An electric fire

A technology of electric furnace and shell part, which is applied in the field of reflective screen of electric furnace and fuel bed of electric furnace, which can solve the problems of confusing configuration and inability to provide the consistency of overall aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will now be described by way of exemplary embodiments of the invention.

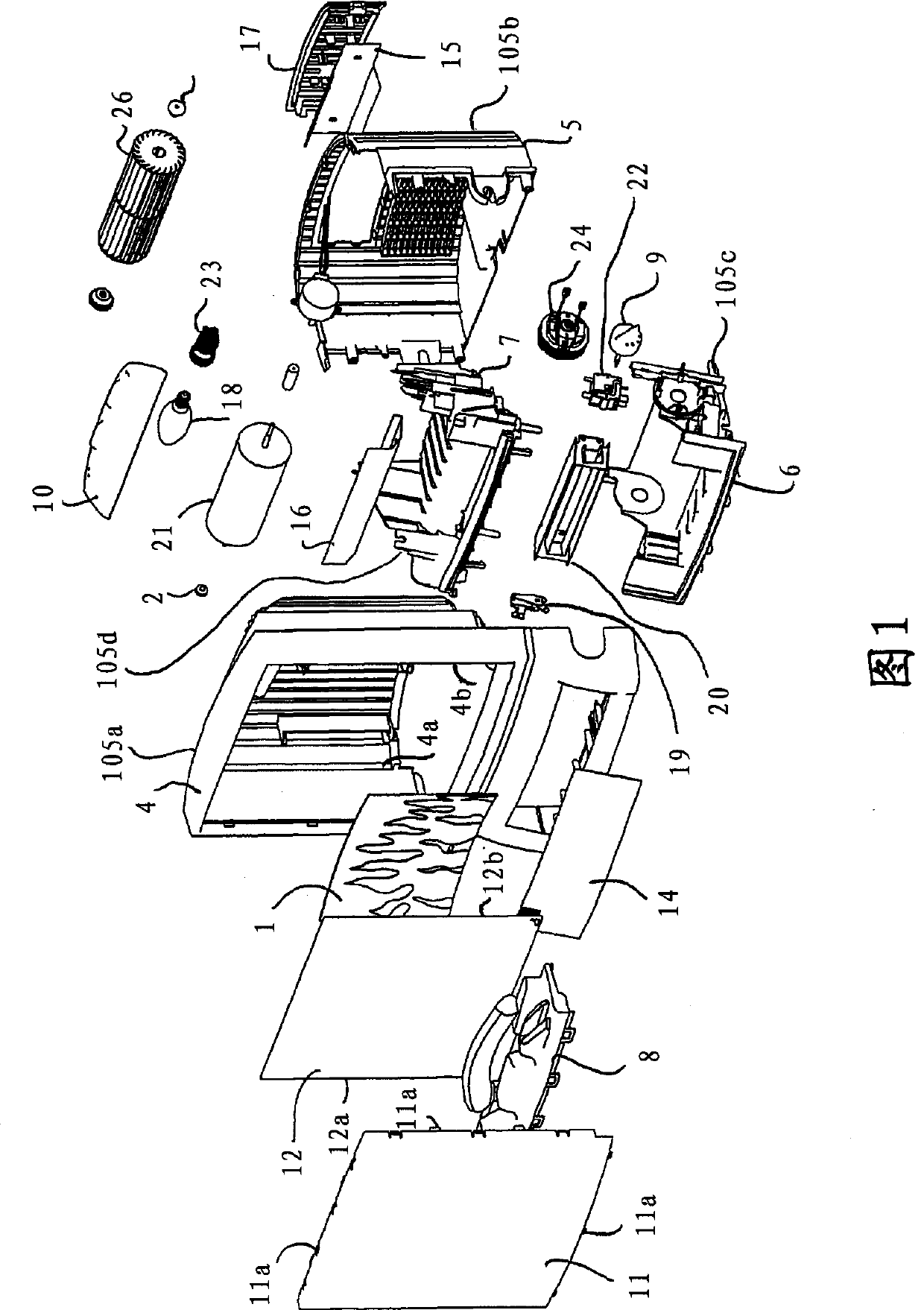

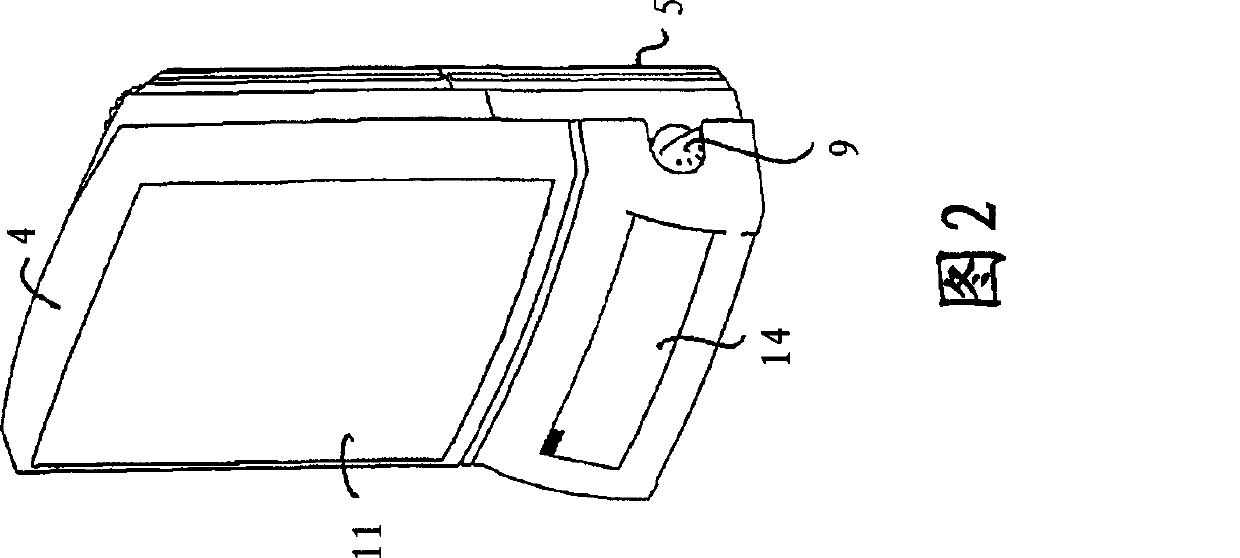

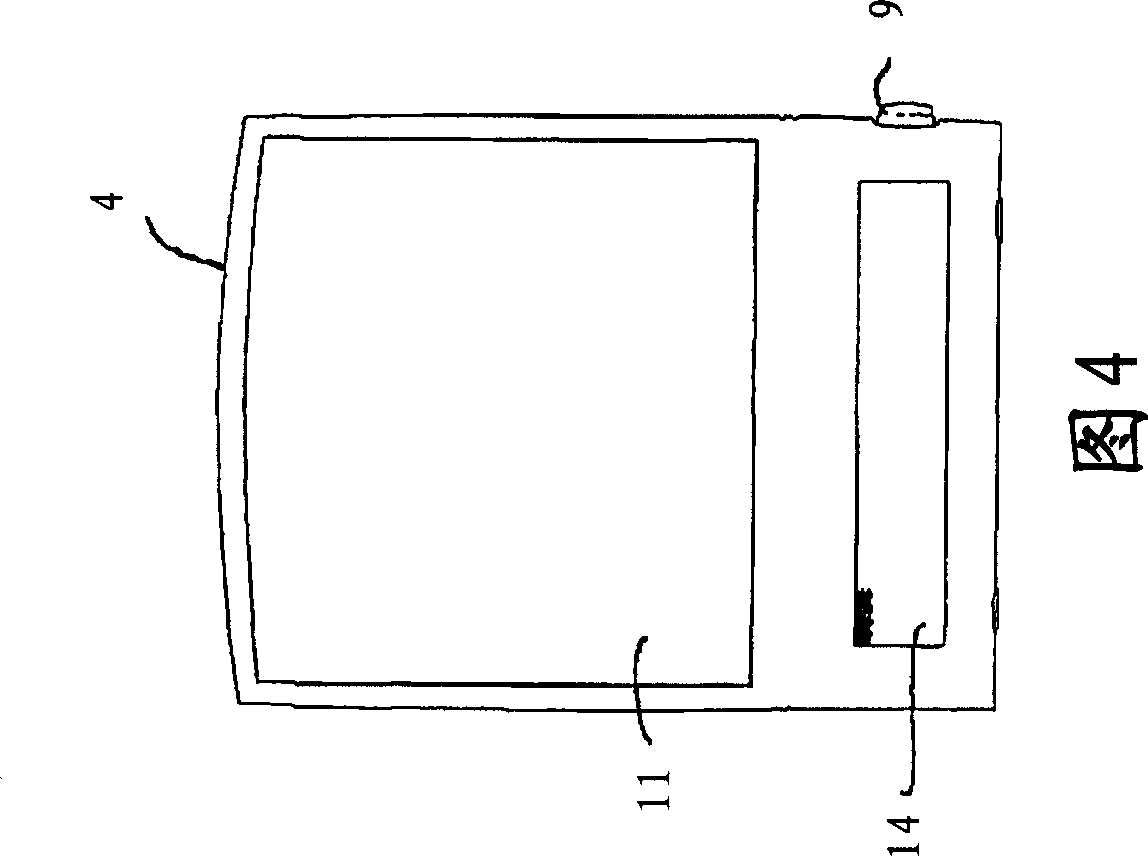

[0030] As shown in FIG. 1 , the electric furnace 100 is made from a plurality of subassemblies 105 . The subassemblies 105 are each formed from individual plastic molded parts, each of which is configured to enable the subassemblies to be snapped together to form the finished electric fire. In the embodiment of FIG. 1 four such subassemblies 105a, 105b, 105c, 105d are provided. By forming an electric furnace from such an assembly, the time required to fully assemble the electric furnace is reduced from about 80 minutes to about 20 minutes, enabling the subassembly method to be fabricated in the time normally required to make an electric furnace using the teachings of the prior art. into 4 electric stoves.

[0031] In the embodiment shown in the exploded view of FIG. 1 , a number of components can be identified. These components can be distinguished into different categorie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com