Novel laminating cold foil stamping structure

A technology of cold foil stamping and film coating, applied in gold powder printing, printing, rotary printing machines, etc., can solve the problems of great impact on quality and efficiency, waste, and increased costs, so as to improve the quality and effect of cold stamping, improve the quality of cold stamping, Avoid the peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

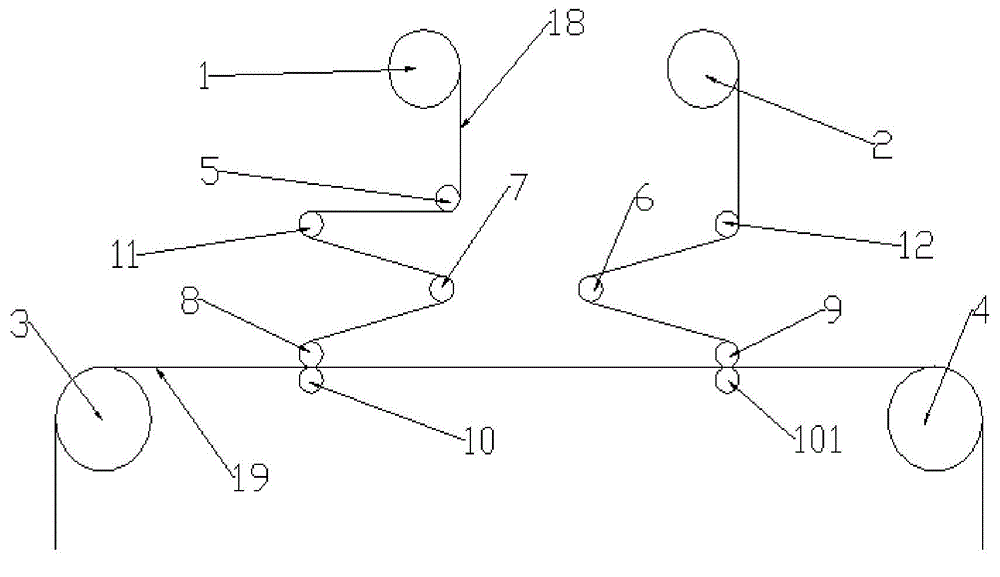

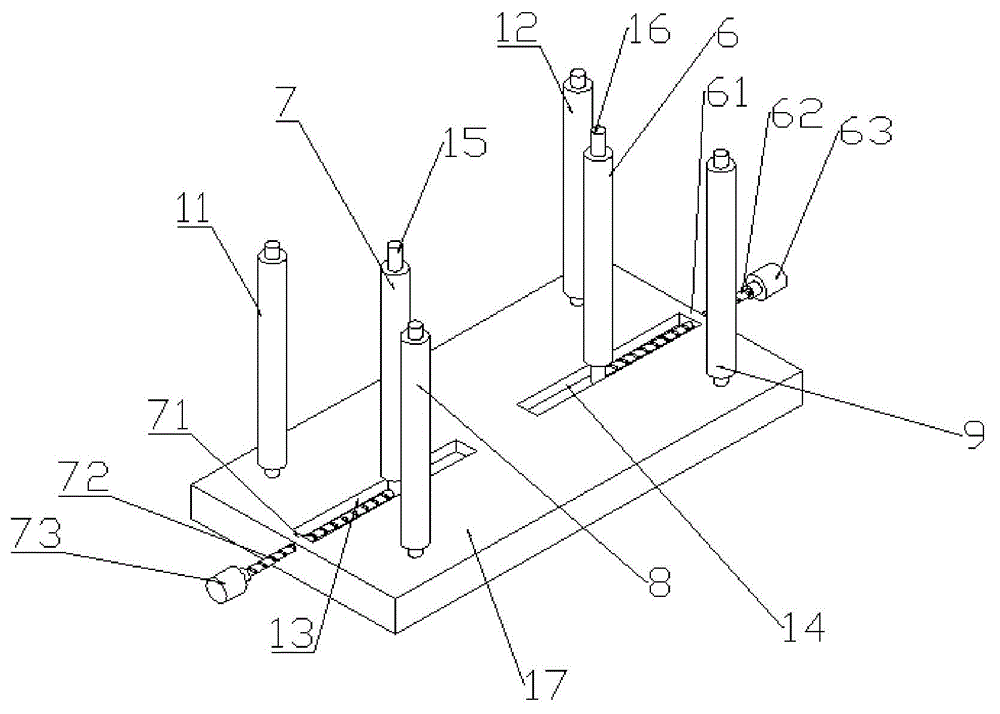

[0023] As shown in Figure 1, the present invention provides a new film-coated cold foil stamping structure including a cold foil stamping unwinding device 1, a cold stamping unit and a cold foil stamping winding device 2. The cold stamping unwinding device 1 is located at the upper left end of the cold stamping unit. The cold stamping winding device 2 is located at the upper right end of the cold stamping unit; the cold stamping unit includes the first reversing guide roller 5, the second reversing guide rail 11, the left adjustment roller 7, the embossing roller 8, the peeling roller 9, and the right adjustment roller 6 and the third reversing guide roller 12, the first reversing guide roller 5 is arranged below the cold stamping unwinding device 1, the second reversing guide roller 11 is arranged on the left lower side of the first reversing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com