Foil stamping die

A technology for stamping dies and foils, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems that foils are not easy to fix, easily deviate from molds, affect processing shape requirements and processing accuracy requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

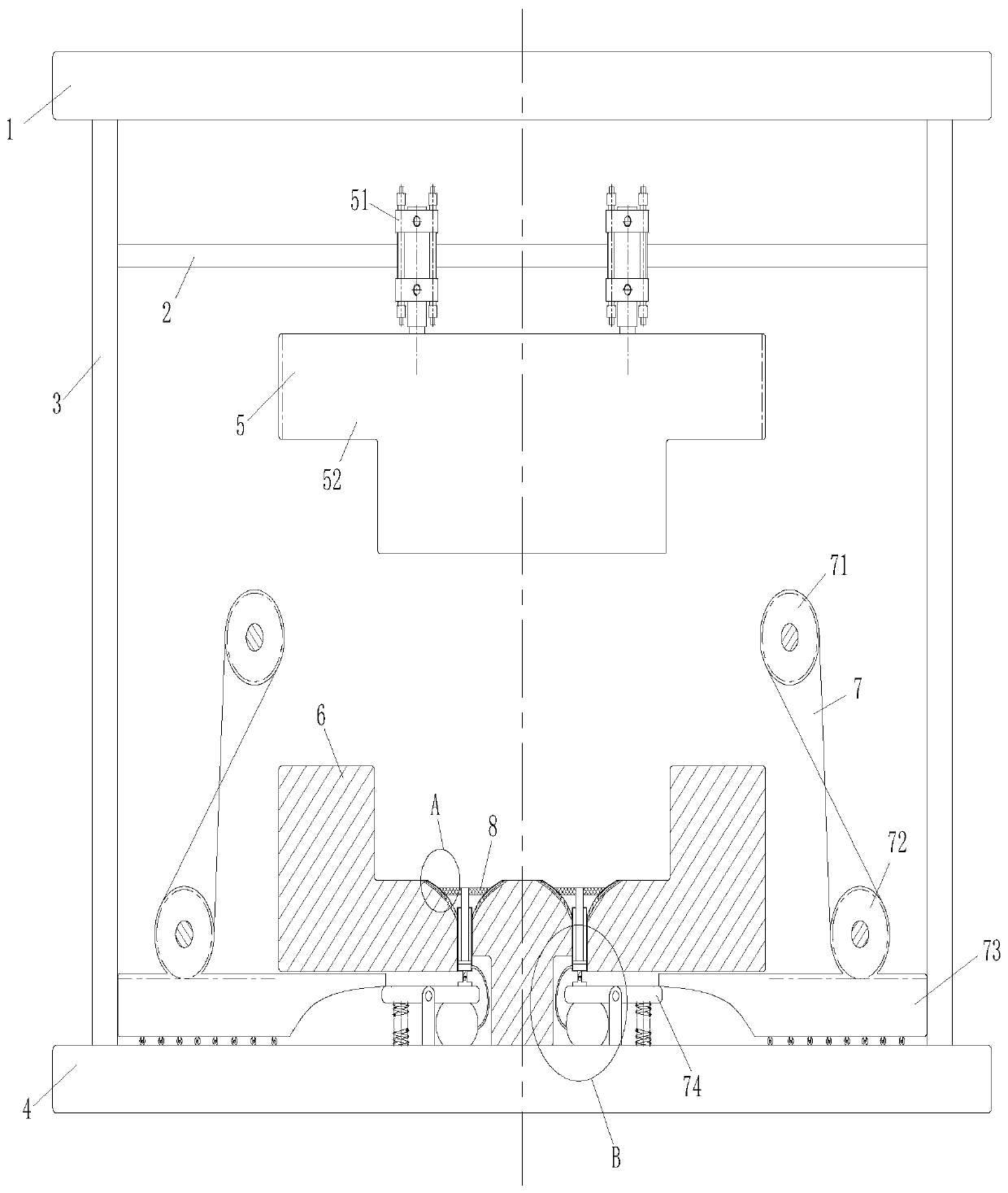

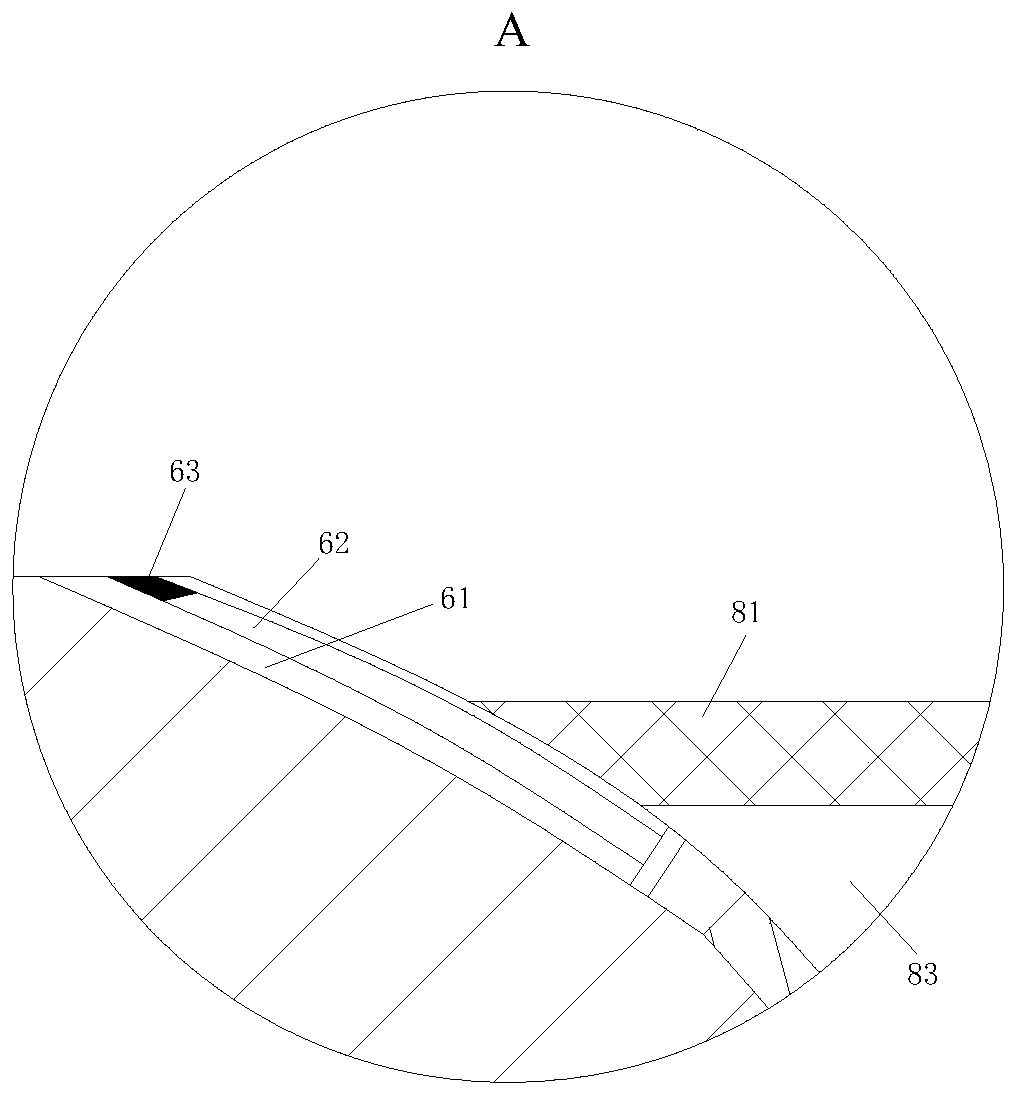

[0024]As an embodiment of the present invention, an air groove 61 is provided on the side wall of the lower die unit 6 around the suction cup 81; a sealing strip 62 is arranged in the air groove 61; The cooperation of 7 pushes the push rod 82 to move up, thereby extruding the gas in the cavity 83, so that the sealing strip 62 is pressed and slides out along the air groove 61, and plays a sealing effect around the suction cup 81, and enhances the adsorption effect of the suction cup 81; When working, when the push plate 73 squeezes one end of the top plate 74 to make the other end of the top plate 74 tilt, it will push the push rod 82 to move upward, thereby squeezing the gas in the cavity 83, and most of the gas plays the role of ejecting the suction cup 81 , and a part of the gas squeezes the sealing strip 62 through the air groove 61, so that the sealing strip 62 slides out from the air groove 61, thereby sealing the surrounding of the suction cup 81, enhancing the adsorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com