Anti-fake bronzed logo used for Internet of Things and capable of changing color for error

A technology of mechanical error and the Internet of Things, applied in the field of bronzing anti-counterfeiting labels, can solve the problems of deviation of hair size and inability to print high-gloss metallic luster, and achieve the effect of improving the difficulty of printing gold forgery and the difficulty of copying and forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

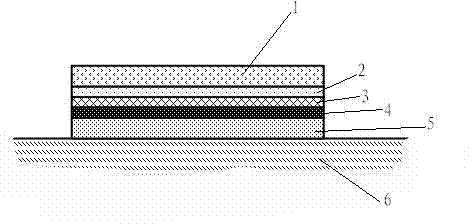

[0040] like figure 1 , figure 2 , image 3 , Image 6 As shown, select a 15-micron thick, biaxially stretched high-temperature resistant PET transparent film roll as the base film layer (1), and coat a layer of 2-micron-thick release agent on one side as the release layer (2) .

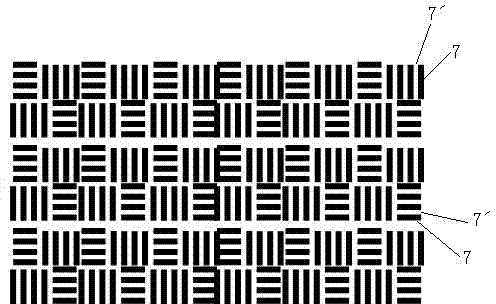

[0041] A layer of yellow, red, blue, white, green and other monochromatic lines (7), (7') arranged alternately with a dyed layer (3) is printed on the release layer (2).

[0042] A layer of metal aluminum is vapor-deposited on the dyed layer (3) as the metal coating (4).

[0043] Coat one layer of bronzing back adhesive adhesive layer (5) on the metal plating layer (4) to make a variegated (or pattern) bronzing film for future use.

[0044]Load the variegated (or pattern) hot stamping film made in the previous step on the hot stamping machine, and use the hot stamping version of the word "Wang" to stamp each stroke color and fine line on the anti-counterfeiting object (6) Different "king" gilt ...

Embodiment 2

[0049] like Figure 5 , Figure 7 As shown, select a 15 micron thick, biaxially stretched high temperature resistant PET transparent film roll as the base film layer (1), and coat a layer of 2 micron thick release agent on one side as the release layer (2) .

[0050] A personalized dyeing layer (3) similar to snowflakes on a TV screen is printed on the release layer (2) with a layer of red and blue monochromatic color blocks (8) and (8') arranged alternately.

[0051] A layer of metallic aluminum is vapor-deposited on the dyed layer (3) as the metal coating (4).

[0052] Coating one layer of bronzing back adhesive adhesive layer (5) on the metal plating layer (4) to make a personalized bronzing film similar to snowflakes on a TV screen for future use.

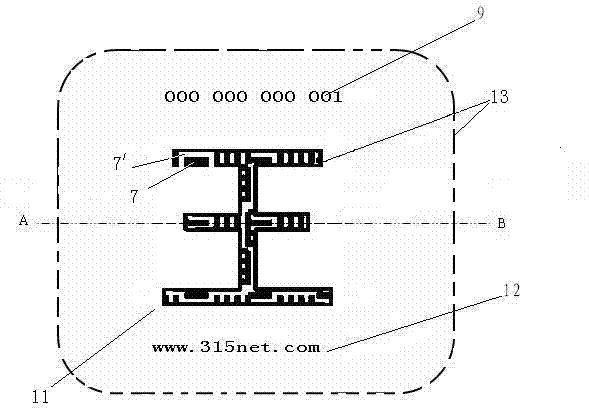

[0053] Use a laser engraving inkjet printer to engrave two-dimensional codes (10) and stamping lines (13) on the personalized hot stamping film similar to TV screen snowflakes made in the previous step to make a two-dimensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com