Patents

Literature

85 results about "Foil stamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foil stamping, typically a commercial print process, is the application of pigment or metallic foil, often gold or silver, but can also be various patterns or what is known as pastel foil which is a flat opaque color or white special film-backed material, to paper where a heated die is stamped onto the foil, making it adhere to the surface leaving the design of the die on the paper. Foil stamping can be combined with embossing to create a more striking 3D image.

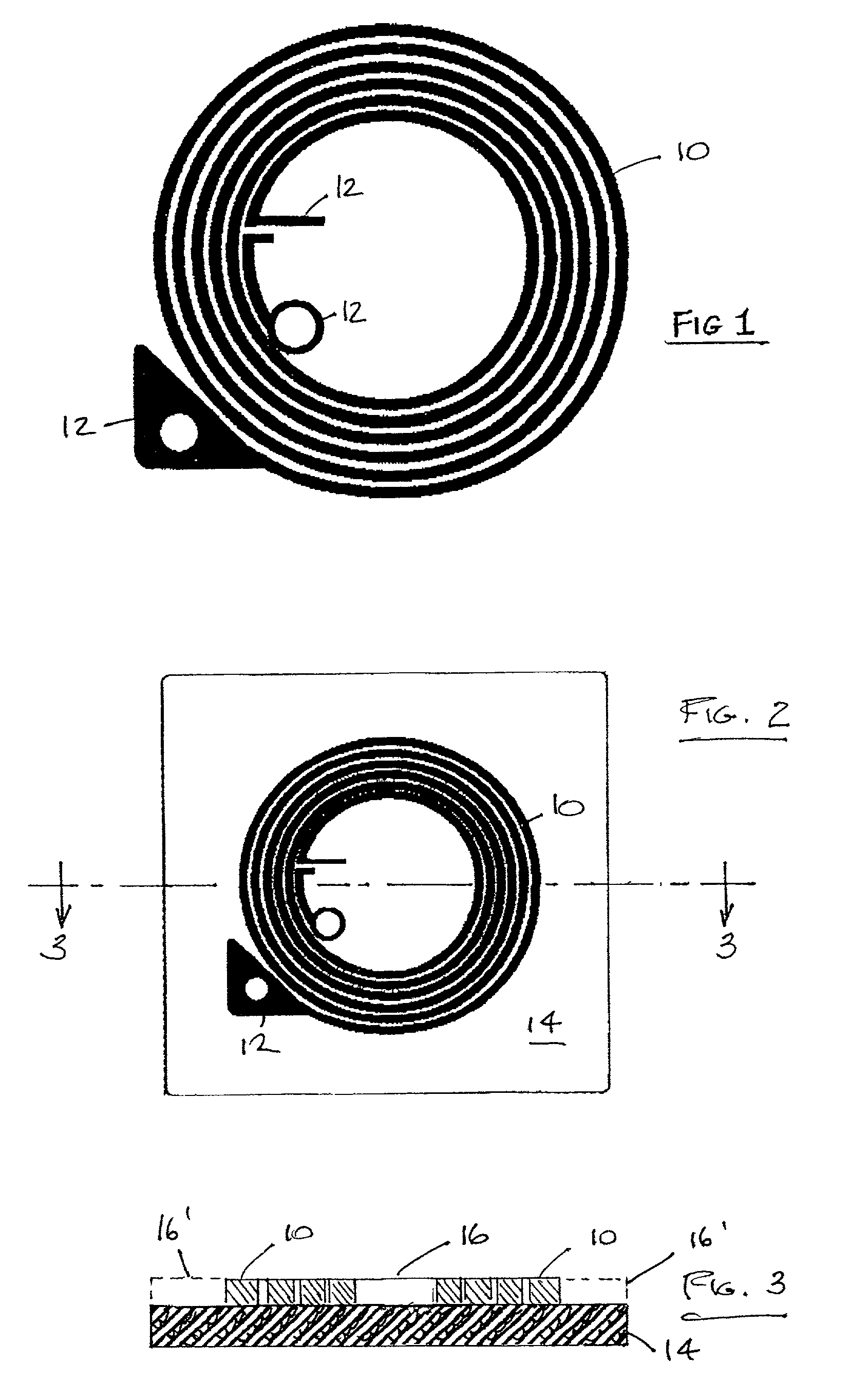

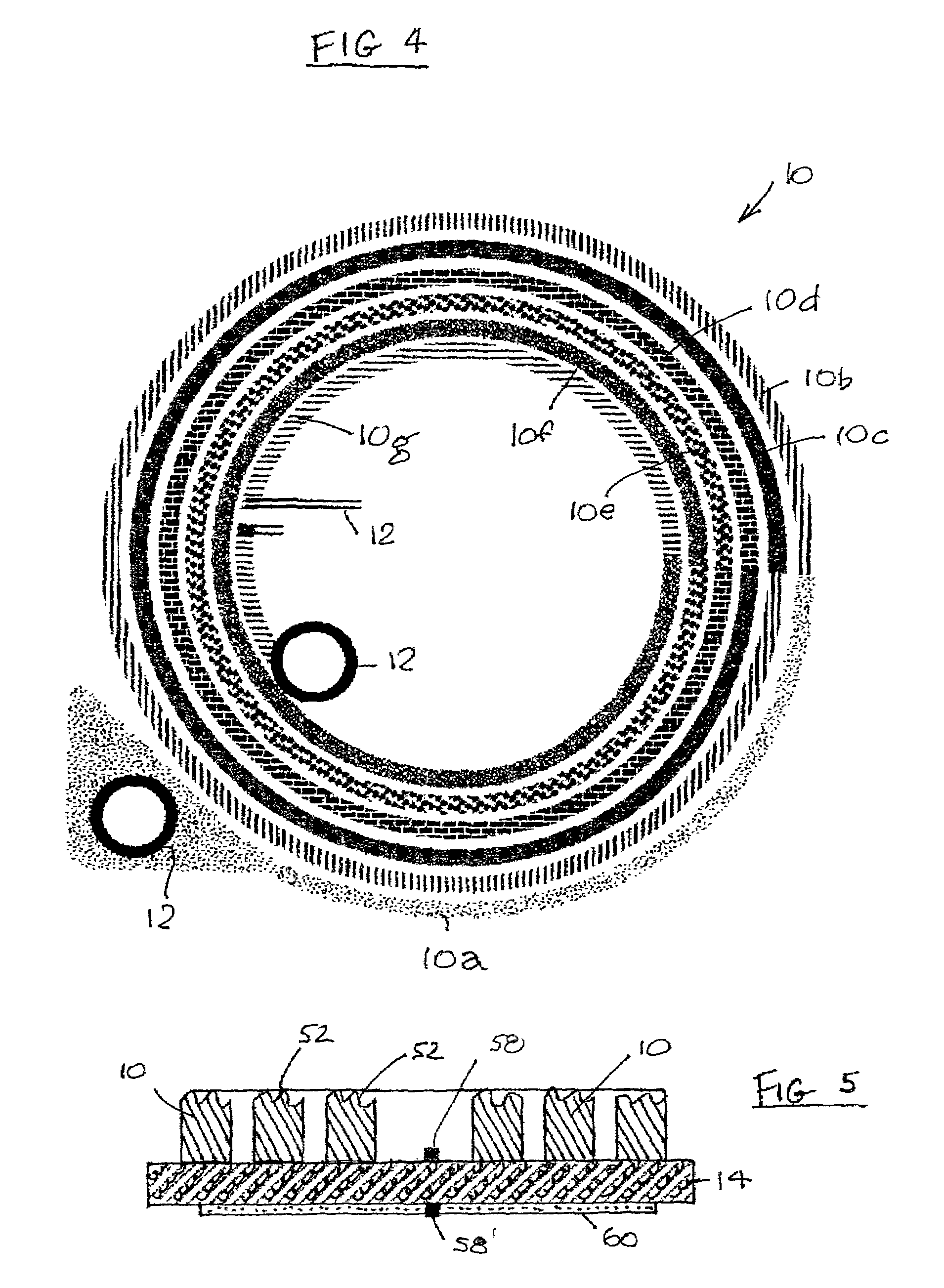

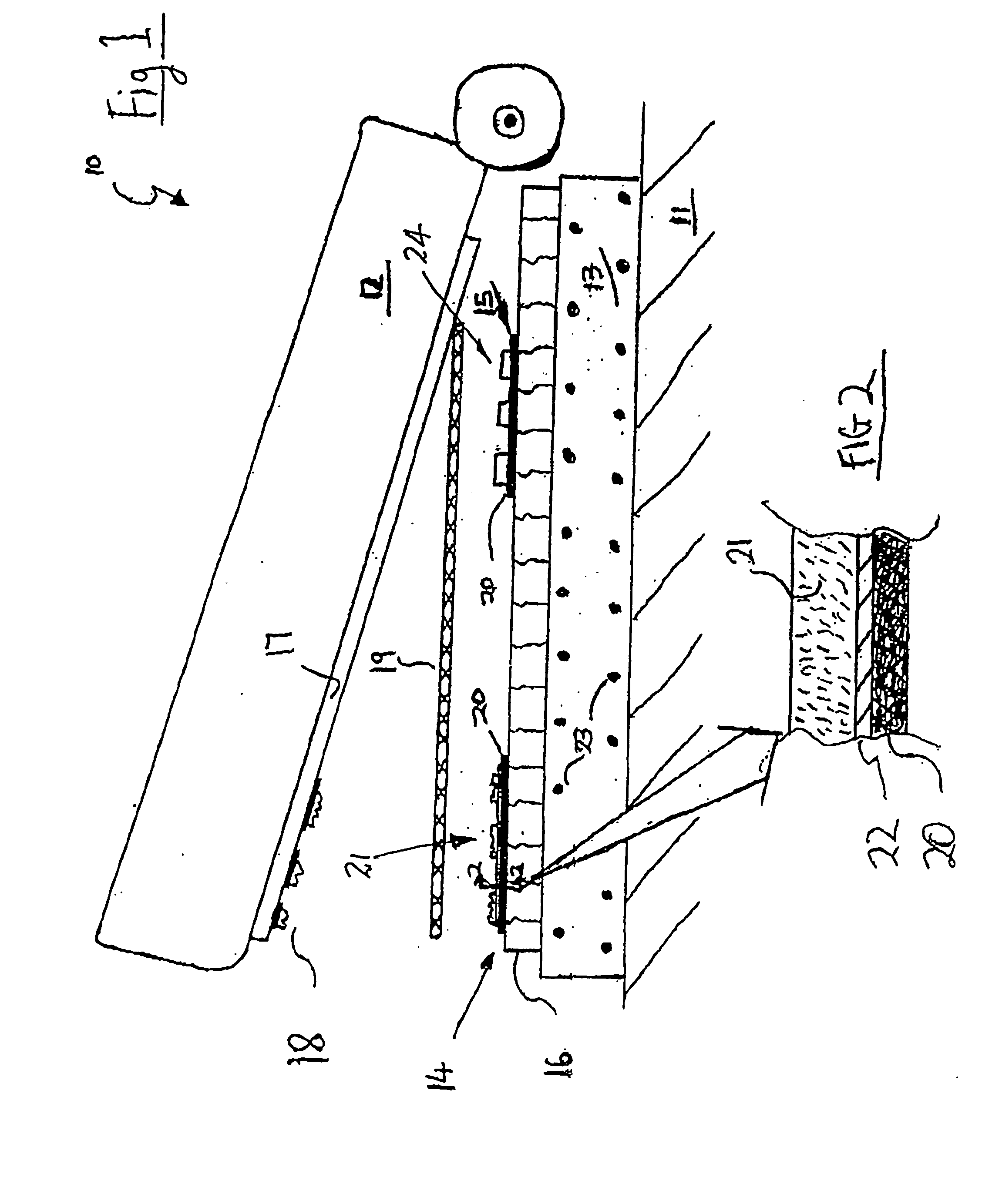

Method for the formation of RF antennas by demetallizing and RF antenna products formed thereby

InactiveUS20020129488A1Simple methodLow costResonant long antennasAntenna arraysCredit cardDot matrix

A thin and flexible radio frequency (RF) antenna tag or label is disclosed which contains an RF circuit connected to an antenna which is created by demetallizing the area around the antenna pattern on a thin, metallized substrate such as a film or paper web. Antenna(s) may be formed on one or both sides of the substrate and can contain printed, holographic, optical variable device, diffractive, dot matrix, computer-generated holograms or computer-generated optical images. The demetallized RF antenna on the substrate can optionally further be transferred to a second substrate or web by means of a cold foil stamping process. The tag or label is thin and flexible, enabling a wide range of applications including RF tagging of anti-theft devices, product packaging of all types, credit cards, passports, admission tickets, stamps, vehicles, badges, fare cards, roadway tolls, customs and immigration checkpoints identification, and animal identification / tracking devices.

Owner:NANOGRAFIX

Method for the formation of RF antennas by demetallizing

InactiveUS7159298B2Thin and flexible tagSimple methodResonant long antennasAntenna arraysCredit cardDot matrix

Owner:NANOGRAFIX

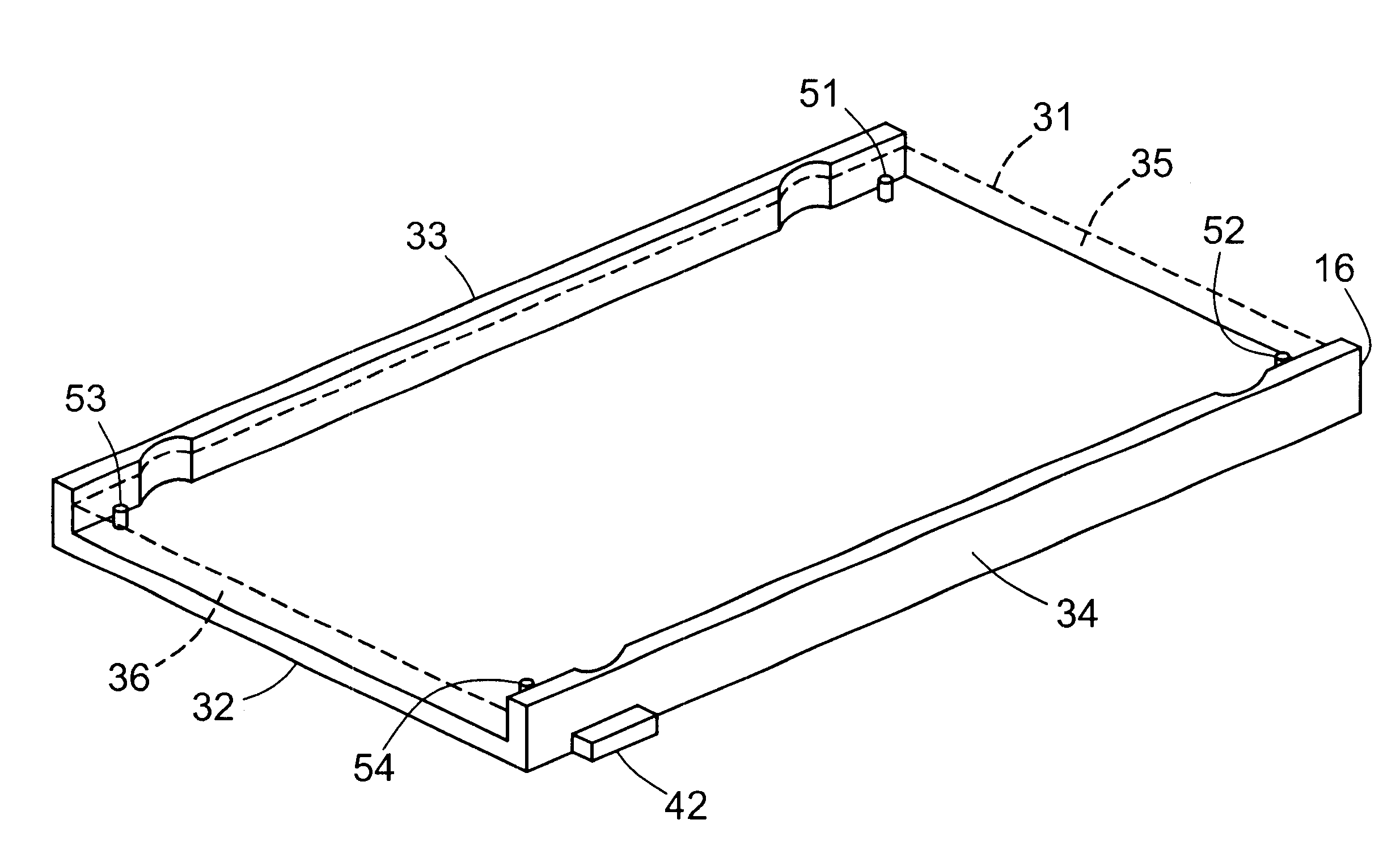

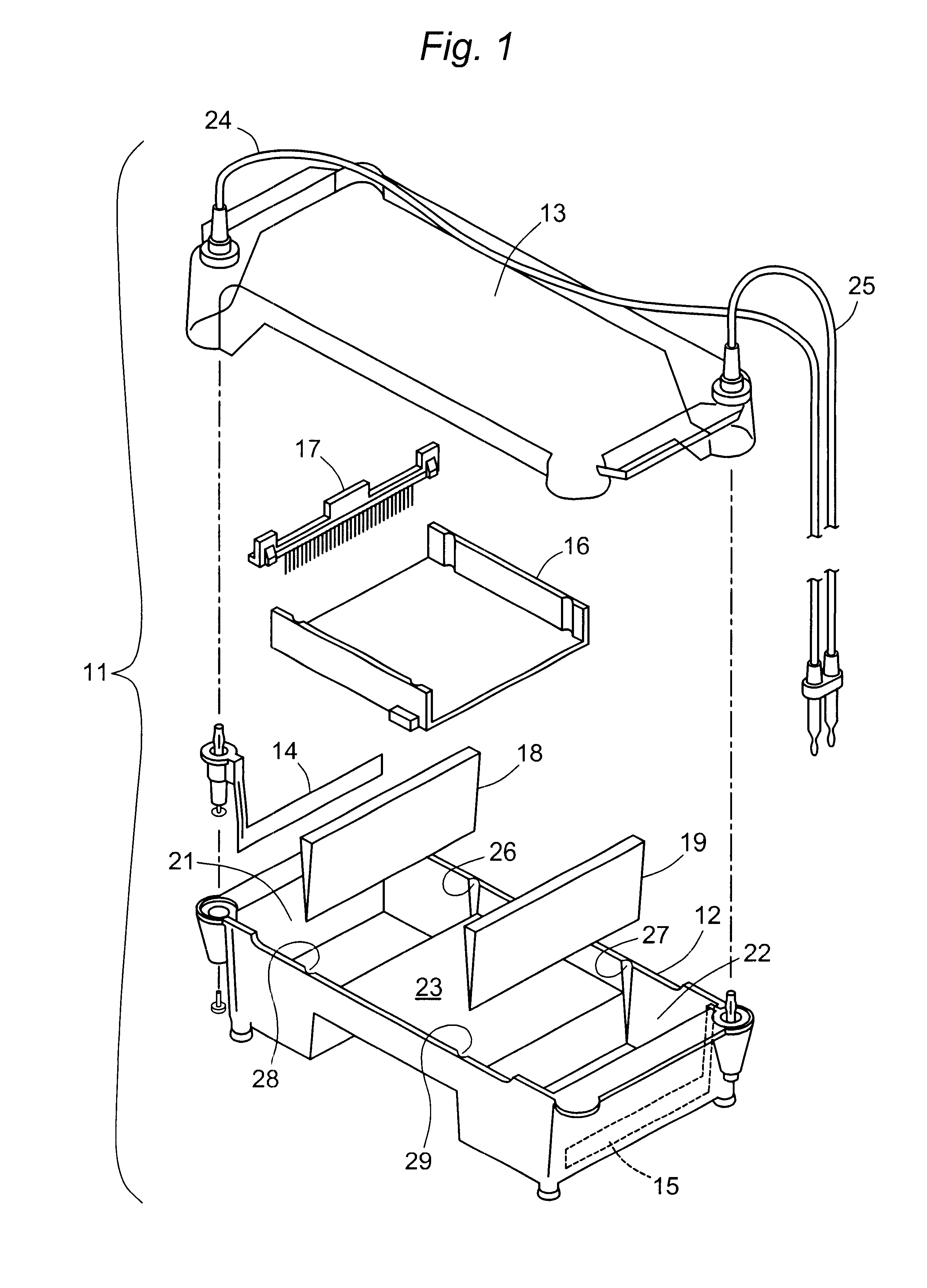

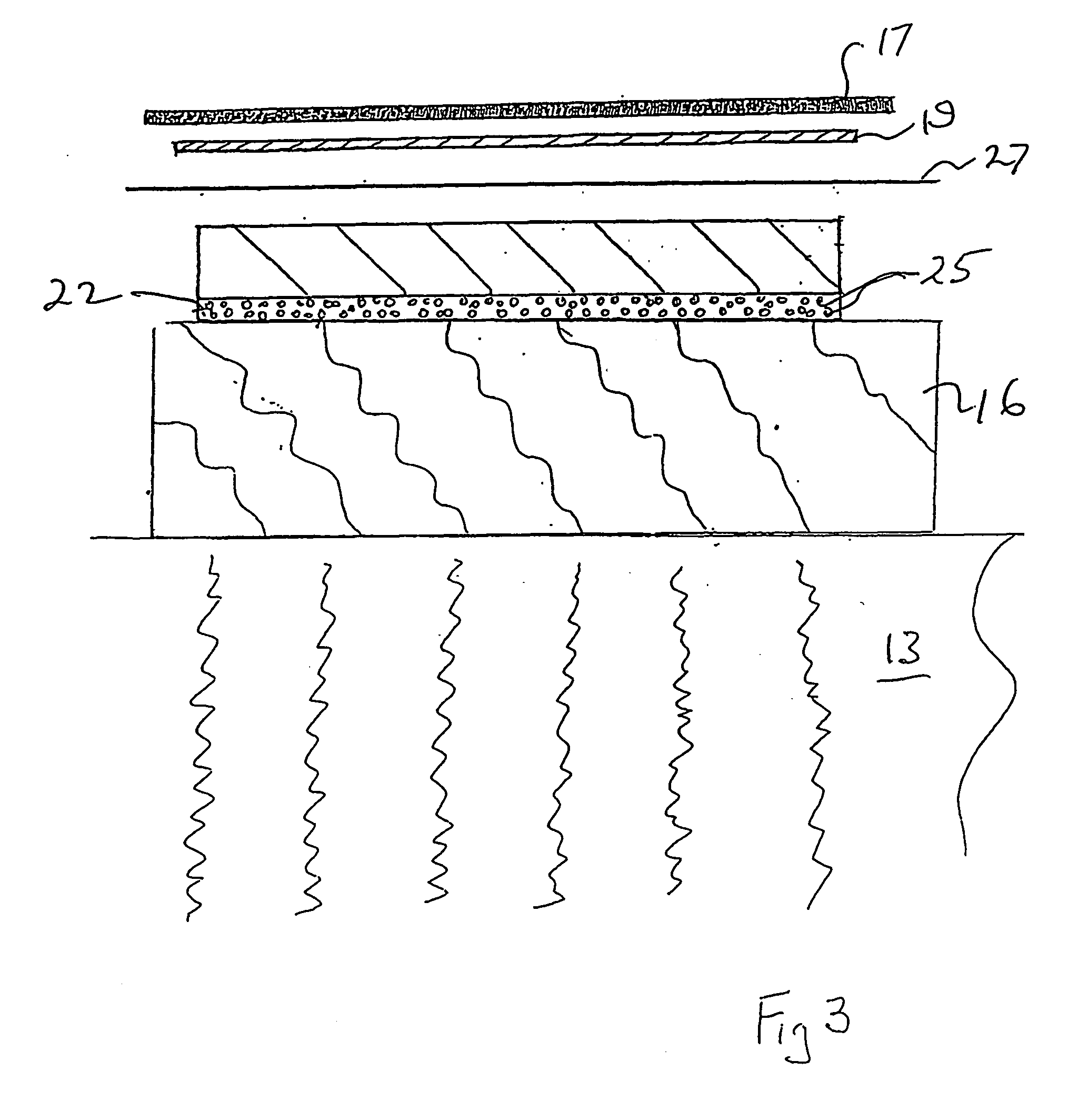

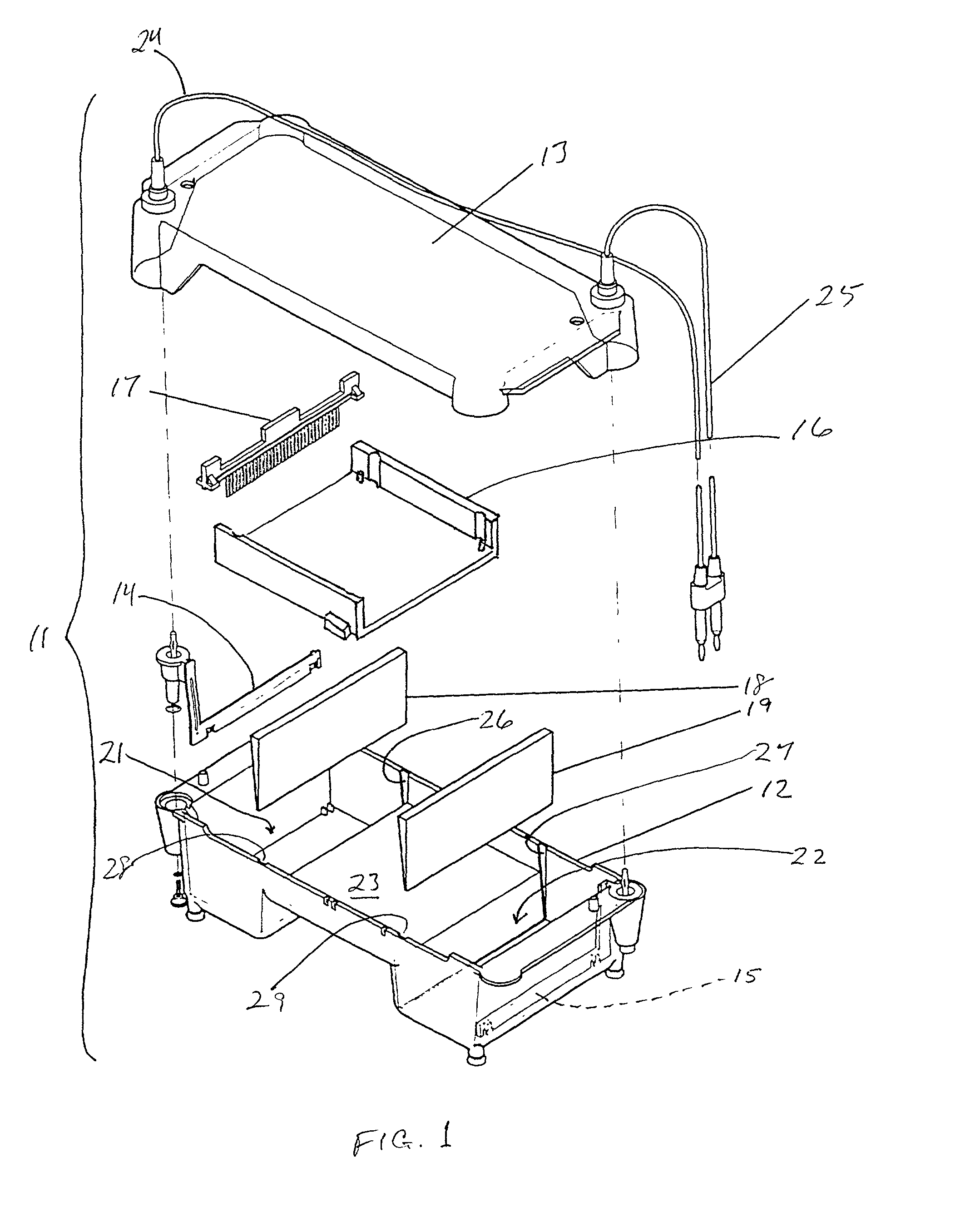

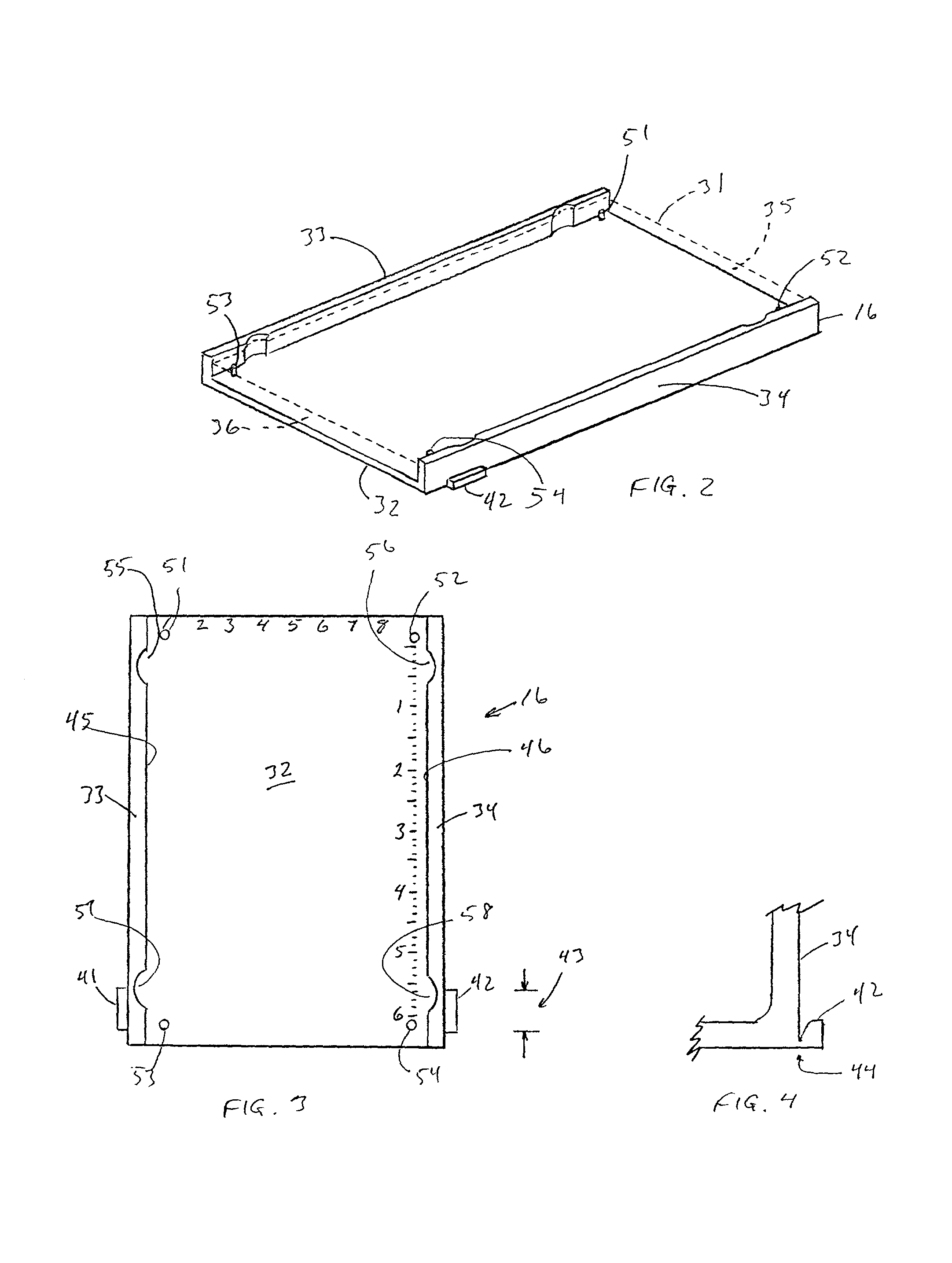

Precast gel and tray combination for submerged gel electrophoresis

A precast slab gel for use in submerged ("submarine") horizontal electrophoresis is formed in a tray that includes a flat base and two raised walls on opposing sides of the base, the walls containing one or more tabs on their outer surfaces, the tabs mating with grooves in the interior walls of the tank. The mating of the tabs with the grooves prevents movement and floating of the tray within to the electrophoresis cell during use. The tabs are designed to mate with grooves that are present in the tank for other purposes, which adds to the versatility of the design. Further versatility is achieved by joining the tabs to the tray walls by thin webs, which make the tabs readily removable, thereby rendering the tray usable in cell tanks that do not contain grooves. Further aspects of the invention include pins or posts extending upward from the tray base to anchor the gel, and the printing of indicia on the tray base by hot foil stamping, with the discovery that indicia printed in this manner are capable of producing a fluorescent image as part of the image produced by fluorescent-dyed protein spots in the electropherogram.< / PTEXT>

Owner:BIO RAD LAB INC

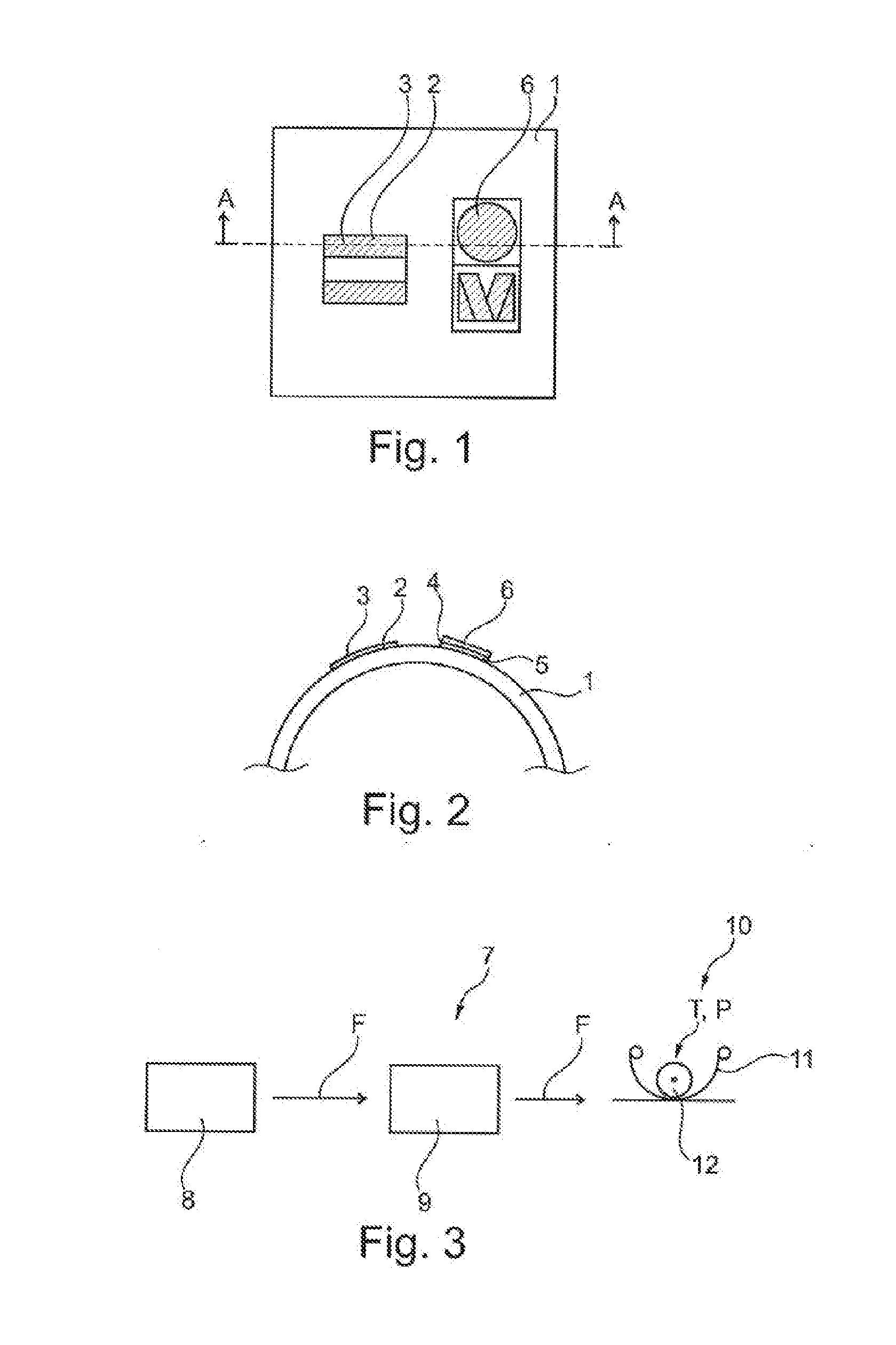

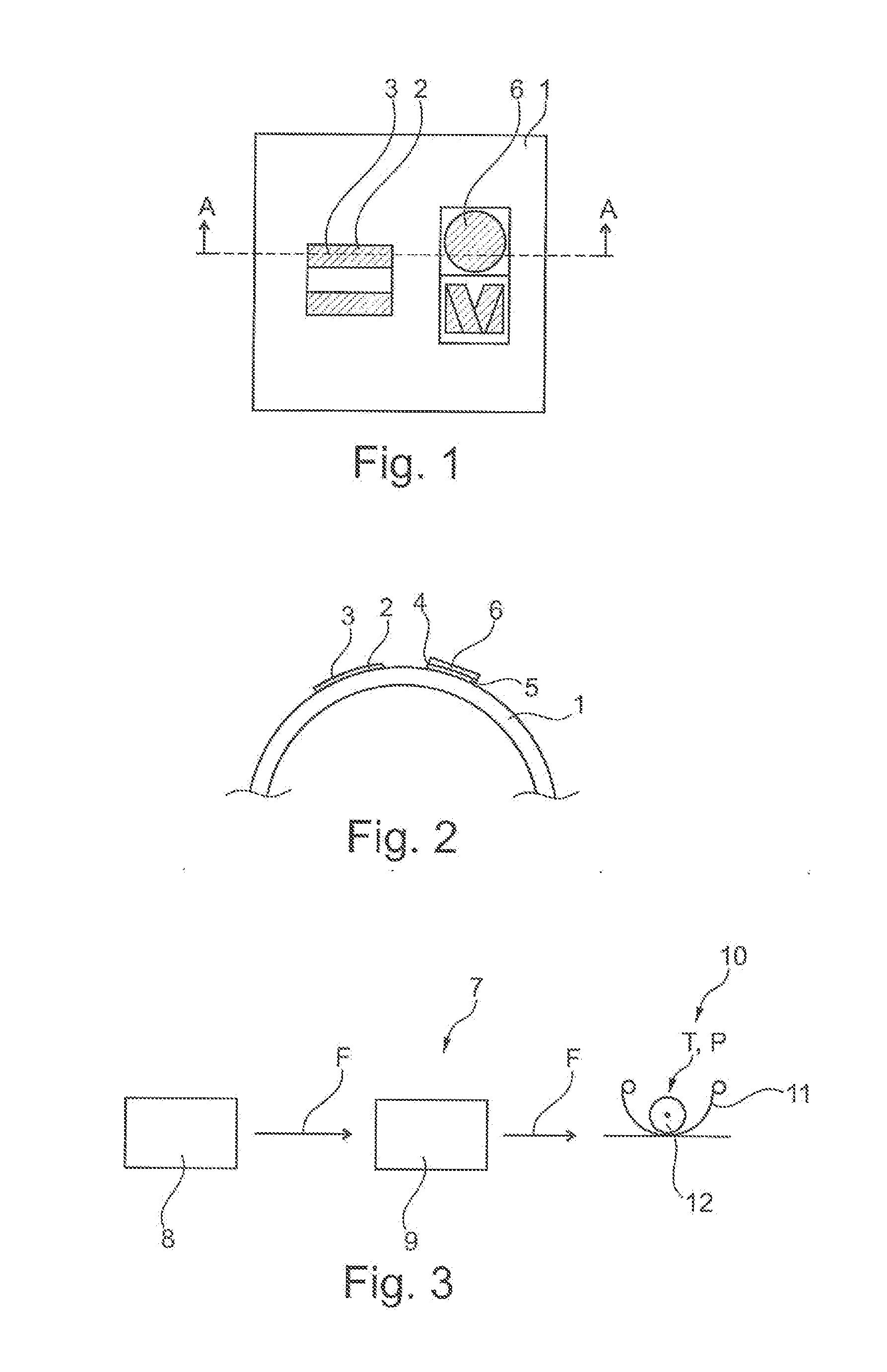

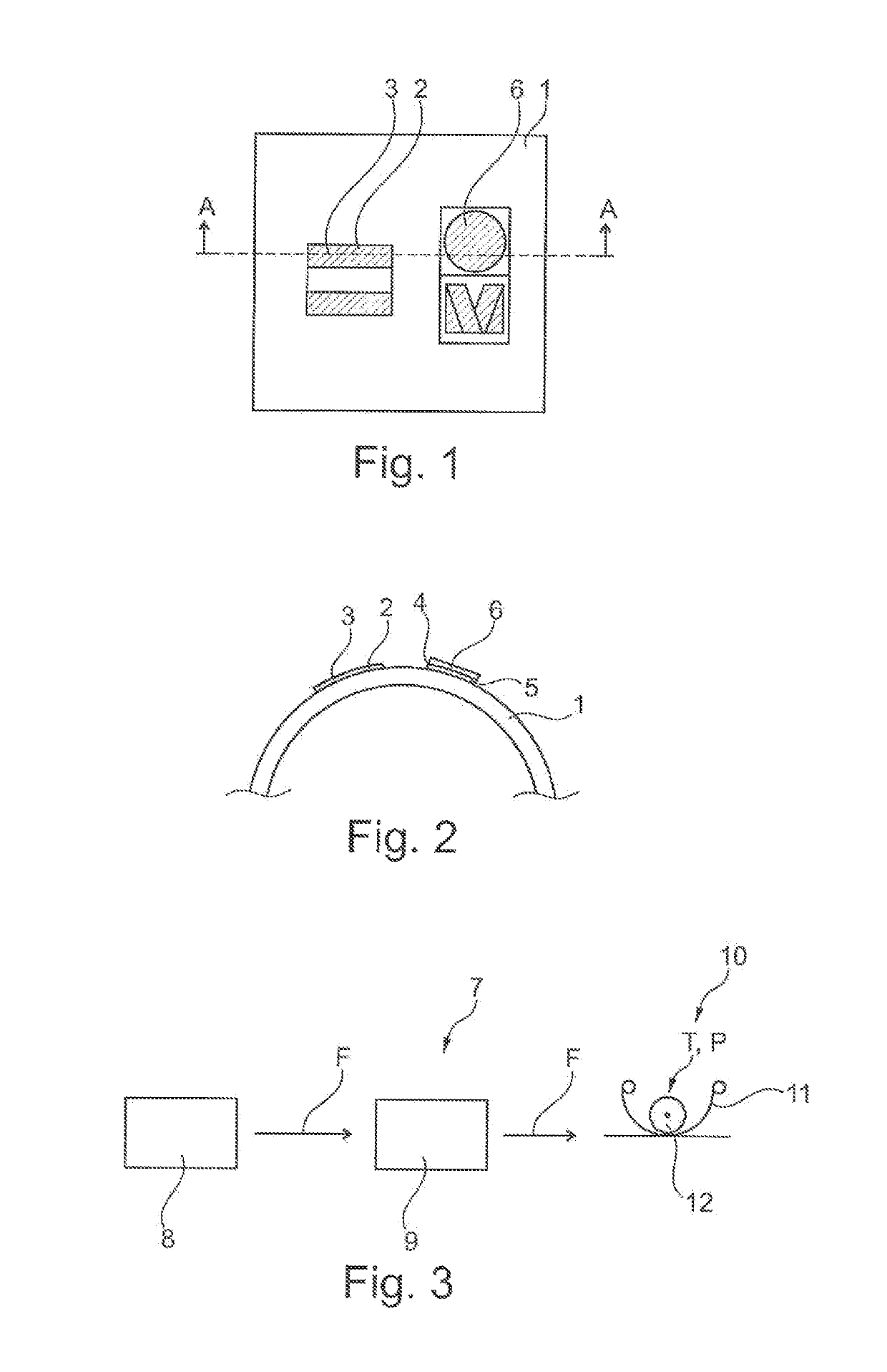

Method for decorating substrates and decorated substrate

ActiveUS20160243814A1Increased process windowLow costDecorative surface effectsScreen printersHot stampingEngineering

A method for decorating substrates, in particular packaging, comprising the steps: printing at least one first decorative pattern (2) on the substrate using a first radiation-curable, preferably UV-curable, printing ink composition (3); printing at least one second decorative pattern (4), using a second radiation-curable, preferably UV-curable, printing ink composition (5), on at least part of the substrate (1) in a region near to the first pattern (2), chronologically before, after, or during the printing of the first pattern; radiation curing of the first and second printing ink compositions (3, 5), preferably directly after the printing of each pattern, the radiation-cured second printing ink composition having a lower glass transition temperature than the radiation-cured first printing ink composition; application of a decorative coating to the second pattern by means of a hot foil stamping process, a hot stamping foil comprising a decorative coating material being pressed against the printed substrate by means of a stamping tool under the application of heat and pressure such that the decorative coating adheres to the second pattern but not to the first pattern.

Owner:MARABU GMBH & CO KG

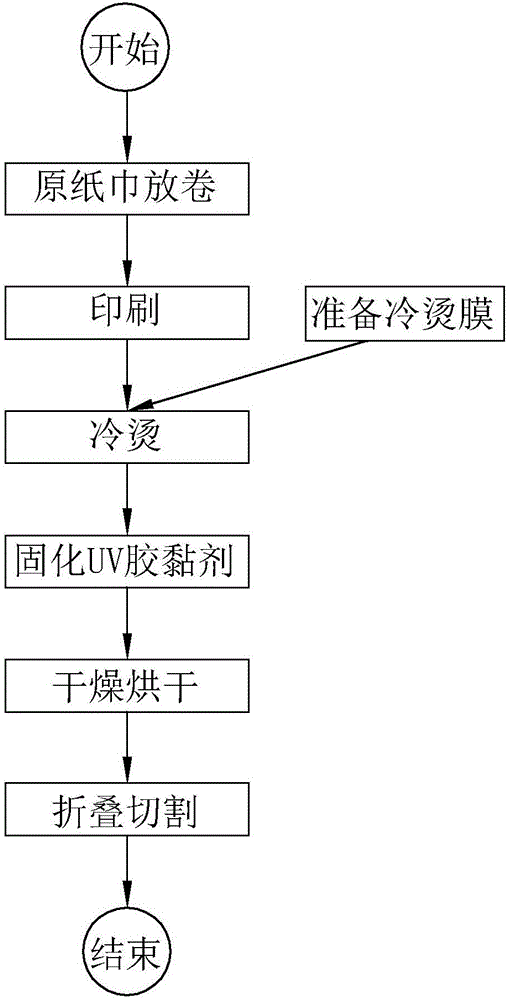

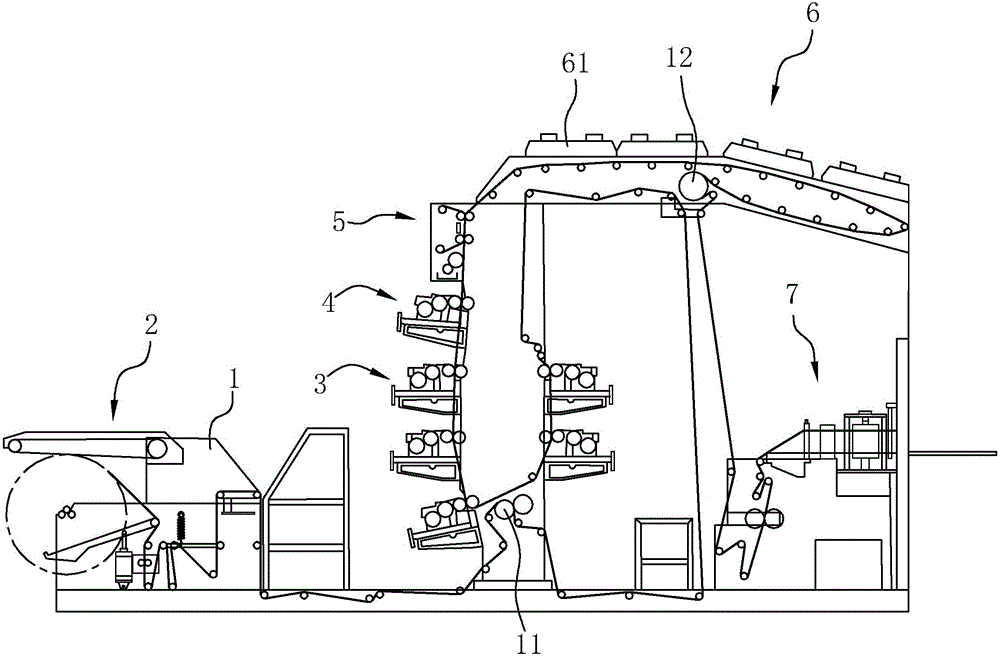

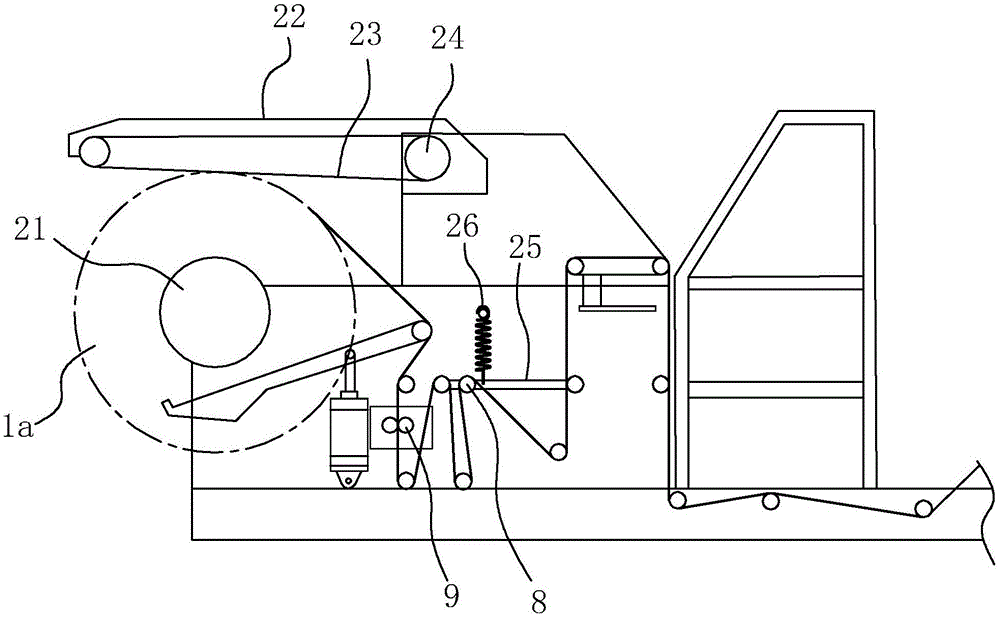

Koldfoil technology and device for flexographic printing of tissue

InactiveCN106585143AIncrease productivityImprove printing qualityLamination ancillary operationsLaminationAdhesiveMetal foil

The invention discloses a koldfoil technology and device for flexographic printing of a tissue. The koldfoil technology comprises the steps of uncoiling, printing, preparing of a cold foil stamping film, cold foil stamping, curing of UV adhesive, drying and folding and cutting. The technology is characterized in that flexographic printing and koldfoil are combined, and thus tissue with more than eight colors can be conveniently printed; in addition, pores in the surface of the original tissue can be filled by preprinting before the koldfoil, and meanwhile, a smooth printing film can be formed on the surface of the original tissue, so that the subsequent koldfoil quality can be improved; the original tissue subjected to koldfoil passes through a UV fixing device and then is dried through a subsequent drying oven, so that the UV adhesive can be sped up to cure, and as a result, the color information of a metal foil film can be perfectly transferred to the original tissue to form a combined tissue; and finally, the combined tissue is folded and cut to obtain a finished product. According to the koldfoil technology and device, the steps of the whole technology are simplified, and the difficulty in implementation of the technology can be reduced.

Owner:宁波弘泰包装新材料科技有限公司

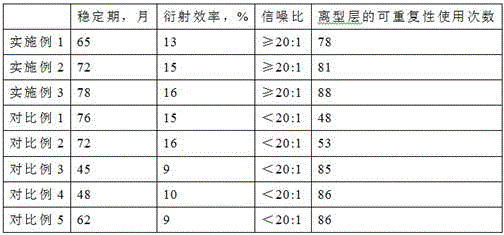

Double-layer holographic anti-counterfeiting transfer paper and production method thereof

ActiveCN106087580AWith double-layer holographic informationImprove anti-counterfeiting performanceFiltration separationCoatingsBiochemical engineeringToluene

The invention relates to a double-layer holographic anti-counterfeiting transfer paper and a production method thereof, and belongs to the technical field of packaging materials. The production method is simple and reliable, the produced double-layer holographic anti-counterfeiting transfer paper has double-layer holographic information and strong anti-counterfeiting property, cold foil stamping UV glue has good adhesion to a vacuum plating layer, and a connecting layer is not used, so the stable period of the above product is greatly prolonged. The product has strong layering sense, allows a BOPP film to be smoothly and completely peeled when the product is used and peeled laterally, has an excellent release property and has a good transfer effect; and a detection result shows that a release layer has very good tolerance to DMF and toluene and resists high temperature, so subsequent layers of the product are convenient to process, and the processed product is flat and smooth, and has the advantages of clear anti-counterfeiting information, long stable time, and easiness in promotion and application.

Owner:云南金明源印刷有限公司

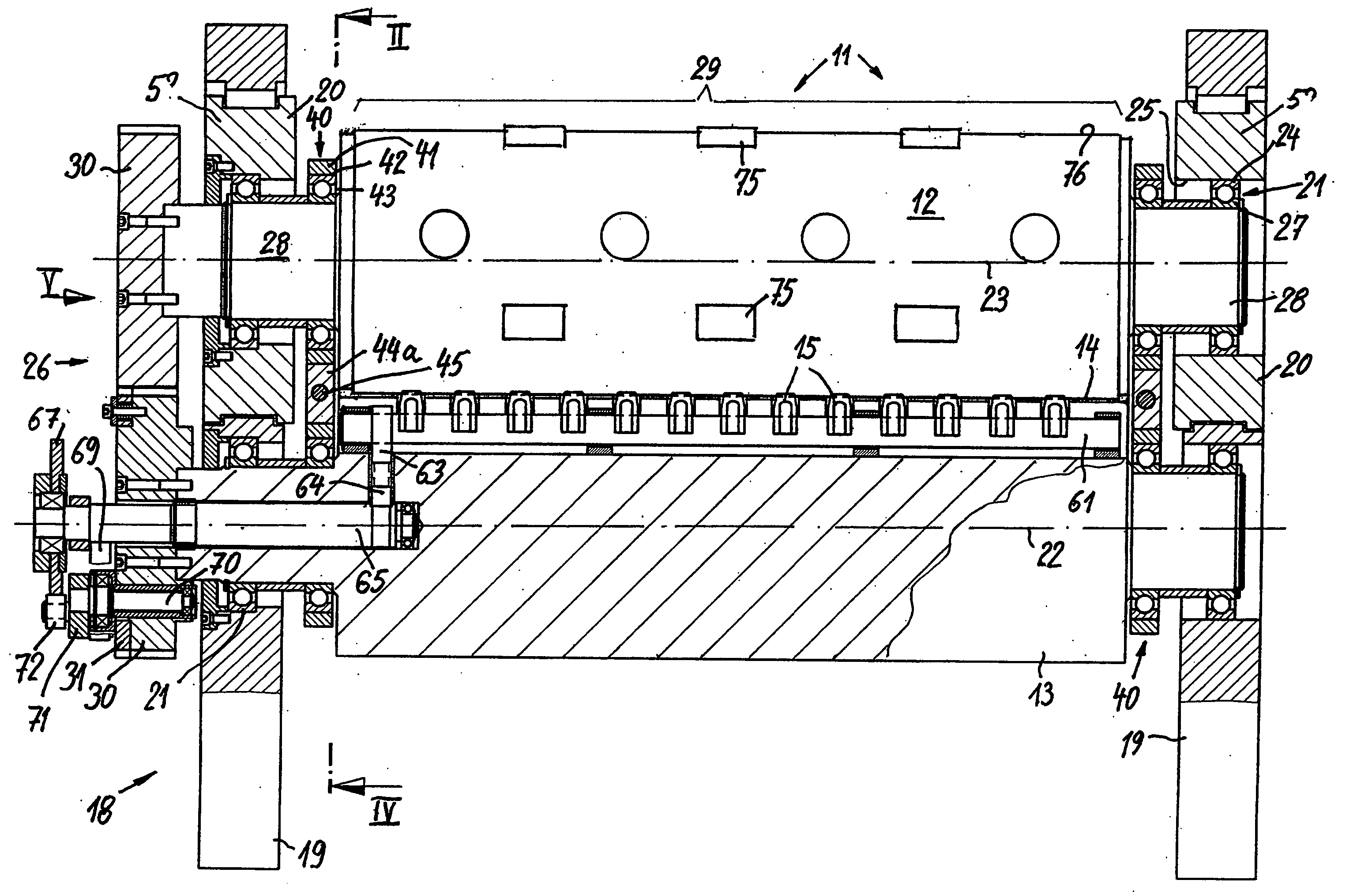

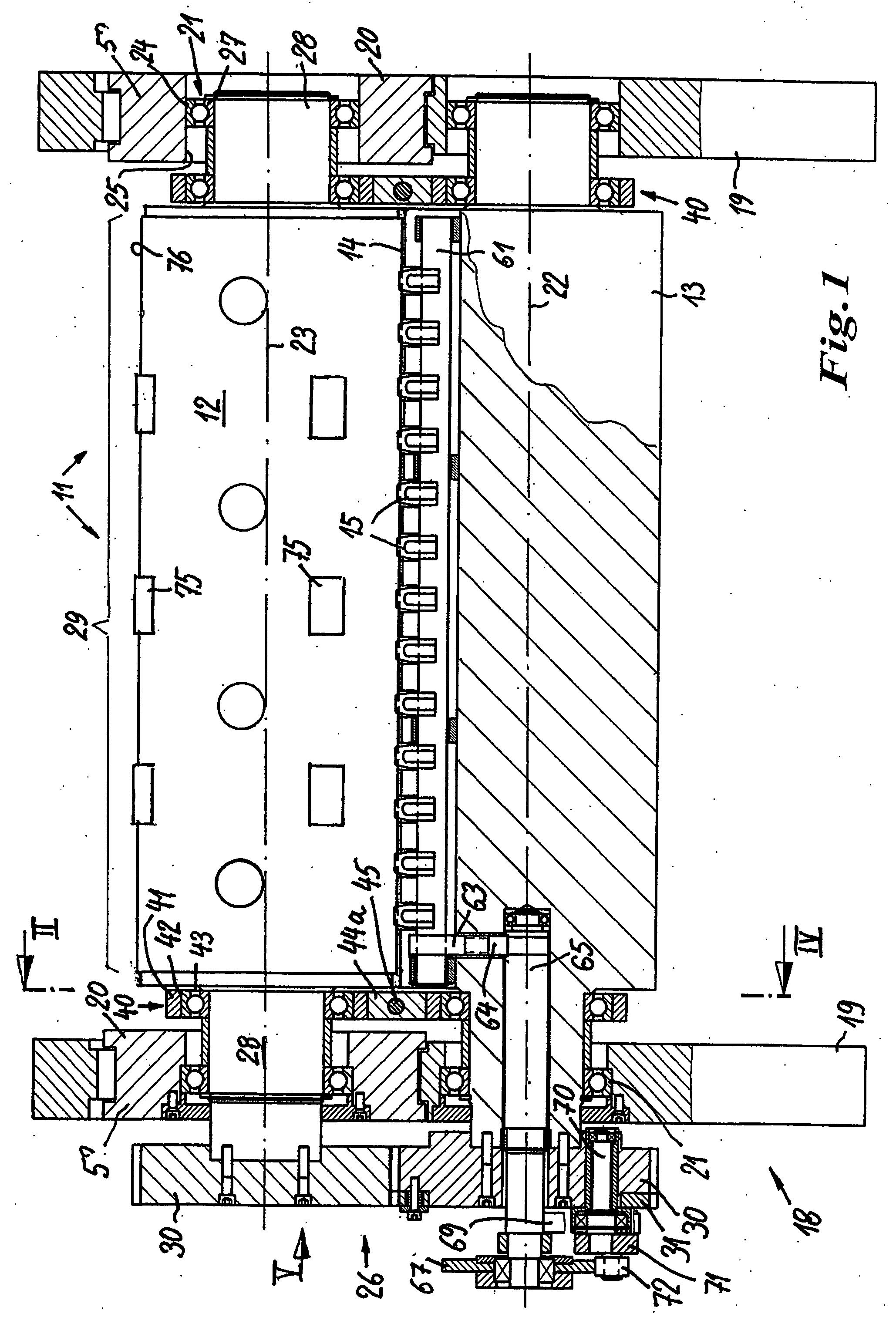

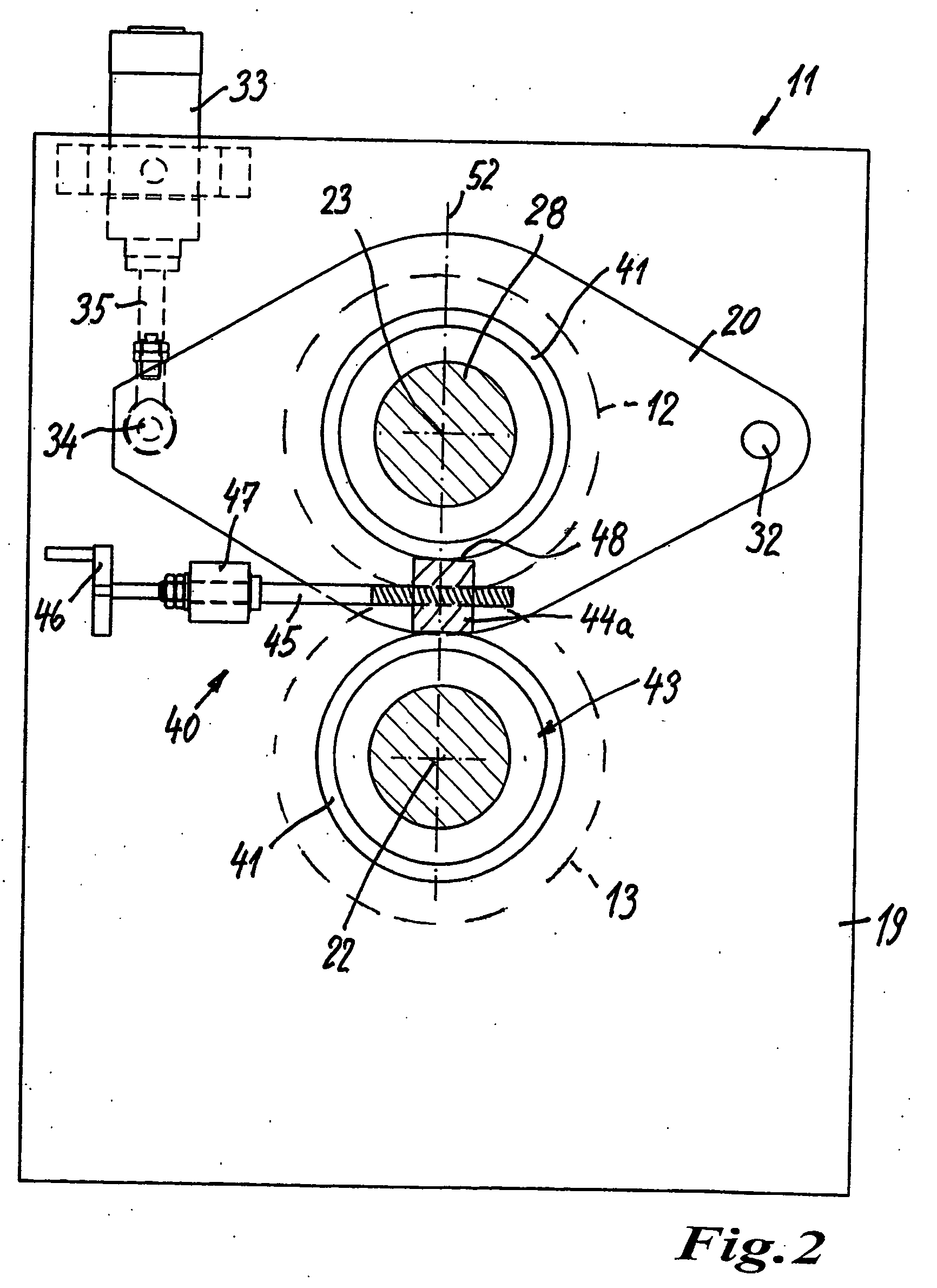

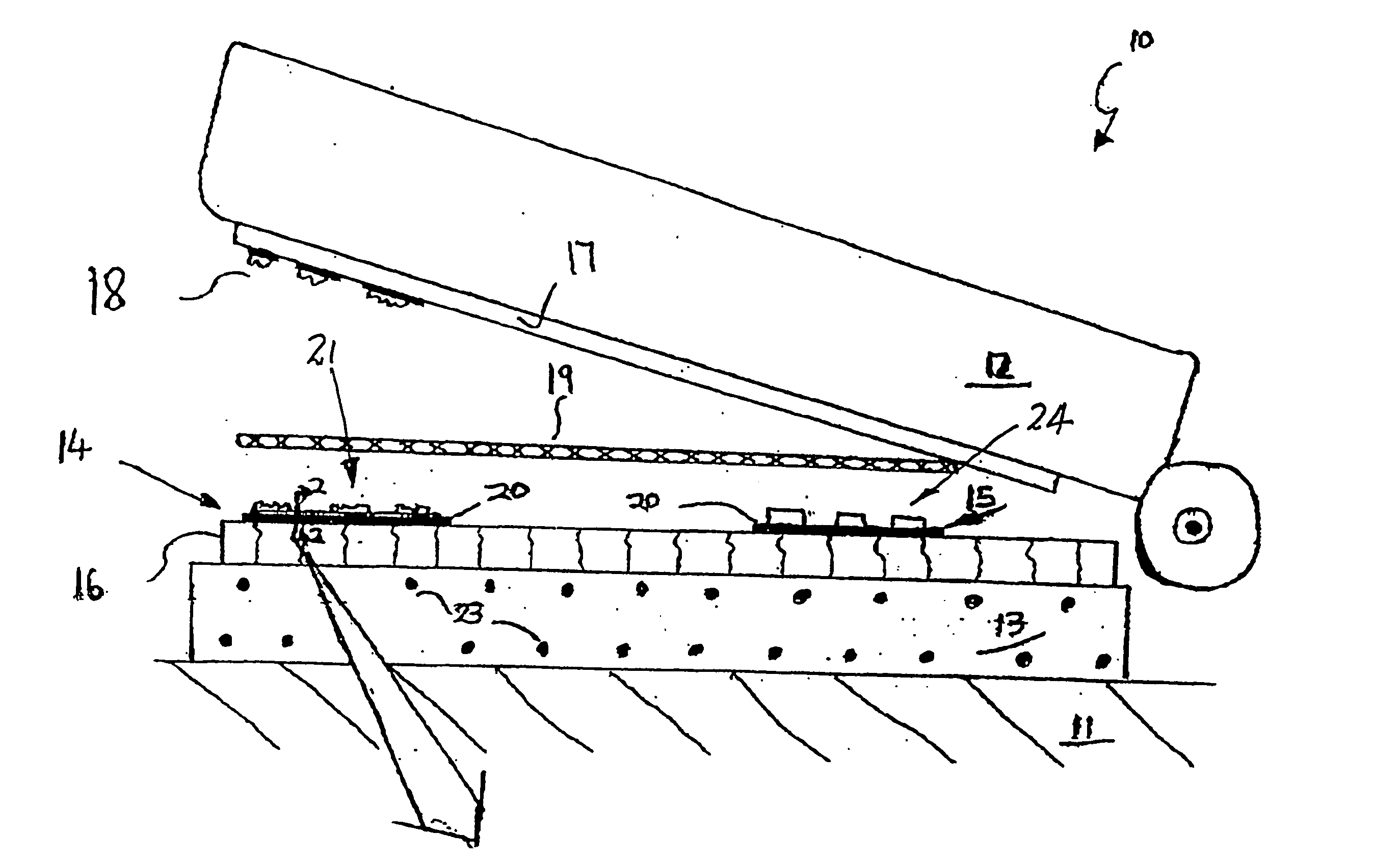

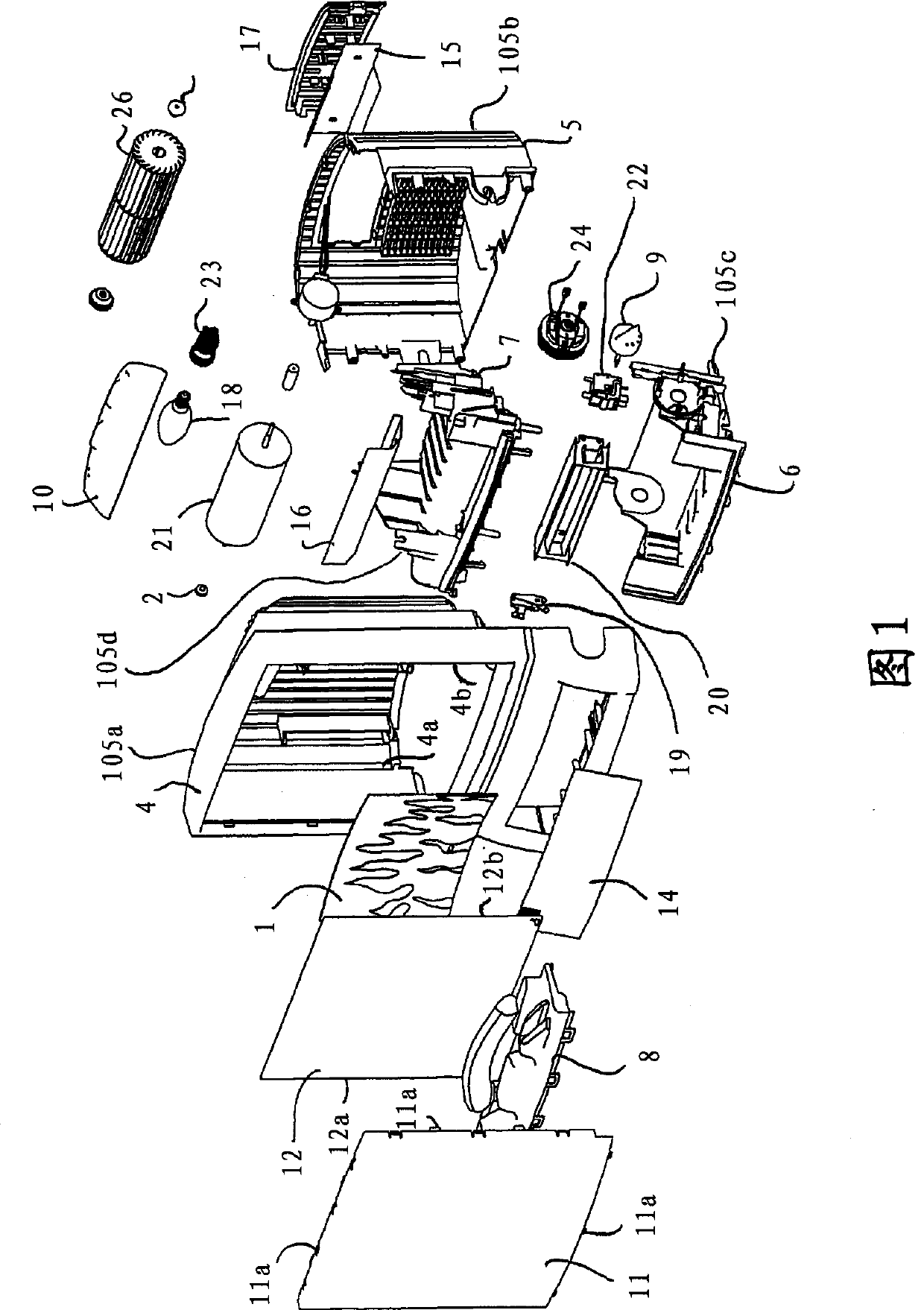

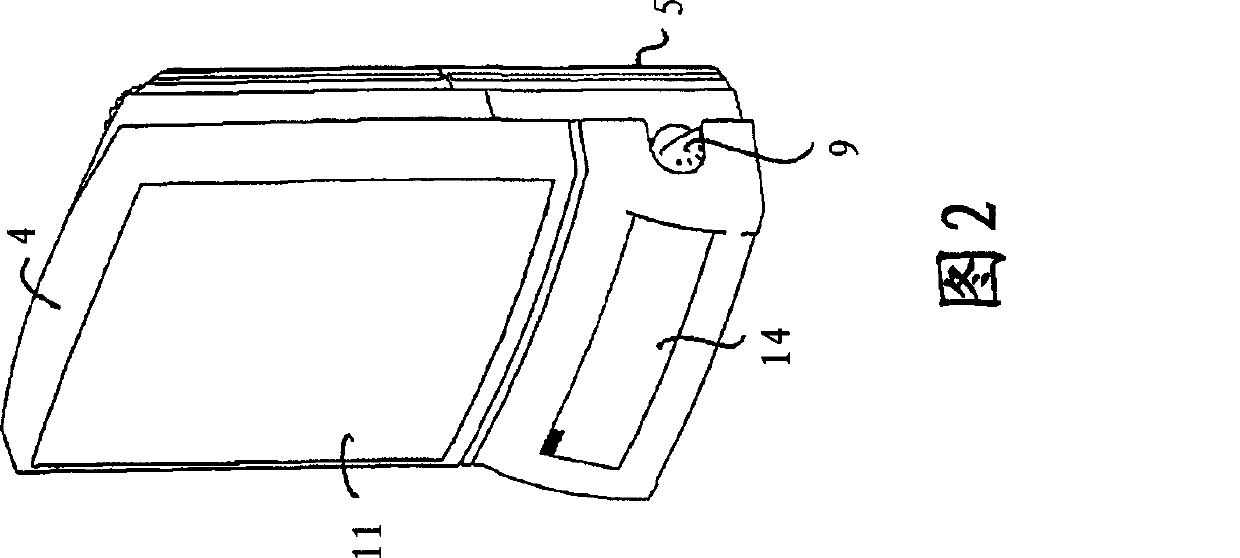

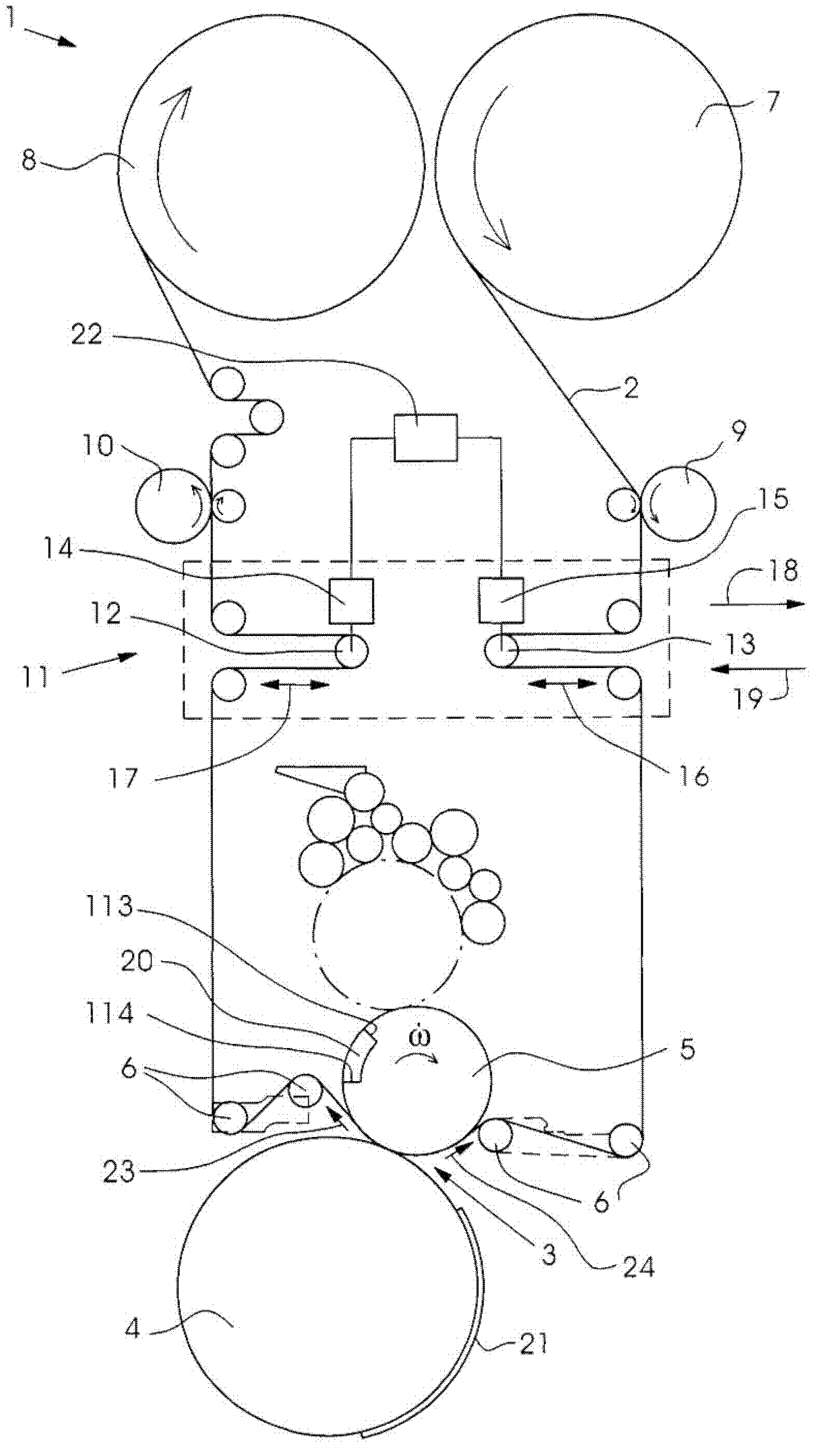

Hot foil stamping or printing device for transferring surface portions onto a flat material

InactiveUS20050178508A1Improved sheet gripper mechanismSubstantial clearance freedomMechanical working/deformationLaminationEngineeringFoil stamping

The hot foil stamping mechanism (11) is used for the transfer of surface portions, such as holograms, etc., onto a flat material (1) in the form of a continuous web or sheet. The hot foil stamping mechanism (11) operating in rotary manner has two cooperating cylinders forming a working gap (14) between them. For maintaining constant and precisely adjusting the working gap (14) adjusting means (40) are provided, which have an adjustable adjusting element (44a-c) engaging between the cylinders (12, 13) and acting on the latter by means of running elements (41, 50). The running elements run on the cylinder. The adjusting means can be anti-friction bearings located on the cylinder journal (28). An adjusting element in the form of a wedge or the like supports the outer ring bearings against one another and consequently maintains a constant cylinder spacing.

Owner:STEUER PRINTING TECH

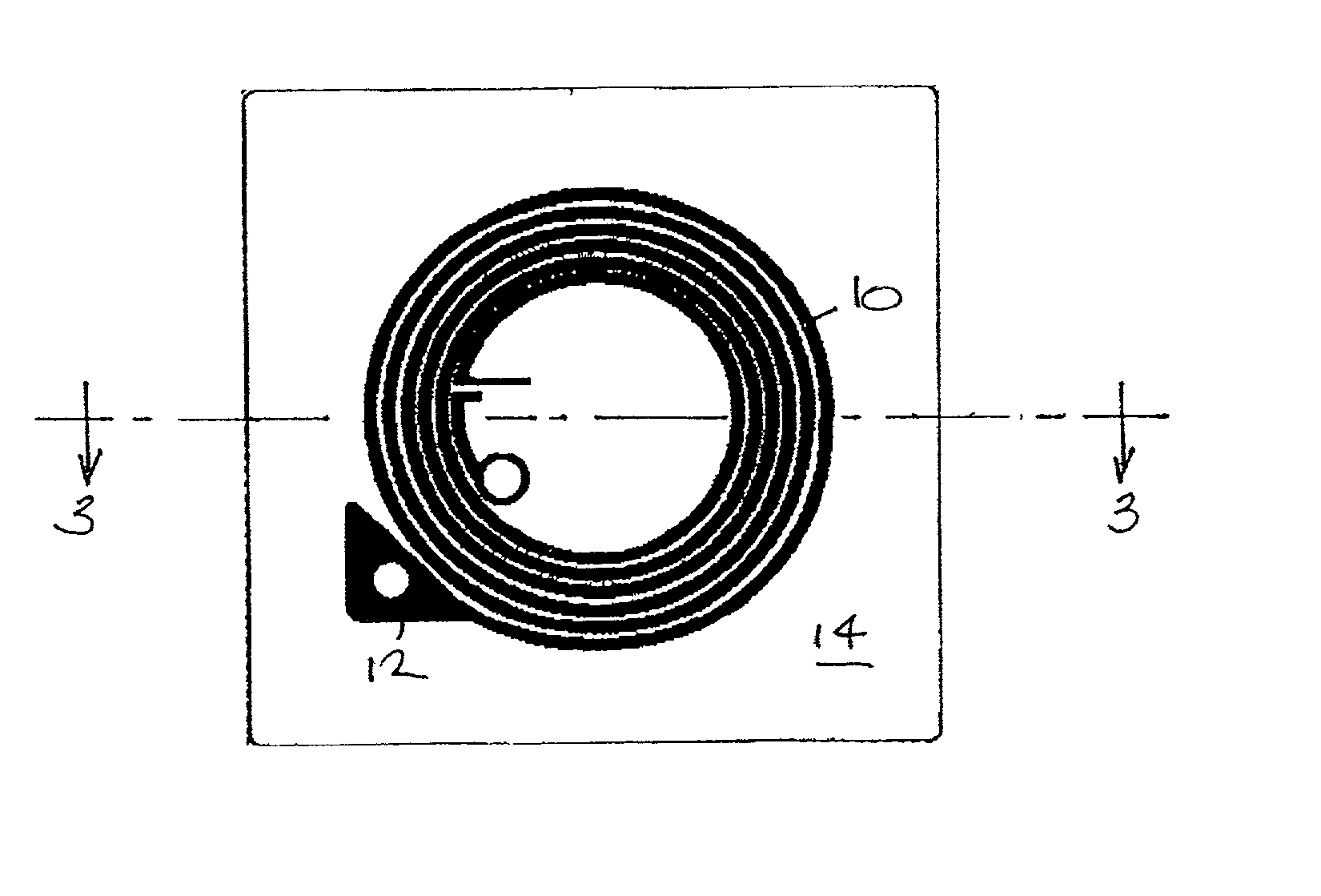

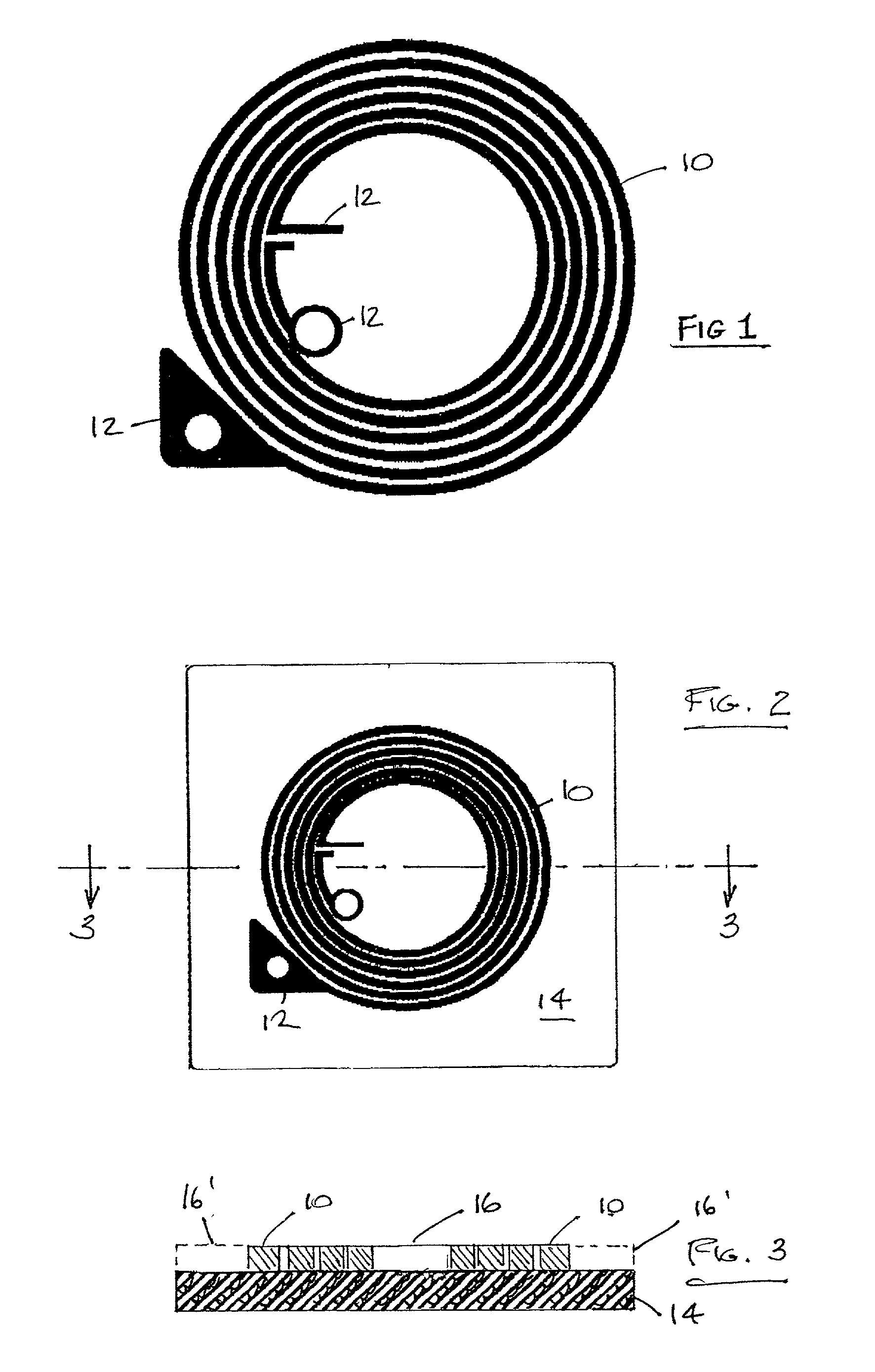

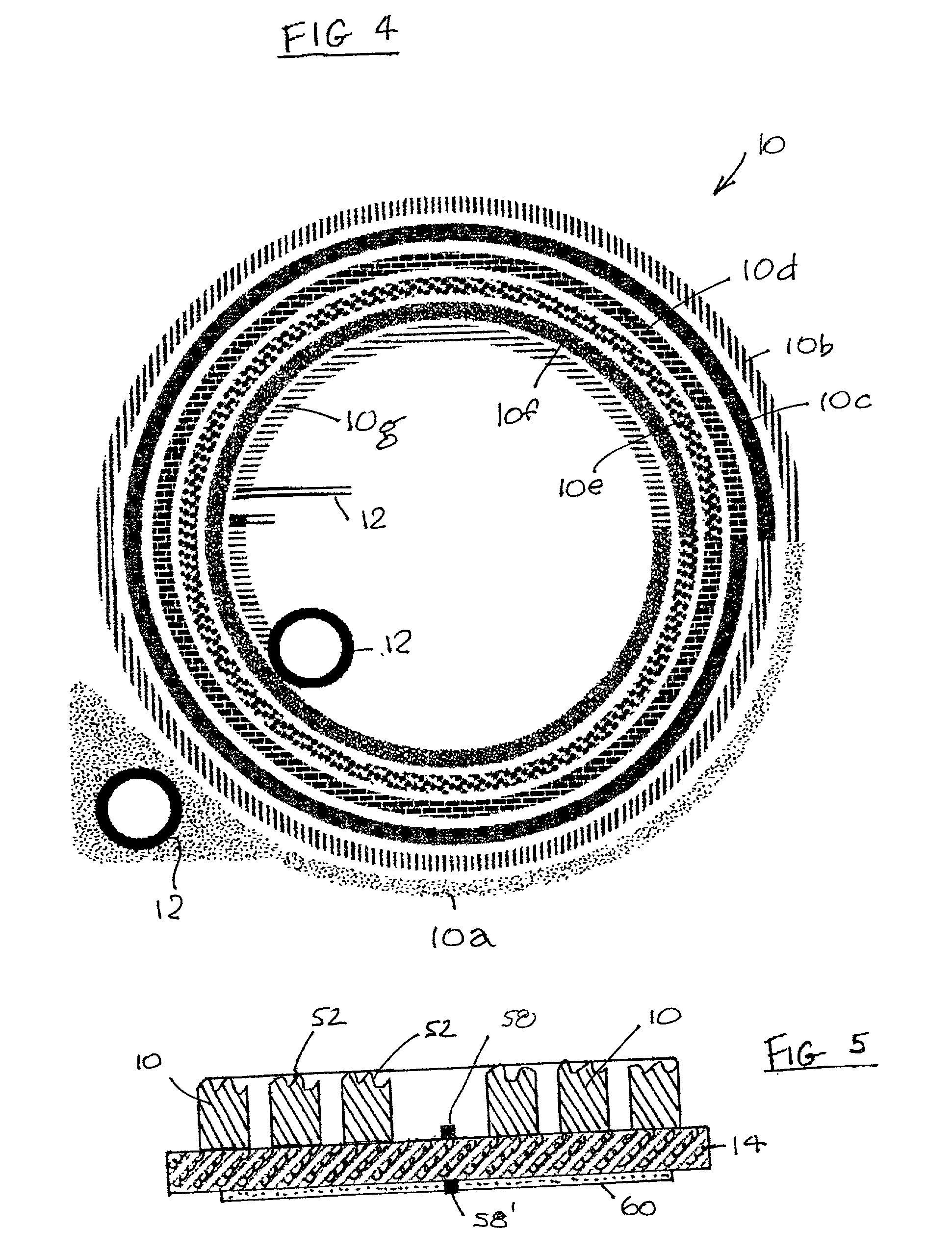

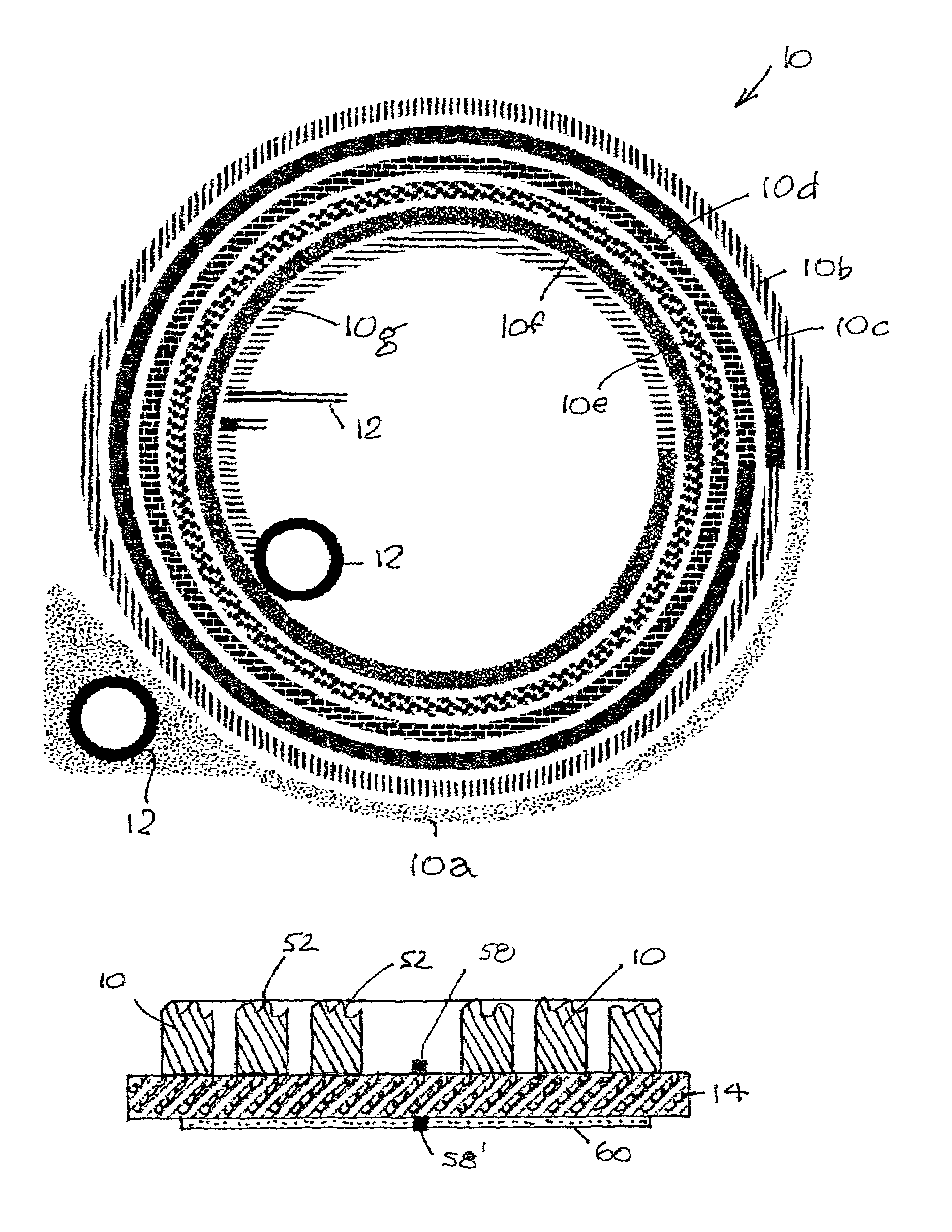

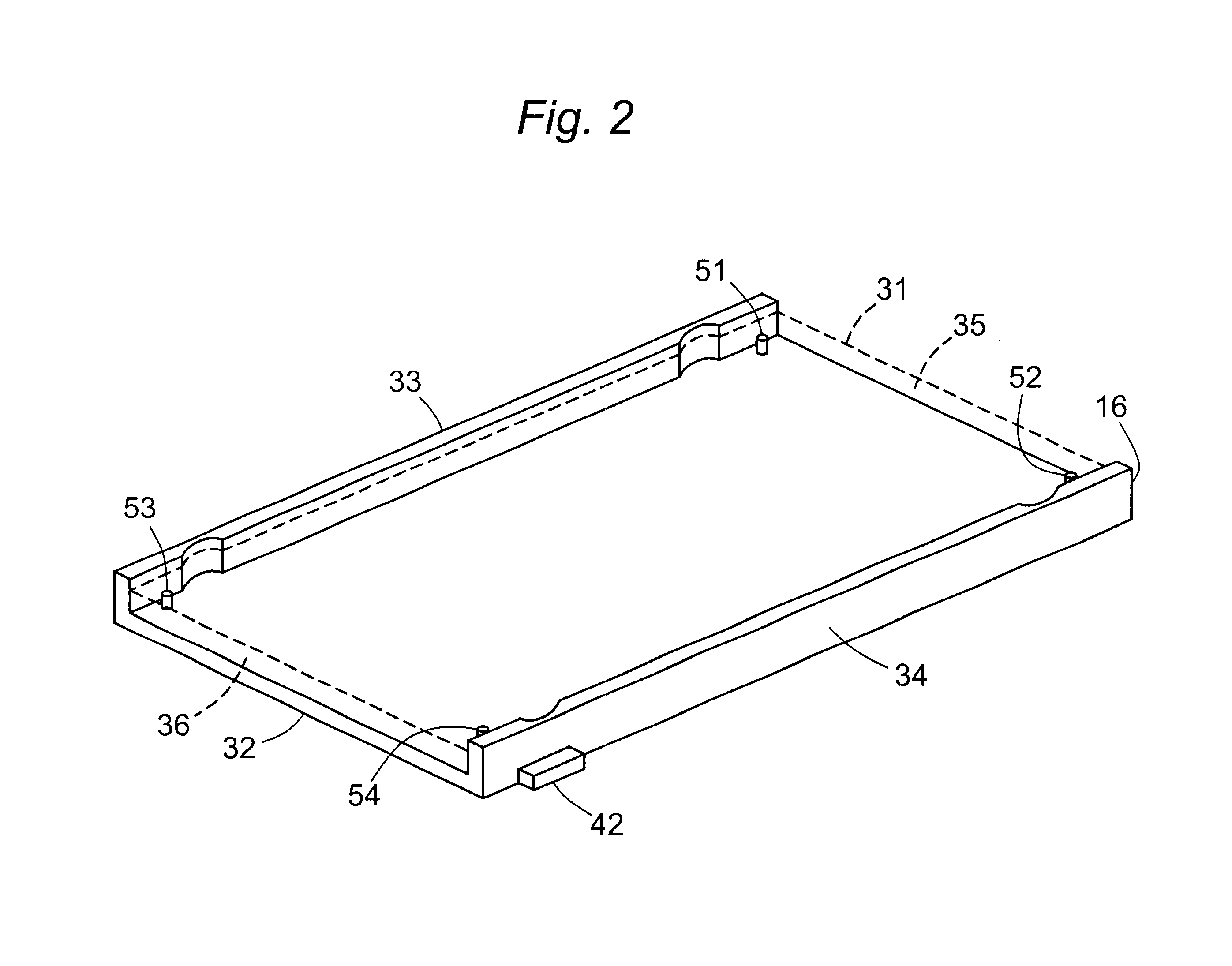

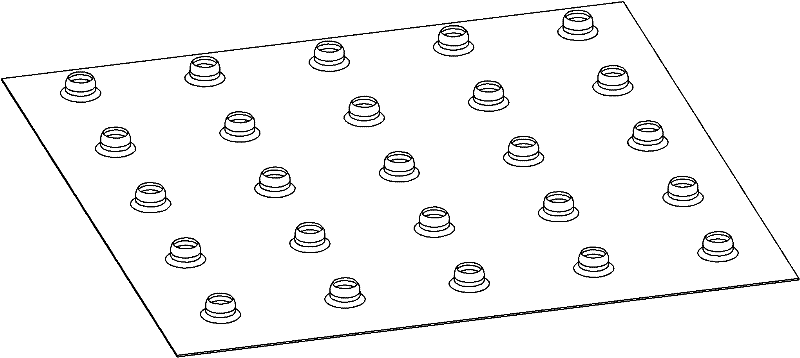

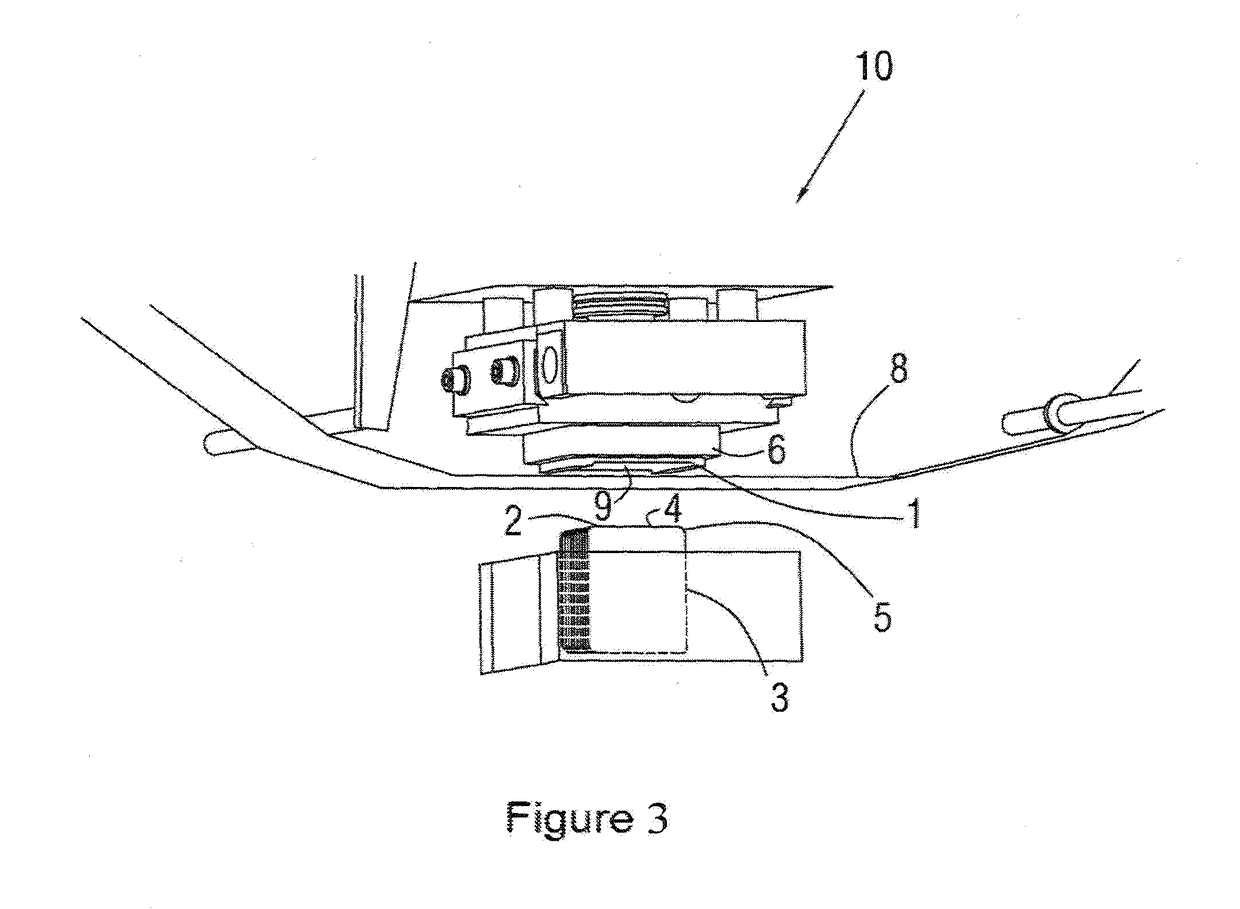

Die plate for a foil stamping machine

A die plate (14) to be used in a foil stamping machine (10). The die plate (14) includes a plate steel back (20) to which there is secured an image layer (21). The image layer (21) is secured to the plate steel back (20) by means of a compressible adhesive (22). Preferably, the adhesive (22) is an acrylic polymer. The image layer (21) is formed of metal such as brass, steel, copper, zinc, aluminium, magnesium, or photo-polymer.

Owner:TMS TECH

An aluminum fin stamping die

InactiveCN102284618ANo crackReduce manufacturing costShaping toolsPerforating toolsPunchingEngineering

The invention discloses a heat exchanger aluminum fin stamping die, which includes an upper template and a lower template. The above-mentioned upper template is provided with a circular die cavity into which the ball-end punch can be inserted correspondingly. The purpose of the invention is to overcome the shortcomings of the prior art and provide a heat exchanger aluminum fin stamping die with low production cost and good aluminum foil stamping quality.

Owner:东洋热交换器(中山)有限公司

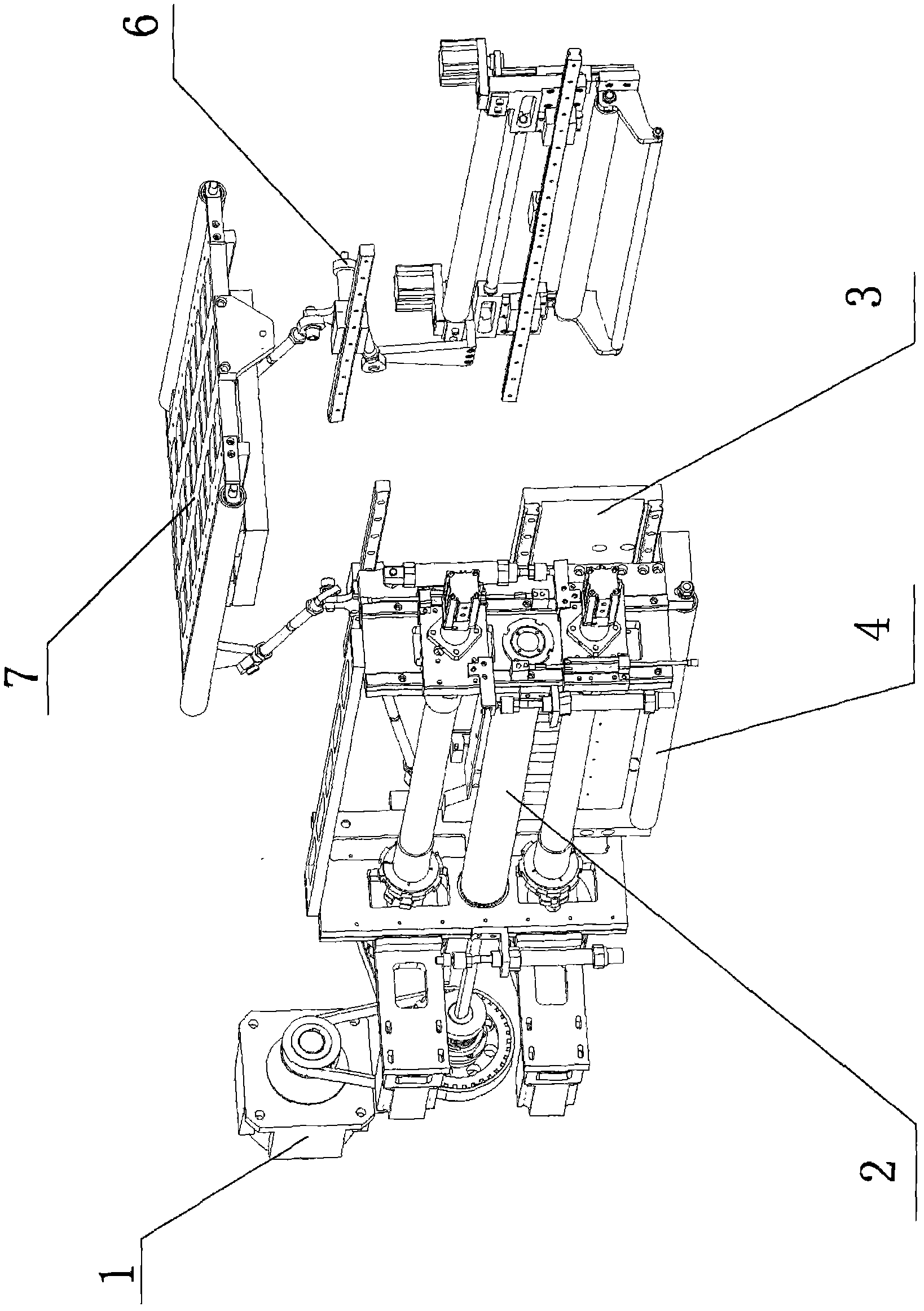

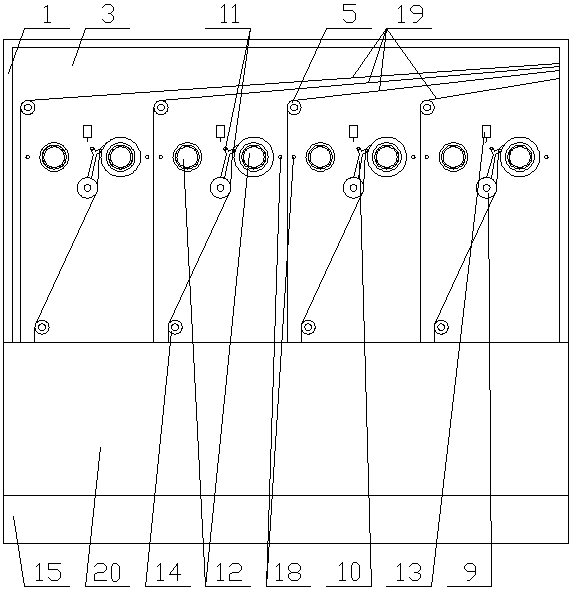

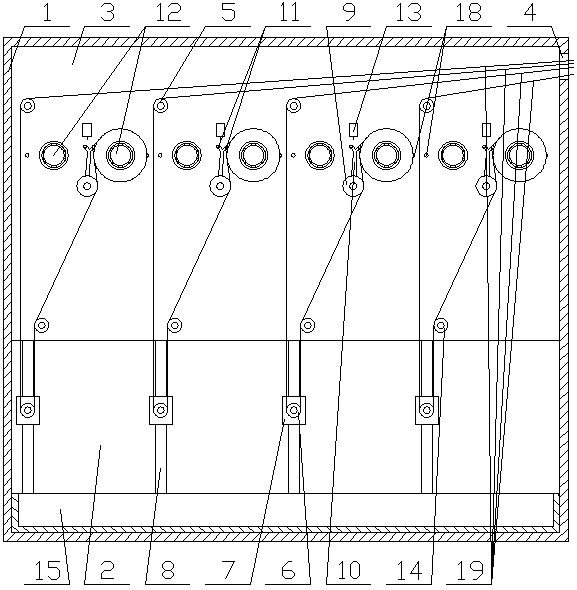

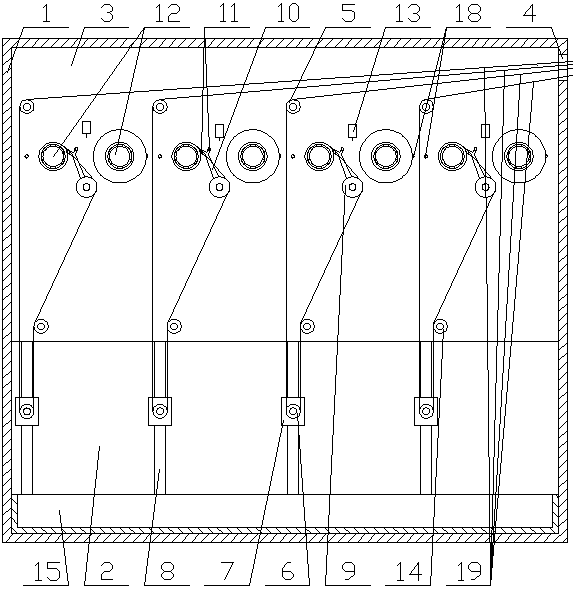

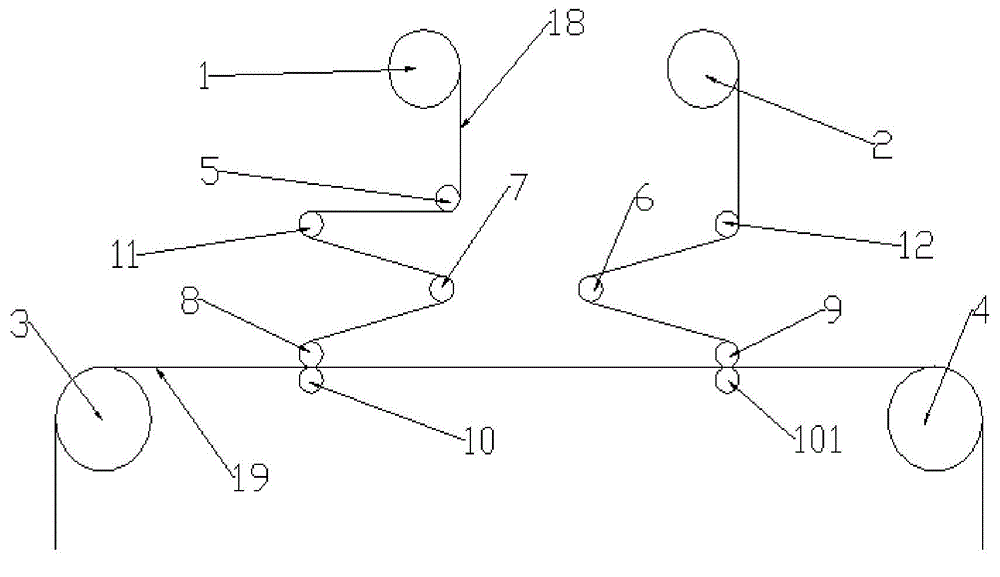

Foil stamping device of stamping machine

InactiveCN102126331AHigh speedIncrease productivityBronze printingRotary pressesFoil stampingConductor Coil

The invention relates to a foil stamping device of a stamping machine. The foil stamping device comprises a driving device of a stamping foil, a linear synchronization device of the stamping foil, a transverse bearing device of the stamping foil, a positioning and guiding device of an unwinding foil, a guide roller connecting device and a transverse shift guiding device, wherein the driving device of the stamping foil, the linear synchronization device of the stamping foil, and the transverse bearing device of the stamping foil together form a foil winding / unwinding device; the transverse shift guiding device is connected with the foil winding / unwinding device, and drives the whole foil winding / unwinding device to move transversely; and the guide roller connecting device is connected with the transverse shift guiding device. As the foil stamping device of the stamping machine adopts an automatic foil winding / unwinding synchronization structure, the foil stamping speed is greatly accelerated, and the production efficiency is improved; meanwhile, as a transverse foil stamping method is adopted, the utilization rate of consumables is improved, and the cost is saved.

Owner:HEBEI YUTIAN XINGYE PRINTING MACHINERY

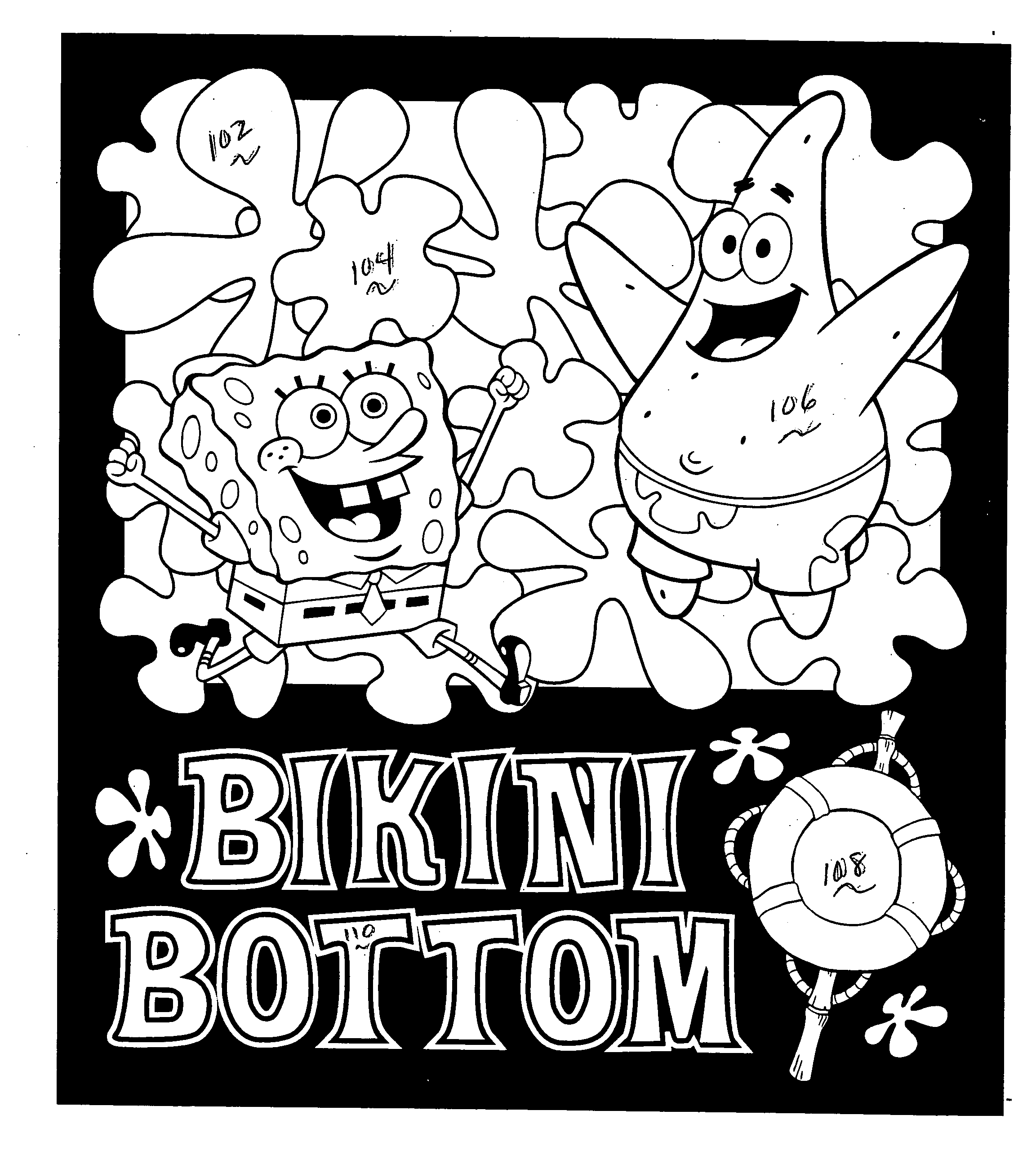

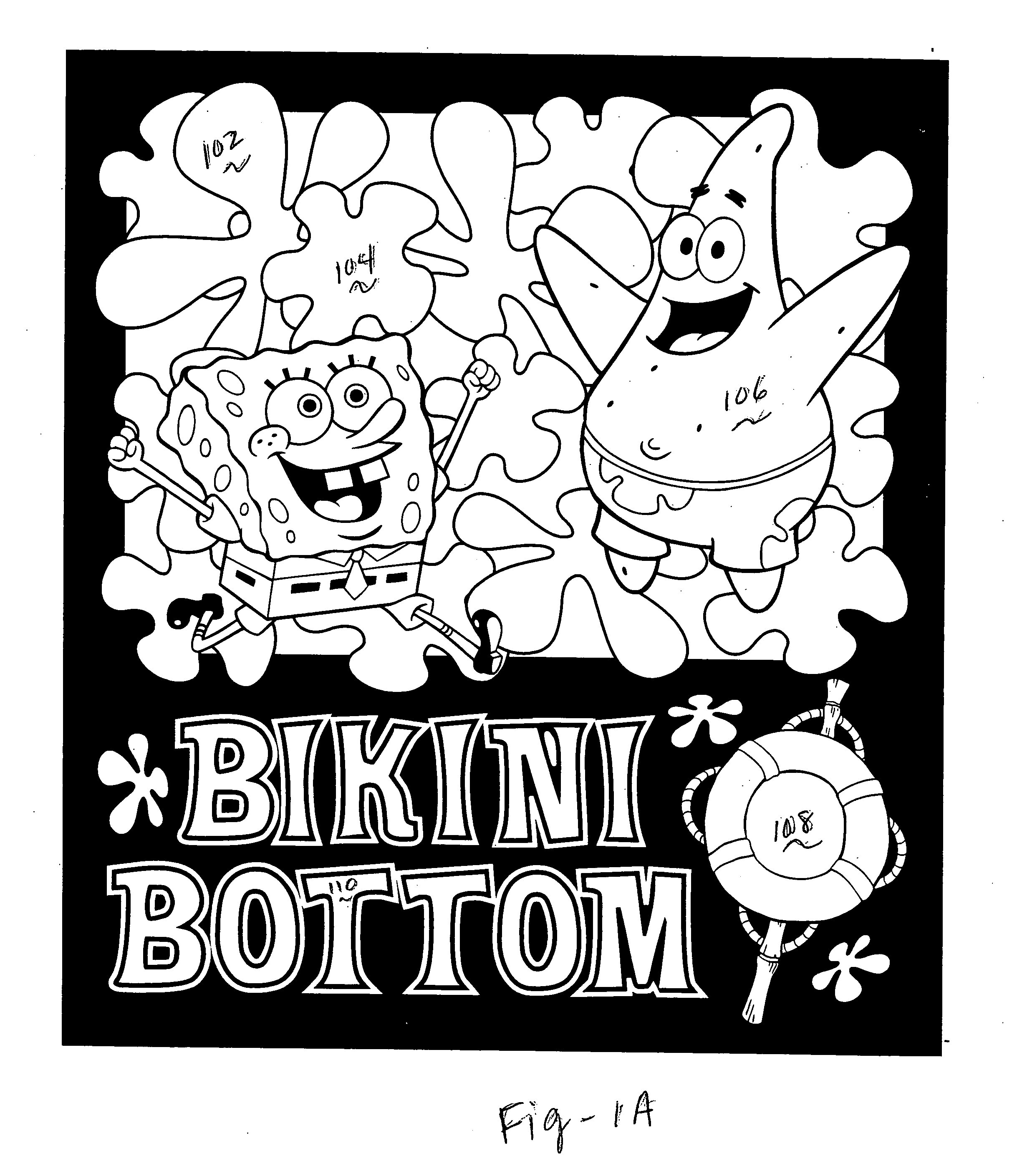

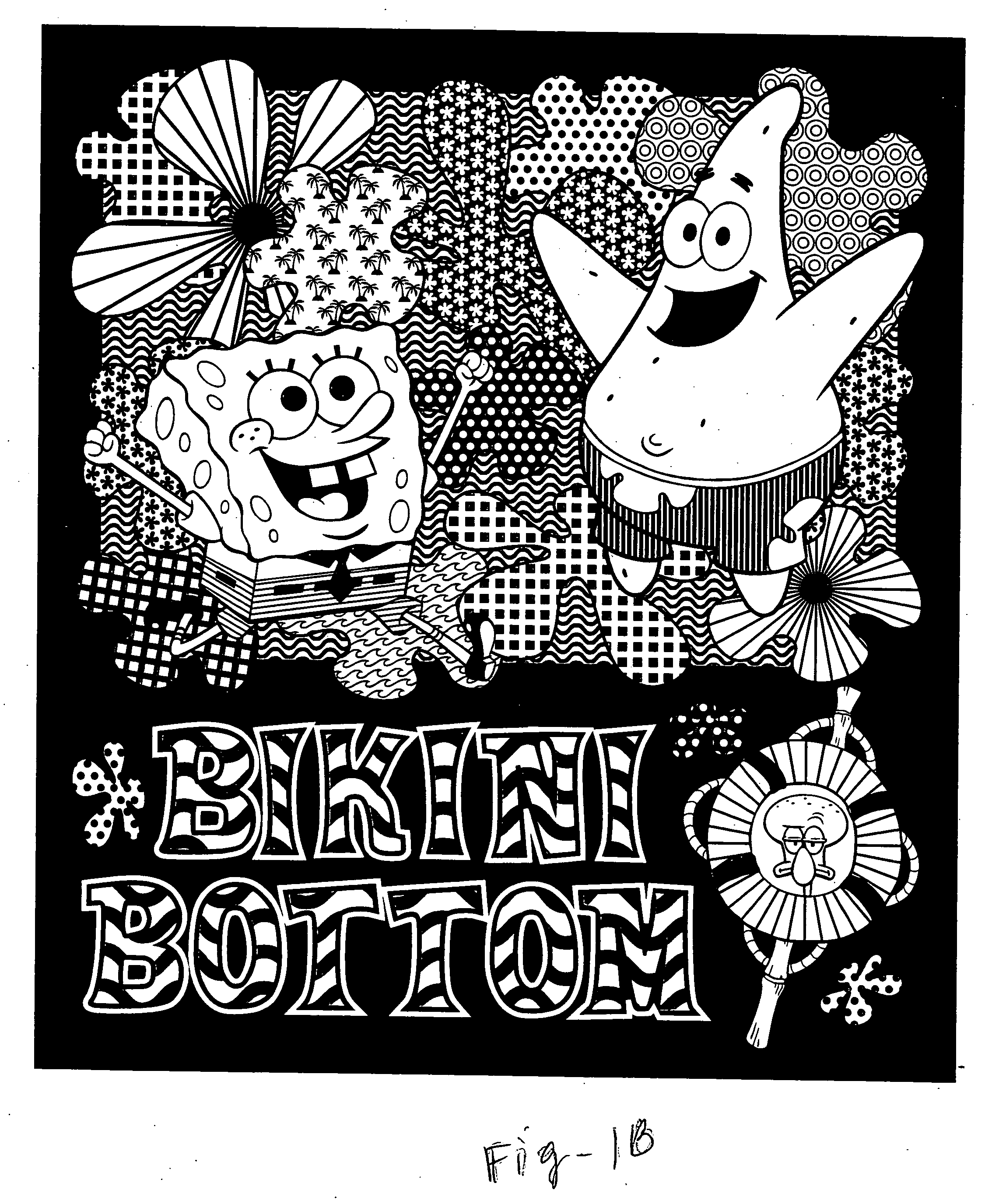

Printed materials with color-change inks to create unique designs

Color-changing inks are used in conjunction with printed material, with defined fields to create unique designs and / or works of art. In the preferred embodiment, pre-printed pages or books are used with fields of invisible inks that are activated with different pens to produce a unique final product. In alternative embodiments, stickers, paints, flocking, foil stamping, thermography, embossing and rubber stamps may be used. In specific embodiments, depictions of cartoon characters or other humans or animals are intermingled with more geometric fields, often with instructions or text explaining to a user what actions should be taken for a desired effect or outcome. Patterns of “invisible inks” having desired properties are pre-printed onto materials according to the invention, such that, through the use of different activator pens, different colors are produced in the various fields, thereby rendering a unique product in each case.

Owner:ELMERS PROD INC

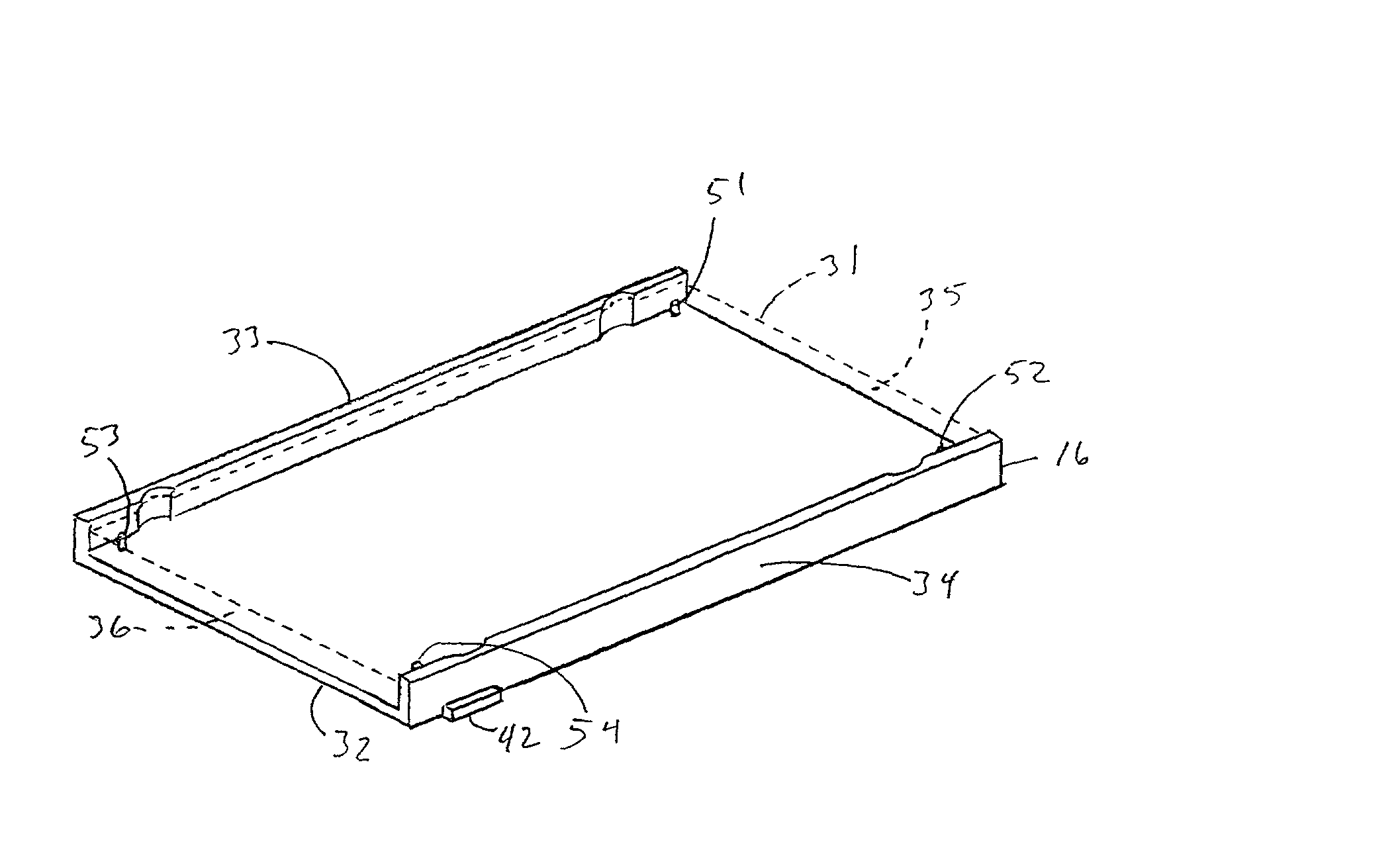

Precast gel and tray combination for submerged gel electrophoresis

A precast slab gel for use in submerged ("submarine") horizontal electrophoresis is formed in a tray that includes a flat base and two raised walls on opposing sides of the base, the walls containing one or more tabs on their outer surfaces, the tabs mating with grooves in the interior walls of the tank. The mating of the tabs with the grooves prevents movement and floating of the tray within to the electrophoresis cell during use. The tabs are designed to mate with grooves that are present in the tank for other purposes, which adds to the versatility of the design. Further versatility is achieved by joining the tabs to the tray walls by thin webs, which make the tabs readily removable, thereby rendering the tray usable in cell tanks that do not contain grooves. Further aspects of the invention include pins or posts extending upward from the tray base to anchor the gel, and the printing of indicia on the tray base by hot foil stamping, with the discovery that indicia printed in this manner are capable of producing a fluorescent image as part of the image produced by fluorescent-dyed protein spots in the electropherogram.

Owner:BIO RAD LAB INC

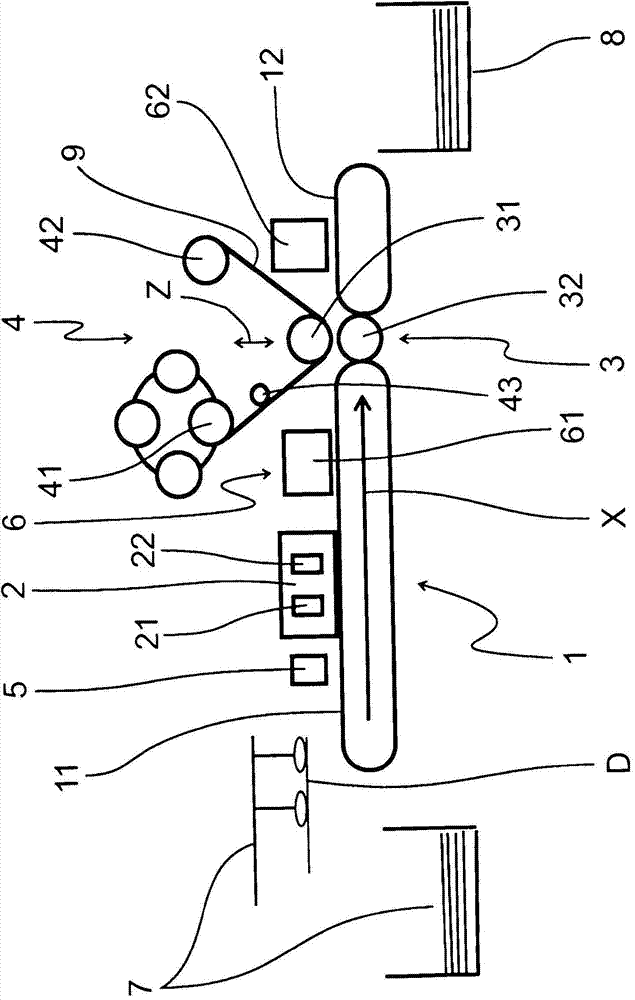

Foil stamping method and corresponding device

InactiveCN103946034AEasy to pressPrecise coatingTransfer printingDecorative surface effectsAdhesiveFoil stamping

The invention relates to a foil stamping method according to which a surface of a printing product (D) is provided with an adhesive layer in places intended to be imprinted prior to a transfer film (9), which consists of a carrier film and a transfer layer adhering thereto by means of a release layer, being placed onto the printing product (D) under the effect of pressure, the transfer layer sticking to the printing product (D) in places intended to be imprinted. Prior to foil printing, an applicable adhesive is applied to the printing product (D), instead of or in addition to the adhesive layer, in the places intended to be semi-embossed and the pressure acts evenly across the entire surface of the printing product (D), namely also on the raised places resulting from semi-embossing and the remaining surroundings during foil printing. The invention further relates to a foil stamping device for transferring a transfer layer which adheres to a carrier film onto the printing product (D) in places intended to be imprinted, said foil stamping device comprising a conveying system (1) for the printing product (D), adhesive application means (2), arranged on the conveying system (1), which provides a surface of the printing product (D) with an adhesive layer in places intended to be imprinted, a foil transfer means (3) having a transfer roller (31) and a foil feeding means (4) associated with the foil transfer means (3), the outer surface of the transfer roller (31) being covered with an elastic cover of a small thickness.

Owner:彼得巴特

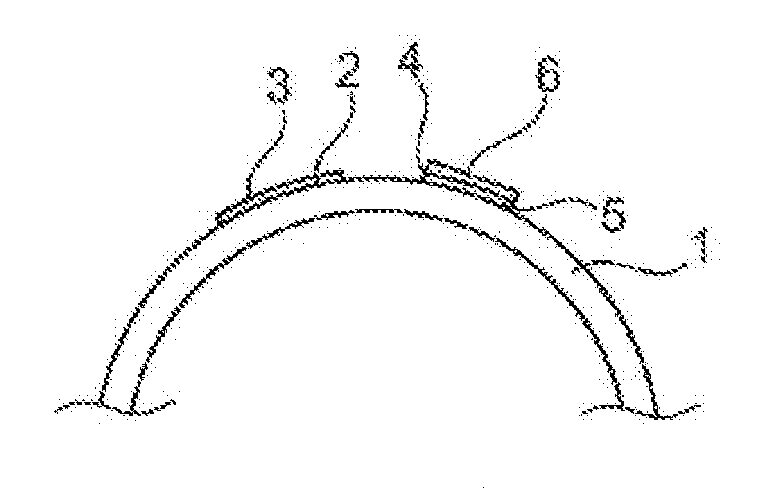

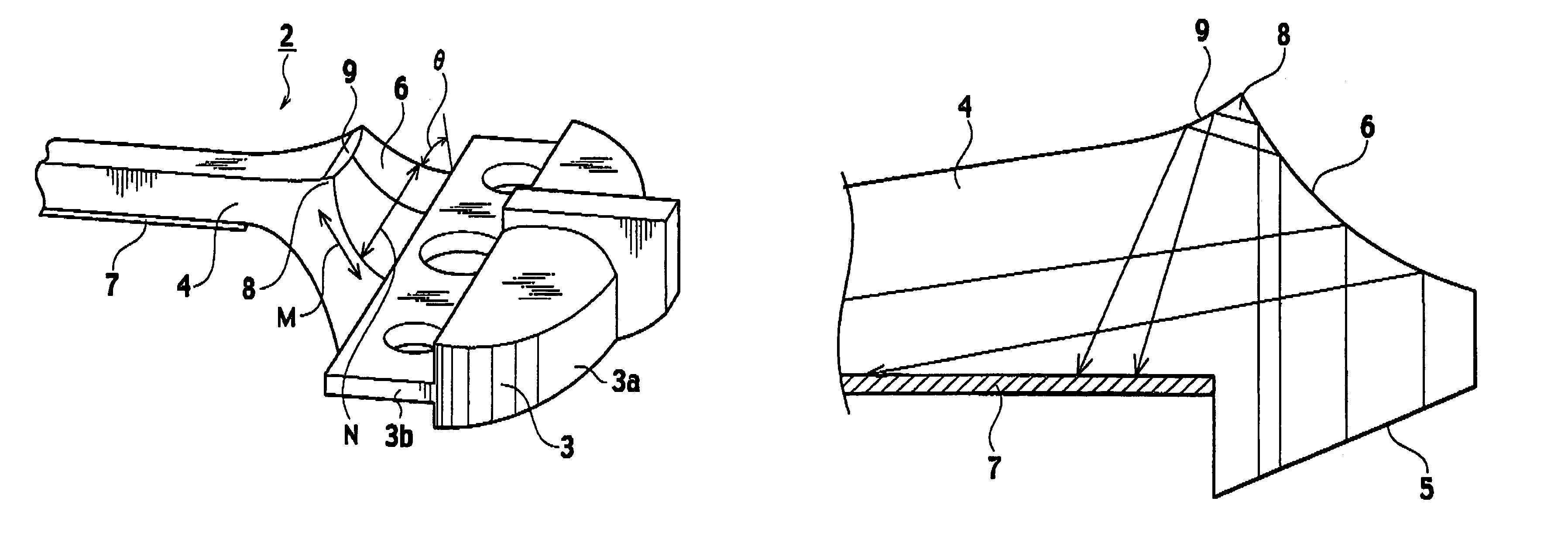

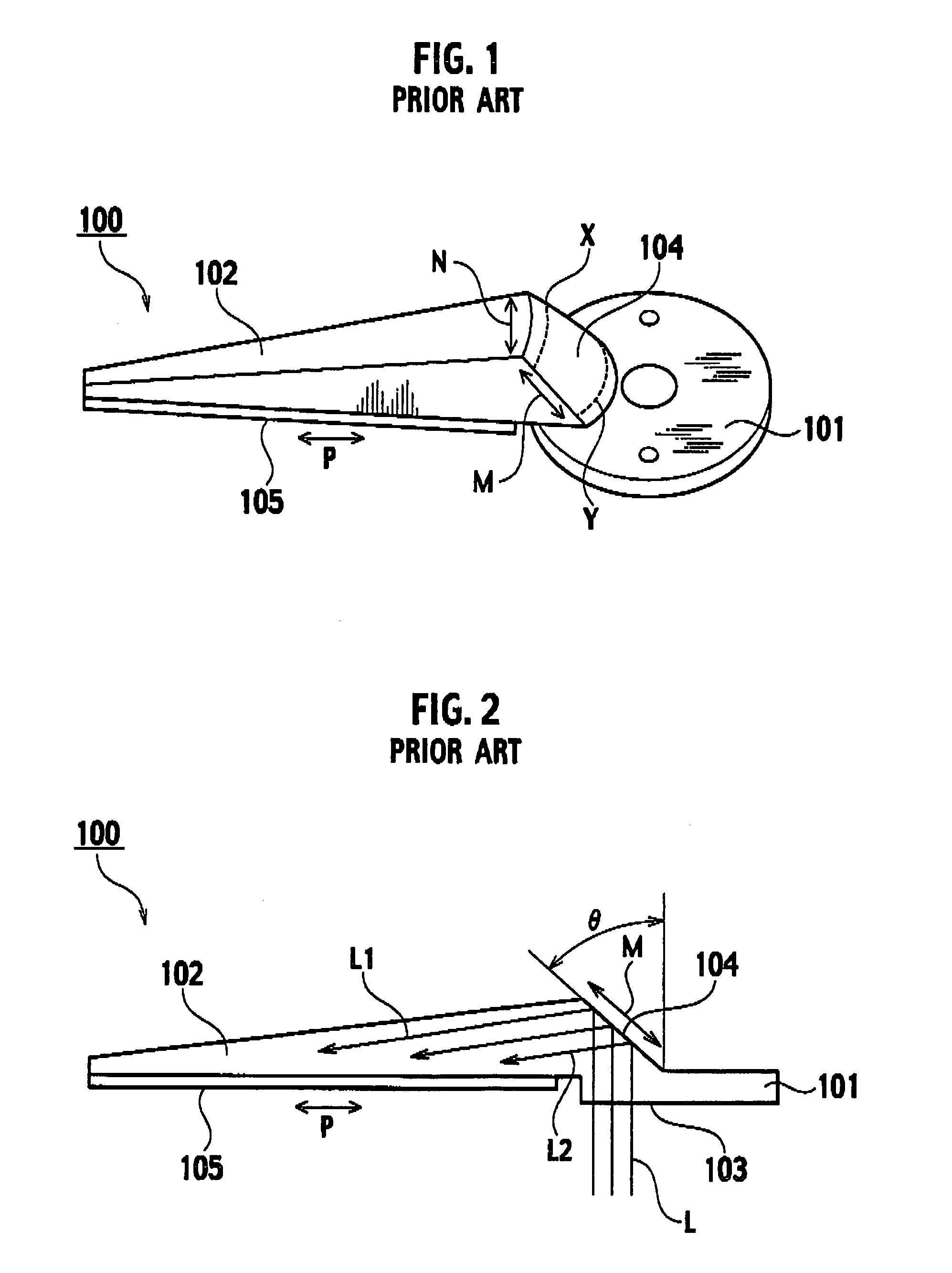

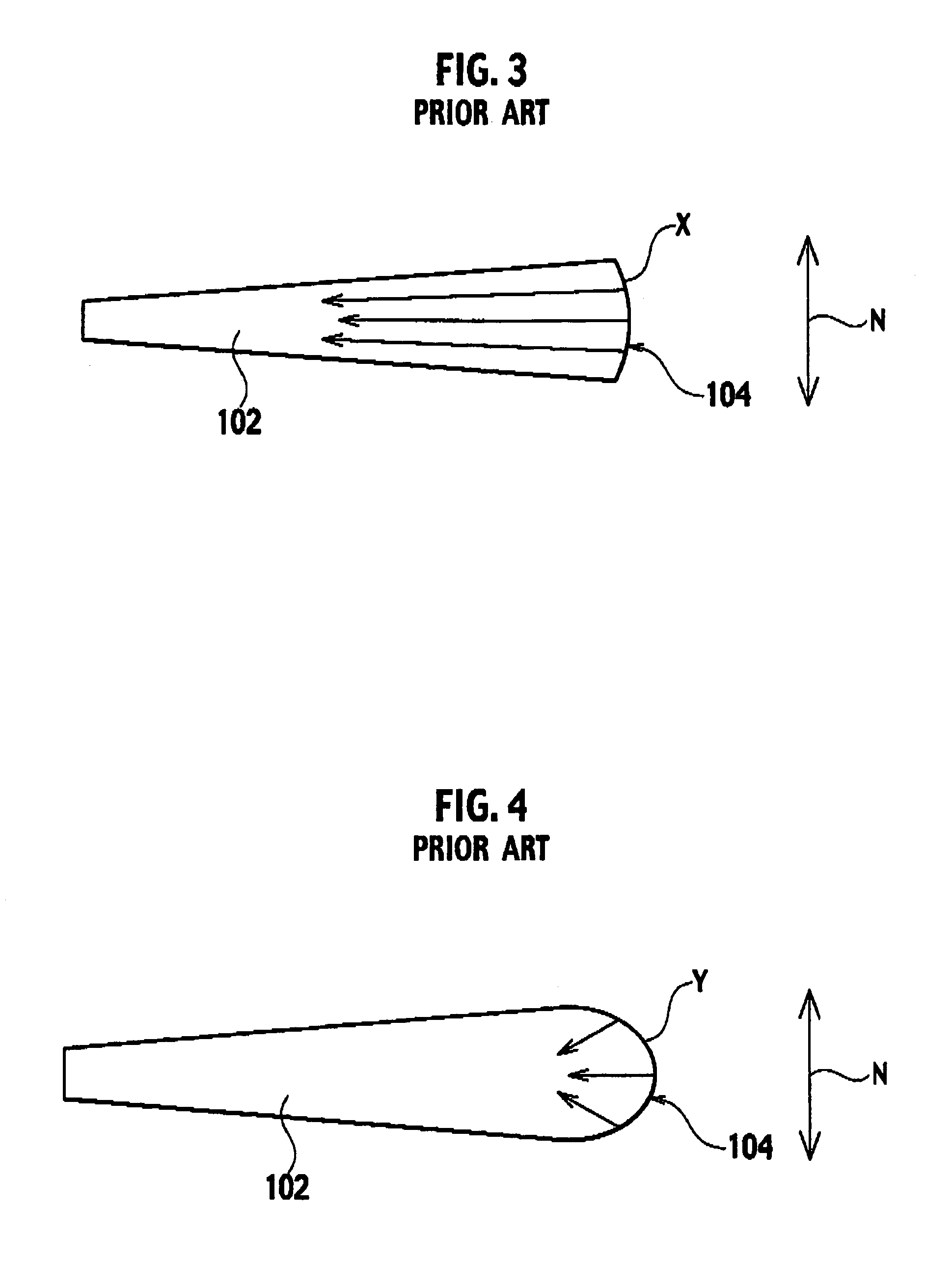

Pointer having a curved Reflective Surface

ActiveUS7635192B2Easily and efficiently lightenedUneven light strengthAircraft componentsMeasurement apparatus componentsEngineeringFoil stamping

A pointer comprises an attached portion and a main body. The attached portion is attached to an instrument. The main body is fixed to the attached portion at a basic portion thereof and extending toward a free portion thereof. The main body has a reflective surface and a foil-stamping layer. The reflective surface is formed at an inclined surface of the basic portion and inclined to a traveling direction of light entering the main body. The foil-stamping layer is formed on a bottom surface of the main body and diffusely reflects light reflected by the reflective surface. The reflective surface is curved like a collective convex lens in a transverse direction of the inclined surface and a diffusive concave lens in a vertical direction of the inclined surface.

Owner:YAZAKI CORP

Gold stamping machine alumite automatic recovering device

PendingCN107720374AContinuous productionIncrease productivityTransfer printingWebs handlingEngineeringFoil stamping

The invention discloses a gold stamping machine alumite automatic recovering device. The front side of a machine case is opened, the top of the interior of the machine case is downwards provided withan L-shaped separating plate, the vertical face of the L-shaped separating plate is parallel to a back plate of the machine case, a feeding opening is formed in the side wall of the machine case and located on the front side of the L-shaped separating plate, and a row of steering rollers are horizontally distributed on the front end face of the separating plate, and an alumite rolling device is arranged at the position, corresponding to each steering roller, on the front end face of the separating plate; the steering rollers are located on the side, far away from the feeding opening, of the alumite rolling device, and a movable rotating roller moving up and down is arranged on the front end face of the back plate, is located below a transverse plate of the L-shaped separating plate, and corresponds to the corresponding steering roller. According to the above structure, the gold stamping machine alumite automatic recovering device achieves non-halting disc replacing operation of gold stamping machine alumite, and therefore a gold stamping machine cannot be influenced by alumite disc replacement, continuous production can be achieved, and the production efficiency of the gold stamping machine is improved.

Owner:JIANGSU JIN JIA NEW PACKAGING MATERIALS CO LTD

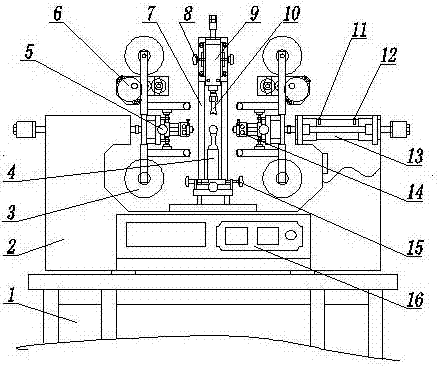

Cylindrical article peripheral face hot stamping machine

A hot stamping machine for cylindrical articles, which is characterized in that a horizontal plate body is installed on the bottom box, a control panel is installed in front of the horizontal plate body, a vertical plate body is installed in the middle behind the horizontal plate body, and the lower part of the vertical plate body is The bottom mold fine-tuning is installed, the bottom mold is installed on the bottom mold fine-tuning, the vertical clamping cylinder is installed on the upper part of the vertical board body, and the clamping cylinder fine-tuning is equipped between the clamping cylinder and the vertical board body, and the cylinder rod of the clamping cylinder is installed. The lower end is equipped with a clamping upper mold; two opposite horizontal hot stamping cylinders are installed on the left and right sides of the vertical board body, and the built-in cylinder rod of the hot stamping cylinder is equipped with a heating head fine-tuning and a heating hot stamping head, and a heating hot stamping head The upper side of the hot stamping head is equipped with a foil rolling mechanism, and the lower side of the heating hot stamping head is equipped with a foil shaft; the hot stamping cylinder is equipped with a front limit switch and a rear limit switch. It solves the problem that it is difficult to hot stamp the peripheral surface of cylindrical objects, and is suitable for hot stamping text or patterns on wooden handles and other items.

Owner:QINGDAO JINGGANG STAMPING PRESS

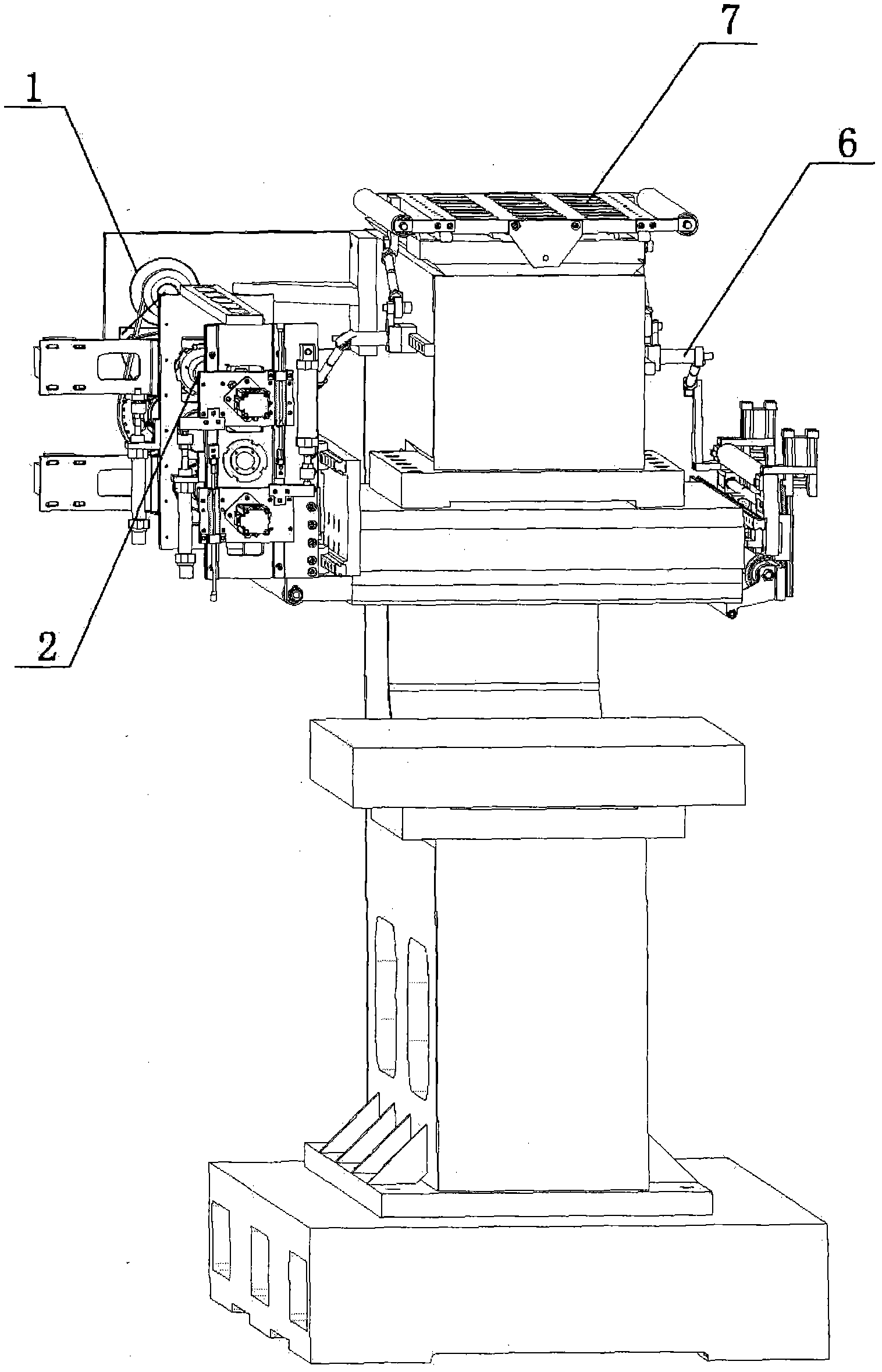

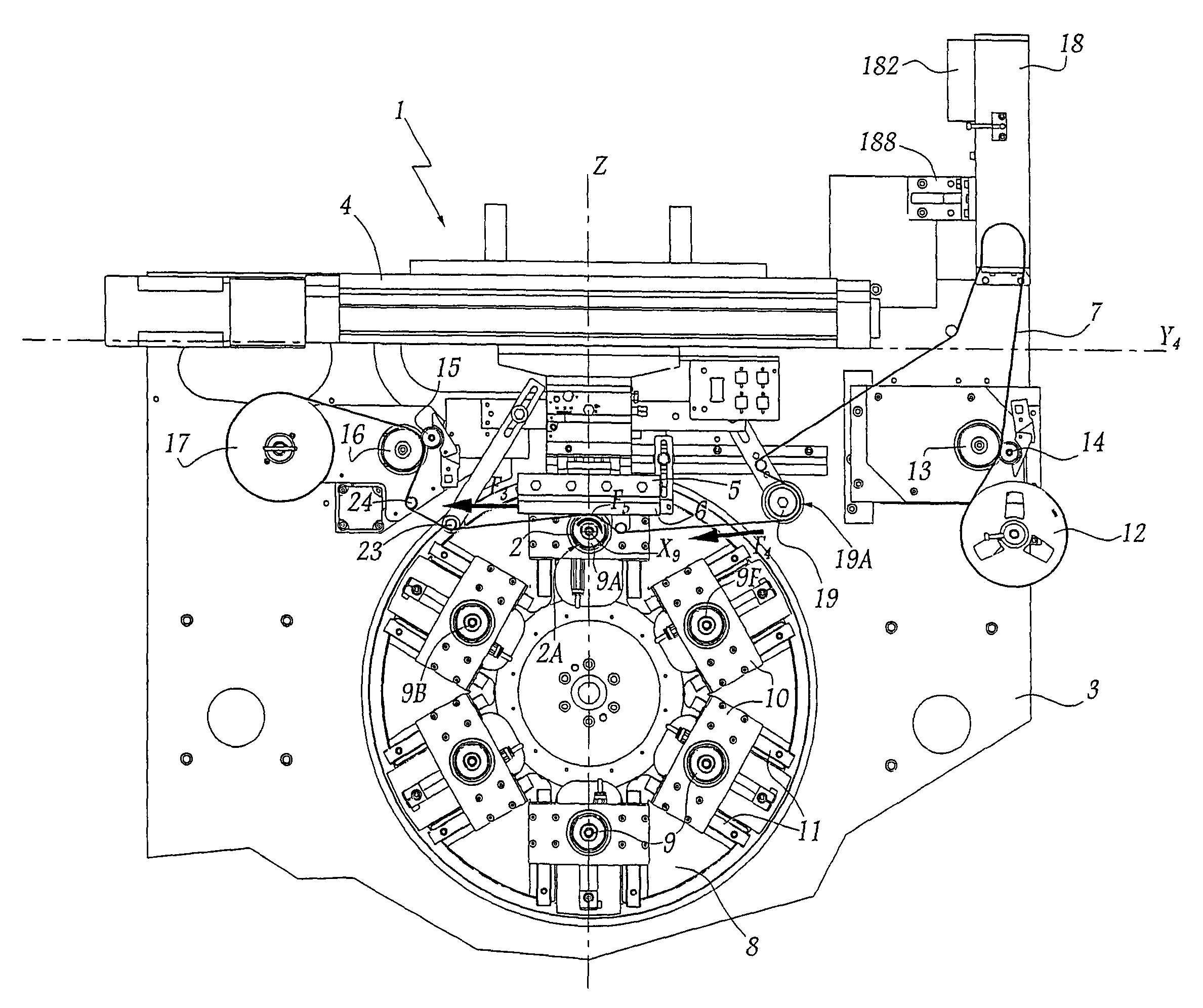

Foil stamping machine

ActiveUS8074568B2Quality improvementImprove reliabilityTransfer printingPrinting mechanismsHot stampingEngineering

A hot stamping machine including a stamping member which presses a stamping foil against a peripheral surface of articles which are successively positioned in a stamping position and wherein stamping foil is removed from an unwinding mechanism for each stamping sequence and passes in succession into a suction box, along a braking surface and opposite the stamping member that urges the foil against an article, and wherein a reserve of foil is available in the suction box between the unwinding means and the braking surface, while the foil is tensioned between the stamping member and the article, during stamping of the article, and between the braking surface and a rewinding mechanism.

Owner:ILLINOIS TOOL WORKS INC

Method for Decorating the Sides of Plastic Cards

Engraver configured to be coupled to a heater piece of a hot foil stamping machine for decorating sides of plastic cards wherein the engraver is made of silicone and capable of being heated up and comprising a recess on its external face opposite to a foil of the hot foil stamping machine, in such a way that a cross-section of said engraver is a negative shape and size of a side of plastic cards, including rounded corners formed by said side and adjacent side, wherein engraver size is dependent on number of plastic cards and the engraver is capable of being heated up and is suitable for being coupled to the heater head piece of the hot foil stamping machine.

Owner:SMART LAYER 3

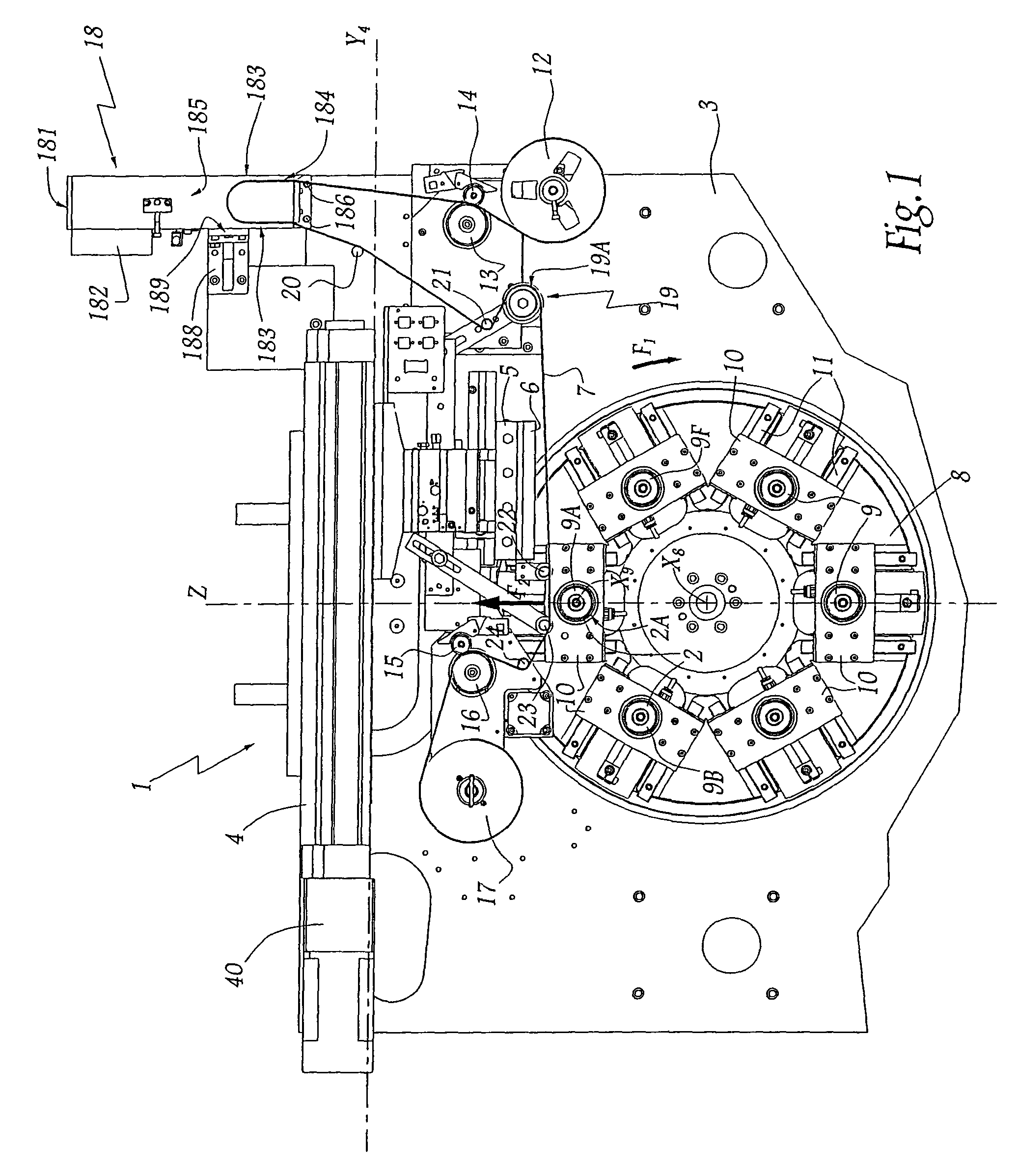

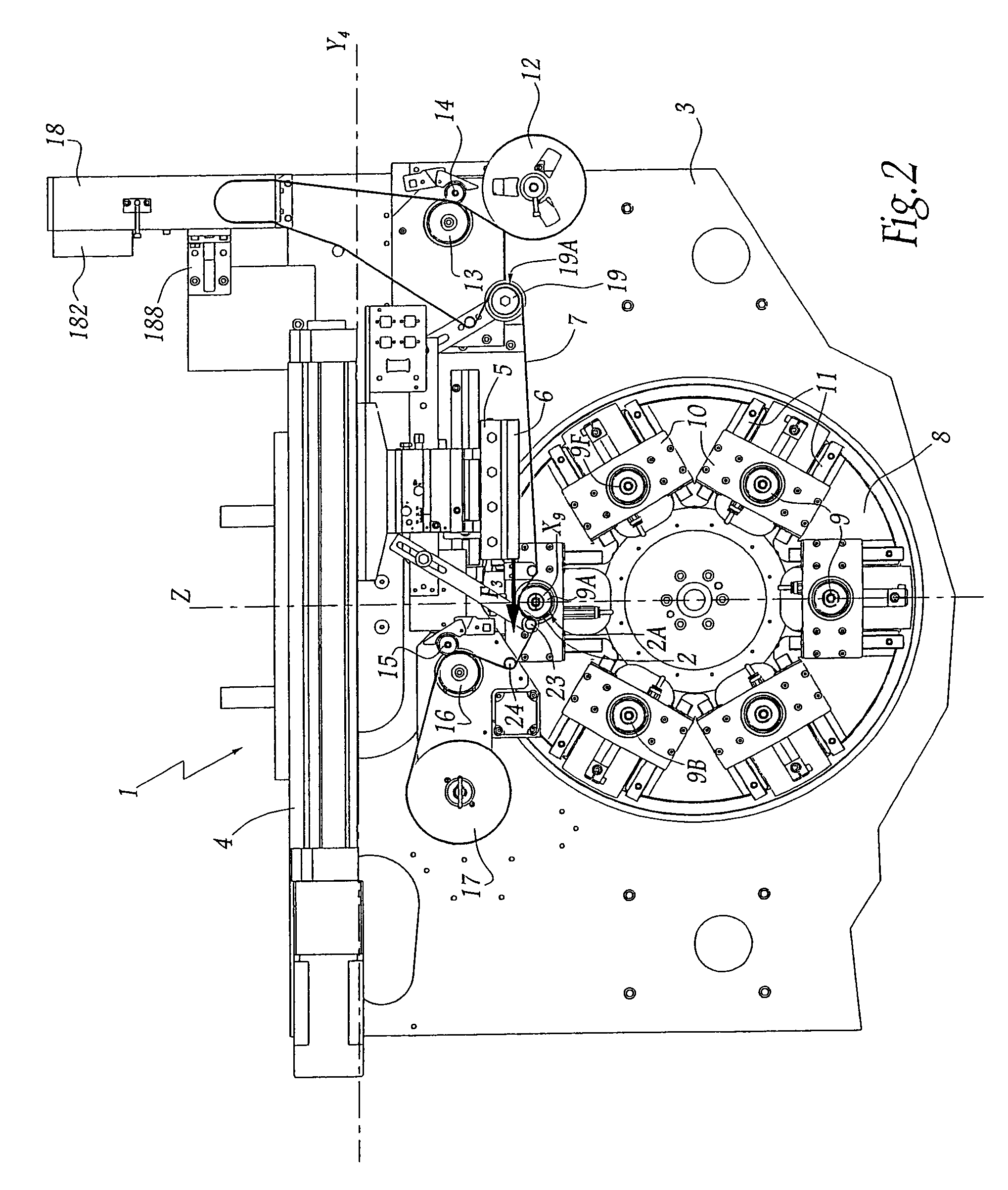

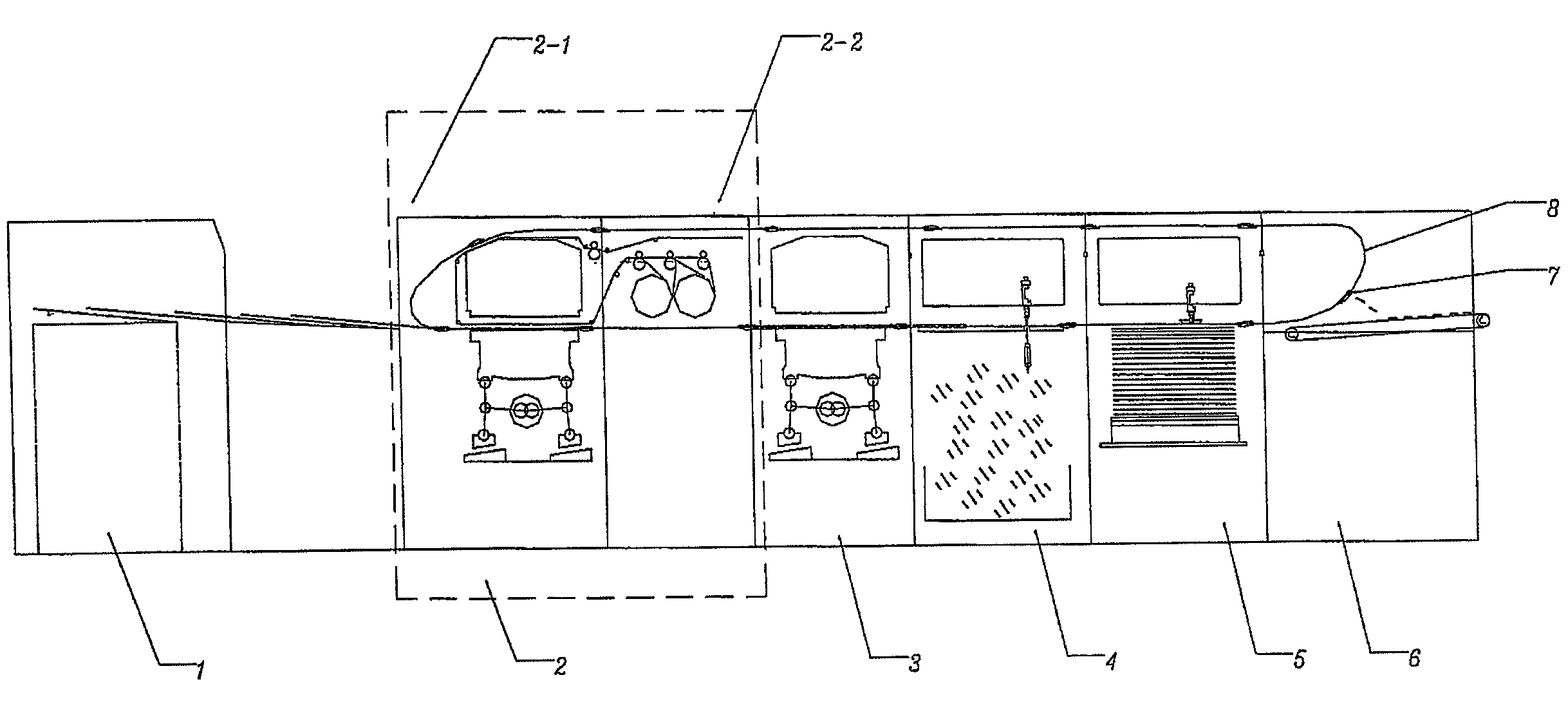

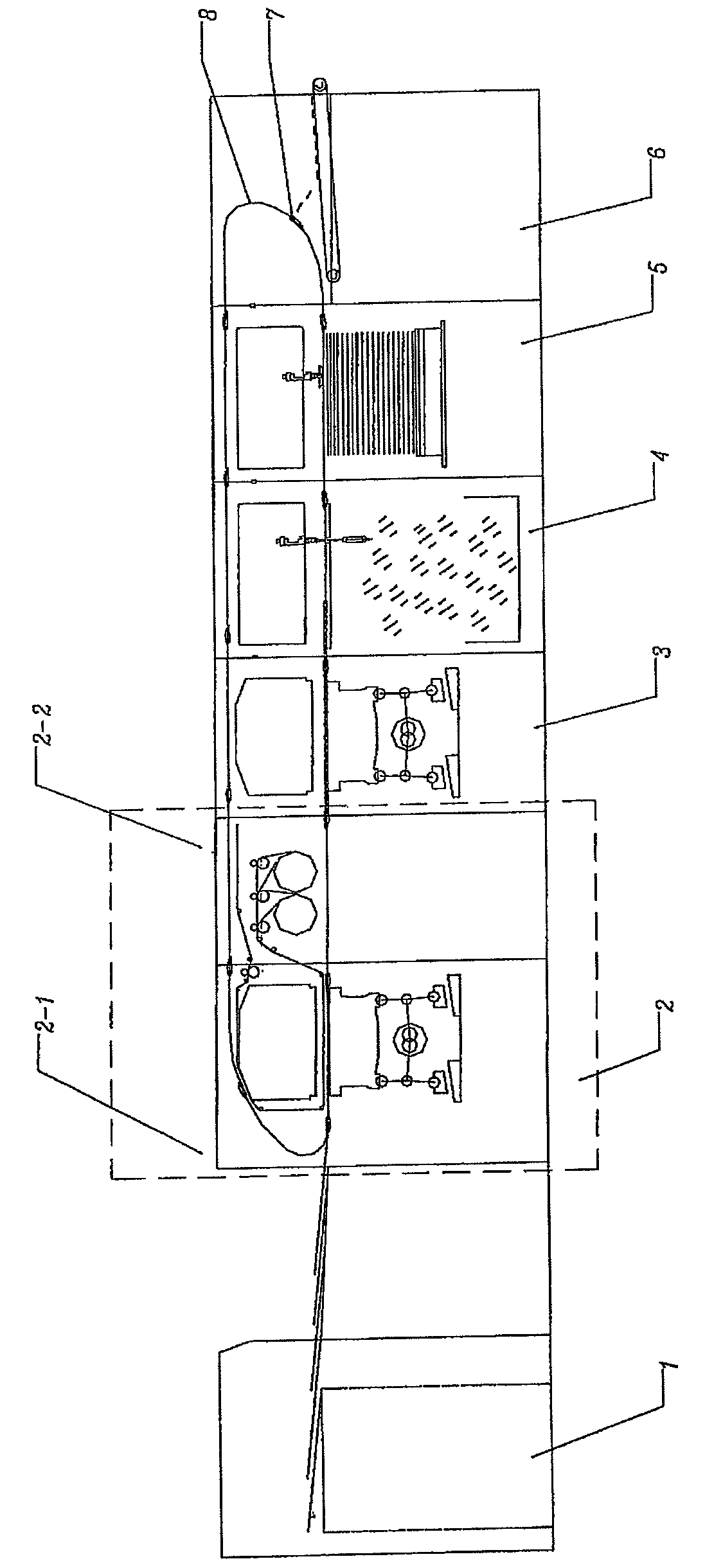

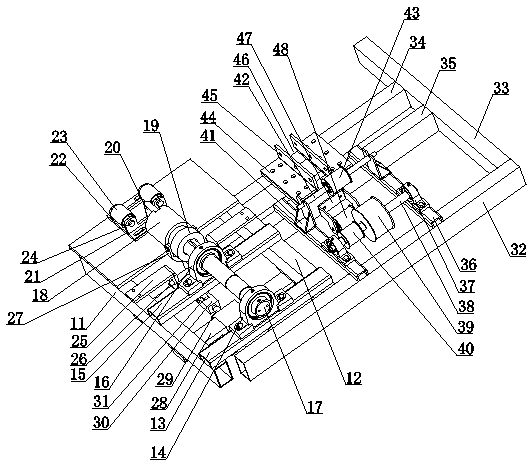

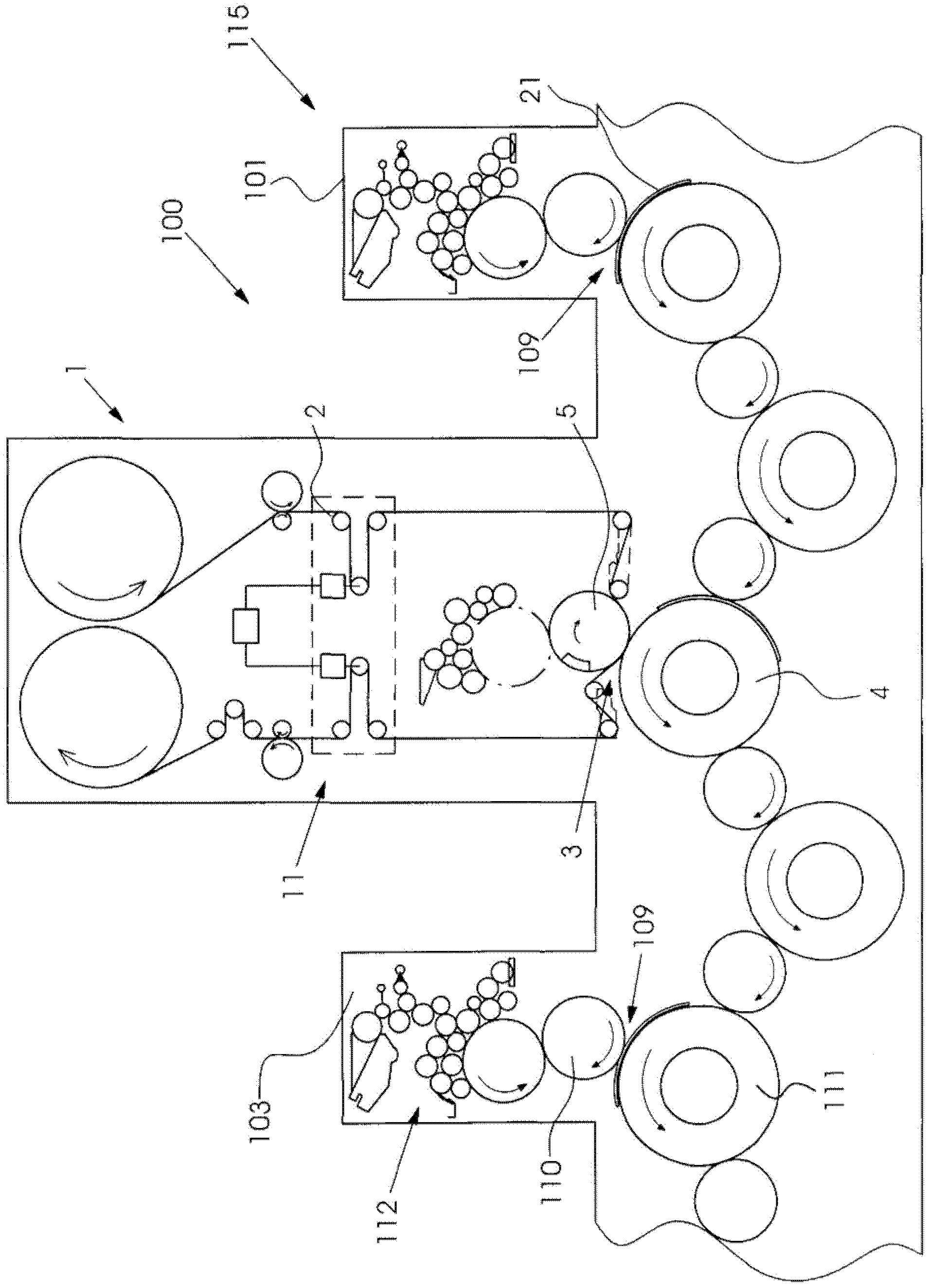

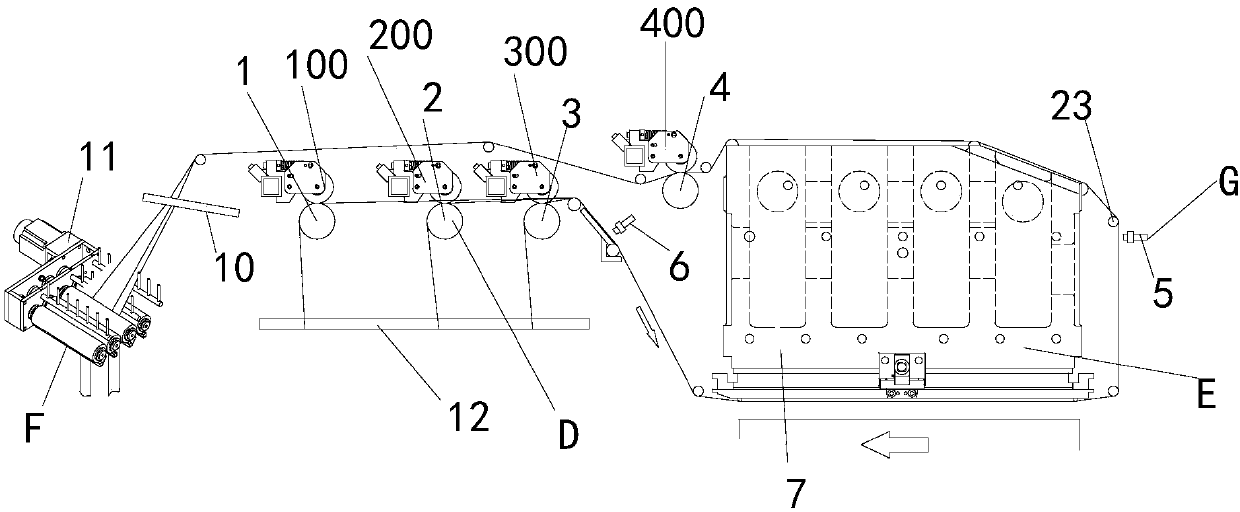

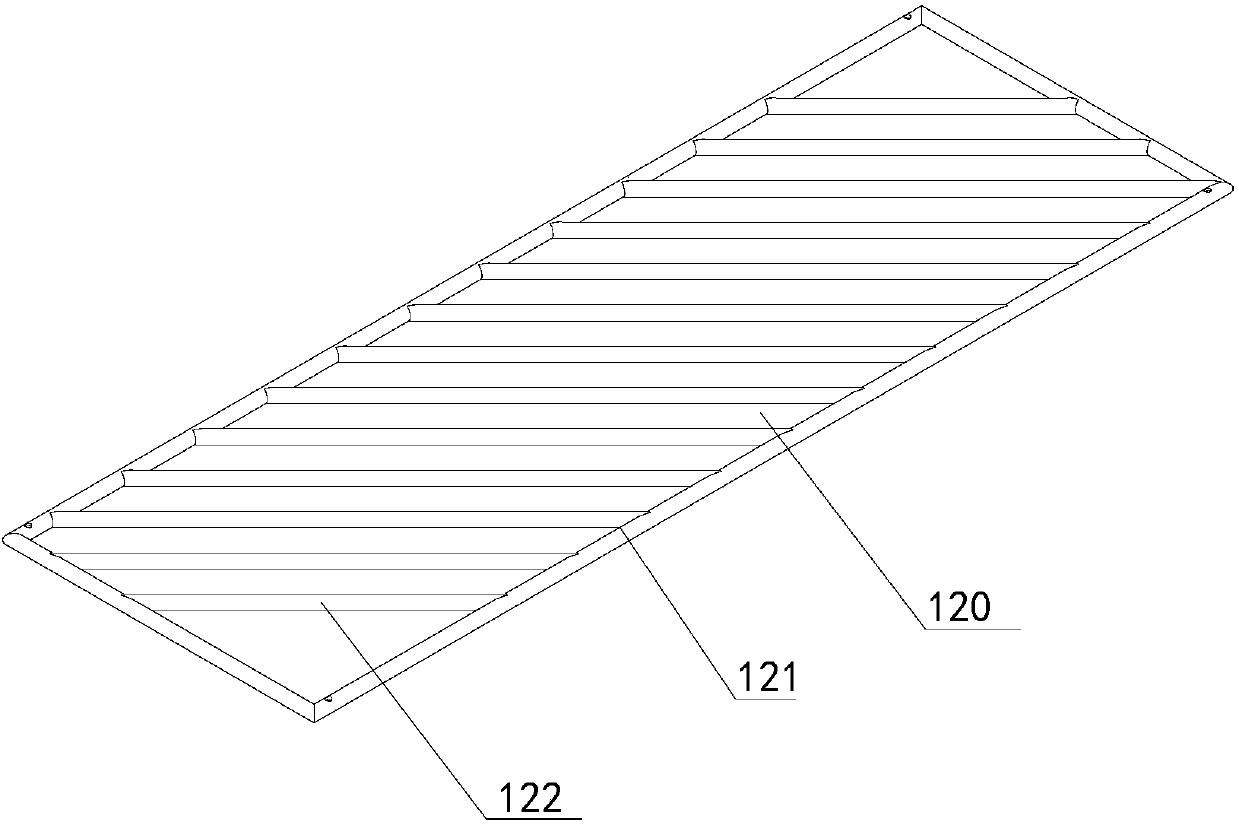

Post-press apparatus and a method to accomplish hot foil stamping, die-cutting and blank separation in a single pass

ActiveUS8337376B2Guarantee product qualityImprove work efficiencyMechanical working/deformationBoxes/cartons making machineryEngineeringFoil stamping

Owner:LIU TIAN SHENG

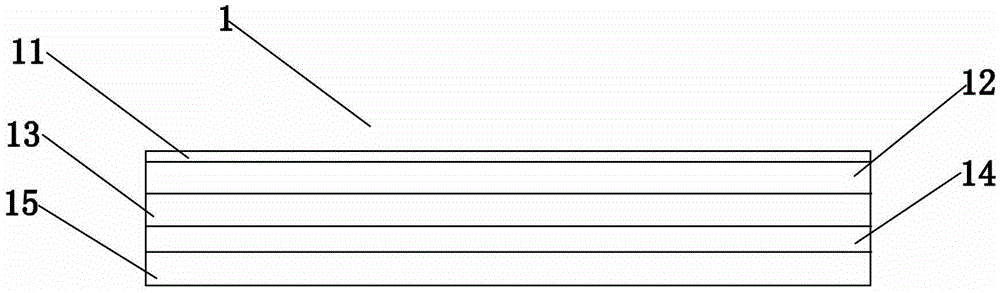

Hot gold foil

InactiveCN105415910AIncrease stickinessReduce manufacturing costSynthetic resin layered productsThermographyHot stampingMetal foil

The invention relates to the technical field of printing and particularly relates to a hot gold foil. The hot gold foil comprises a base film layer, a release layer on the base film layer, a colour layer on the release layer and an aluminium coated layer on the colour layer, wherein an ink layer is arranged at the bottom of the aluminium coated layer, during hot stamping, firstly, a worker can lay one side, provided with the ink layer, of the hot gold foil onto the surface of a to-be-printed object, through heating and pressing of a gold stamping machine and a hot stamping template, the metal foil of the hot gold foil is printed on the surface of the to-be-printed object, during hot stamping, the ink layer provided by the invention is positioned in a high temperature environment with the temperature of more than 100 DEG C, at the moment, the stickiness of the ink layer is increased after melting by heating, and printing onto the to-be-printed object is achieved while the aluminium coated layer and the base film layer are peeled off. With pressure release, the ink layer is quickly cooled and solidified, and the aluminium coated layer is firmly adhered onto the to-be-printed object, so that the metal foil of the hot gold foil is firmly adhered onto the to-be-printed object. Therefore, due to the use of the hot gold foil for gold stamping, the gold stamping process and steps are simplified, the production efficiency is improved, and the product cost of manufacturers is lowered.

Owner:GUANGDONG YINCAI TECH CO LTD

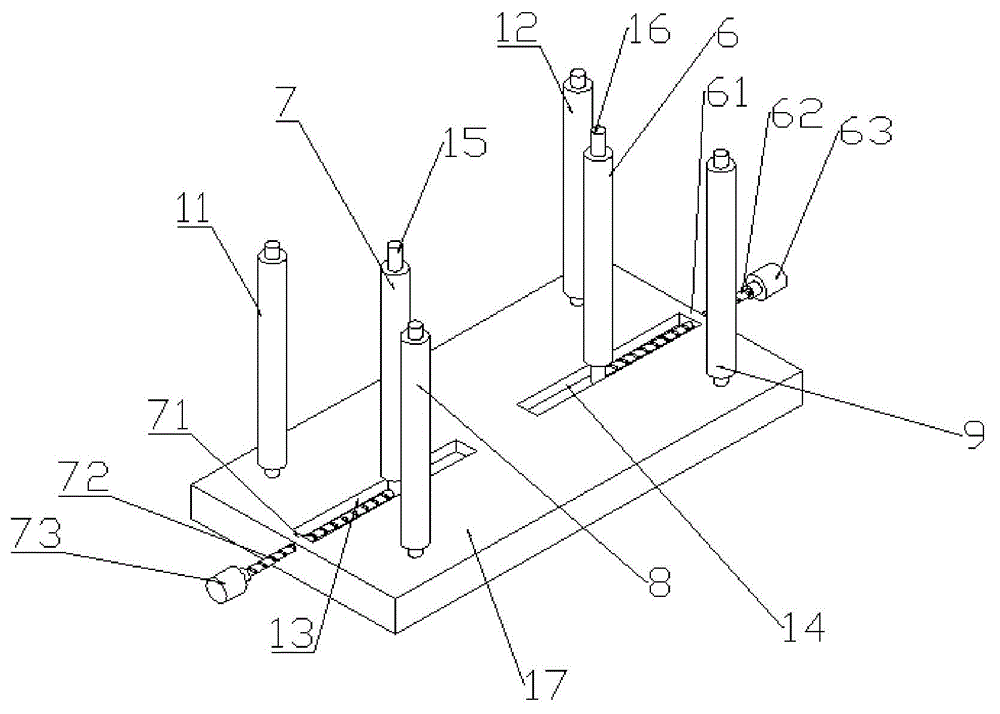

Novel laminating cold foil stamping structure

InactiveCN105365365AImprove cold perm qualityQuality improvementRotary pressesBronze printingEngineeringFoil stamping

The invention provides a novel laminating cold foil stamping structure which comprises a cold foil stamping unreeling device, a cold foil stamping unit and a cold foil stamping reeling device. The cold foil stamping unit comprises a first reversing guide roll, a second reversing guide roll, a left adjusting roll, an impressing roll, a stripping roll, a right adjusting roll and a third reversing guide roll. A left attaching press roll is arranged at the lower end of the impressing roll. A right attaching press roll is arranged at the lower end of the stripping roll. The cold foil stamping unit is fixed to a fixing wall, and a left slide way and a right slide way are arranged on the fixing wall. The left adjusting roll is arranged on the left slide way, a left adjusting shaft is arranged on the left adjusting roll, and the left adjusting shaft is fixed to the left slide way. According to the novel laminating cold foil stamping structure, the cold foil stamping quality of the cold foil stamping technology in an intermittent rotary press can be improved, due to the fact that the left adjusting roll and the right adjusting roll are adjusted, cold stamped foil and printing stock conduct unreeling together during unreeling, it is avoided that the printing stock is stripped from the cold stamped foil, and the cold stamping quality and the effect of cold foil stamping are effectively improved.

Owner:天津市安德诺德印刷股份有限公司

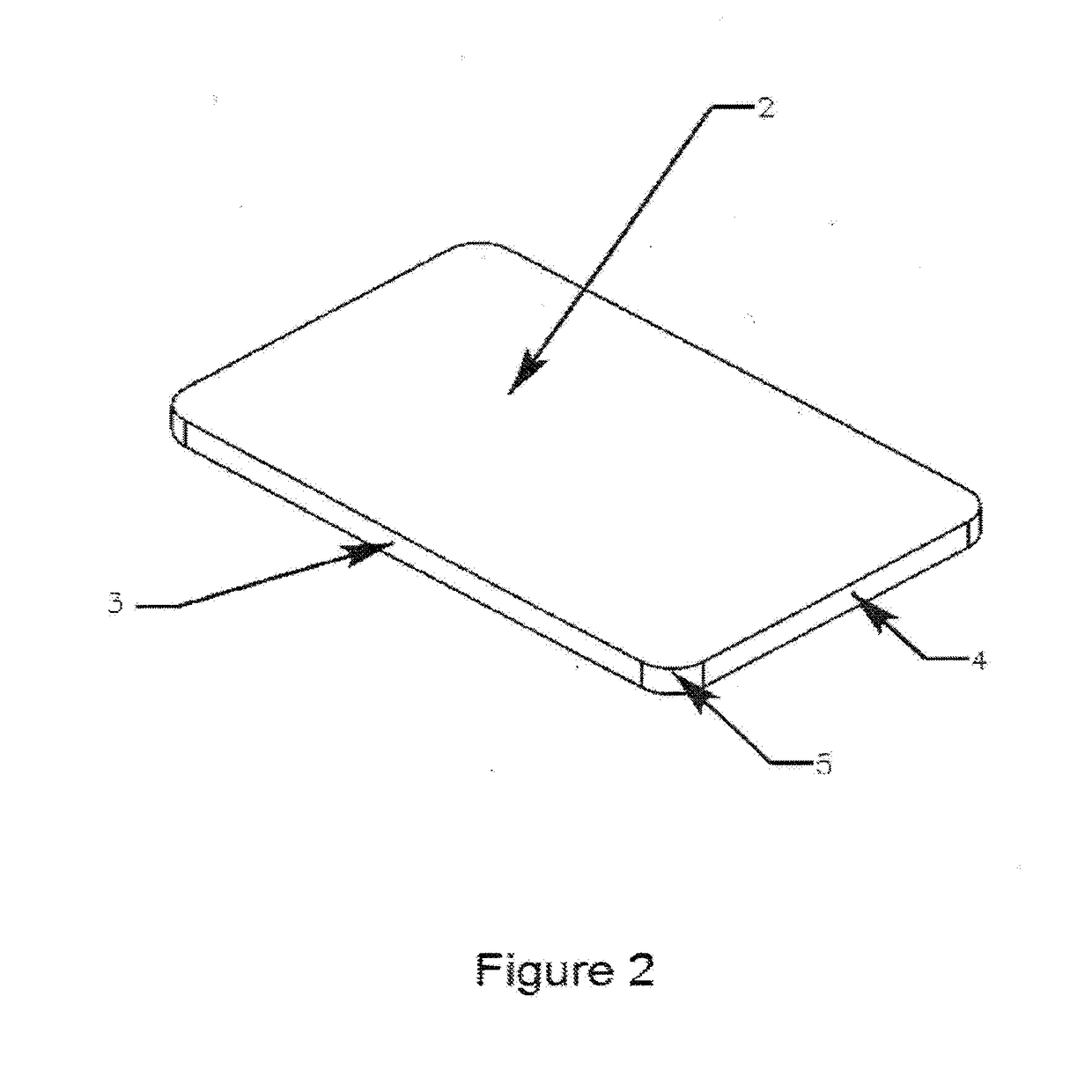

Method for decorating substrates and decorated substrate

ActiveUS10479072B2Hot stamping temperature can be significantly loweredLow costDecorative surface effectsScreen printersHot stampingPolymer science

A method for decorating substrates, in particular packaging, comprising the steps: printing at least one first decorative pattern (2) on the substrate using a first radiation-curable, preferably UV-curable, printing ink composition (3); printing at least one second decorative pattern (4), using a second radiation-curable, preferably UV-curable, printing ink composition (5), on at least part of the substrate (1) in a region near to the first pattern (2), chronologically before, after, or during the printing of the first pattern; radiation curing of the first and second printing ink compositions (3, 5), preferably directly after the printing of each pattern, the radiation-cured second printing ink composition having a lower glass transition temperature than the radiation-cured first printing ink composition; application of a decorative coating to the second pattern by means of a hot foil stamping process, a hot stamping foil comprising a decorative coating material being pressed against the printed substrate by means of a stamping tool under the application of heat and pressure such that the decorative coating adheres to the second pattern but not to the first pattern.

Owner:MARABU GMBH & CO KG

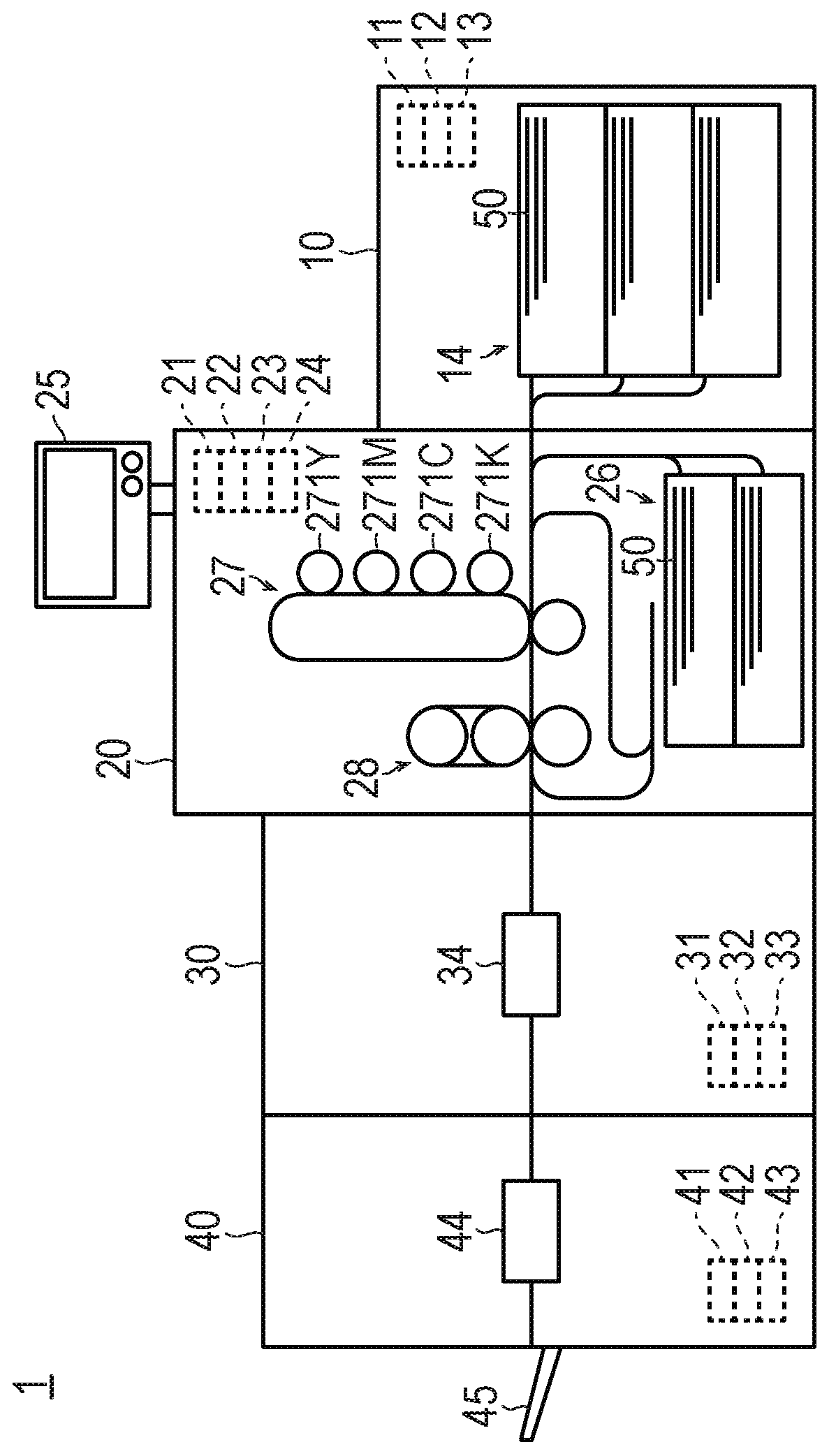

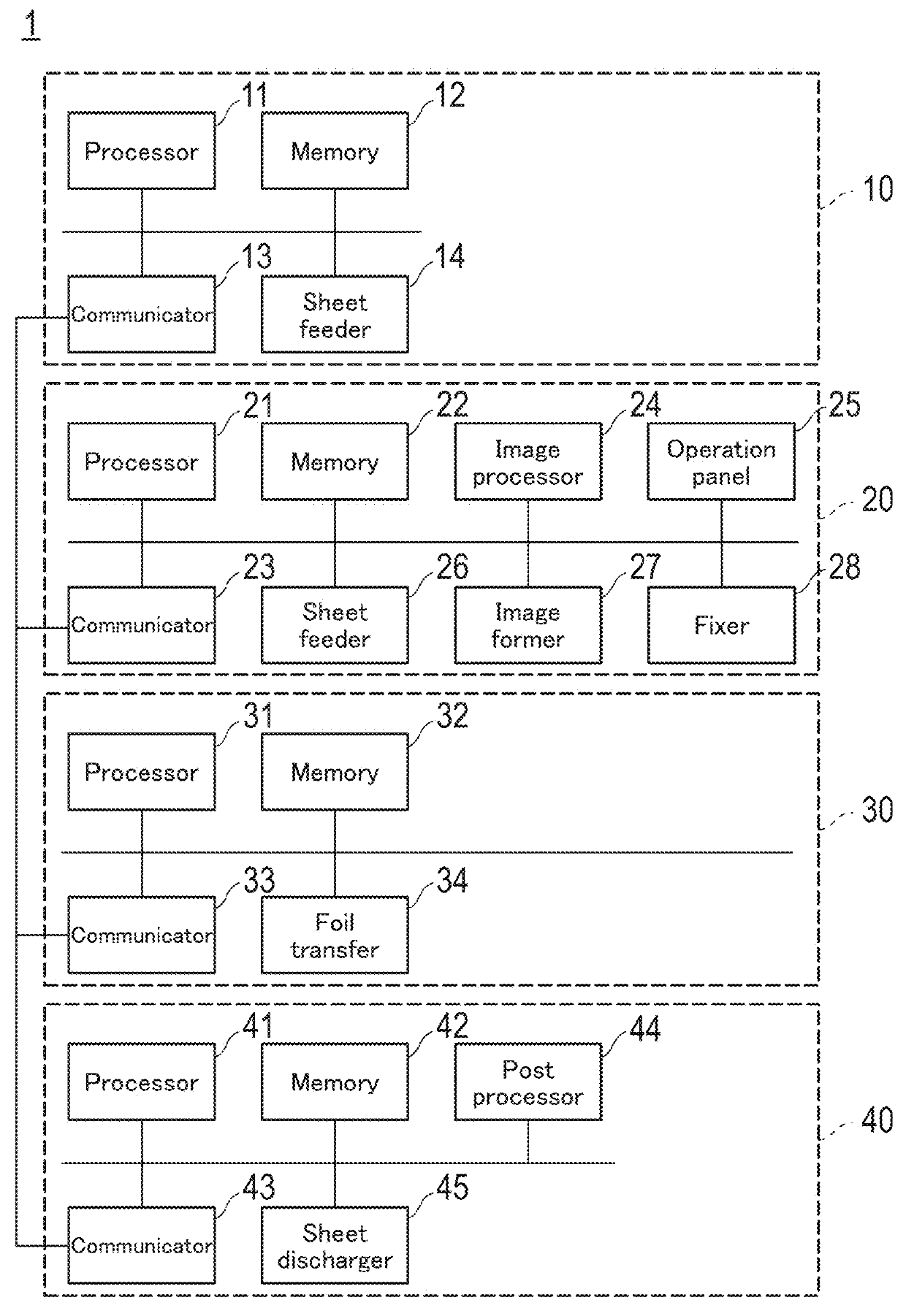

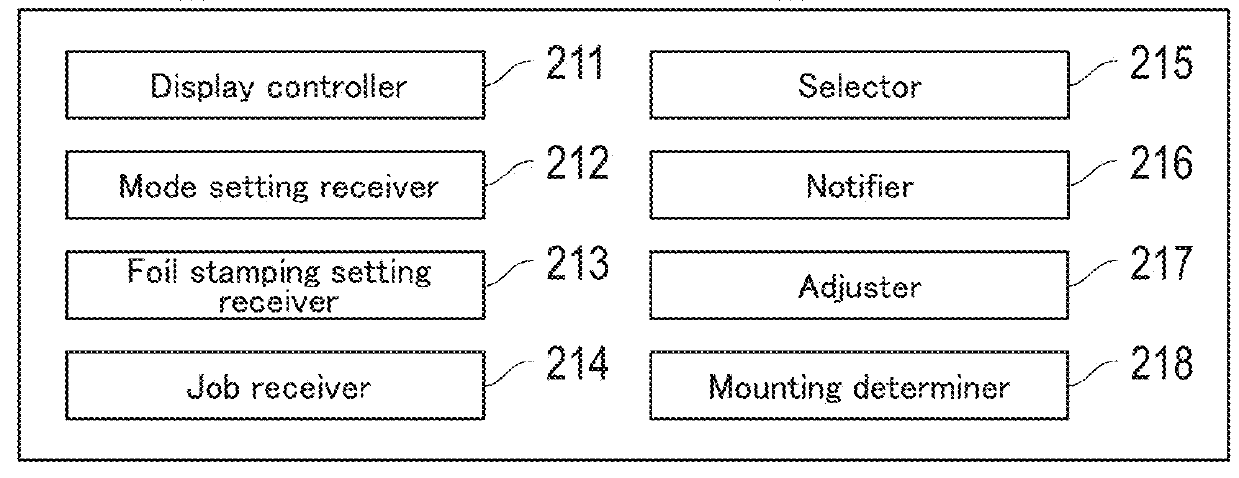

Image forming system and image forming method

An image forming system capable of performing foil stamping printing, which appropriately selects a color of a toner used as an adhesive on the basis of setting regarding the foil stamping printing, is provided. The image forming system includes an image former, a processor, and a foil transfer. The image former has a plurality of imaging units that form an image by toners of different colors. The processor is capable of receiving various types of setting regarding the foil stamping printing, and selects an image formation color, which is a color to be used for forming a foil stamping image, on the basis of the received setting. The foil transfer transfers a foil on the foil stamping image, which is formed by the image former, by using the toner of a color corresponding to the image formation color selected by the processor.

Owner:KONICA MINOLTA INC

An electric fire

InactiveCN101375103ADomestic stoves or rangesElectrical heating fuelFoil stampingMechanical engineering

An electric fire is described. By providing the fire in plastic and forming it from a kit of individual housings that inter-engage with one another to form the completed fire the time required for assembly of the fire is reduced greatly. Also described is a spacer arrangement for a fire, for use in circumstances where the fire is too small for the opening which it is to be located in. Also described is a reflector screen formed using a hot foil stamping technique. Finally, a moulded fuel bed is described which can be used to simulate pebble or glass effects.

Owner:BASIC HOLDINGS CO LTD

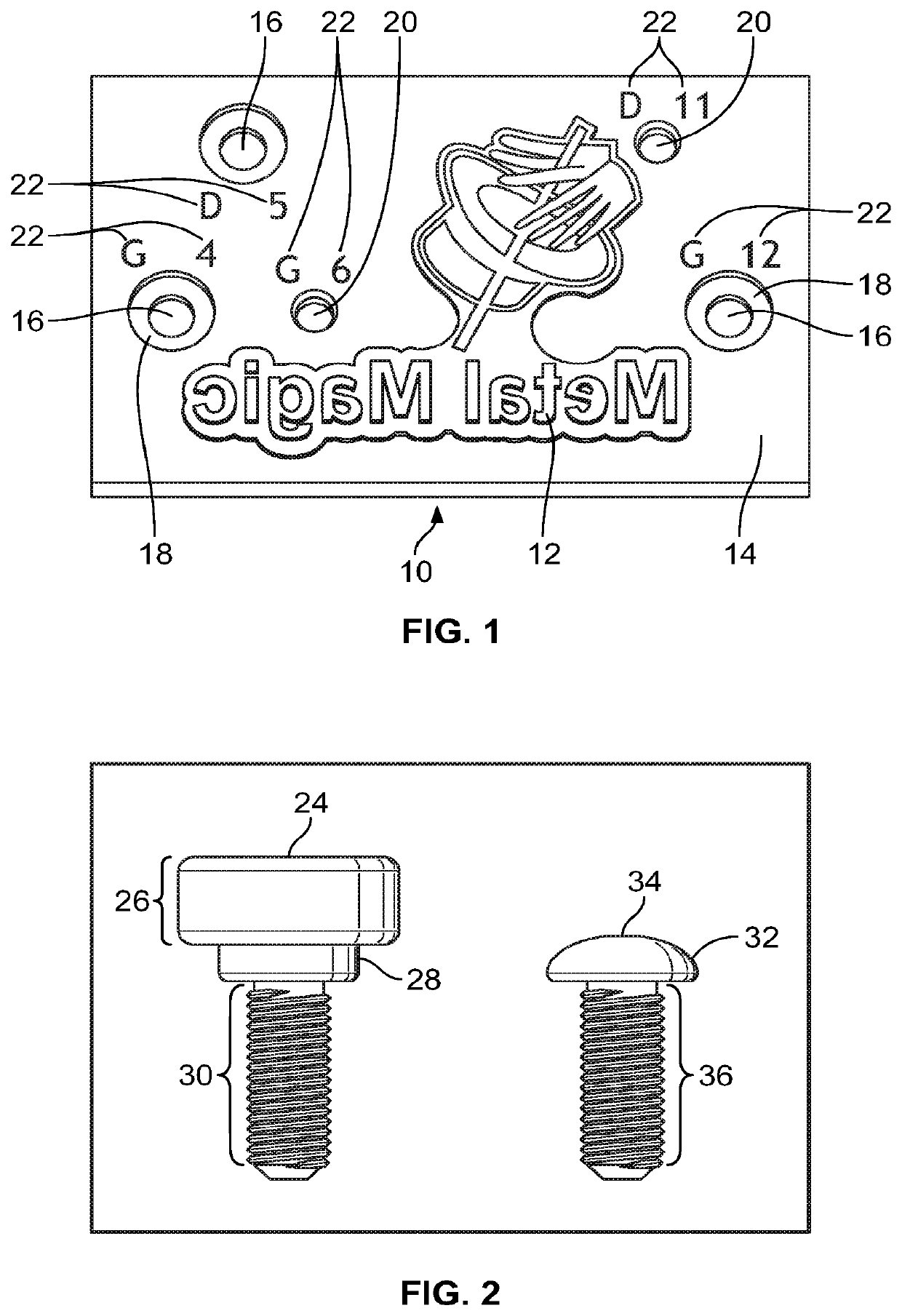

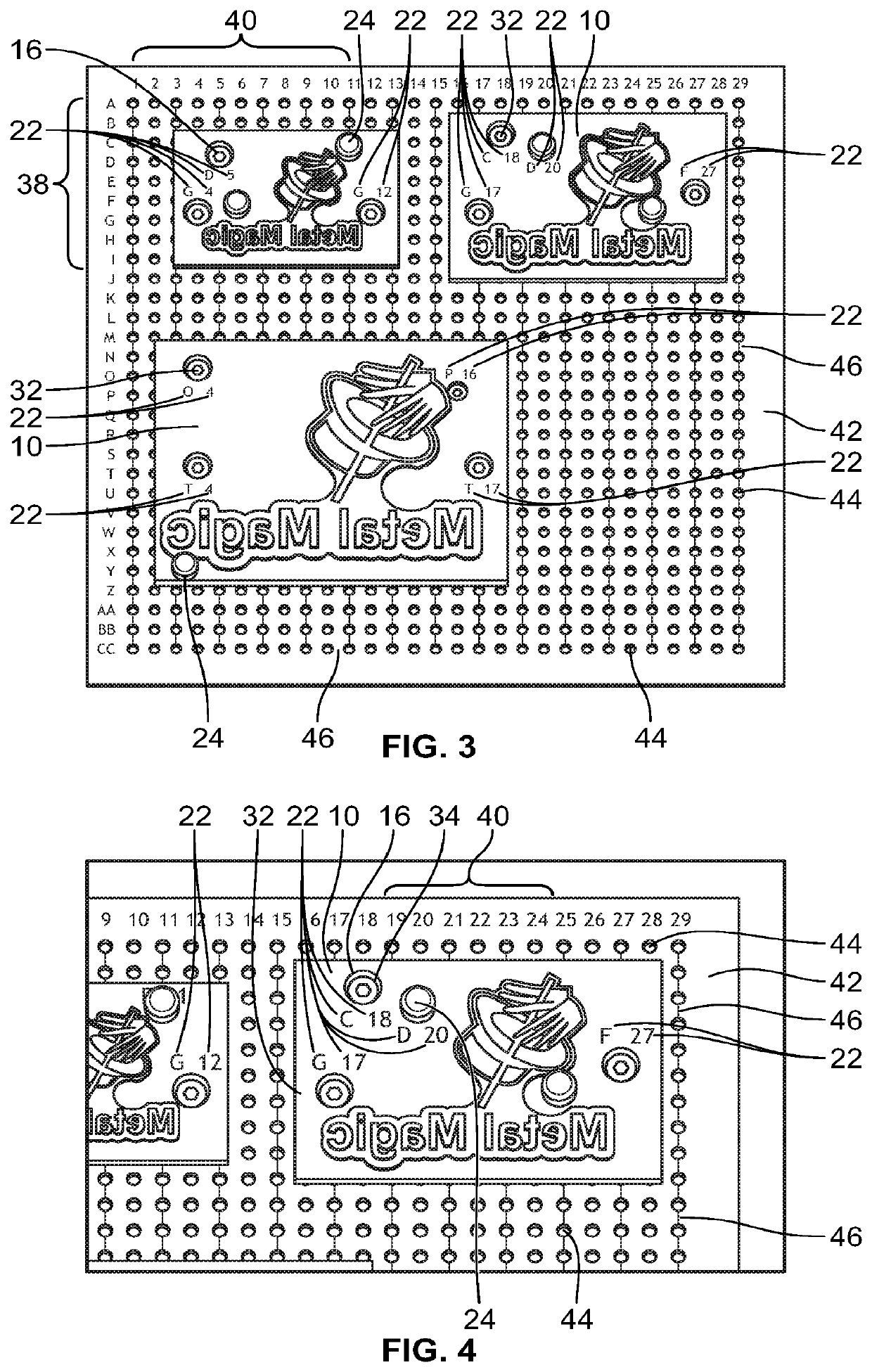

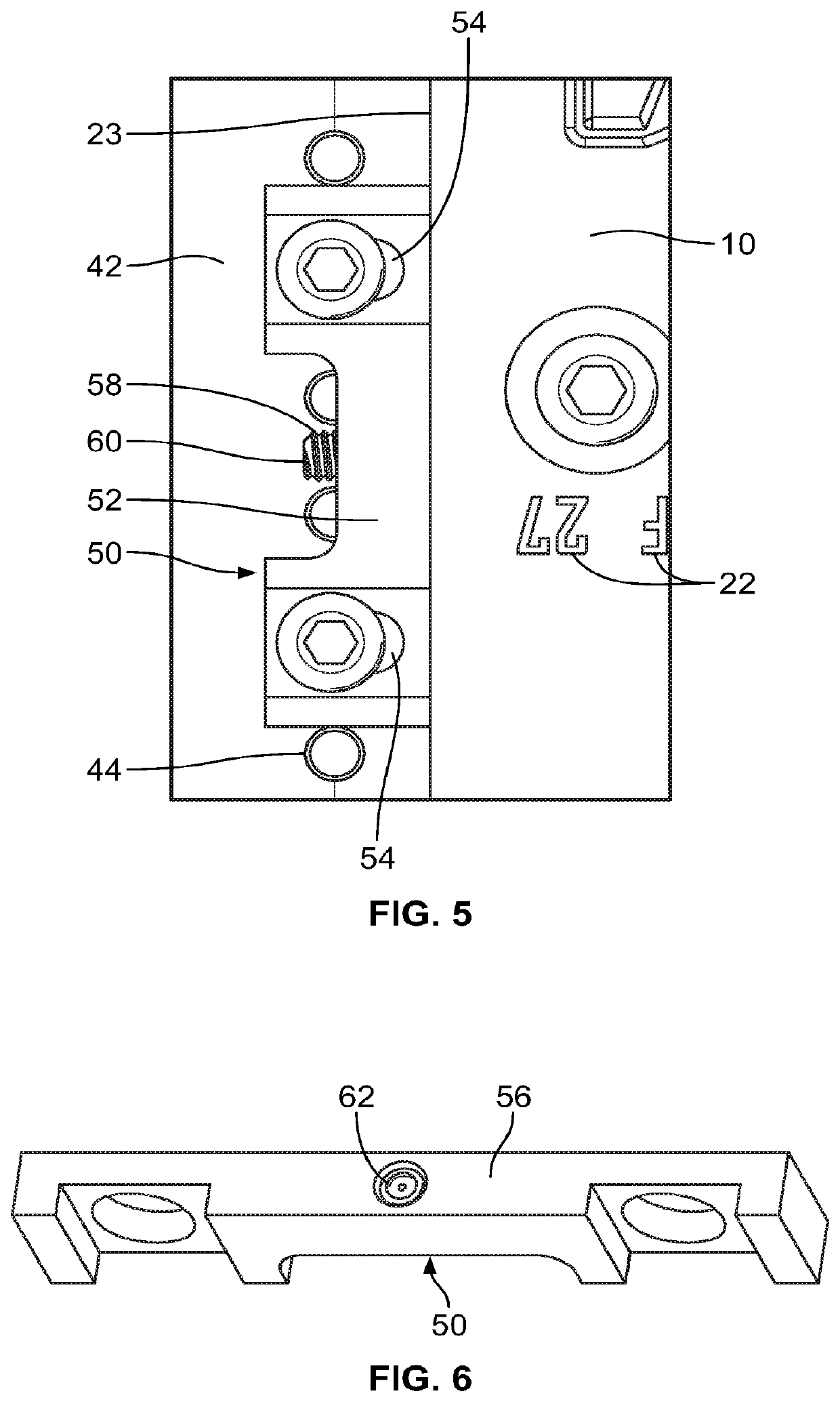

System and method for installing and using graphical dies

A system and method for aligning and installing graphical dies onto an embossing press or foil stamping press is provided. The system includes a number of die support panels having a number of threaded openings disposed in columns and rows in a grid like fashion and identified with x and y axis indicia. The system also includes a number of dies with a number of apertures each identified with a pair of x and y axis indicia. Fasteners and indicia are used to align and attach the dies to the die support panels in a predetermined position. The system preferable further comprises one or more adjusters used to make minute positioning adjustments to the die after it is installed on the panel.

Owner:METAL MAGIC INC

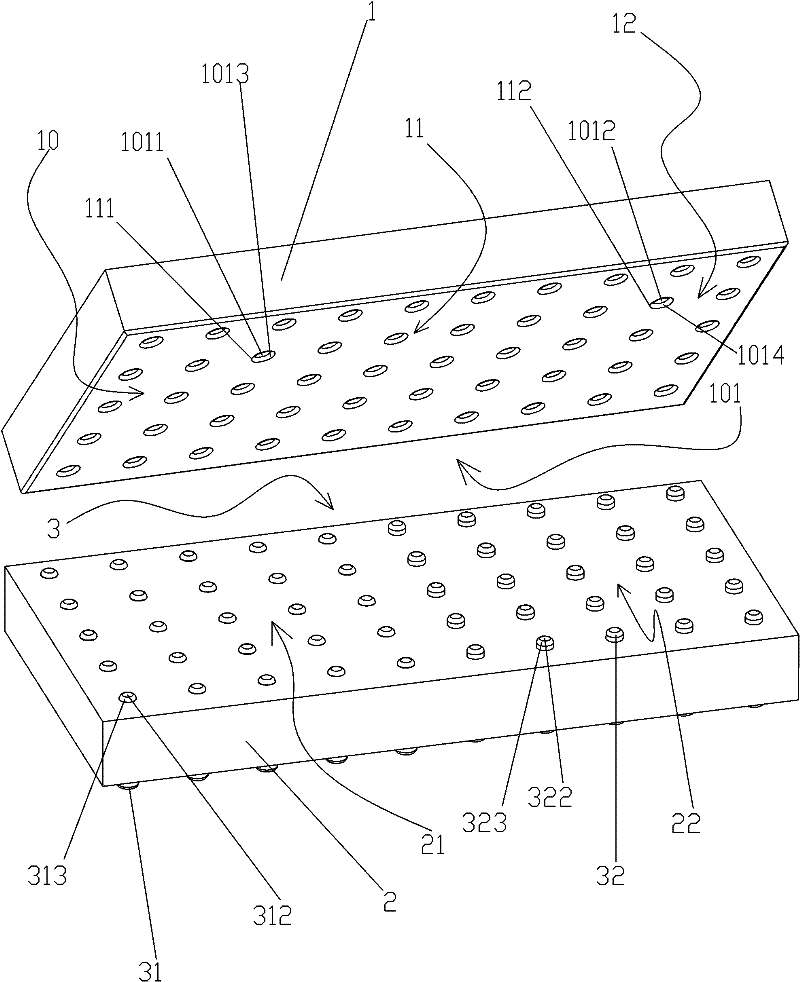

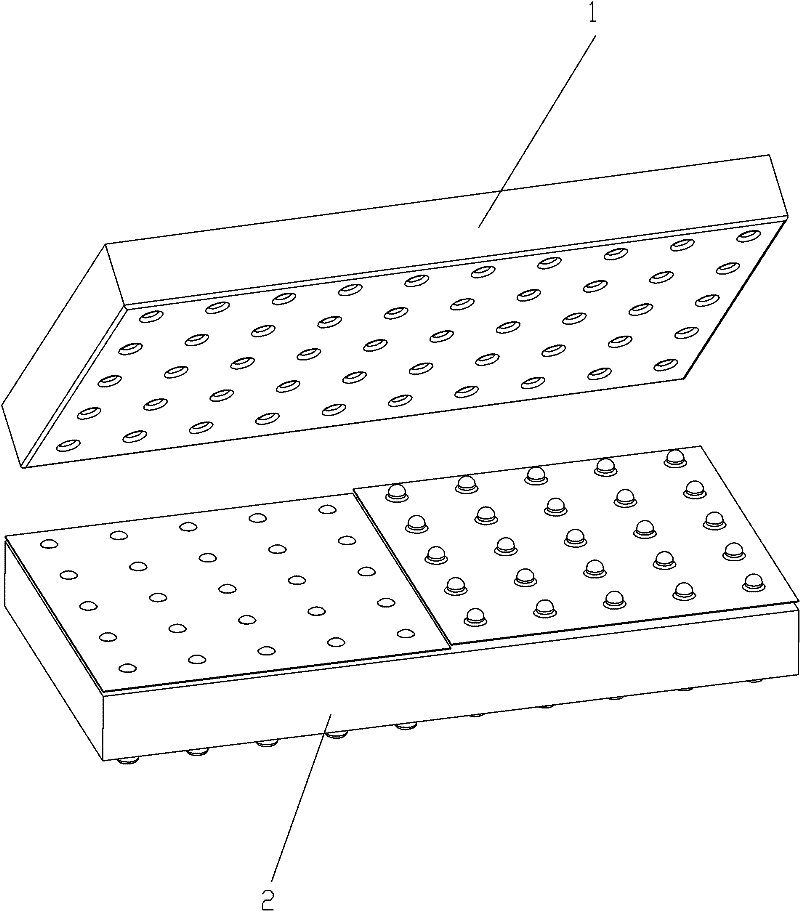

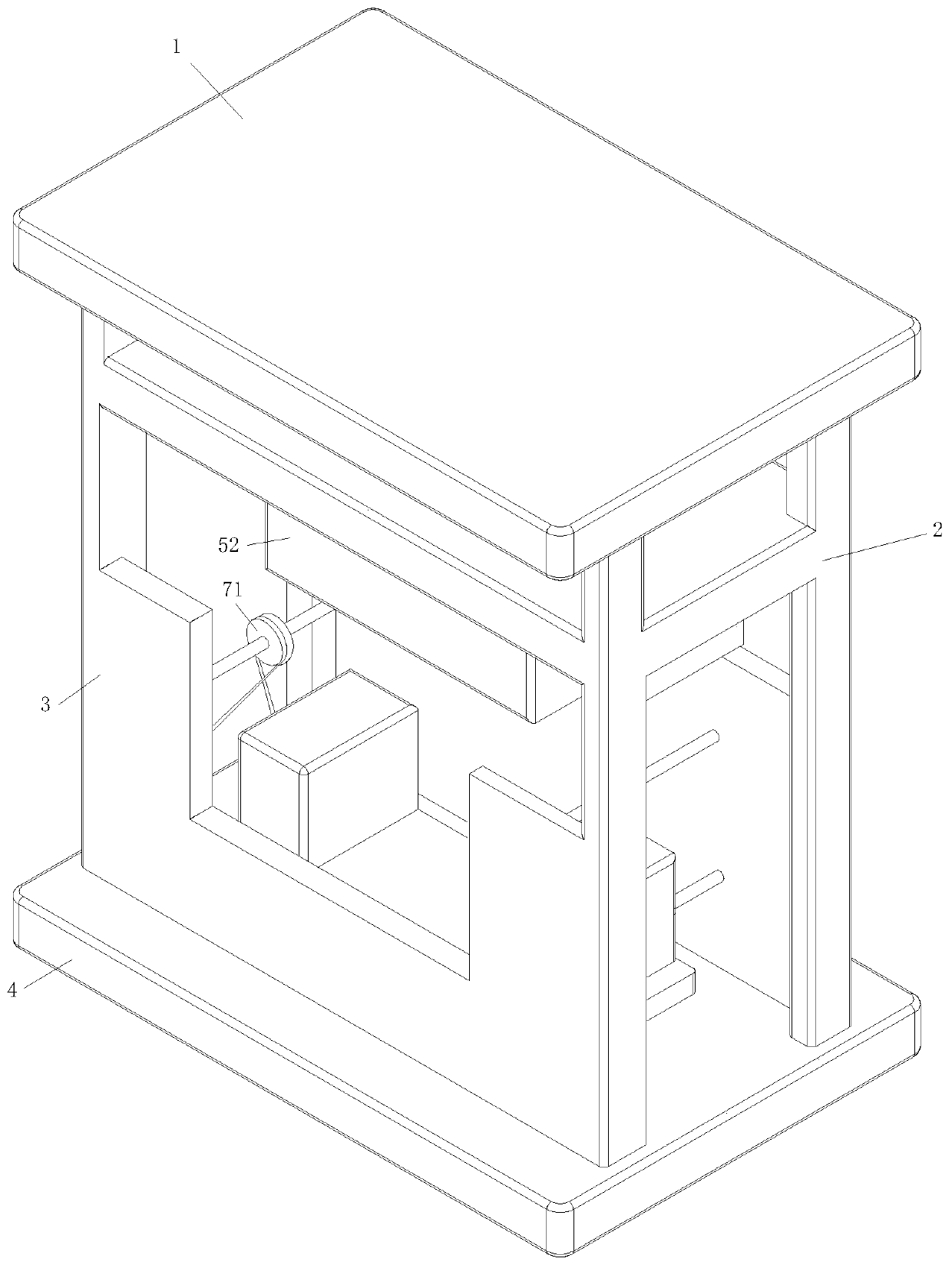

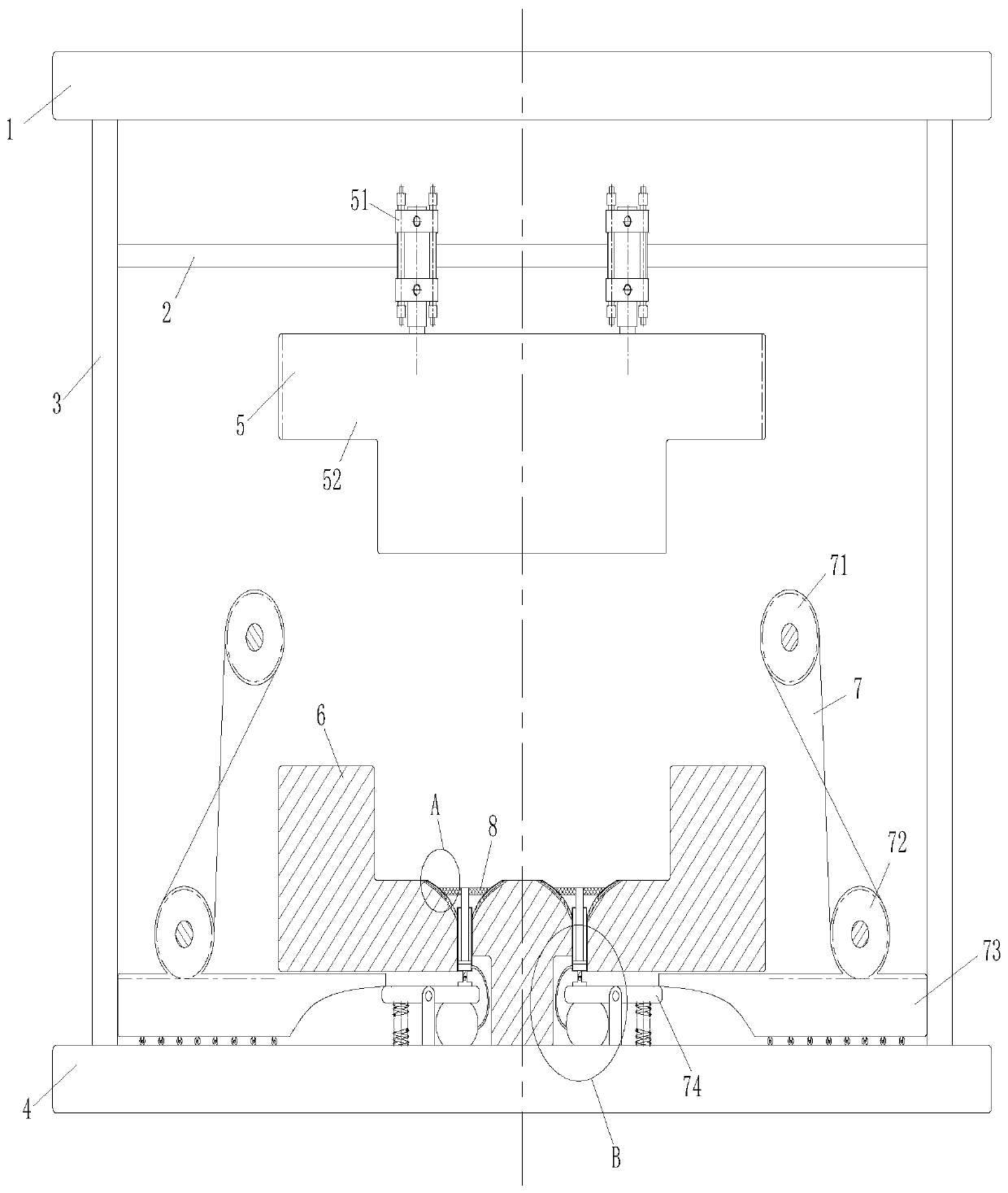

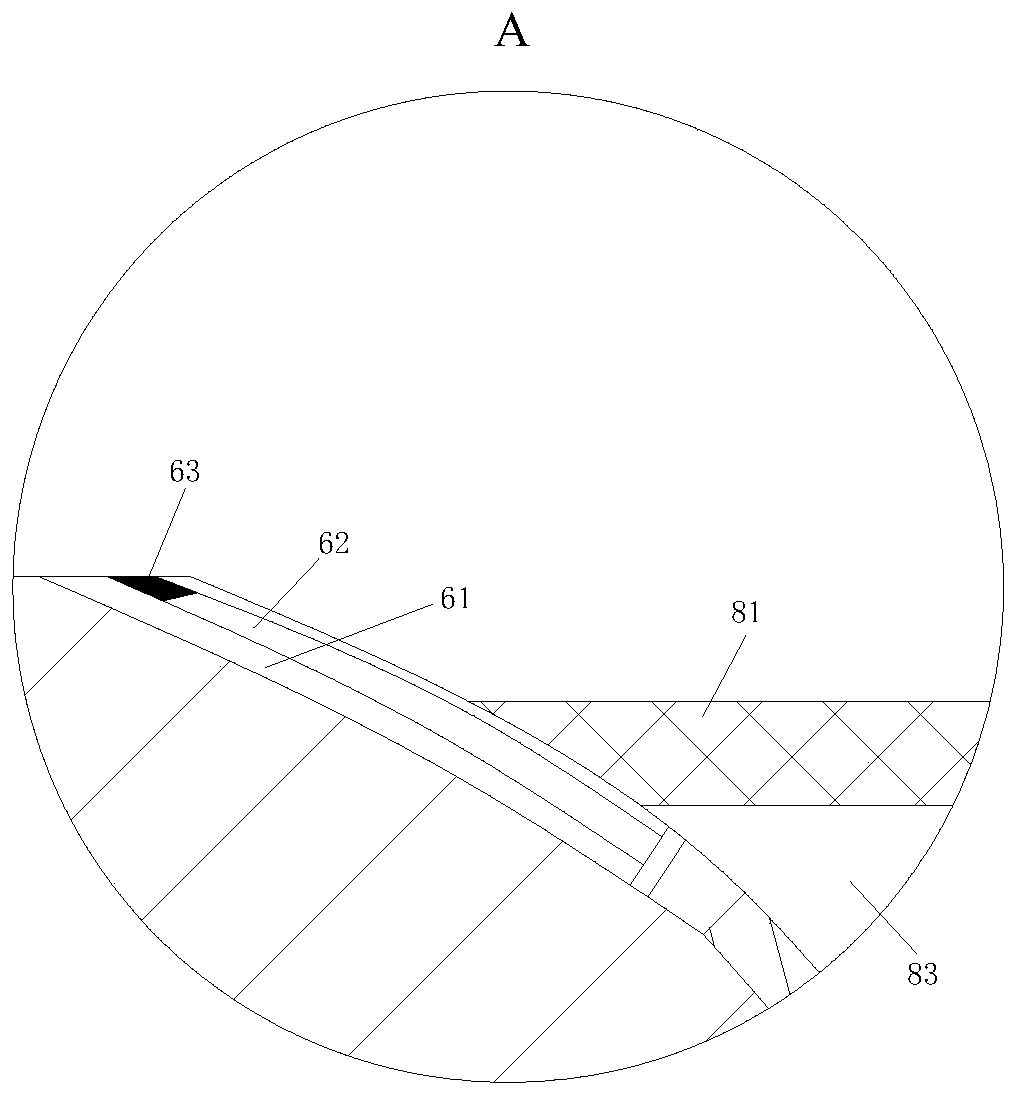

Foil stamping die

The invention relates to the technical field of stamping dies, in particular to a foil stamping die. The foil stamping die comprises a cover plate, a fixed plate, support plates, a bottom plate, an upper stamping die unit, a lower stamping die unit, driving units and adsorption units. The upper ends of the support plates are connected with the lower end face of the cover plate. The lower ends of the support plates are connected with the upper end face of the bottom plate. The two ends of the fixed plate are connected with the two inner side faces of the support plates. The upper stamping die unit comprises cylinders and an upper die plate. The cylinders are fixed to the fixed plate. The output ends of the cylinders are connected with the upper end face of the upper die plate. The lower stamping die unit is fixed to the upper end face of the bottom plate. Each driving unit comprises a gear I, a gear II, a push plate and a top plate. The adsorption units are embedded into the upper surface of the lower stamping die unit. The cylinders, the upper die plate and the driving units cooperate to drive the adsorption units to adsorb foil to be stamped.

Owner:江苏全成奥马热工科技有限公司

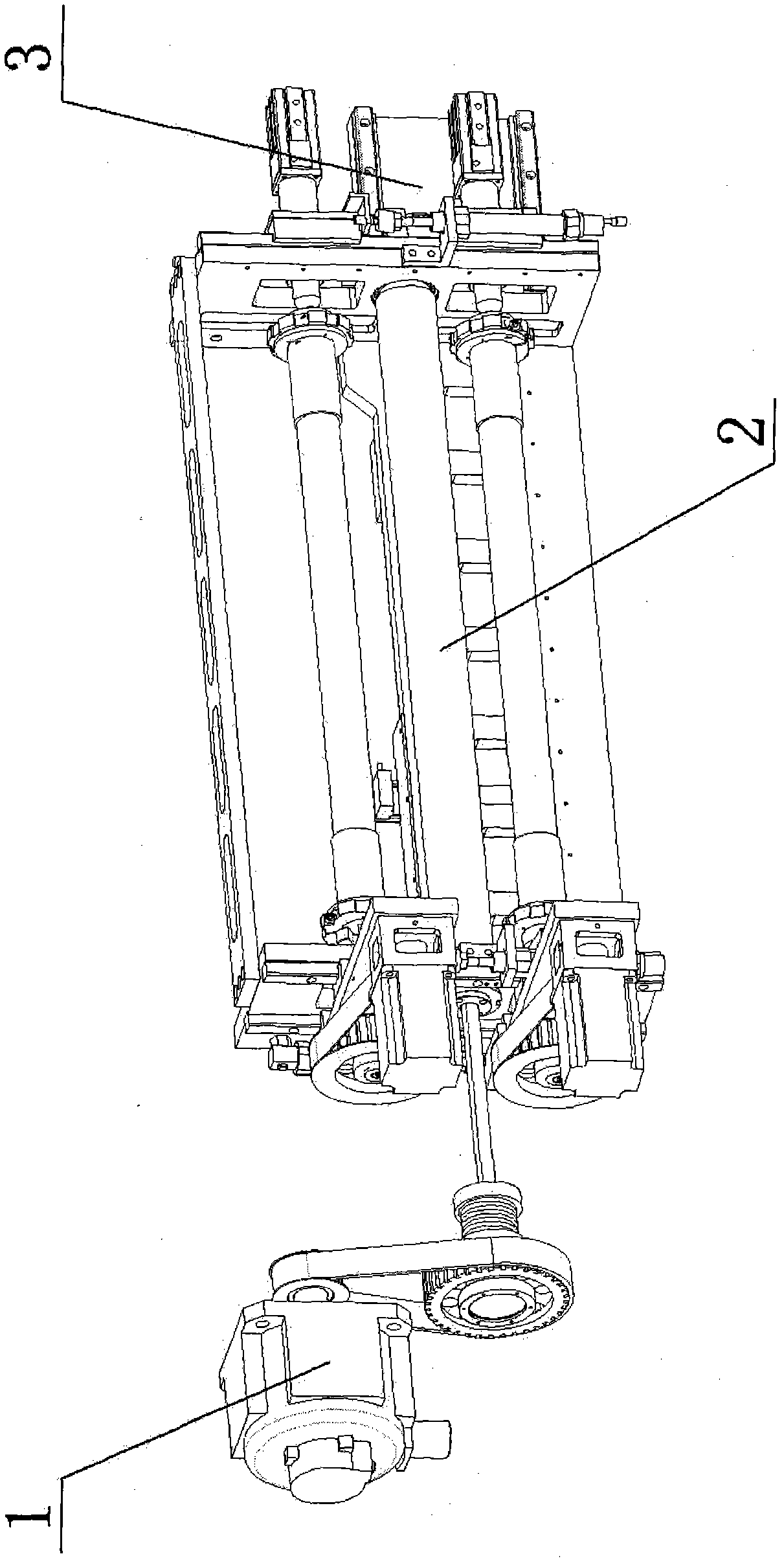

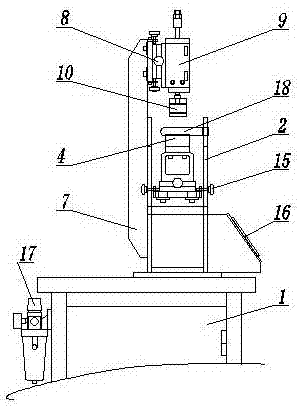

Electrochemical aluminum foil winding traction apparatus for thermoprinting machine

InactiveCN107720371AConvenient limit controlGuaranteed continuous deliveryArticle feedersWebs handlingDocking stationEngineering

The invention discloses an electrochemical aluminum foil winding traction device for a hot stamping machine, which includes a supporting pipe, a docking pipe is provided between the front ends of the supporting pipes, a positioning seat is provided on the docking pipe, and a positioning seat is provided on the docking pipe. A rotating roller is arranged between the positioning seats; a rotating cylinder is arranged at the outer end of the rotating roller; a docking seat is arranged between the rear ends of the supporting pipes, a bottom plate is arranged on the docking seat, and a bottom frame is arranged on both sides of the bottom plate. The top of the guide roller is provided with a guide roller; the axial position of the guide roller is provided with an installation shaft, and the installation shaft is installed on the top of the bottom frame; the front part of the support pipe is provided with a limit side frame. The rotation of the rotary cylinder of the present invention drives the rotary roller to rotate, and the electrochemical aluminum foil used in the hot stamping machine can be wound by the rotary roller, so that the winding and traction control of the electrochemical aluminum foil can be facilitated.

Owner:SUZHOU HONGYE LAMP EQUIP CO LTD

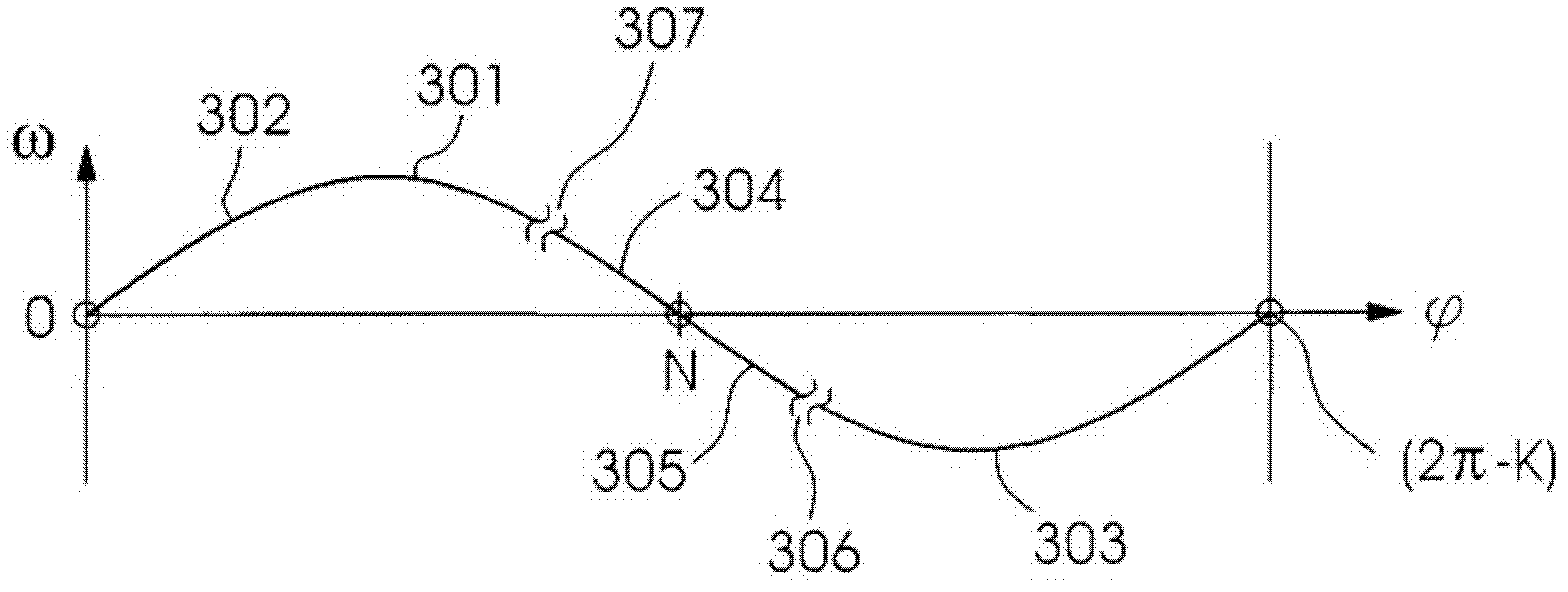

Law of motion of a film timing made up of elementary functions

InactiveCN102642386ARegulation controlShorten the lengthTransfer printingDecorative surface effectsEngineeringFoil stamping

The method involves describing temporary deviation of motion of a film web from synchronous movement of the foil web relative to a transfer cylinder. The film web is temporarily protected, so that a sheet material is protected, and sections (302, 303) of basic functions include an identical pitch in respective contact points (306, 307) and in regions to maintain the speed of the transfer cylinder adjacent to synchronous operation at the cylinder. One of the sections is arranged between print end and print start in a channel region of the cylinder. Independent claims are also included for the following: (1) an apparatus for transferring a transfer layer of a transfer film on a printing substrate (2) a printing machine (3) a computer program product having a set of instructions to perform a method for pulsating a film web during cold-foil stamping process (4) a data storage medium having a set of instructions to perform a method for pulsating a film web during cold-foil stamping process.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Production method of non-baked colorful-gold water printing picture

The invention discloses a production method of a non-baked colorful-gold water printing picture. The production method is characterized by comprising the following steps: designing a sample, manufacturing a film, printing down, manufacturing a silk screen, overprinting a pattern on a carrier in a color distinguishing manner, preparing foil stamping base coat, printing the foil stamping base coat, carrying out light curing, laminating, and packaging. According to the non-baked colorful-gold water printing picture, the non-baked colorful-gold water printing picture produced from the foil stamping base coat has strong adhesive force, can be combined with a gold foil firmly, has high surface hardness, and has water soaking and wine soaking resistance; the non-baked colorful-gold water printing picture has the adhesive force being up to 100%, has the hardness being more than or equal to 2H, has the water-proof and wine-proof effects, and has no abnormity when being soaked in wine for 4h.

Owner:田诚

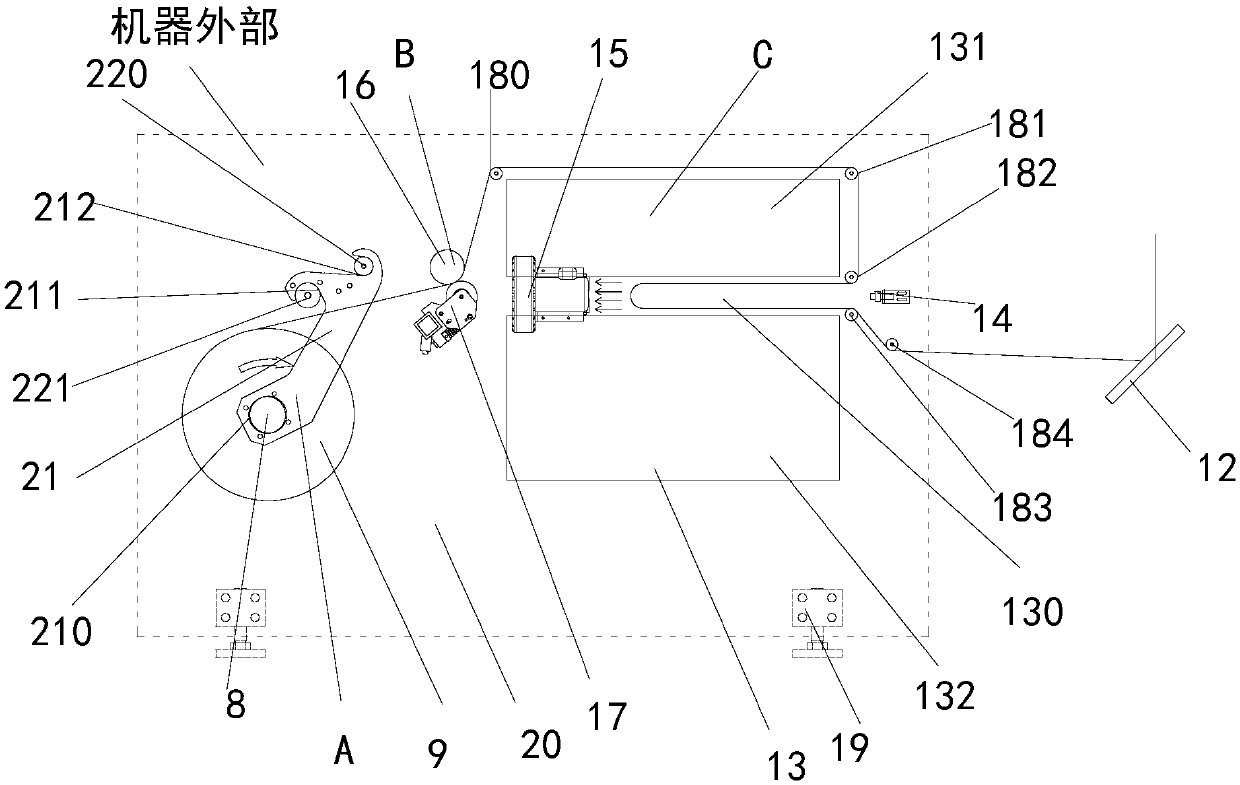

Aluminizer conveying device and stamping press comprising alumite conveying device

The invention relates to an aluminizer conveying device and a stamping press comprising the aluminizer conveying device. The aluminizer conveying device comprises a substrate, a fixing assembly, a transmission assembly, a storage assembly, a distance detecting unit and an aluminum foil coil. The aluminum foil coil is mounted on the fixing assembly. The fixing assembly is fixed on the left side ofthe substrate. The storage assembly is fixed on the right side of the substrate. The transmission assembly is fixed at the periphery of the storage assembly. The distance detecting unit is fixed on the right side of the storage assembly. Aluminum foils are conveyed by the fixing assembly and conveyed into the storage assembly through the transmission assembly for vacuum storage; the distance detecting unit detects the depth of the stored aluminum foils, and deviation of aluminum foil conveying accuracy due to inertia problem caused by the lack of storage is avoided; and finally, aluminizer isconveyed to the stamping press through the transmission assembly. According to the aluminizer conveying device and the stamping press comprising the aluminizer conveying device, the aluminizer can bestored and conveyed at the exterior of the stamping press, the replacing time at every time is shortened while the replacing frequency of the aluminum coils is reduced, and the working efficiency of the stamping press is improved accordingly.

Owner:MASTERWORK GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com