Foil stamping device of stamping machine

A bronzing machine and foil-feeding technology, which is applied to printing machines, gold powder printing, rotary printing machines, etc., can solve the problems of low utilization rate of anodized aluminum, waste of consumables, and tension deformation of anodized aluminum, so as to improve speed and production efficiency, overcome The effect of low utilization rate of consumables and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

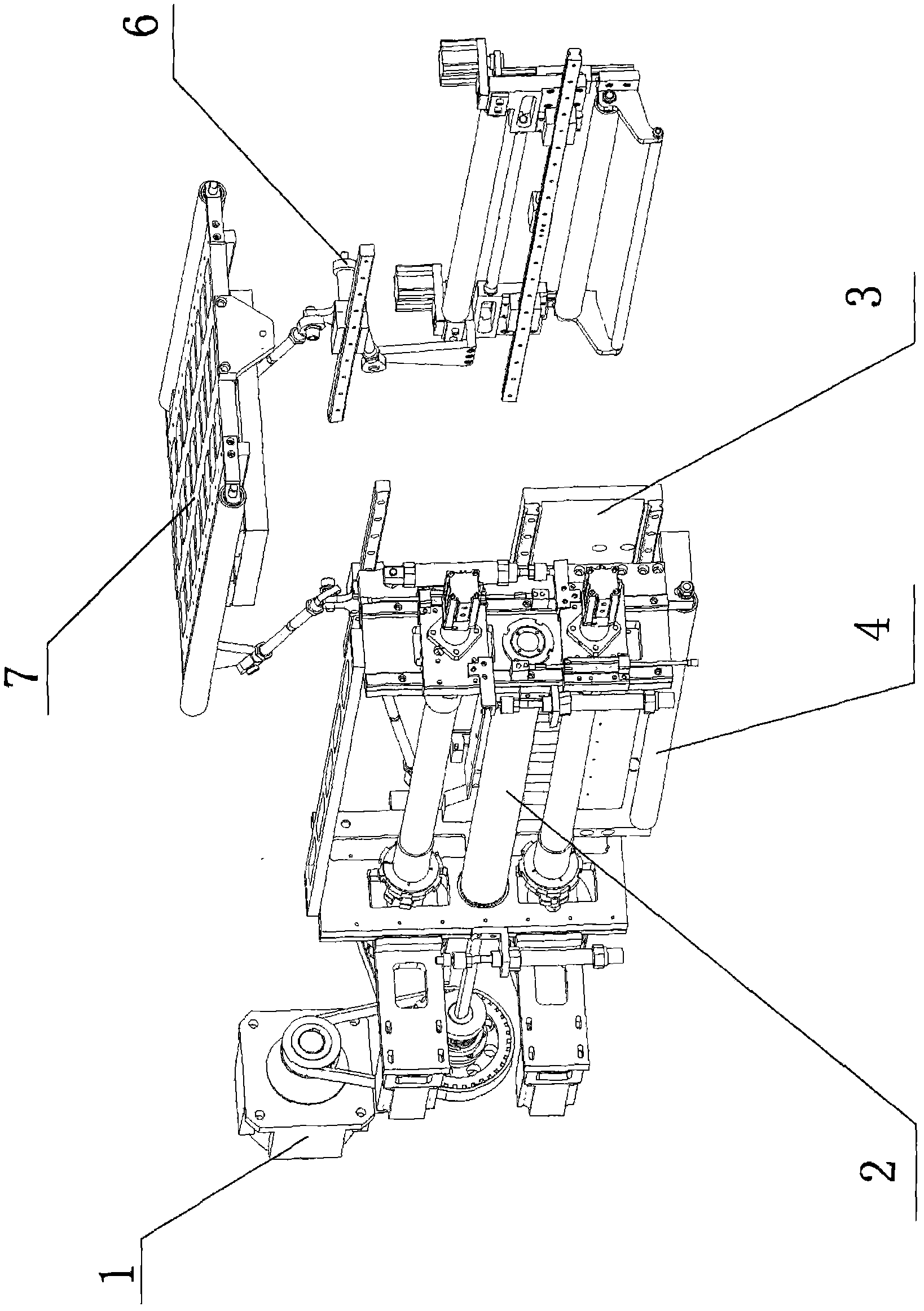

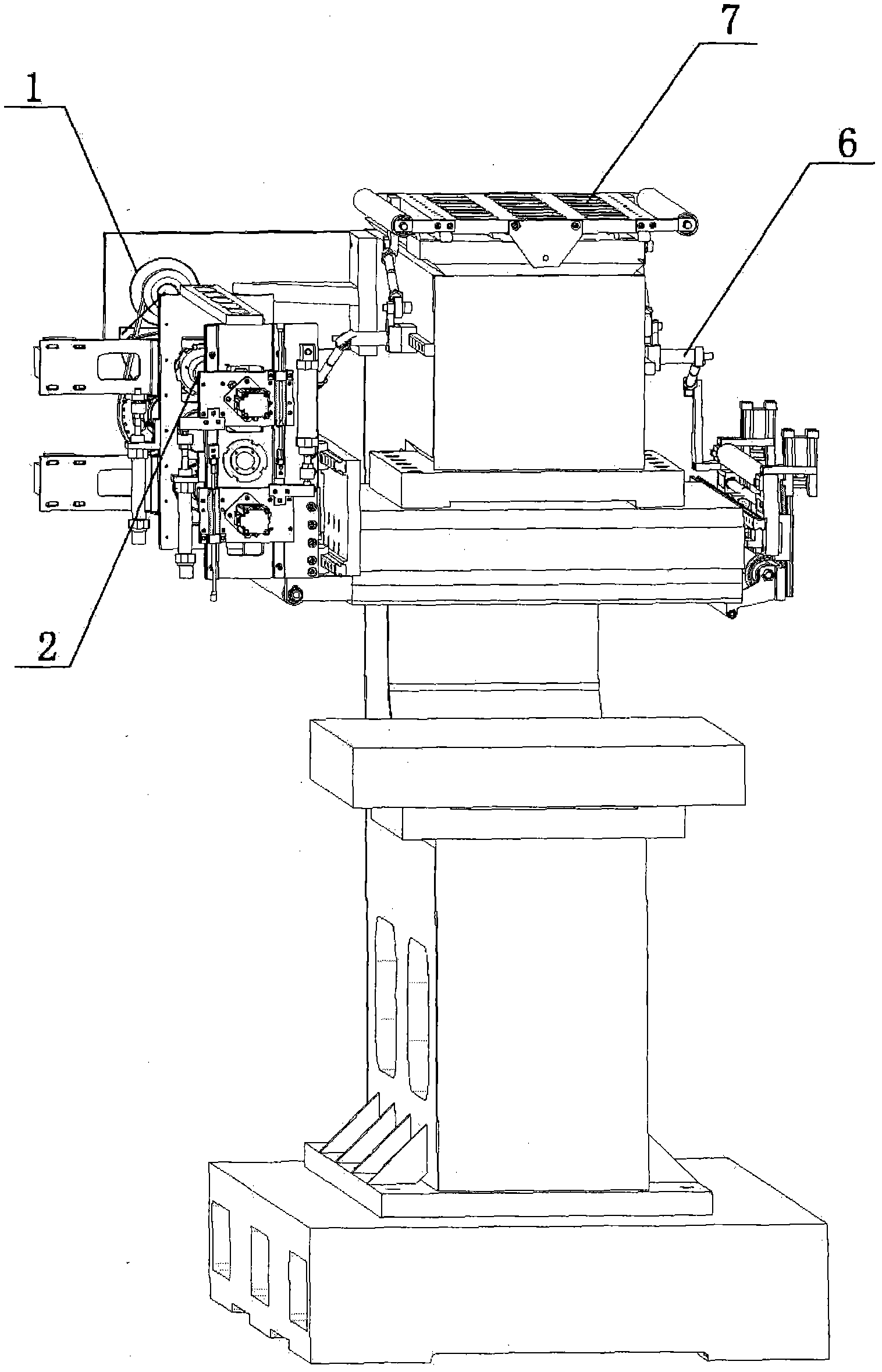

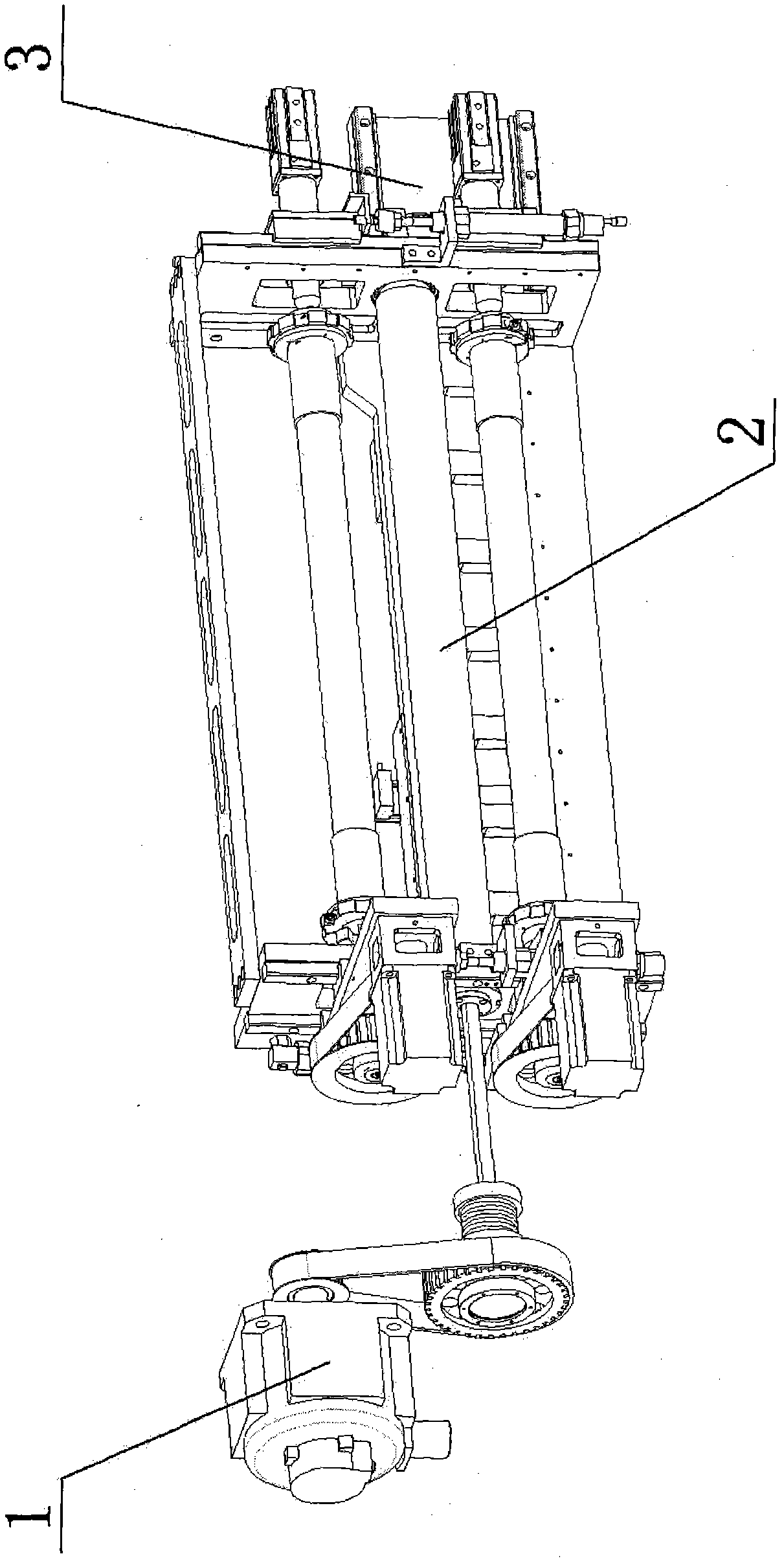

[0022] see Figure 1 to Figure 9 As shown, the present invention is a foil feeding device of a bronzing machine, which consists of a foil feeding drive device 1, a foil feeding linear synchronization device 2, a foil feeding lateral carrying device 3, a foil releasing positioning guide device 4, a guide roller connecting device 6 and Devices such as traversing guide device 7 are formed. Wherein, the foil feeding drive device 1 , the foil feeding linear synchronization device 2 and the foil feeding lateral carrying device 3 jointly form a foil feeding and unwinding device 9 . The traversing guiding device 7 is connected with the foil retracting and unwinding device 9 and drives the entire foil retracting and unwinding device 9 to move laterally; the guide roller connecting device 6 is connected with the traversing guiding device 7 .

[0023] Further, as attached to the manual Figure 4 As shown, the foil feeding driving device 1 includes a first servo motor 11 , a pair of fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com