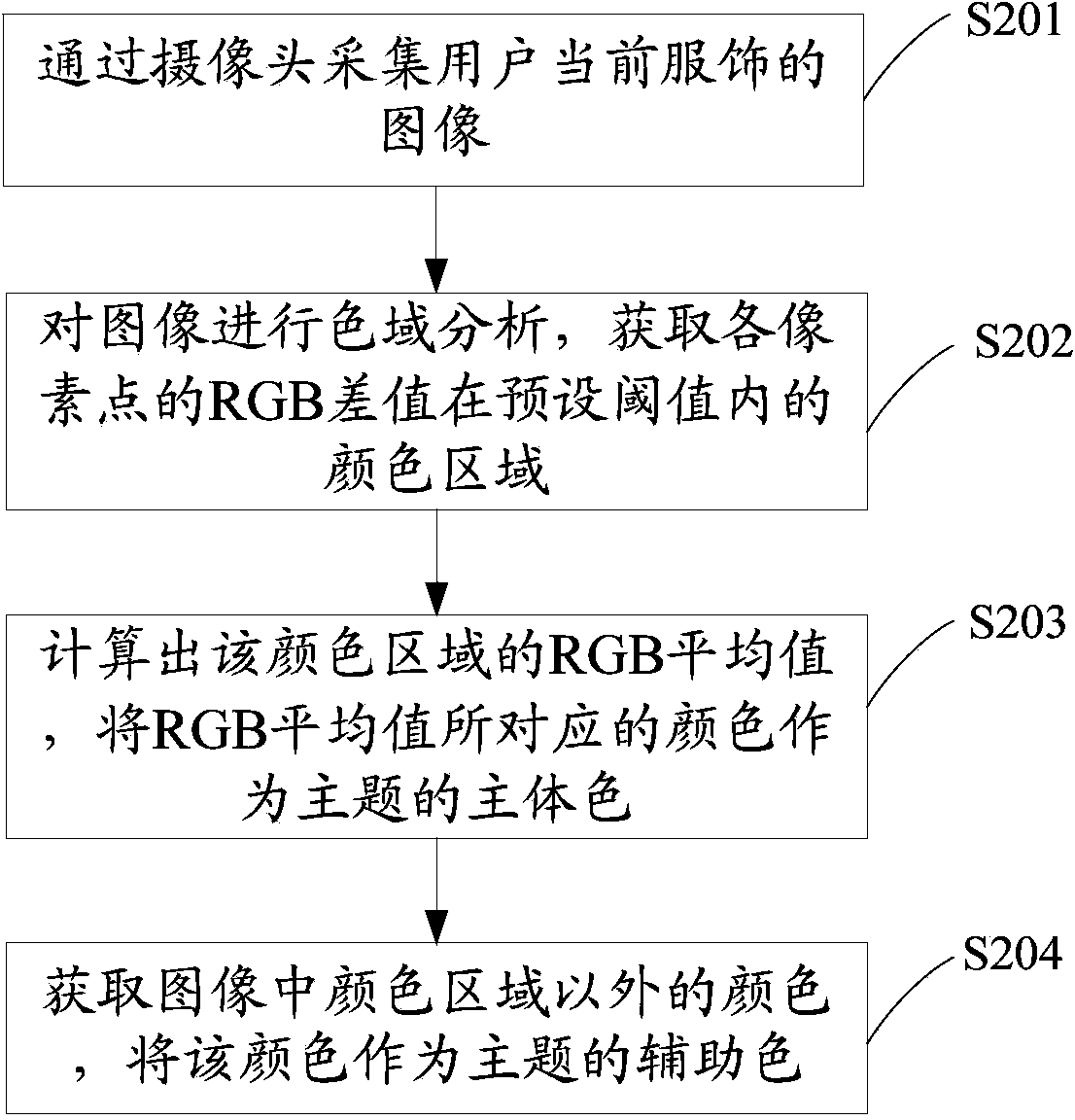

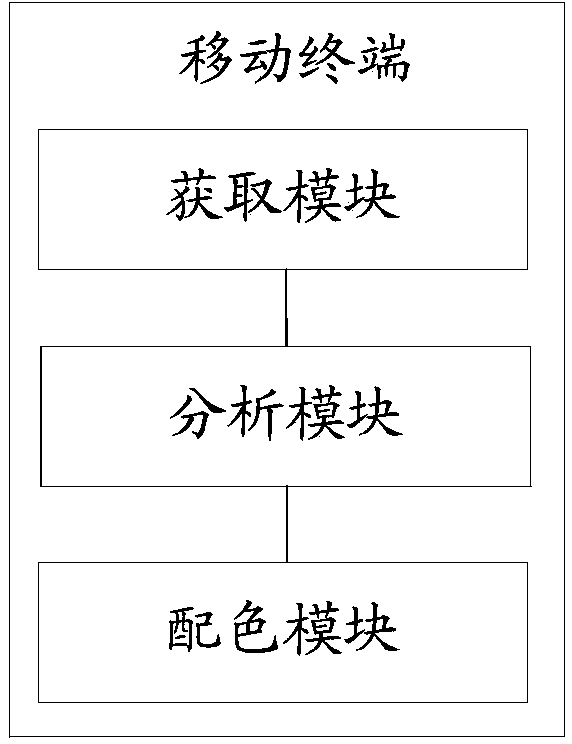

The invention discloses a subject color matching method and a mobile terminal. The subject color matching method comprises the steps that an image is obtained, color gamut analysis is conducted on the image and a color region, in a preset threshold, of RGB difference values of all pixel points is obtained; an RGB average value of the color region is worked out and color matching is conducted on a subject according to the RBG average value. Thus, users can conduct automatic color matching on the subject, and the individual requirements of the users are met. Particularly, the users can obtain an image of current costume through a camera and apply the color of the costume to the subject to enable a corresponding relationship between the color of the costume and the color of the subject to be established, therefore, the individuality of the users is highlighted and interactivity and interestingness are achieved. According to the subject color matching method and the mobile terminal, the color region, in the preset threshold, of the RGB difference values of all the pixel points in the image is obtained, the color of the color region is determined to be the main color of the image, therefore, determination of the main color of the image is simpler and faster, the calculation amount is small, the speed is high and resource consumption is low.

Owner:NUBIA TECHNOLOGY CO LTD

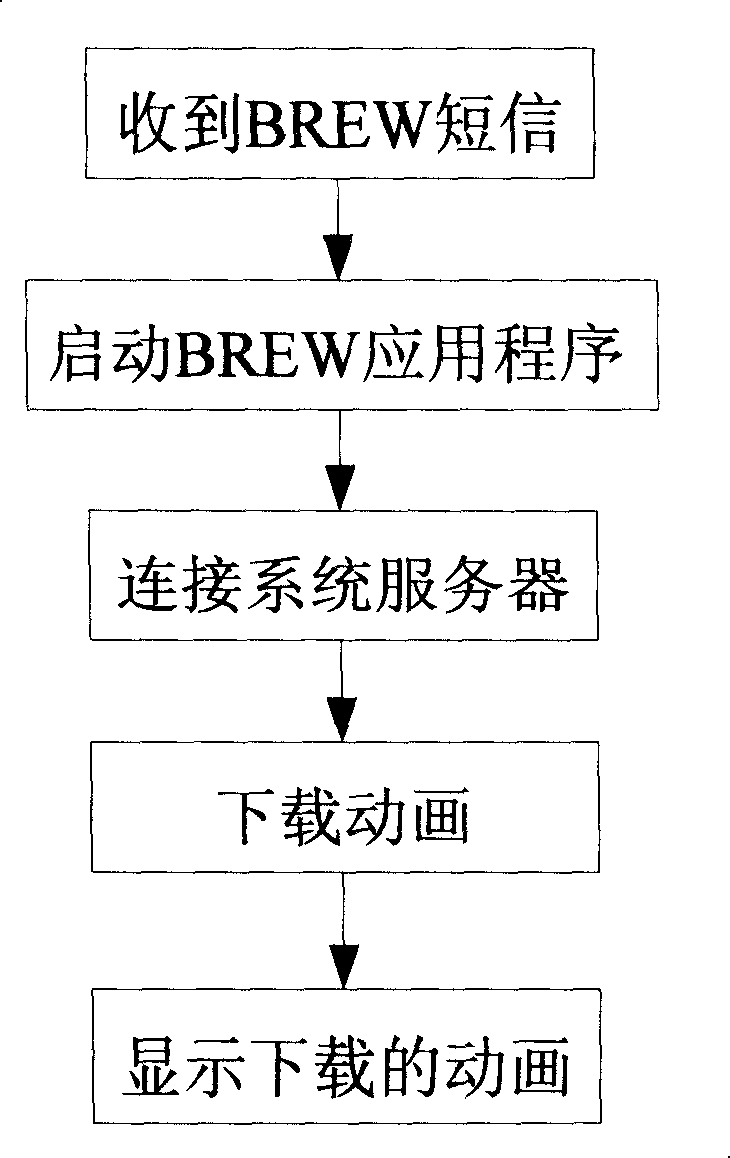

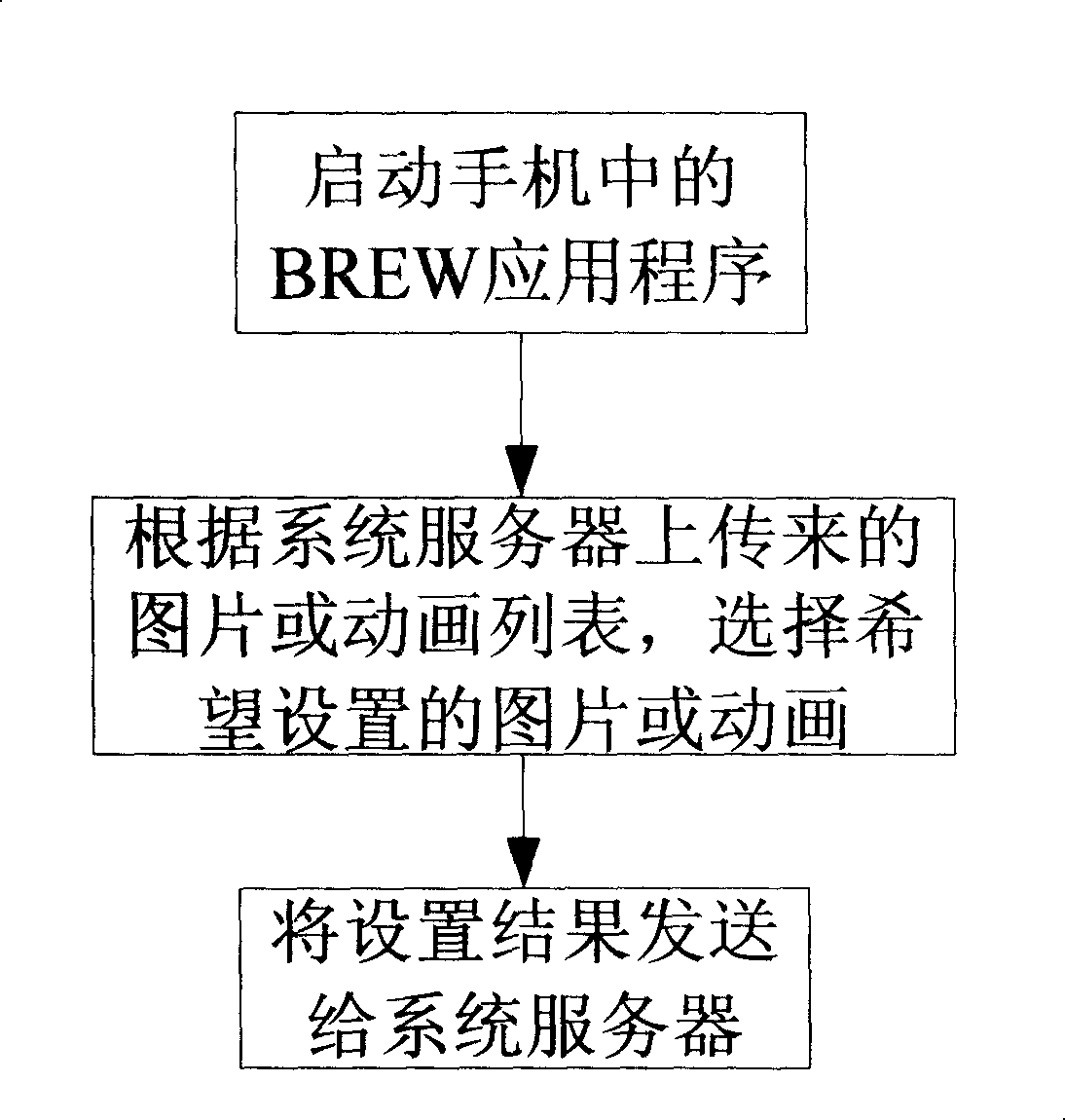

System and method for displaying picture or cartoon of mobile phone incoming call

InactiveCN101207863AHighlight individualityBroaden the market for value-added servicesCalling susbscriber number recording/indicationRadio/inductive link selection arrangementsAnimationEconomic benefits

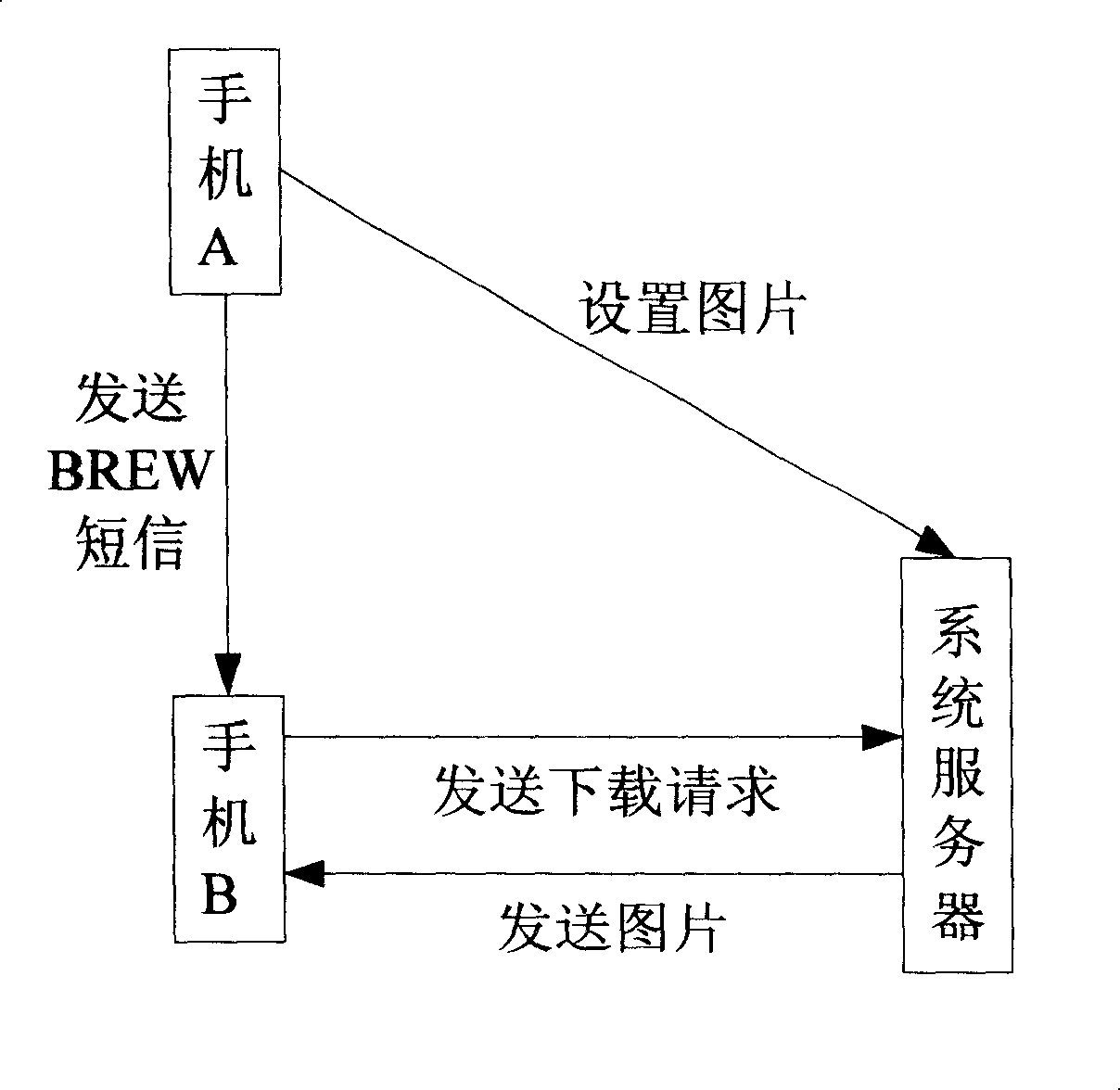

The invention relates to a method for displaying the picture or animation for the incoming call on the mobile phone, which comprises the following steps of: step 1, the calling phone calls the called phone, and sends BREW short message to the called phone; step 2, after receiving the short message, the called phone boots up BREW application program; step 3, the called phone connects to system server via the BREW application program, and downloads the pictures or animations to the mobile phone. When the user makes a call, and the invention sends the preconfigured pictures or animations to the opposite mobile phone. Compared with simple rings, the invention is more vivid, rich and colorful, shows the individuality of the user, and meanwhile further expands the value-added service market, thus the operators gain larger economic benefit.

Owner:LG ELECTRONICS (CHINA) R&D CENT CO LTD

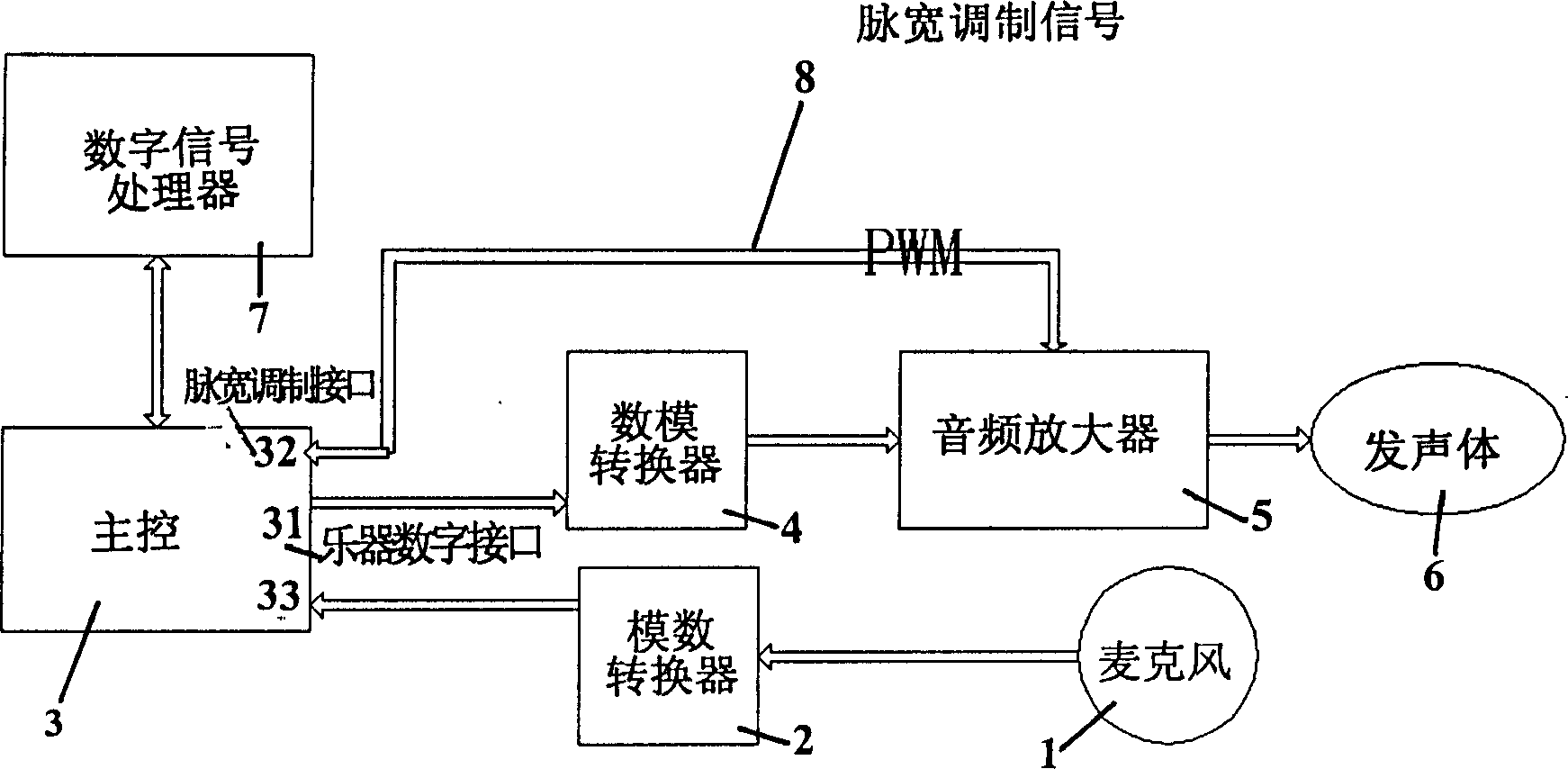

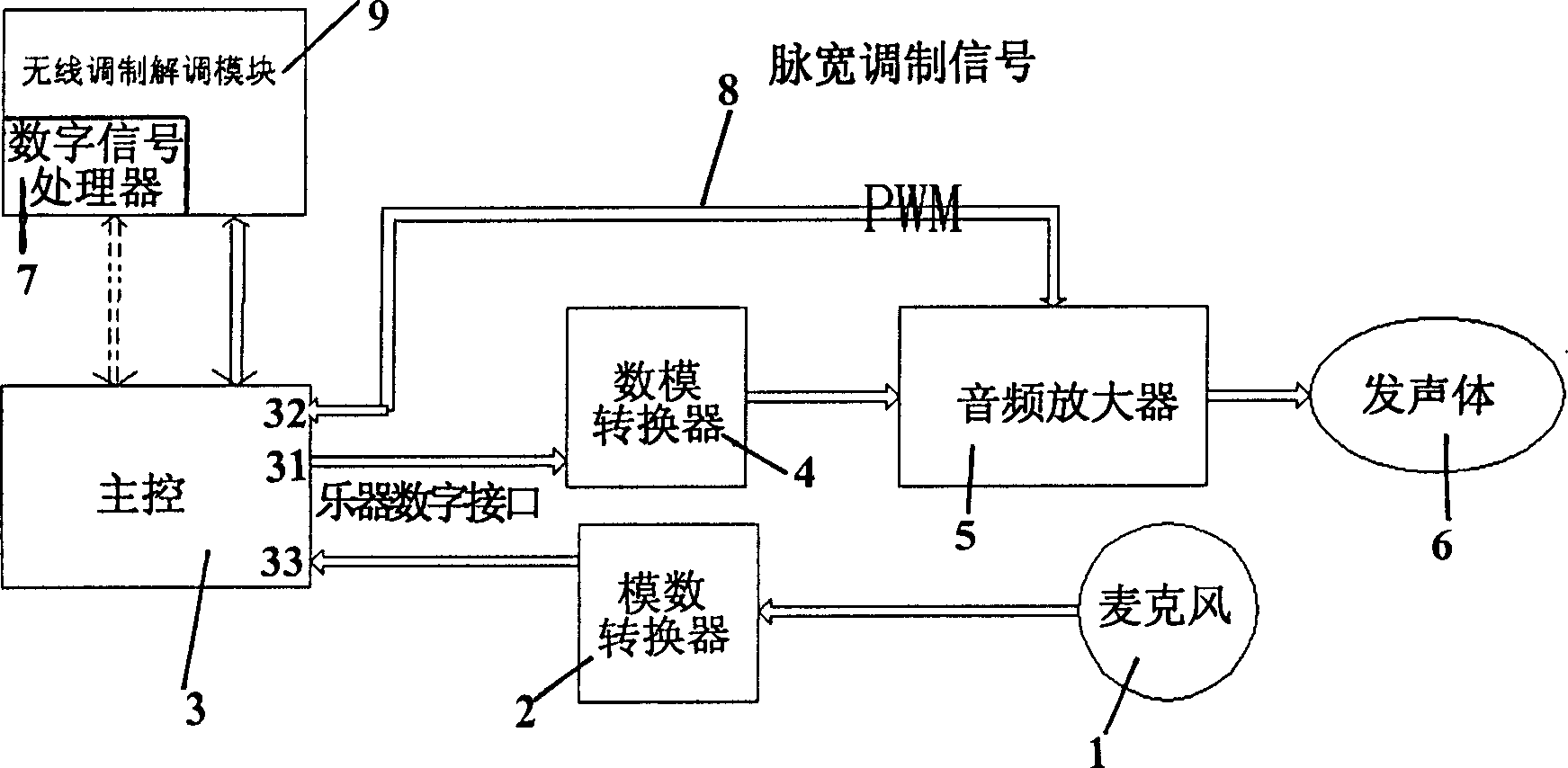

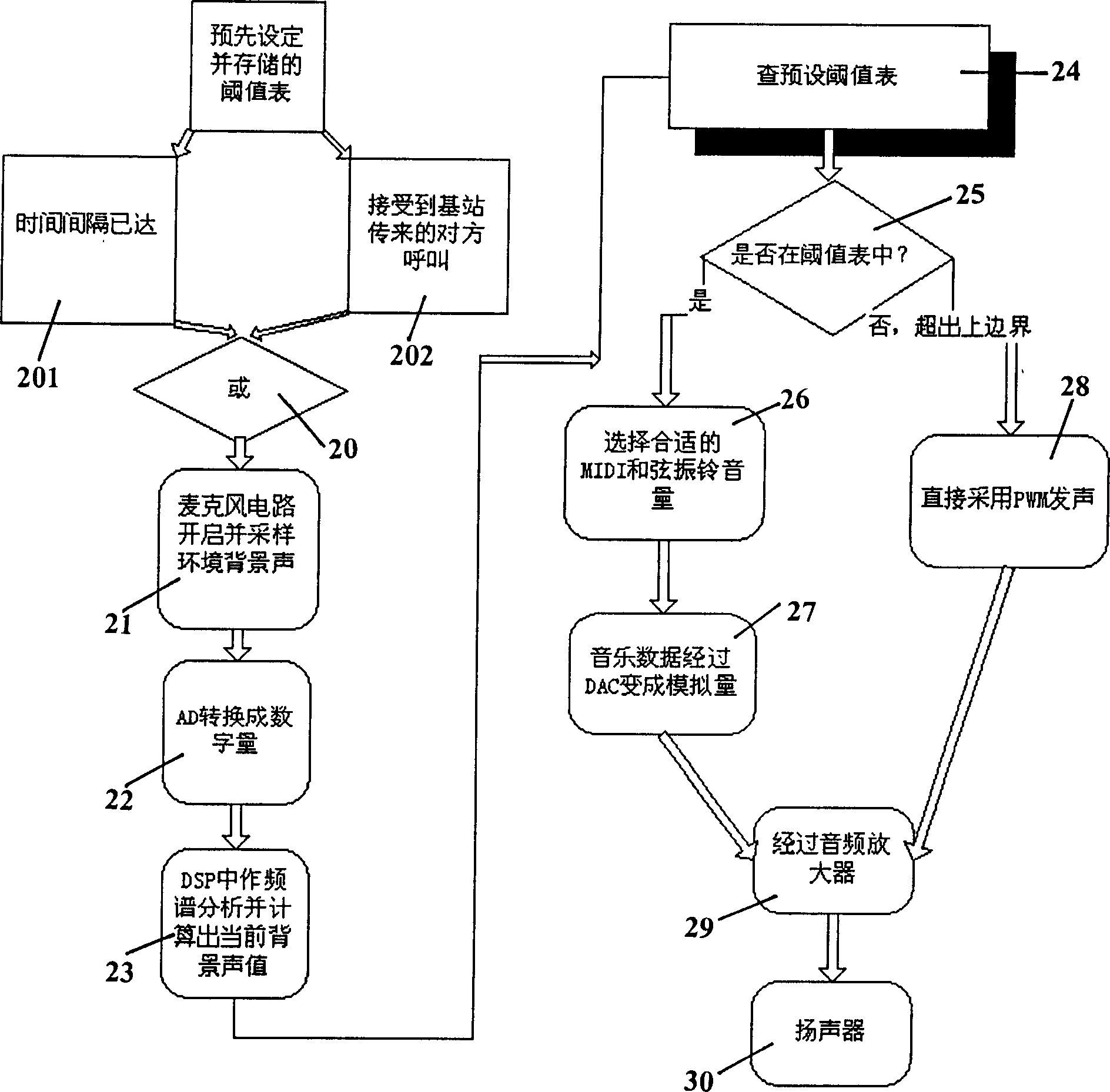

Self-adapting ringing unit cooperate with chord ring

InactiveCN1446013AOvercoming the drawbacks of being prone to missed callsEasy to adjust and effectiveCalling susbscriber number recording/indicationRadio/inductive link selection arrangementsInternal memoryGround noise

An adaptive ringing device includes connecting in sequence of microphone, A / D converter, main controller, D / A converter, audio amplifier and sound with circuit connection as well as digital signal precessor being circuit-connected with the main controller in two-way connection and it have a music instrument digit output to send musical instrument digit signal to D / A converter. Its features are: a. A controllable circuit formed by an output outlet of pulsewidth modulation signal in the said main controller and audio amplifier can send plusewidth modulation signal to audio amplifier as required; b) an adaptive control program for cooperating with chard ringing sound is stored in the nonvolatile internal memory of communication terminal; and c) a back ground noise threshold table is preset and stored in the program storage area of nonvolatile internal memory and it can be called by the adaptive control program.

Owner:LENOVO (BEIJING) LTD

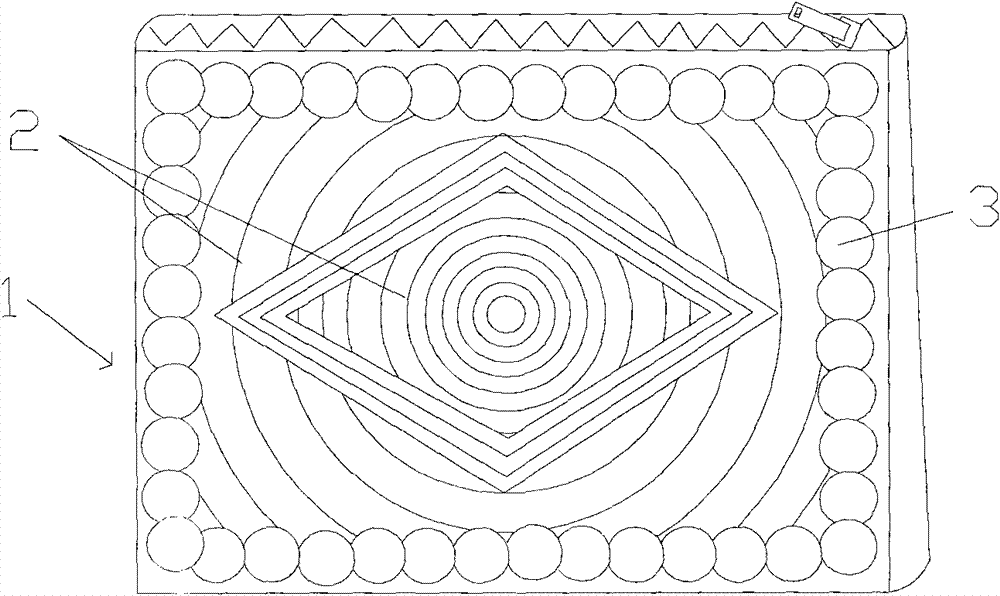

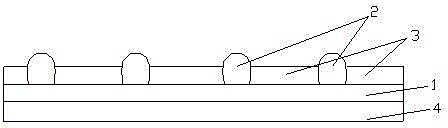

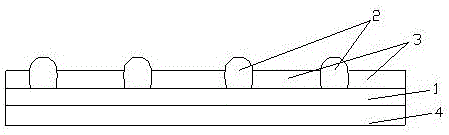

Beaded self-luminous key chain

The invention relates a beaded self-luminous key chain, and belongs to articles for daily use. The beaded self-luminous key chain comprises a key chain body (1), a pendant (3) and link chains (2) which connects the key chain body (1) and the pendant (3), and is characterized in that the pendant (3) is heart-shaped; bead strings (4) are arranged on the outer surface of the pendant (3), each bead string (4) is formed by stringing a plurality of beads; the bead strings (4) are coiled into a plurality of heart-shaped structures, placed concentrically and symmetrically fixed on the front surface and the back surface of the pendant (3); and the surfaces of the key chain body (1) and the link chains (2) are plated with layers of fluorescent powder. The bead strings are coiled into the concentric heart-shaped structures, and individuality of the beaded self-luminous key chain is highlighted, and the beaded self-luminous key chain can emit light at night.

Owner:郭亚娟

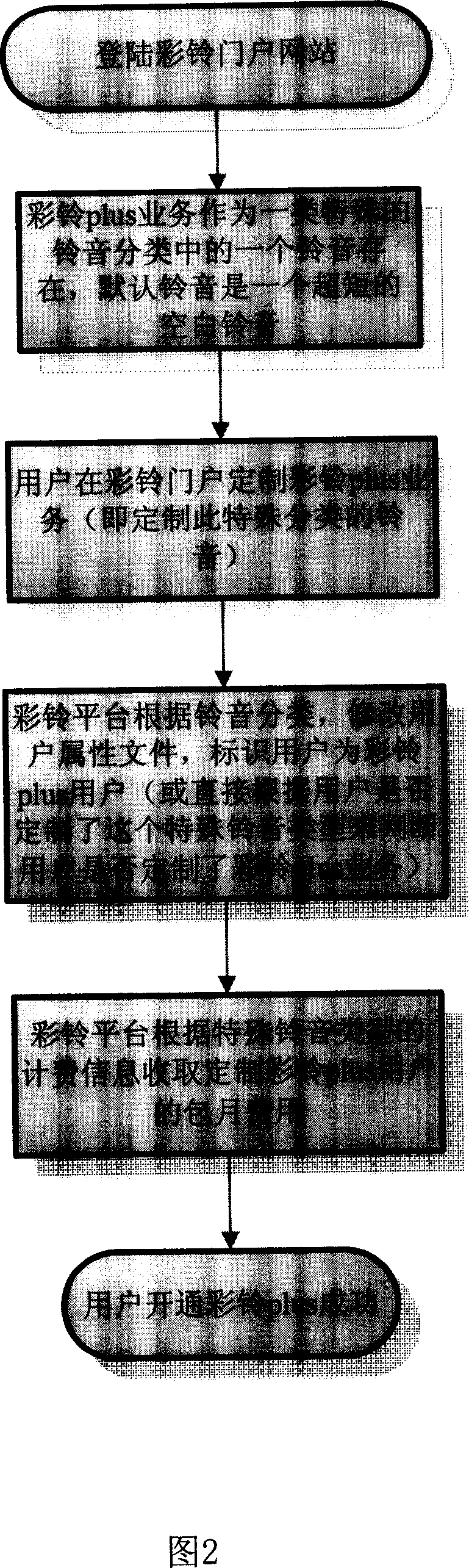

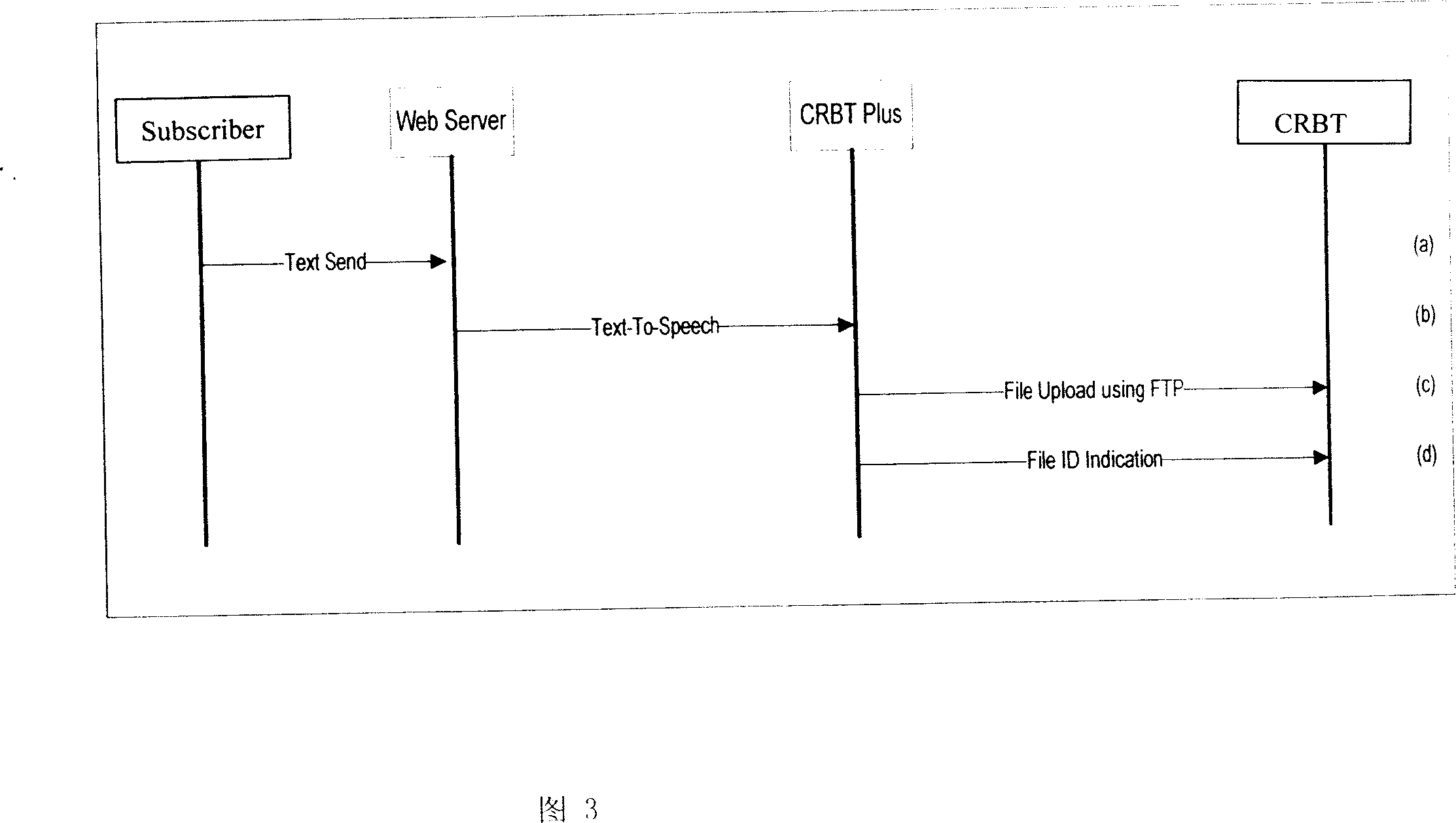

Method for playing color ring back tone

InactiveCN101136961AHighlight individualityImprove interactivitySpecial service for subscribersSound sourcesRing back tone

In the method, the calling user or the called user is as a user, who registers color ring service. The method includes following steps: (1) deterring whether the called user in this call is in idle state; if yes, then executing step (2); otherwise, playing back corresponding cue tone to the calling user, and ending this flow; (2) playing the called user-defined back ring back tone to the calling user, and then playing customized color ring back tone. Moreover, contents for expressing information, mood, and blessing can be added before the customized color ring back based on need. Thus, the said contents are transferred to opposing party directly at moment when the calling user dials through the call. Based on different time periods, calling user can set sound source in pertinence to enhance personality, and raise interaction between users and color ring PLUS service, which allows user to set own text info (or multimedia file in future) as sound source.

Owner:苗文成

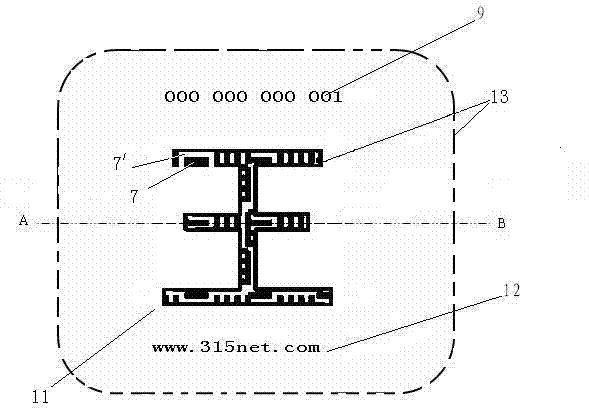

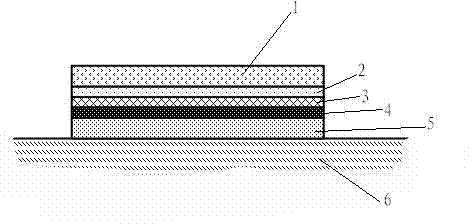

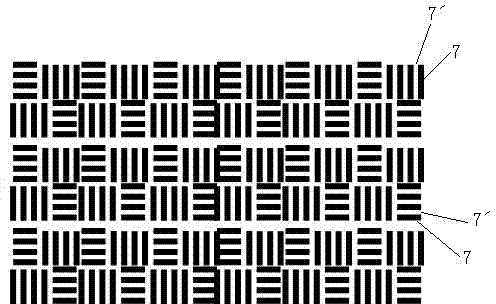

Anti-fake bronzed logo used for Internet of Things and capable of changing color for error

ActiveCN102610163BIncrease the difficulty of copying and forgeryIncrease the difficulty of printing gold forgeryStampsThermographyHot stampingVisual perception

The invention provides an anti-fake bronzed logo used for Internet of Things and capable of changing color for error by using a gilding machine, comprising a base film layer, a release layer, a dyeing layer consisting of single-color lines or color lumps, a metal coating layer and a bonding layer, wherein the feature information of the arrangement and combination of the single-color lines or color lumps is shot and collected, and then is stored in a telephone network or / and web site with logo number. When the anti-fake bronzed logo is used, small change of hot stamping mechanical error can cause features such as bronzing logo color to change greatly. The bronzed logo shows the visual effect of the error, enables the hot stamping error to be notable and is beneficial to manual identification and software identification of the anti-fake logo.

Owner:HAINAN PAIPAIKAN INFORMATION TECH CO LTD

Life-information energy-collecting method and application thereof

InactiveCN101518671AAvoid mindless behaviorAvoid misjudgmentElectrotherapyMicrowave therapyLiving bodyFilling-in

The invention relates to the technical field of health care methods, in particular to a life-information energy-acquiring method and application thereof. The life-information energy-acquiring method comprises the steps of detecting living bodies, replenishing life-information energy, placing the living bodies in a shielding cabin for replenishing the life-information energy, placing life-information acquisition devices or physical focusing devices among the living bodies, transmitting the life-information energy acquired through the life-information acquisition devices to a life-information energy-receiving device through a flexible waveguide system, and enabling the living bodies or water to receive the life-information energy. The invention has the advantages that the invention is an environment-friendly product, is extremely low in manufacture / use cost and energy consumption, applicable to scientific research, medical treatment, health care departments, families and individuals, and convenient to popularize, can be applied to living-body health care, medical treatment, cosmetology, animal / plant breeding and other technical fields, fills in a gap in the technical field in China, and has remarkable social and economic benefit.

Owner:袁心洲

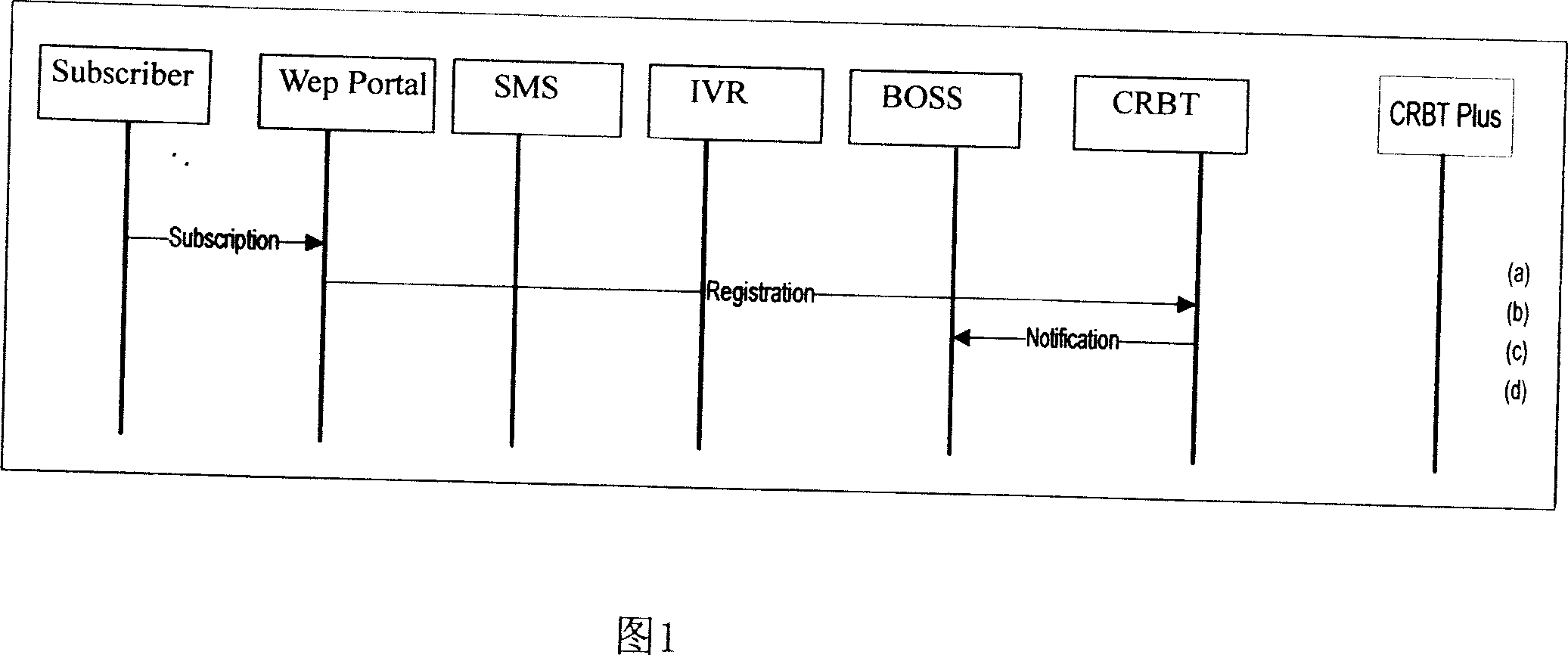

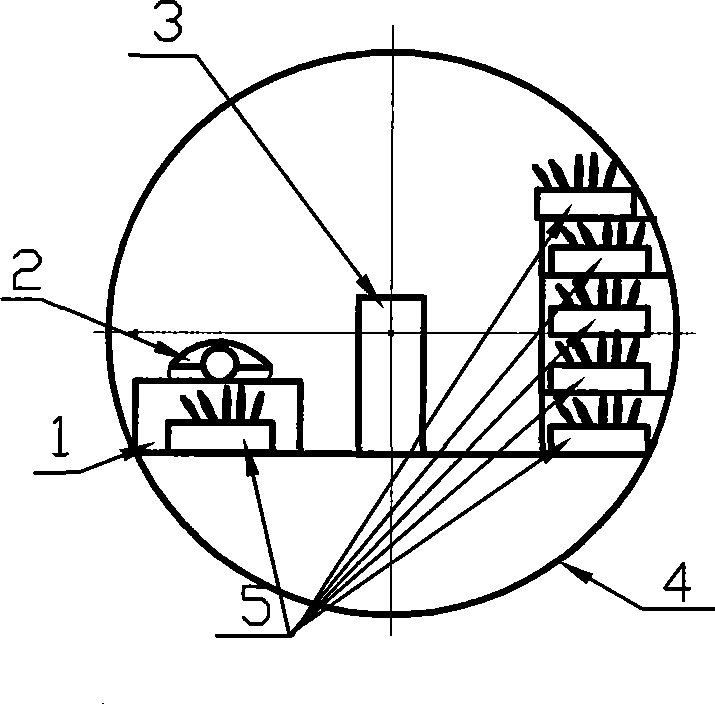

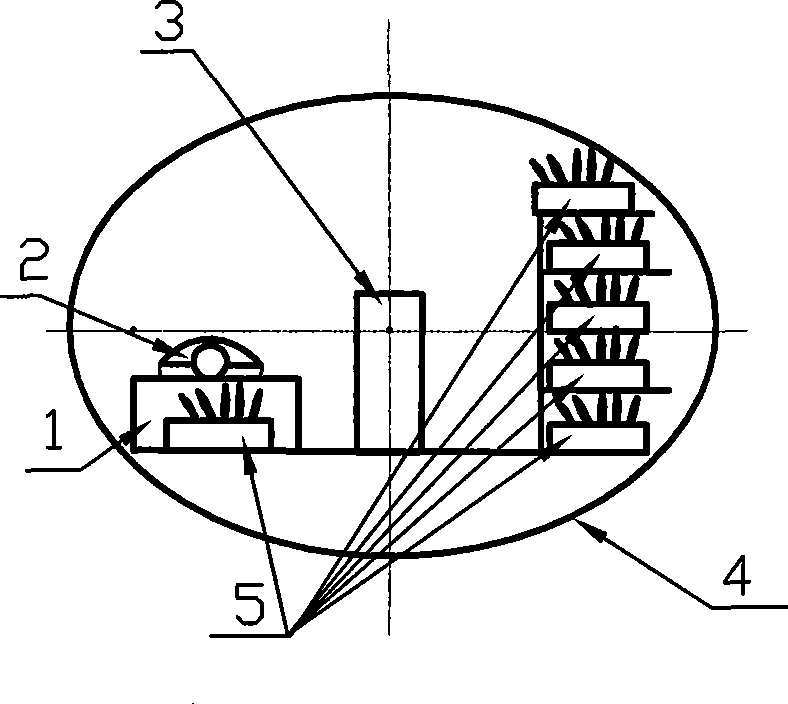

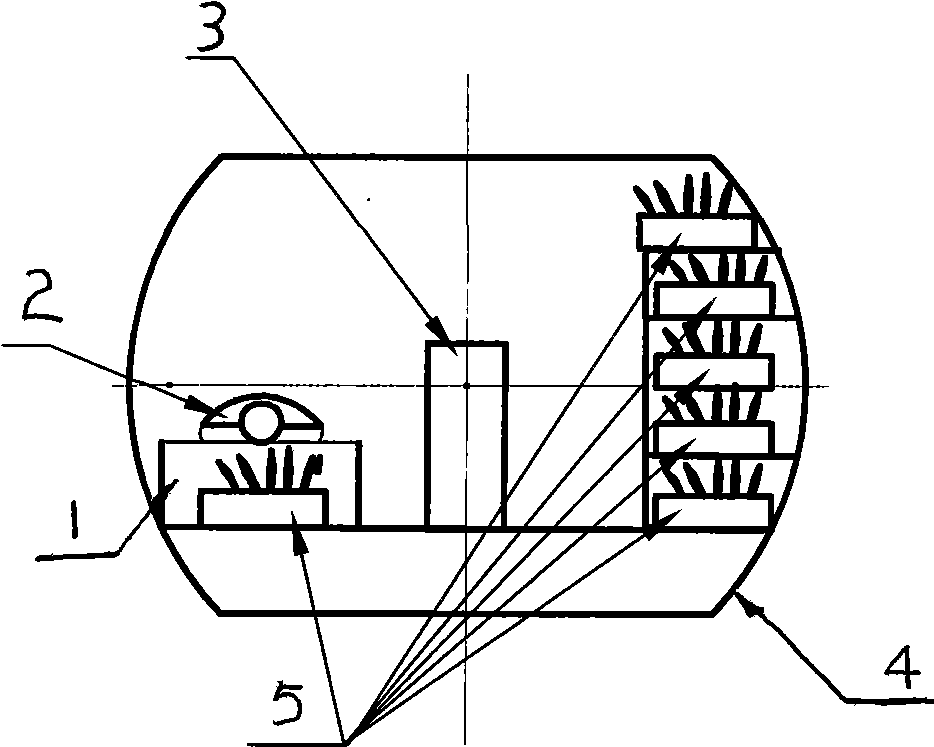

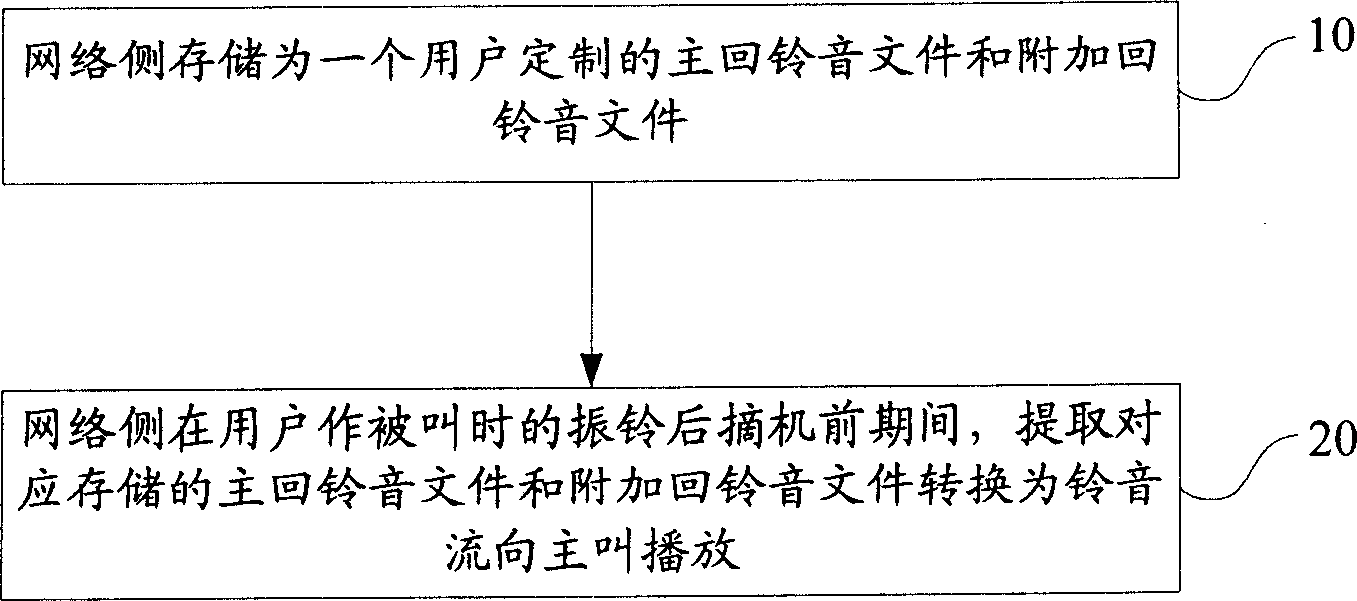

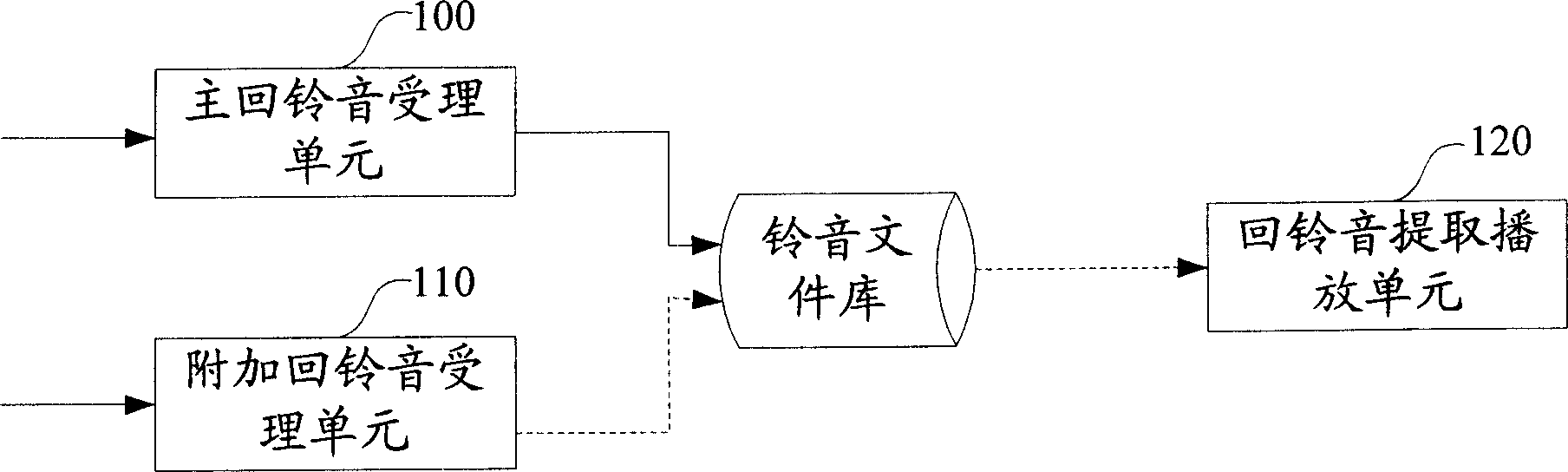

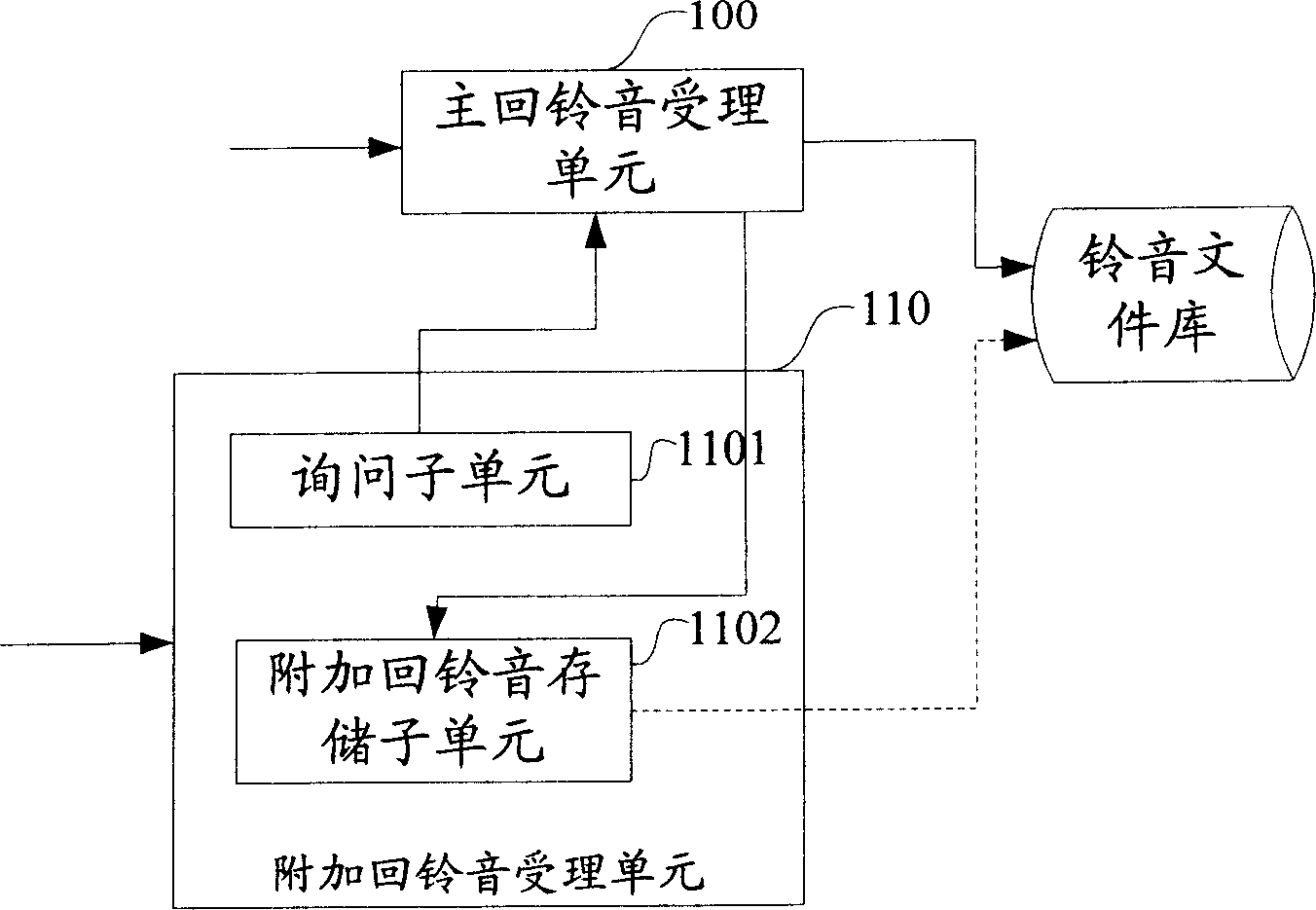

Ring-back tone service implement method and system, ring-back tone service customization method and device

InactiveCN1913558AHighlight individualityImprove interactivitySpecial service for subscribersRing back toneService customization

This invention discloses a method for realizing ring-back services including the network side stores a primary ring-back file and an attached ring-back file drafted by a user and picks up the primary and attached files stored correspondingly to convert them to ring sound flowing to the calling to be played during the period before off-hook and after ringing when the user is as a called one. This invention also discloses a realization system for the ring-back service including a master dealing unit used in accepting the primary file drafted for a user and storing it, an attached dealing unit used in picking up the primary and attached files stored correspondingly and converting them to ring sound to flow to the calling to be played in the period before off-hook and after ringing when the user is as the called.

Owner:HUAWEI TECH CO LTD

Ginger grape Cognac and preparation process thereof

The ginger-grape dry wine is prepared with ginger in 30-35 wt% and grape 65-70 wt%. The preparation process includes the following steps: treating fresh ginger and grape to obtain ginger juice and grape juice; mixing ginger juice, grape juice and distiller's yeast and fermentation; distillation to obtain wine; ageing inside oak tierce for three months; blending, inspection and bottling. The ginger-grape dry wine has unique fragrance of both ginger and grape, the features of grape wine, and excellent health functions of regulating blood and vital energy, strengthening immunity, promoting blood circulation, etc. It is also suitable for use in cooking beef, mutton and fish.

Owner:高国尧

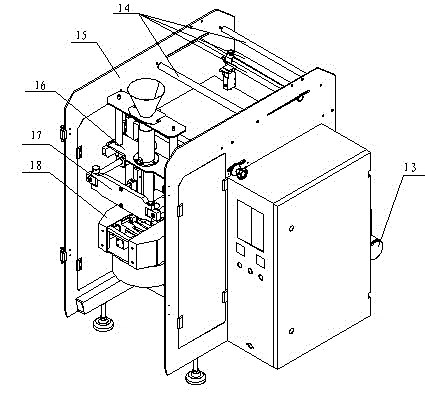

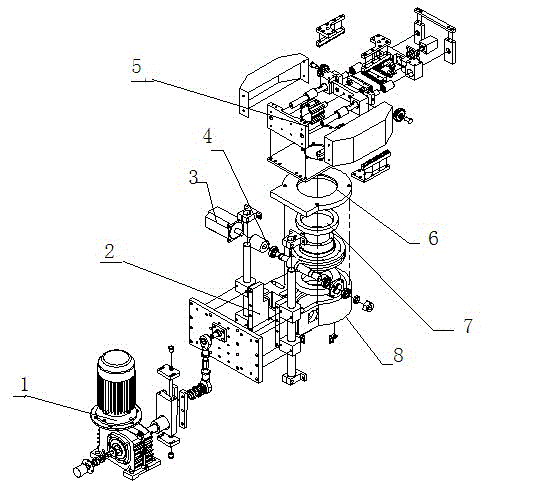

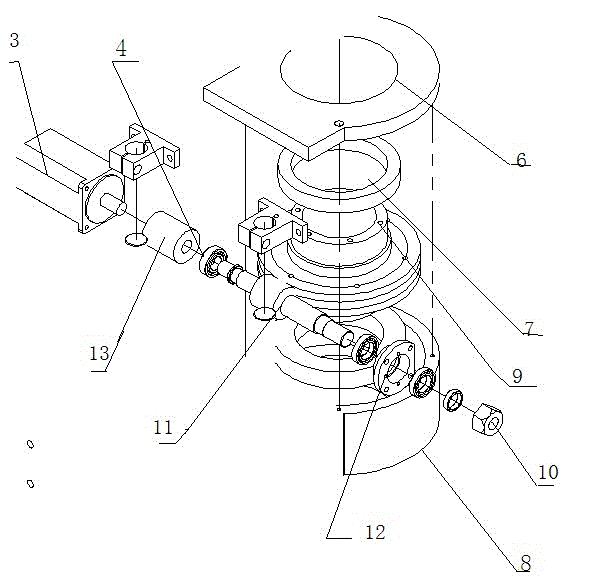

Triangular rhombus bag packaging machine

ActiveCN102717908AGuaranteed uptimeSimple structureWrapper twisting/gatheringSuccessive articlesEngineeringTurbine

The invention discloses a triangular rhombus bag packaging machine, which comprises a rack member, a film support member, a film conveying member, a bag former member, a longitudinal sealing member and a transverse sealing member, wherein the film support member, the film conveying member, the bag former member, the longitudinal sealing member and the transverse sealing member are sequentially installed on the rack member in accordance with the motion direction of the film; the longitudinal sealing member is installed below the bag former member; the transverse sealing member is installed below the longitudinal sealing member; the transverse sealing member comprises a transverse sealing device and a rotational device connected with the transverse sealing device; the rotational device comprises a worm gear pair and a speed reduction device; the speed reduction device comprises a reduction gearbox, a turbine installed inside the reduction gearbox and meshed with the worm gear pair and a reduction gearbox upper cover arranged at the top of the reduction gearbox; the transverse sealing member is installed on the reduction gearbox upper cover; and the worm gear pair is connected with a motor. The triangular rhombus bag packaging machine is simple in structure and capable of packaging triangular rhombus bags and providing a maximum printing pattern area according to demands.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

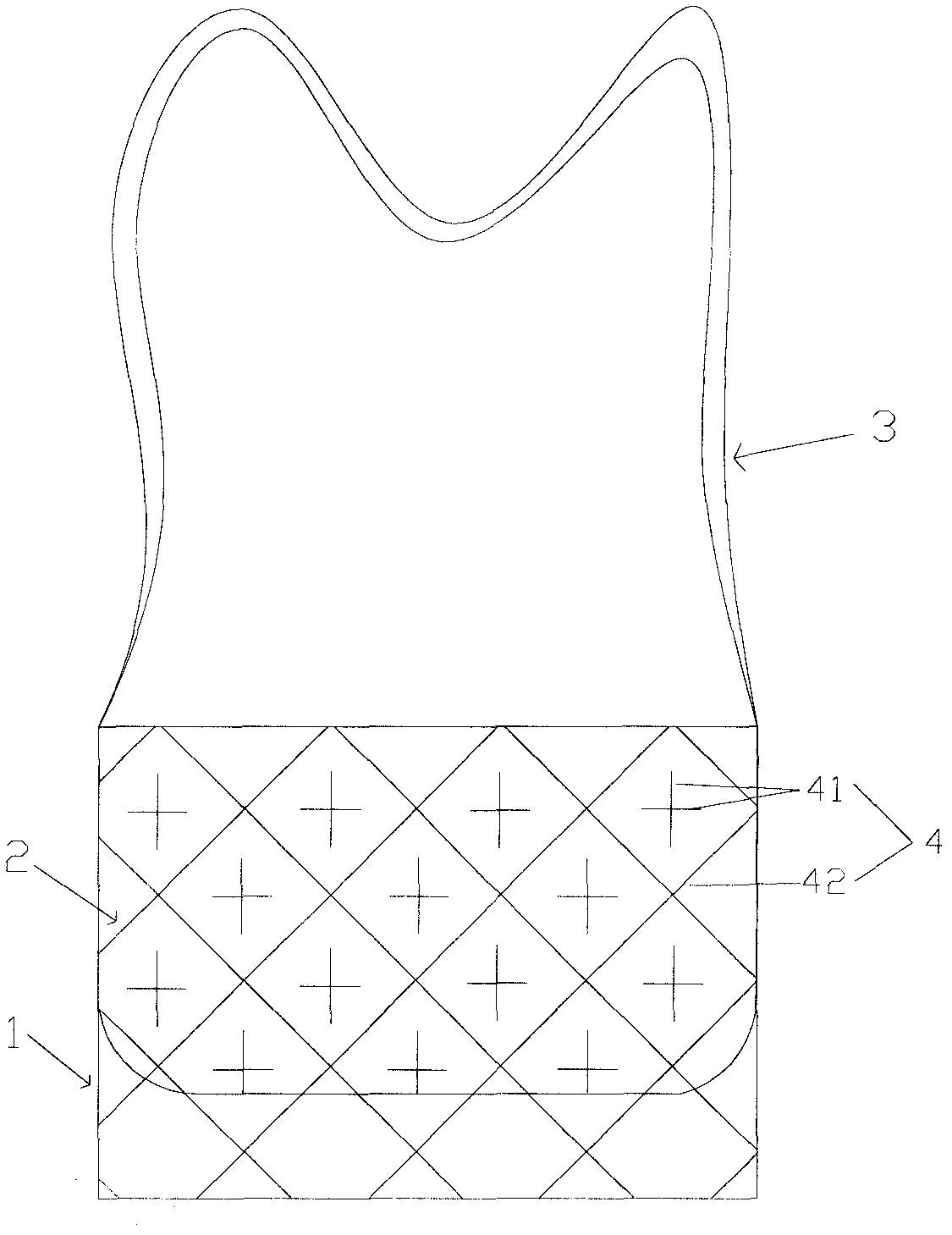

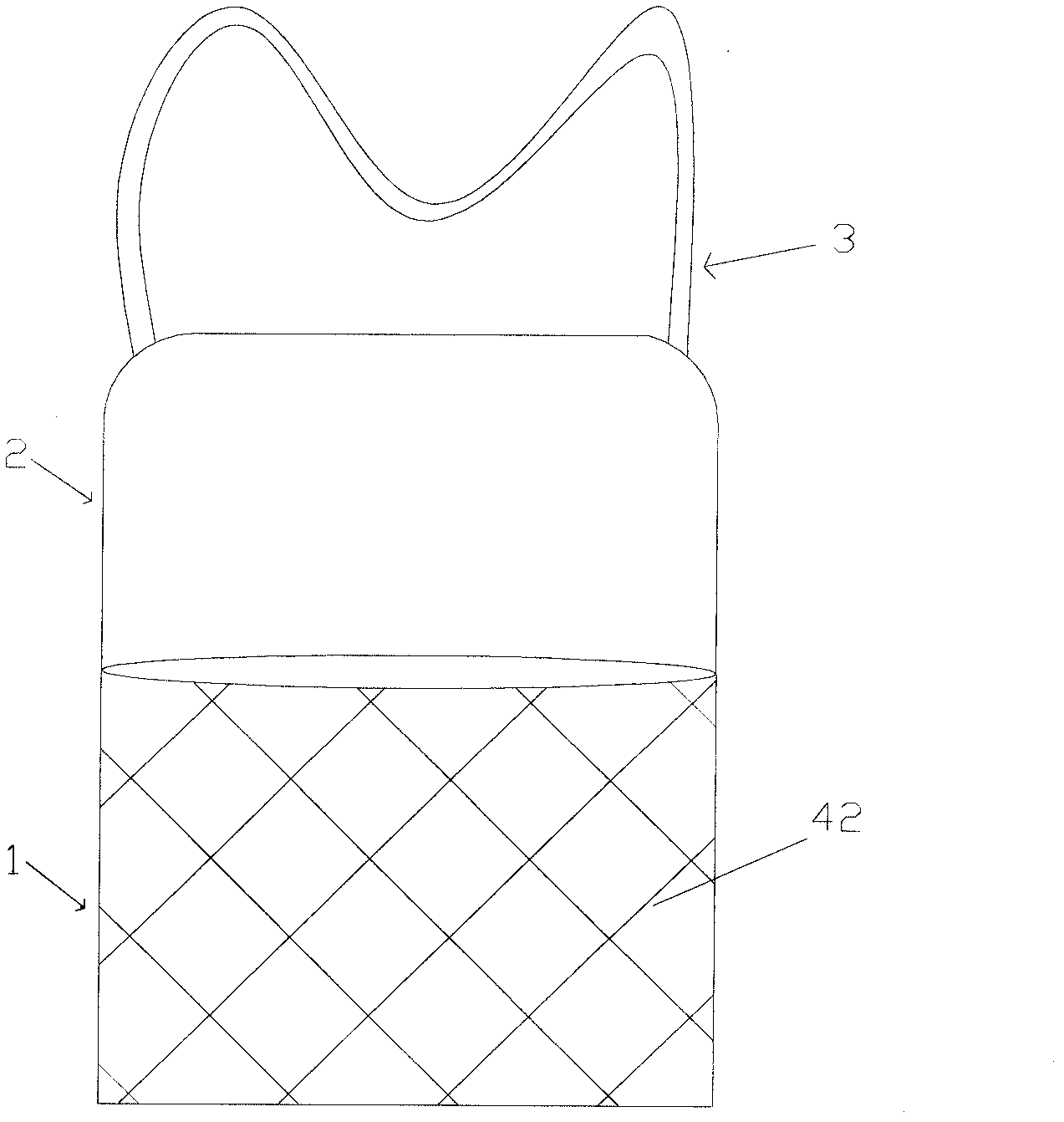

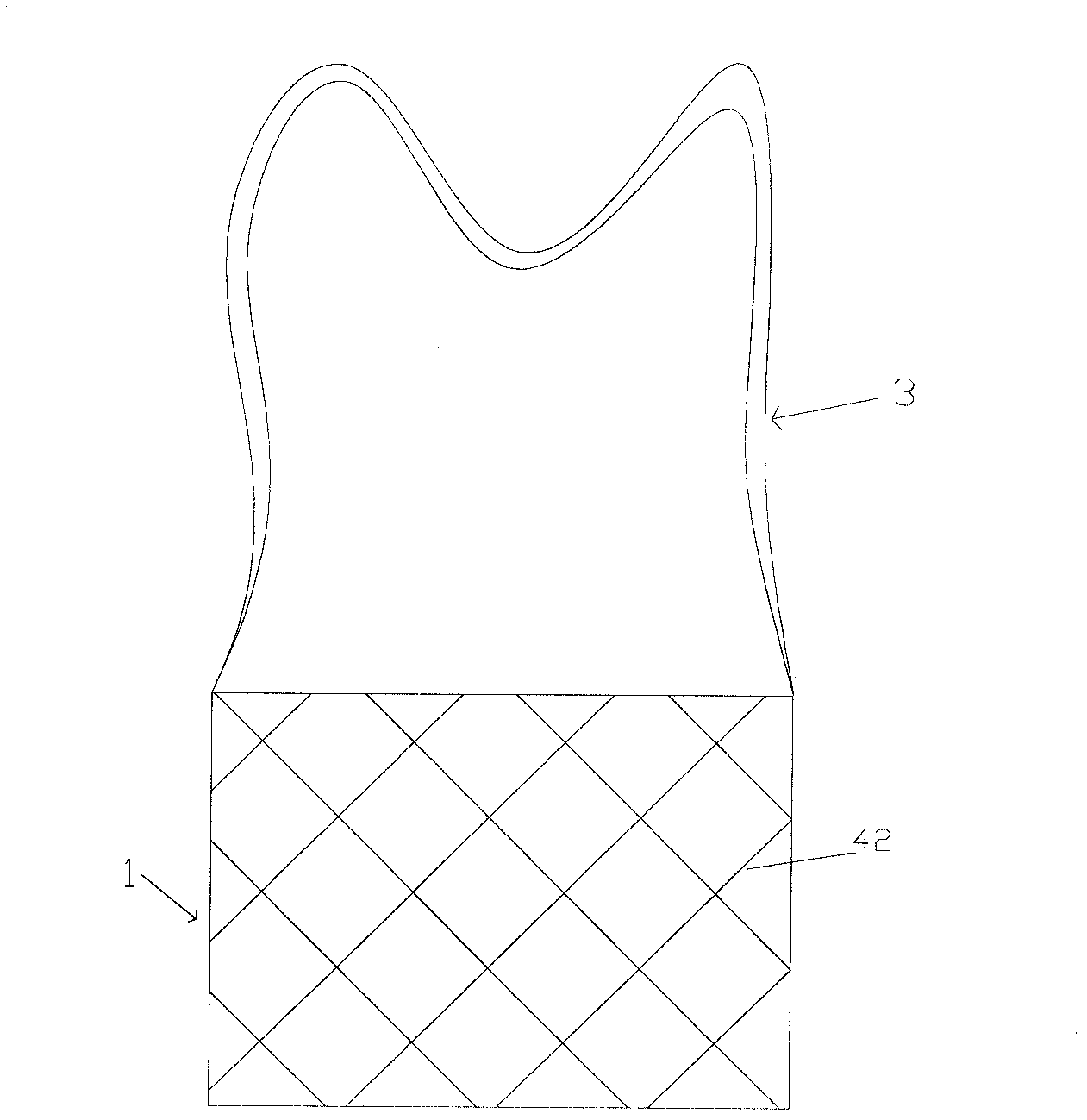

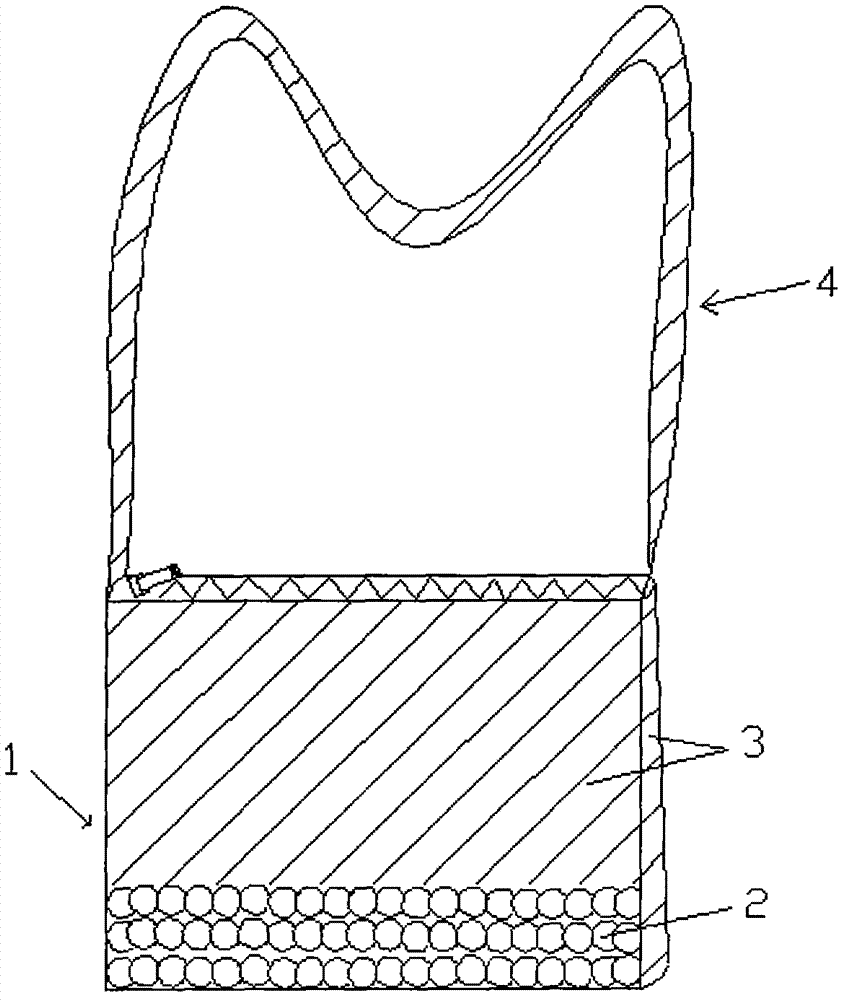

Handbag with beads

Owner:郭亚娟

Cooking process for carrying out composite modification on natural color bamboo paper pulp and natural color wood pulp to form dissolving pulp

ActiveCN102677508AHigh content of pentoseAvoiding the pitfalls of undercookingPulping with acid salts/anhydridesCellulose pulp after-treatment modificationDry weightViscose

The invention discloses a cooking process for carrying out composite modification on natural color bamboo paper pulp and natural color wood pulp to form dissolving pulp. Composite paper pulp is fed into a continuous digester to be cooked; a continuous steaming pipe of the continuous digester is provided with three sections; the section connected with a pre-reaction bin is provided with a T-shaped pipe for adding alkali liquor and a steam pipe for adding steam; the other two sections are provided with steam pipes for adding the steam; the liquor ratio is 1:(2.0 to 4.0); the alkali liquor is NaOH and Na2SO3 and is added according to 17 percent to 30 percent of the oven dry weight; and the compression ratio is 1:(2 to 3.0). According to the invention, the natural color bamboo paper pulp and the natural color wood pulp are used as the raw materials, so that the cost of preparing the dissolving pulp is reduced to a great extent and the quality requirement of the dissolving pulp for viscose is also met.

Owner:YIBIN GRACE GROUP CO LTD

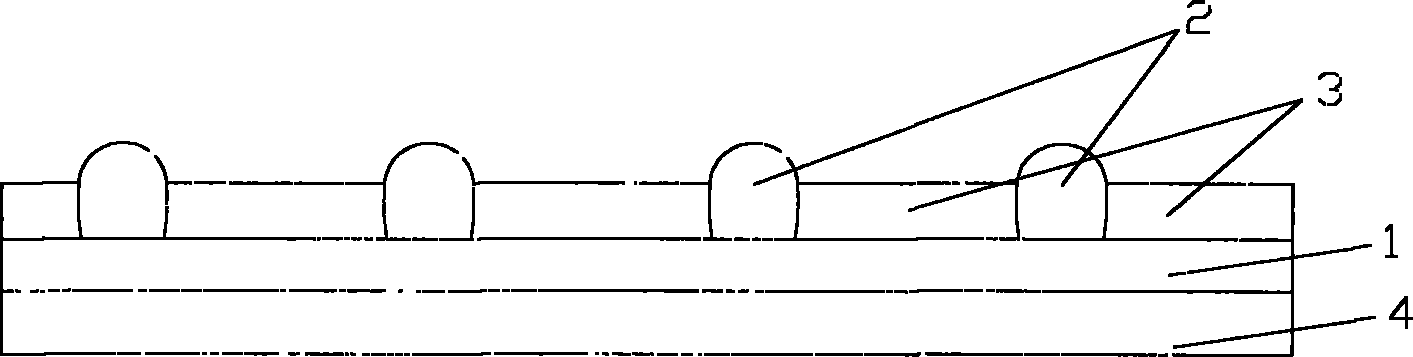

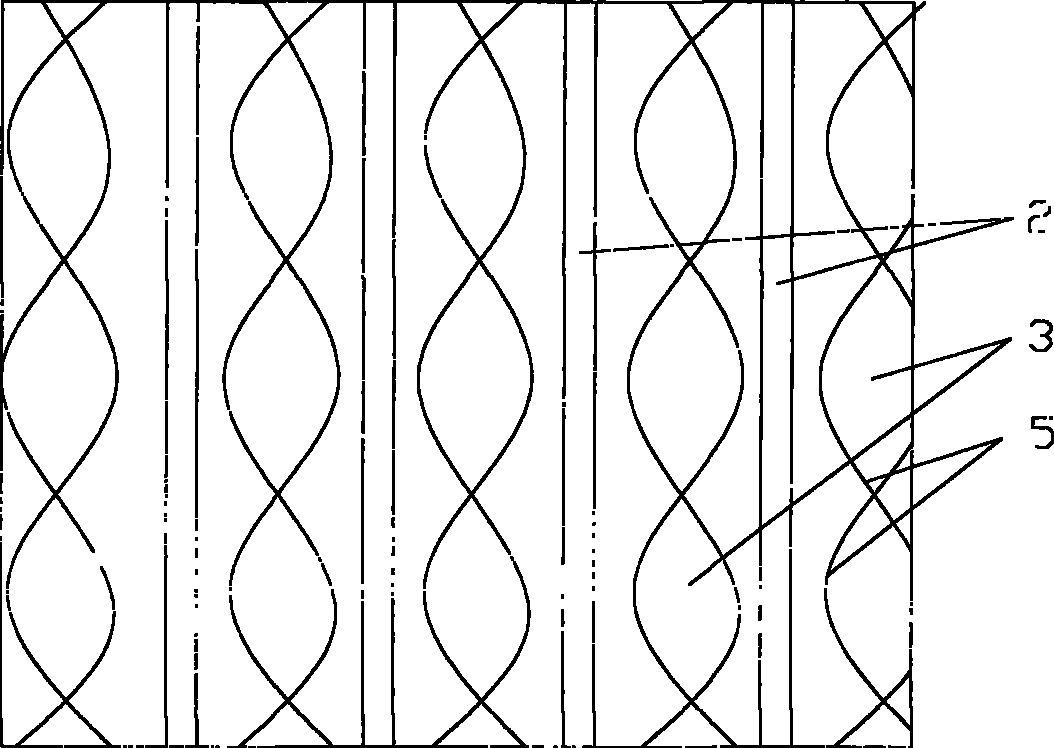

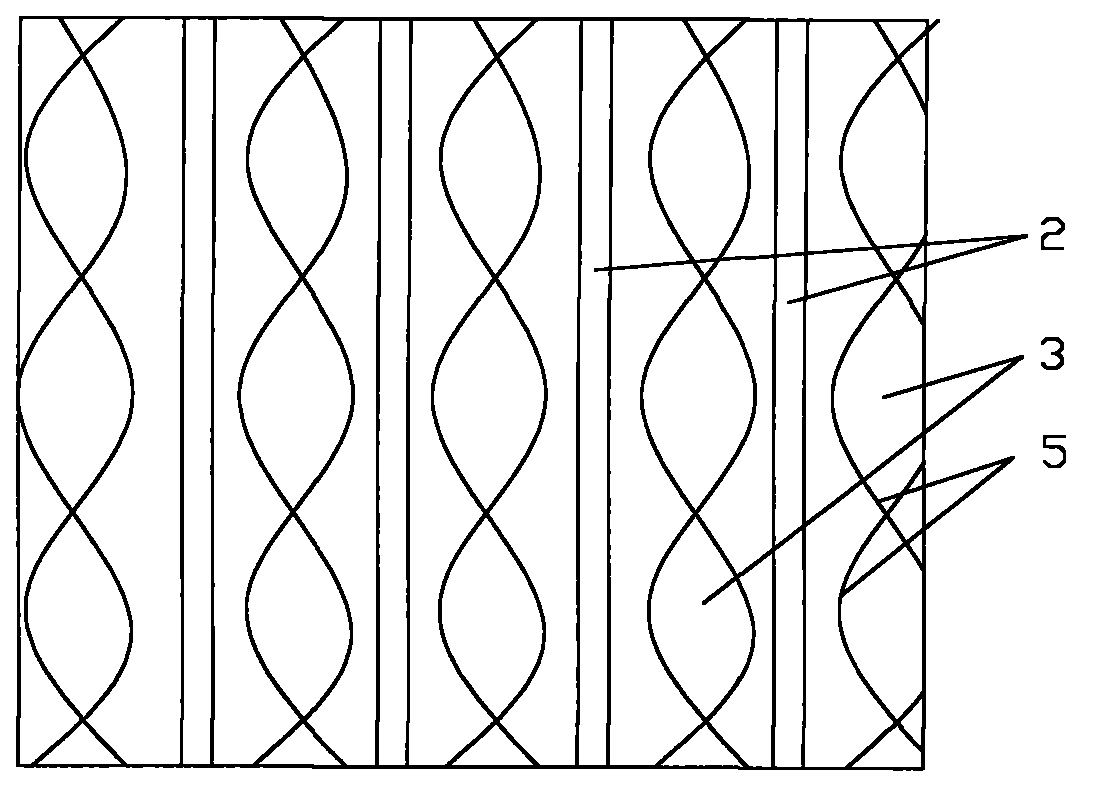

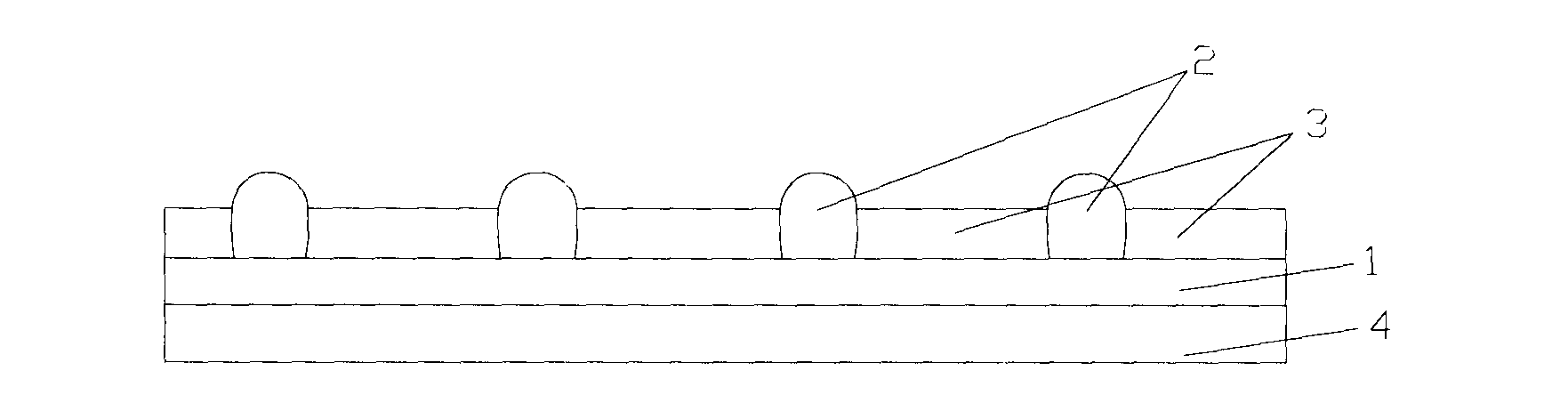

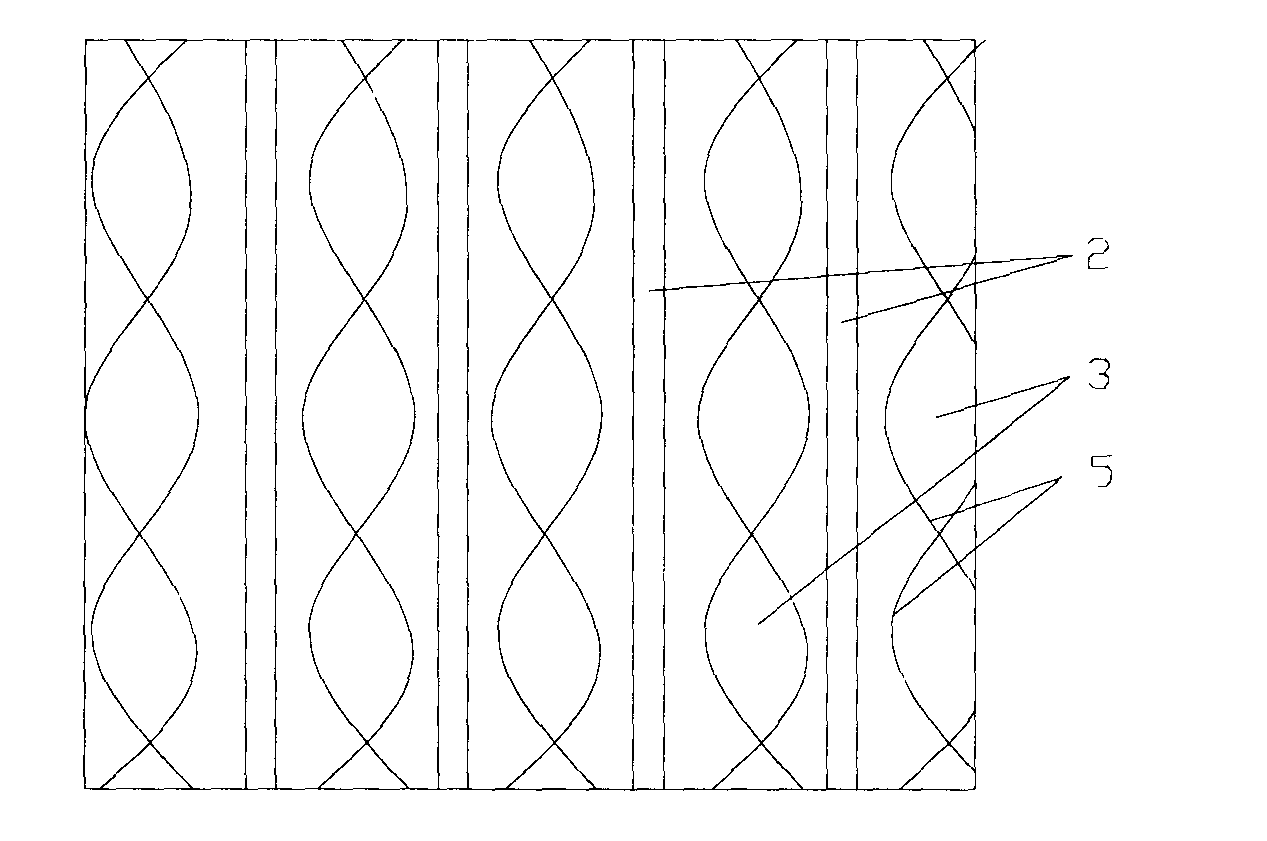

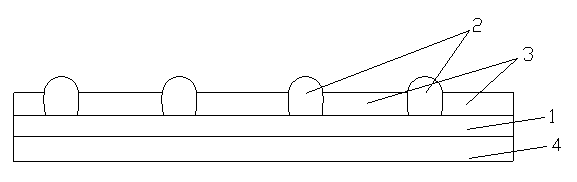

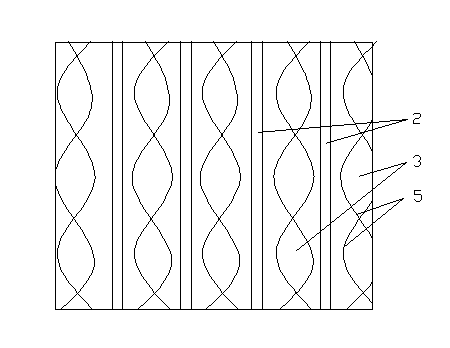

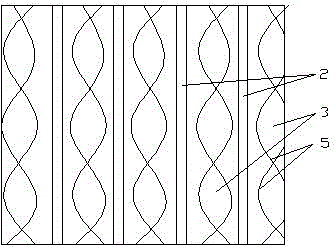

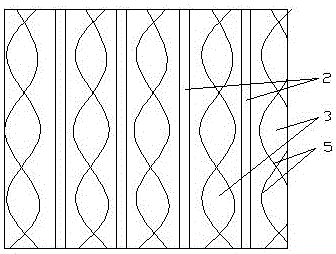

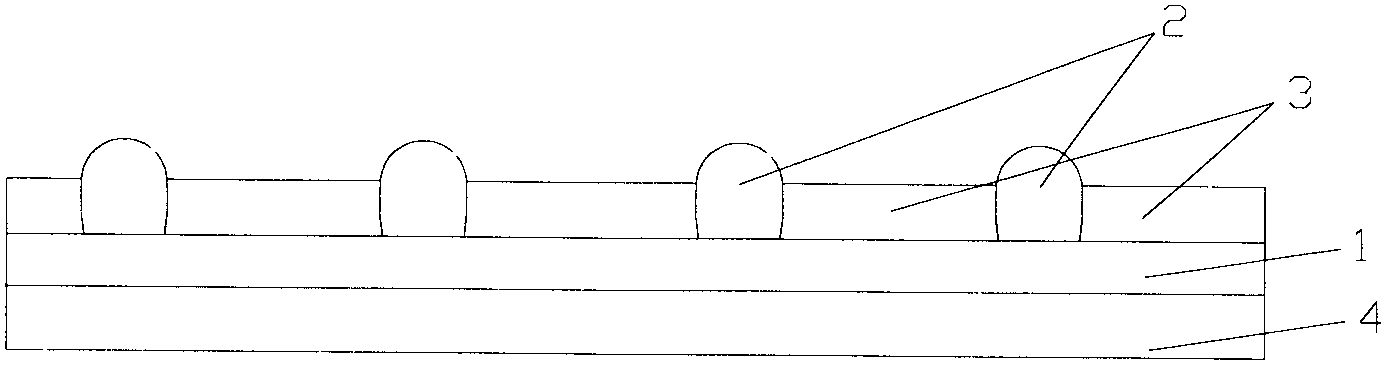

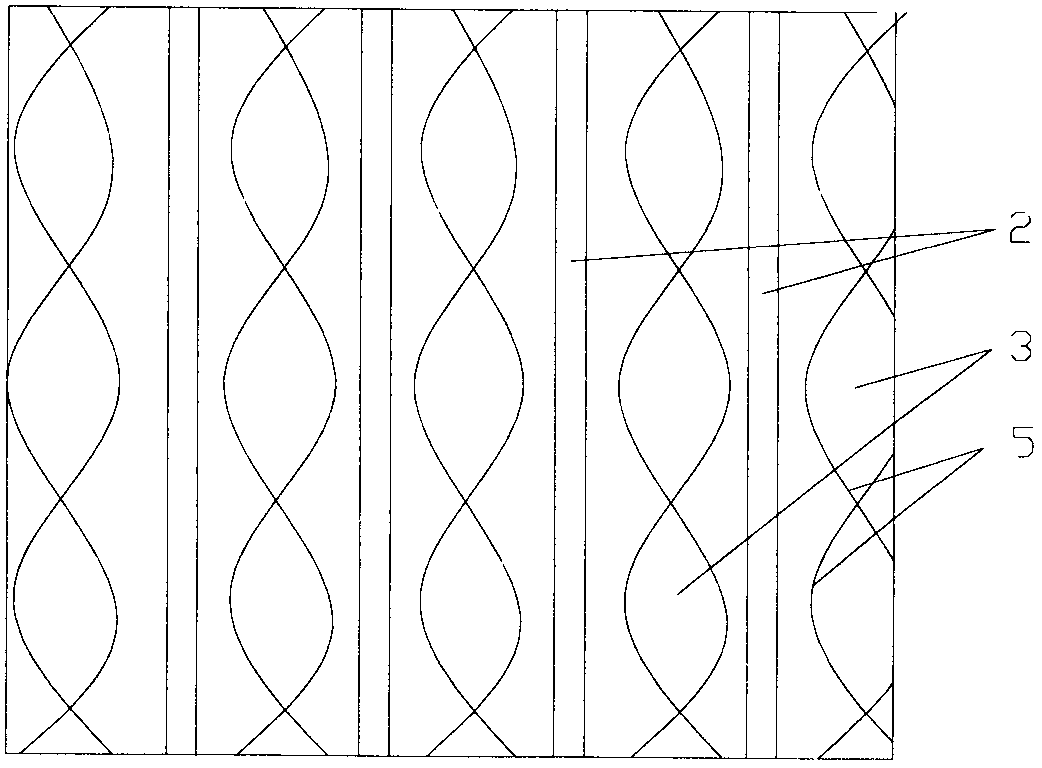

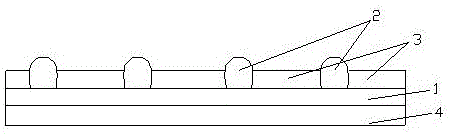

Jacquard fluff strip elastic fabric

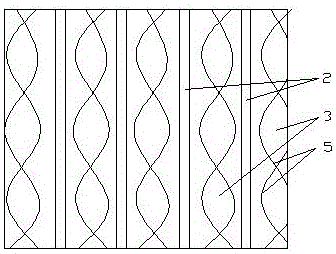

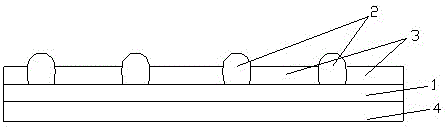

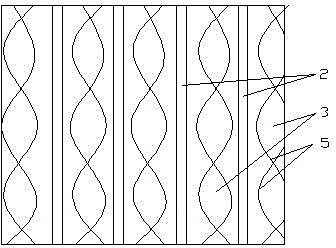

InactiveCN103879049AEnhance layeringHighlight individualityLayered productsWarp knittingLong lastingEngineering

The invention relates to a jacquard fluff strip elastic fabric, which comprises a fabric body (1). The upper surface of the fabric body (1) is provided with jacquard strips (2) and fluff strips (3), and the lower surface is provided with a fluff layer (4). The jacquard strips (2) and the fluff strips (3) are arranged at intervals. The upper surfaces of the fluff strips (3) are provided with ornaments (5). The fabric body (1) is made from a warp knitted fabric, the yarn laying rule is 1-0 / 2-3, the veil adopts 75D / 36T400 polyester fiber fully drawn yarn filament, and the bottom yarn adopts FDY84D / 36F polyester filament. The T400 polyester fiber fully drawn yarn filament is hollow, and has a cross-shaped cross section. The raised fluff strips, jacquard strips and fluff layer enhance the layering sense of the jacquard fluff strip elastic fabric, and at the same time, the embellishment of the ornaments highlights personality. Textiles made from the fabric provided by the invention of have easy elasticity, and are comfortable and long-lasting. The textiles are soft, stiff and smooth, and have good drapability.

Owner:陈建强

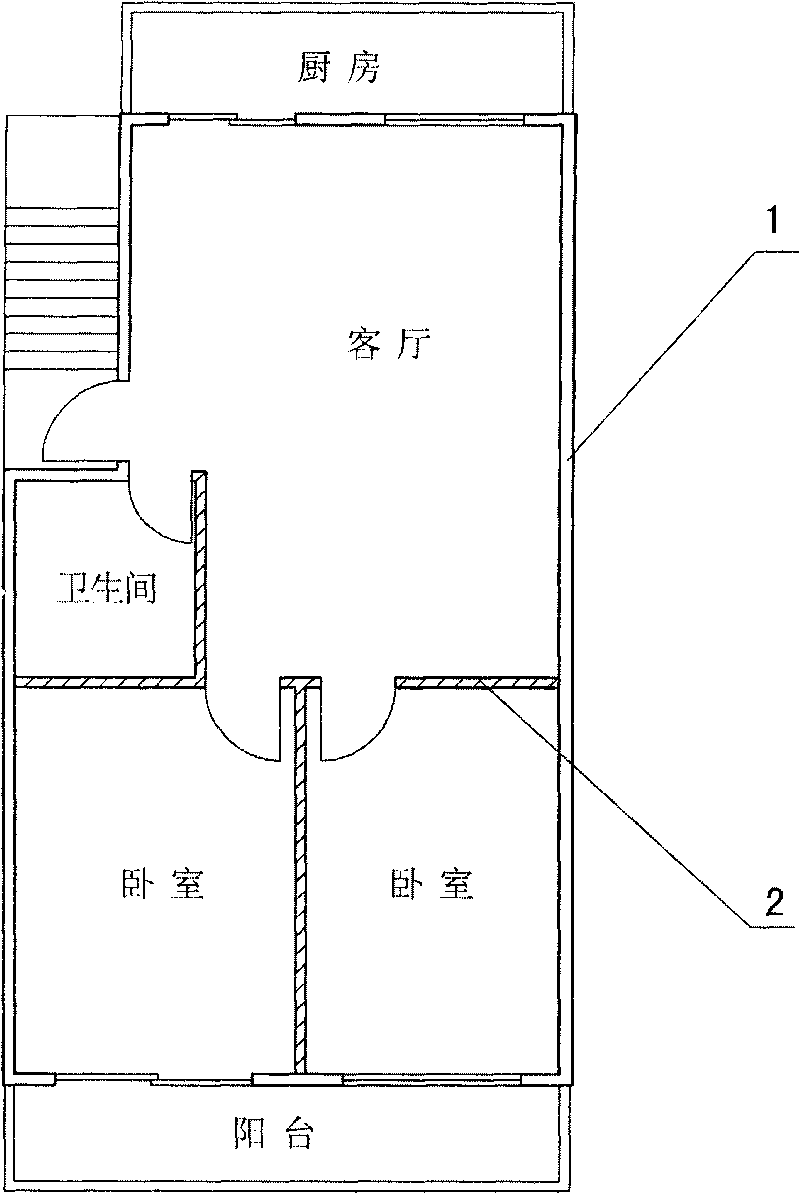

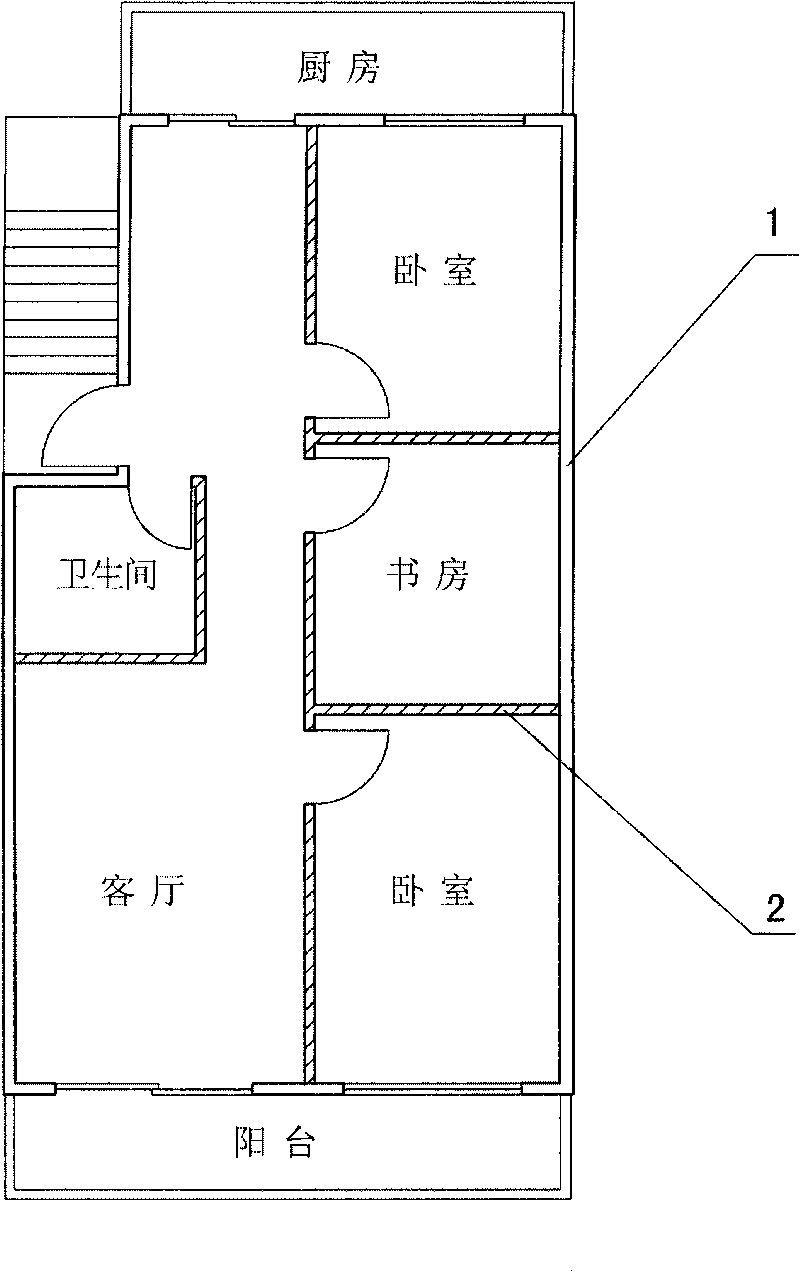

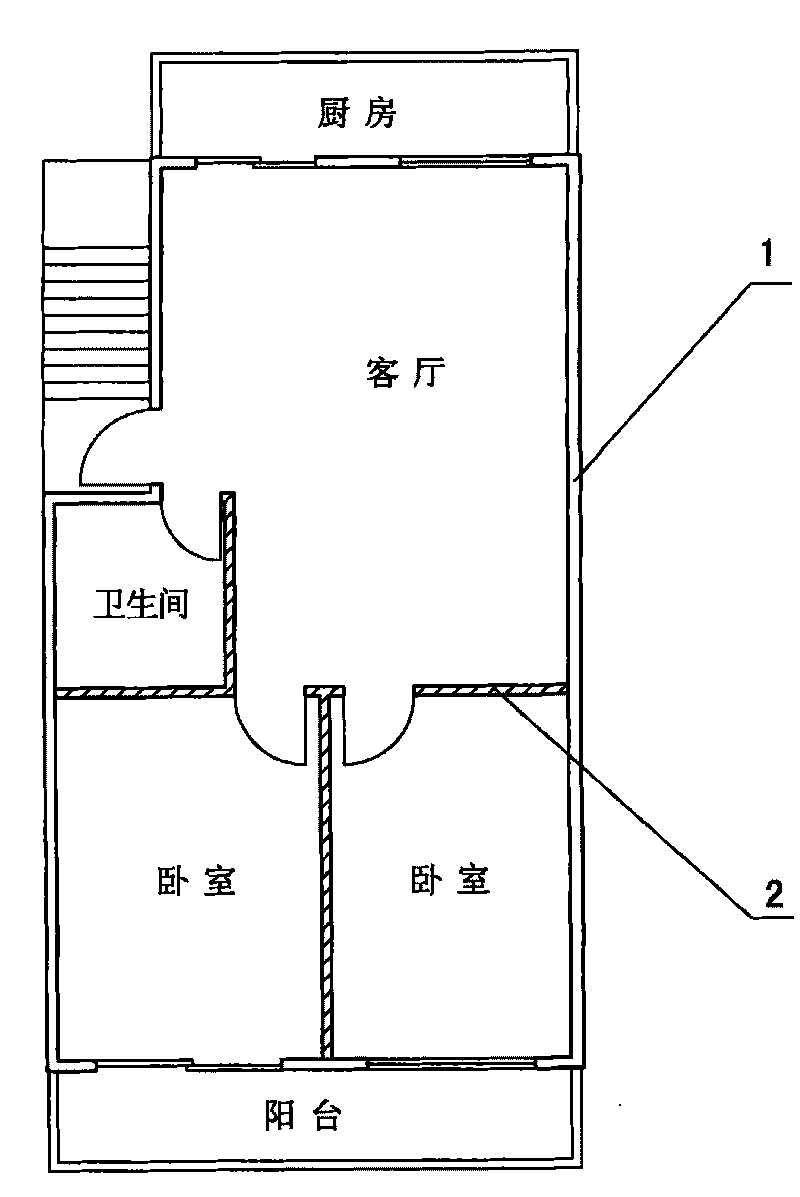

House with flexibly partitioning layout

InactiveCN101736914AImprove construction efficiencyReduce construction costsDwelling buildingHouse buildingGas pipeline

The invention relates to the field of house buildings, in particular to a house with flexibly partitioning layout. In a traditional house, because a room type is determined when the house is built, consumers cannot partition the layout of the house according to per se needs; due to dissatisfaction towards existing room types, many consumers dismantle nonbearing walls in a room so as to repartition the layout, thus a mass of construction wastes are generated to result in resource waste. The house comprises main wall bodies and a house, wherein the main wall bodies are bearing wall bodies of all rooms, the rooms are internally provided with region partitioning wall bodies, and house construction members comprise facilities of heating equipment, various lines, plumbing, gas pipelines and the like. The consumers can flexibly partition indoor layout according to per se needs or preferences. The invention solves the problem that the consumers cannot flexibly partition the indoor layout due to the restrictions of the existing room types, and meanwhile, effectively reduces the construction wastes and protects the environment.

Owner:贺雁广

Cooking process for compound modification of cotton paper pulp, natural color bamboo paper pulp and natural color wood paper pulp into dissolving pulp

InactiveCN104532639AHigh content of pentoseAvoiding the pitfalls of undercookingPulping with inorganic basesPulp and paper industryCotton paper

The present invention discloses a cooking process for compound modification of a cotton paper pulp, a natural color bamboo paper pulp and a natural color wood paper pulp into a dissolving pulp. The cooking process comprises two cooking, wherein the first cooking is used for separately cooking the cotton paper pulp after material preparing, the second cooking is used for cooking the compound paper pulp of the cotton paper pulp being subjected to the first cooking, the natural color bamboo paper pulp after material preparing, and the natural color wood paper pulp after material preparing, the second cooking adopts a continuous cooking device to cook, the continuous steaming pipe of the continuous cooking device is arranged into three sections, the one section connected with a pre-reacting material bin is provided with a T-shaped pipe for adding an alkali liquid and a steam pipe for adding steam, and other two sections are respectively provided with a steam pipe for adding steam. According to the present invention, the raw materials adopt the cotton paper pulp, the natural color bamboo paper pulp and the natural color wood paper pulp, such that the dissolving pulp preparing cost is substantially reduced, the quality requirements of the dissolving pulp for viscose fibers are met, and the performance is diverse.

Owner:CHENGDU GRACE FIBER

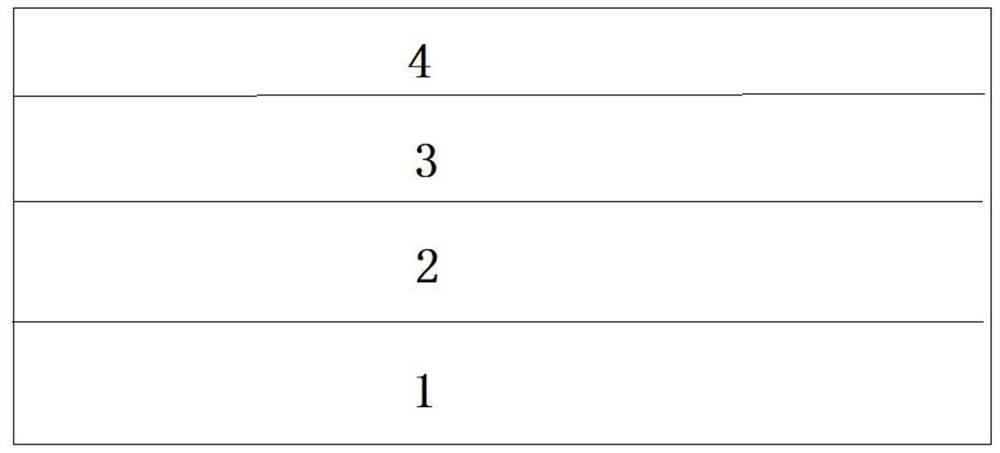

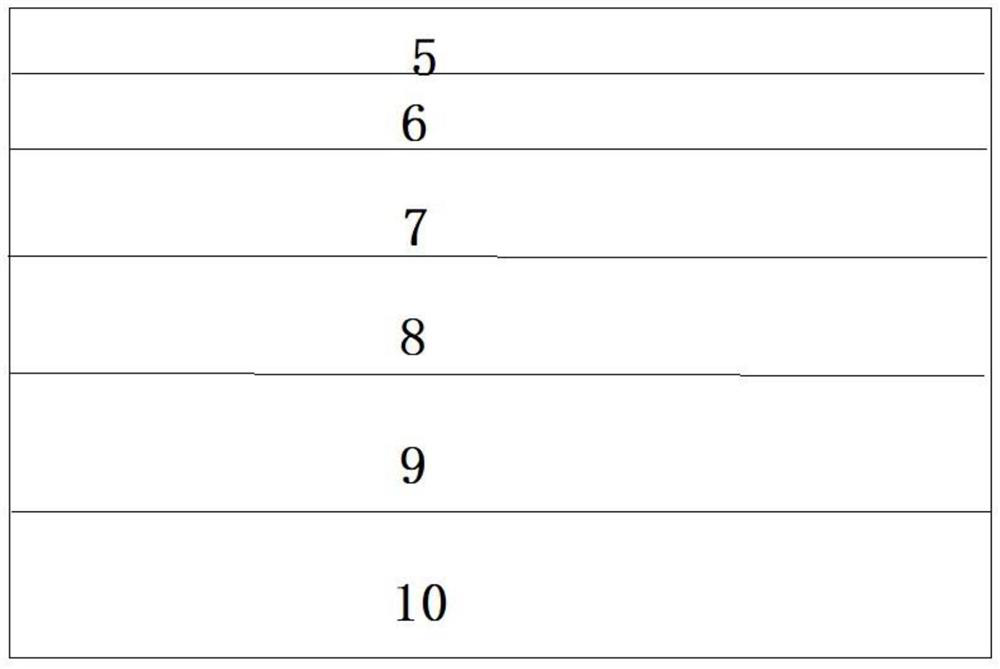

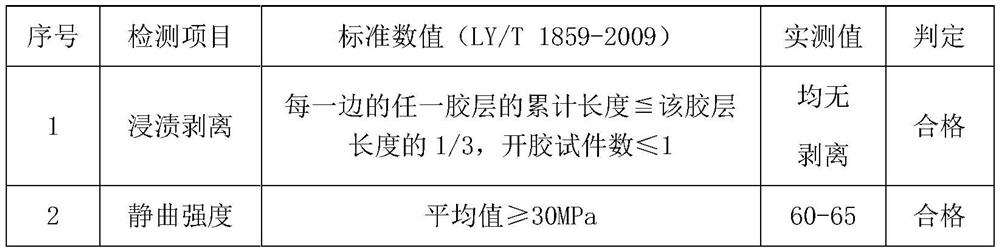

Archaized solid wood composite floor and production process thereof

PendingCN111749425ANo pollution in the processSave resourcesNatural patternsWood veneer joiningSolid woodAdhesive

The invention belongs to the technical field of building materials, and relates to an archaized solid wood floor, in particular to an archaized solid wood composite floor. A crisscross multilayer board base material layer is taken as a main body, the surface of the multilayer board base material layer is coated with adhesive to form a bonding layer, a surface layer is attached, a special archaizedprocessing layer is further arranged on the surface layer, and the uppermost layer is a UV paint layer. The special archaized layer is located between the surface layer and the surface UV paint layer, the thickness of the special archaized layer is between 0.1 mm and 1 mm, and the special archaized layer comprises a hand scraping archaized layer, a wire drawing process layer, a sawtooth grain treatment layer, a color coating process layer, a sand mark treatment layer and a color wiping treatment layer from top to bottom. The present invention also discloses a production process. According tothe archaized solid wood composite floor, the natural texture and the natural color of the wood are retained, the production process is simple, no distortion is lost in the texture pattern, the floorhas good visual characteristics through post-processing, and has relatively high paint adhesion and the like, and the physical and mechanical properties of the produced archaized floor meet the requirements of various indexes.

Owner:圣象地板(句容)有限公司

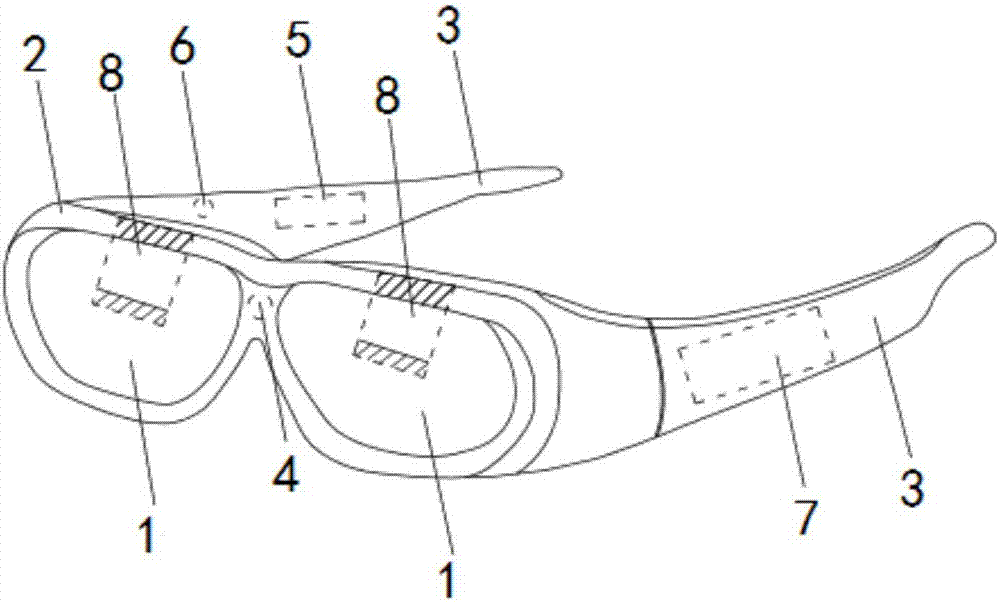

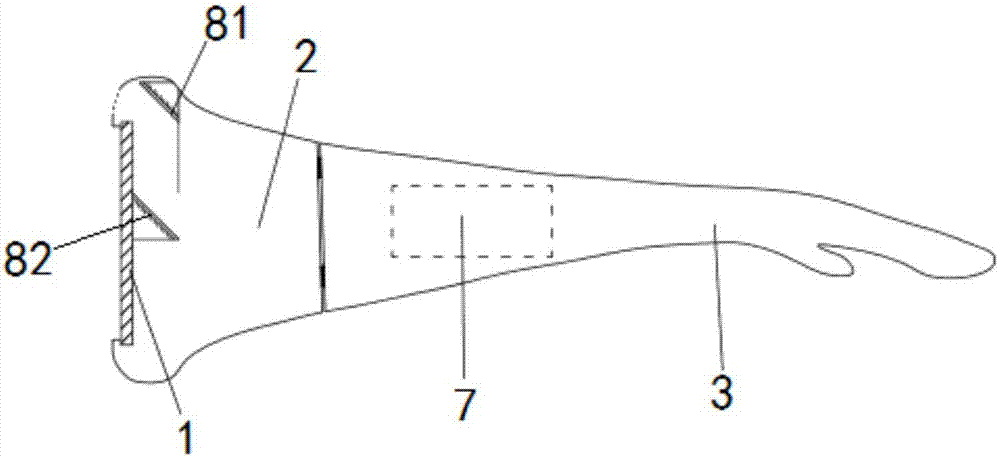

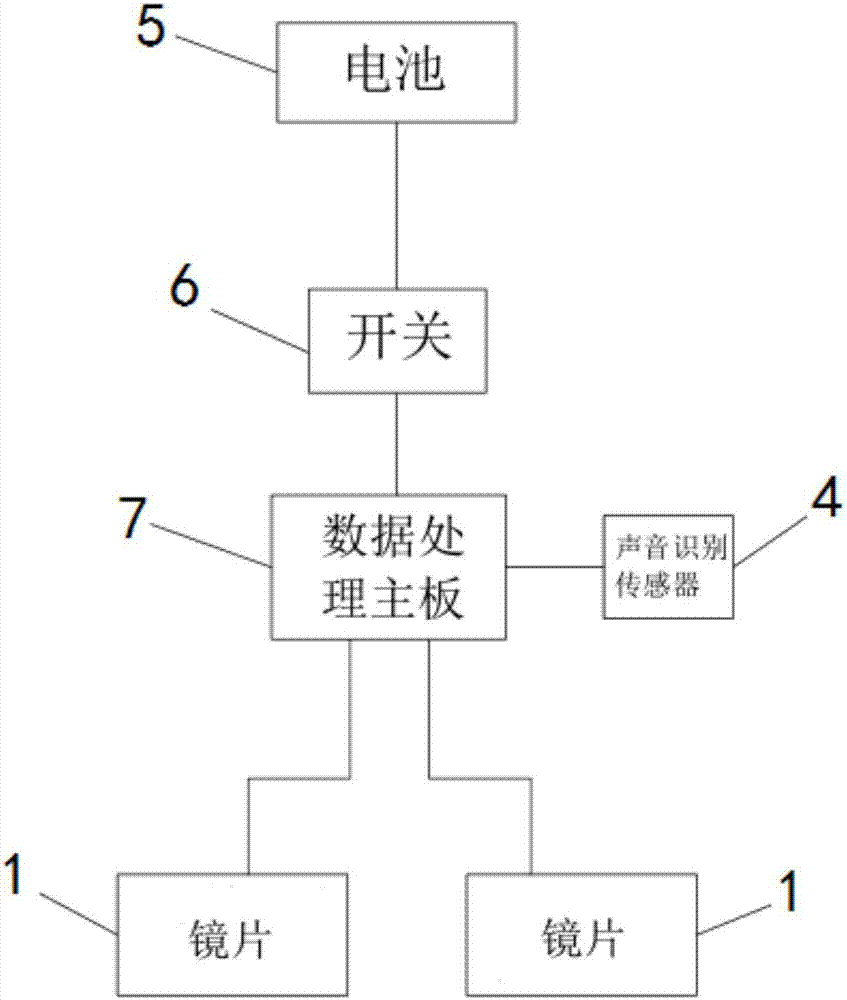

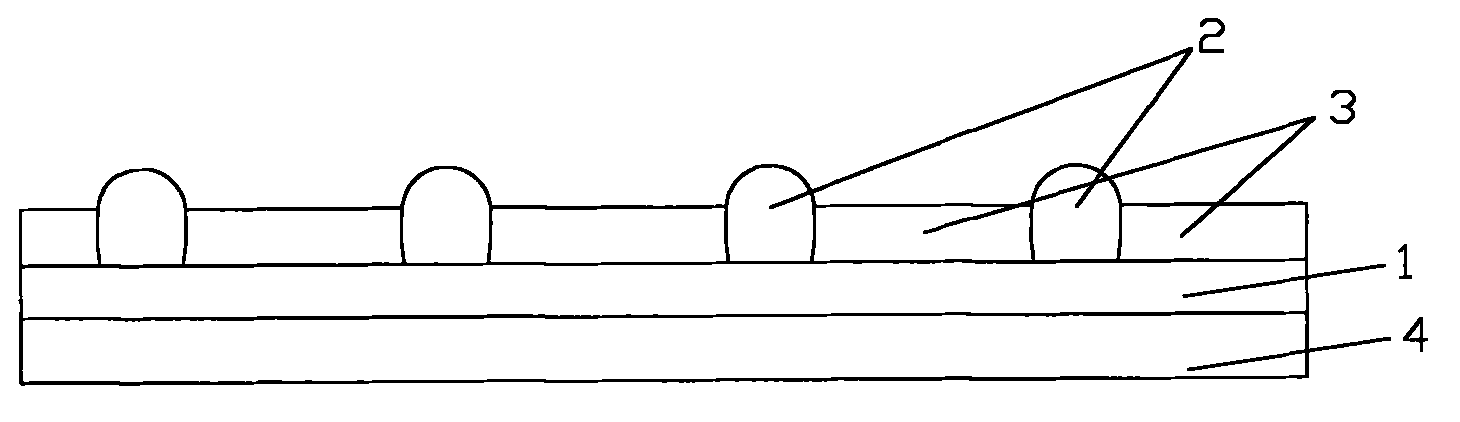

Voice control expression glasses

PendingCN107966822AHigh expressionEasy to understand thoughts and feelingsOptical elementsMedicineEngineering

Owner:白龙

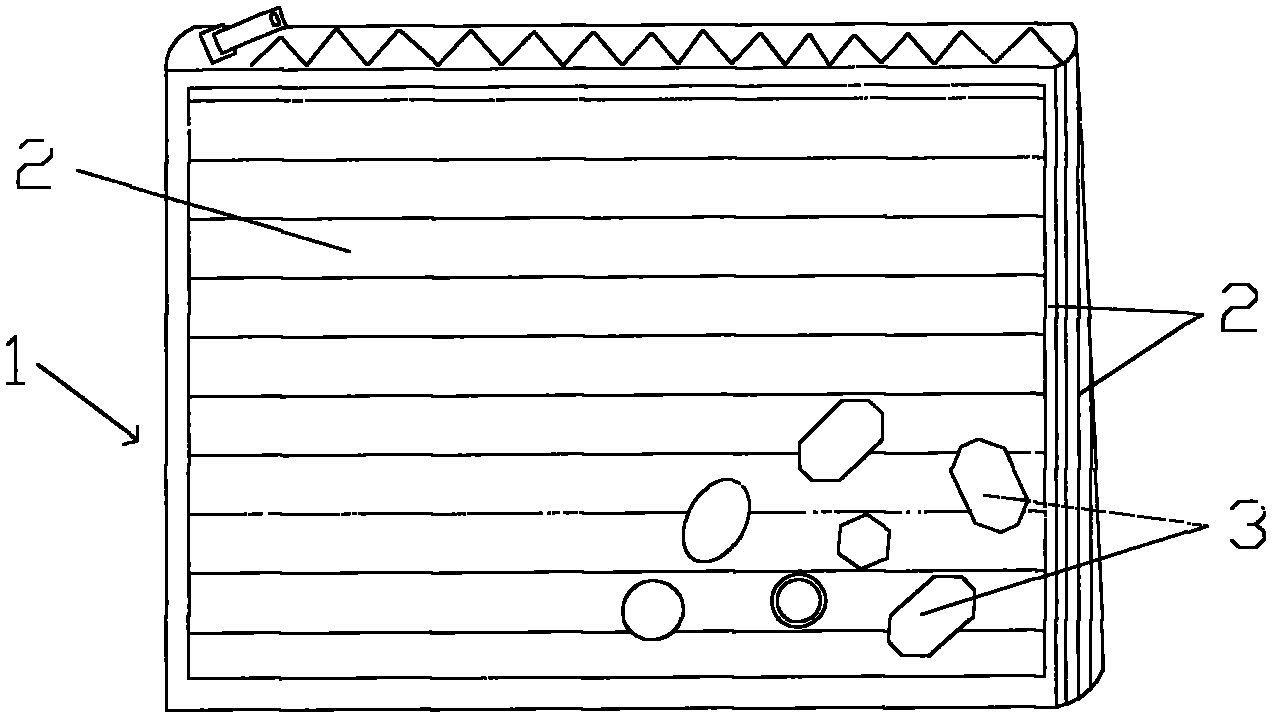

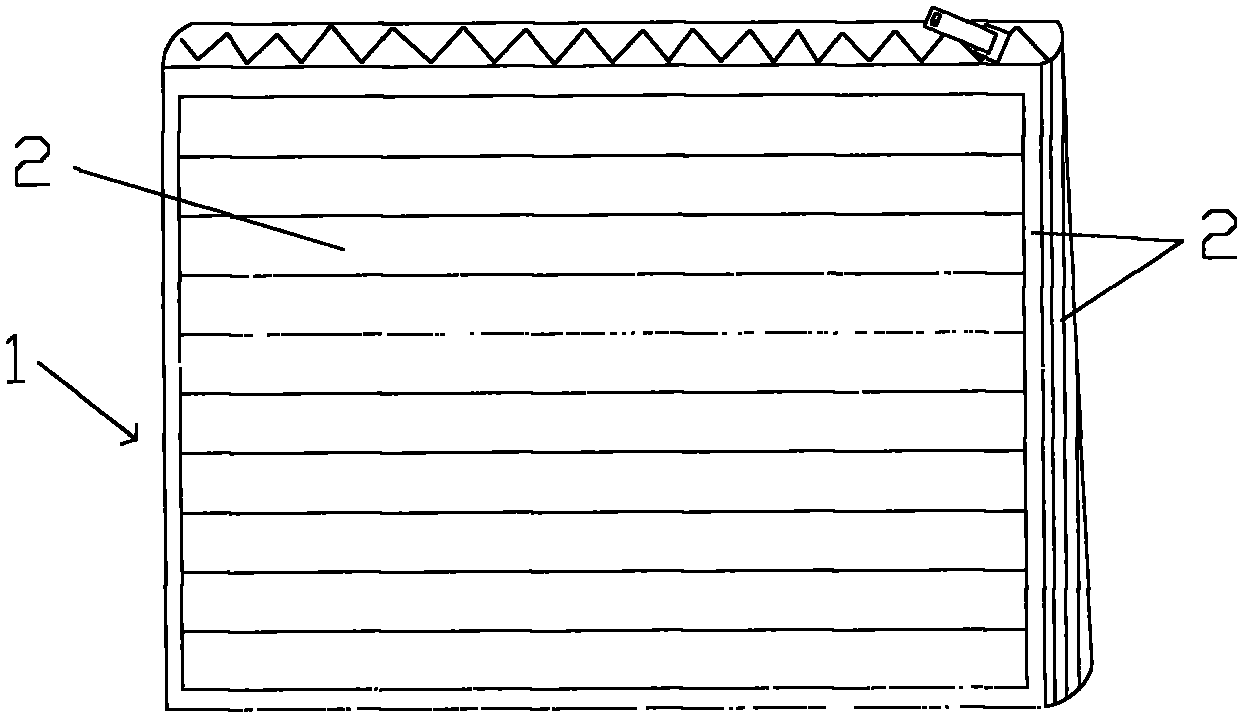

Light-transmitting and breathable jacquard villi strip fabric

InactiveCN103847152AEnhance layeringHighlight individualityLayered productsTextile decorationSurface layerTransmittance

The invention relates to a light-transmitting and breathable jacquard villi strip fabric which comprises a fabric body (1); the upper surface of the fabric body (1) is provided with jacquard strips (2) and villi strips (3), and the lower surface of the fabric body (1) is provided with a villi layer (4); the jacquard strips (2) and the villi strips (3) are arranged at intervals; a decoration (5) is arranged on the upper surfaces of the villi strips (3); the fabric body (1) is made of a textile; the textile is made from a compound fabric which consists of a bottom layer, a middle layer and a surface layer; the bottom layer and the surface are connected into a whole by the middle layer; the surface layer is made of mesh cloth. The layering sense of the light-transmitting and breathable jacquard villi strip fabric is improved by the convex villi strips, the jacquard strips and the villi layer; the light-transmitting and breathable jacquard villi strip fabric is interspersed by the decoration, so that the individuality is highlighted. The light-transmitting and breathable jacquard villi strip fabric has the light transmittance and the air permeability.

Owner:吴栋标

Jacquard fluff strip antimicrobial and crease-resistant fabric

InactiveCN103879059AEnhance layeringHighlight individualitySynthetic resin layered productsTextile decorationEngineeringBamboo charcoal

The invention relates to a jacquard fluff strip antimicrobial and crease-resistant fabric, which comprises a fabric body (1). The upper surface of the fabric body (1) is provided with jacquard strips (2) and fluff strips (3), and the lower surface is provided with a fluff layer (4). The jacquard strips (2) and the fluff strips (3) are arranged at intervals. The upper surfaces of the fluff strips (3) are provided with ornaments (5). The fabric body (1) is made from a textile, which comprises a front crease-resistant layer, an intermediate adhesive layer and a back antibacterial layer. The crease-resistant layer is a polyurethane material with a memory function, the adhesive layer is a thermosetting adhesive layer, and the antibacterial layer is a textile layer containing nano-bamboo charcoal fiber. The raised fluff strips, jacquard strips and fluff layer enhance the layering sense of the jacquard fluff strip antimicrobial and crease-resistant fabric, and also the embellishment of the ornaments highlights personality.

Owner:张英

Digesting process for modifying natural bamboo pulp and bleached wood pulp into dissolving pulp by compounding

ActiveCN102720084AHigh content of pentoseFully cookedNatural cellulose pulp/paperPulping with inorganic basesPulp and paper industryEngineering

The invention discloses a digesting process for modifying natural bamboo pulp and bleached wood pulp into dissolving pulp by compounding. Composite pulp is fed into a continuous digester for digestion, a continuous digesting tube of the continuous digester has three sections, a section connected with a pre-reaction bin is provided with a T-shaped tube for adding an alkaline solution and a steam tube for adding steam, the other two sections are provided with steam tubes for adding steam, and a liquor ratio is 1:(2.0-4.0); the alkaline solution is NaOH, and is added in an amount which is 17 to 23 percent based on the oven dry weight; and the compression ratio is 1:(2-3.0). Because raw materials are the natural bamboo pulp and the bleached wood pulp, the cost of preparing the dissolving pump is reduced to a large extent; meanwhile, the prepared dissolving pulp meets the requirement for the quality of dissolving pulp for viscose.

Owner:YIBIN GRACE GROUP CO LTD

Jacquard fluff strip magnetic fabric

InactiveCN102806715AEnhance layeringPromote body microcirculationLayered productsTextile decorationEngineeringTextile

The present invention relates to a jacquard fluff strip magnetic fabric, and belongs to the field of textile fabrics. The jacquard fluff strip magnetic fabric comprises a fabric body (1), wherein the fabric body (1) is blended with magnetic fibers, a ferrite permanent magnetic microparticle material is uniformly implanted inside fibers and organically combined with the fibers to form the magnetic fibers, the upper surface of the fabric body (1) is provided with jacquard strips (2) and fluff strips (3), the lower surface is provided with a fluff layer (4), the jacquard strips (2) and the fluff strips (3) are aligned at intervals, the jacquard strips (2), the fluff strips (3) and the fluff layer (4) are fixed on the fabric body (1), the upper surfaces of the fluff strips (3) are provided with decorative objects (5), and the decorative objects (5) are fixed on the fluff strips (3). According to the present invention, with the convex fluff strips, the jacquard strips and the fluff layer, a layering effect of the jacquard fluff strip magnetic fabric is enhanced; with decoration of the decorative objects, a special feature is provided; and the fabric body is blended with magnetic fibers so as to provide a physical therapy effect.

Owner:朱浩炳

Bag

Owner:郭亚娟

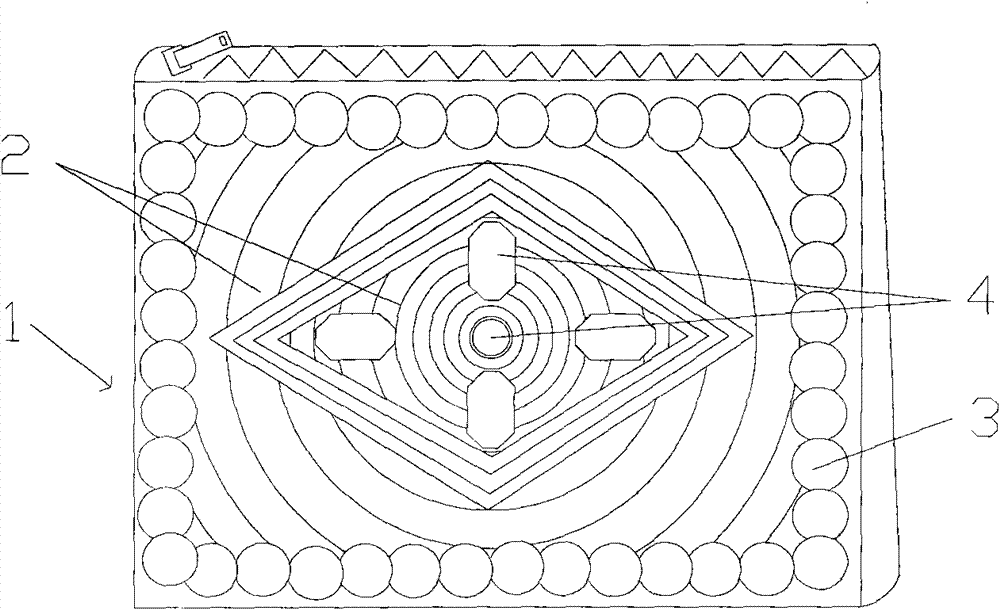

Double-surface bead bag

Owner:郭亚娟

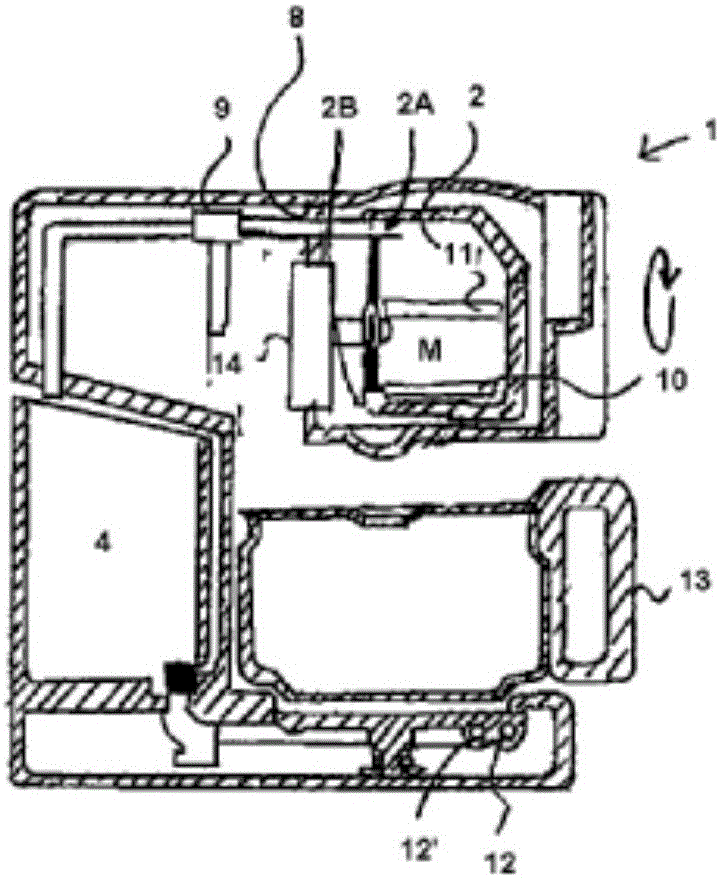

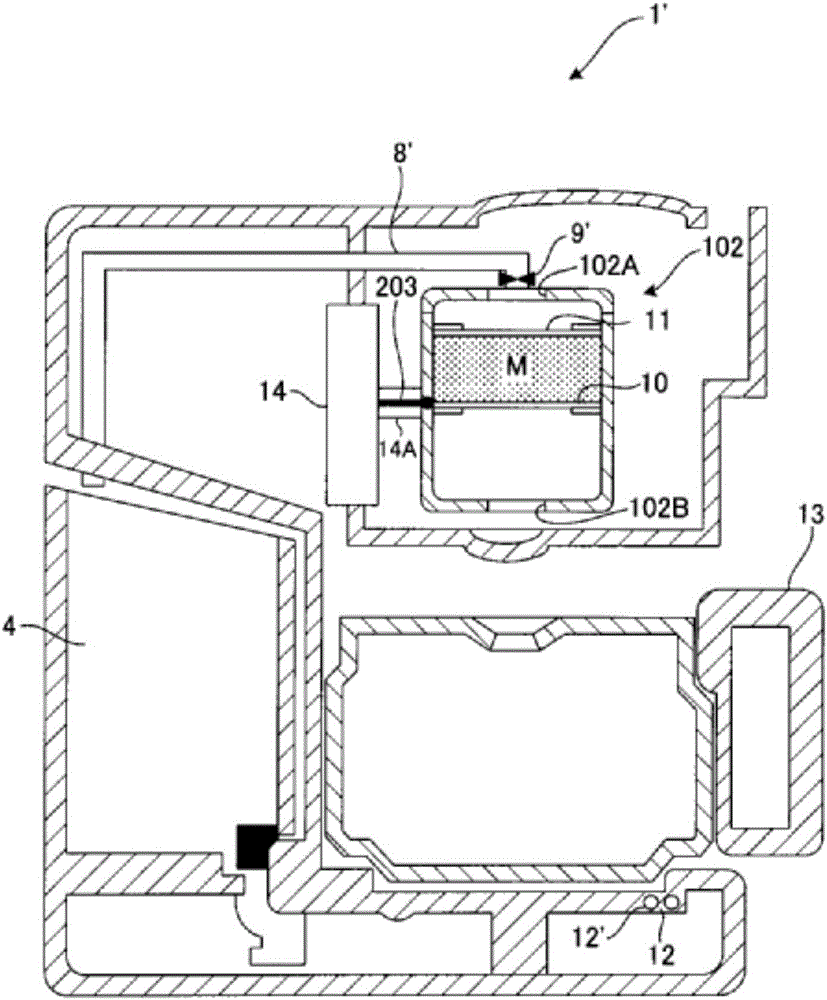

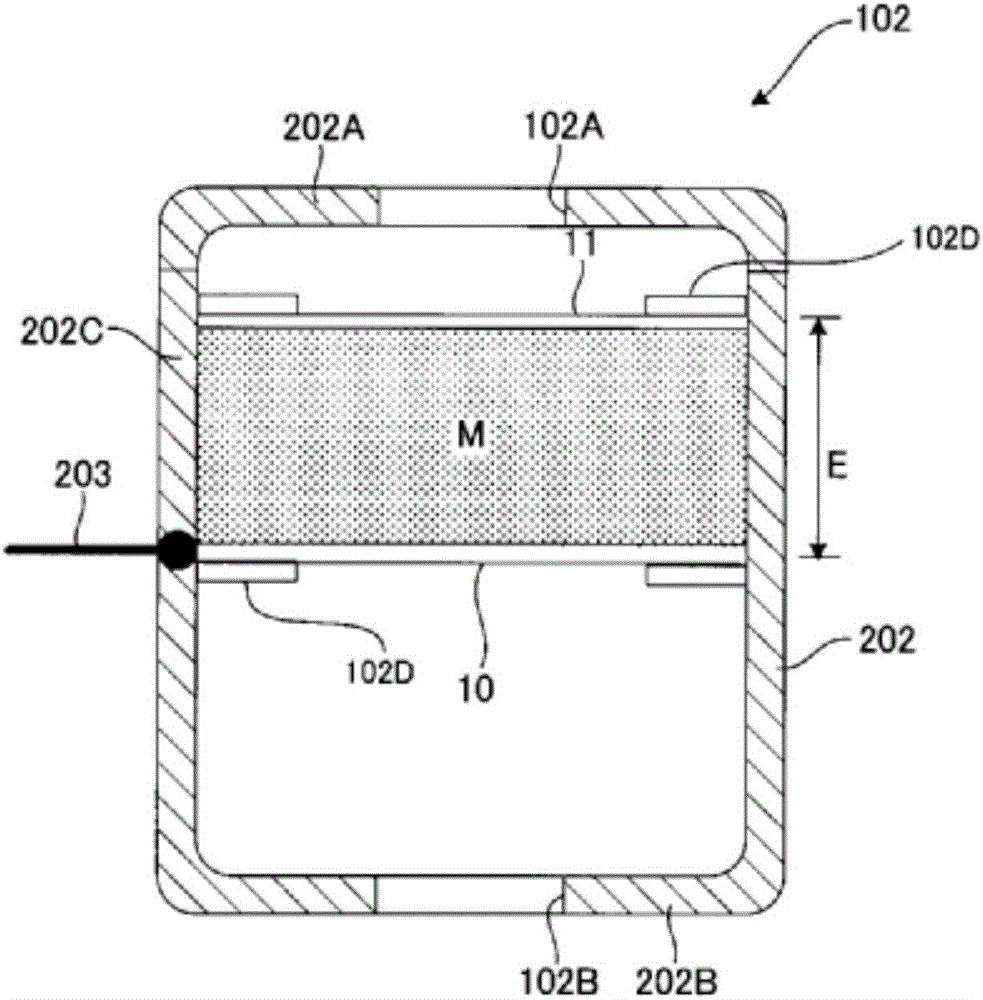

Beverage extraction device

Owner:SUNTORY HLDG LTD

Jacquard nap strip weaving and knitting composite fabric with flame-retardant fabric layer

InactiveCN104872904AEnhance layeringGreat comfort and freedom of movementSynthetic resin layered productsGlass/slag layered productsWeft yarnEngineering

The invention relates to a jacquard nap strip weaving and knitting composite fabric with a flame-retardant fabric layer. The jacquard nap strip weaving and knitting composite fabric with the flame-retardant fabric layer comprises a fabric body (1). The upper surface of the fabric body (1) is provided with jacquard strips (2) and nap strips (3). The lower surface of the fabric body (1) is provided with a nap layer (4). The jacquard strips (2) and the nap strips (3) are arranged alternately. The upper surfaces of the nap strips (3) are provided with ornamentals (5). The fabric body (1) is made of a textile fabric. The textile fabric is formed by interweaving warp yarns and weft yarns in a floating and sinking mode. One kind of the warp yarns and the weft yarns is elastic wrap yarns. Each elastic warp yarn is composed of a spandex filament located at the center and a plurality of nylon low-stretch yarns wrapped on the spandex filament. The protruding nap strips, the jacquard strips and the nap layer enhance the layering sense of the jacquard nap strip weaving and knitting composite fabric with the flame-retardant fabric layer; through the ornamentals, individuality is highlighted.

Owner:JIANGYIN CHENGXIN SPECIAL PRINTING

Handbag with bead inlaid eyelets decoration on both surfaces

The invention relates to a handbag with bead inlaid eyelets decoration on both surfaces. The handbag comprises a bag body (1); a plurality of paillette strings (2) and bead strings (3) are arranged on the outer surface of the handbag body (1); each paillette string (2) is formed by connecting a plurality of paillettes in series; the edge parts of every adjacent paillettes are lapped mutually; the paillette strings (2) are arranged in parallel and respectively fixed to the lower parts of the front surface and the back surface of the handbag body (1); each bead string (3) is formed by connecting a plurality of beads in series; the bag body material is composed of a bottom layer, an intermediate layer and a surface layer; the surface is an eyelet fabric; part of the paillettes of the paillette strings (2) and the beads of the bead strings (3) is inlaid and adhered into the eyelets, and the other part is exposed from the eyelet fabric on the surface layer. According to the handbag with the bead inlaid eyelets decoration on the both surfaces, the bead strings and the paillette strings are symmetrically distributed on the handbag body and reflect mutually, a belt formed by knitting the bead strings is adopted and used as a shoulder girdle, so that the uniqueness of the handbag with bead decoration on the both surfaces can be highlighted.

Owner:郭亚娟

Jacquard weave nap top woven knitted combined fabric with fireproof fabric layer

InactiveCN106690607AEnhance layeringHighlight individualitySynthetic resin layered productsTextile decorationPolyesterEngineering

The invention relates to a jacquard weave nap top woven knitted combined fabric with fireproof fabric layer which comprises a fabric body(1), the fabric body(1) is provided with a jacquard top(2) and a nap top(3) on the upper surface, the tappet(4) is provided in the lower surface; the jacquard weave top(2) and the nap top(3) are arrayed at intervals, an ornament(5) is set on the upper surface of the nap top(3), the fabric is made from the fabric which is interwoven with rising and setting by the warp and the weft, one kind of the warp and the weft are the elastic with polyester coating which is composed of the spandex in the center and multiple low elastic nylon filament which wraps the spandex. The convex nap top, the jacquard top and the tappet strengthen the layering of the jacquard weave nap top woven knitted combined fabric with fireproof fabric layer, at the same time, the ornament highlights individual character.

Owner:顾方钟

Jacquard villus strip light-shielding fabric

The invention relates to a jacquard villus strip light-shielding fabric which comprises a fabric body (1), wherein jacquard strips (2) and villus strips (3) are arranged on the upper surface of the fabric body (1); a villus layer (4) is arranged on the lower surface of the fabric body (1); the jacquard strips (2) and the villus strips (3) are arranged at intervals; ornaments (5) are arranged on the upper surface of the villus strips (3); the fabric body (1) is made of a textile; the textile comprises a surface layer, a lining layer and a middle layer connected between the surface layer and the lining layer; the surface layer and the lining layer are integrally formed by interweaving warps and wefts. Due to the convex villus strips, the jacquard strips and the villus layer, the layering feeling of the jacquard villus strip light-shielding fabric is improved, and meanwhile due to decoration of the ornaments, the individuality of the fabric is highlighted.

Owner:许永新

Compound knit fabric knitted by Jacquard pile slivering machine

InactiveCN105818472AEnhance layeringHighlight individualityLayered productsWoven fabricsYarnStructural engineering

The invention relates to a compound knit fabric knitted by a Jacquard pile slivering machine.The fabric comprises a fabric body, Jacquard strips and pile strips are arranged on the upper surface of the fabric body, a pile layer is disposed on the lower surface of the fabric body, the Jacquard strips and the pile strips are arranged at intervals, ornaments are arranged on the upper surfaces of the pile strips, the fabric body is made from textile formed by interweaving warps and wefts in an overlapping mode, the warps or the wefts are elastic wrapped yarn, and the elastic wrapped yarn is composed of spandex in the center and a plurality of low-elasticity filaments wrapping the spandex.The convex pile strips, the Jacquard strips and the pile layer enhance the layering sense of the compound knit fabric knitted by the Jacquard pile slivering machine.Meanwhile, due to decoration of the ornaments, personalities are highlighted.

Owner:江阴市振新毛纺有限公司

Figured and fluff bar flashing fabric

InactiveCN105015060AEnhance layeringHighlight individualityLayered productsTextile decorationLight reflectionEngineering

The invention relates to a figured and fluff bar flashing fabric which comprises a fabric body (1), wherein figured bars (2) and fluff bars (3) are arranged on the upper surface of the fabric body (1), and a fluff layer (4) is arranged on the lower surface of the fabric body (1); the figured bars (2) and the fluff bars (3) are arrayed at intervals; ornaments (5) are arranged on the upper surfaces of the fluff bars (3); the fabric body (1) is made from a fabric; the fabric is formed by interweaving warp yarns and weft yarns; the sections of the warp yarns and the weft yarns are triangular; the surfaces of the warp yarns and the weft yarns are coated with light reflection layers. Due to the protruded fluff bars, the figured bars and the fluff layer, the sense of layering of the figured and fluff bar flashing fabric is enhanced; meanwhile, by the decoration of the ornaments, the personality is outstanding.

Owner:吴银芝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com